Diversity of Effects of Mechanical Influences on Living Systems and Aqueous Solutions

Abstract

1. Introduction

2. Diversity of Effects of Mechanical Influences on Living Systems and Aqueous Solutions

2.1. Impact Types

2.2. Effects of Mechanical Influences

- The whole organism in vivo;

- Cell cultures;

- Aqueous solutions or deionized water.

2.2.1. Mechanical Impact on Living Systems

2.2.2. Mechanical Impact on Water Solution

2.3. Ultrasound Impact

2.3.1. US Impact on Living Systems

2.3.2. US Impact on Water Solutions

3. Mechanisms of the Mechanical Impact Effects

3.1. Receptor Response of Living Systems. Mechanotransduction

- “elements of cytoskeleton → creation of internal force on the mechanoreceptor from the intracellular matrix → activation of mechanoreceptor → detection of changes in the extracellular matrix under external mechanical stimulation” (inside out).

- “absence of internal force on the mechanoreceptor from the intracellular matrix → inhibition of mechanoreceptor → inhibition of detection of changes in the extracellular matrix under external mechanical stimulation”

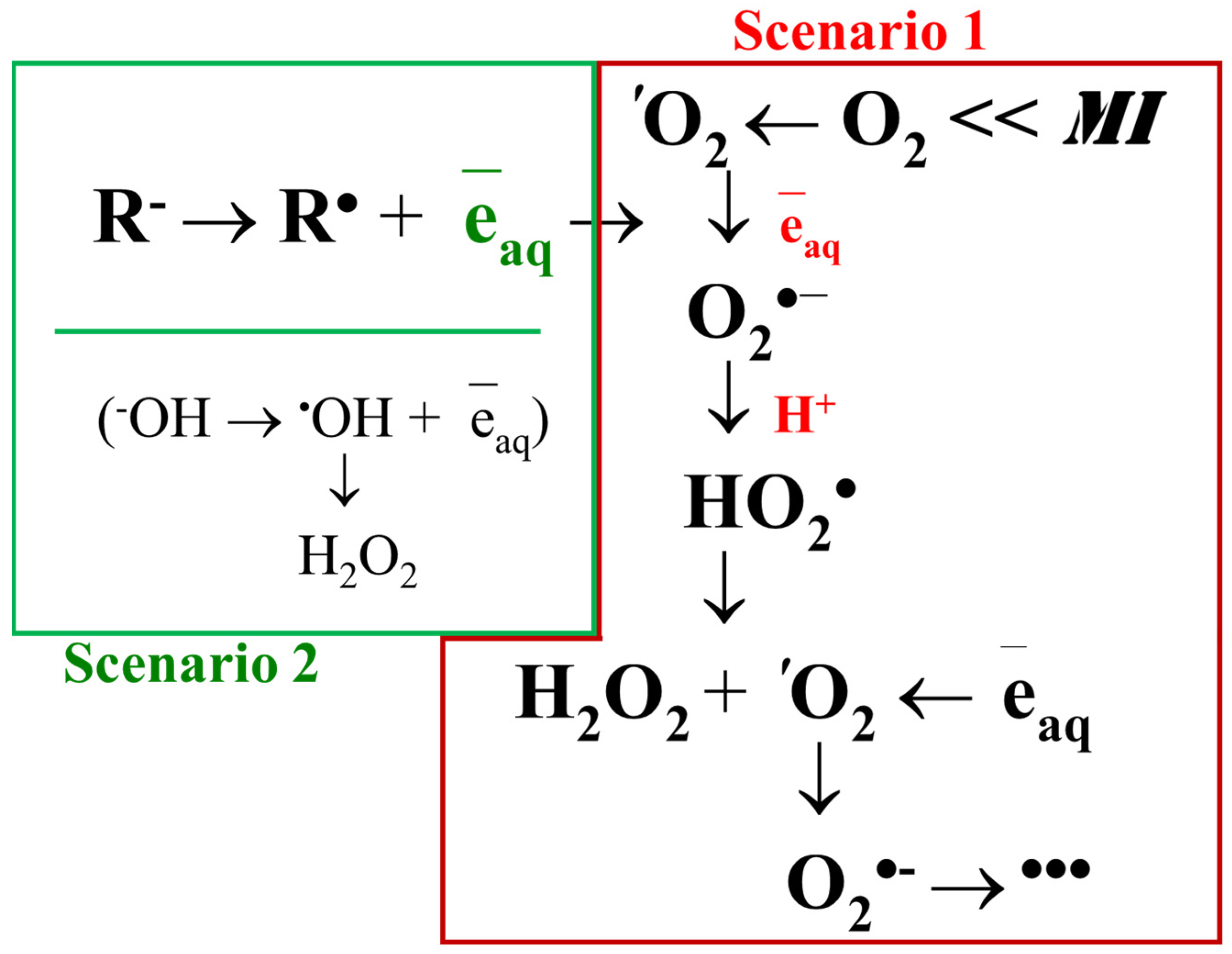

3.2. ROS Generation in Water Solutions

- Activation of oxygen molecules dissolved in water;

- Dissociation of water molecules and hydroxyl anions.

4. Dependence of the Magnitude of the Effects of Mechanical Impacts on Their Characteristics

4.1. Mechanical Influence

4.1.1. Principal Conditions of Realisation of Effects

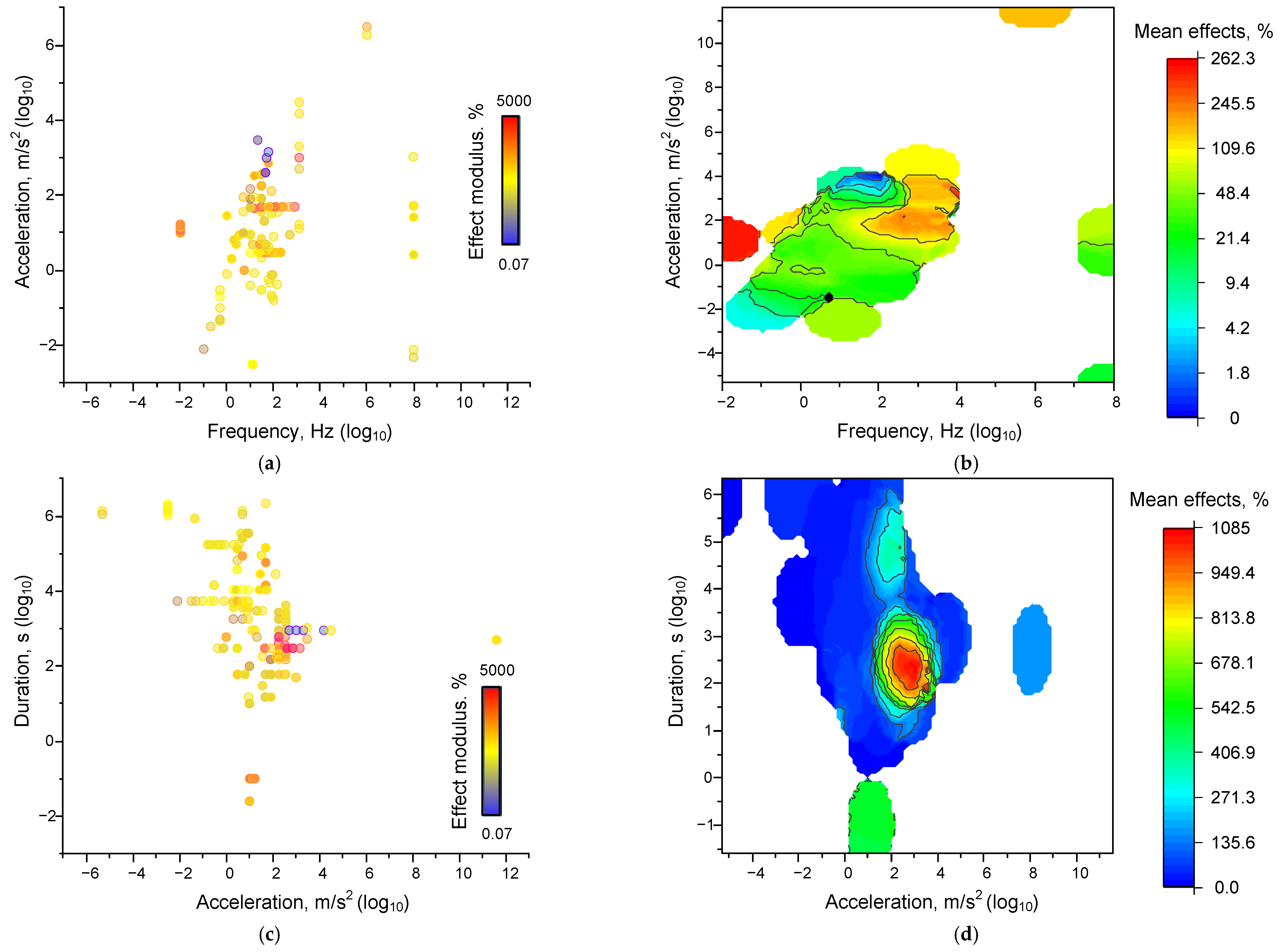

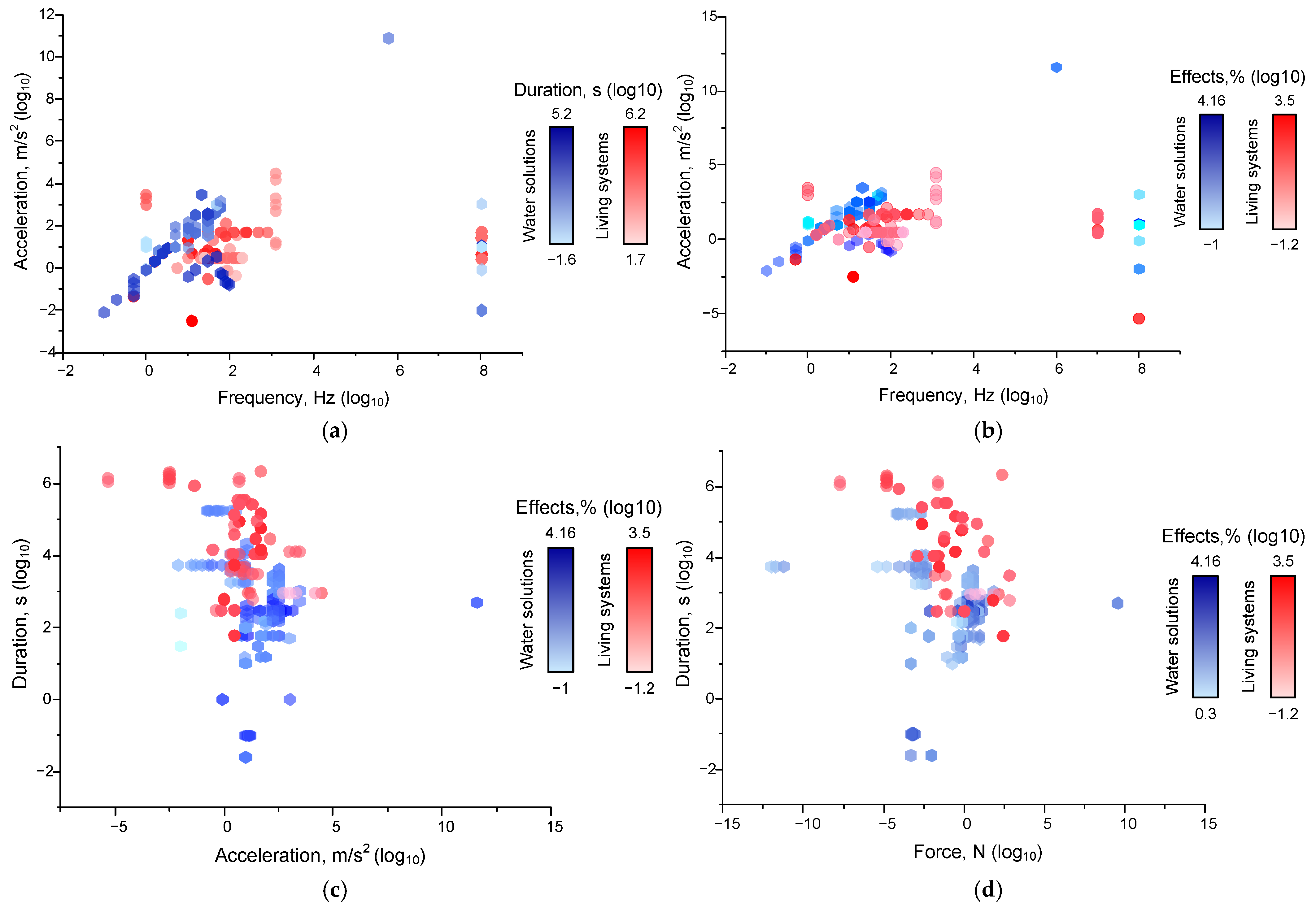

4.1.2. Dependences of Mechanical Effects on the Combination of Factors

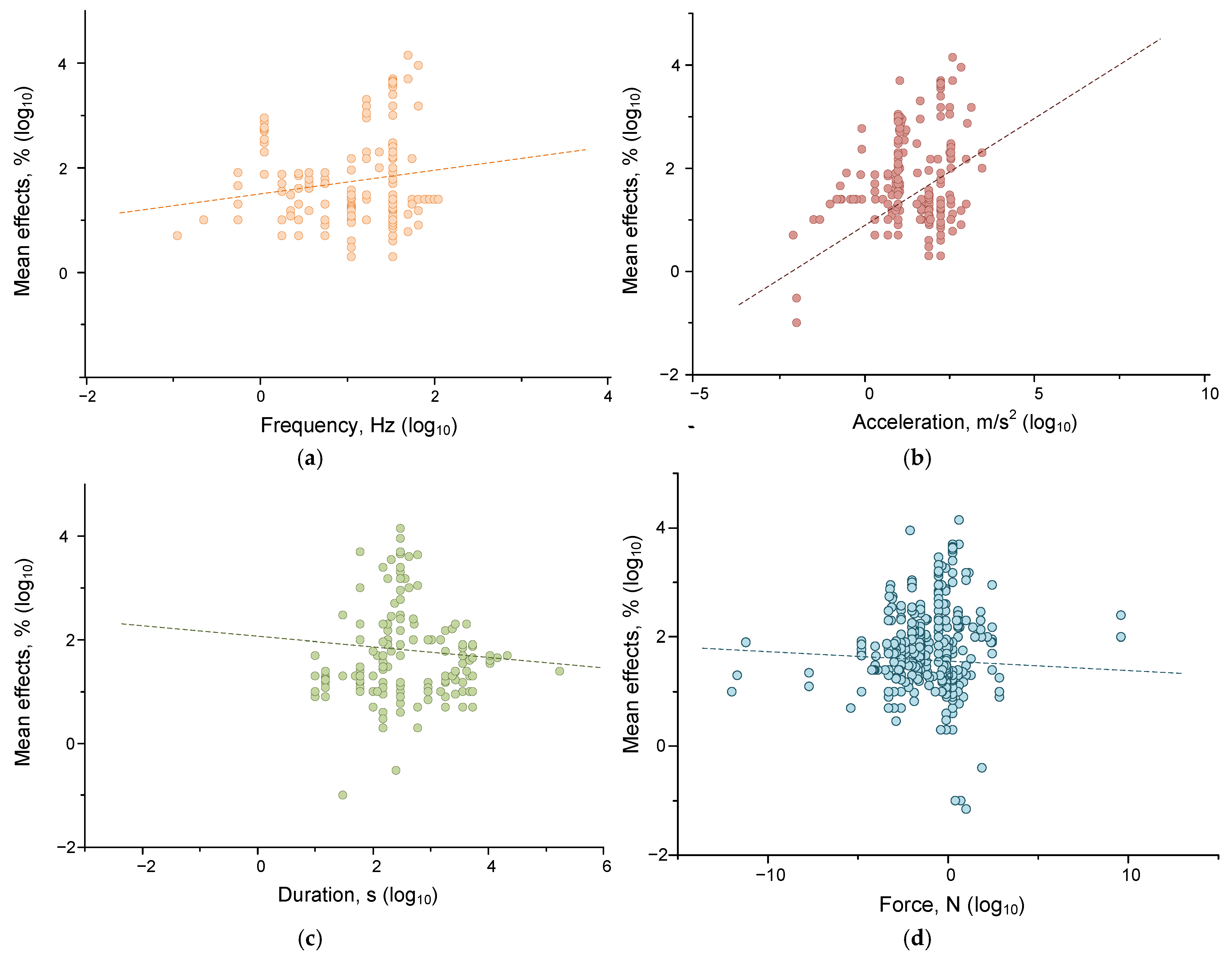

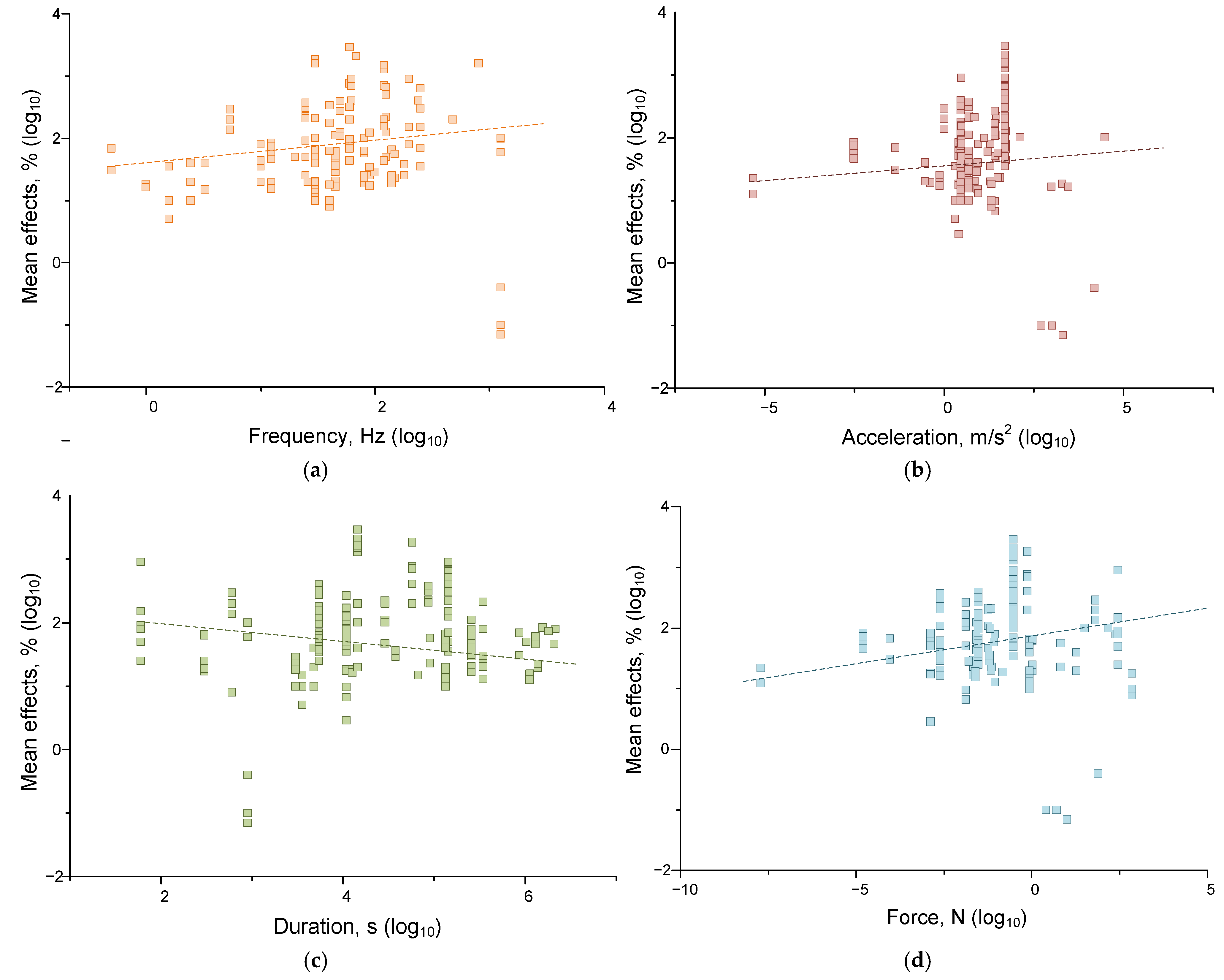

4.1.3. Correlations of Effects from Individual Parameters

4.2. Dependence of the Magnitude of Ultrasound Effects on Its Characteristics

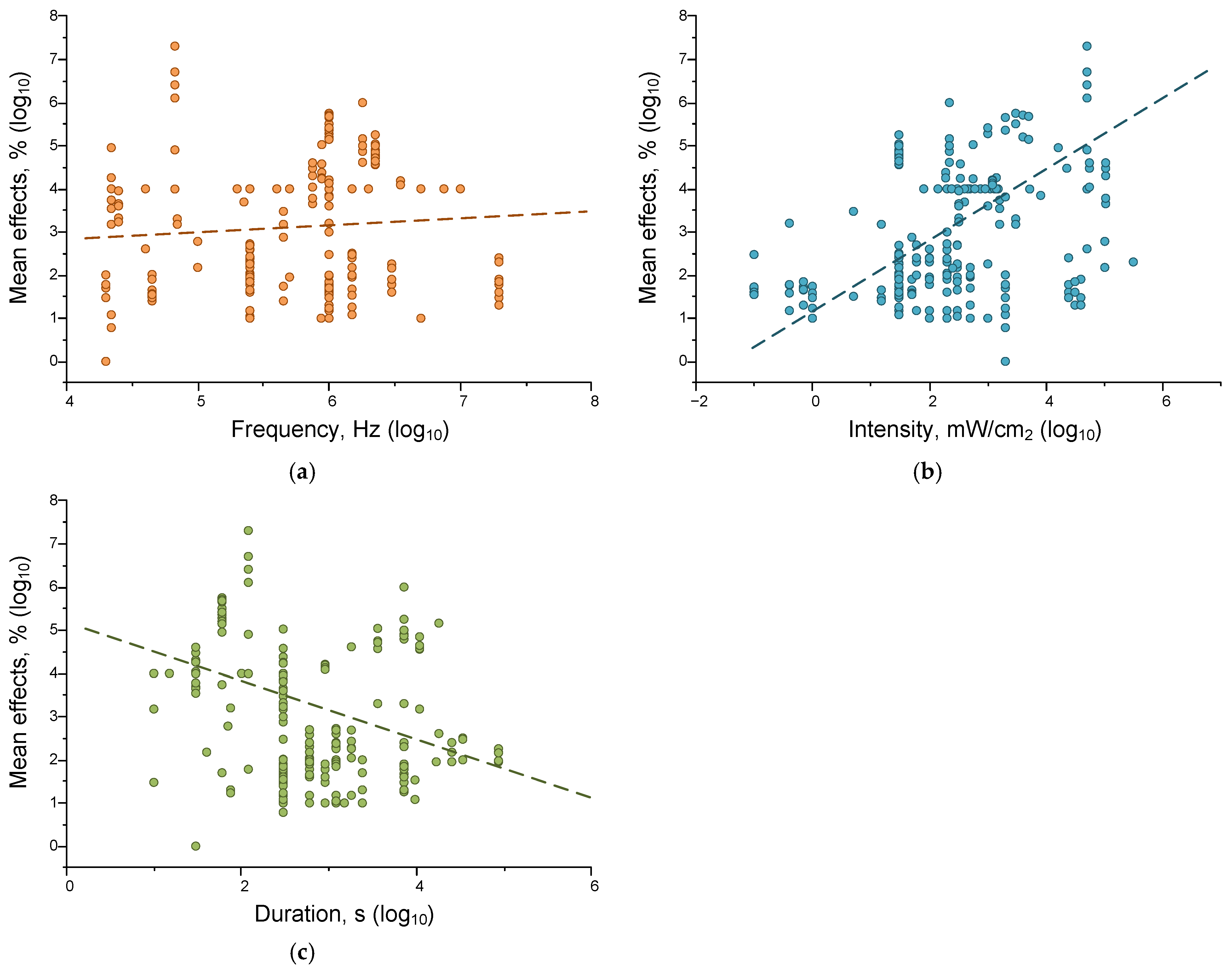

Correlations of Ultrasound Effects on Individual Parameters

5. Limitations and Prospects

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ACAN | Aggrecan |

| AJ | Adherens junctions |

| Akt | RAC-alpha serine/threonine-protein kinase |

| ALP | Alkaline phosphatase |

| ASICs | Acid-sensing ion channels |

| BMDCs | Bone Marrow-Derived Dendritic Cell |

| BrdU | 5-bromo-2′-deoxyuridine |

| BSA | bovine serum albumin |

| CD | Cluster of differentiation |

| Cenpf | Centromere protein F |

| COL2A1 | collagen II type gene |

| CPK | creatine phosphokinase |

| CYP1B1 | cytochrome P450 1B1 gene |

| DKK1 | Dickkopf-related protein 1 |

| DLS | Dynamic light scattering |

| DMEM | Dulbecco’s Modified Eagle Medium |

| DN | double-network |

| E.G7-OVA | T lymphoblast cancer cell line |

| EGF | Epidermal Growth Factor |

| EMR | Electromagnetic radiation |

| ER | Endoplasmic reticulum |

| ERK | Extracellular signal-regulated kinase |

| fMLF | N-Formylmethionine-leucyl-phenylalanine |

| GPCRs | G-protein coupled receptors |

| hAD-MSC | Human amnion-derived mesenchymal stem cells |

| hESC | Human embryonic stem cells |

| HEWL | Hen egg white lysozyme |

| Hk2 | Hexokinase II gene |

| hPDLSC | Human periodontal ligament stem cells |

| IDO | Indoleamine 2,3-dioxygenase |

| IFN | Interferon |

| IGF-I | insulin-like growth factor 1 |

| IgG | Immunoglobulin G |

| IL | Interleukin |

| LINC | Linker of Nucleoskeleton and Cytoskeleton |

| MAPK | Mitogen-activated protein kinase |

| MMP2 | Matrix metalloproteinase-2 |

| MSCs | Mesenchymal stem cells |

| MT-1a | Metallothionein 1A |

| NFAT | Nuclear factor of activated T-cells |

| OCN | Osteocalcin |

| OPG | Osteoprotegerin |

| OSX | Osterix protein |

| PAAm | polyacrylamide |

| Pcdh17 | Protocadherin 17 |

| PEG | poly(ethylene glycol) |

| PGE-2 | Prostaglandin E 2 |

| PHEMA | poly(2-hydroxyethyl methacrylate) |

| PI3K | Phosphoinositide 3-kinases |

| PLA2 | phospholipase A2 |

| PNaAMPS | poly(2-acrylamido-2-methylpropanesulfonic acid sodium salt) |

| PVS | poly(vinyl alcohol) |

| RANKL | Receptor activator of nuclear factor kappa-B ligand |

| ROS | Reactive oxygen species |

| RPMI | Roswell Park Memorial Institute |

| Runx2 | Runt-related transcription factor 2 |

| SACs | stress-activated channels |

| Slc2a1 | major glucose transporter GLUT1 gene |

| SOX | Superoxide dismutase |

| TGF | Transforming growth factor |

| TNF | Tumor necrosis factor |

| TREK | Two-Pore Domain K+ channels |

| TRP | Transient receptor potential channels |

| US | Ultrasound |

| VEGF | Vascular Endothelial Growth Factor |

Appendix A

| # | Solution | Object | Impact Type | Concetration (If Applied) | Frequency. Hz | Amplitude (Value) | Amplitude (Units) | Mass. g | Time. s | Mesured Characterisctic | Effect. % | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Culture medium DMEM | human fibroblasts | Ultrasound | - | 45,000 | 15 | mW/cm2 | 5 | 300 | Cells proliferation | +30% | [102] |

| 2 | Culture medium DMEM | human fibroblasts | Ultrasound | - | 45,000 | 50 | mW/cm2 | 5 | 300 | Cells proliferation | +45% | [102] |

| 3 | Culture medium DMEM | human fibroblasts | Ultrasound | - | 1,000,000 | 0.7 | mW/cm2 | 5 | 300 | Cells proliferation | +45% | [102] |

| 4 | Culture medium DMEM | human fibroblasts | Ultrasound | - | 1,000,000 | 1 | mW/cm2 | 5 | 300 | Cells proliferation | +55% | [102] |

| 5 | Culture medium DMEM | human fibroblasts | Ultrasound | - | 45,000 | 15 | mW/cm2 | 5 | 300 | Collagen expression | +45% | [102] |

| 6 | Culture medium DMEM | human fibroblasts | Ultrasound | - | 45,000 | 50 | mW/cm2 | 5 | 300 | Collagen expression | +38% | [102] |

| 7 | Culture medium DMEM | human osteoblasts | Ultrasound | - | 45,000 | 5 | mW/cm2 | 5 | 300 | Cells proliferation | +32% | [102] |

| 8 | Culture medium DMEM | human fibroblasts | Ultrasound | - | 1,000,000 | 0.1 | mW/cm2 | 5 | 300 | Collagen expression | +49% | [102] |

| 9 | Culture medium DMEM | human fibroblasts | Ultrasound | - | 1,000,000 | 0.4 | mW/cm2 | 5 | 300 | Collagen expression | +58% | [102] |

| 10 | Culture medium DMEM | human fibroblasts | Ultrasound | - | 1,000,000 | 0.7 | mW/cm2 | 5 | 300 | Collagen expression | +53% | [102] |

| 11 | Culture medium DMEM | human osteoblasts | Ultrasound | - | 45,000 | 30 | mW/cm2 | 5 | 300 | Cells proliferation | +36% | [102] |

| 12 | Culture medium DMEM | human osteoblasts | Ultrasound | - | 1,000,000 | 0.7 | mW/cm2 | 5 | 300 | Cells proliferation | +46% | [102] |

| 13 | Culture medium DMEM | human osteoblasts | Ultrasound | - | 1,000,000 | 1 | mW/cm2 | 5 | 300 | Cells proliferation | +38% | [102] |

| 14 | Culture medium DMEM | human osteoblasts | Ultrasound | 45,000 | 15 | mW/cm2 | 5 | 300 | Collagen expression | +45% | [102] | |

| 15 | Culture medium DMEM | human osteoblasts | Ultrasound | - | 45,000 | 50 | mW/cm2 | 5 | 300 | Collagen expression | +37% | [102] |

| 16 | Culture medium DMEM | human osteoblasts | Ultrasound | - | 1,000,000 | 0.1 | mW/cm2 | 5 | 300 | Collagen expression | +53% | [102] |

| 17 | Culture medium DMEM | human osteoblasts | Ultrasound | - | 1,000,000 | 0.4 | mW/cm2 | 5 | 300 | Collagen expression | +38% | [102] |

| 18 | Culture medium DMEM | human osteoblasts | Ultrasound | - | 1,000,000 | 0.4 | mW/cm2 | 5 | 75 | Secretion of IL-1β | +16 | [102] |

| 19 | Culture medium DMEM | human osteoblasts | Ultrasound | - | 1,000,000 | 0.7 | mW/cm2 | 5 | 75 | Secretion of IL-1β | +20% | [102] |

| 20 | Culture medium DMEM | human osteoblasts | Ultrasound | - | 1,000,000 | 1 | mW/cm2 | 5 | 75 | Secretion of IL-1β | +17% | [102] |

| 21 | Culture medium DMEM | human osteoblasts | Ultrasound | - | 450,000 | 30 | mW/cm2 | 5 | 300 | Secretion of IL-8 | +55% | [102] |

| 22 | Culture medium DMEM | human osteoblasts | Ultrasound | - | 1,000,000 | 0.4 | mW/cm2 | 5 | 300 | Secretion of IL-8 | +60% | [102] |

| 23 | Culture medium DMEM | human osteoblasts | Ultrasound | - | 1,000,000 | 0.7 | mW/cm2 | 5 | 300 | Secretion of IL-8 | +70% | [102] |

| 24 | Culture medium DMEM | human osteoblasts | Ultrasound | - | 45,0000 | 5 | mW/cm2 | 5 | 300 | Secretion of EGFb | +3000% | [102] |

| 25 | Culture medium DMEM | human osteoblasts | Ultrasound | - | 45,0000 | 15 | mW/cm2 | 5 | 300 | Secretion of EGFb | +1500% | [102] |

| 26 | Culture medium DMEM | human osteoblasts | Ultrasound | - | 45,0000 | 50 | mW/cm2 | 5 | 300 | Secretion of EGFb | +750% | [102] |

| 27 | Culture medium DMEM | human osteoblasts | Ultrasound | - | 1,000,000 | 0.1 | mW/cm2 | 5 | 300 | Secretion of EGFb | +300% | [102] |

| 28 | Culture medium DMEM | human osteoblasts | Ultrasound | 450,000 | 15 | mW/cm2 | 5 | 300 | Secretion of VEGF | +25% | [102] | |

| 29 | Culture medium DMEM | human osteoblasts | Ultrasound | 1,000,000 | 0.1 | mW/cm2 | 5 | 300 | Secretion of VEGF | +40% | [102] | |

| 30 | Culture medium RPMI 1640 | human monocytes | Ultrasound | - | 45,000 | 15 | mW/cm2 | 5 | 300 | Secretion of IL-1β | +25% | [102] |

| 31 | Culture medium RPMI 1640 | human monocytes | Ultrasound | - | 45,000 | 30 | mW/cm2 | 5 | 300 | Secretion of IL-1β | +103% | [102] |

| 32 | Culture medium RPMI 1640 | human monocytes | Ultrasound | - | 45,000 | 50 | mW/cm2 | 5 | 300 | Secretion of IL-1β | +80% | [102] |

| 33 | Culture medium RPMI 1640 | human monocytes | Ultrasound | - | 45,000 | 15 | mW/cm2 | 5 | 300 | Secretion of VEGF | +25% | [102] |

| 34 | Culture medium RPMI 1640 | human monocytes | Ultrasound | - | 45,000 | 30 | mW/cm2 | 5 | 300 | Secretion of VEGF | +30% | [102] |

| 35 | Culture medium RPMI 1640 | human monocytes | Ultrasound | - | 45,000 | 50 | mW/cm2 | 5 | 300 | Secretion of VEGF | +35% | [102] |

| 36 | Culture medium RPMI 1640 | human monocytes | Ultrasound | - | 1,000,000 | 0.1 | mW/cm2 | 5 | 300 | Secretion of VEGF | +35% | [102] |

| 37 | Culture medium RPMI 1640 | human monocytes | Ultrasound | - | 1,000,000 | 0.4 | mW/cm2 | 5 | 300 | Secretion of VEGF | +15% | [102] |

| 38 | Culture medium RPMI 1640 | human monocytes | Ultrasound | - | 1,000,000 | 1 | mW/cm2 | 5 | 300 | Secretion of VEGF | +10% | [102] |

| 39 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 100 | mW/cm2 | 2 | 600 | Cells differentiation | +10% | [103] |

| 40 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 200 | mW/cm2 | 2 | 600 | Cells differentiation | +15% | [103] |

| 41 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 300 | mW/cm2 | 2 | 600 | Cells differentiation | +15% | [103] |

| 42 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 60 | mW/cm2 | 2 | 1200 | Cells differentiation | +15% | [103] |

| 43 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 100 | mW/cm2 | 2 | 1200 | Cells differentiation | +15% | [103] |

| 44 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 200 | mW/cm2 | 2 | 1200 | Cells differentiation | +10% | [103] |

| 45 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 300 | mW/cm2 | 2 | 1200 | Cells differentiation | +11% | [103] |

| 46 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 30 | mW/cm2 | 2 | 1800 | Cells differentiation | +15% | [103] |

| 47 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 100 | mW/cm2 | 2 | 600 | Concentration of Cyclin D1/β | +60% | [103] |

| 48 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 200 | mW/cm2 | 2 | 600 | Concentration of Cyclin D1/β | +40% | [103] |

| 49 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 300 | mW/cm2 | 2 | 600 | Concentration of Cyclin D1/β | +45% | [103] |

| 50 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 60 | mW/cm2 | 2 | 1200 | Concentration of Cyclin D1/β | +100% | [103] |

| 51 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 100 | mW/cm2 | 2 | 1200 | Concentration of Cyclin D1/β | +90% | [103] |

| 52 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 200 | mW/cm2 | 2 | 1200 | Concentration of Cyclin D1/β | +80% | [103] |

| 53 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 300 | mW/cm2 | 2 | 1200 | Concentration of Cyclin D1/β | +70% | [103] |

| 54 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 30 | mW/cm2 | 2 | 1800 | Concentration of Cyclin D1/β | +110% | [103] |

| 55 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 100 | mW/cm2 | 2 | 600 | Concentration of Cyclin В1/β | +200% | [103] |

| 56 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 200 | mW/cm2 | 2 | 600 | Concentration of Cyclin В1/β | +380% | [103] |

| 57 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 300 | mW/cm2 | 2 | 600 | Concentration of Cyclin В1/β | +500% | [103] |

| 58 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 60 | mW/cm2 | 2 | 1200 | Concentration of Cyclin В1/β | +500% | [103] |

| 59 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 100 | mW/cm2 | 2 | 1200 | Concentration of Cyclin В1/β | +400% | [103] |

| 60 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 200 | mW/cm2 | 2 | 1200 | Concentration of Cyclin В1/β | +530% | [103] |

| 61 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 300 | mW/cm2 | 2 | 1200 | Concentration of Cyclin В1/β | +490% | [103] |

| 62 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 30 | mW/cm2 | 2 | 1800 | Concentration of Cyclin В1/β | +490% | [103] |

| 63 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 100 | mW/cm2 | 2 | 600 | Concentration of Cyclin Е1/β | +80% | [103] |

| 64 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 200 | mW/cm2 | 2 | 600 | Concentration of Cyclin Е1/β | +110% | [103] |

| 65 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 300 | mW/cm2 | 2 | 600 | Concentration of Cyclin Е1/β | +150% | [103] |

| 66 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 60 | mW/cm2 | 2 | 1200 | Concentration of Cyclin Е1/β | +200% | [103] |

| 67 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 100 | mW/cm2 | 2 | 1200 | Concentration of Cyclin Е1/β | +250% | [103] |

| 68 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 200 | mW/cm2 | 2 | 1200 | Concentration of Cyclin Е1/β | +200% | [103] |

| 69 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 300 | mW/cm2 | 2 | 1200 | Concentration of Cyclin Е1/β | +180% | [103] |

| 70 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 30 | mW/cm2 | 2 | 1800 | Concentration of Cyclin Е1/β | +190% | [103] |

| 71 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 100 | mW/cm2 | 2 | 600 | Concentration of Cyclin A1/β | +250% | [103] |

| 72 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 200 | mW/cm2 | 2 | 600 | Concentration of Cyclin A1/β | +100% | [103] |

| 73 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 300 | mW/cm2 | 2 | 600 | Concentration of Cyclin A1/β | +90% | [103] |

| 74 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 60 | mW/cm2 | 2 | 1200 | Concentration of Cyclin A1/β | +250% | [103] |

| 75 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 100 | mW/cm2 | 2 | 1200 | Concentration of Cyclin A1/β | +245% | [103] |

| 76 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 200 | mW/cm2 | 2 | 1200 | Concentration of Cyclin A1/β | +240% | [103] |

| 77 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 300 | mW/cm2 | 2 | 1200 | Concentration of Cyclin A1/β | +70% | [103] |

| 78 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 30 | mW/cm2 | 2 | 1800 | Concentration of Cyclin A1/β | +270% | [103] |

| 79 | Culture medium DMEM | Human amnion-derived mesenchymal stem cells (hAD-MSC) | Ultrasound | - | 250,000 | 30 | mW/cm2 | 2 | 1800 | Cells proliferation | +180% | [103] |

| 80 | Culture medium DMEM | Mouse myoblasts (C2C12) | Ultrasound | - | 500,000 | 500 | mW/cm2 | 1 | 86,400 | Cells proliferation | +90% | [104] |

| 81 | Culture medium DMEM | Mouse myoblasts (C2C12) | Ultrasound | - | 1,000,000 | 500 | mW/cm2 | 1 | 86,400 | Cells proliferation | +95% | [104] |

| 82 | Culture medium DMEM | Mouse myoblasts (C2C12) | Ultrasound | - | 3,000,000 | 500 | mW/cm2 | 1 | 86,400 | Cells proliferation | +150% | [104] |

| 83 | Culture medium DMEM | Mouse myoblasts (C2C12) | Ultrasound | - | 3,000,000 | 1000 | mW/cm2 | 1 | 86,400 | Cells proliferation | +180% | [104] |

| 84 | Culture medium DMEM | Mouse myoblasts (C2C12) | Ultrasound | - | 3,000,000 | 250 | mW/cm2 | 1 | 86,400 | Cells proliferation | +145% | [104] |

| 85 | Culture medium DMEM | Mouse myoblasts (C2C12) | Ultrasound | - | 1,000,000 | 500 | mW/cm2 | 1 | 2400 | myotube width | +20% | [104] |

| 86 | Culture medium DMEM | Mouse myoblasts (C2C12) | Ultrasound | - | 1,000,000 | 500 | mW/cm2 | 1 | 2400 | myotube length | +50% | [104] |

| 87 | Culture medium DMEM | Mouse myoblasts (C2C12) | Ultrasound | - | 5,000,000 | 500 | mW/cm2 | 1 | 2400 | myotube length | +10% | [104] |

| 88 | Culture medium DMEM | Mouse myoblasts (C2C12) | Ultrasound | - | 1,000,000 | 500 | mW/cm2 | 1 | 2400 | fusion index | +100% | [104] |

| 89 | Rat (trauma model) | in vivo | Ultrasound | - | 870,000 | 1000 | mW/cm2 | 250 | 1500 | Total tissue protein content | −10% | [97] |

| 90 | Culture medium DMEM | Mouse myoblasts (C2C12) | Ultrasound | - | 1,500,000 | 30 | mW/cm2 | 10 | 7200 | Cells proliferation | +18% | [113] |

| 91 | Culture medium DMEM | Mouse myoblasts (C2C12) | Ultrasound | - | 1,500,000 | 30 | mW/cm2 | 10 | 9600 | Cells proliferation | +12% | [113] |

| 92 | Culture medium DMEM | Mouse myoblasts (C2C12) | Ultrasound | - | 1,500,000 | 30 | mW/cm2 | 10 | 7200 | Expression of myogenin | +47% | [113] |

| 93 | Culture medium DMEM | Mouse myoblasts (C2C12) | Ultrasound | - | 1,500,000 | 30 | mW/cm2 | 10 | 9600 | Expression of myogenin | +34% | [113] |

| 94 | Culture medium DMEM | Mouse myoblasts (C2C12) | Ultrasound | - | 1,500,000 | 30 | mW/cm2 | 10 | 16,800 | Numbers of regenerating myofibers | +90% | [113] |

| 95 | Culture medium DMEM | Mouse myoblasts (C2C12) | Ultrasound | - | 1,500,000 | 30 | mW/cm2 | 10 | 25,200 | Numbers of regenerating myofibers | +250% | [113] |

| 96 | Culture medium DMEM | Mouse myoblasts (C2C12) | Ultrasound | - | 1,500,000 | 30 | mW/cm2 | 10 | 33,600 | Numbers of regenerating myofibers | +320% | [113] |

| 97 | Culture medium DMEM | Mouse myoblasts (C2C12) | Ultrasound | - | 1,500,000 | 30 | mW/cm2 | 10 | 25,200 | Restoration of fast twitch strength | +150% | [113] |

| 98 | Culture medium DMEM | Mouse myoblasts (C2C12) | Ultrasound | - | 1,500,000 | 30 | mW/cm2 | 10 | 33,600 | Restoration of fast twitch strength | +300% | [113] |

| 99 | Culture medium DMEM | Mouse myoblasts (C2C12) | Ultrasound | - | 1,500,000 | 30 | mW/cm2 | 10 | 25200 | Restoration of tetanus strength strength | +90% | [113] |

| 100 | Culture medium DMEM | Mouse myoblasts (C2C12) | Ultrasound | - | 1,500,000 | 30 | mW/cm2 | 10 | 33600 | Restoration of fast twitch strength | +100% | [113] |

| 101 | in vivo | Wistar rats | Ultrasound | - | 1,000,000 | 1 | mW/cm2 | 220 | 900 | Muscle fibre diameter | +10% | [98] |

| 102 | in vivo | Wistar rats | Ultrasound | - | 1,000,000 | 1 | mW/cm2 | 220 | 900 | BrdU positive cells count | +30% | [98] |

| 103 | Culture medium DMEM | Mouse myoblasts (C2C12) | Ultrasound | - | 3,000,000 | 30 | mW/cm2 | 5 | 900 | Pax7 positive cells count | +60% | [115] |

| 104 | Culture medium DMEM | Mouse myoblasts (C2C12) | Ultrasound | - | 3,000,000 | 30 | mW/cm2 | 5 | 900 | Expression of gene COX2 | +80% | [115] |

| 105 | Culture medium DMEM | Mouse myoblasts (C2C12) | Ultrasound | - | 3,000,000 | 30 | mW/cm2 | 5 | 900 | Proiflammatory cells count | −40% | [115] |

| 106 | Culture medium DMEM | BMDCs | Constant pressure from below | - | 0 | 50,00050,000 | Pa | 5 | 950,400 | Efficiency of glycolysis | −30% | [72] |

| 107 | Culture medium DMEM | BMDCs | Constant pressure from below | - | 0 | 2000 | Pa | 5 | 950,400 | Efficiency of glycolysis | −50% | [72] |

| 108 | Culture medium DMEM | BMDCs | Constant pressure from below | - | 0 | 50,000 | Pa | 5 | 950,400 | Lactase activity | −5% | [72] |

| 109 | Culture medium DMEM | BMDCs | Constant pressure from below | - | 0 | 2000 | Pa | 5 | 950,400 | Lactase activity | −60% | [72] |

| 110 | Culture medium DMEM | BMDCs | Constant pressure from below | - | 0 | 50,000 | Pa | 5 | 950,400 | overall rate curves of oxygen consumption rate | −70% | [72] |

| 111 | Culture medium DMEM | BMDCs | Constant pressure from below | - | 0 | 2000 | Pa | 5 | 950,400 | overall rate curves of oxygen consumption rate | −80% | [72] |

| 112 | Culture medium DMEM | BMDCs | Constant pressure from below | - | 0 | 50,000 | Pa | 5 | 950,400 | Expression of gene Hk2 | −55% | [72] |

| 113 | Culture medium DMEM | BMDCs | Constant pressure from below | - | 0 | 2000 | Pa | 5 | 950,400 | Expression of gene Slc2a1 | −96% | [72] |

| 114 | Culture medium DMEM | BMDCs | Constant pressure from below | - | 0 | 2000 | Pa | 5 | 950,400 | Cells proliferation | −95% | [72] |

| 115 | Culture medium DMEM | BMDCs | Constant pressure from below | - | 0 | 50,000 | Pa | 5 | 950,400 | Tumor size (11 days post E.G7-OVA injection) in WT mice injected with E.G7-OVA cells and WT BMDCs | −50% | [72] |

| 116 | Culture medium DMEM | BMDCs | Constant pressure from below | - | 0 | 50,000 | Pa | 5 | 950,400 | tumor weight (14 days post E.G7-OVA injection) in WT mice injected with E.G7-OVA cells and WT BMDCs | −85% | [72] |

| 117 | Culture medium DMEM | CD8+ T cells | Constant pressure from below | - | 0 | 50,000 | Pa | 5 | 950,400 | Immunology memory | +120% | [72] |

| 118 | Culture medium DMEM | CD4+ T cells | Constant pressure from below | - | 0 | 50,000 | Pa | 5 | 950,400 | Immunology memory | +110% | [72] |

| 119 | Water | Water | Shaking | - | 30 | 12 | mm | 10 | 60 | Chemiluminescence intensity | −20% | [21] |

| 120 | Water | Water | Shaking | - | 30 | 2.3 | mm | 10 | 60 | Chemiluminescence intensity | +25% | [21] |

| 121 | Water | Water | Shaking | - | 10 | 12 | mm | 10 | 15 | Decline rate of chemiluminescence intensity | −20% | [21] |

| 122 | Water | Water | Shaking | - | 10 | 12 | mm | 10 | 60 | Decline rate of chemiluminescence intensity | −25% | [21] |

| 123 | Water | Water | Shaking | - | 30 | 2.3 | mm | 10 | 60 | Decline rate of chemiluminescence intensity | +30% | [21] |

| 124 | Water | Water | Shaking | - | 30 | 2.3 | mm | 10 | 60 | Standard deviation of chemiluminescence intensity | +10% | [21] |

| 125 | Water | BSA | Shaking | 1 mg/mL | 30 | 2.3 | mm | 10 | 15 | Chemiluminescence intensity | −20% | [21] |

| 126 | Water | BSA | Shaking | 1 mg/mL | 10 | 12 | mm | 10 | 15 | Chemiluminescence intensity | −15% | [21] |

| 127 | Water | BSA | Shaking | 1 mg/mL | 10 | 12 | mm | 10 | 60 | Chemiluminescence intensity | −10% | [21] |

| 128 | Water | BSA | Shaking | 1 mg/mL | 30 | 2.3 | mm | 10 | 15 | Chemiluminescence intensity | −8% | [21] |

| 129 | Water | BSA | Shaking | 1 mg/mL | 30 | 2.3 | mm | 10 | 60 | Chemiluminescence intensity | −20% | [21] |

| 130 | Water | BSA | Shaking | 1 mg/mL | 30 | 2.3 | mm | 10 | 15 | Chemiluminescence intensity | −12% | [21] |

| 131 | Water | BSA | Shaking | 1 mg/mL | 30 | 2.3 | mm | 10 | 60 | Chemiluminescence intensity | −20% | [21] |

| 132 | Water | BSA | Shaking | 1 mg/mL | 10 | 2.3 | mm | 10 | 15 | Decline rate of chemiluminescence intensity | −18% | [21] |

| 133 | Water | BSA | Shaking | 1 mg/mL | 10 | 12 | mm | 10 | 15 | Decline rate of chemiluminescence intensity | −17% | [21] |

| 134 | Water | BSA | Shaking | 1 mg/mL | 10 | 12 | mm | 10 | 60 | Decline rate of chemiluminescence intensity | −16% | [21] |

| 135 | Water | BSA | Shaking | 1 mg/mL | 30 | 2.3 | mm | 10 | 15 | Decline rate of chemiluminescence intensity | −25% | [21] |

| 136 | Water | BSA | Shaking | 1 mg/mL | 30 | 2.3 | mm | 10 | 60 | Decline rate of chemiluminescence intensity | −16% | [21] |

| 137 | Water | BSA | Shaking | 1 mg/mL | 30 | 2.3 | mm | 10 | 60 | Standard deviation of chemiluminescence intensity | −10% | [21] |

| 138 | Water | Human IgG | Alternating magnetic field | 1 mg/mL | 50 | 50 | мкТл | 10 | 300 | Chemiluminescence intensity | +10% | [21] |

| 139 | Water | Human IgG | Alternating magnetic field | 1 mg/mL | 8 | 50 | мкТл | 10 | 300 | Standard deviation of chemiluminescence intensity | +5% | [21] |

| 140 | Hanks’ balanced salts solution | Murine neutrophils (Male Balb/c mice weighing 22–25 g) | Alternating magnetic field | 2.5 × 105 cells/mL | 12.6 | 0.01 | мкТл | 5400 | fMLF-induced ROS generation | +45% | [32] | |

| 141 | Hanks’ balanced salts solution | Murine neutrophils (Male Balb/c mice weighing 22–25 g) | Alternating magnetic field | 2.5 × 105 cells/mL | 12.6 | 0.05 | мкТл | 5400 | fMLF-induced ROS generation | +45% | [32] | |

| 142 | Water | Viscum album Quercus L. 3. plant extract | Turbulent mixing | 0.1% (10−3) | 10 | 2 | sm | 10 | 150 | local connected fractal dimension | −27% | [22] |

| 143 | Water | Viscum album Quercus L. 3. plant extract | Circular mixing | 0.1% (10−3) | 10 | 2 | sm | 10 | 150 | local connected fractal dimension | +3% | [22] |

| 144 | Water | Viscum album Quercus L. 3. plant extract | Turbulent mixing | 0.1% (10−3) | 10 | 2 | sm | 10 | 150 | mass fractal dimension | −9% | [22] |

| 145 | Water | Viscum album Quercus L. 3. plant extract | Circular mixing | 0.1% (10−3) | 10 | 2 | sm | 10 | 150 | mass fractal dimension | +2% | [22] |

| 146 | Water | Viscum album Quercus L. 3. plant extract | Turbulent mixing | 0.1% (10−3) | 10 | 2 | sm | 10 | 150 | lacunarity | +37% | [22] |

| 147 | Water | Viscum album Quercus L. 3. plant extract | Circular mixing | 0.1% (10−3) | 10 | 2 | sm | 10 | 150 | lacunarity | +4% | [22] |

| 148 | Water | Viscum album Quercus L. 3. plant extract | Turbulent mixing | 0.1% (10−3) | 10 | 2 | sm | 10 | 150 | ascending second moment | +30% | [22] |

| 149 | Water | Viscum album Quercus L. 3. plant extract | Circular mixing | 0.1% (10−3) | 10 | 2 | sm | 10 | 150 | ascending second moment | −15% | [22] |

| 150 | Water | Viscum album Quercus L. 3. plant extract | Turbulent mixing | 0.1% (10−3) | 10 | 2 | sm | 10 | 150 | contrast | −30% | [22] |

| 151 | Water | Viscum album Quercus L. 3. plant extract | Circular mixing | 0.1% (10−3) | 10 | 2 | sm | 10 | 150 | contrast | −12% | [22] |

| 152 | Water | Viscum album Quercus L. 3. plant extract | Turbulent mixing | 0.1% (10−3) | 10 | 2 | sm | 10 | 150 | Correlation | +30% | [22] |

| 153 | Water | Viscum album Quercus L. 3. plant extract | Circular mixing | 0.1% (10−3) | 10 | 2 | sm | 10 | 150 | Correlation | +90% | [22] |

| 154 | Water | Viscum album Quercus L. 3. plant extract | Turbulent mixing | 0.1% (10−3) | 10 | 2 | sm | 10 | 150 | Entropy | −3% | [22] |

| 155 | Water | Viscum album Quercus L. 3. plant extract | Circular mixing | 0.1% (10−3) | 10 | 2 | sm | 10 | 150 | Entropy | +2% | [22] |

| 156 | Hanks’ balanced salts solution | Murine neutrophils (Male Balb/c mice weighing 22–25 g) | Alternating magnetic field | 2.5 × 105 cells/mL | 0 | 0 | 0 | 3600 | fMLF-induced ROS production primered by PMA | −21% | [33] | |

| 157 | Hanks’ balanced salts solution | Murine neutrophils (Male Balb/c mice weighing 22–25 g) | Alternating magnetic field | 2.5 × 105 cells/mL | 12.6 | 0.1 | мкТл | 3600 | fMLF-induced ROS production primered by PMA | +67% | [33] | |

| 158 | Hanks’ balanced salts solution | Murine neutrophils (Male Balb/c mice weighing 22–25 g) | Alternating magnetic field | 2.5 × 105 cells/mL | 48.5 | 0.1 | мкТл | 3600 | fMLF-induced ROS production primered by PMA | +635% | [33] | |

| 159 | Hanks’ balanced salts solution | Murine neutrophils (Male Balb/c mice weighing 22–25 g) | Alternating magnetic field | 2.5 × 105 cells/mL | 12.6 | 0.1 | мкТл | 2400 | fMLF-induced ROS generation | +36% | [34] | |

| 160 | Hanks’ balanced salts solution | Murine neutrophils (Male Balb/c mice weighing 22–25 g) | Alternating magnetic field | 2.5 × 105 cells/mL | 48.5 | 0.1 | мкТл | 2400 | fMLF-induced ROS generation | −19% | [34] | |

| 161 | Water | IFNγ | Circular mixing | 0.1 М | 50 | 1 | sm | 10 | 50 | Conductivity of the solution | +20% | [16] |

| 162 | Water | polyclonal antibodies to human IFNγ | Circular mixing | 26 μg/mL | 50 | 1 | sm | 10 | 50 | Solurion EMR | +150% | [17] |

| 163 | Water | Lactose | Strokes | 820 nM | 21 | 300 (20) | g (CM) | 24 | 1050 | Luminescence at 550 nm | +100% | [24] |

| 164 | Water | Lactose | Strokes | 820 нМ | 21 | 300 (20) | g (CM) | 24 | 525 | Luminescence at 550 nm | +200% | [24] |

| 165 | 20 mM histidine buffer. | antistreptavidin IgG1 | Downfall | 1 mg/mL | 0 | 25.6 | sm | 1 | 0.025 | Particle counts (protein aggregation?) | +150% | [91] |

| 166 | 20 mM histidine buffer. | antistreptavidin IgG1 | Downfall | 1 mg/mL | 0 | 51.2 | sm | 1 | 0.025 | Particle counts | +300% | [91] |

| 167 | 20 mM histidine buffer. | antistreptavidin IgG1 | Downfall | 1 mg/mL | 0 | 76.8 | sm | 1 | 0.025 | Particle counts | +1000% | [91] |

| 168 | 20 mM histidine buffer. | antistreptavidin IgG1 | Downfall | 1 mg/mL | 0 | 102.4 | sm | 1 | 0.025 | Particle counts | +350% | [91] |

| 169 | 20 mM histidine buffer. | antistreptavidin IgG1 | Downfall | 35 mg/mL | 0 | 25.6 | sm | 1 | 0.025 | Particle counts | +900% | [91] |

| 170 | 20 mM histidine buffer. | antistreptavidin IgG1 | Downfall | 35 mg/mL | 0 | 51.2 | sm | 1 | 0.025 | Particle counts | +1100% | [91] |

| 171 | 20 mM histidine buffer. | antistreptavidin IgG1 | Downfall | 35 mg/mL | 0 | 76.8 | sm | 1 | 0.025 | Particle counts | +1000% | [91] |

| 172 | 20 mM histidine buffer. | human growth hormone | Downfall | 35 mg/mL | 0 | 102.4 | sm | 1 | 0.025 | Particle counts | +800% | [91] |

| 173 | 20 mM histidine buffer | human growth hormone | Downfall | 1.75 mg/mL | 0 | 102.4 | sm | 1 | 0.025 | Particle counts | +60% | [91] |

| 174 | 20 mM histidine buffer. | antistreptavidin IgG1 | Downfall | 1 mg/mL | 0 | 25.6 | sm | 1 | 0.025 | recovered from the walls of dropped vials following treatment with urea | +20% | [91] |

| 175 | 20 mM histidine buffer | antistreptavidin IgG1 | Downfall | 1 mg/mL | 0 | 76.8 | sm | 1 | 0.025 | recovered from the walls of dropped vials following treatment with urea | +110% | [91] |

| 176 | 20 mM histidine buffer. | antistreptavidin IgG1 | Downfall | 1 mg/mL | 0 | 102.4 | sm | 1 | 0.025 | recovered from the walls of dropped vials following treatment with urea | +180% | [91] |

| 177 | 20 mM histidine buffer | antistreptavidin IgG1 | Downfall | 35 mg/mL | 0 | 51.2 | sm | 1 | 0.025 | recovered from the walls of dropped vials following treatment with urea | +60% | [91] |

| 178 | 20 mM histidine buffer. | antistreptavidin IgG1 | Downfall | 35 mg/mL | 0 | 76.8 | sm | 1 | 0.025 | recovered from the walls of dropped vials following treatment with urea | +120% | [91] |

| 179 | 20 mM histidine buffer | antistreptavidin IgG1 | Downfall | 35 mg/mL | 0 | 102.4 | sm | 1 | 0.025 | recovered from the walls of dropped vials following treatment with urea | +90% | [91] |

| 180 | 20 mM histidine buffer | antistreptavidin IgG1 | Downfall | 1 mg/mL | 0 | 25.6 | sm | 1 | 0.025 | recovered from the walls of dropped vials following treatment with guanidine hydrochloride | +35% | [91] |

| 181 | 20 mM histidine buffer. | antistreptavidin IgG1 | Downfall | 1 mg/mL | 0 | 76.8 | sm | 1 | 0.025 | recovered from the walls of dropped vials following treatment with guanidine hydrochloride | +30% | [91] |

| 182 | 20 mM histidine buffer | antistreptavidin IgG1 | Downfall | 35 mg/mL | 0 | 51.2 | sm | 1 | 0.025 | recovered from the walls of dropped vials following treatment with guanidine hydrochloride | +200% | [91] |

| 183 | Water | Echinacea | succussion strokes | 0.8 × 10−2 g/mL | 1 | 20 | sm | 0.05 | 100 | Characteristics of crystal shape after evaporation | +10% | [23] |

| 184 | Water | Echinacea | succussion strokes | 0.8 × 10−2 g/mL | 1 | 20 | sm | 0.05 | 10 | Characteristics of crystal shape after evaporation | +8% | [23] |

| 185 | Water | Baptisia | succussion strokes | 0.8 × 10−3 g/mL | 1 | 20 | sm | 0.05 | 100 | Characteristics of crystal shape after evaporation | −10% | [23] |

| 186 | Water | Baptisia | succussion strokes | 0.8 × 10−3 g/mL | 1 | 20 | sm | 0.05 | 10 | Characteristics of crystal shape after evaporation | −10% | [23] |

| 187 | Water | Baptisia | succussion strokes | 0.8 × 10−4 g/mL | 1 | 20 | sm | 0.05 | 100 | Characteristics of crystal shape after evaporation | +60% | [23] |

| 188 | Water | Baptisia | succussion strokes | 0.8 × 10−4 g/mL | 1 | 20 | sm | 0.05 | 10 | Characteristics of crystal shape after evaporation | +50% | [23] |

| 189 | Water | Luffa | succussion strokes | 0.8 × 10−4 g/mL | 1 | 20 | sm | 0.05 | 100 | Characteristics of crystal shape after evaporation | −20% | [23] |

| 190 | Water | Luffa | succussion strokes | 0.8 × 10−4 g/mL | 1 | 20 | sm | 0.05 | 10 | Characteristics of crystal shape after evaporation | −20% | [23] |

| 191 | Water | Spongia | succussion strokes | 0.8 × 10−6 g/mL | 1 | 20 | sm | 0.05 | 100 | Characteristics of crystal shape after evaporation | +5% | [23] |

| 192 | Water | Spongia | succussion strokes | 0.8 × 10−6 g/mL | 1 | 20 | sm | 0.05 | 10 | Characteristics of crystal shape after evaporation | +10% | [23] |

| 193 | Water | IgG | Vertical shaking | IgG molecules 3 × 1012 cm−3 | 5 | 10 | mm | 20 | 30 | DLS peak intensity ~200 nm (bubble count) | +300% | [6] |

| 194 | Water +36.7% ethanol | IgG | Vertical shaking | IgG molecules 3 × 1012 cm−3 | 5 | 10 | mm | 20 | 30 | DLS peak intensity ~200 nm (bubble count) | +20% | [6] |

| 195 | Water | - | Shaking | - | 30 | 5 | mm | 10 | 300 | Concentration of molecular oxigen | −4% | [80] |

| 196 | Water | - | Shaking | - | 30 | 5 | mm | 10 | 600 | Concentration of molecular oxigen | −5% | [80] |

| 197 | Water | - | Shaking | - | 30 | 5 | mm | 10 | 900 | Concentration of molecular oxigen | −7% | [80] |

| 198 | Water | - | Shaking | - | 30 | 5 | mm | 10 | 1800 | Concentration of molecular oxigen | −8% | [80] |

| 199 | Water | - | Shaking | - | 30 | 5 | mm | 10 | 2700 | Concentration of molecular oxigen | −9% | [80] |

| 200 | Water | - | Shaking | - | 30 | 5 | mm | 10 | 600 | Water temperature | +2% | [80] |

| 201 | Water | - | Shaking | - | 30 | 5 | mm | 10 | 900 | Water temperature | +15% | [80] |

| 202 | Water | - | Shaking | - | 30 | 5 | mm | 10 | 1800 | Water temperature | +20% | [80] |

| 203 | Water | - | Shaking | - | 30 | 5 | mm | 10 | 2700 | Water temperature | +24% | [80] |

| 204 | Water | - | Shaking | - | 15 | 5 | mm | 10 | 300 | Concentration of molecular oxigen | −10% | [80] |

| 205 | Water | - | Shaking | - | 45 | 5 | mm | 10 | 300 | Concentration of molecular oxigen | −13% | [80] |

| 206 | Water | - | Shaking | - | 60 | 5 | mm | 10 | 300 | Concentration of molecular oxigen | −15% | [80] |

| 207 | Water | - | Shaking | - | 30 | 5 | mm | 10 | 300 | light scattering intensity | +50% | [80] |

| 208 | Water | - | Shaking | - | 30 | 5 | mm | 10 | 900 | pH | +12% | [80] |

| 209 | Water | - | Shaking | - | 30 | 5 | mm | 10 | 1800 | pH | +16% | [80] |

| 210 | Water | - | Shaking | - | 30 | 5 | mm | 10 | 2700 | pH | +17% | [80] |

| 211 | Water | - | Shaking | - | 45 | 5 | mm | 10 | 300 | pH | +6% | [80] |

| 212 | Water | - | Shaking | - | 60 | 5 | mm | 10 | 300 | pH | +8% | [80] |

| 213 | Water | - | Shaking | - | 15 | 5 | mm | 10 | 300 | Concentration of H2O2 | +2000% | [80] |

| 214 | Water | - | Shaking | - | 30 | 5 | mm | 10 | 300 | Concentration of H2O2 | +5000% | [80] |

| 215 | Water | - | Shaking | - | 45 | 5 | mm | 10 | 300 | Concentration of H2O2 | +14000% | [80] |

| 216 | Water | - | Shaking | - | 30 | 5 | mm | 10 | 60 | Concentration of H2O2 | +1000% | [80] |

| 217 | Water | - | Shaking | - | 30 | 5 | mm | 10 | 150 | Concentration of H2O2 | +2500% | [80] |

| 218 | Water | - | Shaking | - | 30 | 5 | mm | 10 | 210 | Concentration of H2O2 | +3500% | [80] |

| 219 | Water | - | Shaking | - | 30 | 5 | mm | 10 | 300 | Concentration of H2O2 | +4500% | [80] |

| 220 | Water | - | Shaking | - | 30 | 5 | mm | 10 | 180 | Concentration of OH-radicals | +1500% | [80] |

| 221 | Water | - | Shaking | - | 30 | 5 | mm | 10 | 300 | Concentration of OH-radicals | +2500% | [80] |

| 222 | Water | - | Shaking | - | 30 | 5 | mm | 10 | 420 | Concentration of OH-radicals | +4000% | [80] |

| 223 | Water | - | Shaking | - | 30 | 5 | mm | 10 | 600 | Concentration of OH-radicals | +4300% | [80] |

| 224 | Water | - | Shaking | - | 15 | 5 | mm | 10 | 300 | Concentration of OH-radicals | +900% | [80] |

| 225 | Water | - | Shaking | - | 45 | 5 | mm | 10 | 300 | Concentration of OH-radicals | +5000% | [80] |

| 226 | Water | - | Shaking | - | 60 | 5 | mm | 10 | 300 | Concentration of OH-radicals | +9000% | [80] |

| 227 | Water | O2 gas | Creating an aerosol with N2 | - | Constant | 5 | μL/min | 0.011 | 60 | Concentration of H2O2 | +50 | [90] |

| 228 | Water | O2 gas | Creating an aerosol with N2 | - | Constant | 5 | μL/min | 0.011 | 120 | Concentration of H2O2 | +50% | [90] |

| 229 | Water | O2 gas | Creating an aerosol with N2 | - | Constant | 5 | μL/min | 0.011 | 180 | Concentration of H2O2 | +100% | [90] |

| 230 | Water | O2 gas | Creating an aerosol with N2 | - | Constant | 5 | μL/min | 0.011 | 240 | Concentration of H2O2 | +500% | [90] |

| 231 | Water | O2 gas | Creating an aerosol with N2 | - | Constant | 5 | μL/min | 0.011 | 300 | Concentration of H2O2 | +600% | [90] |

| 232 | Water | O2 gas | Creating an aerosol with N2 | - | Constant | 5 | μL/min | 0.011 | 420 | Concentration of H2O2 | +1000% | [90] |

| 233 | Water | O2 gas | Creating an aerosol with N2 | - | Constant | 5 | μL/min | 0.011 | 1800 | Concentration of H2O2 | −15% | [90] |

| 234 | Water | O2 gas | Creating an aerosol with N2 | - | Constant | 5 | μL/min | 0.011 | 3600 | Concentration of H2O2 | −35% | [90] |

| 235 | Water | O2 gas | Creating an aerosol with N2 | - | Constant | 5 | μL/min | 0.011 | 14,400 | Concentration of H2O2 | −45% | [90] |

| 236 | Water | O2 gas | Creating an aerosol with N2 | - | Constant | 5 | μL/min | 0.011 | 21,600 | Concentration of H2O2 | −50% | [90] |

| 237 | Water | - | Mixing | - | 12 | 1 | sm | 10 | 500 | Absorption at 180–220 sm−1 | +30% | [82] |

| 238 | Water | - | Mixing | - | 12 | 1 | sm | 10 | 50 | Wavelength of maximum absorption | +80% (280–340 нм) | [83] |

| 239 | Water | - | Mixing | - | 12 | 1 | sm | 10 | 50 | Wavelength of maximum absorption | +18% (280–330 нм) | [83] |

| 240 | Water | - | Mixing | - | 12 | 1 | sm | 10 | 50 | Fluorescence intensity | +400% | [83] |

| 240 | Water | - | Vibration | 1,000,000 | 1 | sm | 10 | 500 | Redox potentials ΔE | +1 mV (+100%) | [89] | |

| 240 | Water coated by oil layes 10 mm | Vibration | 1,000,000 | 1 | sm | 10 | 500 | Redox potentials ΔE | +2.5 mV (+250%) | [89] | ||

| 241 | Water | AcEu solutions | Microfluidic mixing | - | Constant | 400 35.5–250.6 | Reynolds number | 10 | 30 | Position of the IR band maximum of the OH groups’ stretching vibrations on Raman spectrum | +0.1% | [94] |

| 242 | Water | AcEu solutions | Microfluidic mixing | - | Constant | 400 35.5–250.6 | Reynolds number | 10 | 250 | Position of the IR band maximum of the OH groups’ stretching vibrations on Raman spectrum | 0.3 | [94] |

| 243 | 25 mM 4-(2-hydroxyethyl)-1-piperazineethanesulfonic acid sodium buffer (pH 7.0) | HEWL | Shaking | 12.5 mg/mL | 10 | 99 | мкм | 0.15 | 172,800 | Protein crystallisation success | −25% | [92] |

| 244 | 25 mM 4-(2-hydroxyethyl)-1-piperazineethanesulfonic acid sodium buffer (pH 7.0) | HEWL | Shaking | 12.5 mg/mL | 15 | 94.2 | мкм | 0.15 | 172,800 | Protein crystallisation success | −25% | [92] |

| 245 | 25 mM 4-(2-hydroxyethyl)-1-piperazineethanesulfonic acid sodium buffer (pH 7.0) | HEWL | Shaking | 12.5 mg/mL | 30 | 60 | мкм | 0.15 | 172,800 | Protein crystallisation success | −25% | [92] |

| 246 | 25 mM 4-(2-hydroxyethyl)-1-piperazineethanesulfonic acid sodium buffer (pH 7.0) | HEWL | Shaking | 12.5 mg/mL | 50 | 34.8 | мкм | 0.15 | 172,800 | Protein crystallisation success | −25% | [92] |

| 247 | 25 mM 4-(2-hydroxyethyl)-1-piperazineethanesulfonic acid sodium buffer (pH 7.0) | HEWL | Shaking | 12.5 mg/mL | 60 | 4 | мкм | 0.15 | 172,800 | Protein crystallisation success | −25% | [92] |

| 248 | 25 mM 4-(2-hydroxyethyl)-1-piperazineethanesulfonic acid sodium buffer (pH 7.0) | HEWL | Shaking | 12.5 mg/mL | 70 | 2.4 | мкм | 0.15 | 172,800 | Protein crystallisation success | −25% | [92] |

| 249 | 25 mM 4-(2-hydroxyethyl)-1-piperazineethanesulfonic acid sodium buffer (pH 7.0) | HEWL | Shaking | 12.5 mg/mL | 80 | 0.85 | мкм | 0.15 | 172,800 | Protein crystallisation success | −25% | [92] |

| 250 | 25 mM 4-(2-hydroxyethyl)-1-piperazineethanesulfonic acid sodium buffer (pH 7.0) | HEWL | Shaking | 12.5 mg/mL | 90 | 0.6 | мкм | 0.15 | 172,800 | Protein crystallisation success | −25% | [92] |

| 251 | 25 mM 4-(2-hydroxyethyl)-1-piperazineethanesulfonic acid sodium buffer (pH 7.0) | HEWL | Shaking | 12.5 mg/mL | 100 | 0.4 | мкм | 0.15 | 172,800 | Protein crystallisation success | −25% | [92] |

| 252 | 0.1 M acetate buffer pH 4.5 | HEWL | Ultrasound | 25 mg/mL | 100,000 | 100,000 | mW/cm2 | 9.4 | 40 | Number of protein crystals | +150% | [93] |

| 253 | 0.1 M acetate buffer pH 4.5 | HEWL | Ultrasound | 25 mg/mL | 100,000 | 100,000 | mW/cm2 | 9.4 | 70 | Number of protein crystals | +600% | [93] |

| 254 | 0.1 M acetate buffer pH 4.8 | HEWL 40,000 U/mg | Flow rate oscillations | 50 mg/mL | 1.6 | 20 | mm | 0.5 | 3600 | Concentration of protein after precipitation in 100 mg/mL NaCl | −5% | [209] |

| 255 | 0.1 M acetate buffer pH 4.8 | HEWL 40,000 U/mg | Flow rate oscillations | 50 mg/mL | 2.5 | 20 | mm | 0.5 | 3600 | Concentration of protein after precipitation in 100 mg/mL NaCl | −10% | [209] |

| 256 | 0.1 M acetate buffer pH 4.8 | HEWL 40,000 U/mg | Flow rate oscillations | 50 mg/mL | 3.3 | 20 | mm | 0.5 | 3600 | Concentration of protein after precipitation in 100 mg/mL NaCl | −15% | [209] |

| 257 | 0.1 M acetate buffer pH 4.8 | HEWL 40,000 U/mg | Flow rate oscillations | 50 mg/mL | 1.6 | 20 | mm | 0.5 | 4800 | Concentration of protein after precipitation in 100 mg/mL NaCl | −10% | [209] |

| 258 | 0.1 M acetate buffer pH 4.8 | HEWL 40,000 U/mg | Flow rate oscillations | 50 mg/mL | 2.5 | 20 | mm | 0.5 | 4800 | Concentration of protein after precipitation in 100 mg/mL NaCl | −20% | [209] |

| 259 | 0.1 M acetate buffer pH 4.8 | HEWL 40,000 U/mg | Flow rate oscillations | 50 mg/mL | 3.3 | 20 | mm | 0.5 | 4800 | Concentration of protein after precipitation in 100 mg/mL NaCl | −40% | [209] |

| 260 | 0.1 M acetate buffer pH 4.8 | HEWL 40,000 U/mg | Flow rate oscillations | 50 mg/mL | 1.6 | 20 | mm | 0.5 | 10,800 | Concentration of protein after precipitation in 100 mg/mL NaCl | −35% | [209] |

| 261 | 0.1 M acetate buffer pH 4.8 | HEWL 40,000 U/mg | Flow rate oscillations | 50 mg/mL | 2.5 | 20 | mm | 0.5 | 10,800 | Concentration of protein after precipitation in 100 mg/mL NaCl | −40% | [209] |

| 262 | 0.1 M acetate buffer pH 4.8 | HEWL 40,000 U/mg | Flow rate oscillations | 50 mg/mL | 3.3 | 20 | mm | 0.5 | 10,800 | Concentration of protein after precipitation in 100 mg/mL NaCl | −50% | [209] |

| 263 | 0.1 M acetate buffer pH 4.8 | HEWL 40,000 U/mg | Flow rate oscillations | 90 mg/mL | 1.6 | 20 | mm | 0.5 | 1800 | Concentration of protein after precipitation in 100 mg/mL NaCl | −5% | [209] |

| 264 | 0.1 M acetate buffer pH 4.8 | HEWL 40,000 U/mg | Flow rate oscillations | 90 mg/mL | 2.5 | 20 | mm | 0.5 | 1800 | Concentration of protein after precipitation in 100 mg/mL NaCl | −5% | [209] |

| 265 | 0.1 M acetate buffer pH 4.8 | HEWL 40,000 U/mg | Flow rate oscillations | 90 mg/mL | 3.3 | 20 | mm | 0.5 | 1800 | Concentration of protein after precipitation in 100 mg/mL NaCl | −60% | [209] |

| 266 | 0.1 M acetate buffer pH 4.8 | HEWL 40,000 U/mg | Flow rate oscillations | 90 mg/mL | 1.6 | 20 | mm | 0.5 | 3600 | Concentration of protein after precipitation in 100 mg/mL NaCl | −50% | [209] |

| 267 | 0.1 M acetate buffer pH 4.8 | HEWL 40,000 U/mg | Flow rate oscillations | 90 mg/mL | 2.5 | 20 | mm | 0.5 | 3600 | Concentration of protein after precipitation in 100 mg/mL NaCl | −70% | [209] |

| 268 | 0.1 M acetate buffer pH 4.8 | HEWL 40,000 U/mg | Flow rate oscillations | 90 mg/mL | 3.3 | 20 | mm | 0.5 | 3600 | Concentration of protein after precipitation in 100 mg/mL NaCl | −80% | [209] |

| 269 | 0.1 M acetate buffer pH 4.8 | HEWL 40,000 U/mg | Flow rate oscillations | 90 mg/mL | 1.6 | 20 | mm | 0.5 | 5400 | Concentration of protein after precipitation in 100 mg/mL NaCl | −75% | [209] |

| 270 | 0.1 M acetate buffer pH 4.8 | HEWL 40,000 U/mg | Flow rate oscillations | 90 mg/mL | 2.5 | 20 | mm | 0.5 | 5400 | Concentration of protein after precipitation in 100 mg/mL NaCl | −78% | [209] |

| 271 | 0.1 M acetate buffer pH 4.8 | HEWL 40,000 U/mg | Flow rate oscillations | 90 mg/mL | 3.3 | 20 | mm | 0.5 | 5400 | Concentration of protein after precipitation in 100 mg/mL NaCl | −80% | [209] |

| 272 | 0.1 M acetate buffer pH 4.8 | HEWL 40,000 U/mg | Flow rate oscillations | 50 mg/mL | 0.1 | 20 | mm | 0.5 | 5400 | Concentration of protein after precipitation in 100 mg/mL NaCl | −5% | [209] |

| 273 | 0.1 M acetate buffer pH 4.8 | HEWL 40,000 U/mg | Flow rate oscillations | 50 mg/mL | 0.2 | 20 | mm | 0.5 | 5400 | Concentration of protein after precipitation in 100 mg/mL NaCl | −10% | [209] |

| 274 | 0.1 M acetate buffer pH 4.8 | HEWL 40,000 U/mg | Flow rate oscillations | 50 mg/mL | 0.5 | 20 | mm | 0.5 | 5400 | Concentration of protein after precipitation in 100 mg/mL NaCl | −45% | [209] |

| 275 | 0.1 M acetate buffer pH 4.8 | HEWL 40,000 U/mg | Flow rate oscillations | 50 mg/mL | 1 | 20 | mm | 0.5 | 5400 | Concentration of protein after precipitation in 100 mg/mL NaCl | −75% | [209] |

| 276 | 0.1 M acetate buffer pH 4.8 | HEWL 40,000 U/mg | Flow rate oscillations | 50 mg/mL | 0.5 | 5 | mm | 0.5 | 5400 | Concentration of protein after precipitation in 100 mg/mL NaCl | −10% | [209] |

| 277 | 0.1 M acetate buffer pH 4.8 | HEWL 40,000 U/mg | Flow rate oscillations | 50 mg/mL | 0.5 | 10 | mm | 0.5 | 5400 | Concentration of protein after precipitation in 100 mg/mL NaCl | −20% | [209] |

| 278 | 0.1 M acetate buffer pH 4.8 | HEWL 40,000 U/mg | Flow rate oscillations | 50 mg/mL | 0.5 | 30 | mm | 0.5 | 5400 | Concentration of protein after precipitation in 100 mg/mL NaCl | −80% | [209] |

| 279 | Water | 1 mmol (110 μL) benzaldehyde was with 1 mmol (145 μL) aminoacetaldehyde diethyl | Atomization (formations of nanobubbles in the flow N2) | 1 mmol | 0 | 30 | mL/min | 0.00000002 | 0.01 | Pomeranz–Fritsch reaction rate | +588% | [29] |

| 280 | Methanol | 1 mmol (110 μL) benzaldehyde was with 1 mmol (145 μL) aminoacetaldehyde diethyl | Atomization (formations of nanobubbles in the flow N2) | 1 mmol | 0 | 30 | mL/min | 0.00000002 | 0.01 | Pomeranz–Fritsch reaction rate | +644% | [29] |

| 281 | ACN/DMF (1:1; v/v) | 1 mmol (110 μL) benzaldehyde was with 1 mmol (145 μL) aminoacetaldehyde diethyl | Atomization (formations of nanobubbles in the flow N2) | 1 mmol | 0 | 30 | mL/min | 0.00000002 | 0.01 | Pomeranz–Fritsch reaction rate | +233% | [29] |

| 282 | 1% (v/v) m-NBA in water | 1 mmol (110 μL) benzaldehyde was with 1 mmol (145 μL) aminoacetaldehyde diethyl | Atomization (formations of nanobubbles in the flow N2) | 1 mmol | 0 | 30 | mL/min | 0.00000002 | 0.01 | Pomeranz–Fritsch reaction rate | +736% | [29] |

| 283 | Water | Bi3TiNbO9 | Ultrasound | not applicable. solid catalyst | 40,000 | 50,000 | mW/cmm2 | 10 | 18,000 | H2O2 production | +40,705% | [126] |

| 284 | Water | - | Shaking | - | 30 | 1 | sm | 10 | 60 | H2O2 production | +100% | [84] |

| 285 | Water | - | Shaking | - | 30 | 1 | sm | 10 | 150 | H2O2 production | +200% | [84] |

| 286 | Water | - | Shaking | - | 30 | 1 | sm | 10 | 210 | H2O2 production | +280% | [84] |

| 287 | Water | - | Shaking | - | 30 | 1 | sm | 10 | 300 | H2O2 production | +300% | [84] |

| 288 | Water | - | Shaking | - | 30 | 0.5 | sm | 10 | 60 | H2O2 production | +20% | [86] |

| 289 | Water | - | Shaking | - | 30 | 0.5 | sm | 10 | 150 | H2O2 production | +50% | [86] |

| 290 | Water | - | Shaking | - | 30 | 0.5 | sm | 10 | 210 | H2O2 production | +60% | [86] |

| 291 | Water | - | Shaking | - | 30 | 0.5 | sm | 10 | 300 | H2O2 production | +80% | [86] |

| 292 | Water | - | Shaking (turbulent) | - | 15 | 1 | sm | 10 | 300 | H2O2 production | +150% | [85] |

| 293 | Water | - | Shaking (turbulent) | - | 30 | 1 | sm | 10 | 300 | H2O2 production | +250% | [85] |

| 294 | Water | - | Shaking (turbulent) | - | 60 | 1 | sm | 10 | 300 | H2O2 production | +1500% | [85] |

| 295 | Water | - | Shaking (turbulent) | - | 30 | 1 | sm | 10 | 900 | [O2] concentration | +100% | [85] |

| 296 | Water | - | Shaking (turbulent) | - | 30 | 1 | sm | 10 | 1500 | [O2] concentration | +100% | [85] |

| 297 | Water | - | Shaking (turbulent) | - | 30 | 1 | sm | 10 | 1800 | [O2] concentration | +150% | [85] |

| 298 | Water | - | Shaking (turbulent) | - | 30 | 1 | sm | 10 | 2400 | [O2] concentration | +160% | [85] |

| 299 | Water | - | Shaking (turbulent) | - | 30 | 1 | sm | 10 | 2700 | [O2] concentration | +200% | [85] |

| 300 | Water | - | Shaking (turbulent) | - | 30 | 1 | sm | 10 | 4200 | [O2] concentration | +200% | [85] |

| 301 | Water | - | Shaking (laminar) | - | 30 | 1 | sm | 10 | 900 | [O2] concentration | +10% | [85] |

| 302 | Water | - | Shaking (laminar) | - | 30 | 1 | sm | 10 | 1500 | [O2] concentration | +10% | [85] |

| 303 | Water | - | Shaking (laminar) | - | 30 | 1 | sm | 10 | 1800 | [O2] concentration | +20% | [85] |

| 304 | Water | - | Shaking (laminar) | - | 30 | 1 | sm | 10 | 2400 | [O2] concentration | +20% | [85] |

| 305 | Water | - | Shaking (laminar) | - | 30 | 1 | sm | 10 | 2700 | [O2] concentration | +25% | [85] |

| 306 | Water | - | Shaking (laminar) | - | 30 | 1 | sm | 10 | 4200 | [O2] concentration | +25% | [85] |

| 307 | Hedysarum laeve seedlings | - | Shaking 45° | - | 2 | 6.4 | m/sm2 | 1 | 60 | Primary stem length | −15% | [55] |

| 308 | Hedysarum laeve seedlings | - | Shaking 45° | - | 2 | 6.4 | m/sm2 | 1 | 60 | Leaf numbe | −15% | [55] |

| 309 | Hedysarum laeve seedlings | - | Shaking 45° | - | 2 | 6.4 | m/sm2 | 1 | 60 | Basal diameter | −12% | [55] |

| 310 | Hedysarum laeve seedlings | - | Shaking 45° | - | 2 | 6.4 | m/sm2 | 1 | 60 | Total biomass | −30% | [55] |

| 311 | Water | - | Downfall of drops | 0 | 0 | 1 | m | 0.05 | 0.1 | [H2O2] concentration | +300% | [27] |

| 312 | Water | - | Downfall of drops | 0 | 0 | 2 | m | 0.05 | 0.1 | [H2O2] concentration | +550% | [27] |

| 313 | Water | - | Downfall of drops | 0 | 0 | 3 | m | 0.05 | 0.1 | [H2O2] concentration | +750% | [27] |

| 314 | Water | - | Downfall of drops | 0 | 0 | 4 | m | 0.05 | 0.1 | [H2O2] concentration | +900% | [27] |

| 315 | Water | - | Downfall of drops | 0 | 0 | 1 | m | 0.05 | 0.1 | [OH] concentration | +200% | [27] |

| 316 | Water | - | Downfall of drops | 0 | 0 | 2 | m | 0.05 | 0.1 | [OH] concentration | +350% | [27] |

| 317 | Water | - | Downfall of drops | 0 | 0 | 3 | m | 0.05 | 0.1 | [OH] concentration | +500% | [27] |

| 318 | Water | - | Downfall of drops | 0 | 0 | 4 | m | 0.05 | 0.1 | [OH] concentration | +550% | [27] |

| 319 | Water | PNaAMPS/PAAm double-network (DN) hydrogels | Stretching | 1.4 М | 0 | 1.07 | Value of the first Lame parameter λ | 20 | 1800 | Normalised width w(t)/w(0) | +2% | [95] |

| 321 | Water | PNaAMPS/PAAm double-network (DN) hydrogels | Stretching | 1.4 М | 0 | 1.14 | Value of the first Lame parameter λ | 20 | 1800 | Normalised width w(t)/w(0) | +2% | [95] |

| 322 | Water | PNaAMPS/PAAm double-network (DN) hydrogels | Stretching | 1.4 М | 0 | 1.21 | Value of the first Lame parameter λ | 20 | 1800 | Normalised width w(t)/w(0) | +1% | [95] |

| 323 | Water | PNaAMPS/PAAm double-network (DN) hydrogels | Stretching | 1.4 М | 0 | 1.23 | Value of the first Lame parameter λ | 20 | 1800 | Normalised width w(t)/w(0) | +0% | [95] |

| 324 | Water | PNaAMPS/PAAm double-network (DN) hydrogels | Stretching | 1.4 М | 0 | 1.27 | Value of the first Lame parameter λ | 20 | 1800 | Normalised width w(t)/w(0) | −1.5% | [95] |

| 325 | Water | PNaAMPS/PAAm double-network (DN) hydrogels | Stretching | 1.4 М | 0 | 1.32 | Value of the first Lame parameter λ | 20 | 1800 | Normalised width w(t)/w(0) | −2% | [95] |

| 326 | Water | PNaAMPS/PAAm double-network (DN) hydrogels | Stretching | 1.4 М | 0 | 1.38 | Value of the first Lame parameter λ | 20 | 1800 | Normalised width w(t)/w(0) | −3% | [95] |

| 327 | Water | PNaAMPS/PAAm double-network (DN) hydrogels | Stretching | 1.4 М | 0 | 1.07 | Value of the first Lame parameter λ | 20 | 1800 | normalized engineering stress σ(t)/σ(0) | −6% | [95] |

| 328 | Water | PNaAMPS/PAAm double-network (DN) hydrogels | Stretching | 1.4 М | 0 | 1.14 | Value of the first Lame parameter λ | 20 | 1800 | normalized engineering stress σ(t)/σ(0) | −0% | [95] |

| 329 | Water | PNaAMPS/PAAm double-network (DN) hydrogels | Stretching | 1.4 М | 0 | 1.21 | Value of the first Lame parameter λ | 20 | 1800 | normalized engineering stress σ(t)/σ(0) | −0% | [95] |

| 330 | Water | PNaAMPS/PAAm double-network (DN) hydrogels | Stretching | 1.4 М | 0 | 1.23 | Value of the first Lame parameter λ | 20 | 1800 | normalized engineering stress σ(t)/σ(0) | −1% | [95] |

| 331 | Water | PNaAMPS/PAAm double-network (DN) hydrogels | Stretching | 1.4 М | 0 | 1.27 | Value of the first Lame parameter λ | 20 | 1800 | normalized engineering stress σ(t)/σ(0) | −3% | [95] |

| 332 | Water | PNaAMPS/PAAm double-network (DN) hydrogels | Stretching | 1.4 М | 0 | 1.32 | Value of the first Lame parameter λ | 20 | 1800 | normalized engineering stress σ(t)/σ(0) | −14% | [95] |

| 333 | Water | PNaAMPS/PAAm double-network (DN) hydrogels | Stretching | 1.4 М | 0 | 1.38 | Value of the first Lame parameter λ | 20 | 1800 | normalized engineering stress σ(t)/σ(0) | −17% | [95] |

| 334 | waste water after blowing by 99.99% N2 | T. denitrificans. immobilised on electrod | Mixing | 99.99% N2 | 10 | 5 | mm | 26.2 | 259,200 | Concntration of Na+ | −20% | [79] |

| 335 | waste water after blowing by 99.99% N2 | T. denitrificans. immobilised on electrod | Mixing | 99.99% N2 | 10 | 5 | mm | 26.2 | 259,200 | Electrode voltage | +80% | [79] |

| 336 | waste water after blowing by 99.99% N2 | T. denitrificans. immobilised on electrod | Mixing | 99.99% N2 | 10 | 5 | mm | 26.2 | 259,200 | Consumption of NO3- | +35% | [79] |

| 337 | Water | - | Mixing | - | 10 | 37 | mm | 30 | 180 | Concentration of bulk nanobubbles | +150% | [96] |

| 338 | Water | - | Mixing | - | 5 | 37 | mm | 30 | 180 | Concentration of bulk nanobubbles | +80% | [96] |

| 339 | Water | - | Mixing | - | 15 | 37 | mm | 30 | 180 | Concentration of bulk nanobubbles | +200% | [96] |

| 340 | Water | - | Mixing | - | 15 | 37 | mm | 30 | 180 | Concentration of bulk nanobubbles | +30% | [96] |

| 341 | Water | - | Mixing | - | 15 | 37 | mm | 30 | 60 | Concentration of bulk nanobubbles | +200% | [96] |

| 342 | Water | - | Mixing | - | 15 | 37 | mm | 30 | 360 | Concentration of bulk nanobubbles | +1500% | [96] |

| 343 | Water | - | Mixing | - | 15 | 37 | mm | 30 | 600 | Concentration of bulk nanobubbles | +1100% | [96] |

| 344 | Water | - | Ultrasound | - | 22,000 | 2000 | mW/cm2 | 5000 | 300 | pH | +6% | [121] |

| 345 | Water | - | Ultrasound | - | 100,0001,000,000 | 2000 | mW/cm2 | 5000 | 300 | pH | −17% | [121] |

| 346 | Water (artesian) | total hardness. carbonate hardness; Ca+2 content; Mg+2 content; pH 7. sulfates. chlorides | Ultrasound | 16.6 mg-eq/L. 4.8 mg-eq/. 17.7 mg/L. 8.9 mg/L. 7.8 mg/L. 576 mg/L. 12.0 mg/L | 22,000 | 2000 | mW/cm2 | 5000 | 300 | pH | +12% | [121] |

| 347 | Water | Clay particles | Ultrasound | 20 mg/mL | 20,000 | 2000 | mW/cm2 | 1000 | 10 | Precipitation rate | −30% | [124] |

| 348 | Water | Clay particles | Ultrasound | 20 mg/mL | 20,000 | 2000 | mW/cm2 | 1000 | 30 | Precipitation rate | +1% | [124] |

| 349 | Water | Clay particles | Ultrasound | 20 mg/mL | 20,000 | 2000 | mW/cm2 | 1000 | 60 | Precipitation rate | +50% | [124] |

| 350 | Water | Clay particles | Ultrasound | 20 mg/mL | 20,000 | 2000 | mW/cm2 | 1000 | 120 | Precipitation rate | +60% | [124] |

| 351 | Water | Clay particles | Ultrasound | 20 mg/mL | 20,000 | 2000 | mW/cm2 | 1000 | 300 | Precipitation rate | +101% | [124] |

| 352 | Mouse | in vivo | Sinusoidal vibrations | - | 45 | 0.3 | g | 21 | 37,800 | Number of lectin-positive vessels | −29% | [20] |

| 353 | Mouse | in vivo | Sinusoidal vibrations | - | 45 | 0.3 | g | 21 | 37,800 | α-actin-positive vessels | −36% | [20] |

| 355 | Rabbit | in vivo | Shaking | - | 60 | 5 | g | 4900 | 2,160,000 | Myelin fibre diameter | +80% | [53] |

| 356 | Human | in vivo | Vibration | - | 25 | 3 | m/s2 | 92,900 | 60 | vibration intensity transmission | +90% | [51] |

| 357 | Human | in vivo | Vibration | - | 200 | 3 | m/s2 | 92,900 | 60 | vibration intensity transmission | +900% | [51] |

| 358 | Human | in vivo | Vibration | - | 25 | 3 | m/s2 | 92,900 | 60 | Apparent mass | −50% | [51] |

| 359 | Human | in vivo | Vibration | - | 200 | 3 | m/s2 | 92,900 | 60 | Apparent mass | −80% | [51] |

| 360 | Human | in vivo | Vibration | - | 25 | 3 | m/s2 | 92,900 | 60 | Mechanical impedance | +25% | [51] |

| 361 | Human | in vivo | Vibration | - | 200 | 3 | m/s2 | 92,900 | 60 | Mechanical impedance | +150% | [51] |

| 362 | Rat | in vivo | Vibration | - | 80 | 32 | m/s2 | 205 | 90,000 | Length of nerve regeneration by 6 days | +57% | [54] |

| 363 | Rat | in vivo | Vibration | - | 80 | 32 | m/s2 | 205 | 90,000 | Length of nerve regeneration by 6 days | +23% | [54] |

| 364 | Rat | in vivo | Vibration | - | 81 | 0.5 | mm | 240 | 28,800 | Expression of IGF-I in nerve fibers | +100% | [210] |

| 365 | Rat. tail | in vivo | Vertical shaking | - | 62.5 | 49 | m/s2 | 6 | 144,00 | Expression of MT-1a | +700% | [40] |

| 366 | Rat. tail | in vivo | Vertical shaking | - | 125 | 49 | m/s2 | 6 | 144,00 | Expression of MT-1a | +660% | [40] |

| 367 | Rat. tail | in vivo | Vertical shaking | - | 250 | 49 | m/s2 | 6 | 144,00 | Expression of MT-1a | +630% | [40] |

| 368 | Rat. tail | in vivo | Vertical shaking | - | 62.5 | 49 | m/s2 | 6 | 144,00 | Expression of IL-6 | +900% | [40] |

| 369 | Rat. tail | in vivo | Vertical shaking | - | 125 | 49 | m/s2 | 6 | 144,00 | Expression of IL-6 | +500% | [40] |

| 370 | Rat. tail | in vivo | Vertical shaking | - | 250 | 49 | m/s2 | 6 | 14,400 | Expression of IL-6 | +300% | [40] |

| 371 | Rat. tail | in vivo | Vertical shaking | - | 62.5 | 49 | m/s2 | 6 | 144,00 | Expression of IL-6 | +400% | [40] |

| 372 | Rat. tail | in vivo | Vertical shaking | - | 125 | 49 | m/s2 | 6 | 144,00 | Expression of IL-6 | +220% | [40] |

| 373 | Rat. tail | in vivo | Vertical shaking | - | 250 | 49 | m/s2 | 6 | 14,400 | Internal diameter of the caudal vein | −70% | [40] |

| 374 | Rat. tail | in vivo | Vertical shaking | - | 250 | 49 | m/s2 | 6 | 144,00 | Vascular smooth muscle thickness | +35% | [40] |

| 375 | Rat. tail | in vivo | Vertical shaking | - | 125 | 49 | m/s2 | 6 | 14,400 | Synthesis of nitrotyrosine | +125% | [40] |

| 376 | Rat. tail | in vivo | Vertical shaking | - | 250 | 49 | m/s2 | 6 | 144,00 | Synthesis of nitrotyrosine | +150% | [40] |

| 377 | Rat. tail | in vivo | Vertical shaking | - | 125 | 49 | m/s2 | 6 | 144,00 | Synthesis of IL-6 | +50% | [40] |

| 378 | Rat. tail | in vivo | Vertical shaking | - | 250 | 49 | m/s2 | 6 | 14,400 | Synthesis of IL-6 | +70% | [40] |

| 379 | Rat. tail | in vivo | Vertical shaking | - | 60 | 49 | m/s2 | 5 | 14,000 | Number of vacuoles in endothelial cells | +2900% | [41] |

| 380 | Rat. tail | in vivo | Vertical shaking | - | 120 | 49 | m/s2 | 5 | 14,000 | Number of vacuoles in endothelial cells | +1300% | [41] |

| 381 | Rat. tail | in vivo | Vertical shaking | - | 30 | 49 | m/s2 | 5 | 144,00 | Number of ruptures of the inner vessel wall | +1600: | [41] |

| 382 | Rat. tail | in vivo | Vertical shaking | - | 69 | 49 | m/s2 | 5 | 144,00 | Number of ruptures of the inner vessel wall | +2100% | [41] |

| 383 | Rat. tail | in vivo | Vertical shaking | - | 120 | 49 | m/s2 | 5 | 14,400 | Number of ruptures of the inner vessel wall | +1500% | [41] |

| 384 | Rat. tail | in vivo | Vertical shaking | - | 800 | 49 | m/s2 | 5 | 14,400 | Number of ruptures of the inner vessel wall | +1600% | [41] |

| 385 | Rat. tail | in vivo | Vertical shaking | - | 30 | 49 | m/s2 | 5 | 14,400 | Expression of NFATc3 | +100% | [41] |

| 386 | Rat. tail | in vivo | Vertical shaking | - | 60 | 49 | m/s2 | 5 | 14,400 | Expression of NFATc3 | +200% | [41] |

| 387 | Rat. tail | in vivo | Vertical shaking | - | 120 | 49 | m/s2 | 5 | 14,400 | Expression of NFATc3 | +200% | [41] |

| 388 | Rat. lower limbs | in vivo | Vertical shaking | - | 30 | 49 | m/s2 | 15 | 57,600 | Total plasma creatine phosphokinase (t-CPK) activity | +1830% | [42] |

| 389 | Rat. lower limbs | in vivo | Vertical shaking | - | 60 | 49 | m/s2 | 15 | 57,600 | Total plasma creatine phosphokinase (t-CPK) activity | +760% | [42] |

| 390 | Rat. lower limbs | in vivo | Vertical shaking | - | 120 | 49 | m/s2 | 15 | 57,600 | Total plasma creatine phosphokinase (t-CPK) activity | +700% | [42] |

| 391 | Rat. lower limbs | in vivo | Vertical shaking | - | 240 | 49 | m/s2 | 15 | 57,600 | Total plasma creatine phosphokinase (t-CPK) activity | +400% | [42] |

| 392 | Rat. lower limbs | in vivo | Vertical shaking | - | 480 | 49 | m/s2 | 15 | 57,600 | Total plasma creatine phosphokinase (t-CPK) activity | +200% | [42] |

| 393 | Culture medium DMEM | Mouse Fibroblast Cells | Sinusoidal shaking | - | 1250 | 16.5 | m/s2 | 5 | 900 | Cells viability | −59% | [57] |

| 394 | Culture medium DMEM | Mouse Fibroblast Cells | Shock shaking | - | 1250 | 12.9 | m/s2 | 5 | 900 | Cells viability | −99% | [57] |

| 395 | Culture medium DMEM | Mouse red blood cells | Shock shaking | - | 1250 | 30,000 | m/s2 | 5 | 900 | Erythrocyte lysis | +100% | [57] |

| 396 | Culture medium DMEM | Mouse red blood cells | Shock shaking | - | 1250 | 15,000 | m/s2 | 5 | 900 | Erythrocyte lysis | +0.4% | [57] |

| 397 | Culture medium DMEM | Mouse red blood cells | Shock shaking | - | 1250 | 2000 | m/s2 | 5 | 900 | Erythrocyte lysis | +0.07% | [57] |

| 398 | Culture medium DMEM | Mouse red blood cells | Shock shaking | - | 1250 | 1000 | m/s2 | 5 | 900 | Erythrocyte lysis | +0.1% | [57] |

| 399 | Culture medium DMEM | Mouse red blood cells | Shock shaking | - | 1250 | 500 | m/s2 | 5 | 900 | Erythrocyte lysis | +0.1% | [57] |

| 400 | Human | in vivo | Vibration | - | 5.5 | 74.4 | N | 60,000 | 600 | Peak inspiratory flow rate | +136% | [52] |

| 401 | Human | in vivo | Vibration | - | 5.5 | 74.4 | N | 60,000 | 600 | Inspired volume | +200% | [52] |

| 402 | Human | in vivo | Vibration | - | 5.5 | 74.4 | N | 60,000 | 600 | expired volume | +290% | [52] |

| 403 | Human. healthy pre-pubertal boys | in vivo | Vibration (platform) | - | 40 | 2.1 | g | 34,000 | 600 | Legs’ skin temperature | +8% | [46] |

| 404 | Human. healthy pre-pubertal boys | in vivo | Vibration (platform) | - | 40 | 2.1 | g | 34,000 | 3000 | P1NP plasma level after 8 days | +18% | [46] |

| 405 | Human. healthy pre-pubertal boys | in vivo | Vibration (platform) | - | 40 | 2.1 | g | 34,000 | 3000 | CTx plasma level after 8 days | +10% | [46] |

| 406 | Rat with titanium hip implants | in vivo | Vibration (whole body) | - | 80 | 0.3 | g | 353 | 300 | Bone-to-implant contact | +63% | [48] |

| 407 | Rat with titanium hip implants | in vivo | Vibration (whole body) | - | 140 | 0.3 | g | 353 | 300 | Bone-to-implant contact | +65% | [48] |

| 408 | Rat with titanium hip implants | in vivo | Vibration (whole body) | - | 26 | 0.3 | g | 353 | 300 | Peri-implant bone formation | +20% | [48] |

| 409 | Rat with titanium hip implants | in vivo | Vibration (whole body) | - | 80 | 0.3 | g | 353 | 300 | Peri-implant bone formation | +25% | [48] |

| 410 | Rat with titanium hip implants | in vivo | Vibration (whole body) | - | 140 | 0.043 | g | 353 | 300 | Peri-implant bone formation | +19% | [48] |

| 411 | Rat with titanium hip implants | in vivo | Vibration (whole body) | - | 140 | 0.3 | g | 353 | 300 | Peri-implant bone formation | +25% | [48] |

| 412 | Rat with removed ovaries (osteoporosis model) | in vivo | Vibration (whole body) | - | 30 | 0.3 | g | 285 | 134,400 | Obesity | −50% | [28] |

| 413 | Rat with removed ovaries (osteoporosis model) | in vivo | Vibration (whole body) | 30 | 0.3 | g | 285 | 67,200 | Bone mineral densities | +15% | [28] | |

| 414 | Rat with removed ovaries (osteoporosis model) | in vivo | Vibration (whole body) | - | 30 | 0.3 | g | 285 | 134,400 | Vertebra compression test (maximum load) | −18% | [28] |

| 415 | Rat (healthy) | in vivo | Vibration (whole body) | - | 30 | 0.3 | g | 285 | 134,400 | vertebra compression test (rigidity) | −45% | [28] |

| 416 | Rat with removed ovaries (osteoporosis model) | in vivo | Vibration (whole body) | - | 30 | 0.3 | g | 285 | 134,400 | Osteoblastic Cell Viability | −10% | [28] |

| 417 | Rat (healthy) | in vivo | Vibration (whole body) | - | 30 | 0.3 | g | 285 | 134,400 | Osteoblastic Cell Viability | −12% | [28] |

| 418 | Rat (healthy) | in vivo | Vibration (whole body) | - | 30 | 0.3 | g | 285 | 134,400 | Alkaline phosphatase (ALP) activity 4 day | +15% | [28] |

| 419 | Rat (healthy) | in vivo | Vibration (whole body) | - | 30 | 0.3 | g | 285 | 134,400 | alkaline phosphatase (ALP) activity 7 day | −10% | [28] |

| 420 | Rat (healthy) | in vivo | Vibration (whole body) | - | 30 | 0.3 | g | 285 | 134,400 | Expression of ALP | −66% | [28] |

| 421 | Rat with removed ovaries (osteoporosis model) | in vivo | Vibration (whole body) | - | 30 | 0.3 | g | 285 | 134,400 | Expression of ALP | −50% | [28] |

| 422 | Rat (healthy) | in vivo | Vibration (whole body) | - | 30 | 0.3 | g | 285 | 134,400 | Expression of MMP2 | −40% | [28] |

| 423 | Rat with removed ovaries (osteoporosis model) | in vivo | Vibration (whole body) | - | 30 | 0.3 | g | 285 | 134,400 | Expression of MMP2 | −40% | [28] |

| 424 | Rat (healthy) | in vivo | Vibration (whole body) | - | 30 | 0.3 | g | 285 | 134,400 | Expression of OSX | −10% | [28] |

| 425 | Rat with removed ovaries (osteoporosis model) | in vivo | Vibration (whole body) | - | 30 | 0.3 | g | 285 | 134,400 | Expression of OSX | +20% | [28] |

| 426 | C57BL/6 mouse | in vivo | Vibration (whole body) | - | 90 | 0.75 | m/s2 | 27.5 | 300 | Arterial blood pressure | +25% | [39] |

| 427 | C57BL/6 mouse | in vivo | Vibration (whole body) | - | 80 | 0.75 | m/s2 | 27.5 | 300 | Heart beat rate | +19% | [39] |

| 428 | C57BL/6 mouse | in vivo | Vibration (whole body) | - | 90 | 0.75 | m/s2 | 27.5 | 300 | Heart beat rate | +17% | [39] |

| 429 | Human | in vivo | Vibration (whole body) | - | 30 | 0.3 | m/s2 | 61500 | 14,400 | Bone mineralisation density | +40% | [44] |

| 430 | Human | in vivo | Vibration (whole body) | - | 30 | 0.3 | m/s2 | 61500 | 14,400 | TRAP synthesis | −20% | [44] |

| 431 | Culture medium DMEM | Human embryonic stem cells (hESC) | Ultrasound | - | 19,690,000 | 24,000 | mW | 5 | 7200 | Expression of markers of neuronal differentiation and Alk | +250% | [116] |

| 432 | Culture medium DMEM | Human embryonic stem cells (hESC) | Ultrasound | - | 19,690,000 | 310,000 | mW | 5 | 7200 | Expression of markers of neuronal differentiation and Alk | +200% | [116] |

| 433 | Culture medium DMEM | Human embryonic stem cells (hESC) | Ultrasound | - | 19,690,000 | 24,000 | mW | 5 | 7200 | Expression of Cenpf | +40% | [116] |

| 434 | Culture medium DMEM | Human embryonic stem cells (hESC) | Ultrasound | - | 19,690,000 | 31,000 | mW | 5 | 7200 | Expression of Cenpf | +20% | [116] |

| 435 | Culture medium DMEM | Human embryonic stem cells (hESC) | Ultrasound | - | 19,690,000 | 39,000 | mW | 5 | 7200 | Expression of Cenpf | −30% | [116] |

| 436 | Culture medium DMEM | Human embryonic stem cells (hESC) | Ultrasound | - | 19,690,000 | 24,000 | mW | 5 | 7200 | Expression of actin | −30% | [116] |

| 437 | Culture medium DMEM | Human embryonic stem cells (hESC) | Ultrasound | - | 19,690,000 | 31,000 | mW | 5 | 7200 | Expression of actin | −40% | [116] |

| 438 | Culture medium DMEM | Human embryonic stem cells (hESC) | Ultrasound | - | 19,690,000 | 39,000 | mW | 5 | 7200 | Expression of actin | −80% | [116] |

| 439 | Culture medium DMEM | Human embryonic stem cells (hESC) | Ultrasound | - | 19,690,000 | 24,000 | mW | 5 | 7200 | Expression of Pcdh17 | +60% | [116] |

| 440 | Culture medium DMEM | Human embryonic stem cells (hESC) | Ultrasound | - | 19,690,000 | 31,000 | mW | 5 | 7200 | Expression of Pcdh17 | +70% | [116] |

| 441 | Culture medium DMEM | Human embryonic stem cells (hESC) | Ultrasound | - | 19,690,000 | 39,000 | mW | 5 | 7200 | Expression of Pcdh17 | +20% | [116] |

| 442 | Culture medium DMEM | SHED: stem cells from human exfoliated deciduous teeth | Centrifugation | - | - | 100 | g | 5 | 30 min. every 24 h.. 7 дней | Cells proliferation | −16.32% | [25] |

| 443 | Culture medium DMEM | SHED: stem cells from human exfoliated deciduous teeth | Centrifugation | - | - | 200 | g | 5 | 30 min. every 24 h.. 7 дней | Cells proliferation | −18.36% | [25] |

| 444 | Culture medium DMEM | SHED: stem cells from human exfoliated deciduous teeth | Centrifugation | - | - | 300 | g | 5 | 30 min. every 24 h.. 7 дней | Cells proliferation | −16.32% | [25] |

| 445 | Culture medium α-MEM | MC3T3-E1 | Vibration | - | 12.5 | 0.5 | G | 5 | 1,382,400 | Confluency | +19.4% | [26] |

| 446 | Culture medium α-MEM | MC3T3-E1 | Vibration | - | 12.5 | 0.5 | G | 4 | 1,123,200 | Confluency | +15.6% | [26] |

| 447 | Culture medium α-MEM | MC3T3-E1 | Constant flow | - | 0 | 0.28 ± 0.02 | mL/min | 4 | 1,382,400 | Confluency | −22.2% | [26] |

| 448 | Culture medium α-MEM | MC3T3-E1 | Constant flow | - | 0 | 0.28 ± 0.02 | mL/min | 4 | 1,123,200 | Confluency | +12.5% | [26] |

| 449 | Culture medium α-MEM | human PDL stem cells | Vibration | - | 50 | 0.3 | G | 10 | 30 min. every 24 h. | Alkaline phosphatase activity | +123.8% | [211] |

| 450 | Culture medium α-MEM | human PDL stem cells | Vibration | - | 60 | 0.3 | G | 10 | 30 min. every 24 h. | Alkaline phosphatase activity | +96.23% | [211] |

| 451 | Culture medium α-MEM | human PDL stem cells | Vibration | - | 10 | 0.3 | G | 10 | 30 min. every 24 h. | Expression of gene Runx2 | −43.75% | [211] |

| 452 | Culture medium α-MEM | human PDL stem cells | Vibration | - | 40 | 0.3 | G | 10 | 30 min. every 24 h. | Expression of gene Runx2 | +175% | [211] |

| 453 | Culture medium α-MEM | human PDL stem cells | Vibration | - | 50 | 0.3 | G | 10 | 30 min. every 24 h. | Expression of gene Runx2 | +275% | [211] |

| 454 | Culture medium α-MEM | human PDL stem cells | Vibration | - | 60 | 0.3 | G | 10 | 30 min. every 24 h. | Expression of gene Runx2 | +68.75% | [211] |

| 455 | Culture medium α-MEM | human PDL stem cells | Vibration | - | 90 | 0.3 | G | 10 | 30 min. every 24 h. | Expression of gene Runx2 | +34.37% | [211] |

| 456 | Culture medium α-MEM | human PDL stem cells | Vibration | - | 180 | 0.3 | G | 10 | 30 min. every 24 h. | Expression of gene Runx2 | −25% | [211] |

| 457 | Culture medium α-MEM | human PDL stem cells | Vibration | - | 20 | 0.3 | G | 10 | 30 min. every 24 h. | Expression of gene Osx | −50% | [211] |

| 458 | Culture medium α-MEM | human PDL stem cells | Vibration | - | 40 | 0.3 | G | 10 | 30 min. every 24 h. | Expression of gene Osx | +62.5% | [211] |

| 459 | Culture medium α-MEM | human PDL stem cells | Vibration | - | 50 | 0.3 | G | 10 | 30 min. every 24 h. | Expression of gene Osx | +109.3% | [211] |

| 460 | Culture medium α-MEM | human PDL stem cells | Vibration | - | 60 | 0.3 | G | 10 | 30 min. every 24 h. | Expression of gene Osx | −43.75% | [211] |

| 461 | Culture medium α-MEM | human PDL stem cells | Vibration | - | 120 | 0.3 | G | 10 | 30 min. every 24 h. | Expression of gene Osx | −43.75% | [211] |

| 462 | Culture medium α-MEM | human PDL stem cells | Vibration | - | 150 | 0.3 | G | 10 | 30 min. every 24 h. | Expression of gene Osx | −56.25% | [211] |

| 463 | Culture medium α-MEM | human PDL stem cells | Vibration | - | 180 | 0.3 | G | 10 | 30 min. every 24 h. | Expression of gene Osx | +37.5% | [211] |

| 464 | Culture medium α-MEM | human PDL stem cells | Vibration | - | 40 | 0.3 | G | 10 | 30 min. every 24 h. | Osteocalcin levels (OCN) | +340.9% | [211] |

| 465 | Culture medium α-MEM | human PDL stem cells | Vibration | - | 50 | 0.3 | G | 10 | 30 min. every 24 h. | Osteocalcin levels (OCN) | +390.9% | [211] |

| 466 | Culture medium α-MEM | human PDL stem cells | Vibration | - | 60 | 0.3 | G | 10 | 30 min. every 24 h. | Osteocalcin levels (OCN) | +318.18% | [211] |

| 467 | Culture medium α-MEM | human PDL stem cells | Vibration | - | 90 | 0.3 | G | 10 | 30 min. every 24 h. | Osteocalcin levels (OCN) | +122.72% | [211] |

| 468 | Culture medium α-MEM | human PDL stem cells | Vibration | - | 120 | 0.3 | G | 10 | 30 min. every 24 h. | Osteocalcin levels (OCN) | +154.54% | [211] |

| 469 | Culture medium DMEM low glucose | mesenchymal stem cells (MSCs) | Stretching | - | 0.03 | 5 | % | 2 | 240 min/day | Collagen content | +26.22% | [67] |

| 470 | StemFit AK02N | iPSC | Vibration | - | 100 | 0.02 | mm | 2 | 3000 | Cells differentiation | −28.5% | [68] |

| 471 | StemFit AK02N | iPSC | Vibration | - | 150 | 0.04 | mm | 2 | 3000 | Cells differentiation | −22.85% | [68] |

| 472 | (DMEM)/Ham’s F12 | human adipose-derived stem cells (hASCs) | Cyclic stretching | - | 0.5 | 5% | % | 2 | 864,000 | Expression of CYP1B1 | +68.18% | [69] |

| 473 | (DMEM)/Ham’s F12 | human adipose-derived stem cells (hASCs) | Cyclic stretching | - | 0.5 | 5% | % | 2 | 864,000 | Metabolic activity | −30.6% | [69] |

| 474 | Ham’s F–12 K | Chinese Hamster Ovary (CHO)-adherent cells | Vibration | - | 10–500 | <1 | g | 10 | 345,600 | Cells proliferation | +79% | [56] |

| 475 | Freestyle CHO Expression | Chinese Hamster Ovary (CHO)- suspension cells | Vibration | - | 10–500 | <1 | g | 10 | 345,600 | Cells proliferation | −13.0% | [56] |

| 476 | Freestyle CHO Expression | Chinese Hamster Ovary (CHO)- suspension cells | Vibration | - | 30 | 0.7 | g | 10 | 345,600 | Cells proliferation | +210% | [56] |

| 477 | RPMI | Е-cells | Vibration | - | 30 | 0.7 | g | 10 | 345,600 | Cells proliferation | +20.3% | [56] |

| 478 | DMEM | Primary fibrochondrocytes | Cyclic stretching | - | 1 | 8 | % | 2 | 28,800 | Expression of COL2A1 | +110% | [59] |

| 479 | DMEM | Primary fibrochondrocytes | Cyclic stretching | - | 1 | 8 | % | 2 | 28,800 | Expression of SOX9 | +200% | [59] |

| 480 | DMEM | Primary fibrochondrocytes | Cyclic stretching | - | 1 | 8 | % | 2 | 28,800 | Expression of ACAN | +215.78% | [59] |

| 481 | DMEM | Primary fibrochondrocytes | Cyclic stretching | - | 1 | 8 | % | 2 | 28,800 | Proportion of BrdU-positive cells | +46.6% | [59] |

| 482 | DMEM | Human osteoblast-like cells primary explant cultures | Vibration | - | 60 | 30 | µm | 5 | 96 h | Confluency | +23.07% | [60] |