Early Fault Diagnosis of Bearings Using an Improved Spectral Kurtosis by Maximum Correlated Kurtosis Deconvolution

Abstract

:1. Introduction

2. Theoretical Background

2.1. MCKD Technique

2.2. Spectral Kurtosis

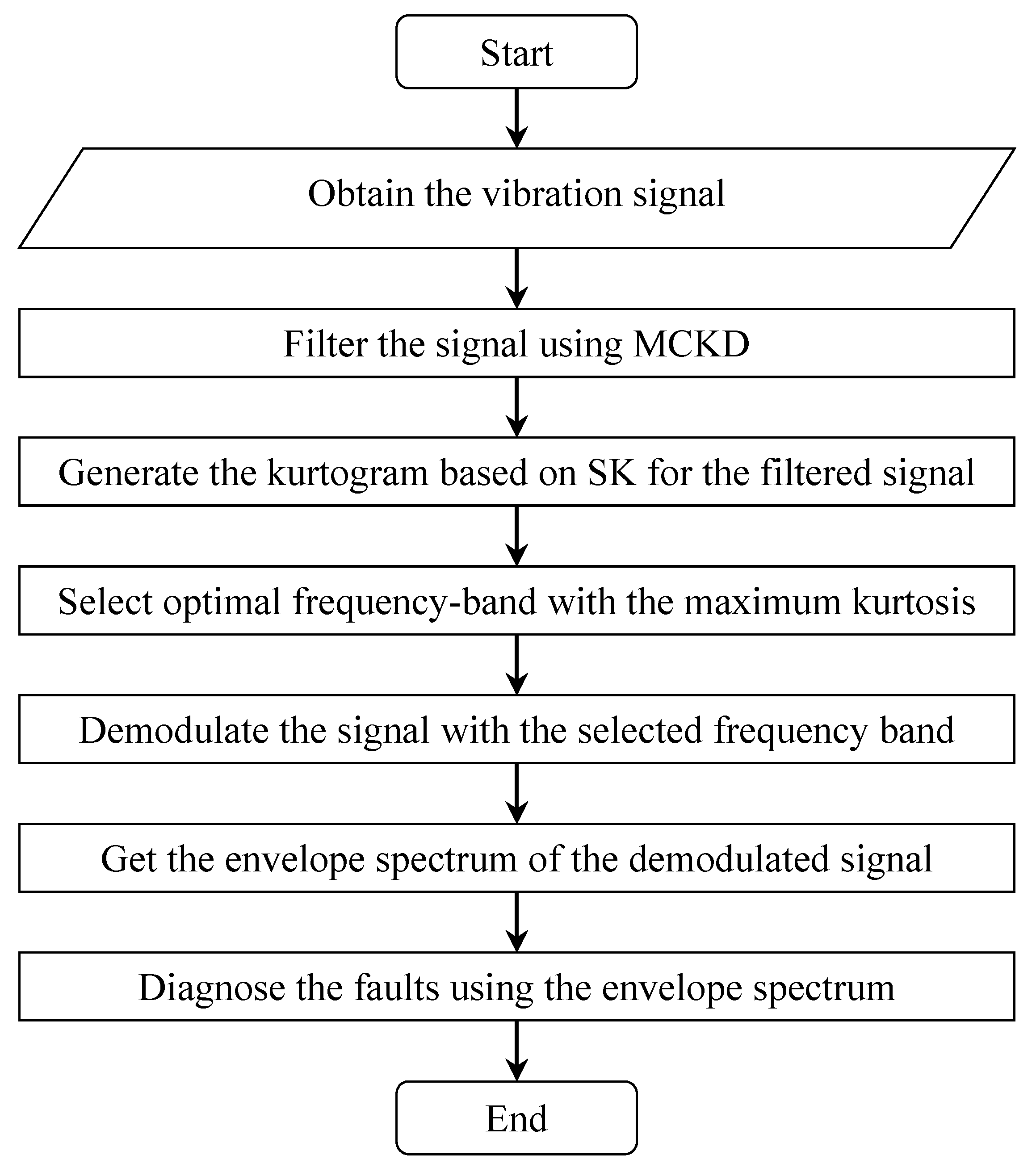

3. The Proposed Method

- (1)

- Obtain an original vibration signal x(n) of the bearings and filter it by MCKD. Since periodic impulses excited by an incipient defect of bearings are weak and always masked by other components of the vibration signal, MCKD is used to filter the signal x(n) and enhance these periodic fault impulses. The filter coefficient w(l) is determined by Equation (5) and the filtered signal y(n) is the convolution result of x(n) with w(l).

- (2)

- Generate the kurtogram of the filtered signal y(n). The 1/2-binary and 1/3-binary trees of filter-banks are obtained first and then implemented on the signal y(n). In consequence, a series of filtered signals is produced. Let (n) be the sequence of the filtered signal issued from the ith filter at the kth level of the filter-bank tree, thus (n) is the complex envelope of y(n) positioned on frequency fi and bandwidth (∆f)k. Then the kurtogram is constructed with the kurtosis values calculated by all the sequences (n).

- (3)

- Select the (n) with the maximum kurtosis in the kurtogram and implement the envelope analysis on the sequence. As a result, the envelope spectrum with an optimal frequency band is obtained and it may demodulate the fault information buried in the original signal x(n).

- (4)

- Detect the fault characteristic frequency in the envelope spectrum and diagnose the fault types.

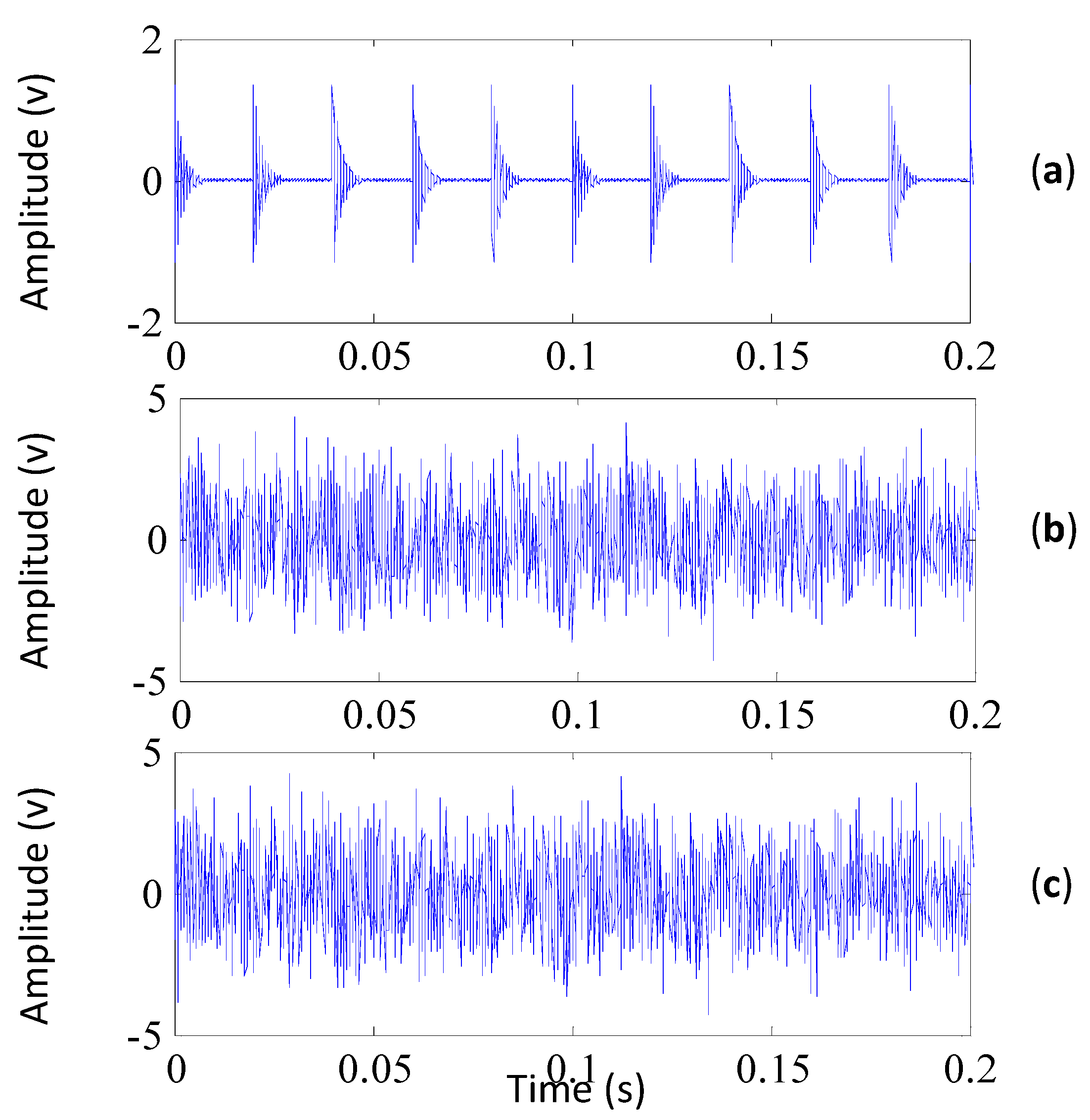

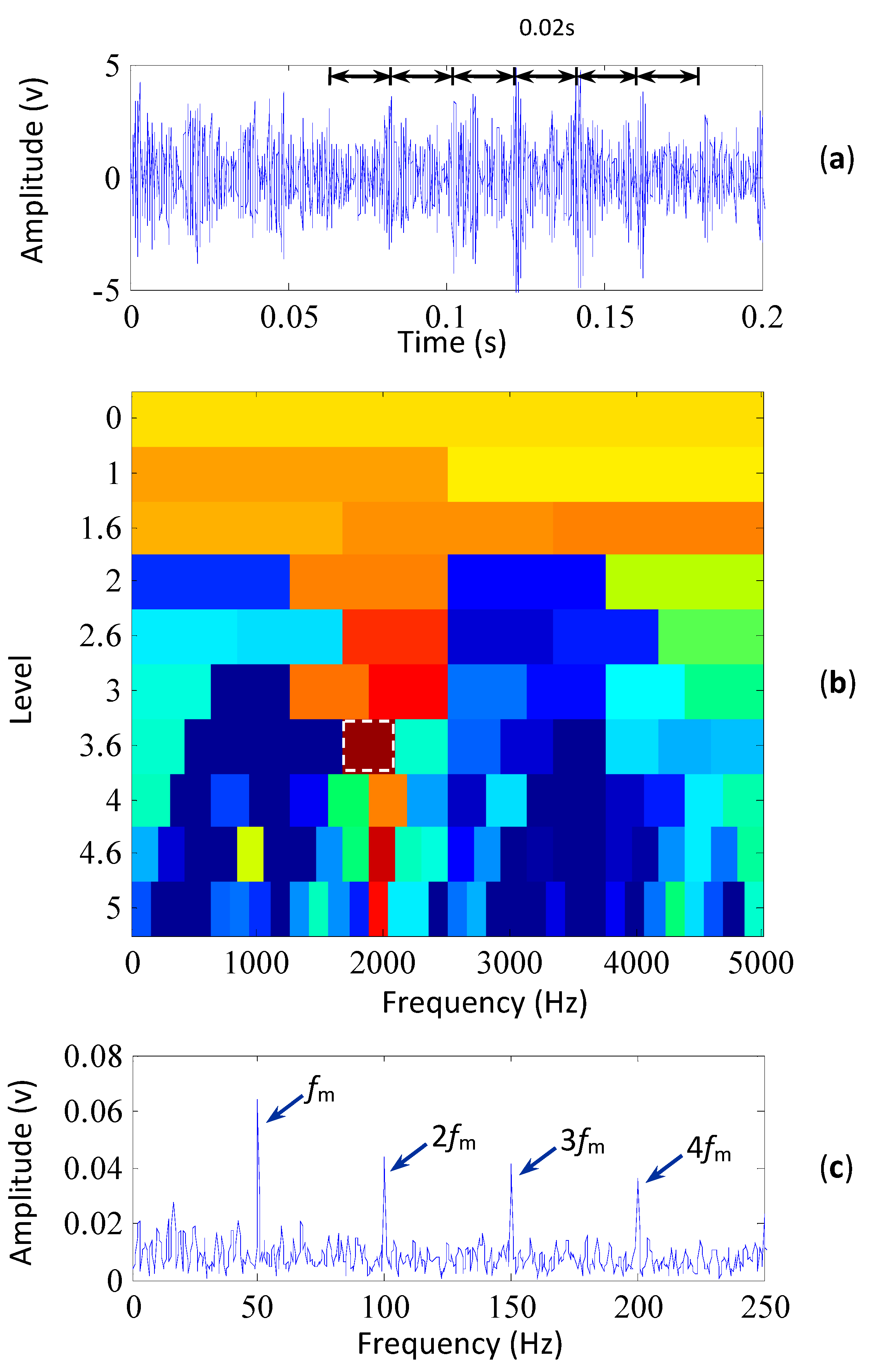

4. Simulation Illustration

5. Applications

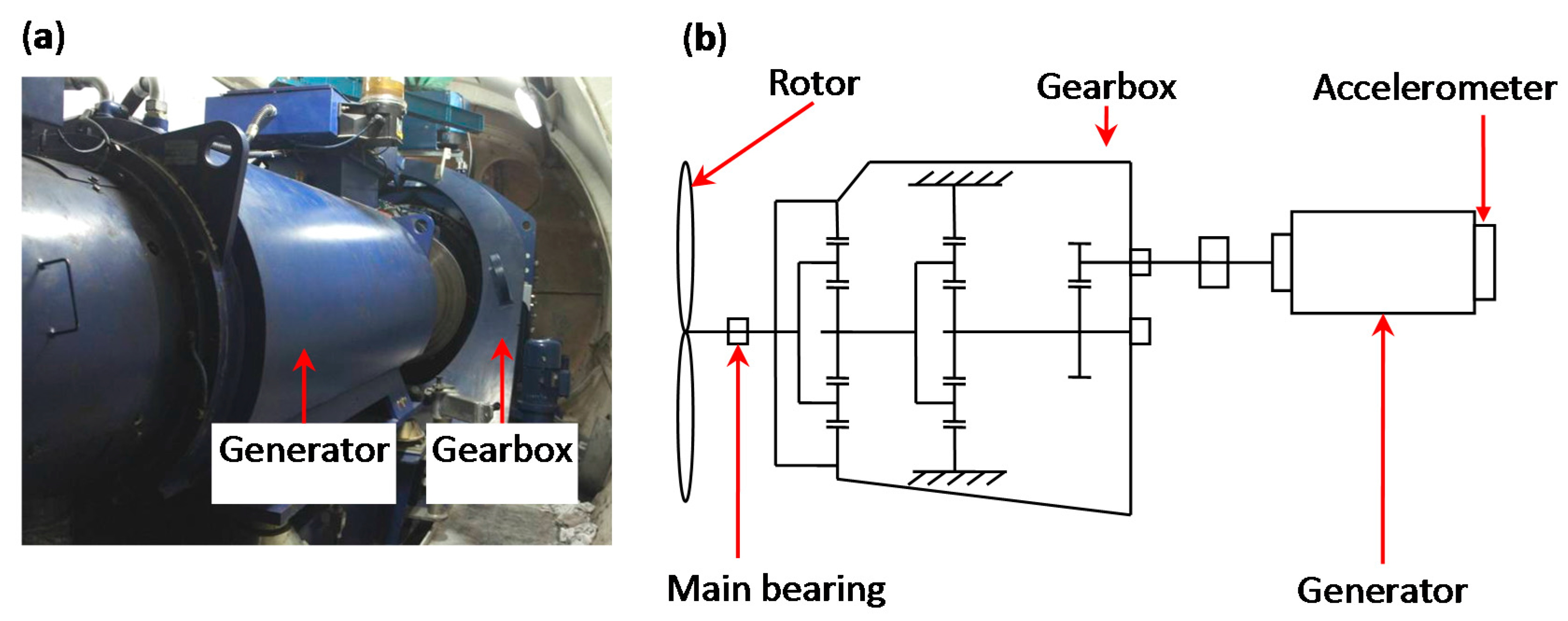

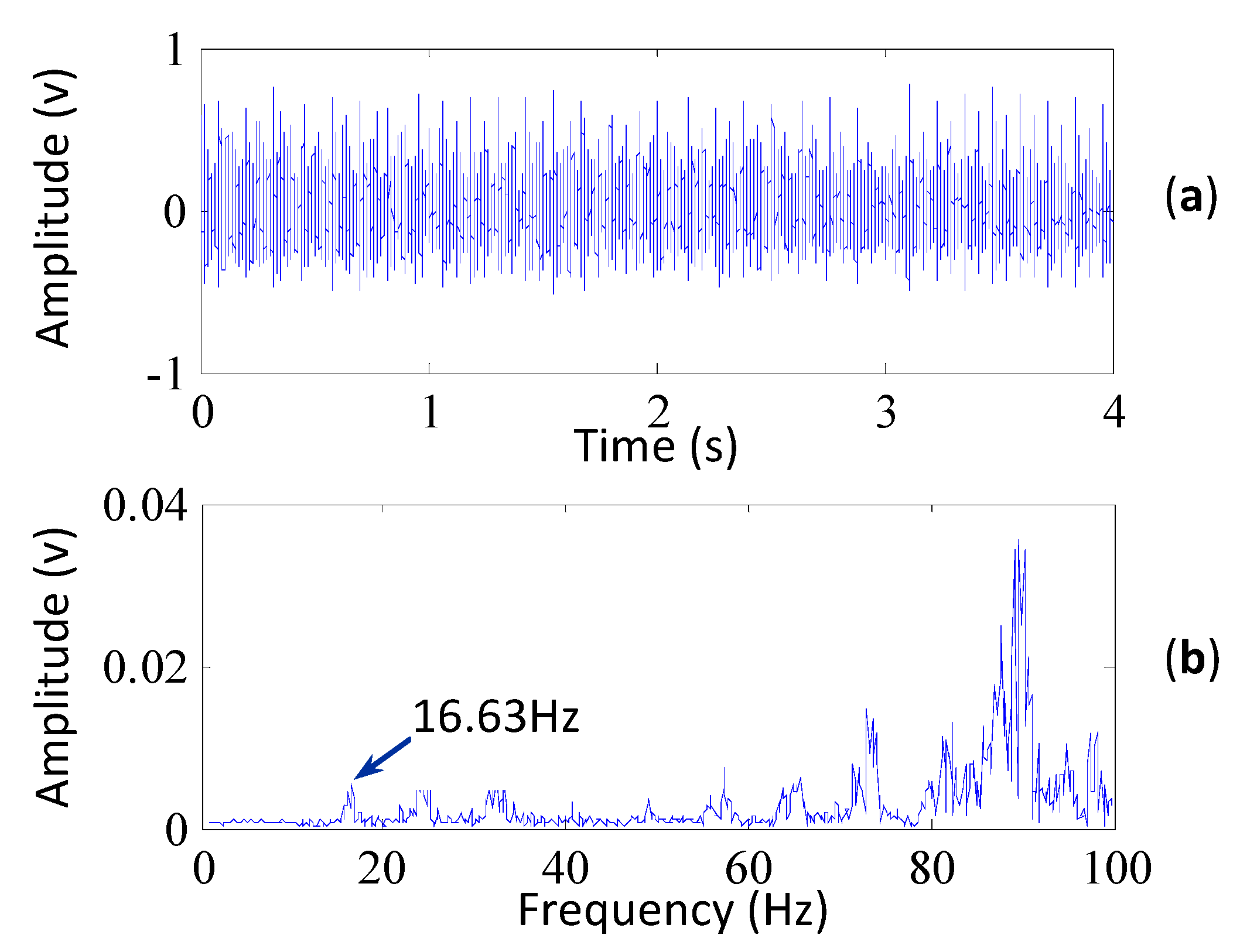

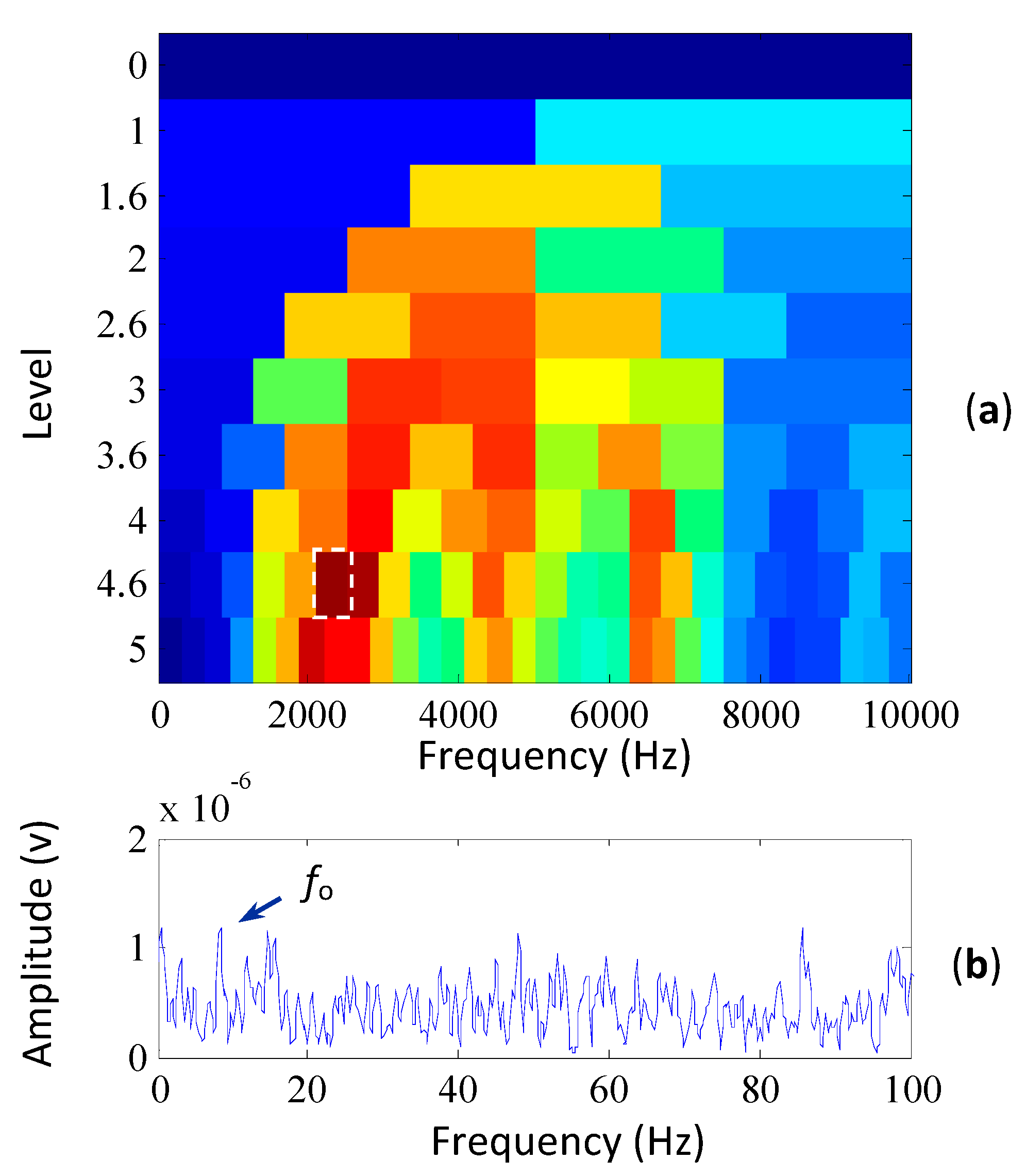

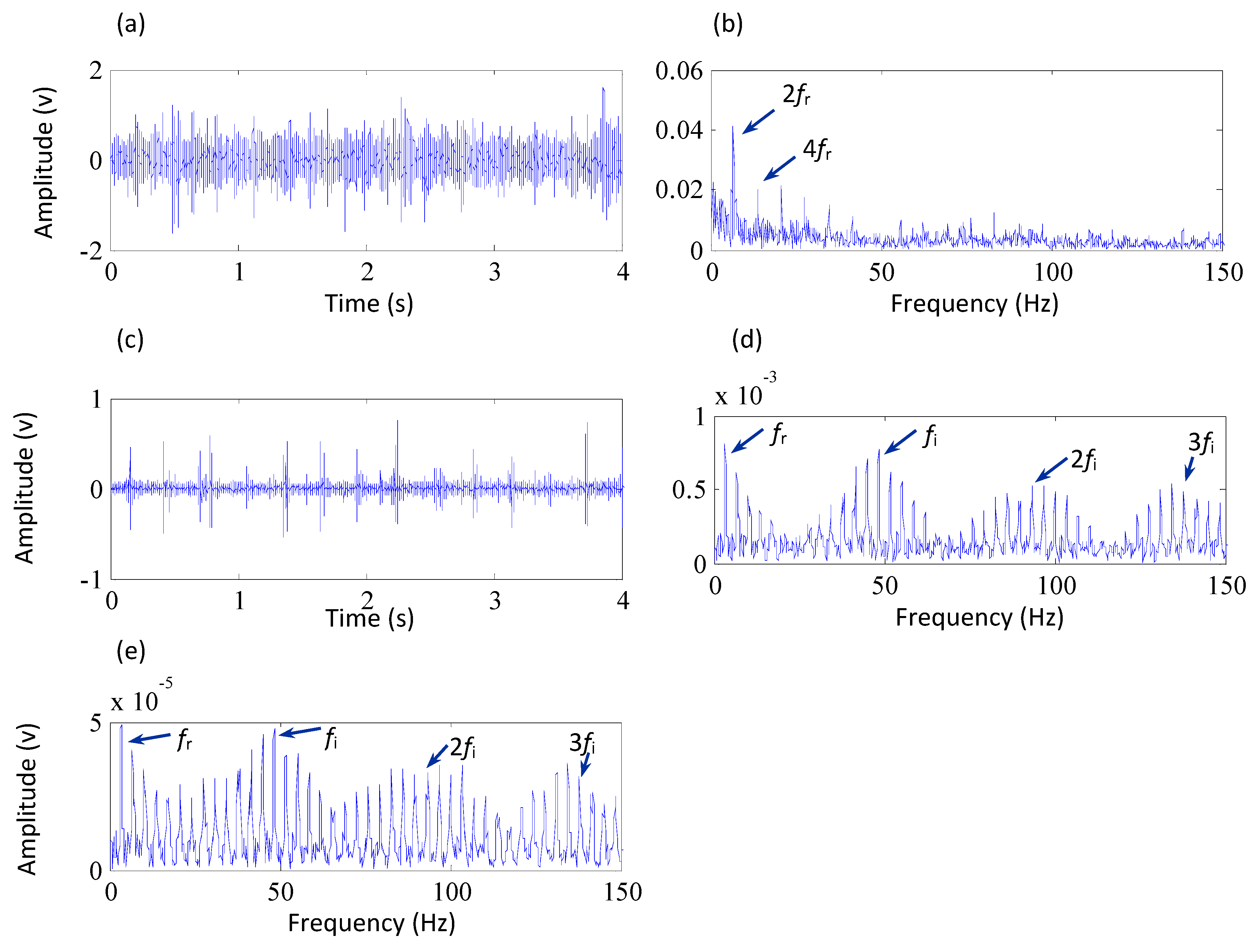

5.1. Diagnosis of Wind Turbine Bearing Faults

| Outer Race | Inner Race | Rolling Element | Rotational Speed of Shaft (Hz) |

|---|---|---|---|

| 3.38 | 4.62 | 3.05 | 2.45 |

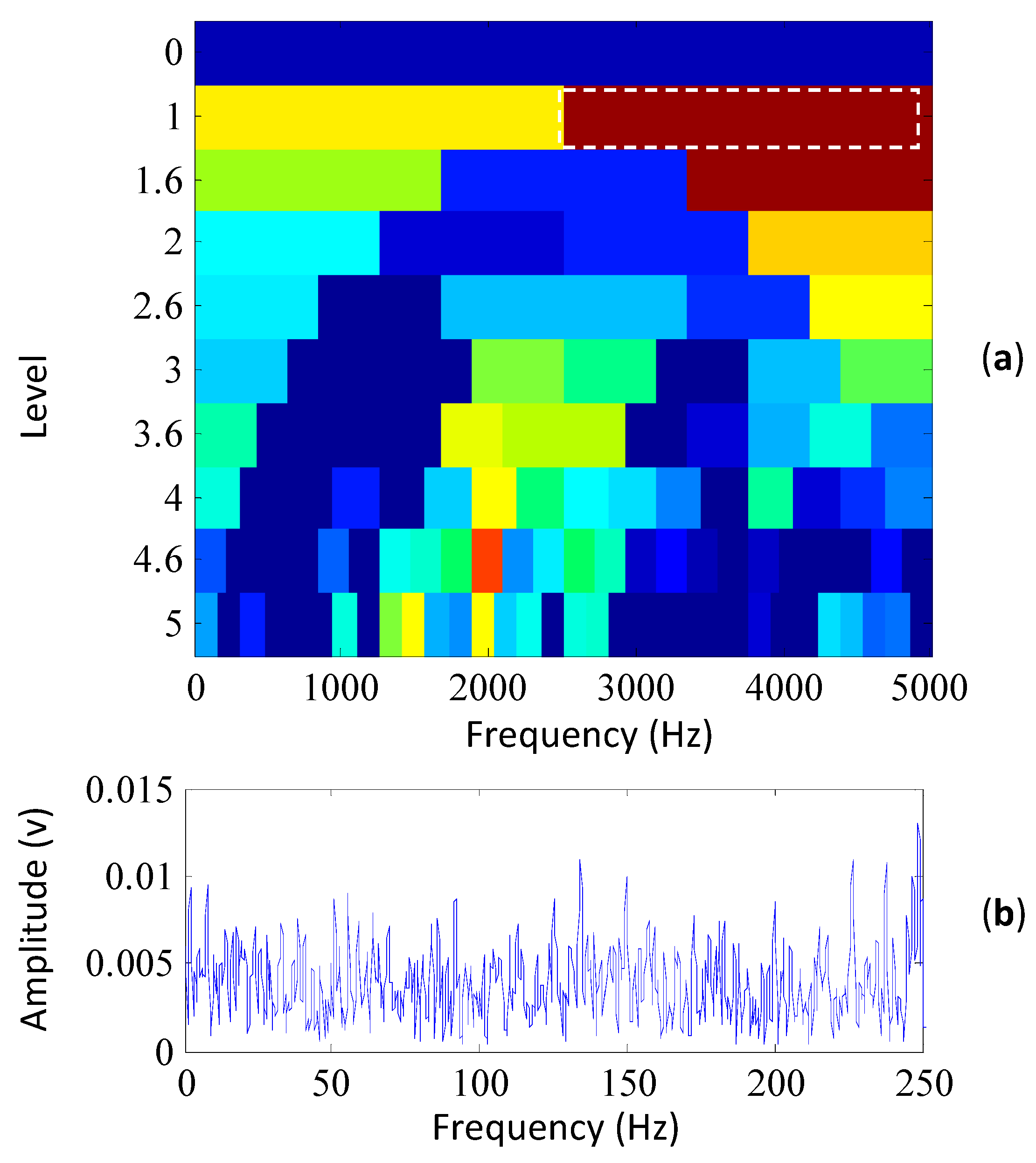

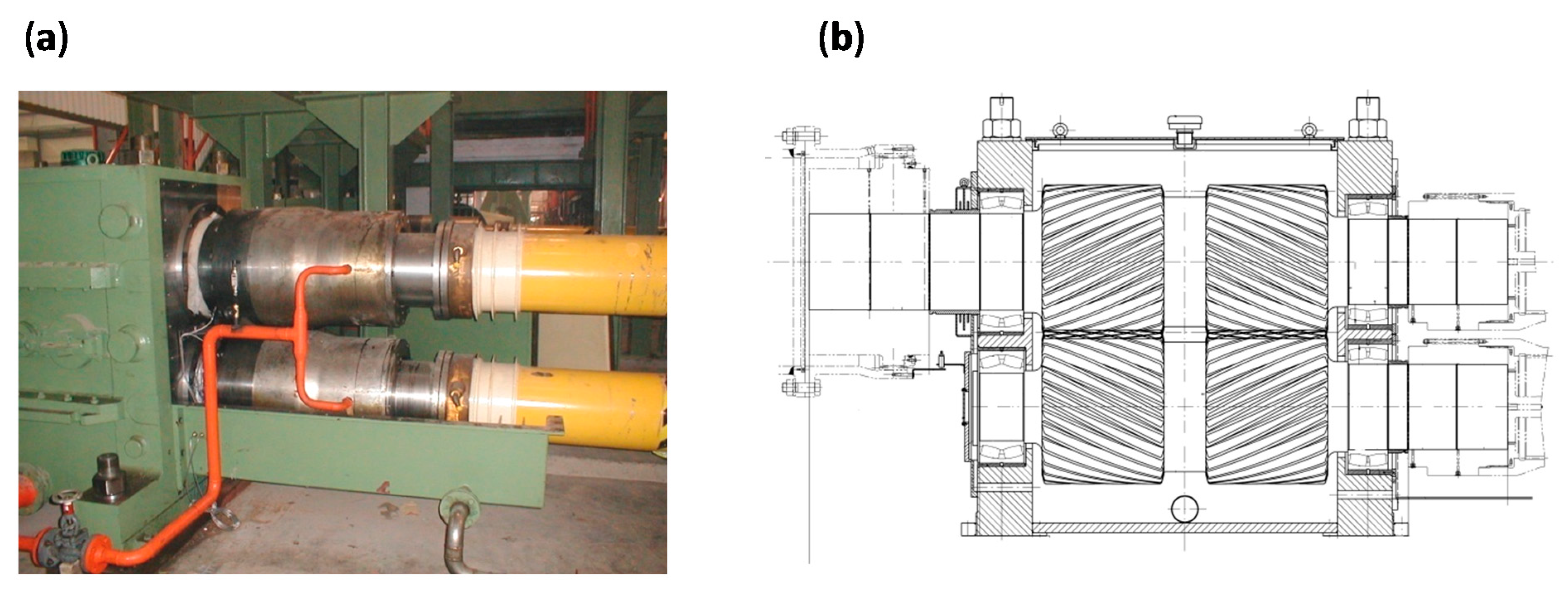

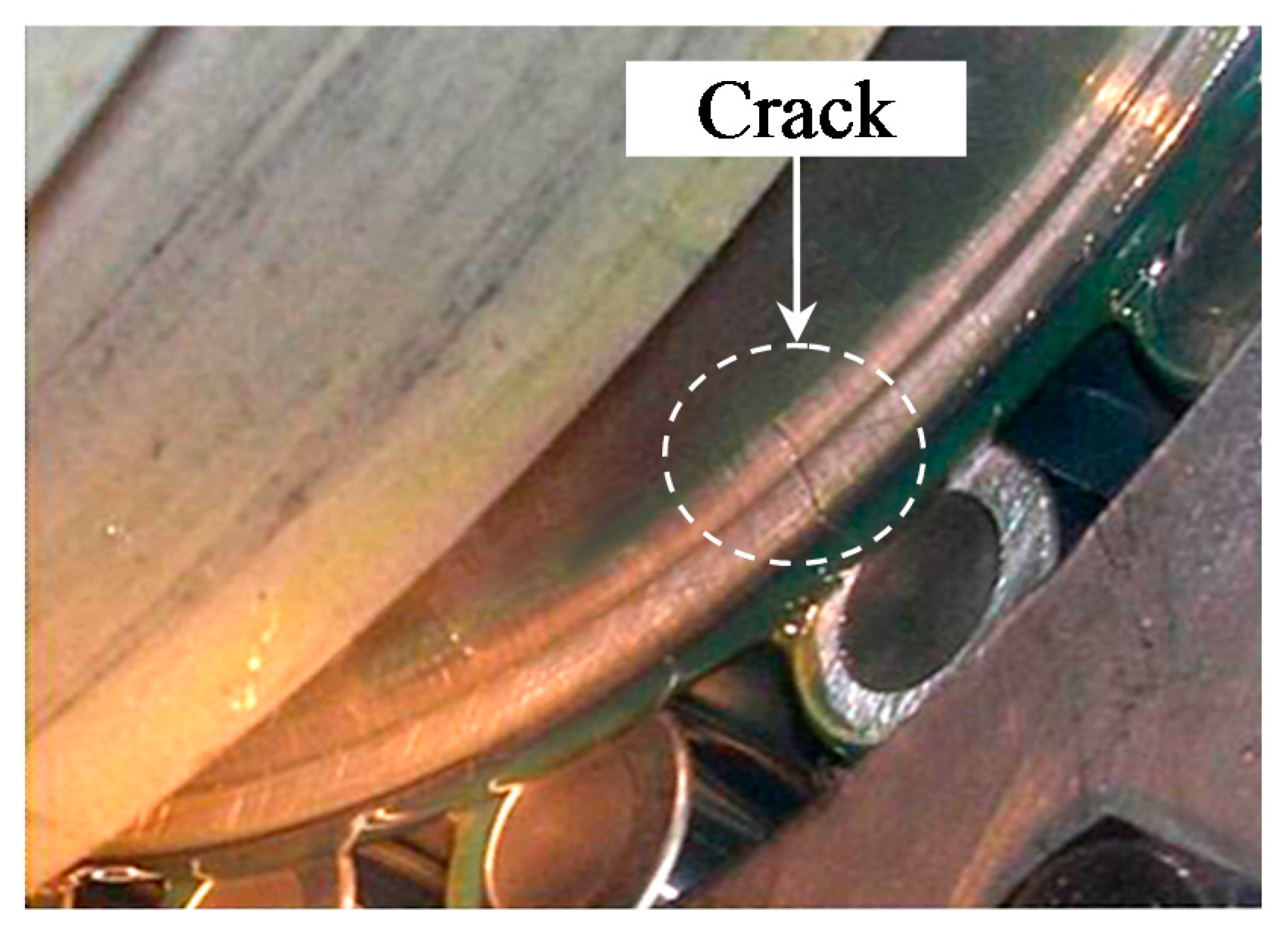

5.2. Diagnosis of Rolling Mill Bearing Faults

| Outer Race | Inner Race | Rolling Element | Rotational Speed of Shaft (Hz) |

|---|---|---|---|

| 10.44 | 13.86 | 3.61 | 3.36 |

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Shen, C.Q.; Wang, D.; Kong, F.R. Fault diagnosis of rotating machinery based on the statistical parameters of wavelet packet paving and a generic support vector regressive classifier. Measurement 2013, 46, 1551–1564. [Google Scholar] [CrossRef]

- Lei, Y.G.; Li, N.P.; Lin, J.; Wang, S.Z. Fault diagnosis of rotating machinery based on an adaptive ensemble empirical mode decomposition. Sensors 2013, 13, 16950–16964. [Google Scholar] [CrossRef] [PubMed]

- Randall, R.B.; Antoni, J. Rolling element bearing diagnostics—A tutorial. Mech. Syst. Signal Process. 2011, 25, 485–520. [Google Scholar] [CrossRef]

- Tchakoua, P.; Wamkeue, R.; Ouhrouche, M.; Slaoui-Hasnaoui, F.; Tameghe, T.A.; Ekemb, G. Wind turbine condition monitoring: State-of-the-art review, new trends, and future challenges. Energies 2014, 7, 2595–2630. [Google Scholar] [CrossRef]

- Wang, D.; Sun, S.L.; Peter, W.T. A general sequential Monte Carlo method based optimal wavelet filter: A Bayesian approach for extracting bearing fault features. Mech. Syst. Signal Process. 2015, 52, 293–308. [Google Scholar] [CrossRef]

- He, Q.B.; Wang, X.X.; Zhou, Q. Vibration sensor data denoising using a time-frequency manifold for machinery fault diagnosis. Sensors 2014, 14, 382–402. [Google Scholar] [CrossRef] [PubMed]

- Liu, J. Shannon wavelet spectrum analysis on truncated vibration signals for machine incipient fault detection. Meas. Sci. Technol. 2012, 23. [Google Scholar] [CrossRef]

- Shen, C.Q.; Liu, F.; Wang, D. A doppler transient model based on the laplace wavelet and spectrum correlation assessment for locomotive bearing fault diagnosis. Sensors 2013, 13, 15726–15746. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.B.; He, Q.B.; Kong, F.R. Stochastic resonance in an underdamped system with pinning potential for weak signal detection. Sensors 2015, 15, 21169–21195. [Google Scholar] [CrossRef] [PubMed]

- Peter, W.T.; Wang, D. The design of a new sparsogram for fast bearing fault diagnosis: Part 1 of the two related manuscripts that have a joint title as “Two automatic vibration-based fault diagnostic methods using the novel sparsity measurement—Parts 1 and 2”. Mech. Syst. Signal Process. 2013, 40, 499–519. [Google Scholar] [CrossRef]

- Lei, Y.G.; Lin, J.; He, Z.J.; Zi, Y.Y. Application of an improved kurtogram method for fault diagnosis of rolling element bearings. Mech. Syst. Signal Process. 2011, 25, 1738–1749. [Google Scholar] [CrossRef]

- Wang, Y.X.; Xiang, J.W.; Markert, R.; Liang, M. Spectral kurtosis for fault detection, diagnosis and prognostics of rotating machines: A review with applications. Mech. Syst. Signal Process. 2016, 66, 679–698. [Google Scholar] [CrossRef]

- Antoni, J. Fast computation of the kurtogram for the detection of transient faults. Mech. Syst. Signal Process. 2007, 21, 108–124. [Google Scholar] [CrossRef]

- Wang, Y.X.; Liang, M. An adaptive SK technique and its application for fault detection of rolling element bearings. Mech. Syst. Signal Process. 2011, 25, 1750–1764. [Google Scholar] [CrossRef]

- Wang, D.; Peter, W.T.; Tsui, K.L. An enhanced Kurtogram method for fault diagnosis of rolling element bearings. Mech. Syst. Signal Process. 2013, 35, 176–199. [Google Scholar] [CrossRef]

- Xu, X.Q.; Zhao, M.; Lin, J.; Lei, Y.G. Periodicity-based kurtogram for random impulse resistance. Meas. Sci. Technol. 2015, 26. [Google Scholar] [CrossRef]

- Wang, H.C.; Chen, J.; Dong, G.M. Fault diagnosis of rolling bearing’s early weak fault based on minimum entropy de-convolution and fast Kurtogram algorithm. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2014. [Google Scholar] [CrossRef]

- Fan, Z.Q.; Li, H.Z. A hybrid approach for fault diagnosis of planetary bearings using an internal vibration sensor. Measurement 2015, 64, 71–80. [Google Scholar] [CrossRef]

- McDonald, G.L.; Zhao, Q.; Zuo, M.J. Maximum correlated Kurtosis deconvolution and application on gear tooth chip fault detection. Mech. Syst. Signal Process. 2012, 33, 237–255. [Google Scholar] [CrossRef]

- Feng, Z.P.; Liang, M.; Zhang, Y.; Hou, S.M. Fault diagnosis for wind turbine planetary gearboxes via demodulation analysis based on ensemble empirical mode decomposition and energy separation. Renew. Energy 2012, 47, 112–126. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, F.; Lei, Y.; Shan, H.; Lin, J. Early Fault Diagnosis of Bearings Using an Improved Spectral Kurtosis by Maximum Correlated Kurtosis Deconvolution. Sensors 2015, 15, 29363-29377. https://doi.org/10.3390/s151129363

Jia F, Lei Y, Shan H, Lin J. Early Fault Diagnosis of Bearings Using an Improved Spectral Kurtosis by Maximum Correlated Kurtosis Deconvolution. Sensors. 2015; 15(11):29363-29377. https://doi.org/10.3390/s151129363

Chicago/Turabian StyleJia, Feng, Yaguo Lei, Hongkai Shan, and Jing Lin. 2015. "Early Fault Diagnosis of Bearings Using an Improved Spectral Kurtosis by Maximum Correlated Kurtosis Deconvolution" Sensors 15, no. 11: 29363-29377. https://doi.org/10.3390/s151129363

APA StyleJia, F., Lei, Y., Shan, H., & Lin, J. (2015). Early Fault Diagnosis of Bearings Using an Improved Spectral Kurtosis by Maximum Correlated Kurtosis Deconvolution. Sensors, 15(11), 29363-29377. https://doi.org/10.3390/s151129363