Fault Diagnosis Based on Chemical Sensor Data with an Active Deep Neural Network

Abstract

:1. Introduction

- (a)

- The poor ability of learning complex nonlinear relationships because of such a shallow architecture [17];

- (b)

- The features are only extracted based on signal-based techniques, and the model performance strongly depend on expert and a priori knowledge, which have significant limitations in terms of applicability.

- (1)

- Deep learning is able to learn the feature of diagnosis sensor data adaptively for intelligent fault diagnosis rather than merely relying on manual extraction.

- (2)

- The method performed excellently in obtaining the potential information and fault characteristics of raw sensor data by multiple non-linear transformations and approximate non-linear functions and presented higher diagnosis accuracy than methods based on shallow architecture. Therefore, the proposed method is a preferred approach for diagnosis in complex chemical systems.

- (3)

- The combination of deep learning and active learning is proposed in the chemical fault diagnosis, which improves the existing diagnosis methods significantly. Compared with available active learning methods, a novel active learning criterion combined with BvSB and LFP is presented, which is an active labeling method for the cost-effective selection of chemical sensor data to be labeled and achieves the selection of the most valuable samples for inducing the DNN in chemical fault diagnosis, thus improving the model performance maximally.

2. Applicability Analysis and Model Preparation

2.1. Advantage of Deep Learning with Chemical Sensor Data

2.2. Sparse Auto-Encoder

2.3. Method of Data Preprocessing in Models

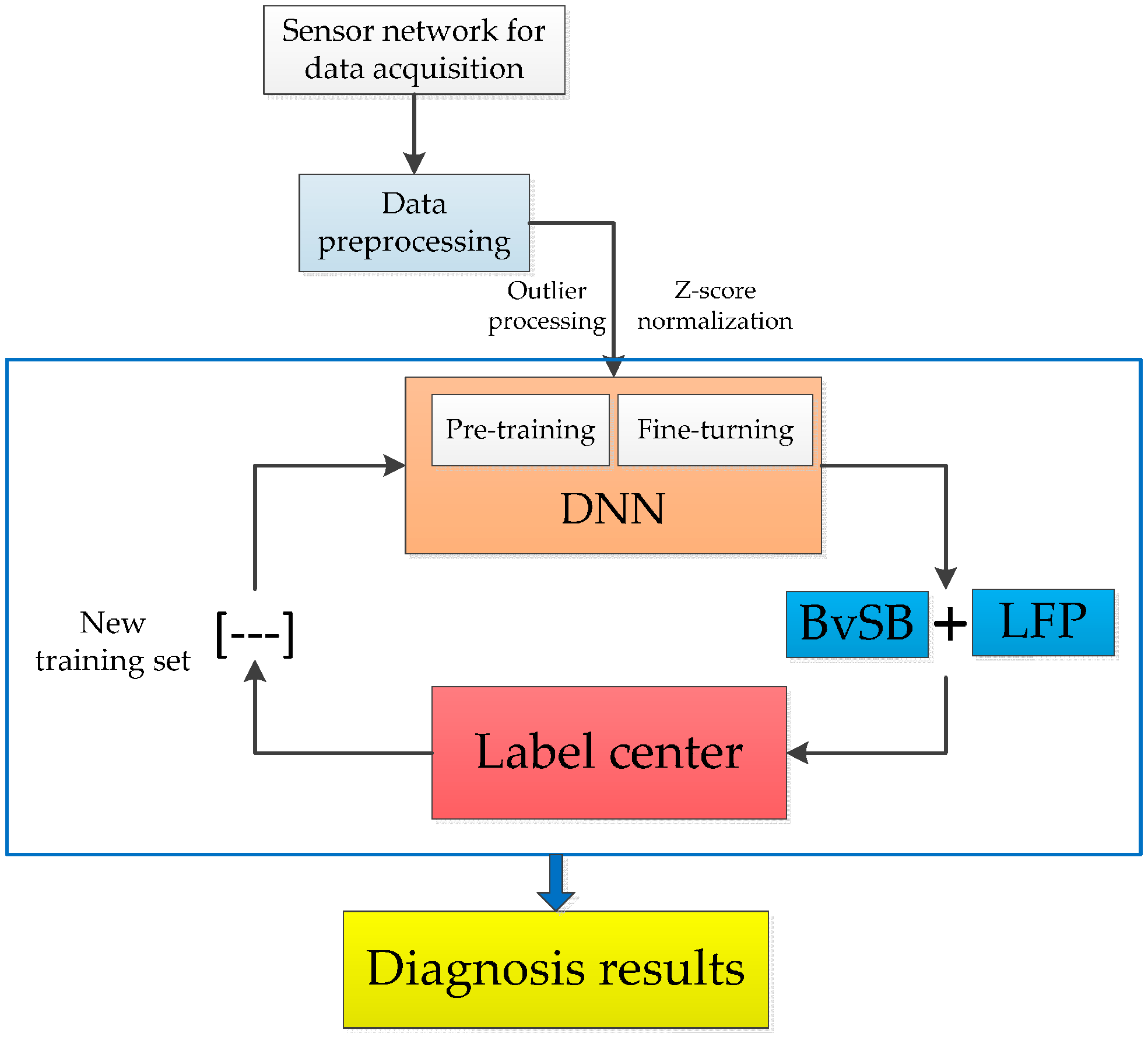

3. A Fault Diagnosis Method with Active Deep Network

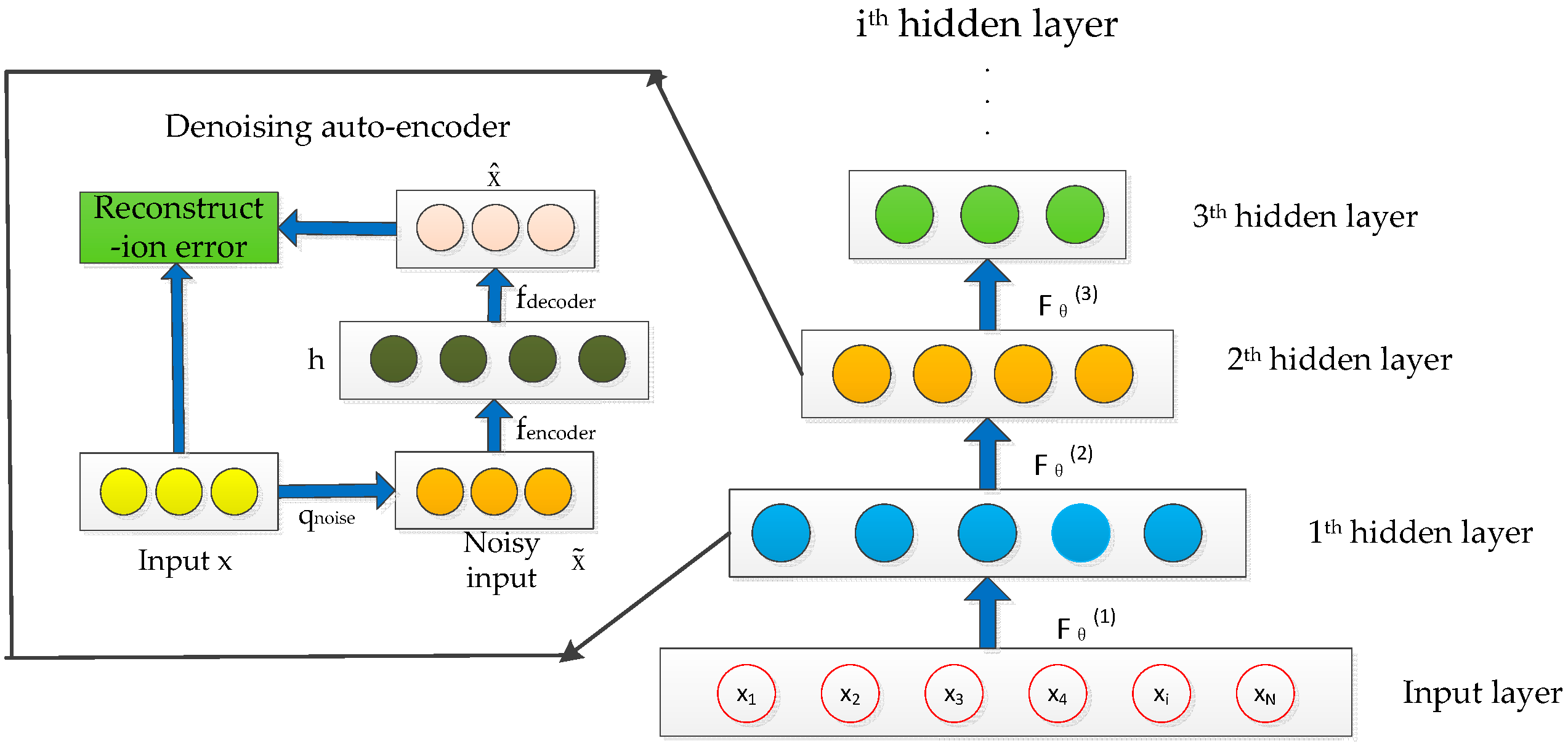

3.1. Unsupervised Learning Using SDAE

3.2. Supervised Learning Stage and Fine-Tuning

3.3. Active Learning Procedure for DNN (AL-DNN)

| Algorithm 1: AL-DNN |

Input:

Output:

Main step:

End |

4. Experimental Study

4.1. Data Description

4.1.1. Case Study 1: UCI Dataset—Dataset for Sensorless Drive Diagnosis Dataset

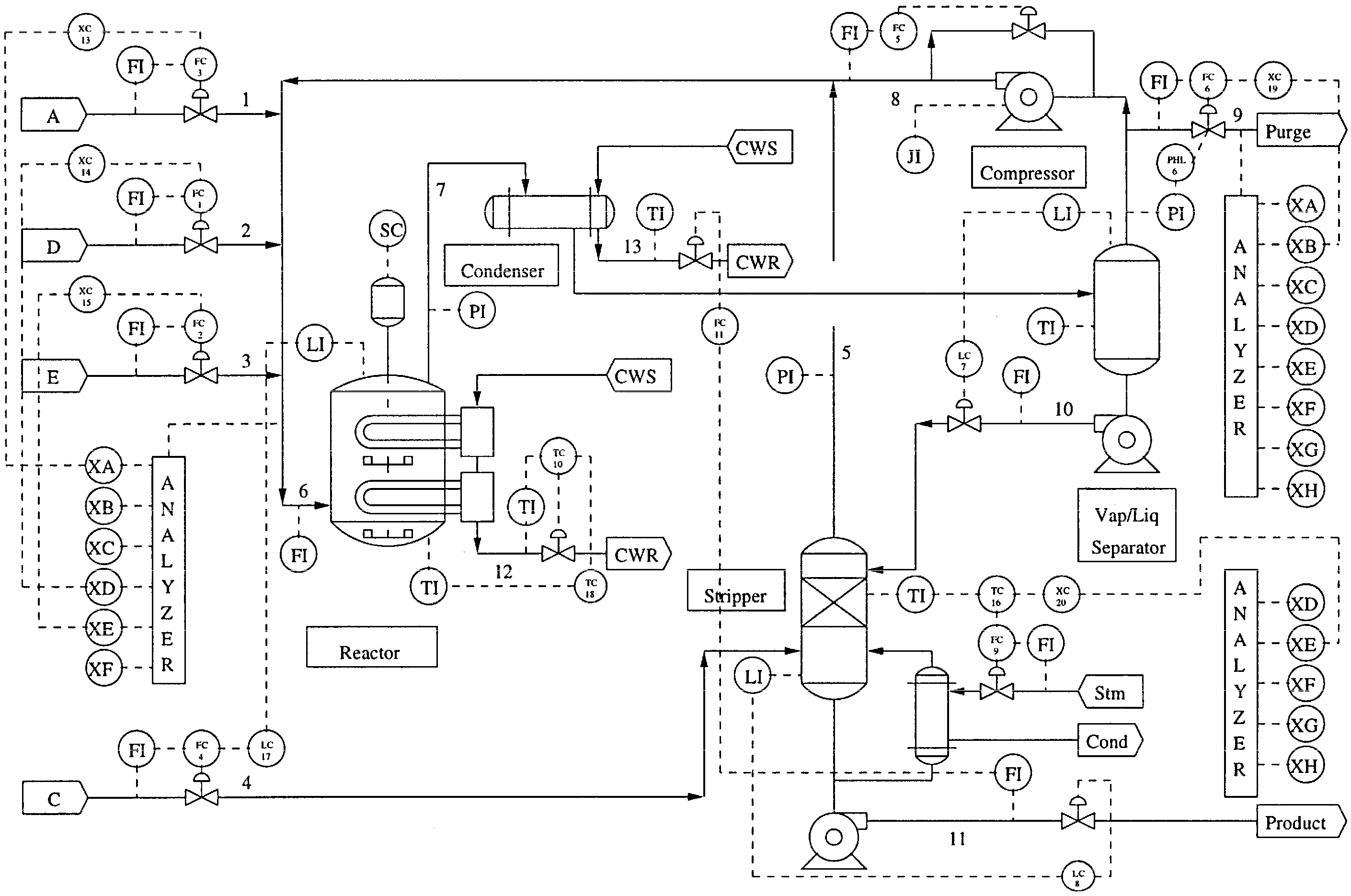

4.1.2. Case Study 2: TE Dataset—Dataset for Tennessee Eastman Process (TEP)

4.2. Experiment Setup

4.3. Result and Analysis in Different Diagnosis Cases

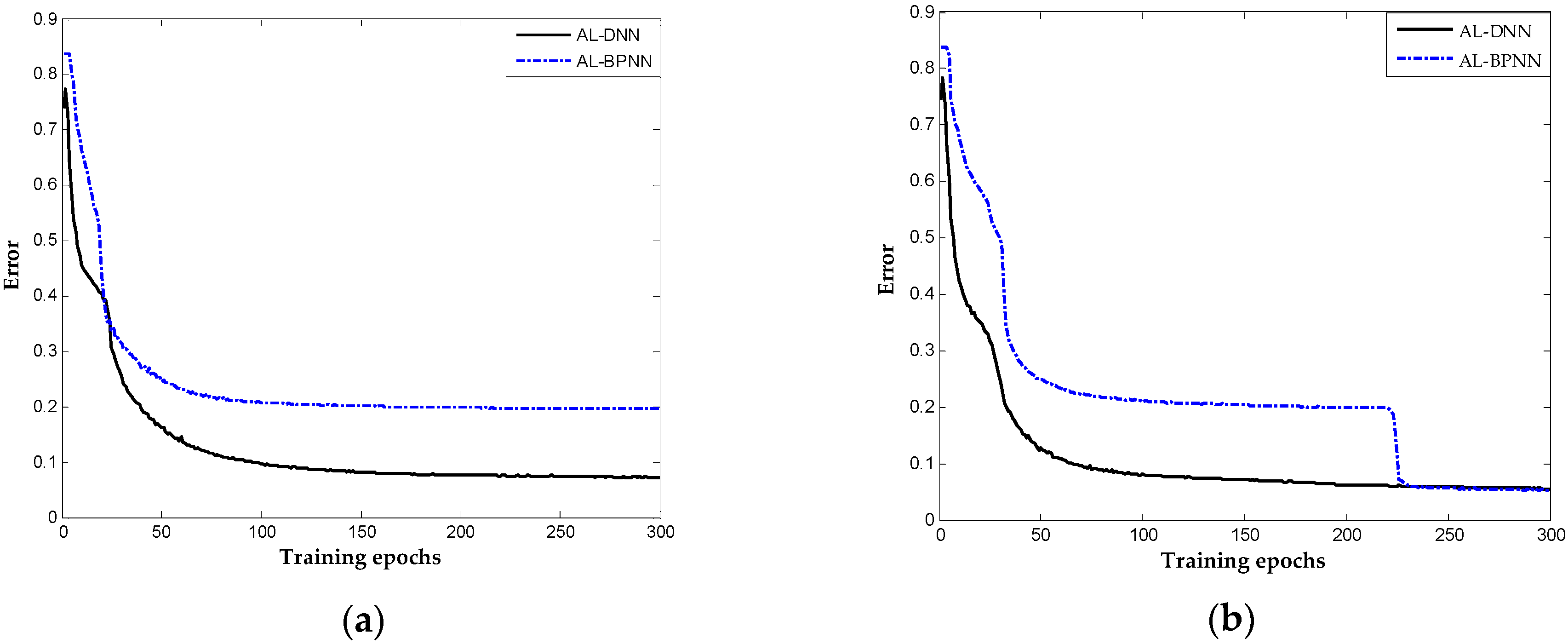

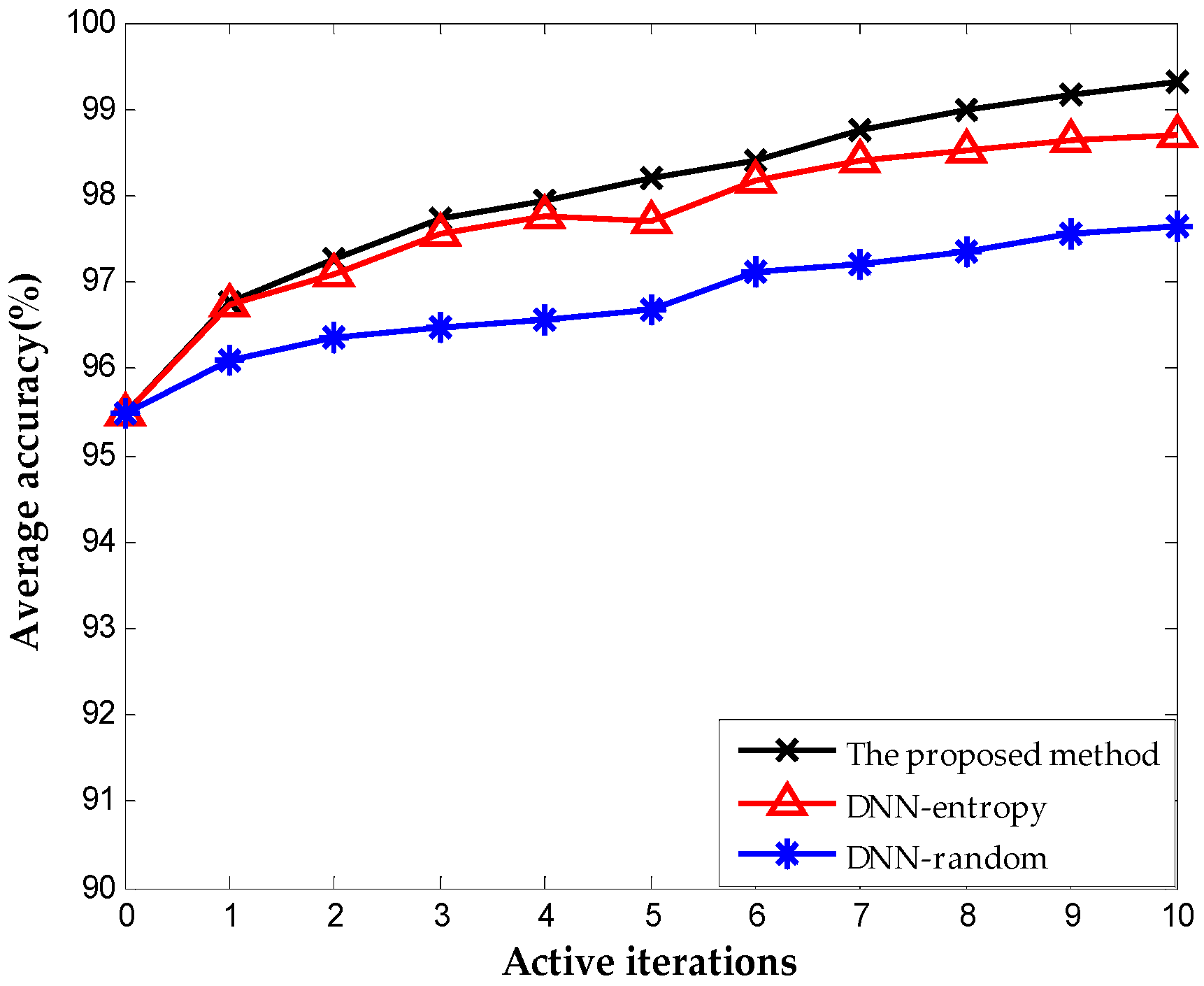

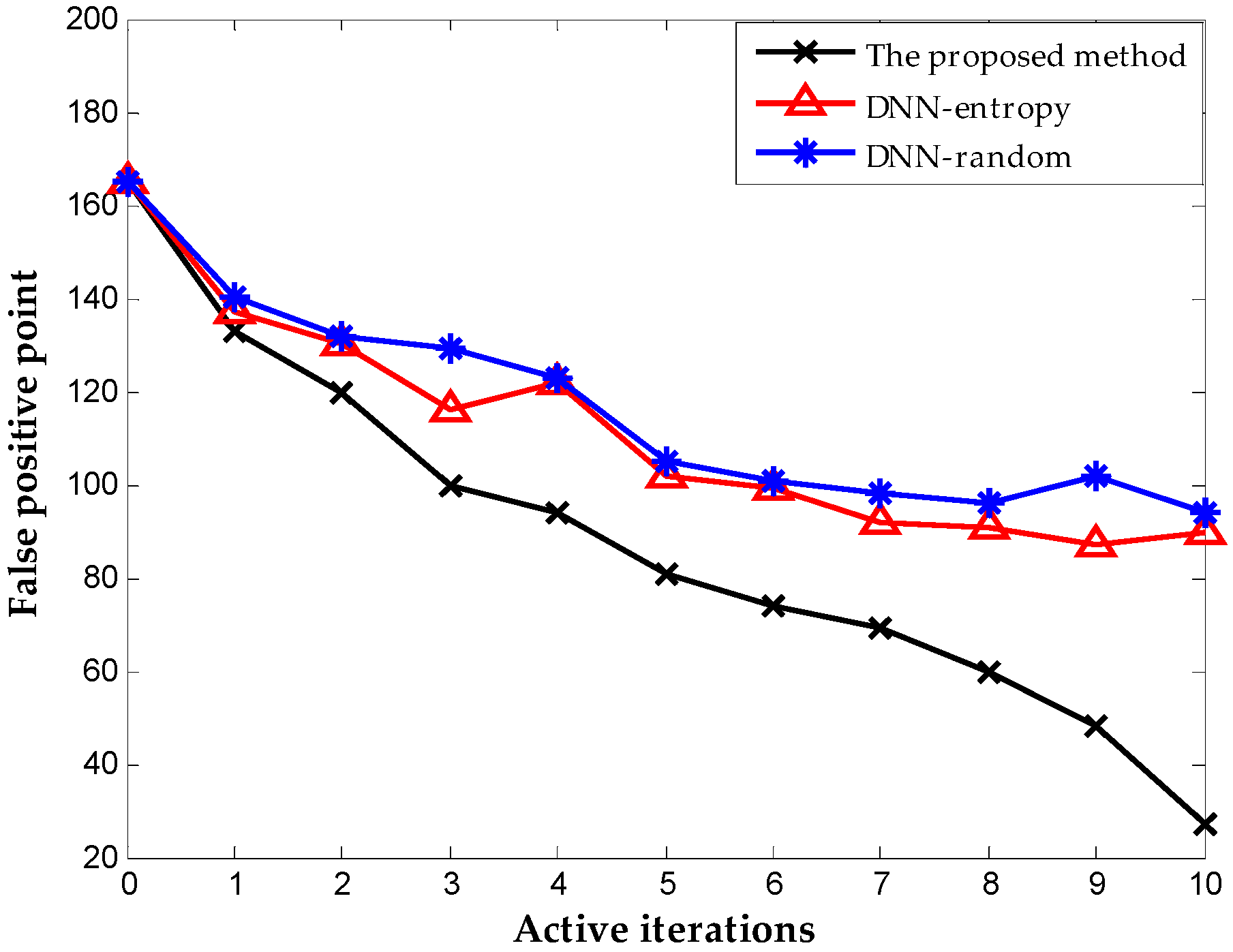

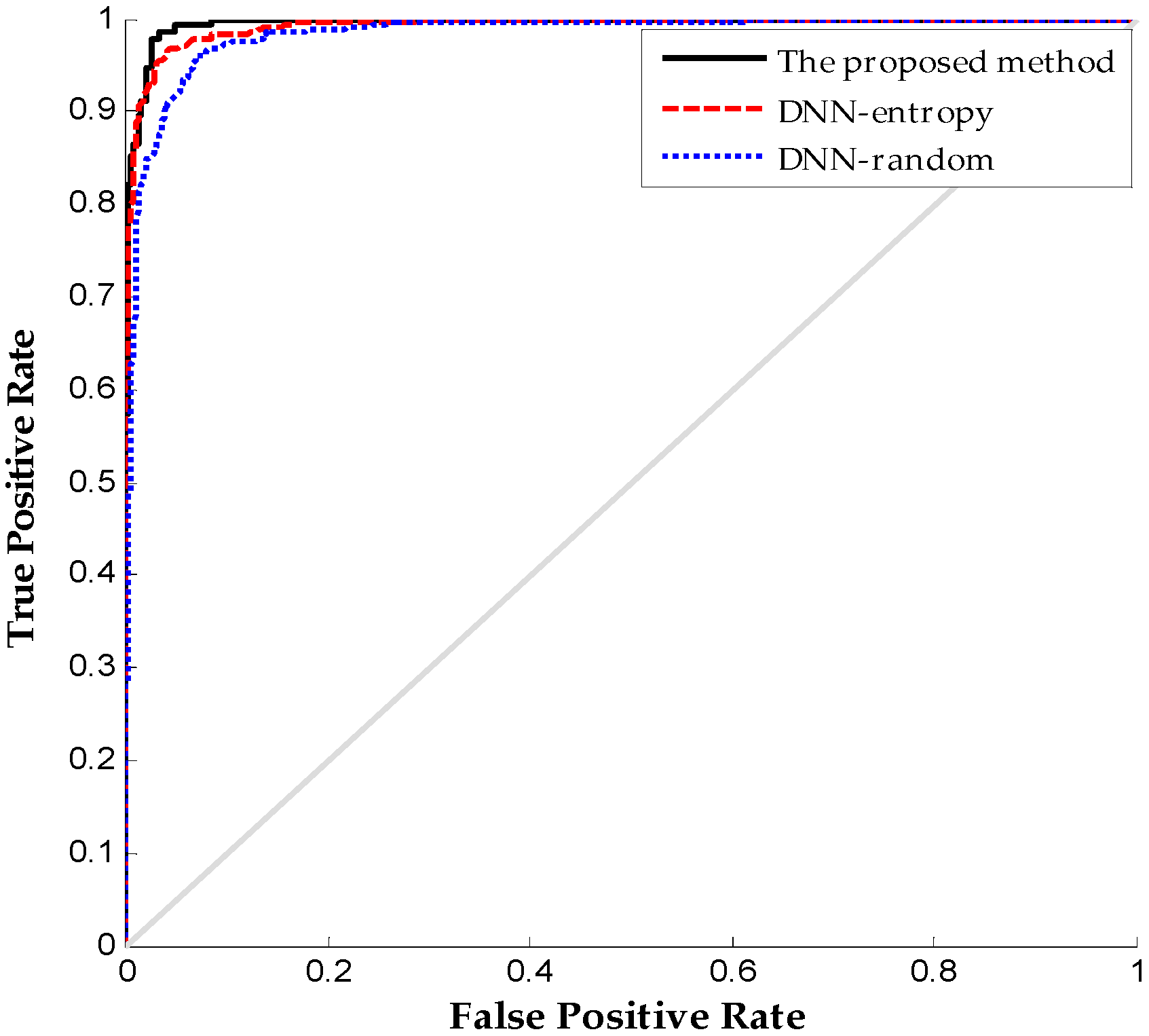

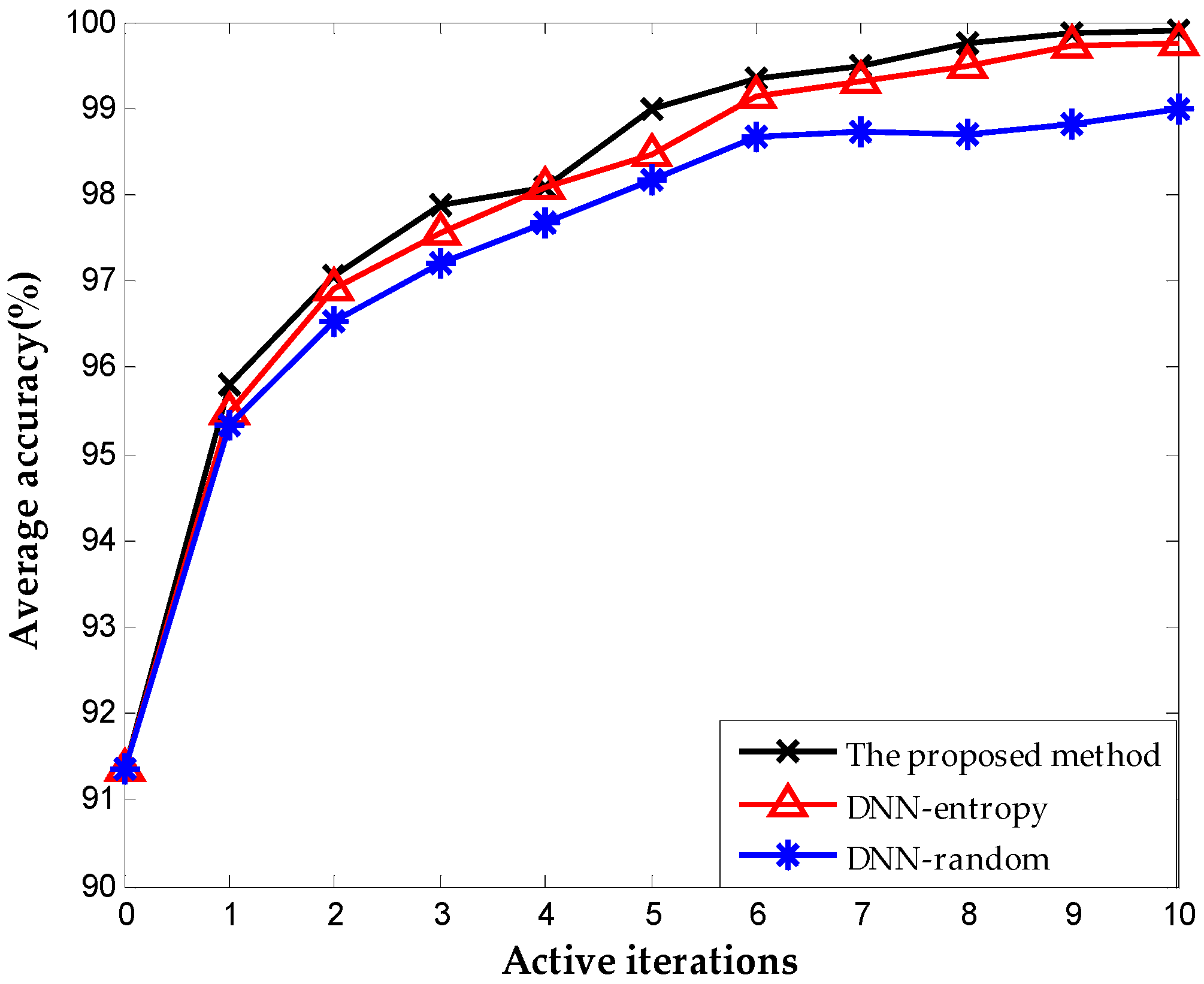

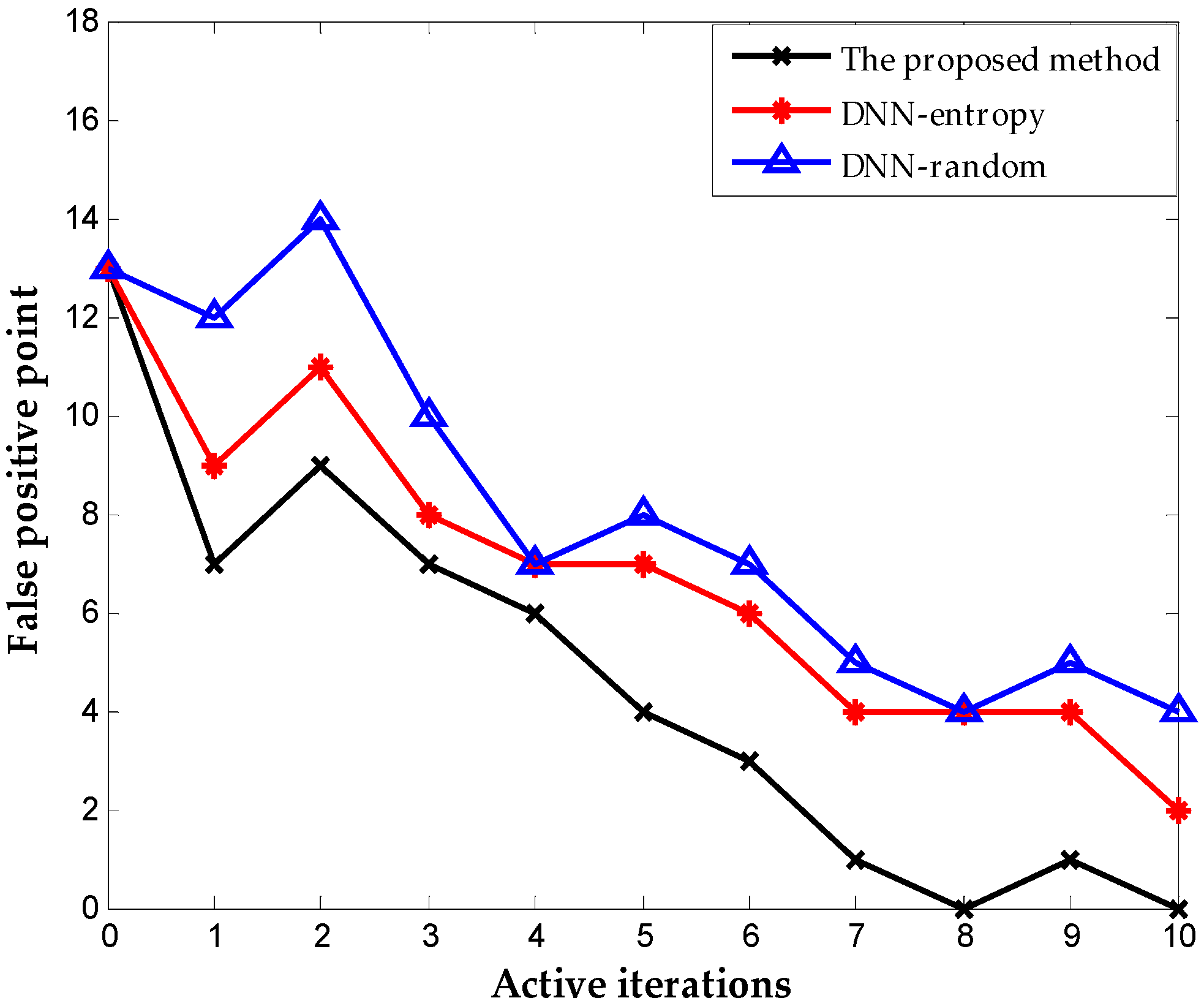

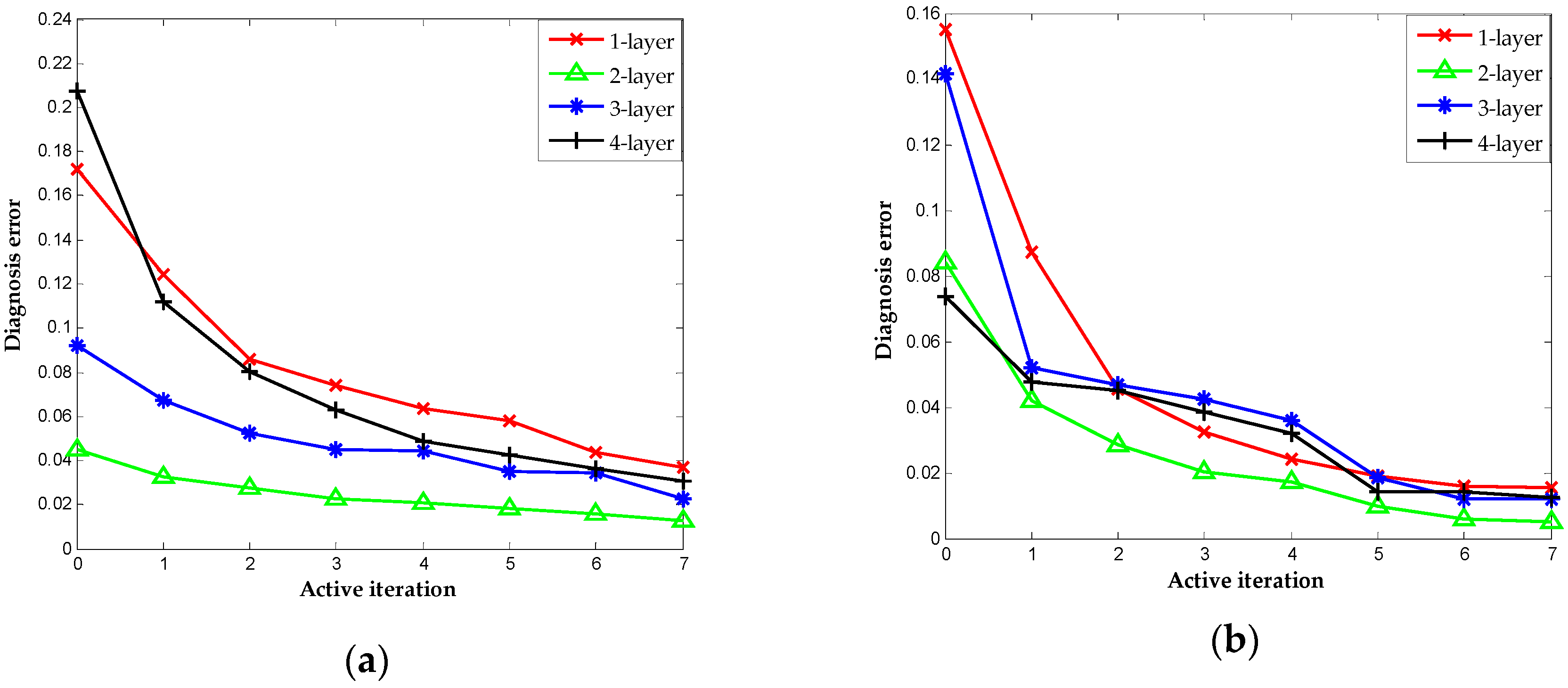

4.3.1. Result on UCI Dataset

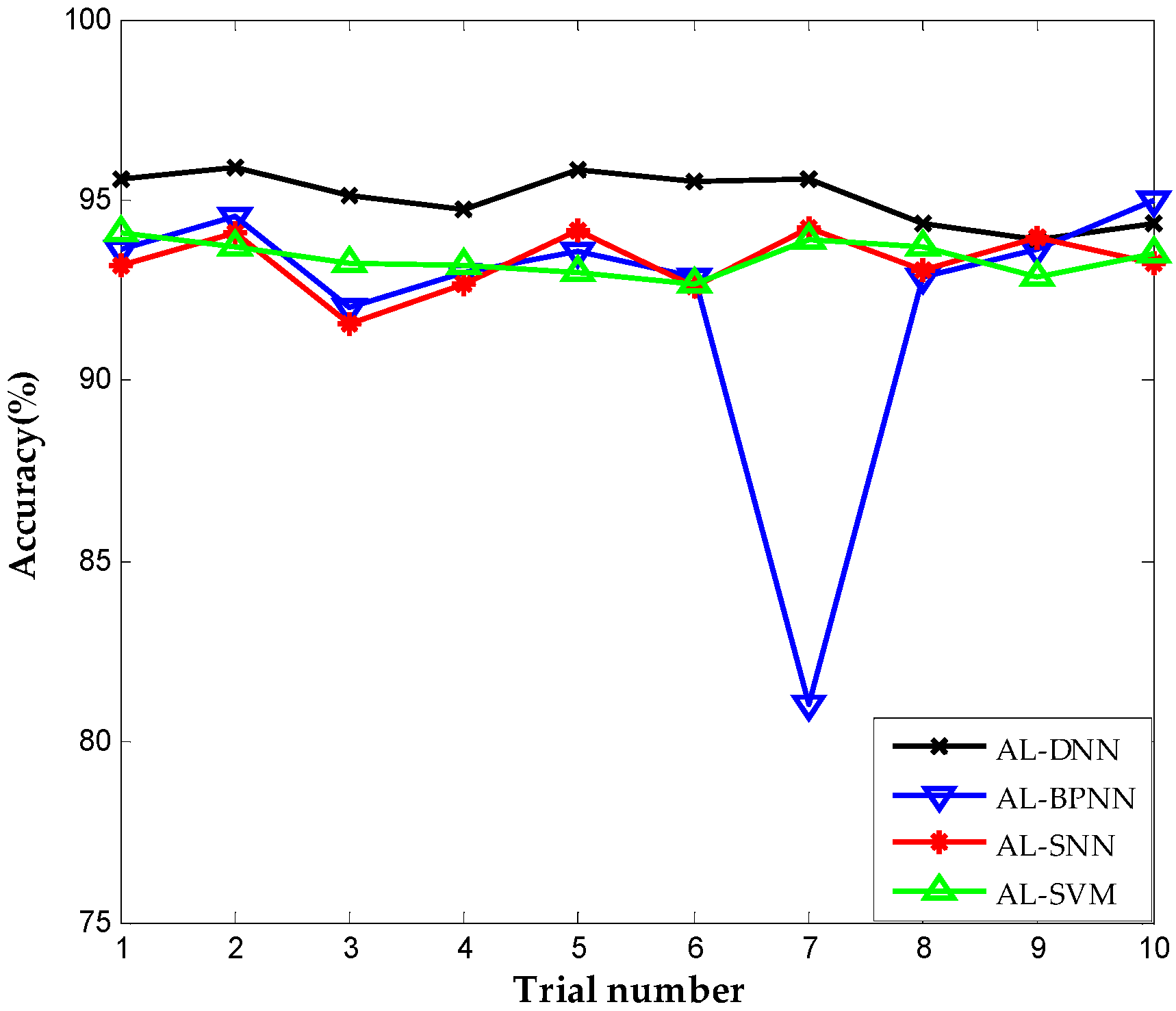

4.3.2. Result on TE Dataset

4.4. Discussion

5. Conclusions

- (1)

- It is able to adaptively mine the feature from the measured sensor signals or data by multiple non-linear transformations and approximate non-linear functions that provide more potential information for various diagnosis issues;

- (2)

- It is an efficient approach for the use of unlabeled sensor data that improves the nature of the diagnosis model in an unsupervised learning;

- (3)

- It relies on a novel active learning criterion compared with available methods to select the most valuable sensor data and improve the DNN significantly, which requires less labeled sensor data during the iterative labeling process.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Yélamos, I.; Escudero, G.; Graells, M.; Puigjaner, L. Performance assessment of a novel fault diagnosis system based on support vector machines. Comput. Chem. Eng. 2009, 33, 244–255. [Google Scholar] [CrossRef]

- Monroy, I.; Benitez, R.; Escudero, G.; Graells, M. A semi-supervised approach to fault diagnosis for chemical processes. Comput. Chem. Eng. 2010, 34, 631–642. [Google Scholar] [CrossRef]

- Tamilselvan, P.; Wang, P. Failure diagnosis using deep belief learning based health state classification. Reliab. Eng. Syst. Saf. 2013, 115, 124–135. [Google Scholar] [CrossRef]

- Kambatla, K.; Kollias, G.; Kumar, V.; Grama, A. Trends in big data analytics. J. Parallel Distrib. Comput. 2014, 74, 2561–2573. [Google Scholar] [CrossRef]

- Dai, X.; Gao, Z. From model, signal to knowledge: A data-driven perspective of fault detection and diagnosis. IEEE Trans. Ind. Inform. 2013, 9, 2226–2238. [Google Scholar] [CrossRef]

- Isermann, R. Model-based fault-detection and diagnosis–status and applications. Annu. Rev. Control 2005, 29, 71–85. [Google Scholar] [CrossRef]

- Li, F.; Upadhyaya, B.R.; Coffey, L.A. Model-based monitoring and fault diagnosis of fossil power plant process units using group method of data handling. ISA Trans. 2009, 48, 213–219. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Lin, J.; Karim, R. An angle-based subspace anomaly detection approach to high-dimensional data: With an application to industrial fault detection. Reliab. Eng. Syst. Saf. 2015, 142, 482–497. [Google Scholar] [CrossRef]

- Jia, F.; Lei, Y.; Lin, J.; Zhou, X.; Lu, N. Deep neural networks: A promising tool for fault characteristic mining and intelligent diagnosis of rotating machinery with massive data. Mech. Syst. Signal Process. 2016, 72, 303–315. [Google Scholar] [CrossRef]

- Mahadevan, S.; Shah, S.L. Fault detection and diagnosis in process data using one-class support vector machines. J. Process Control 2009, 19, 1627–1639. [Google Scholar] [CrossRef]

- Eslamloueyan, R. Designing a hierarchical neural network based on fuzzy clustering for fault diagnosis of the Tennessee-Eastman process. Appl. Soft Comput. 2011, 11, 1407–1415. [Google Scholar] [CrossRef]

- Zhang, X.; Zhou, J. Multi-fault diagnosis for rolling element bearings based on ensemble empirical mode decomposition and optimized support vector machines. Mech. Syst. Signal Process. 2013, 41, 127–140. [Google Scholar] [CrossRef]

- Azadeh, A.; Saberi, M.; Kazem, A.; Ebrahimipoura, V.; Nourmohammadzadeha, A.; Saberid, Z. A flexible algorithm for fault diagnosis in a centrifugal pump with corrupted data and noise based on ANN and support vector machine with hyper-parameters optimization. Appl. Soft Comput. 2013, 13, 1478–1485. [Google Scholar] [CrossRef]

- Amar, M.; Gondal, I.; Wilson, C. Vibration spectrum imaging: A novel bearing fault classification approach. IEEE Trans. Ind. Electron. 2015, 62, 494–502. [Google Scholar] [CrossRef]

- Bin, G.F.; Gao, J.J.; Li, X.J.; Dhillon, B.S. Early fault diagnosis of rotating machinery based on wavelet packets—Empirical mode decomposition feature extraction and neural network. Mech. Syst. Signal Process. 2012, 27, 696–711. [Google Scholar] [CrossRef]

- Martí, L.; Sanchez-Pi, N.; Molina, J.M.; Garcia, A.C. Anomaly detection based on sensor data in petroleum industry applications. Sensors 2015, 15, 2774–2797. [Google Scholar] [CrossRef] [PubMed]

- Shang, C.; Yang, F.; Huang, D.; Lyu, W. Data-driven soft sensor development based on deep learning technique. J. Process Control 2014, 24, 223–233. [Google Scholar] [CrossRef]

- Hinton, G.E.; Osindero, S.; Teh, Y.W. A fast learning algorithm for deep belief nets. Neural Comput. 2006, 18, 1527–1554. [Google Scholar] [CrossRef] [PubMed]

- Lu, W.; Wang, X.; Yang, C.; Zhang, T. A novel feature extraction method using deep neural network for rolling bearing fault diagnosis. In Proceedings of the IEEE 27th Chinese Control and Decision Conference (CCDC), Qingdao, China, 23–25 May 2015.

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. Imagenet classification with deep convolutional neural networks. In Proceedings of the Advances in neural information processing systems, Lake Tahoe, NV, USA, 3–8 December 2012; pp. 1097–1105.

- Nair, V.; Hinton, G.E. Rectified linear units improve restricted boltzmann machines. In Proceedings of the 27th International Conference on Machine Learning (ICML-10), Haifa, Israel, 21–24 June 2010; pp. 807–814.

- Socher, R.; Bengio, Y.; Manning, C.D. Deep learning for NLP (without magic). In Proceedings of the Tutorial Abstracts of ACL 2012, Association for Computational Linguistics, Jeju Island, Korea, 8–14 July 2012.

- Gan, M.; Wang, C. Construction of hierarchical diagnosis network based on deep learning and its application in the fault pattern recognition of rolling element bearings. Mech. Syst. Signal Process. 2016, 72, 92–104. [Google Scholar] [CrossRef]

- Sun, W.; Shao, S.; Zhao, R.; Yan, R.; Zhang, X.; Chen, X. A sparse auto-encoder-based deep neural network approach for induction motor faults classification. Measurement 2016, 89, 171–178. [Google Scholar] [CrossRef]

- Xie, D.; Bai, L. A Hierarchical Deep Neural Network for Fault Diagnosis on Tennessee-Eastman Process. In Proceedings of the IEEE 14th International Conference on Machine Learning and Applications (ICMLA), Miami, FL, USA, 9–11 December 2015; pp. 745–748.

- Zhu, X. Semi-Supervised Learning Literature Survey. Comput. Sci. 2008, 37, 63–77. [Google Scholar]

- Bordes, A.; Ertekin, S.; Weston, J.; Bottou, L. Fast kernel classifiers with online and active learning. J. Mach. Learn. Res. 2005, 6, 1579–1619. [Google Scholar]

- Tuia, D.; Pasolli, E.; Emery, W.J. Using active learning to adapt remote sensing image classifiers. Remote Sens. Environ. 2011, 115, 2232–2242. [Google Scholar] [CrossRef]

- Al Rahhal, M.M.; Bazi, Y.; AlHichri, H.; Alajlan, N.; Melgani, F.; Yager, R.R. Deep learning approach for active classification of electrocardiogram signals. Inf. Sci. 2016, 345, 340–354. [Google Scholar] [CrossRef]

- Settles, B. Active Learning Literature Survey; University of Wisconsin: Madison, WI, USA, 2010; Volume 52, p. 11. [Google Scholar]

- Bellala, G.; Stanley, J.; Bhavnani, S.K.; Scott, C. A rank-based approach to active diagnosis. IEEE Trans. Pattern Anal. Mach. Intell. 2013, 35, 2078–2090. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Li, M.; Xu, J.; Song, G. An effective procedure exploiting unlabeled data to build monitoring system. Expert Syst. Appl. 2011, 38, 10199–10204. [Google Scholar] [CrossRef]

- Bengio, Y. Learning deep architectures for AI. Found. Trends Mach. Learn. 2009, 2, 1–127. [Google Scholar] [CrossRef]

- Najafabadi, M.M.; Villanustre, F.; Khoshgoftaar, T.M.; Seliya, N.; Wald, R.; Muharemagic, E. Deep learning applications and challenges in big data analytics. J. Big Data 2015, 2, 1. [Google Scholar] [CrossRef]

- Vincent, P.; Larochelle, H.; Lajoie, I.; Bengio, Y.; Manzagol, P.A. Stacked denoising autoencoders: Learning useful representations in a deep network with a local denoising criterion. J. Mach. Learn. Res. 2010, 11, 3371–3408. [Google Scholar]

- Larochelle, H.; Bengio, Y.; Louradour, J.; Lamblin, P. Exploring strategies for training deep neural networks. J. Mach. Learn. Res. 2009, 10, 1–40. [Google Scholar]

- Kullback, S.; Leibler, R.A. On information and sufficiency. Ann. Math. Stat. 1951, 22, 79–86. [Google Scholar] [CrossRef]

- Rumelhart, D.E.; Hinton, G.E.; Williams, R.J. Learning representations by back-propagating errors. Cognit. Model. 1988, 5, 1. [Google Scholar] [CrossRef]

- Ellingson, B.M.; Zaw, T.; Cloughesy, T.F.; Naeini, K.M.; Lalezari, S.; Mong, S.; Lai, A.; Nghiemphu, P.L.; Pope, W.B. Comparison between intensity normalization techniques for dynamic susceptibility contrast (DSC)-MRI estimates of cerebral blood volume (CBV) in human gliomas. J. Magn. Reson. Imaging 2012, 35, 1472–1477. [Google Scholar] [CrossRef] [PubMed]

- Downs, J.J.; Vogel, E.F. A plant-wide industrial process control problem. Comput. Chem. Eng. 1993, 17, 245–255. [Google Scholar] [CrossRef]

- Ruiz, D.; Nougués, J.; Calderón, Z.; Espuna, A.; Puigjaner, L. Neural network based framework for fault diagnosis in batch chemical plants. Comput. Chem. Eng. 2000, 24, 777–784. [Google Scholar] [CrossRef]

| Description | Type |

|---|---|

| A/C feed ratio, B composition constant | 1 |

| B composition, A/C ration constant | 2 |

| Reactor cooling water inlet temperature | 3 |

| Condenser cooling water inlet temperature | 4 |

| A feed loss | 5 |

| C header pressure loss-reduced availability | 6 |

| Unknown fault | 7 |

| Parameter | DNN for Case Study 1 | DNN for Case Study 2 |

|---|---|---|

| Learning rate | 0.1 | 0.05 |

| Mini-batch | 100 | 50 |

| Momentum | 0.9 | 0.9 |

| Number of epoch | 100 | 100 |

| Coefficient of sparsity penalty | 0.05 | 0.05 |

| Noise level | 0.5 | 0.1 |

| Fault Type | Type 1 | Type 2 | Type 3 | Type 4 | Type 5 | Type 6 | Type 7 |

|---|---|---|---|---|---|---|---|

| The proposed method | 99.09% | 98.69% | 99.18% | 94.78% | 100% | 100% | 96.87% |

| DNN-entropy | 100% | 99.26% | 99.71% | 92.75% | 99.69% | 98.13% | 96.24% |

| DNN-random | 97.98% | 99.80% | 96.34% | 95.32% | 100% | 96.11% | 95.98% |

| AL-BPNN | 95.06% | 82.60% | 89.86% | 93.03% | 94.24% | 97.57% | 91.03% |

| AL-SNN | 97.26% | 77.56% | 75.36% | 87.10% | 84.37% | 94.56% | 89.26% |

| AL-SVM | 95.14% | 86.94% | 90.53% | 90.02% | 91.57% | 95.67% | 92.31% |

| Configuration | Case Study 1 | Case Study 2 |

|---|---|---|

| The unit number of hidden layer | {100} | {100} |

| The unit number of hidden layer | {200,100} | {100,50} |

| The unit number of hidden layer | {200,100,50} | {200,100,50} |

| The unit number of hidden layer | {300,200,100,50} | {200,100,100,50} |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, P.; Hu, Z.; Liu, J.; Yu, S.; Wu, F. Fault Diagnosis Based on Chemical Sensor Data with an Active Deep Neural Network. Sensors 2016, 16, 1695. https://doi.org/10.3390/s16101695

Jiang P, Hu Z, Liu J, Yu S, Wu F. Fault Diagnosis Based on Chemical Sensor Data with an Active Deep Neural Network. Sensors. 2016; 16(10):1695. https://doi.org/10.3390/s16101695

Chicago/Turabian StyleJiang, Peng, Zhixin Hu, Jun Liu, Shanen Yu, and Feng Wu. 2016. "Fault Diagnosis Based on Chemical Sensor Data with an Active Deep Neural Network" Sensors 16, no. 10: 1695. https://doi.org/10.3390/s16101695

APA StyleJiang, P., Hu, Z., Liu, J., Yu, S., & Wu, F. (2016). Fault Diagnosis Based on Chemical Sensor Data with an Active Deep Neural Network. Sensors, 16(10), 1695. https://doi.org/10.3390/s16101695