Capacitive Micromachined Ultrasonic Transducers (CMUTs) for Underwater Imaging Applications

Abstract

:1. Introduction

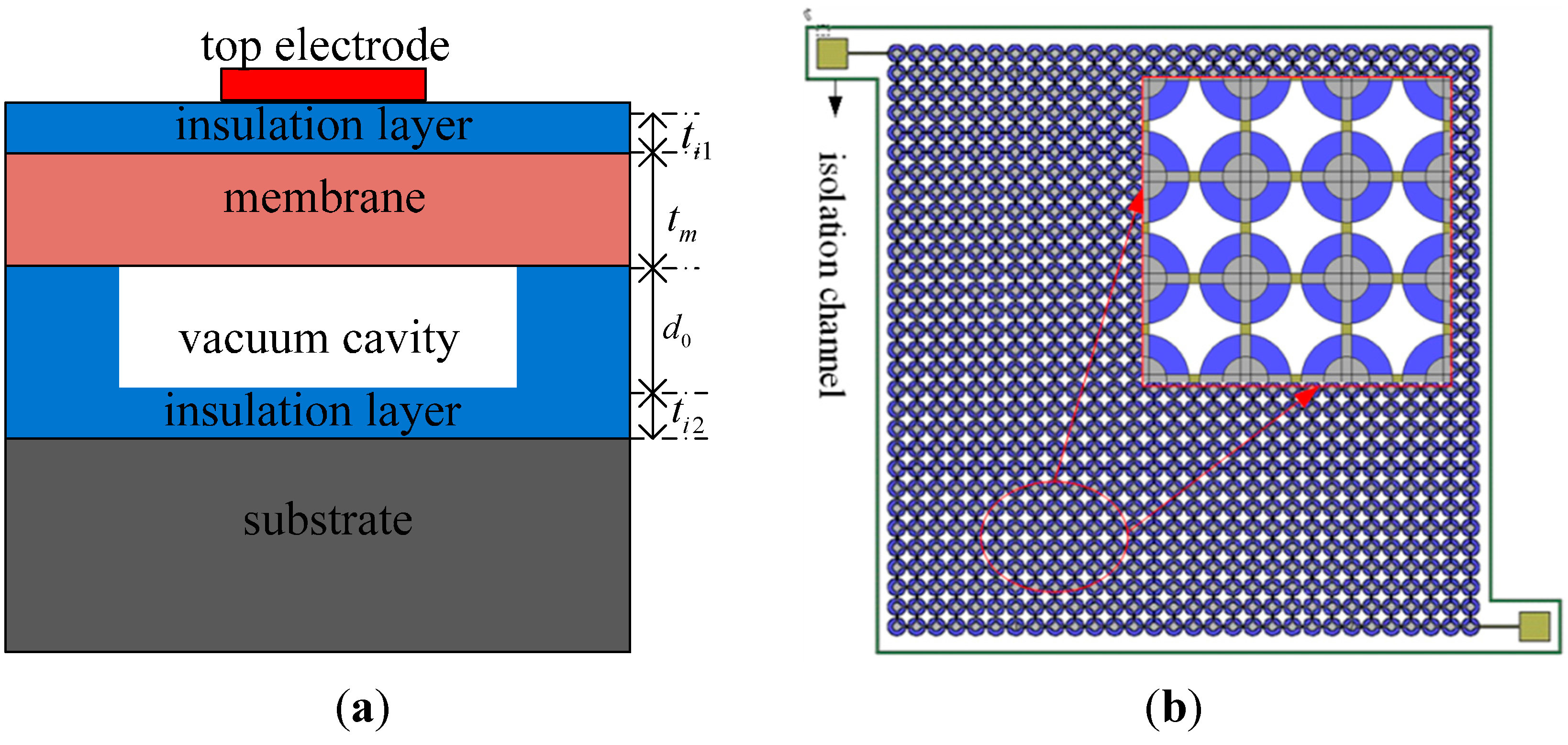

2. Structural Design

| Parameters | Value |

|---|---|

| Membrane radius/μm | 90 |

| Membrane thickness/μm | 2.8 |

| Electrode radius/μm | 45 |

| Electrode thickness/μm | 1 |

| Number of cells | 900 |

| Electrode insulation layer thickness/μm | 0.15 |

| Insulation layer thickness/μm | 0.15 |

| Cavity height/μm | 0.65 |

3. Fabrication Process

| Parameter | SOI Wafer | Silicon Wafer | |

|---|---|---|---|

| Size (inches) | 6 | 6 | |

| Conductive type | Device layer | P | P |

| Handle wafer | N | ||

| Resistivity (ohm∙cm) | Device layer | 0.01–0.08 | 0.01–0.02 |

| Handle wafer | 0.01–0.02 | ||

| Orientation | (100) | (100) | |

| Thickness (μm) | Device layer | 2.8 ± 0.1 | 400 ± 10 |

| Box layer | 0.8 ± 0.08 | ||

| Handle wafer | 430 ±15 | ||

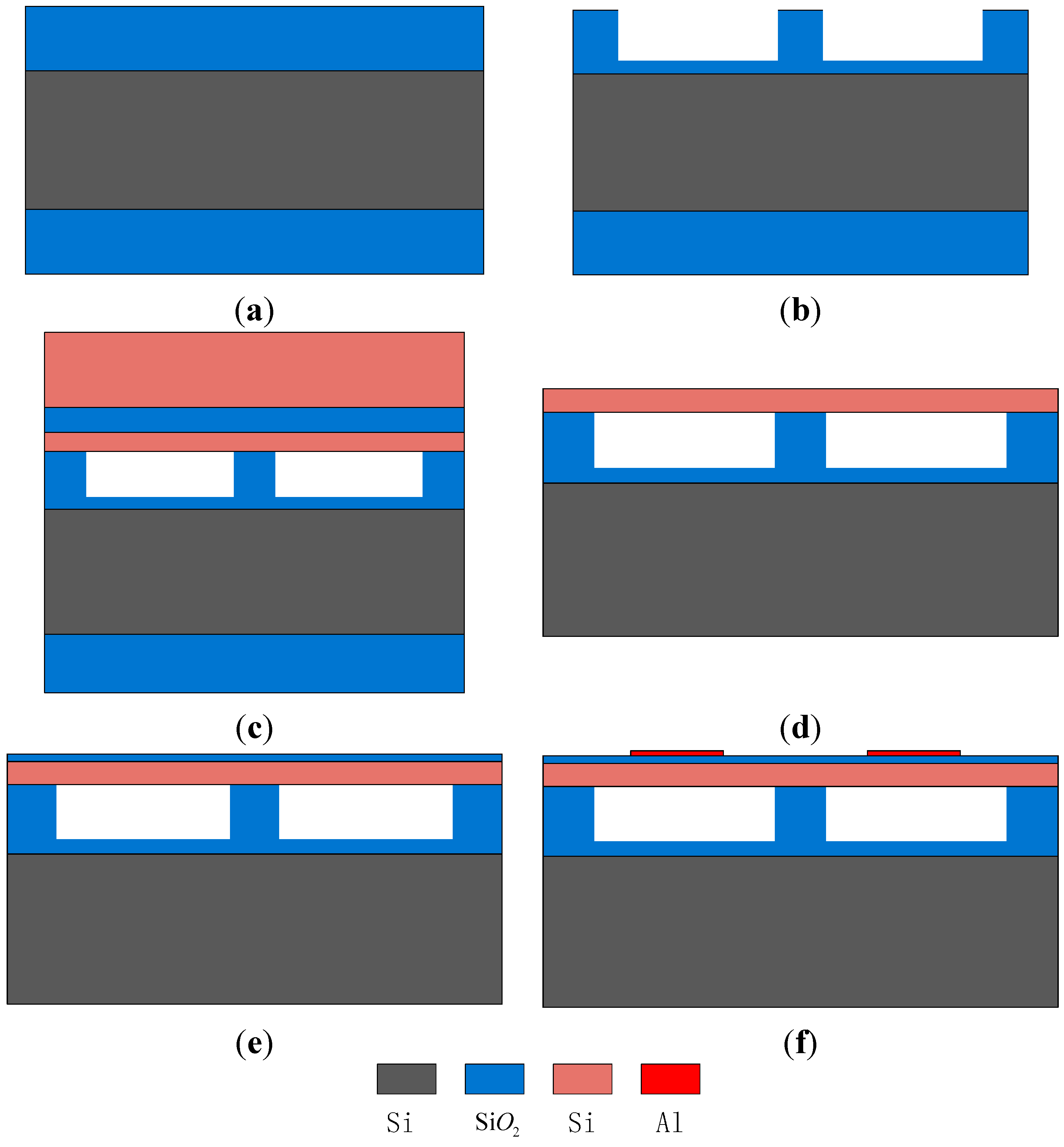

- Step 1

- Standard RCA cleaning is performed on both the silicon wafer and the SOI wafer to remove organic matter, dust and oxide layers.

- Step 2

- The silicon wafer is then oxidized to form a 0.8- oxide layer, which will be part-etched to form cavities, as shown in Figure 2a.

- Step 3

- Gluing and exposure processes are performed on the front area of the silicon wafer; a 0.65- oxide layer is etched to form the cavities and a 0.15- oxide layer is left behind to prevent membrane contact with the substrate, as shown in Figure 2b.

- Step 4

- Step 5

- The handle layer of the SOI wafer, the buried oxide (box) layer of the SOI wafer and the oxide layer are etched to produce the basic transducer structure, as shown in Figure 2d.

- Step 6

- A silicon dioxide layer is deposited on the vibration membrane to prevent the formation of an ohmic contact between the top electrodes and the vibration membrane, as shown in Figure 2e.

- Step 7

- A metal layer is sputtered on the vibration membrane by the evaporation method, and the top electrodes and pads are formed by the peeling method, as shown in Figure 2f.

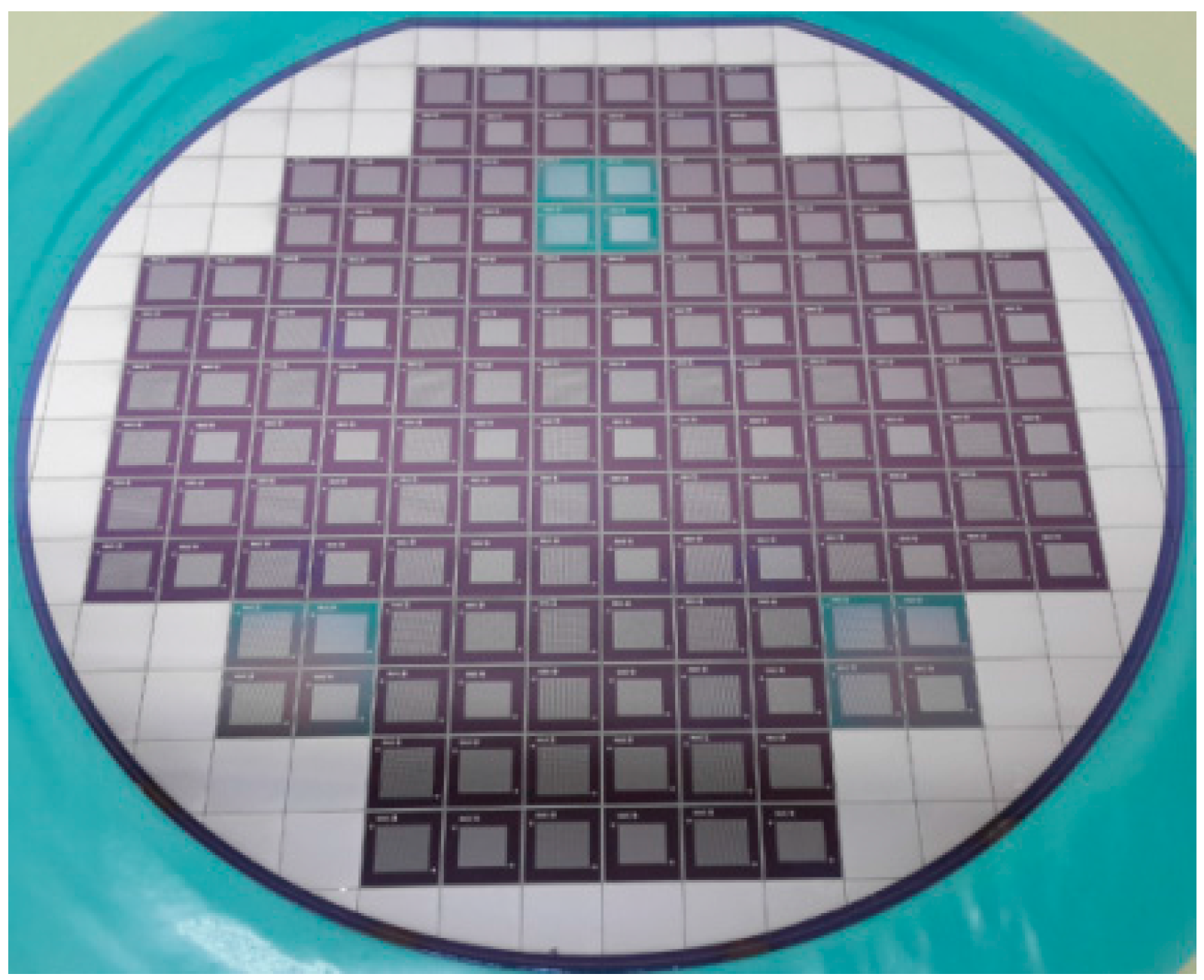

4. Experimental Results

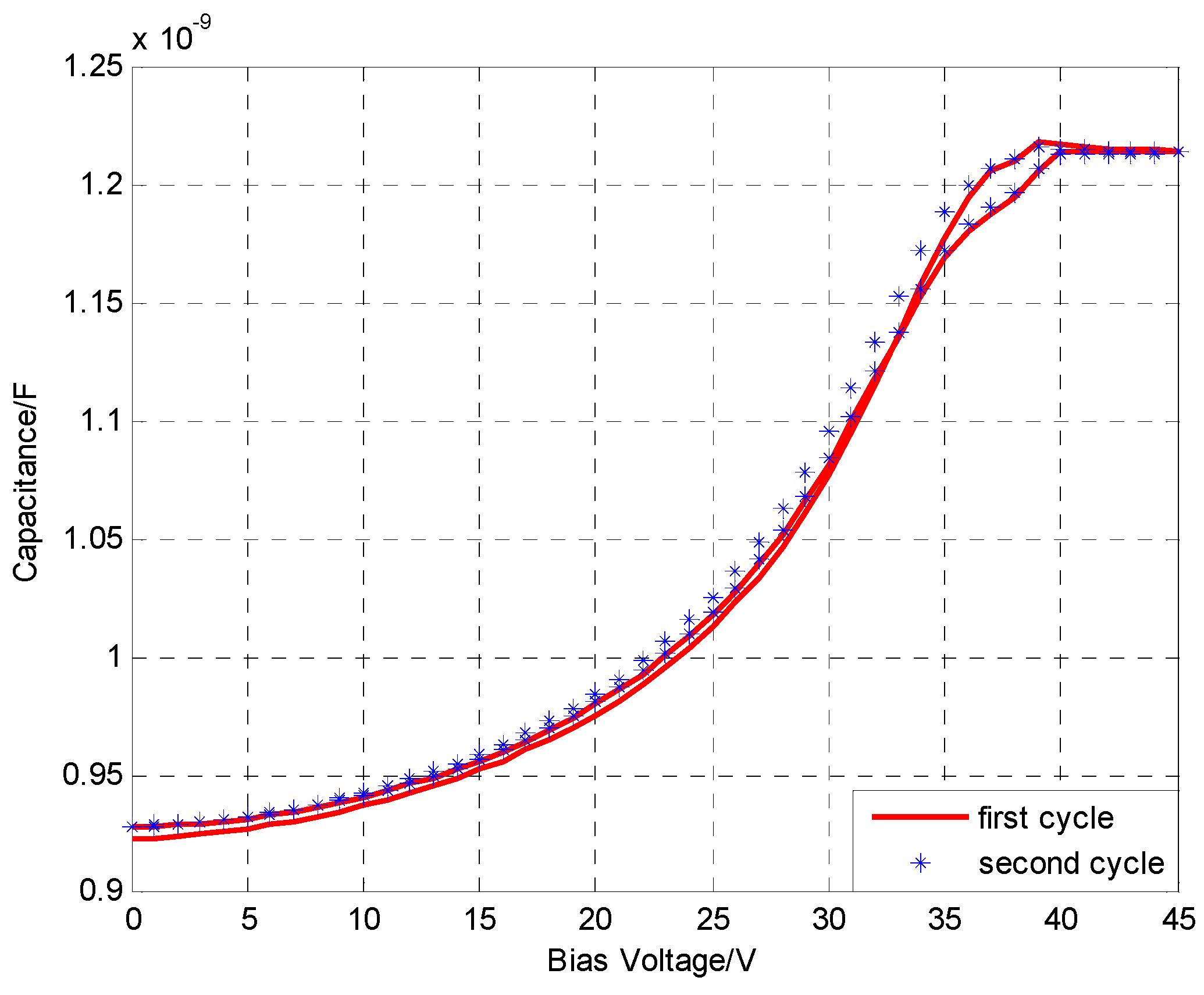

4.1. C-V Characteristics

4.2. Underwater Experiments

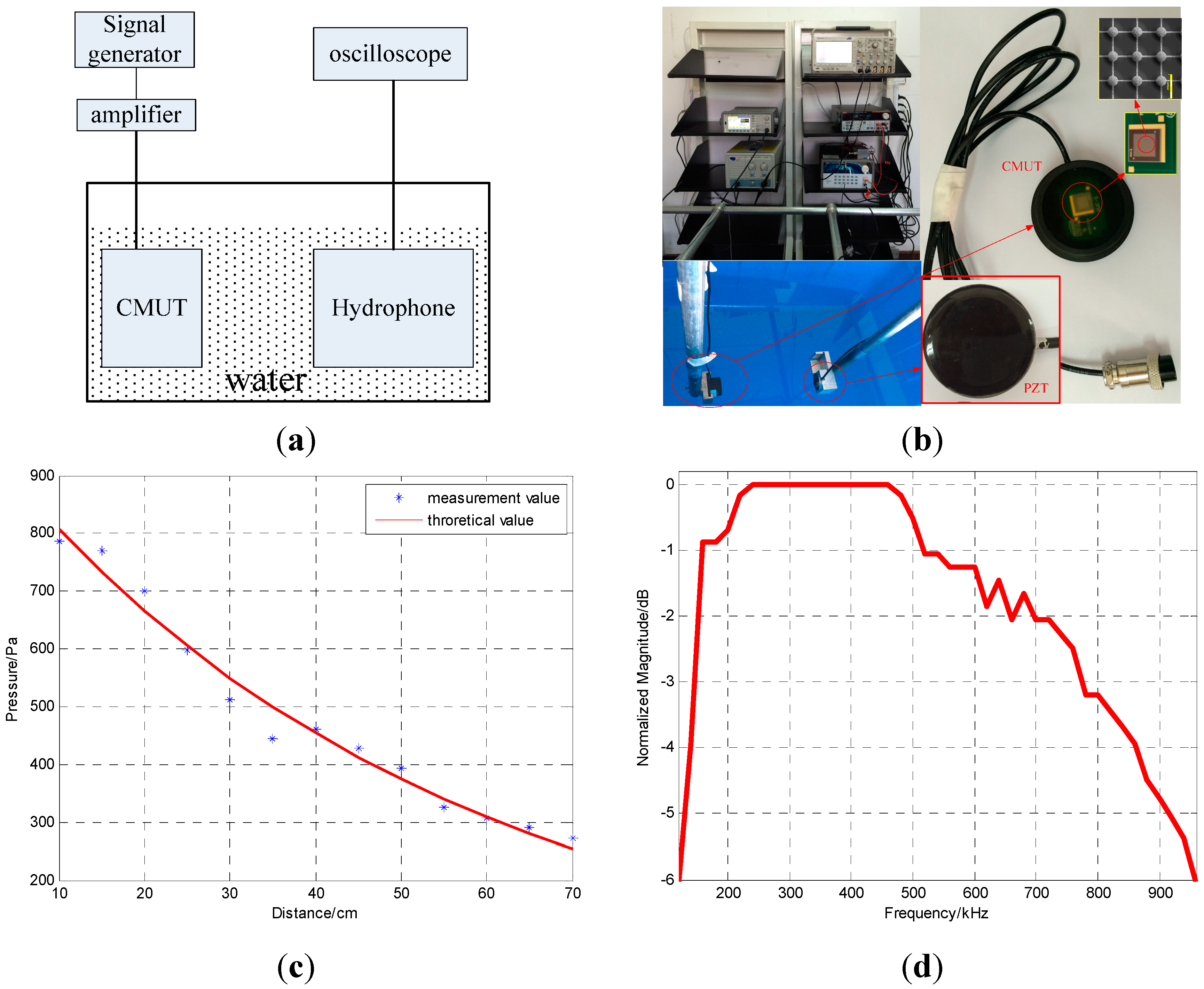

4.2.1. Output Pressure and Bandwidth Testing

| Distance/cm | Measurement Pressure/Pa | Theoretical Pressure/Pa | Derivation Pressure/Pa | |

|---|---|---|---|---|

| 1 | 10.00 | 786.7700 | 807.3977 | 20.6277 |

| 2 | 15.00 | 769.6664 | 733.4918 | −36.1746 |

| 3 | 20.00 | 701.2516 | 666.3509 | −34.9007 |

| 4 | 25.00 | 598.6294 | 605.3558 | 6.7264 |

| 5 | 30.00 | 513.1109 | 549.9440 | 36.8331 |

| 6 | 35.00 | 444.6961 | 499.6043 | 54.9082 |

| 7 | 40.00 | 461.7998 | 453.8725 | −7.9273 |

| 8 | 45.00 | 427.5924 | 412.3269 | −15.2655 |

| 9 | 50.00 | 393.3850 | 374.5841 | −18.8009 |

| 10 | 55.00 | 324.9702 | 340.2962 | 15.3260 |

| 11 | 60.00 | 307.8665 | 309.14684 | 1.28034 |

| 12 | 65.00 | 290.7628 | 280.8488 | −9.9140 |

| 13 | 70.00 | 273.6591 | 255.1410 | −18.5181 |

4.2.2. Distance Testing

| Real Distance/cm | Measurement Distance/cm | Deviation/cm | |

|---|---|---|---|

| 1 | 5 | 5.65 | 0.65 |

| 2 | 10 | 11.46 | 1.46 |

| 3 | 15 | 15.22 | 0.22 |

| 4 | 20 | 21.72 | 1.72 |

| 5 | 25 | 26.45 | 1.45 |

| 6 | 30 | 31.67 | 1.67 |

| 7 | 35 | 36.37 | 1.37 |

| 8 | 40 | 41.25 | 1.25 |

| 9 | 45 | 46.30 | 1.3 |

| 10 | 50 | 51.31 | 1.31 |

| 11 | 55 | 55.85 | 0.85 |

| 12 | 60 | 61.23 | 1.23 |

| 13 | 65 | 65.83 | 0.83 |

| 14 | 70 | 70.67 | 0.67 |

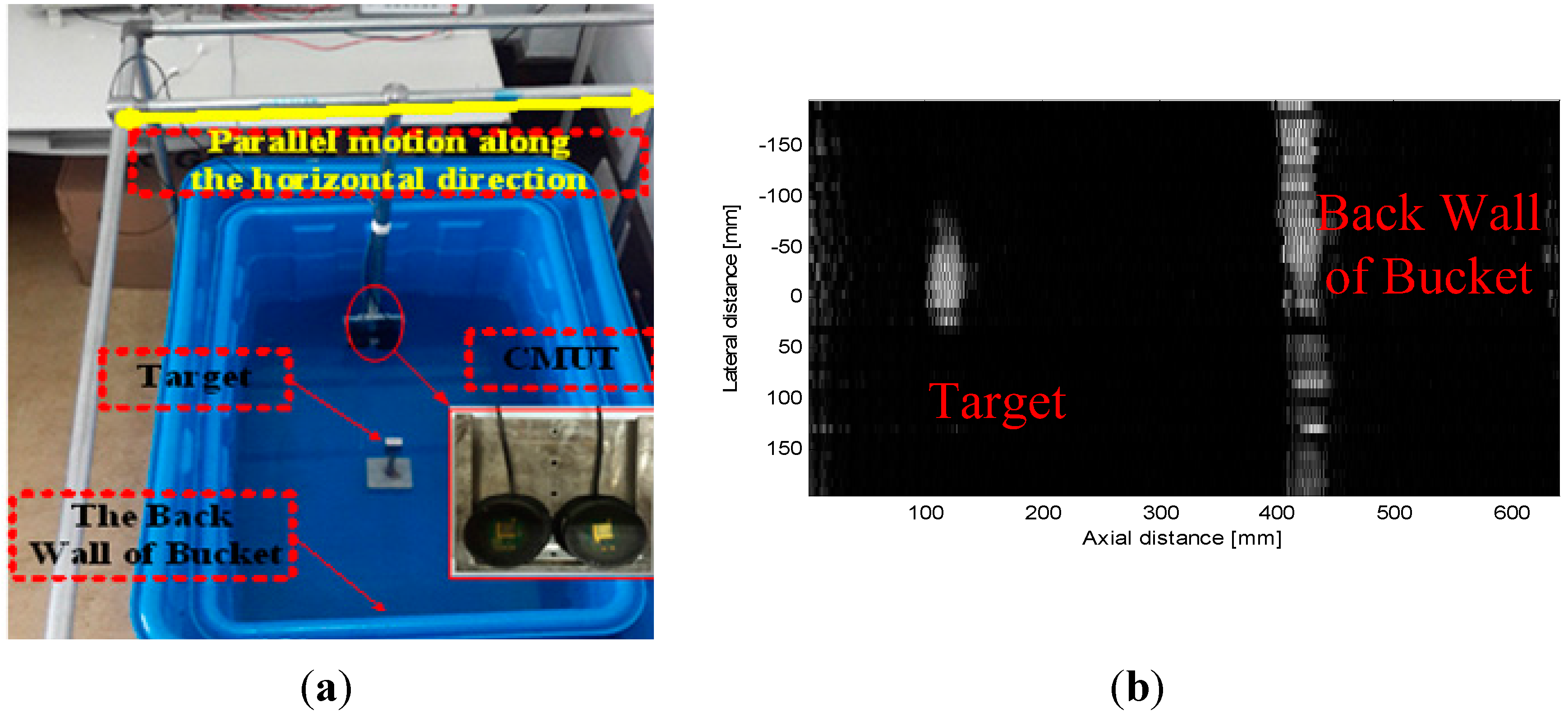

4.2.3. Underwater Imaging

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Oralkan, O.; Ergun, A.S.; Cheng, C.H.; Johnson, J.A.; Karaman, M.; Khuri-Yakub, B.T. Underwater acoustic imaging using capacitive micromachined ultrasonic transducer arrays. In Proceedings of the OCEANS’02 MTS/IEEE, Biloxi, MI, USA, 29–31 October 2002; pp. 2354–2360.

- Sutton, J.L. Underwater acoustic imaging. IEEE Proc. 1979, 67, 554–566. [Google Scholar] [CrossRef]

- Oralkan, O.; Ergun, A.S.; Johnson, J.A.; Karaman, M.; Demirci, U.; Kaviani, K.; Lee, T.H.; Khuri-Yakub, B.T. Capacitive micromachined ultrasonic transducers: Next-generation arrays for acoustic imaging? IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2002, 49, 1596–1610. [Google Scholar] [CrossRef] [PubMed]

- Ito, S.; Suzuki, T.; Ito, T.; Katoh, O.; Ojio, S.; Sato, H.; Ehara, M.; Suzuki, T.; Kawase, Y.; Myoishi, M.; et al. Novel Technique Using Intravascular Ultrasound-Guided Guidewire Cross in Coronary Intervention for Uncrossable Chronic Total Occlusions. Circ. J. 2004, 68, 1088–1092. [Google Scholar] [CrossRef] [PubMed]

- Courtney, B.K.; Munce, N.R.; Anderson, K.J.; Thind, A.S.; Leung, G.; Radau, P.E.; Foster, F.S.; Vitkin, I.A.; Schwartz, R.S.; Dick, A.J.; et al. Innovations in imaging for chronic total occlusions: A glimpse into the future of angiography’s blind-spot. Eur. Heart J. 2008, 29, 583–593. [Google Scholar] [CrossRef] [PubMed]

- Park, K.K.; Lee, H.; Kupnik, M.; Khuri-Yakub, B.T. Fabrication of Capacitive Micromachined Ultrasonic Transducers via Local Oxidation and Direct Wafer Bonding. J. Microelectromech. Syst. 2011, 20, 95–103. [Google Scholar] [CrossRef]

- Ladabaum, I.; Khuri-Yakub, B.T.; Spoliansky, D.; Haller, M.I. Micromachined ultrasonic transducers (MUTs). In Proceedings of the 1995 IEEE Ultrasonics Symposium, Seattle, WA, USA, 7–10 November 1995; Volume 1, pp. 501–504.

- Jeong, B.; Kim, D.; Hong, S.; Chung, S.; Shin, H. Performance and reliability of new CMUT design with improved efficiency. Sens. Actuators A Phys. 2013, 199, 325–333. [Google Scholar] [CrossRef]

- Emadi, T.A.; Buchanan, D.A. Multiple moving membrane CMUT with enlarged membrane displacement and low pull-down voltage. IEEE Electron Device Lett. 2013, 34, 1578–1580. [Google Scholar] [CrossRef]

- Ergun, A.S.; Yaralioglu, G.G.; Khuri-Yakub, B.T. Capacitive micromachined ultrasonic transducers: Theory and technology. Am. Soc. Civ. Eng. 2014, 16, 76–84. [Google Scholar] [CrossRef]

- Jin, X.; Ladabaum, I.; Khuri-Yakub, B.T. The microfabrication of capacitive ultrasonic transducers. J. Microelectromech. Syst. 1998, 7, 295–302. [Google Scholar]

- Salim, M.S.; Malek, M.F.A.; Heng, R.B.W.; Juni, K.M.; Sabri, N. Capacitive Micromachined Ultrasonic Transducers: Technology and Application. J. Med. Ultrasound 2012, 20, 8–31. [Google Scholar] [CrossRef]

- Cianci, E.; Foglietti, V.; Caliano, G.; Pappalardo, M. Micromachined capacitive ultrasonic transducers fabricated using silicon on insulator wafers. Microelectron. Eng. 2002, 61–62, 1025–1029. [Google Scholar] [CrossRef]

- Suo, X. Simulation and Deformation Analysis of CMUT Membrane; South China University of Technology: Guangzhou, China, 2013. [Google Scholar]

- Chen, J.; Cheng, X.; Chen, C.; Li, P. A Capacitive Micromachined Ultrasonic Transducer Array for Minimally Invasive Medical Diagnosis. J. Microelectromech. Syst. 2008, 17, 599–610. [Google Scholar] [CrossRef]

- Liu, J.; Oakley, C.; Shandas, R. Capacitive micromachined ultrasonic transducers using commercial multi-user MUMPs process: Capability and limitations. Ultrasonics 2009, 49, 765–773. [Google Scholar] [CrossRef] [PubMed]

- Doody, B.C.; Cheng, X.; Rich, A.C.; Lemmerhirt, D.F.; White, R.D. Modeling and Characterization of CMOS-Fabricated Capacitive Micromachined Ultrasound Transducers. J. Microelectromech. Syst. 2011, 20, 104–118. [Google Scholar] [CrossRef]

- Helin, P.; Czarnecki, P.; Verbist, A.; Bryce, G.; Rottenberg, X. Severi S: Poly-SiGe-based CMUT array with high acoustical pressure. In Proceedings of the 2012 IEEE 25th International Conference on Micro Electro Mechanical Systems (MEMS), Paris, France, 29 January–2 February 2012; pp. 305–308.

- Olcum, S.; Oguz, K.; Senlik, M.N.; Yamaner, F.Y.; Bozkurt, A.; Atalar, A.; Koymen, H. Wafer bonded capacitive micromachined underwater transducers. In Proceedings of the 2009 IEEE International Ultrasonics Symposium (IUS), Rome, Italy, 20–23 September 2009; pp. 976–979.

- Jin, X.; Ladabaum, I.; Degertekin, F.; Calmes, S.; Khuri-Yakub, B.T. Fabrication and characterization of surface micromachined capacitive ultrasonic immersion transducers. J. Microelectromech. Syst. 1999, 8, 100–114. [Google Scholar]

- Wong, S.H.; Kupnik, M.; Watkins, R.D.; Butts-Pauly, K.; Khuri-Yakub, B.T. Capacitive Micromachined Ultrasonic Transducers for Therapeutic Ultrasound Applications. IEEE Trans. Biom. Eng. 2010, 57, 114–123. [Google Scholar] [CrossRef] [PubMed]

- Logan, A.S. The Design, Fabrication and Characterization of Capacitive Micromachined Ultrasonic Transducers for Imaing Applications. Ph.D. Thesis, The University of Waterloo, Waterloo, ON, Canada, 2010. [Google Scholar]

- Li, Y.; He, C.; Zhang, J.; Zhang, H.; Song, J.; Xue, C. Design and analysis of MEMS capacitive ultrasonic transducer. Transducer Microsyst. Technol. 2014, 33, 73–75. [Google Scholar]

- Zhuang, X. Capacitive Micromachined Ultrasonic Transducers with Through-Wafer Interconnects. Ph.D. Thesis, Stanford University, Stanford, CA, USA, 2008. [Google Scholar]

- Bozkurt, A.; Ladabaum, I.; Atalar, A.; Khuri-Yakub, B.T. Theory and analysis of electrode size optimization for capacitive microfabricated ultrasonic transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1999, 46, 1364–1374. [Google Scholar] [CrossRef] [PubMed]

- Emadi, T.A.; Buchanan, D.A. Development of a novel configuration for a MEMS transducer for low bias and high resolution imaging applications. Proc. SPIE 2014, 8976. [Google Scholar] [CrossRef]

- Tong, Q.Y.; Cha, G.; Gafiteanu, R.; Gosele, U. Low temperature wafer direct bonding. J. Microelectromech. Syst. 1994, 3, 29–35. [Google Scholar] [CrossRef]

- Tsuji, Y.; Kupnik, M.; Khuri-Yakub, B.T. Low temperature process for CMUT fabrication with wafer bonding technique. In Proceedings of the Ultrasonics Symposium (IUS), San Diego, CA, USA, 11–14 October 2010; pp. 551–554.

- Feng, N. Ultrasonics Handbook; Nanjing University Press: Nanjing, China, 2006; pp. 16–31. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, J.; Xue, C.; He, C.; Zhang, R.; Mu, L.; Cui, J.; Miao, J.; Liu, Y.; Zhang, W. Capacitive Micromachined Ultrasonic Transducers (CMUTs) for Underwater Imaging Applications. Sensors 2015, 15, 23205-23217. https://doi.org/10.3390/s150923205

Song J, Xue C, He C, Zhang R, Mu L, Cui J, Miao J, Liu Y, Zhang W. Capacitive Micromachined Ultrasonic Transducers (CMUTs) for Underwater Imaging Applications. Sensors. 2015; 15(9):23205-23217. https://doi.org/10.3390/s150923205

Chicago/Turabian StyleSong, Jinlong, Chenyang Xue, Changde He, Rui Zhang, Linfeng Mu, Juan Cui, Jing Miao, Yuan Liu, and Wendong Zhang. 2015. "Capacitive Micromachined Ultrasonic Transducers (CMUTs) for Underwater Imaging Applications" Sensors 15, no. 9: 23205-23217. https://doi.org/10.3390/s150923205

APA StyleSong, J., Xue, C., He, C., Zhang, R., Mu, L., Cui, J., Miao, J., Liu, Y., & Zhang, W. (2015). Capacitive Micromachined Ultrasonic Transducers (CMUTs) for Underwater Imaging Applications. Sensors, 15(9), 23205-23217. https://doi.org/10.3390/s150923205