Cultivation and Characterization of Cynara Cardunculus for Solid Biofuels Production in the Mediterranean Region

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials and Methods

2.2 Kinetic Modeling

3. Results and Discussion

3.1. Cardoon Origin and Cultivation

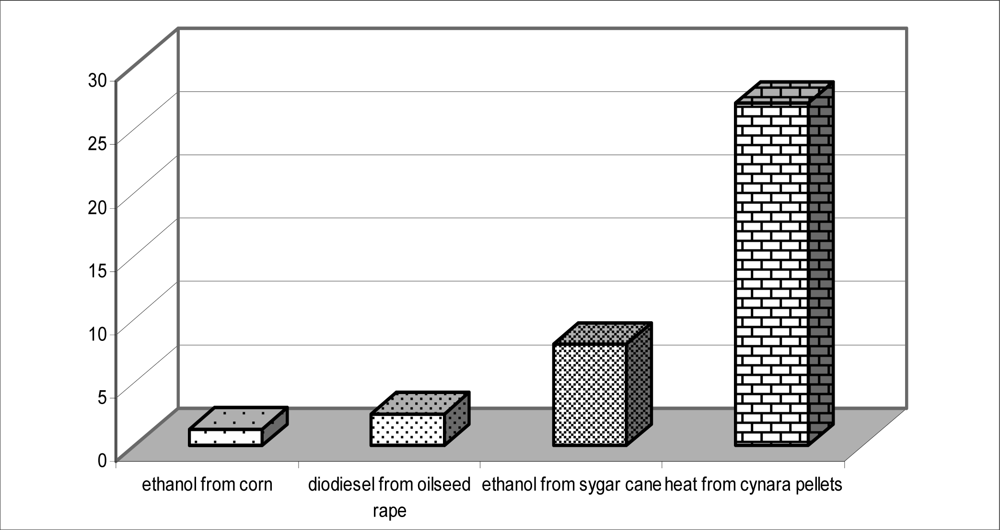

3.2. Environmental Benefits from Cardoon Cultivation

3.3. Energy Production and Cost

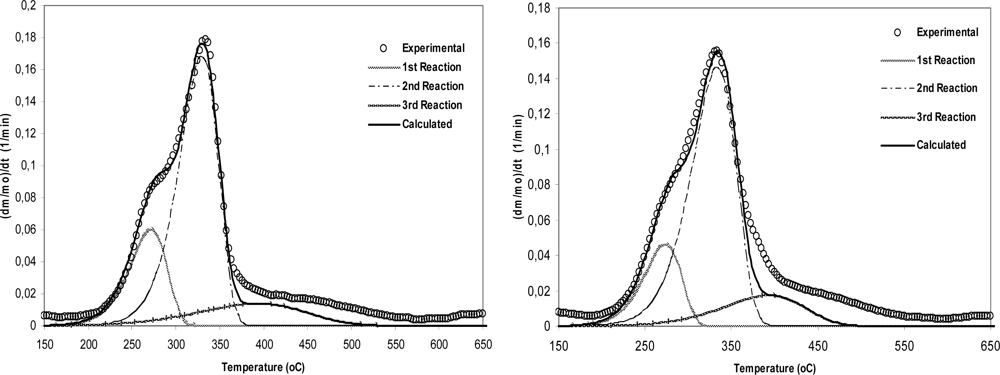

3. 4. Pyrolysis and Kinetic Modeling of the Cardoon Biofuels

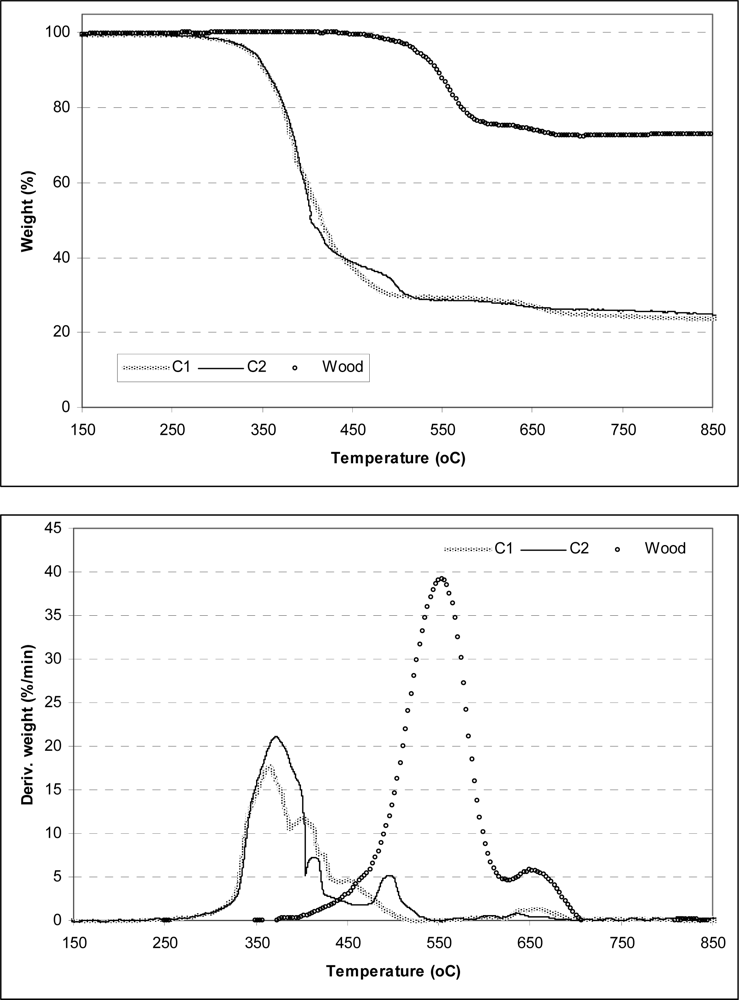

3.5. Combustion Behaviour of the Fuels

3.5.1. Combustion of the pure fuels

3.5.2. Char combustion of the fuels

4. Conclusions

Nomenclature

| A | pre-exponential factor [s−1] |

| Ctotal | Total conversion [% w/w] |

| ci | fraction of volatiles produced by the ith component |

| dai/dt | conversion rate |

| dm/dt | mass loss rate |

| E | activation energy [kJ/mol] |

| M | number of parameters involved in the model |

| m0 | initial dry sample mass [10−3 kg] |

| mchar | final char yield [mg] |

| (mchar)calc | calculated final char yield [10−3 kg] |

| (mchar)exp | experimental final char yield [10−3 kg] |

| mchar,i | final char yield of the i component [10−3 kg] |

| mi | actual sample mass of the i component [10−3 kg] |

| N | number of individual reactions |

| O.F.DTG | objective function |

| R | gas constant [kJ mol−1K−1] |

| Rmax | Maximum combustion rate [10−2/min] |

| T | temperature [°C or K] |

| Tin | initial combustion temperature [°C] |

| Tmax | temperature at max combustion rate [°C] |

| Tmax rate | temperature at max pyrolysis rate [°C] |

| Z | number of the measured data points |

| αi | conversion (reacted fraction) |

References and Notes

- Raccuia, SA; Mainolfi, A; Mandolino, G; Melilli, MG. Genetic diversity in Cynara cardunculus revealed by AFLP markers: Comparison between cultivars and wild types from Sicily. Plant Breeding 2004b, 123, 280–284. [Google Scholar] [Green Version]

- Raccuia, SA; Cavallaro, V; Melilli, MG. Intraspecific variability in Cynara cardunculus L. var. sylvestris Lam. Sicilian populations: seed germination under salt and moisture stresses. J Arid Environ 2004a, 56, 107–116. [Google Scholar] [Green Version]

- Fernandez, J; Curt, MD; Aguado, PL. Industrial applications of Cynara cardunculus L. for energy and other uses. Ind Crop Prod 2006, 24, 222–229. [Google Scholar] [Green Version]

- Raccuia, SA; Melilli, MG. Cynara cardunculus L., a potential source of inulin in Mediterranean environment: screening of genetic variability. Austr J Agri Res 2004, 55, 693–698. [Google Scholar] [Green Version]

- Raccuia, SA; Melilli, MG. Plant Architecture And Biomass Partitioning Variation As Affected By Plant Density In Cynara Cardunculus L. Var. Sylvestris Lam. In ISHS Acta Horticulturae 730: VI International Symposium on Artichoke, Cardoon and Their Wild Relatives; ISHS: Leuven, Belgium, 2004. [Google Scholar]

- Curt, MD; Sanchez, G; Fernandez, J. The potential of Cynara cardunculus L. for seed oil production in a perennial cultivation system. Biomass Bioenergy 2002, 23, 33–46. [Google Scholar] [Green Version]

- Fernandez, J; Curt, MD. State-of-the-art of Cynara cardunculus as an energy crop. Proceedings of the 2nd World Conference on Biomass for Energy, Industry and Climate Protection, 10-14/5/2004, Rome, Italy; Vol (I), pp. 22–27.

- Piscioneri, I; Sharma, N; Baviello, G; Orlandini, S. Promising industrial energy crop, Cynara cardunculus: a potential source for biomass production and alternative energy. Energ Convers Manage 2000, 41, 1091–1105. [Google Scholar] [Green Version]

- Raccuia, SA; Melilli, MG. Biomass and grain oil yields in Cynara cardunculus L. Genotypes grown in a Mediterranean environment. Field Crop Res 2007, 101, 187–197. [Google Scholar] [Green Version]

- Gonzales, J; Perez, F; Fernandez, J; Lezaun, JA; Rodriguez, D; Perea, F; Romero, C; Ochoa, MJ; Garcia, M. Study of Cynara cardunculus L. lignocellulosic biomass production in dry conditions. Acta Hortic 2004, 660, 221–227. [Google Scholar] [Green Version]

- U.S.D.A. Soil Survey Staff. Soil Taxonomy: A basic system of soil classification for making and interpreting soil surveys. In Agric Handbook 466; US Department of Agriculture: Washington, DC, 1975; p. 754. [Google Scholar]

- Skodras, G; Grammelis, P; Basinas, P. Pyrolysis and combustion behaviour of coal-MBM blends. Biores Technol 2007, 98, 1–8. [Google Scholar] [Green Version]

- Grønli, MG; Antal, MJ, Jr; Varhegyi, G. A round-robin study of cellulose pyrolysis kinetics by thermogravimetry. Ind Eng Chem Res 1999, 38, 2238–2244. [Google Scholar] [Green Version]

- Antal, MJ; Varhegyi, G. Cellulose pyrolysis kinetics: The current state of knowledge. Ind Eng Chem Res 1995, 34, 703. [Google Scholar] [Green Version]

- Gomez, CJ; Meszaros, E; Jakab, E; Velo, E; Puigjaner, L. Thermogravimetry/mass spectrometry study of woody residues and an herbaceous biomass crop using PCA techniques. J Anal Appl Pyrolysis 2007, 80, 416–426. [Google Scholar] [Green Version]

- Kastanaki, E; Vamvuka, D; Grammelis, P; Kakaras, E. Thermogravimetric studies of the behavior of lignite-biomass blends during devolatilization. Fuel Process Technol 2002, 77–78, 159–166. [Google Scholar] [Green Version]

- Boateng, AA; Jung, HG; Adler, PR. Pyrolysis of energy crops including alfalfa stems, reed canarygrass and eastern gamagrass. Fuel 2006, 85, 2450–2457. [Google Scholar] [Green Version]

- Raveendran, K; Ganesh, A; Khilar, KC. Pyrolysis characteristics of biomass and biomass components. Fuel 1996, 75, 8. [Google Scholar] [Green Version]

- Heikkinen, JM; Hordijk, JC; de Jong, W; Spliethoff, H. Thermogravimetry as a tool to classify waste components to be used for energy generation. J Anal Appl Pyrolysis 2004, 71, 883–900. [Google Scholar] [Green Version]

- Skodras, G; Grammelis, P; Basinas, P; Kakaras, E; Sakellaropoulos, G. Pyrolysis and combustion characteristics of biomass and waste derived feedstock. Ind Eng Chem Res 2006, 45, 3791–3799. [Google Scholar] [Green Version]

- Grammelis, P; Basinas, P; Malliopoulou, A; Sakellaropoulos, G. Pyrolysis kinetics and combustion of waste recovered fuels. Fuel. in press.

- Grammelis, P. Energy utilization of biomass in a fluidized bed facility; Ph.D thesis; National Technical University of Athens, 2003. [Google Scholar]

- Varhegyi, G. Mathematical Modeling of Char Reactivity in Ar-O2 and CO2-O2 Mixtures. Energy Fuels 1996, 10, 1208–1214. [Google Scholar] [Green Version]

- Kastanaki, E; Vamvuka, D. A comparative reactivity and kinetic study on the combustion of coal–biomass char blends. Fuel 2006, 85, 1186–1193. [Google Scholar] [Green Version]

- Carmen, Branca. Colomba Di Blasi, Global Kinetics of Wood Char Devolatilization and Combustion. Energy and Fuels 2003, 17, 1609–1615. [Google Scholar] [Green Version]

- Antal, MJ; Mok, WSL. Review of methods for improving the yield of charcoal from biomass. Energy Fuels 1990, 4, 3. [Google Scholar] [Green Version]

- Born, J. Biofuels: Are they the solution? National Geographic Central Issue, October. 2007. [Google Scholar]

- Encinar, JM; González, JF; González, J. Fixed-bed pyrolysis of Cynara cardunculus L. Product yields and compositions. Fuel Process Technol 2000, 68, 209–222. [Google Scholar] [Green Version]

- Aho, M; Gilb, A; Taipalea, R; Vainikkaa, P; Vesala, H. A pilot-scale fireside deposit study of co-firing Cynara with two coals in a fluidized bed. Fuel 2008, 87, 58–69. [Google Scholar] [Green Version]

- Encinar, JM; Gonzalez, JF; Gonzalez, J. Steam gasification of cynara cardunculus L.: Influence of variables. Fuel Process Technol 2002, 75, 27–43. [Google Scholar] [Green Version]

- Gomez, CJ; Manya, JJ; Velo, E; Puigjaner, L. Further applications of a revisited summative model for kinetics of biomass pyrolysis. Ind Eng Chem Res 2004, 43, 901–906. [Google Scholar] [Green Version]

- Sentorum, C; Kucukbayrak, S. Effect of mineral matter on the burning profile of lignites. Thermochim Acta 1996, 285, 35–46. [Google Scholar] [Green Version]

- Rubiera, F; Arenillas, A; Fuente, E; Miles, N; Pis, JJ. Effect of the grinding behaviour of coal blends on coal utilization for combustion. Powder Technol 1999, 105, 351–356. [Google Scholar] [Green Version]

- Olivella, MA; de las Heras, FXC. Study of the reactivities of chars from sulfur rich Spanish coals, Thermochimica Acta. Thermochimica Acta 2002, 385, 171–175. [Google Scholar] [Green Version]

- Russell, NV; Beeleyb, TJ; Mana, C-K; Gibbinsa, JR; Williamson, J. Development of TG measurements of intrinsic char combustion reactivity for industrial and research purposes. Fuel Process Technol 1998, 57, 113–130. [Google Scholar] [Green Version]

| Location | Coordinates | Year of Establishment | Studied Factors | Rainfall (mm) | Total dry matter (min–max; in t/ha) |

|---|---|---|---|---|---|

| Velestino

Magenisia Clay-loam (0.1 ha) | 39°12′N

22°14′E 87 m alt | 9/3/1999 | 3 densities (0.6, 1 and 2 pl/m2)

2 N-levels (0 and 60 kg N/ha) 4 replicates | ≈ 450

mm per year | 2nd year: 9.3–15.8

3rd year: 5.7–11.4 4th year: 7.6–11.5 |

| Velestino

Magenisia Clay-loam (0.15 ha) | 39°12′N

22°14′E 87 m alt | 9/9/2004 | 3 irrigations (350, 100 & 0 mm)

3 N-levels (0, 50 & 100 kg N/ha) 3 replicates | ≈ 450

mm per year | 1st year: 5.2–6.3

2nd year: 11.1–15.1 3rd year: 12.1–18.6 4th year: ongoing |

| Palamas

Karditsa Loamy 0.1 ha) | 39°25′N

22°05′E 105 m alt | 13/4/2006 | 2 irrigations (180 & 0 mm)

3 N-levels (0, 80 & 160 kg N/ha) 4 replicates | ≈ 450

mm per year | 1st year: 3.7–4.5

2nd year: 27.1–30.8 3rd year: ongoing |

| Palamas

Karditsa Loamy (4 ha) | 39°25′N

22°05′E 109 m alt | 11/4/2007 | 2 irrigation (150 & 0 mm)

Demonstration field | ≈ 450

mm per year | 1st year: 2.3–3.2

2nd year: ongoing |

| Mouries

Kilkis Sandy (4 ha) | 41°14′N

22°45′E 250 m alt | 14/4/2007 | 2 irrigation (150 & 0 mm)

Demonstration field | ≈ 600

mm per year | 1st year: 1.1–2.9

2nd year: ongoing |

| Agrinion

Sandy clay (1.3 ha) | 38°40′N

21°14′E 42 m alt | 12/9/2007 | Demonstration field | ≈ 650

mm per year | 1st year: ongoing |

| Perivolaki

Sandy (2.2 ha) | 39°12′N

22°14′E 87 m alt | 14/3/2007 | Demonstration field

Weed competition experiments | ≈ 450

mm per year | 1st year: 2.1–2.9

2nd year: ongoing |

| Fyteies

Kilkis Clay (4 ha) | 38°40′N

21°14′E 50 m alt | 7/5/2007 | 2 irrigation (150 & 0 mm)

Demonstration field | ≈ 650

mm per year | 1st year: <1.5

2nd year: ongoing |

| Samples

| Proximate analysis (wt%, as received)

| Ultimate analysis (wt%, dry basis)

| HHV (MJ/kg, dry basis) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Moisture | V.M.A | Fixed Carbon | Ash | C | H | N | S | OB | ||

| C1 | 8.2 | 70.0 | 14.6 | 7.2 | 40.6 | 5.5 | 0.9 | 0.1 | 45.0 | 13.7 |

| C2 | 7.9

| 71.8

| 13.4

| 6.9

| 43.7

| 6.0

| 1.8

| 0.05

| 40.9

| 16.3

|

| Encinar et al [28, 30] | - | 77.3C | 14.3C | 8.4C | 46.7 | 4.8 | 0.7 | 0.1 | 47.7 | 18.2 |

| Samples | Particle size (μm) | Initial decomposition temperature (°C) | Max decomposition rate (min−1×10−2) | Temperature at max decomposition rate (°C) | Total conversion (w/w%) |

|---|---|---|---|---|---|

| C1 | 150–250 | 224 | 11.5 | 335 | 78 |

| 250–500

| 226

| 13.8

| 334

| 76

| |

| C2 | 150–250 | 223 | 11.9 | 336 | 78.2 |

| 250–500 | 228 | 12.8 | 334 | 77.4 |

| Samples

| Hemicellulose

| Cellulose

| Lignin

| |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Particle size (μm) | A (min−1) | E (kJ/mol) | c (%) | A (min−1) | E (kJ/mol) | c (%) | A (min−1) | E (kJ/mol) | c (%) | |

| C1 | 150–250 | 1.7 × 1010 | 108.6 | 16.9 | 3.2 × 1011 | 134.1 | 53.3 | 4.6 × 103 | 59.6 | 19.7 |

| 250–500

| 9 × 1010 | 115.1

| 18.9

| 4.6 × 1011 | 135.7

| 54.8

| 2.3 × 103 | 54.5

| 24.8

| |

| C2 | 150–250 | 5.4 × 106 | 73.2 | 14.5 | 9.3 × 107 | 95.2 | 51.5 | 4 × 103 | 60.5 | 34.2 |

| 250–500

| 5.8 × 1010 | 113.6

| 14.8

| 7.9 × 109 | 116.8

| 54.5

| 6.5 × 104 | 72.8

| 31.3

| |

| Wood-based material [20] | 2.6 × 1011 | 131.1 | 25.3 | 3.3 × 103 | 203.2 | 64 | 3.3 × 103 | 56.7 | 9.8 | |

| Samples | Particle size (μm) | Initial combustion temperature (°C) | Max combustion rate (min−1×10−2) | Temperature at max combustion rate (°C) | Time (min) | Total conversion (%w/w) |

|---|---|---|---|---|---|---|

| C1 | 150–250 | 198 | 46 | 292 | 44 | 92.8 |

| 250–500

| 196

| 31.2

| 291

| 45

| 92.6

| |

| C2 | 150–250 | 200 | 16.8 | 322 | 42 | 93.5 |

| 250–500 | 188 | 18.6 | 318 | 43 | 92.9 |

| Samples | Particle size (μm) | Initial combustion temperature (°C) | Max combustion rate (min−1×10−2) | Temperature at max combustion rate (°C) | Time (min) | Total conversion (%w/w) |

|---|---|---|---|---|---|---|

| C1 | 150–250 | 277 | 20.5 | 353 | 45 | 70.2 |

| 250–500

| 291

| 17.4

| 365

| 33

| 75.8

| |

| C2 | 150–250 | 296 | 23.3 | 368 | 36 | 69.4 |

| 250–500 | 297 | 21.1 | 372 | 40 | 74.8 |

Share and Cite

Grammelis, P.; Malliopoulou, A.; Basinas, P.; Danalatos, N.G. Cultivation and Characterization of Cynara Cardunculus for Solid Biofuels Production in the Mediterranean Region. Int. J. Mol. Sci. 2008, 9, 1241-1258. https://doi.org/10.3390/ijms9071241

Grammelis P, Malliopoulou A, Basinas P, Danalatos NG. Cultivation and Characterization of Cynara Cardunculus for Solid Biofuels Production in the Mediterranean Region. International Journal of Molecular Sciences. 2008; 9(7):1241-1258. https://doi.org/10.3390/ijms9071241

Chicago/Turabian StyleGrammelis, Panagiotis, Anastasia Malliopoulou, Panagiotis Basinas, and Nicholas G. Danalatos. 2008. "Cultivation and Characterization of Cynara Cardunculus for Solid Biofuels Production in the Mediterranean Region" International Journal of Molecular Sciences 9, no. 7: 1241-1258. https://doi.org/10.3390/ijms9071241

APA StyleGrammelis, P., Malliopoulou, A., Basinas, P., & Danalatos, N. G. (2008). Cultivation and Characterization of Cynara Cardunculus for Solid Biofuels Production in the Mediterranean Region. International Journal of Molecular Sciences, 9(7), 1241-1258. https://doi.org/10.3390/ijms9071241