CFD Studies on Biomass Thermochemical Conversion

Abstract

:1. Introduction

2. CFD modeling principles

3. CFD sub-models of Biomass Thermochemical Conversion Process

3.1 Basic governing equations

3.2 Thermochemical reaction submodels

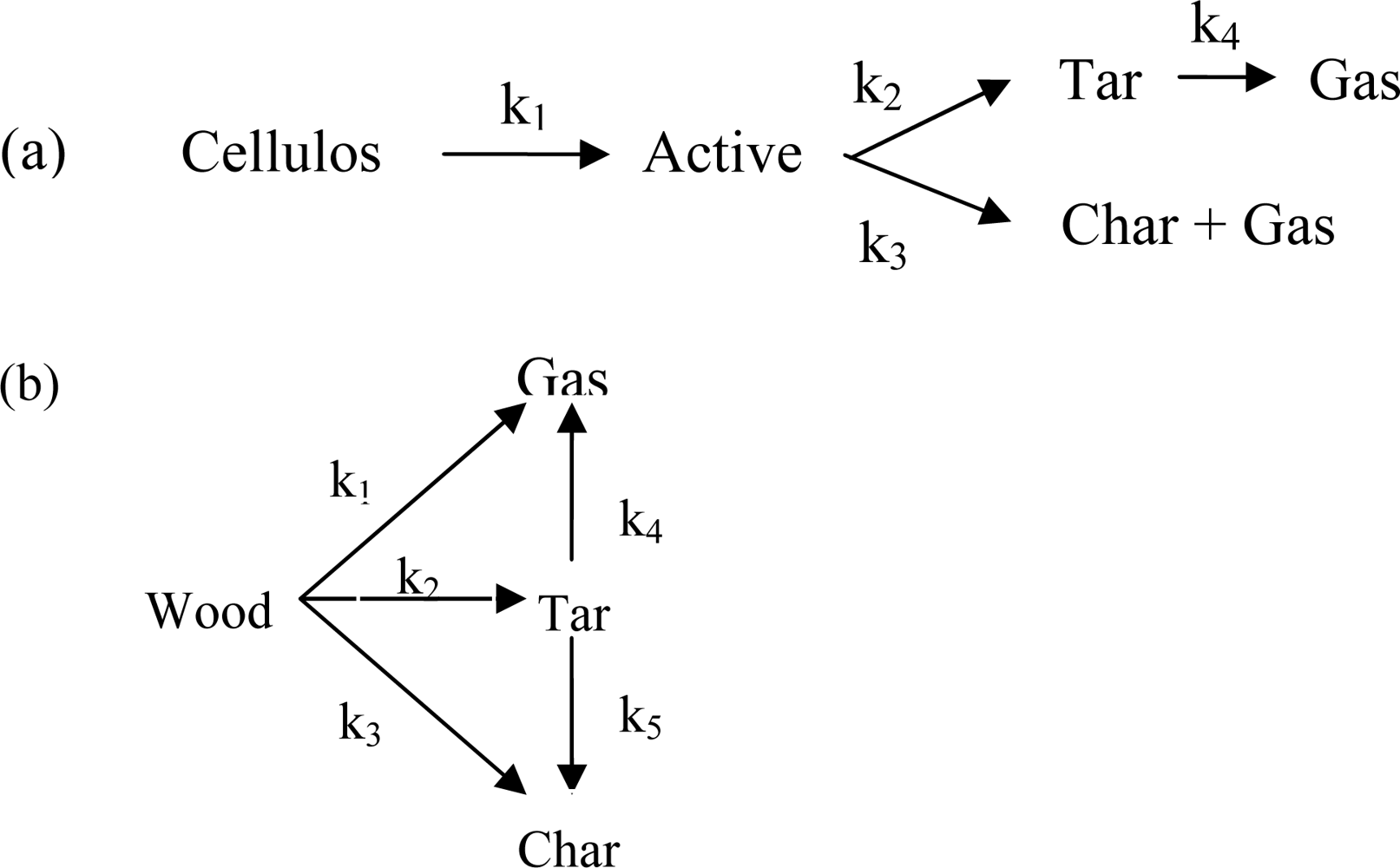

3.2.1 Devolatilization submodels

3.2.2 Secondary cracking submodels

3.2.3 Homogenous gas-phase reactions submodels

3.2.4 Heterogeneous reactions submodels

4. Additional physical models

4.1 Turbulent flow

4.1.1 RANS-based models

4.1.2 LES models

4.2 Radiation modeling

4.2.1. Discrete Ordinates model

4.2.2. P-1 model

4.2.3. Rosseland model

4.2.4 Discrete Transfer Radiation Model

4.3 Mixture fraction model

4.4 Porous media and two-phase model

4.5 The Lagrangian particle model

5. CFD Applications in Biomass Thermochemical Conversion Process

5.1 Applications in biomass gasification and pyrolysis

5.2 Applications in biomass combustion or co-firing boilers and furnaces

5.3 Applications in the NOx release

6. Conclusions

References and Notes

- Blasi, CD. Modeling chemical and physical processes of wood and biomass pyrolysis. Progress in Energy and Combustion Science 2008, 34, 47–90. [Google Scholar] [Green Version]

- Eaton, AM; Smoot, LD; Hill, SC; Eatough, CN. Components, formulations, solutions, evaluation, and application of comprehensive combustion models. Progress in Energy and Combustion Science 1999, 25, 387–436. [Google Scholar] [Green Version]

- Xia, B; Sun, DW. Applications of computational fluid dynamics (CFD) in the food industry: a review. Computers and Electronics in Agriculture 2002, 34(1–3), 5–24. [Google Scholar] [Green Version]

- Norton, T; Sun, DW; Grant, J; Fallon, R; Dodd, V. Applications of computational fluid dynamics (CFD) in the modelling and design of ventilation systems in the agricultural industry: A review. Bioresource Technology 2007, 98(12), 2386–2414. [Google Scholar] [Green Version]

- Mohan, D; Charles, U; Pittman, J; Steele, PH. Pyrolysis of Wood/Biomass for Bio-oil: A Critical Review. Energy & Fuels 2006, 20, 848–889. [Google Scholar] [Green Version]

- Moghtaderi, B. The state-of-the-art in pyrolysis modelling of lignocellulosic solid fuels. Fire and Materials 2006, 30(1), 1–34. [Google Scholar] [Green Version]

- Wurzenberger, JC; Wallner, S; Raupenstrauch, H; Khinast, JG. Thermal conversion of biomass: Comprehensive reactor and particle modeling. Aiche Journal 2002, 48(10), 2398–2411. [Google Scholar] [Green Version]

- Corella, J; Sanz, A. Modeling circulating fluidized bed biomass gasifiers. A pseudo-rigorous model for stationary state. Fuel Processing Technology 2005, 86(9), 1021–1053. [Google Scholar] [Green Version]

- Babu, BV; Chaurasia, AS. Pyrolysis of biomass: improved models for simultaneous kinetics and transport of heat, mass and momentum. Energy Conversion and Management 2004, 45(9–10), 1297–1327. [Google Scholar] [Green Version]

- Kobayashi, H; Howard, JB; Sarofim, AF. Coal devolatilization at high temperatures. Proc. 16th International Symposium on Combustion; 1976. [Google Scholar]

- Fluent Inc. FLUENT 6.1 User’s Guide; 2003. [Google Scholar]

- Sheng, CD; Azevedo, JLT. Modeling biomass devolatilization using the chemical percolation devolatilization model for the main components. Proceedings of the Combustion Institute 2003, 29, 407–414. [Google Scholar] [Green Version]

- Pallares, J; Arauzo, I; Williams, A. Integration of CFD codes and advanced combustion models for quantitative burnout determination. Fuel 2007, 86, 2283–2290. [Google Scholar] [Green Version]

- Habibi, A; Merci, B; Heynderickx, GJ. Impact of radiation models in CFD simulations of steam cracking furnaces. Computers & Chemical Engineering 2007, 31(11), 1389–1406. [Google Scholar] [Green Version]

- Fletcher, DF; Haynes, BS; Christo, FC; Joseph, SD. A CFD based combustion model of an entrained flow biomass gasifier. Applied Mathematical Modelling 2000, 24(3), 165–182. [Google Scholar] [Green Version]

- Gerun, L; Paraschiv, M; Vijeu, R; Bellettre, J; Tazerout, M; Gøbel, B; Henriksen, U. Numerical investigation of the partial oxidation in a two-stage downdraft gasifier. Fuel 2008, 87, 1383–1393. [Google Scholar] [Green Version]

- Xiu, SN; Wang, NN; Yi, WM; Li, BM; Shahbazi, G. Validation of kinetic parameter values for prediction of pyrolysis behaviour of corn stalks in a horizontal entrained-flow reactor. Biosystems Engineering 2008, 100, 79–85. [Google Scholar] [Green Version]

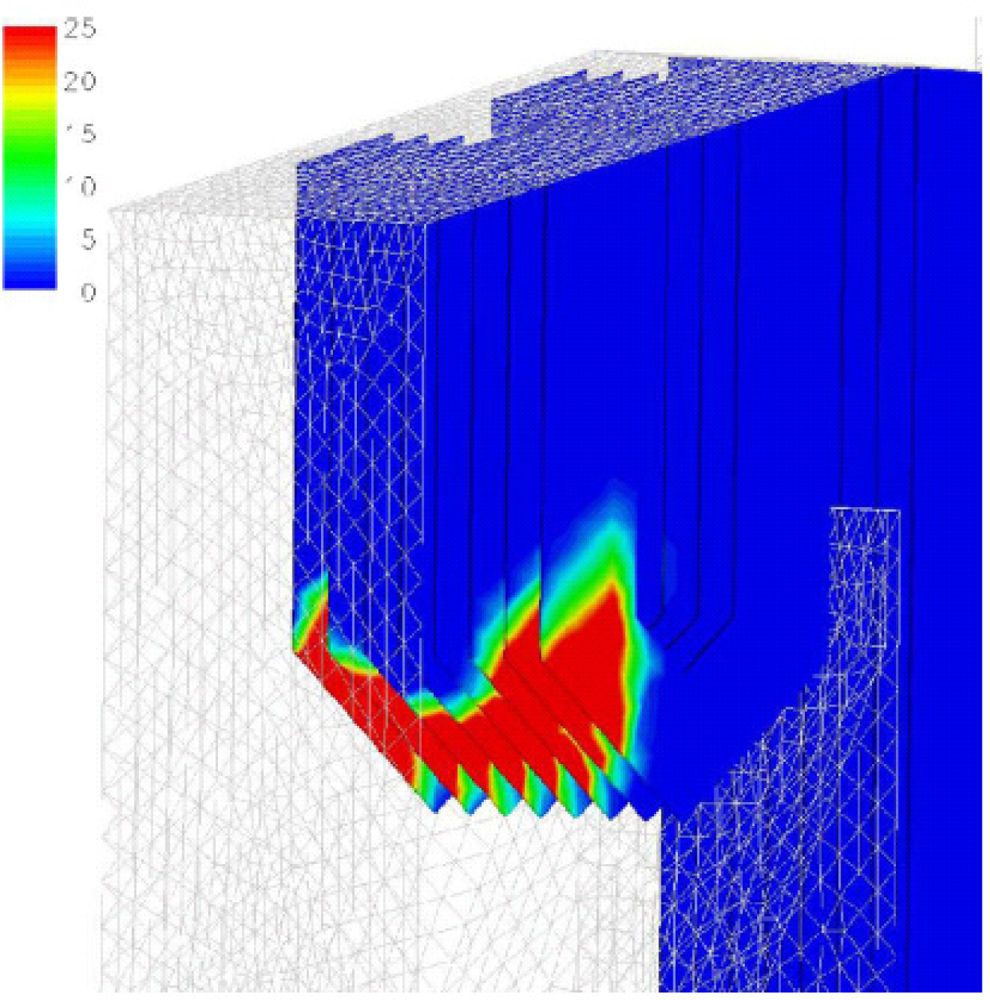

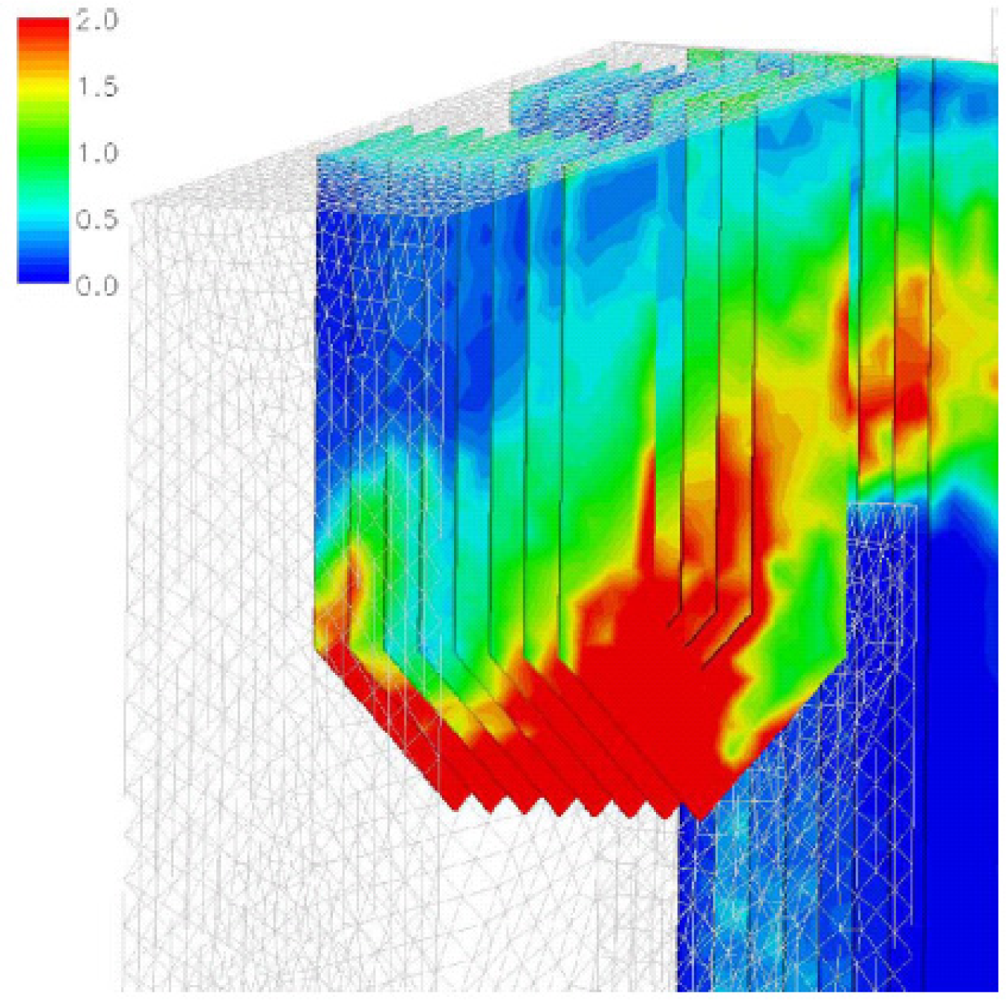

- Yuen, RKK; Yeoh, GH; Davis, GD; Leonardi, E. Modelling the pyrolysis of wet wood – I. Three-dimensional formulation and analysis. International Journal of Heat and Mass Transfer 2007, 50, 4371–4386. [Google Scholar] [Green Version]

- Yuen, RKK; Yeoh, GH; Davis, GD; Leonardi, E. Modelling the pyrolysis of wet wood – II. Three-dimensional cone calorimeter simulation. International Journal of Heat and Mass Transfer 2007, 50, 4387–4399. [Google Scholar] [Green Version]

- Yang, YB; Sharifi, VN; Swithenbank, J. Converting moving-grate incineration from combustion to gasification--Numerical simulation of the burning characteristics. Waste Management 2007, 27, 645–655. [Google Scholar] [Green Version]

- Marklund, M; Tegman, R; Gebart, R. CFD modelling of black liquor gasification: Identification of important model parameters. Fuel 2007, 86, 1918–1926. [Google Scholar] [Green Version]

- Sharma, AK. Modeling fluid and heat transport in the reactive, porous bed of downdraft (biomass) gasifier. International Journal of Heat and Fluid Flow 2007, 28, 1518–1530. [Google Scholar] [Green Version]

- Luo, ZY; Wang, SR; Cen, KF. A model of wood flash pyrolysis in fluidized bed reactor. Renewable Energy 2005, 30(3), 377–392. [Google Scholar] [Green Version]

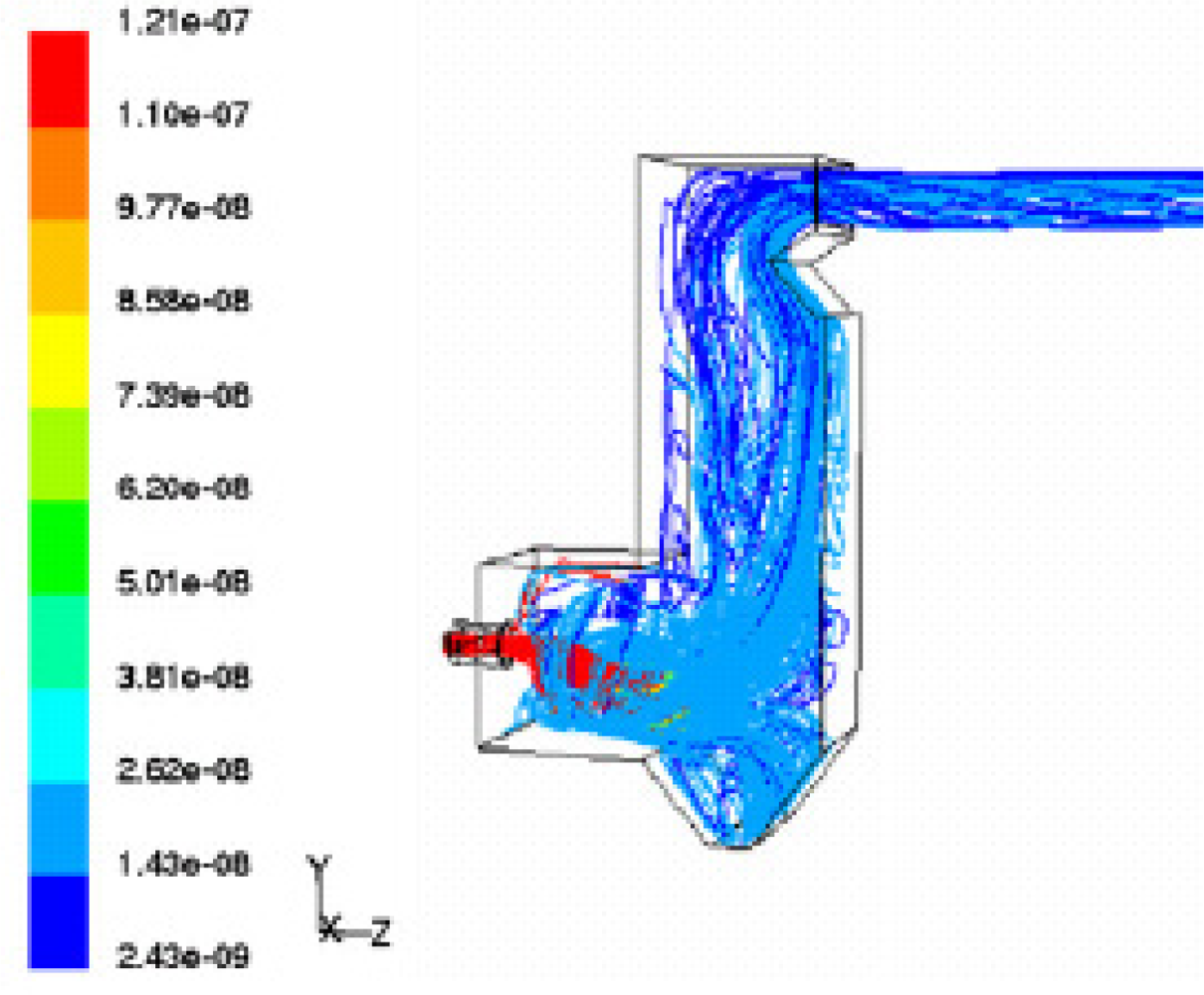

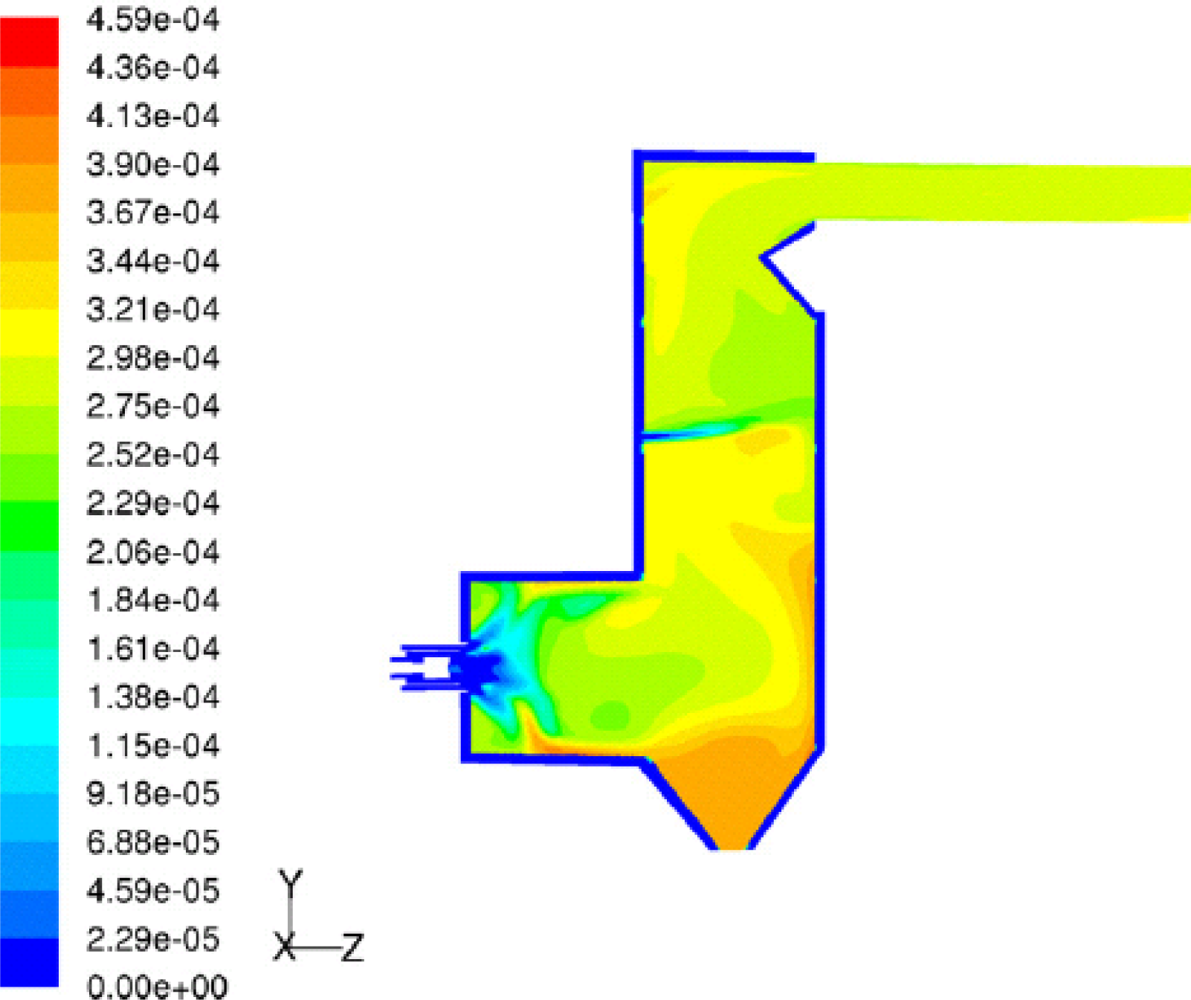

- Dixon, TF; Mann, AP; Plaza, F; Gilfillan, WN. Development of advanced technology for biomass combustion – CFD as an essential tool. Fuel 2005, 84(10), 1303–1311. [Google Scholar] [Green Version]

- Kær, SK. Numerical modelling of a straw-fired grate boiler. Fuel 2004, 83(9), 1183–1190. [Google Scholar] [Green Version]

- Kær, SK; Rosendahl, LA; Baxter, LL. Towards a CFD-based mechanistic deposit formation model for straw-fired boilers. Fuel 2006, 85(5–6), 833–848. [Google Scholar] [Green Version]

- Kær, SK; Rosendahl, L. Extending the Modelling Capacity of CFD Codes Applied to Biomass-Fired Boilers. Proc. ECOS, Copenhangen, Denmark, Jun 30-Jul 2, 2003; pp. 251–264.

- Kær, SK; Rosendahl, LA; Baxter, LL. Extending the Capability of CFD Codes to Assess Ash Related Problems in Biomass Fired Boilers. Proc. 227th ACS Annual Meeting, Anaheim California, Mar 28-Apr 1, 2004. Division of Fuel Chemistry, No. 12.

- Shanmukharadhya, KS. Simulation and thermal analysis of the effect of fuel size on combustion in an industrial biomass furnace. Energy & Fuels 2007, 21(4), 1895–1900. [Google Scholar] [Green Version]

- Marias, F. A model of a rotary kiln incinerator including processes occurring within the solid and the gaseous phases. Computers & Chemical Engineering 2003, 27(6), 813–825. [Google Scholar] [Green Version]

- Shanmukharadhya, KS; Sudhakar, KG. Effect of fuel moisture on combustion in a bagasse fired furnace. Journal of Energy Resources Technology-Transactions of the Asme 2007, 129(3), 248–253. [Google Scholar] [Green Version]

- Dixit, CSB; Paul, PJ; Mukunda, HS. Part II: Computational studies on a pulverised fuel stove. Biomass & Bioenergy 2006, 30(7), 684–691. [Google Scholar] [Green Version]

- Goddard, CD; Yang, YB; Goodfellow, J; Sharifi, VN; Swithenbank, J; Chartier, J; Mouquet, D; Kirkman, R; Barlow, D; Moseley, S. Optimisation study of a large waste-to-energy plant using computational modelling and experimental measurements. Journal of the Energy Institute 2005, 78(3), 106–116. [Google Scholar] [Green Version]

- Abbas, T; Awais, MM; Lockwood, FC. An artificial intelligence treatment of devolatilization for pulverized coal and biomass in co-fired flames. Combustion and Flame 2003, 132(3), 305–318. [Google Scholar] [Green Version]

- Backreedy, RI; Fletcher, LM; Jones, JM; Ma, L; Pourkashanian, M; Williams, A. Co-firing pulverised coal and biomass: a modeling approach. Proceedings of the Combustion Institute 2005, 30, 2955–2964. [Google Scholar] [Green Version]

- Syred, N; Kurniawan, K; Grifths, T; Gralton, T; Ray, R. Development of fragmentation models for solid fuel combustion and gasification as subroutines for inclusion in CFD codes. Fuel 2007, 86(14), 2221–2231. [Google Scholar] [Green Version]

- Tan, CK; Wilcox, SJ; Ward, J. Use of artificial intelligence techniques for optimisation of co-combustion of coal with biomass. Journal of the Energy Institute 2006, 79(1), 19–25. [Google Scholar] [Green Version]

- Gera, D; Mathur, MP; Freeman, MC; Robinson, A. Effect of large aspect ratio of biomass particles on carbon burnout in a utility boiler. Energy & Fuels 2002, 16(6), 1523–1532. [Google Scholar] [Green Version]

- Ma, L; Jones, JM; Pourkashanian, M; Williams, A. Modelling the combustion of pulverized biomass in an industrial combustion test furnace. Fuel 2007, 86(12–13), 1959–1965. [Google Scholar] [Green Version]

- Miltner, M. Process simulation and CFD calculations for the development of an innovative baled biomass-fired combustion chamber. Applied Thermal Engineering 2007, 27(7), 1138–1143. [Google Scholar] [Green Version]

- Zarnescu, V; Pisupati, SV. An integrative approach for combustor design using CFD methods. Energy & Fuels 2002, 16(3), 622–633. [Google Scholar] [Green Version]

- Saario, A; Oksanen, A. Comparison of global ammonia chemistry mechanisms in biomass combustion and selective noncatalytic reduction process conditions. Energy & Fuels 2008, 22(1), 297–305. [Google Scholar] [Green Version]

- Norstrom, T; Kilpinen, P; Brink, A; Vakkilainen, E; Hupa, M. Comparisons of the validity of different simplified NH3-oxidation mechanisms for combustion of biomass. Energy & Fuels 14, 947–952. [Green Version]

- Weydahl, T; Bugge, M; Gran, IR; Ertesvag, IS. Computational modeling of nitric oxide formation in biomass combustion. Applied Mechanics and Engineering 2002, 7, 125–142. [Google Scholar] [Green Version]

- Rogerson, JW; Kent, JH; Bilger, RW. Conditional moment closure in a bagasse-fired boiler. Proceedings of the Combustion Institute 2007, 31, 2805–2811. [Google Scholar] [Green Version]

| Technology | Residence time | Heating rate | Temperature °C | Aim Products | Oxidizer amount |

|---|---|---|---|---|---|

| carbonation | very long (days) | low | low (~400) | charcoal | absence |

| fast pyrolysis | short (<2 sec) | high (>1000°C/s) | moderate (~500) | bio-oil, chemicals | limited |

| gasification | long | high | high (~800) | Gas, chemicals | limited |

| combustion | long | high | high | heat | enough |

| Application | Code | Dim | Aim/Outcome | Turb. Model | Extra Model | Agreement with Exp. | Authors |

|---|---|---|---|---|---|---|---|

| Entrained flow gasifier [15] | CFX4 | 3D | Products mass fraction distribution; temperature contours; swirl velocity distribution | Std

k – ε RSM | Lagrangia n | Acceptable | Fletcher, D. F. |

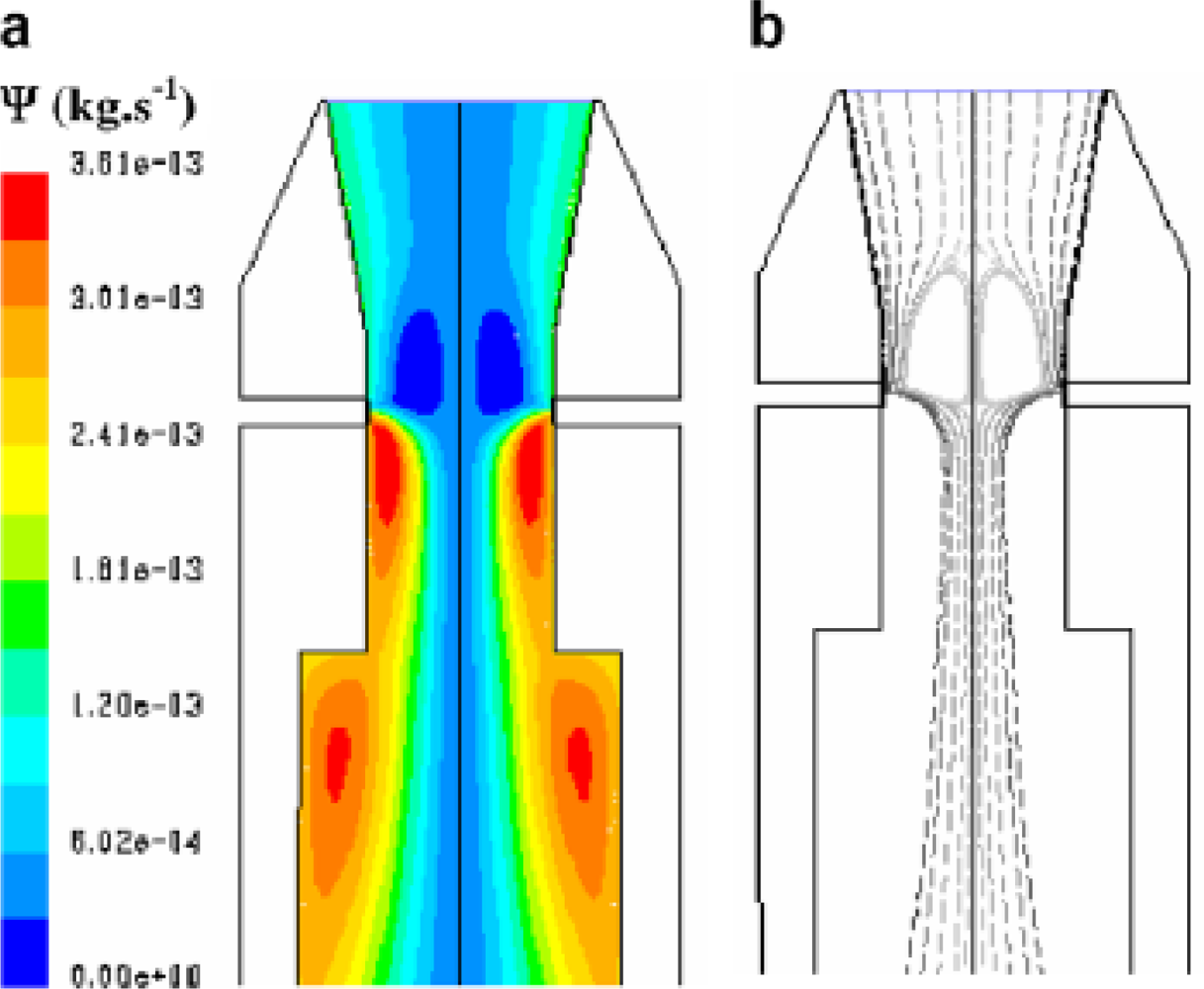

| Two-stage downdraft gasifier [16] | Fluent | 2D | To investigate in detail the oxidation zone; temperature profile; velocity pattern; tar conversion mechanism study | RNG

k – ε | DOM | Satisfactory | Gerun, L. |

| Horizontal entrained-flow reactor [17] | Fluent | 2D | Predictions of flow, temperature and conversion; sensitivity of the kinetic parameters of pulverized corn stalk fast pyrolysis | n/a | Lagrangia n | Reasonable | Xiu, S. N. |

| Cone calorimeter reactor [18, 19] | Code | 3D | To model heat transfer and pyrolysis within dry and wet wood specimens, and the mixing and pilot ignition of the released volatiles | n/a | Porous | n/a | Yuen, R. K. K. |

| Moving packed bed [20] | Fluent | 2D | Detailed comparisons between the combustion mode and gasification mode in a waste moving-grate furnace | Std

k – ε | DOM | n/a | Yang, Y. B. |

| Entrained flow gasifier [21] | CFX | 2D | To model black liquor gasification, model parameters identification and sensitivity analysis | Std

k – ε | Lagrangia n

DTRM | n/a | Marklund , M. |

| Downdraft gasifier [22] | Code | 3D | Temperature profile, pressure drop, model parametric analysis | n/a | Porous | n/a | Sharma, A. K. |

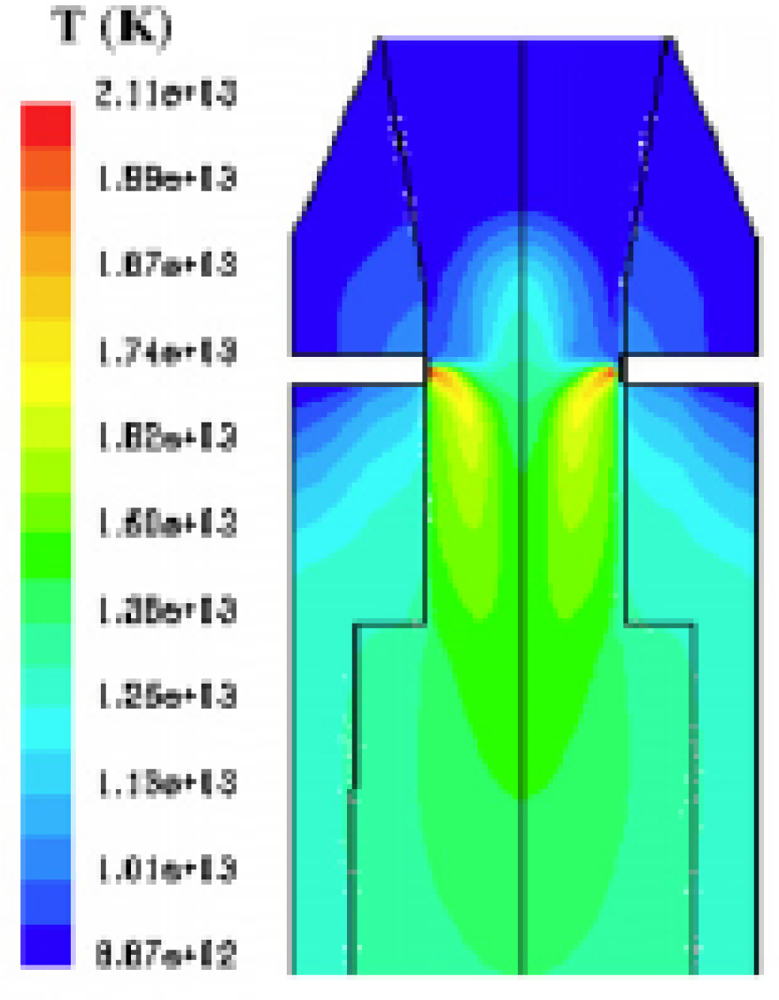

| Fluidized bed flash pyrolysis [23] | Code | 3D | An integrated model proposed to predict wood fast pyrolysis for bio-oil | n/a | Radiation | Good | Luo, Z. Y. |

| Application | Code | Dim | Aim/Outcome | Turb. Model | Extra Model | Agreement with Exp. | Authors |

|---|---|---|---|---|---|---|---|

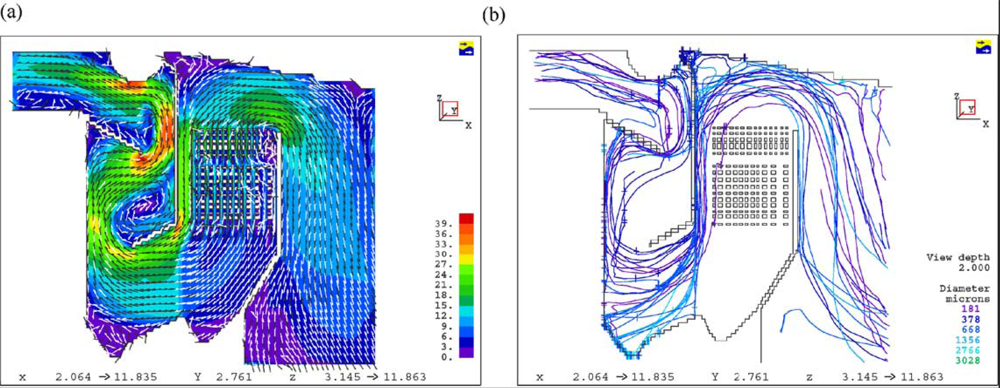

| Bagasse fired boilers[24] | Furnace | 3D | Tube erosion; heat transfer Airheater corrosion; Swirl burner | Std

k – ε | Lagrangian; porous | Acceptable | Dixon, T. F. |

| Straw-fired grate boiler [25–28] | CFX | 3D | To provide insight into the boilers; heat transfer predictions; To predict ash deposition | RNG

k – ε | DTRM | Good | Kær, S. K. |

| Combustion Furnace[29] | Fluent | 3D | Particle tracks, temperature contours | Std

k – ε | Lagrangian; DOM | n/a | Shanmukharadhya, K. S. |

| Waste rotary kiln incinerator [30] | Fluent | 3D | To describe the processes occurring within the gaseous phase of the kiln and of the post combustion chamber | Std

k – ε | P1 | n/a | Marias, F. |

| Bagasse-fired furnaces [31] | Fluent | 3D | To gain insight into the effect of moisture on the flame front. | k – ε | Lagrangian; P1 | n/a | Shanmukharadhya, K. S. |

| Tube stove[32] | CFX-TASCf low | 3D | To understand the aero-thermo-chemical behaviour of the stove operation in combustion and gasification modes | n/a | c-phase | Excellent | Dixit, C. S. B |

| Waste-to-energy plant[33] | Fluent

FLIC | To maximize the energy recovery efficiency of waste-to-energy plants | k − ω | DOM | n/a | Goddar, C. D. |

| Application | Code | Dim | Aim/Outcome | Turb. Model | Extra model | Agreement with Exp. | Authors |

|---|---|---|---|---|---|---|---|

| Biomass and coal co-fired[34] | CINAR | 3D | A new approach based on neural networks is proposed | k – ε | Radiation; Lagrangian | n/a | Abbas, T. |

| Co-firing[ 35] | Fluent 6.1 | 3D | To predict the behaviour of the biomass in the coal flame. | RNG

k – ε | P1

FG-biomass | n/a | Backreedy, R. I. |

| Co-firing combustors [36] | Fluent UDF code | To develop a fragmentation subroutine applicable to Fluent via a UDF. | n/a | Lagrangian; fragmentation model | Reasonable | Syred, N. | |

| Co-combustion boilers[37] | Fluent 6.1 MAT- LAB | 3D | To optimize burner operation in conventional pulverized-coal-fired boilers | Std k – ε | DOM | n/a | Tan, C. K. |

| Biomass utility boiler[38] | Fluent 5.6 | 3D | To examine the impact of the large aspect ratio of biomass particles on carbon burnout in cofiring switchgrass/coal. | Std k – ε | Lagrangian; DOM | n/a | Gera, D. |

| Application | Code | Dim | Aim/Outcome | Turb, Model | Extra Model | Agreement with Exp. | Authors |

|---|---|---|---|---|---|---|---|

| Test furnace [39] | Code | 3D | Particle tracks, temperature contours, NO formation, potassium concentration | RNG

k – ε | Lagrangian; P1; radiation; NOx Formation; potassium release; | Good | Ma, L. |

| Combustion chamber [40] | Fluent 5.5 | 3D | Prediction of gaseous emission | SST- k – ω | Lagrangian; DTRM; NOx- model | Good | Miltner, M. |

| Pilot down-fired combustor [41] | Fluent 5.0 | 3D | To describe the processes occurring within the gaseous phase of the kiln and of the post combustion chamber | k – ε | P1; Lagrangian; NOx module | n/a | Zarnes-cu, V. |

| Fluidized beds [42] | Fluent 6.2 | 3D | To compare the performance of five global ammonia chemistry mechanisms in full-scale boiler CFD modeling. | Std

k – ε | DOM; Global Ammonia Chemistry Mechanism s | Well under special conditions | Saario, A. |

| Biomass combustion [43] | Code | 1D | Comparisons of the Validity of Different Simplified NH3-Oxidation Mechanisms for Combustion of Biomass | n/a | Ammonia oxidation mechanisms | n/a | Norstrom, T. |

| Wood stove [44] | Spider | 2D | To model nitric-oxide formation from fuel-bound nitrogen in biomass turbulent non-premixed flames. | Std

k – ε | DTRM | n/a | Weydahl, T. |

| Bagasse-fired boiler [45] | Furnace | 3D | To apply conditional moment closure (CMC) in a to obtain predictions of CO and NO in the flue gas. | Std

k – ε | Lagrangian; DTRM; PDF; conditional moment closure equation | Reasonable | Rogerson, J. W. |

Share and Cite

Wang, Y.; Yan, L. CFD Studies on Biomass Thermochemical Conversion. Int. J. Mol. Sci. 2008, 9, 1108-1130. https://doi.org/10.3390/ijms9061108

Wang Y, Yan L. CFD Studies on Biomass Thermochemical Conversion. International Journal of Molecular Sciences. 2008; 9(6):1108-1130. https://doi.org/10.3390/ijms9061108

Chicago/Turabian StyleWang, Yiqun, and Lifeng Yan. 2008. "CFD Studies on Biomass Thermochemical Conversion" International Journal of Molecular Sciences 9, no. 6: 1108-1130. https://doi.org/10.3390/ijms9061108

APA StyleWang, Y., & Yan, L. (2008). CFD Studies on Biomass Thermochemical Conversion. International Journal of Molecular Sciences, 9(6), 1108-1130. https://doi.org/10.3390/ijms9061108