Two-Dimensional Automatic Measurement for Nozzle Flow Distribution Using Improved Ultrasonic Sensor

Abstract

:1. Introduction

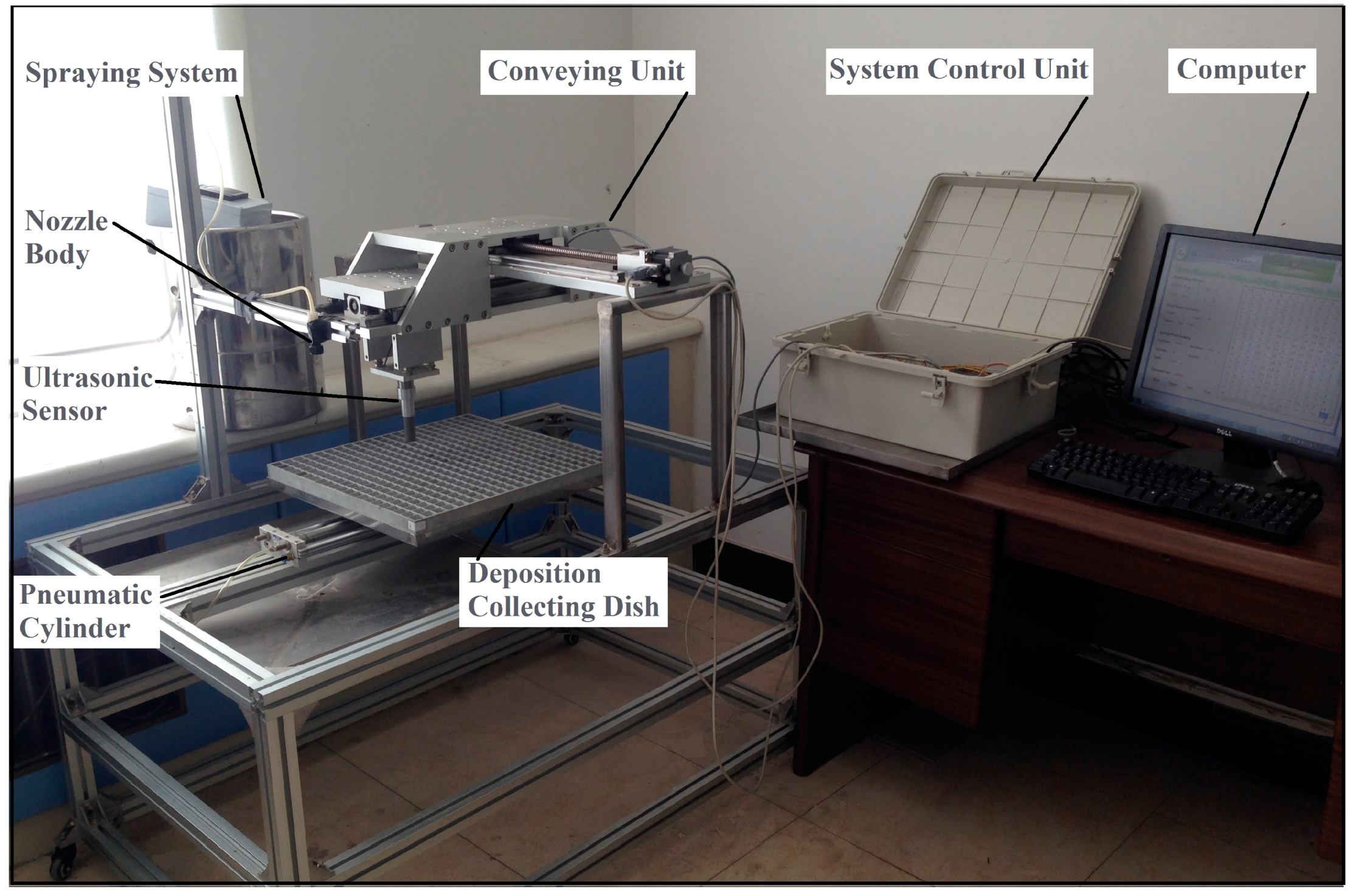

2. Materials and Methods

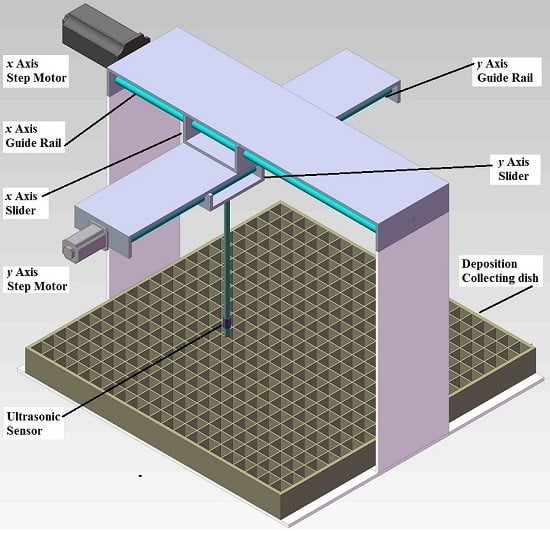

2.1. Design of a Two-Dimensional Liquid-Level Measurement System

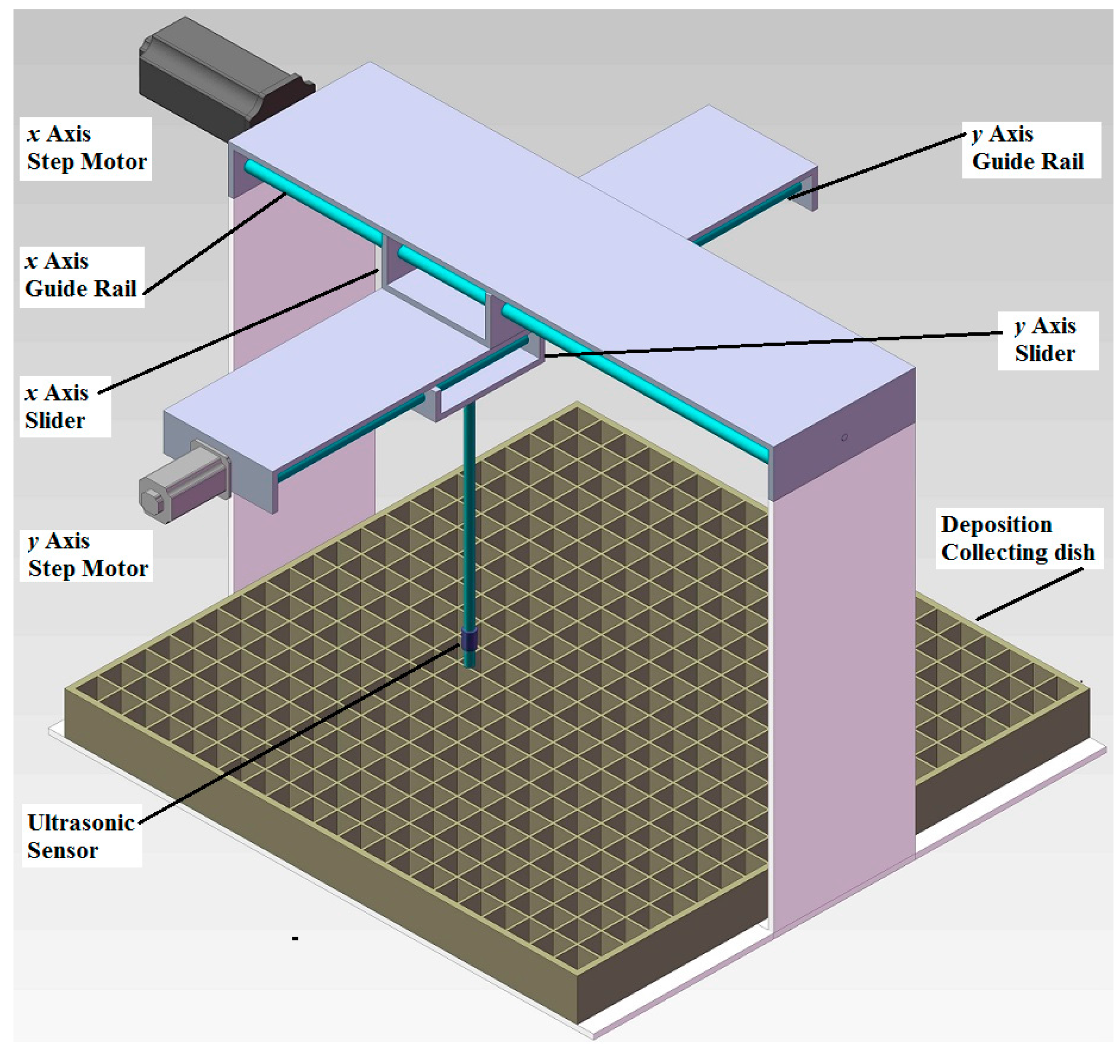

2.2. Design of the System Control Unit

2.3. Enclosure of the Ultrasonic Sensor

| Tube Inner Diameter (mm) | Was the Wall of the Tube Detected? | ||||

|---|---|---|---|---|---|

| 12.0 | Tube length (mm) | 113 | 91 | 72 | 55 |

| Detected? | Yes | Yes | Yes | Yes | |

| 14.5 | Tube length (mm) | 152 | 128 | 107 | 89 |

| Detected? | Yes | Yes | Yes | No | |

| Liquid Volume/mL | Ultrasonic Sensor Output | Liquid Level Reading | |||||

|---|---|---|---|---|---|---|---|

| Reading 1 | Reading 2 | Reading 3 | Reading 4 | Reading 5 | Average Reading | ||

| 0 | 480 | 481 | 479 | 481 | 480 | 480.3 | 0.0 |

| 3 | 436 | 435 | 440 | 437 | 435 | 436.0 | 44.3 |

| 6 | 388 | 391 | 390 | 388 | 387 | 388.7 | 91.7 |

| 9 | 324 | 324 | 324 | 324 | 326 | 324.0 | 156.3 |

| 12 | 274 | 273 | 276 | 274 | 272 | 273.7 | 206.7 |

| 14 | 248 | 247 | 248 | 249 | 249 | 248.3 | 232.0 |

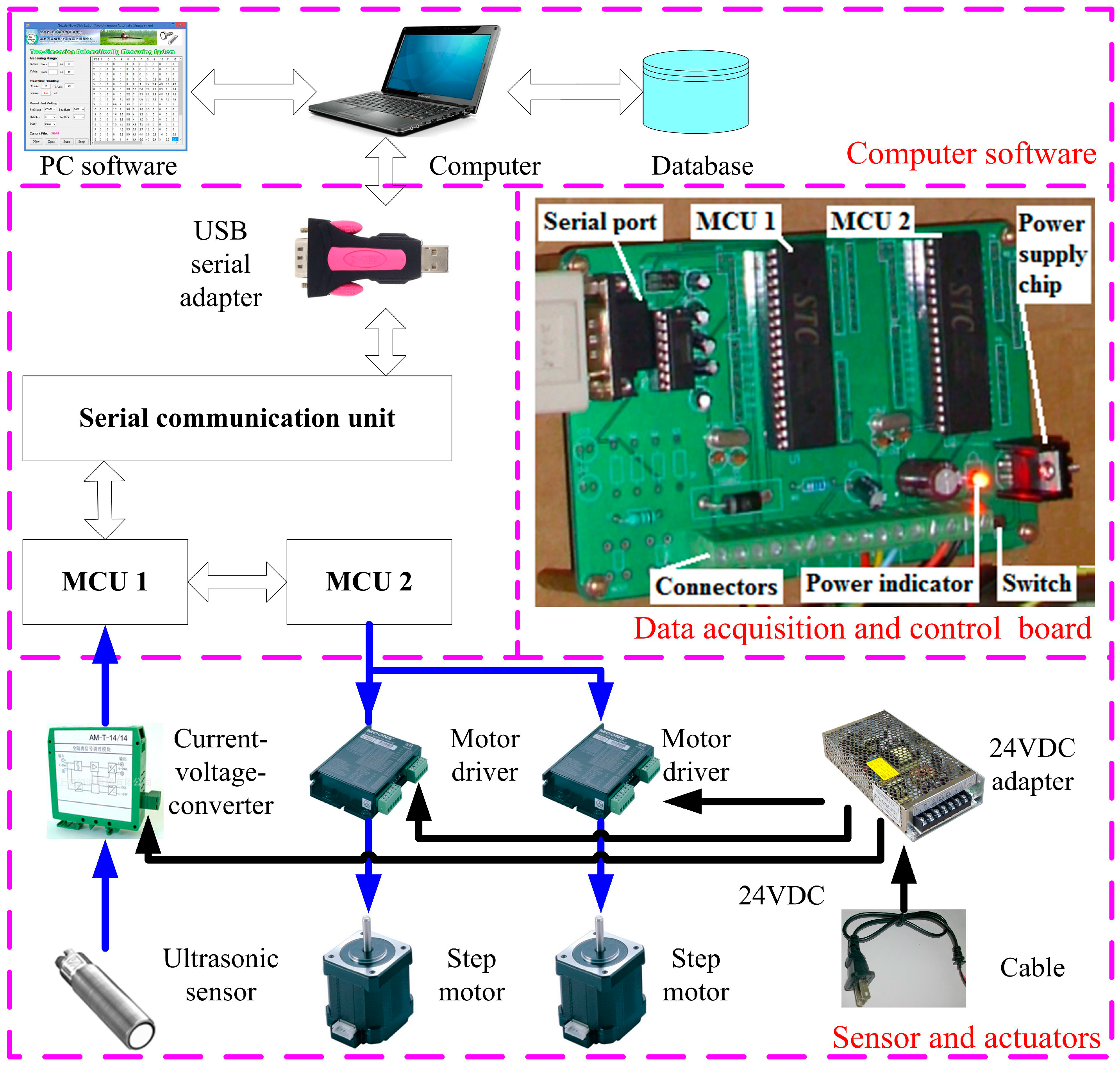

2.4. Development of Computer Software

- Set up the measuring ranges and the serial port.

- Create a new file by clicking the “New” button, or open an existing file by clicking the “Open” button.

- Run the software using the “Start” button. The software sent the commands to the data acquisition and control board to move the ultrasonic sensor step by step. When the sensor was above a trough, the sensor data were acquired five times and the average volume was calculated.

- Stop the software by pressing the “Stop” button.

2.5. System Performance Test

2.6. Nozzle Flow Distribution Measurement

| Real Liquid Volume/mL | Ultrasonic Sensor Reading | Liquid Volume Calculated/mL | Relative Error/% | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Reading 1 | Reading 2 | Reading 3 | Reading 4 | Reading 5 | Average Reading | Liquid Level Reading | |||

| 0 | 480 | 478 | 476 | 479 | 479 | 478.7 | 0 | 0 | 0 |

| 2 | 453 | 446 | 449 | 452 | 450 | 450.3 | 28.4 | 2.12 | 6.12 |

| 2 | 449 | 453 | 450 | 451 | 449 | 450.0 | 28.7 | 2.15 | 7.27 |

| 2 | 448 | 451 | 452 | 448 | 451 | 450.0 | 28.7 | 2.15 | 7.27 |

| 4 | 419 | 420 | 418 | 418 | 416 | 418.3 | 60.4 | 4.14 | 3.56 |

| 4 | 417 | 422 | 416 | 420 | 418 | 418.3 | 60.4 | 4.14 | 3.56 |

| 4 | 416 | 418 | 418 | 419 | 417 | 417.7 | 61.0 | 4.18 | 4.52 |

| 6 | 379 | 379 | 379 | 380 | 380 | 379.3 | 99.4 | 6.21 | 3.56 |

| 6 | 380 | 379 | 379 | 378 | 379 | 379.0 | 99.7 | 6.23 | 3.84 |

| 6 | 380 | 377 | 380 | 379 | 380 | 379.7 | 99.0 | 6.20 | 3.28 |

| 8 | 348 | 349 | 346 | 351 | 348 | 348.3 | 130.4 | 7.74 | −3.23 |

| 8 | 341 | 342 | 341 | 343 | 340 | 341.3 | 137.4 | 8.09 | 1.13 |

| 8 | 342 | 343 | 344 | 338 | 352 | 343.0 | 135.7 | 8.01 | 0.08 |

| 10 | 305 | 304 | 303 | 304 | 303 | 303.7 | 175.0 | 10.09 | 0.90 |

| 10 | 301 | 306 | 306 | 306 | 307 | 306.0 | 172.7 | 9.96 | −0.43 |

| 10 | 308 | 310 | 310 | 311 | 309 | 309.7 | 169.0 | 9.75 | −2.50 |

| 12 | 277 | 275 | 276 | 275 | 276 | 275.7 | 203.0 | 11.83 | −1.43 |

| 12 | 274 | 272 | 272 | 273 | 273 | 272.7 | 206.0 | 12.03 | 0.27 |

| 12 | 278 | 277 | 274 | 278 | 275 | 276.7 | 202.0 | 11.76 | −1.99 |

| 14 | 247 | 247 | 248 | 248 | 249 | 247.7 | 231.0 | 13.91 | −0.67 |

| 14 | 247 | 248 | 248 | 247 | 246 | 247.3 | 231.4 | 13.93 | −0.47 |

| 14 | 248 | 249 | 247 | 248 | 246 | 247.7 | 231.0 | 13.91 | −0.67 |

3. Experiments and Results

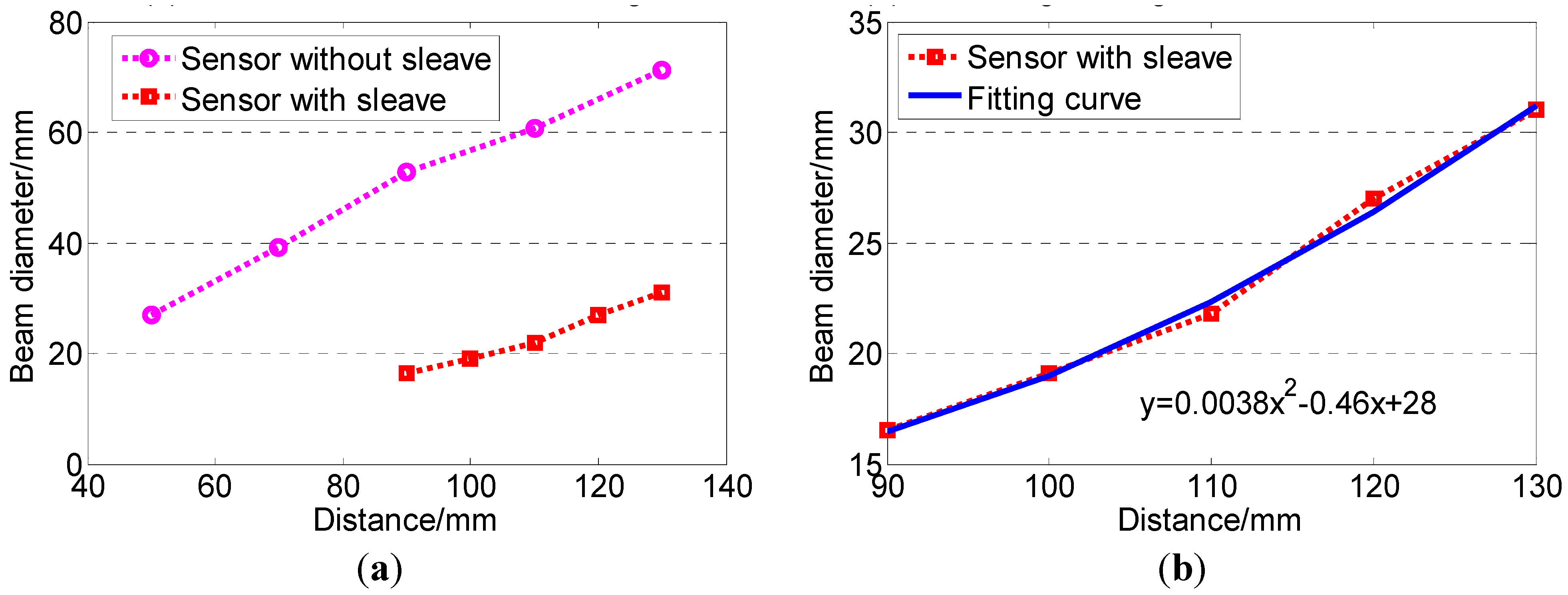

3.1. Beam Diameter Test

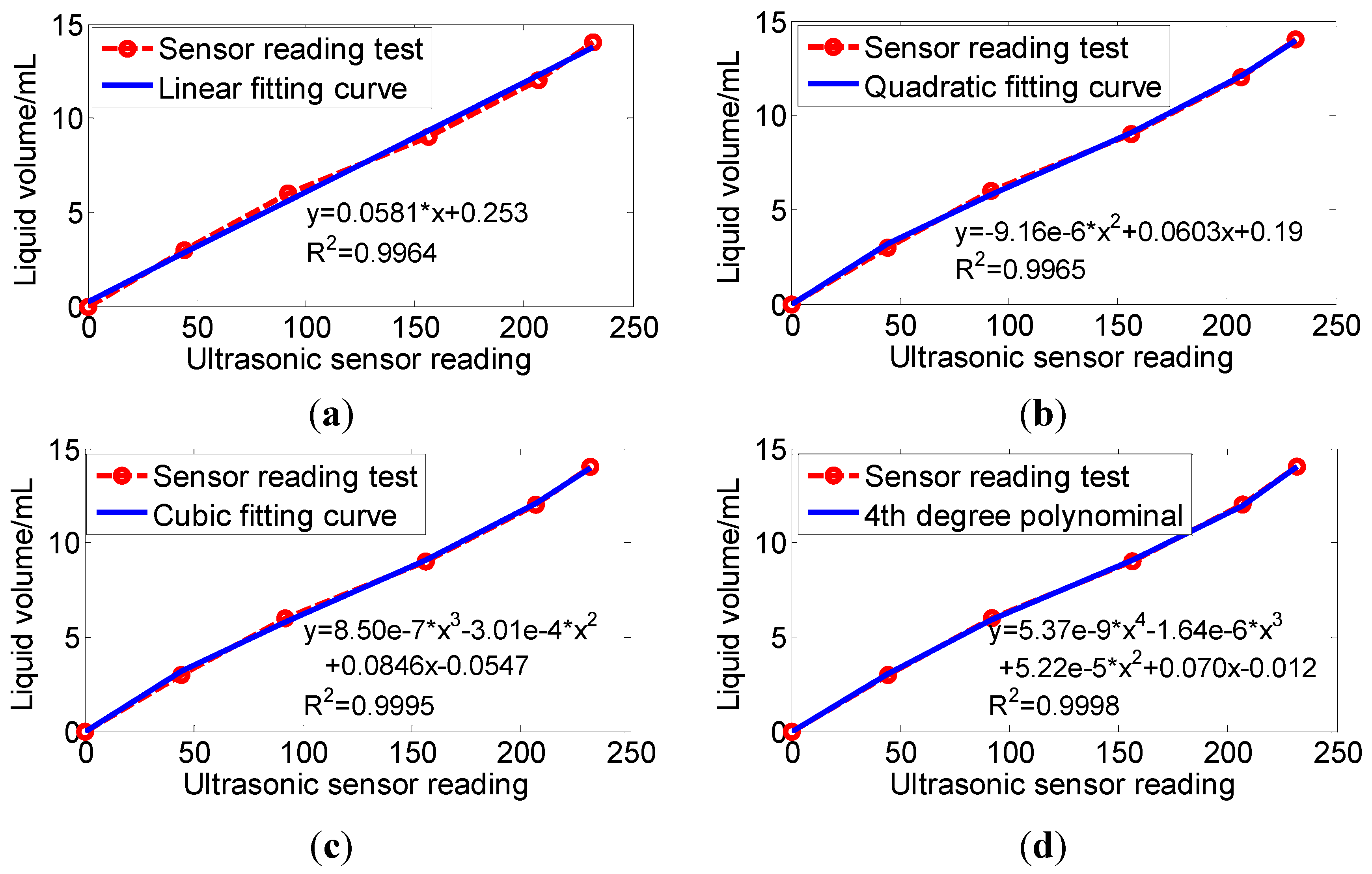

3.2. Calibration for the Volume Calculation

3.3. System Performance Test

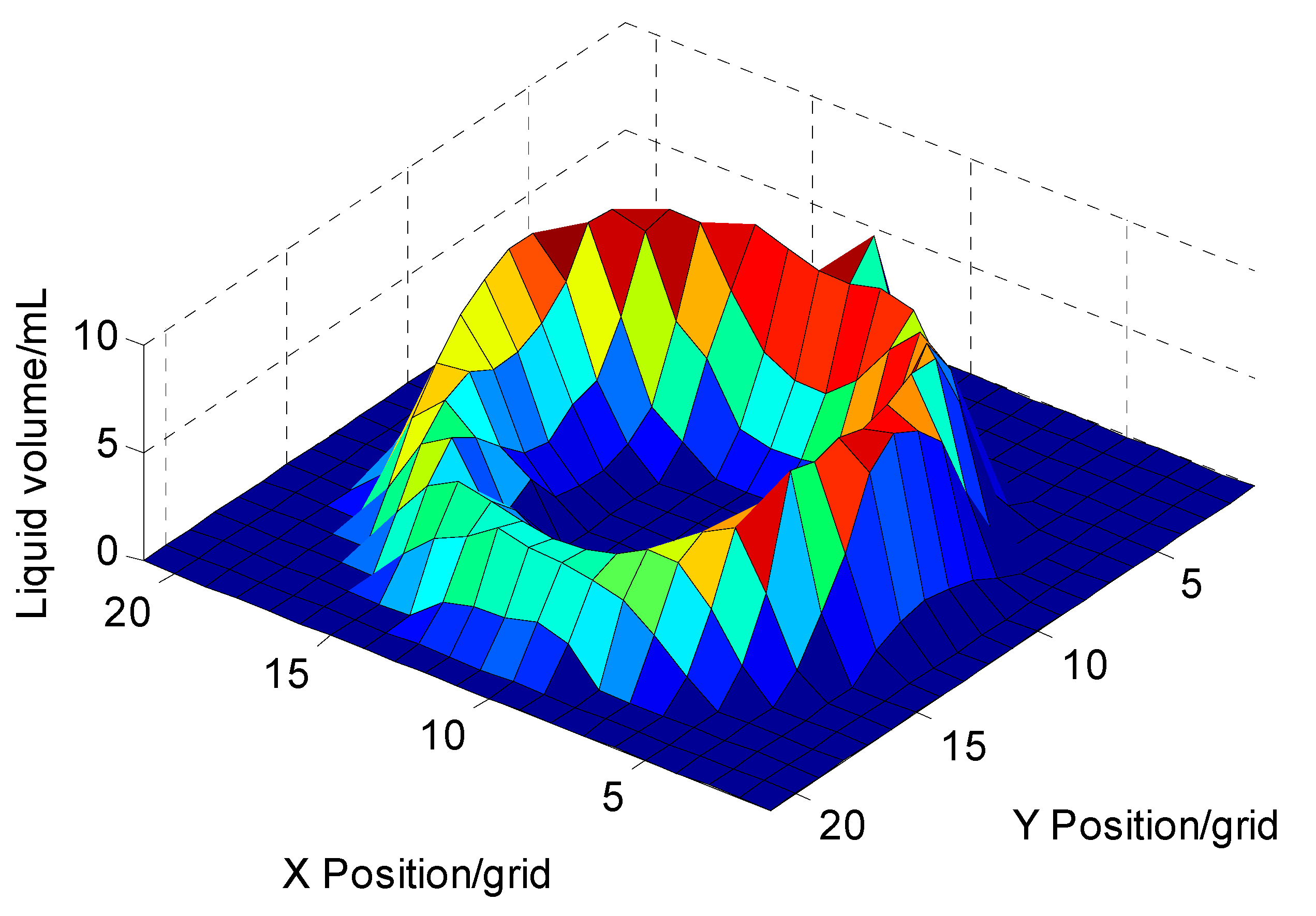

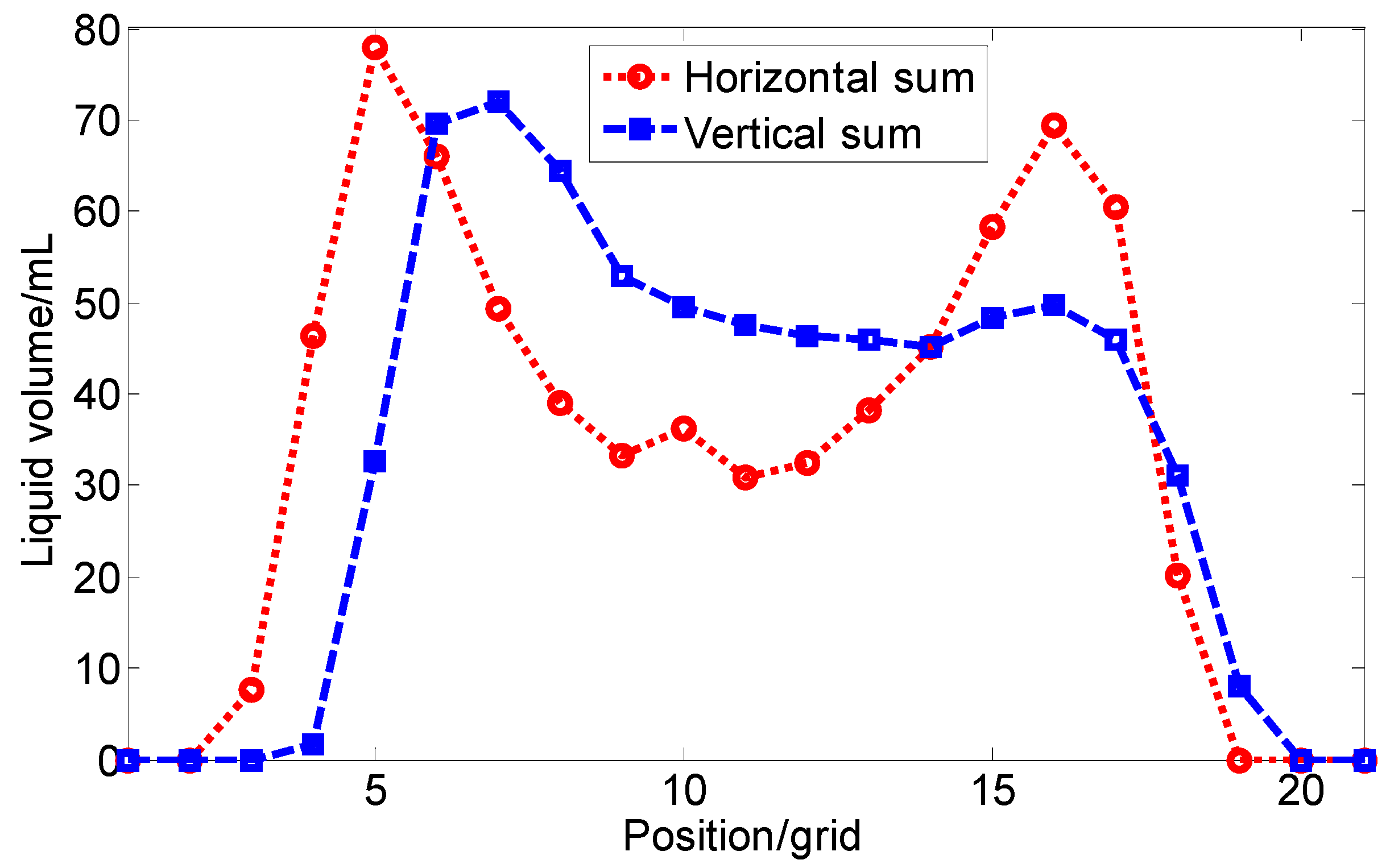

3.4. Nozzle Flow Distribution Measurement Application

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Gil, E.; Llorens, J.; Llop, J.; Fàbregas, X.; Escolà, A.; Rosell-Polo, J.R. Variable rate sprayer. Part 2—Vineyard prototype: Design, implementation, and validation. Comput. Electron. Agric. 2013, 95, 136–150. [Google Scholar] [CrossRef]

- Lan, Y.; Thomson, S.J.; Huang, Y.; Hoffmann, W.C.; Zhang, H. Current status and future directions of precision aerial application for site-specific crop management in the USA. Comput. Electron. Agric. 2010, 74, 34–38. [Google Scholar] [CrossRef]

- Juraske, R.; Fantke, P.; Ramírez, A.C.R.; González, A. Pesticide residue dynamics in passion fruits: Comparing field trial and modelling results. Chemosphere 2012, 89, 850–855. [Google Scholar] [CrossRef] [PubMed]

- Lee, W.S.; Alchanatis, V.; Yang, C.; Hirafuji, M.; Moshou, D.; Li, C. Sensing technologies for precision specialty crop production. Comput. Electron. Agric. 2010, 74, 2–33. [Google Scholar] [CrossRef]

- Pergher, G.; Gubiani, R.; Cividino, S.R.S.; Dell’Antonia, D.; Lagazio, C. Assessment of spray deposition and recycling rate in the vineyard from a new type of air-assisted tunnel sprayer. Crop Prot. 2013, 45, 6–14. [Google Scholar] [CrossRef]

- Poulsen, M.E.; Wenneker, M.; Withagen, J.; Christensen, H.B. Pesticide residues in individual versus composite samples of apples after fine or coarse spray quality application. Crop Prot. 2012, 35, 5–14. [Google Scholar] [CrossRef]

- Escolà, A.; Rosell-Polo, J.R.; Planas, S.; Gil, E.; Pomar, J.; Camp, F.; Llorens, J.; Solanelles, F. Variable rate sprayer. Part 1—Orchard prototype: Design, implementation and validation. Comput. Electron. Agric. 2013, 95, 122–135. [Google Scholar] [CrossRef]

- Jeon, H.Y.; Zhu, H. Development of variable-rate sprayer for nursery liner applications. Trans. ASABE 2012, 55, 303–312. [Google Scholar] [CrossRef]

- Foqué, D.; Pieters, J.G.; Nuyttens, D. Spray deposition and distribution in a bay laurel crop as affected by nozzle type, air assistance and spray direction when using vertical spray booms. Crop Prot. 2012, 41, 77–87. [Google Scholar] [CrossRef]

- Jensen, P.K.; Lund, I.; Nuyttens, D. Spray liquid distribution and biological efficacy of commercially available nozzles used for precision weed control. Biosyst. Eng. 2013, 116, 316–325. [Google Scholar] [CrossRef]

- Xie, Y.; Gao, S.; Eslamian, M. Fundamental Study on the Effect of Spray Parameters on Characteristics of P3HT:PCBM Active Layers Made by Spray Coating. Coatings 2015, 5, 488–510. [Google Scholar] [CrossRef]

- Deng, W.; He, X.; Ding, W. Droplet size and spray pattern characteristics of PWM-based continuously variable spray. Int. J. Agric. Biol. Eng. 2009, 2, 8–18. [Google Scholar]

- Khot, L.R.; Ehsani, R.; Albrigo, G.; Larbi, P. A.; Landers, A.; Campoy, J.; Wellington, C. Air-assisted sprayer adapted for precision horticulture: Spray patterns and deposition assessments in small-sized citrus canopies. Biosyst. Eng. 2012, 113, 76–85. [Google Scholar]

- Khot, L.R.; Ehsani, R.; Albrigo, G.; Landers, A.J.; Larbi, P.A. Spray pattern investigation of an axial-fan airblast precision sprayer using a modified vertical patternator. Appl. Eng. Agric. 2012, 28, 647–654. [Google Scholar] [CrossRef]

- Ashgriz, N. Spray Droplet Sizer 2015. Available online: http://www.google.com/patents/US8988681 (accessed on 24 March 2015).

- Bukhari, S.F.A.; Yang, W. Multi-interface Level Sensors and New Development in Monitoring and Control of Oil Separators. Sensors 2006, 6, 380–389. [Google Scholar] [CrossRef]

- Arvoh, B.K.; Skeie, N.-O.; Halstensen, M. Estimation of gas/liquid and oil/water interface levels in an oil/water/gas separator based on pressure measurements and regression modelling. Sep. Purif. Technol. 2013, 107, 204–210. [Google Scholar] [CrossRef]

- Campbell, G.A.; Mutharasan, R. Sensing of liquid level at micron resolution using self-excited millimeter-sized PZT-cantilever. Sens. Actuators A Phys. 2005, 122, 326–334. [Google Scholar] [CrossRef]

- Wang, T.-H.; Lu, M.-C.; Hsu, C.-C.; Chen, C.-C.; Tan, J.-D. Liquid-level measurement using a single digital camera. Measurement 2009, 42, 604–610. [Google Scholar] [CrossRef]

- Gong, H.; Song, H.; Zhang, S.; Ni, K.; Dong, X. An optical liquid level sensor based on polarization-maintaining fiber modal interferometer. Sens. Actuators A Phys. 2014, 205, 204–207. [Google Scholar] [CrossRef]

- Golnabi, H. Design and operation of a fiber optic sensor for liquid level detection. Opt. Lasers Eng. 2004, 41, 801–812. [Google Scholar] [CrossRef]

- Zhang, W.; Dong, M.; Zhu, L.; Guo, Y.; Chang, H. Research on Dynamic Method of Liquid Level Detection Based on the Probe Type Capacitance Sensor. AASRI Procedia 2012, 3, 546–552. [Google Scholar] [CrossRef]

- Crabit, A.; Colin, F.; Bailly, J.S.; Ayroles, H.; Garnier, F. Soft water level sensors for characterizing the hydrological behaviour of agricultural catchments. Sensors 2011, 11, 4656–4673. [Google Scholar] [CrossRef] [PubMed]

- Pieraccini, M.; Mecatti, D.; Dei, D.; Parrini, F.; Macaluso, G.; Spinetti, A.; Puccioni, F. Microwave sensor for molten glass level measurement. Sens. Actuators A Phys. 2014, 212, 52–57. [Google Scholar] [CrossRef]

- Deighton, M.O. A new ultrasonic technique for the measurement of liquid level. Ultrasonics 1982, 20, 13–17. [Google Scholar]

- Sakharov, V.E.; Kuznetsov, S. A.; Zaitsev, B.D.; Kuznetsova, I.E.; Joshi, S.G. Liquid level sensor using ultrasonic Lamb waves. Ultrasonics 2003, 41, 319–322. [Google Scholar] [CrossRef]

- Cal, P.H. Ultrasonic sensor for liquid-level inspection in bottles. Sens. Actuators 1997, 61, 256–259. [Google Scholar]

- Terzic, J.; Nagarajah, C.R.; Alamgir, M. Fluid level measurement in dynamic environments using a single ultrasonic sensor and Support Vector Machine (SVM). Sens. Actuators A Phys. 2010, 161, 278–287. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhai, C.; Zhao, C.; Wang, X.; Wang, N.; Zou, W.; Li, W. Two-Dimensional Automatic Measurement for Nozzle Flow Distribution Using Improved Ultrasonic Sensor. Sensors 2015, 15, 26353-26367. https://doi.org/10.3390/s151026353

Zhai C, Zhao C, Wang X, Wang N, Zou W, Li W. Two-Dimensional Automatic Measurement for Nozzle Flow Distribution Using Improved Ultrasonic Sensor. Sensors. 2015; 15(10):26353-26367. https://doi.org/10.3390/s151026353

Chicago/Turabian StyleZhai, Changyuan, Chunjiang Zhao, Xiu Wang, Ning Wang, Wei Zou, and Wei Li. 2015. "Two-Dimensional Automatic Measurement for Nozzle Flow Distribution Using Improved Ultrasonic Sensor" Sensors 15, no. 10: 26353-26367. https://doi.org/10.3390/s151026353

APA StyleZhai, C., Zhao, C., Wang, X., Wang, N., Zou, W., & Li, W. (2015). Two-Dimensional Automatic Measurement for Nozzle Flow Distribution Using Improved Ultrasonic Sensor. Sensors, 15(10), 26353-26367. https://doi.org/10.3390/s151026353