A Dipping Duration Study for Optimization of Anodized-Aluminum Pressure-Sensitive Paint

Abstract

: Anodized-aluminum pressure-sensitive paint (AA-PSP) uses the dipping deposition method to apply a luminophore on a porous anodized-aluminum surface. We study the dipping duration, one of the parameters of the dipping deposition related to the characterization of AA-PSP. The dipping duration was varied from 1 to 100,000 s. The properties characterized are the pressure sensitivity, temperature dependency, and signal level. The maximum pressure sensitivity of 65% is obtained at the dipping duration of 100 s, the minimum temperature dependency is obtained at the duration of 1 s, and the maximum signal level is obtained at the duration of 1,000 s, respectively. Among the characteristics, the dipping duration most influences the signal level. The change in the signal level is a factor of 8.4. By introducing a weight coefficient, an optimum dipping duration can be determined. Among all the dipping parameters, such as the dipping duration, dipping solvent, and luminophore concentration, the pressure sensitivity and signal level are most influenced by the dipping solvent.1. Introduction

Anodized-aluminum pressure-sensitive paint (AA-PSP) is an optical sensor, which gives global information in unsteady flow measurements [1]. AA-PSP consists of a molecular pressure probe of a luminophore and an anodized aluminum as a supporting matrix. The luminophore is applied on the anodized-aluminum surface by the dipping deposition method [2]. This method requires a luminophore, a solvent, and an anodized-aluminum coating. The anodized coating is dipped in the luminophore solution to apply the luminophore on the coating surface. In previous reports the AA-PSP was optimized by controlling the dipping deposition parameters [2,3]. Sakaue reported the effects of solvent on the characteristics of AA-PSP [2]. By varying the solvent, he found that dichloromethane gave the best pressure sensitivity and signal level. Sakaue and Ishii controlled the luminophore concentration in the dipping deposition to optimize the AA-PSP characteristics [3]. They varied the luminophore concentration from 0.001 to 10 mM. A luminophore concentration of 0.1 mM provided optimum conditions for the pressure sensitivity, temperature dependency, and signal level. In these reports, a dipping duration in the dipping deposition was fixed at one hour.

The dipping duration can be another important parameter that influences the AA-PSP characteristics, because it would influence the amount of luminophore applied on the anodized-aluminum surface. The effects on the dipping duration as well as the above mentioned dipping parameters would give us fundamental knowledge to apply various luminophores on the anodized aluminum coating. In this paper, we varied the dipping duration related to the AA-PSP characterizations for optimizing AA-PSP. Steady-state characterizations are focused on the present study, because an unsteady-state characterization of response time was minimal related to the dipping deposition method [2]. These characterizations are the pressure sensitivity, temperature dependency, and signal level.

2. Experiment

We chose bathophen ruthenium (GFS Chemicals) as a conventional luminophore for AA-PSP. Based on the previous reports [2,3], dichloromethane was chosen as a solvent, and the luminophore solution concentration was fixed at 0.1 mM. The anodized coating thickness was 10 ± 1 μm measured by an eddy current apparatus (Kett, LZ-330). To study the effect of dipping duration, it was varied from 1 to 100,000 s. Table 1 lists the conditions of the AA-PSP preparation. Prepared AA-PSPs are labeled based on their dipping conditions, which are also listed in Table 1 as Sample ID. AAPSP3600 provides the same conditions reported in [3]. For each dipping condition, three samples were prepared to study the repeatability of dipping procedures.

We used a spectrometer combined with a pressure- and temperature-controlled chamber for AA-PSP characterizations. This spectrometer system characterizes the luminescent spectrum of an AA-PSP with varying pressures and temperatures. The excitation wavelength was set at 460 nm. The luminescent signal, I, was determined by the integration of AA-PSP spectrum from 600 to 700 nm. The test gas was dry air. Throughout all calibrations, the reference conditions were chosen at 100 kPa and 25 °C. All calibrations were averaged by three data sets prepared by the same dipping procedures. Standard deviation was calculated as an error bar. Details of the system can be found in [2]. The definition and procedures used to derive the characterizations are described in Sections 2.1. through 2.3.

2.1. Pressure Characterization

The pressure was controlled from 5 to 120 kPa with a constant temperature at 25 °C for the pressure characterization. Based on the Stern-Volmer relationship, the luminescent intensity, I, is related to a quencher [4]:

Pressure sensitivity, σ(%), describes the change in I over a given pressure change. This corresponds to a slope of Equation (2) at the reference conditions:

To discuss the effects of σ on the dipping duration, it is normalized as follows:

2.2. Temperature Characterization

For the temperature characterization, the temperature was controlled from 10 to 50 °C with a constant pressure at 100 kPa. This can be described as the third order polynomial in Equation (5):

To discuss the effects of δ on the dipping duration, it is normalized as follows:

2.3. Luminescent Signal Characterization

For the luminescent signal characterization, all the AA-PSPs were measured with the same optical setup in the spectrometer system but replacing the AA-PSP in the chamber at the reference conditions. We non-dimensionalized I by that of AAPSP3600, which is our reference AA-PSP. We call this as the signal level, η, shown in Equation (8):

To discuss the effects of η on the dipping duration, it is normalized as follows:

3. Characterization Results

3.1. Pressure Sensitivity

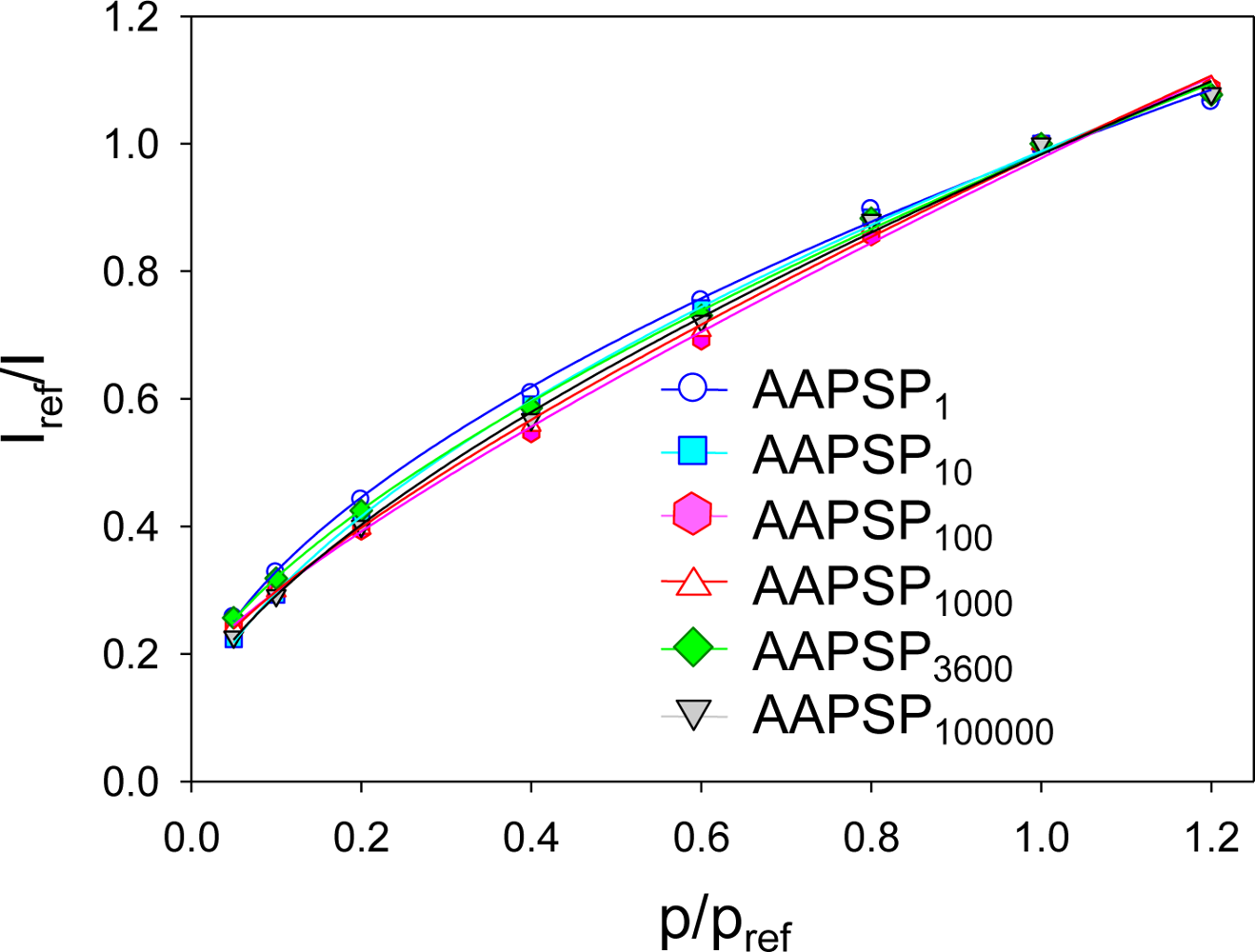

Figure 1 shows the pressure calibrations of AA-PSPs. Calibration points were fitted with Equation (2). The value of σ was determined from Equation (3). The maximum σ of 65% and the minimum σ of 52% were obtained from AAPSP100 and AAPSP1, respectively. We prepared three samples for each dipping duration. The mean values are shown with their standard deviations as error bars (Table 2). When we consider the error, the difference in σ was around 60% for the dipping duration over 100 s. Even though the fifth order difference in the dipping duration was provided, a minimal effect was seen on the pressure sensitivity.

3.2. Temperature Dependency

Figure 2 shows the temperature calibrations of AA-PSPs. The calibrations were fitted with Equation (5). The temperature calibrations showed the decrease in I with increase temperature.

The value of δ was determined from Equation (6) (Table 2). With increase the dipping duration, we can see that δ decreased until 100 s and increased over this dipping duration. The difference of δ was roughly a factor of 2. The variation of δ was greater than that of the error bar. Compared to the effect on the pressure sensitivity, the dipping duration showed a greater effect on the temperature dependency.

3.3. Signal Level

The value of η was determined from Equation (8) (Table 2). There was a peak dipping duration to maximize η. The maximum η was obtained from AAPSP1000, whose dipping duration was 1,000 s. For a short dipping duration, the luminophore would remain in the luminophore solution instead of applying onto the anodized surface. Roughly, the difference of η was a factor of 8.5 by varying the dipping duration. Even though we increased the dipping duration over 1,000 s, η decreased. This may be due to the concentration quenching [4]. The variation of η was greater than that of the error bar. Compared to the effect on the pressure sensitivity and temperature dependency, the dipping duration showed the greatest effect on the signal level.

4. Discussion

4.1. Optimum Dipping Duration

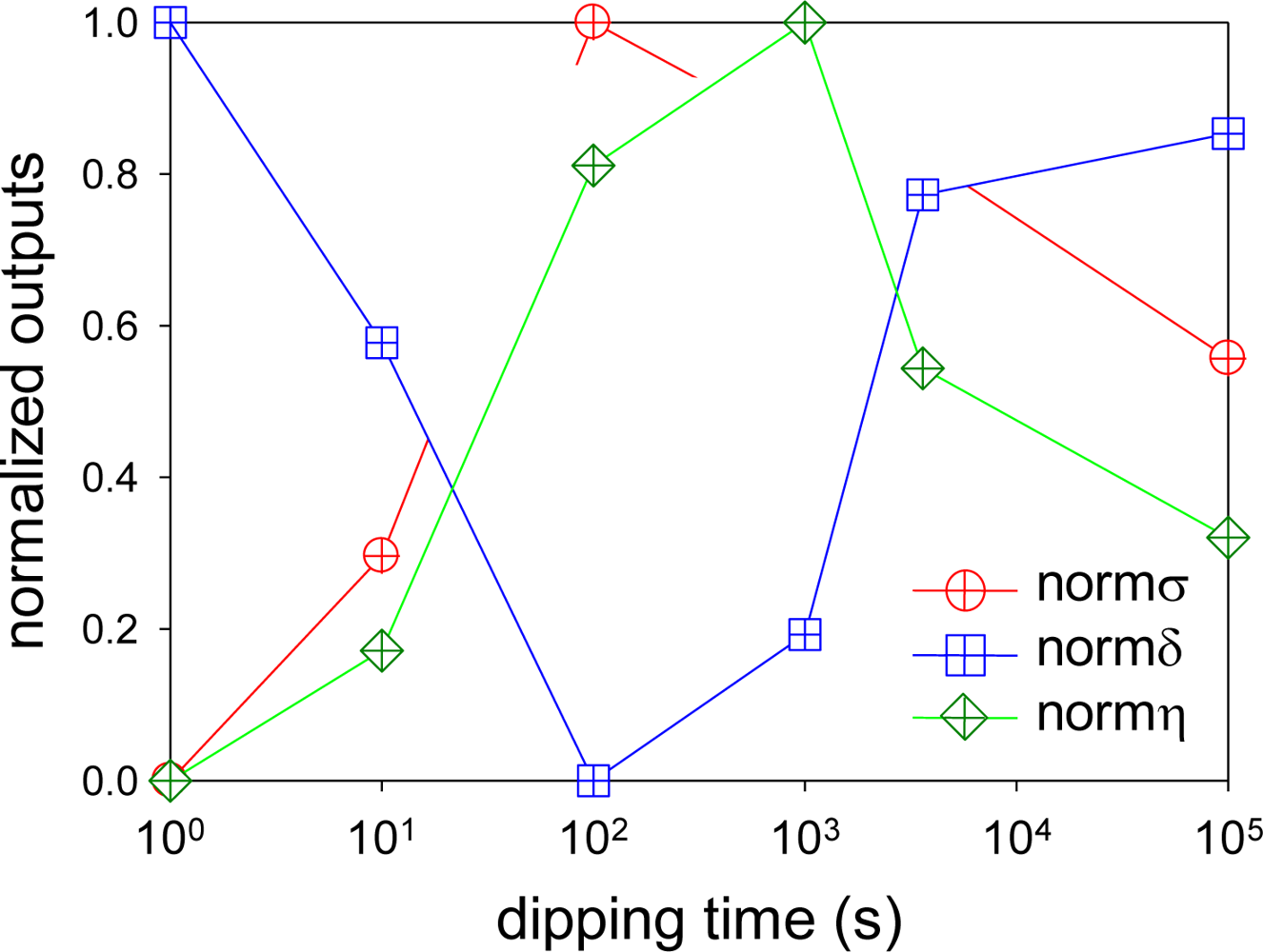

As a pressure sensor, we need δ to be close to zero or zero itself. At the same time, we need a higher σ as well as a higher η to give a higher luminescent output for a given pressure. These conditions match when all the normalized outputs in Figure 3 are the maximum. Unfortunately, the outputs did not show the desired case. The values of normσ and normη have similar trend but normδ is basically the opposite.

To determine an optimum dipping duration, we introduce weight coefficients, ασ αδ, and αη. A sum of these coefficients is unity. We arbitrarily determine the importance of these coefficients depending on our sensing purposes. By using weight coefficients, we determine an optimum value, nopt, as follows:

Equation (10) tells us that the maximum nopt gives an optimum dipping duration for given weight coefficients. If we need to maximize σ but neglect the other factors, we can set ασ as unity and others as zero. This condition is labeled as condition *1, and nopt is listed in Table 3. In this weight condition, AAPSP100 gives an optimum. If we design an AA-PSP such that all three outputs are equally important, we set ασ, αδ, and αη as 1/3. The value nopt was listed in Table 3 as condition *2. In this weight condition, AAPSP3600 gives an optimum. By introducing nopt, we can design an AA-PSP for our sensing purposes related to the dipping duration.

4.2. Repeatability

The errors shown in Table 2 were caused by the differences in the dipping deposition. Factors causing the errors may be the luminophore concentration, dipping duration, and dipping temperature. These factors can be minimized by preparing an AA-PSP at the same time. However, to discuss the repeatability of AA-PSP preparation, each AA-PSP was dipped separately. Because we used the same luminophore solution, the first factor can be fairly neglected. Even though carefully controlled, ±1 s difference in the dipping duration would be considered. Based on the presented results, this difference may not greatly influence to the pressure sensitivity, but the error may appear to the temperature dependency and signal level. The third factor was fixed at 25 °C in our experiment. There may be a small variation in a temperature control during the dipping process. This would be a factor in the dipping deposition to influence the AA-PSP characterizations. Another factor besides the dipping deposition to cause the error may be the calibration fitting error. It is related to the determination of calibration constants, which is directly related to the AA-PSP characterizations. This error can be minimized by increasing calibration points. Sakaue and Ishii reported the error estimation of the repeating cycle of pressure and temperature calibrations for a given AA-PSP [3]. AAPSP3600 was calibrated repeatedly by increasing and decreasing the pressures and temperatures. The pressure sensitivity showed ±0.3% error, and the temperature dependency showed ±0.6 %/°C error. The preparation procedure gave one order magnitude in error for the pressure sensitivity, while for the temperature dependency, both error sources showed the same order of magnitude.

5. Conclusions

This paper discussed the parameters in the dipping deposition method for optimizing anodized-aluminum pressure-sensitive paint (AA-PSP). The parameters were the dipping duration, dipping solvent, and luminophore concentration. The first parameter was varied from 1 to 100,000 s relating to the AA-PSP characterizations of the pressure sensitivity, temperature dependency, and signal level. The maximum pressure sensitivity was obtained at the dipping duration of 100 s, the minimum temperature dependency was obtained at the duration of 1 s, and the maximum signal level was obtained at the duration of 1,000 s, respectively. Among the characterizations, the dipping duration most influenced the signal level, which showed the difference of the signal level by a factor of 8.4. By introducing a weight coefficient, an optimum dipping duration can be determined. Among all the dipping parameters, it was found that the pressure sensitivity and signal level were most influenced by the dipping solvent.

Acknowledgments

This project has been supported by Grand-In-Aid Young Scientist B.

References

- Kameda, M; Tabei, T; Nakakita, K; Sakaue, H; Asai, K. Image Measurement of Unsteady Pressure Fluctuation by a Pressure-Sensitive Coating on Porous Anodized Aluminum. Meas. Sci. Technol 2005, 16, 2517–2524. [Google Scholar]

- Sakaue, H. Luminophore Application Method of Anodized Aluminum Pressure Sensitive Paint as a Fast Responding Global Pressure Sensor. Rev. Sci. Instrum 2005, 76, 084101. [Google Scholar]

- Sakaue, H; Ishii, K. Optimization of Anodized-Aluminum Pressure-Sensitive Paint by Controlling Luminophore Concentration. Sensors 2010, 10, 6836–6847. [Google Scholar]

- Lakowicz, JR. Principles of Fluorescence Spectroscopy; Kluwer Academic/Plenum Publishers: New York, NY, USA, 1999; Chapter 1.4.A. [Google Scholar]

- Liu, T; Sullivan, JP. Pressure and Temperature Sensitive Paints; Springer Verlag: Heidelberg, Germany, 2004; Chapter 7; pp. 27–31. [Google Scholar]

| Sample ID | Dipping Duration (s) |

|---|---|

| AAPSP1 | 1 |

| AAPSP10 | 10 |

| AAPSP100 | 100 |

| AAPSP1000 | 1,000 |

| AAPSP3600 | 3,600 |

| AAPSP100000 | 100,000 |

| Sample ID | Pressure Sensitivity σ (%) | Temperature Dependency δ (%/°C) | Signal Level η (%) |

|---|---|---|---|

| AAPSP1 | 52 ± 1 | −1.10 ± 0.10 | 20.0 ± 2.8 |

| AAPSP10 | 56 ± 2 | −1.63 ± 0.30 | 45.2 ± 6.8 |

| AAPSP100 | 65 ± 2 | −2.35 ± 0.22 | 139.4 ± 20.4 |

| AAPSP1000 | 63 ± 2 | −2.11 ± 0.11 | 167.1 ± 17.1 |

| AAPSP3600 | 62 ± 4 | −1.38 ± 0.15 | 100.0 ± 14.8 |

| AAPSP100000 | 59 ± 4 | −1.28 ± 0.21 | 67.2 ± 11.2 |

| Sample ID | nopt *1 | nopt *2 |

|---|---|---|

| AAPSP1 | 0.00 | 0.33 |

| AAPSP10 | 0.30 | 0.34 |

| AAPSP100 | 1.00 | 0.60 |

| AAPSP1000 | 0.85 | 0.68 |

| AAPSP3600 | 0.82 | 0.71 |

| AAPSP100000 | 0.56 | 0.58 |

© 2010 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/.)

Share and Cite

Sakaue, H.; Ishii, K. A Dipping Duration Study for Optimization of Anodized-Aluminum Pressure-Sensitive Paint. Sensors 2010, 10, 9799-9807. https://doi.org/10.3390/s101109799

Sakaue H, Ishii K. A Dipping Duration Study for Optimization of Anodized-Aluminum Pressure-Sensitive Paint. Sensors. 2010; 10(11):9799-9807. https://doi.org/10.3390/s101109799

Chicago/Turabian StyleSakaue, Hirotaka, and Keiko Ishii. 2010. "A Dipping Duration Study for Optimization of Anodized-Aluminum Pressure-Sensitive Paint" Sensors 10, no. 11: 9799-9807. https://doi.org/10.3390/s101109799

APA StyleSakaue, H., & Ishii, K. (2010). A Dipping Duration Study for Optimization of Anodized-Aluminum Pressure-Sensitive Paint. Sensors, 10(11), 9799-9807. https://doi.org/10.3390/s101109799