A Novel Fabrication of Heterogeneous Saponified Poly(Vinyl Alcohol)/Pullulan Blend Film for Improved Wound Healing Application

Abstract

1. Introduction

2. Results and Discussion

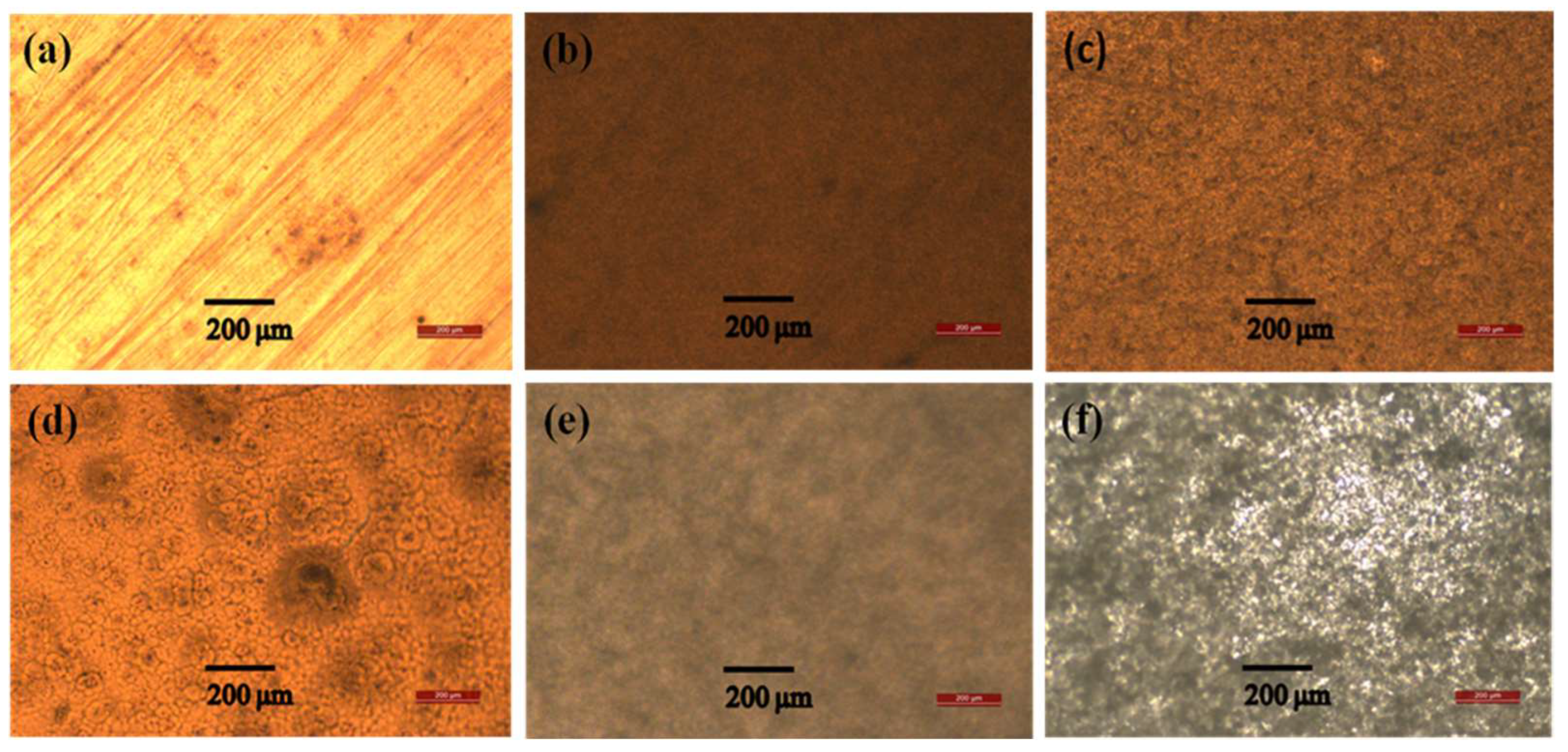

2.1. OM

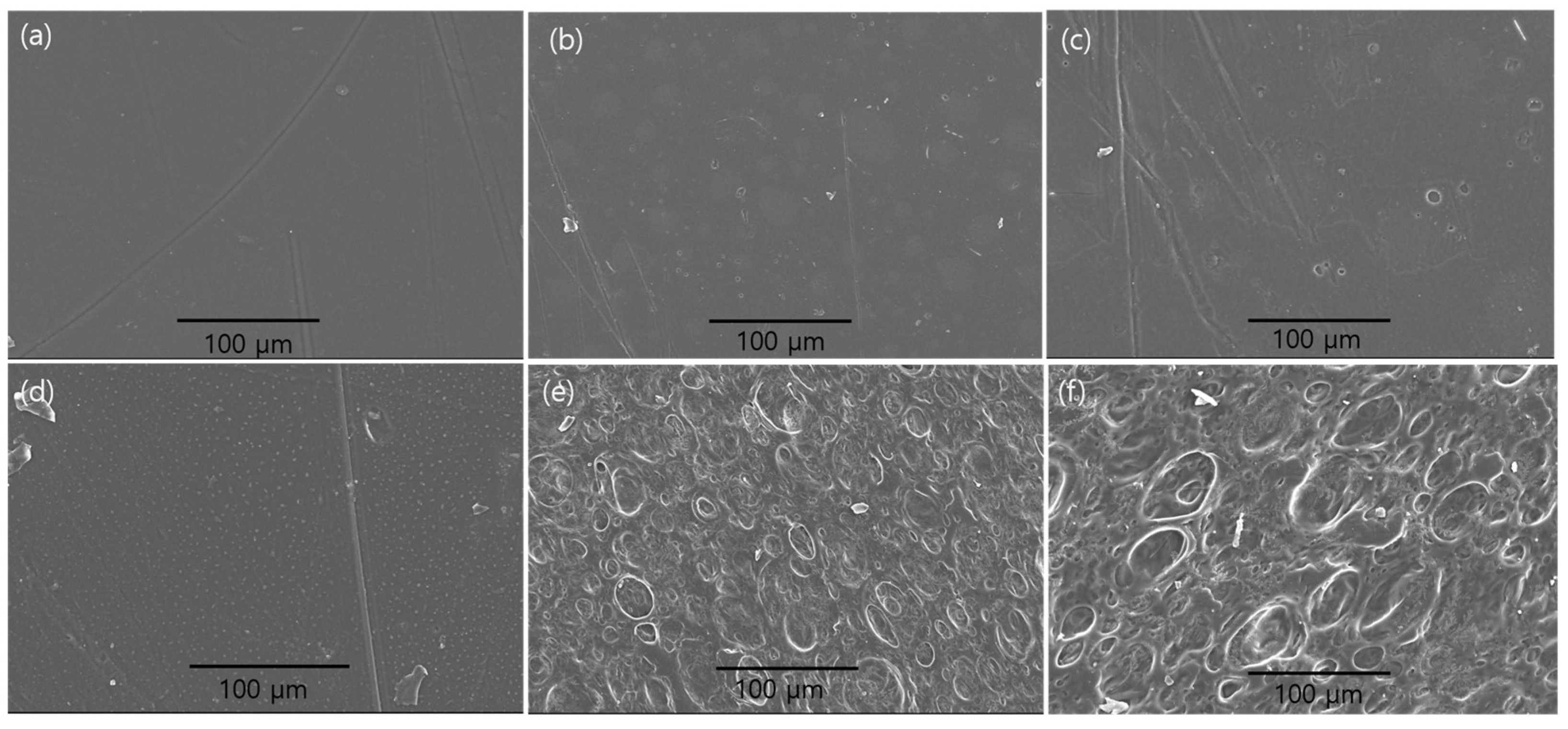

2.2. SEM

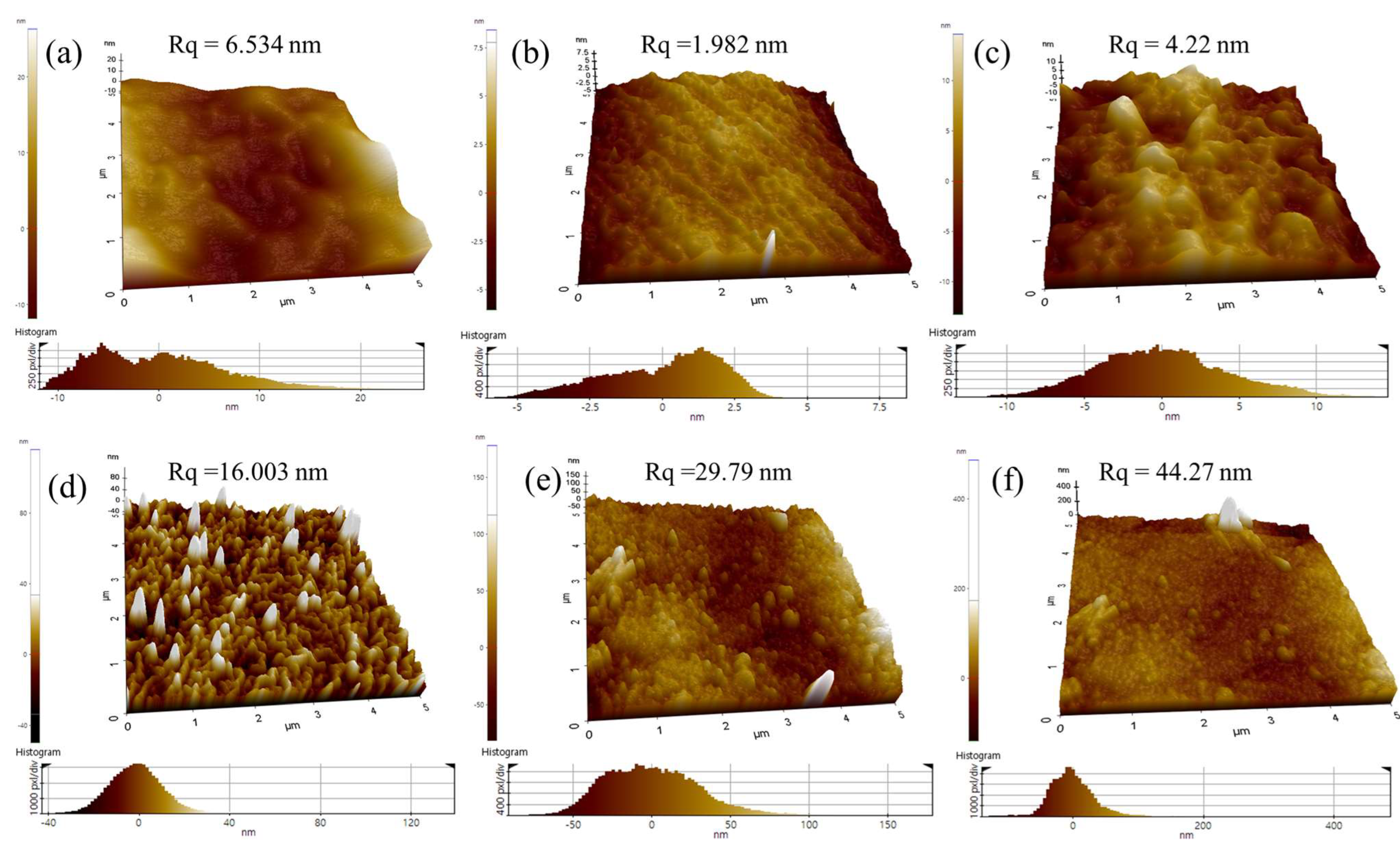

2.3. AFM

2.4. FT-IR Spectroscopy

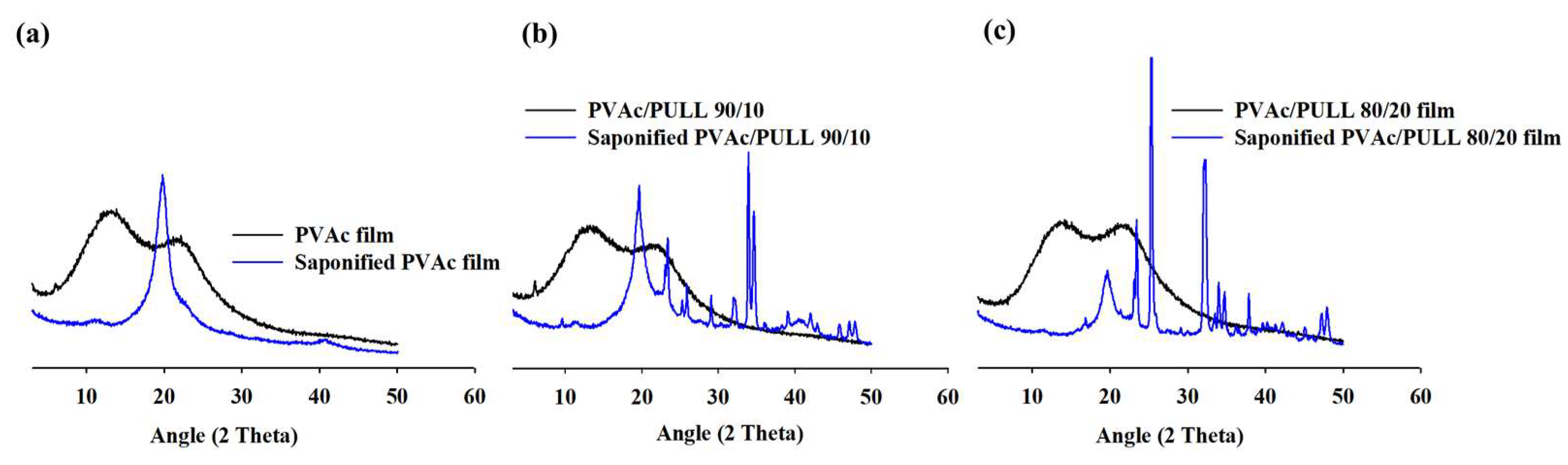

2.5. XRD

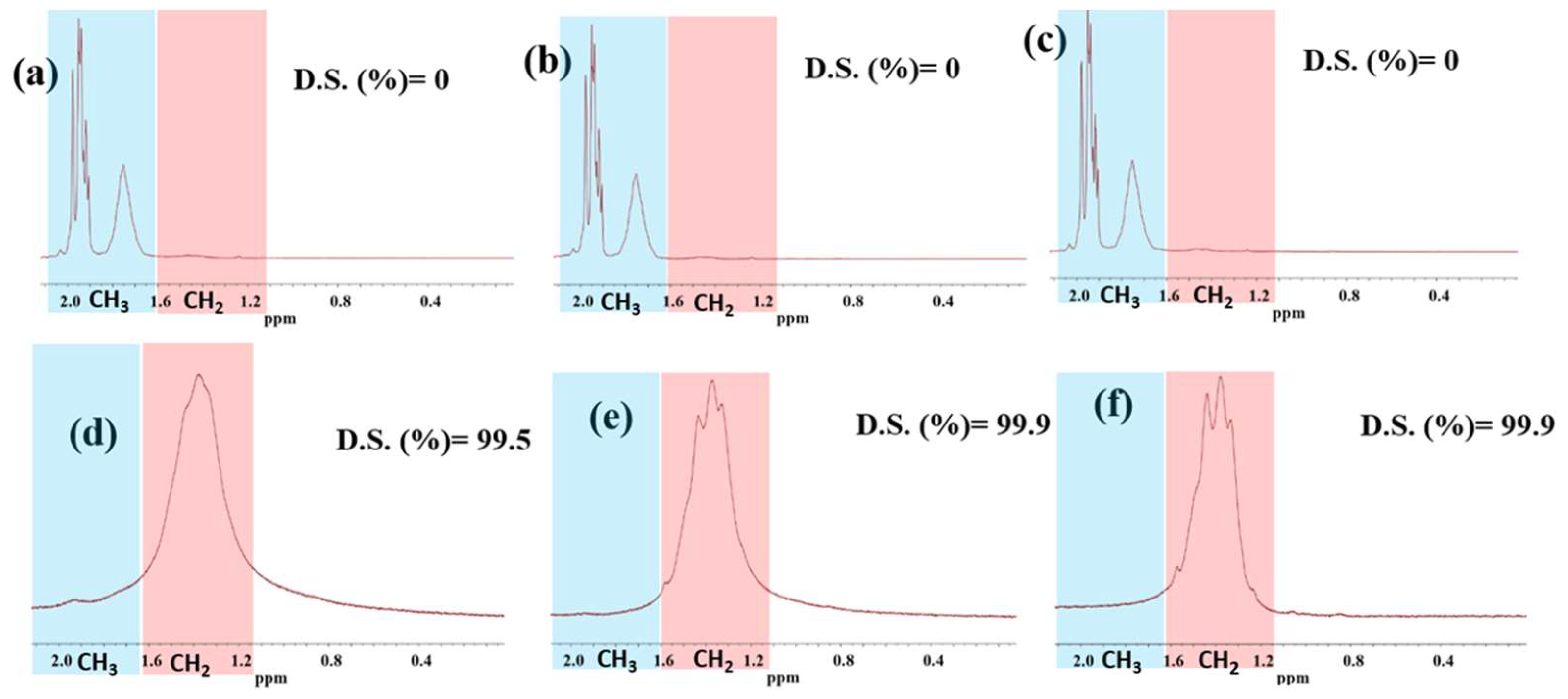

2.6. 1H-NMR Spectroscopy

2.7. Contact Angle Analysis

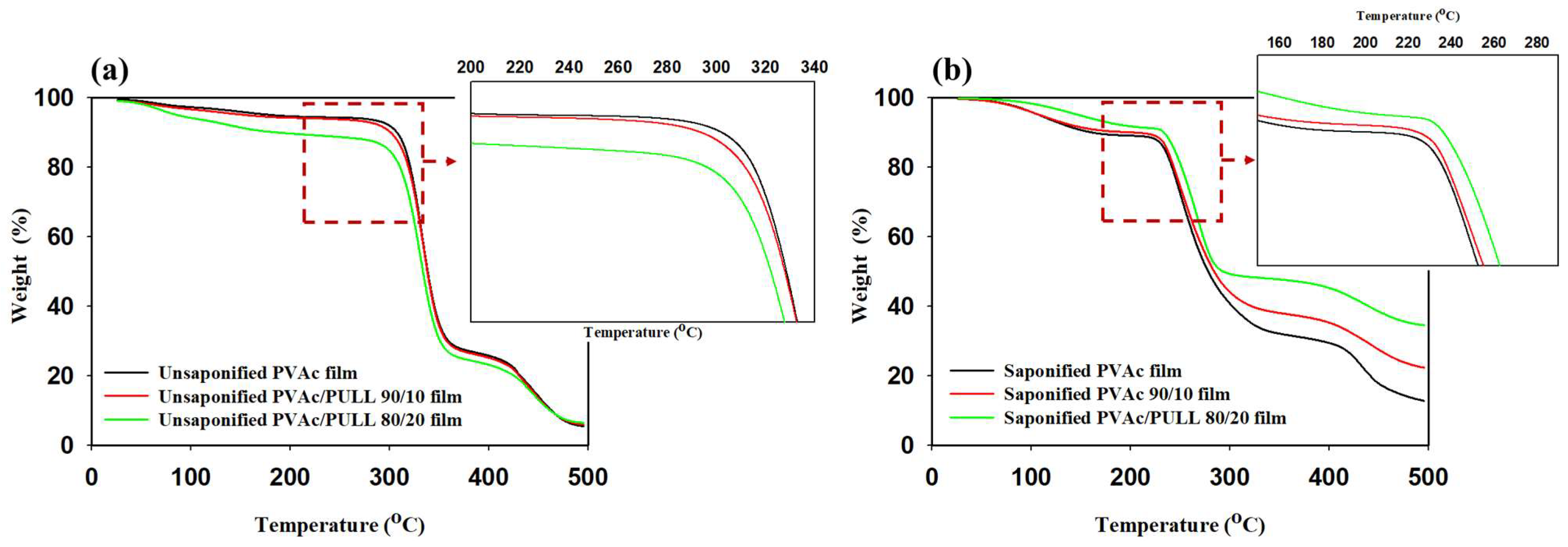

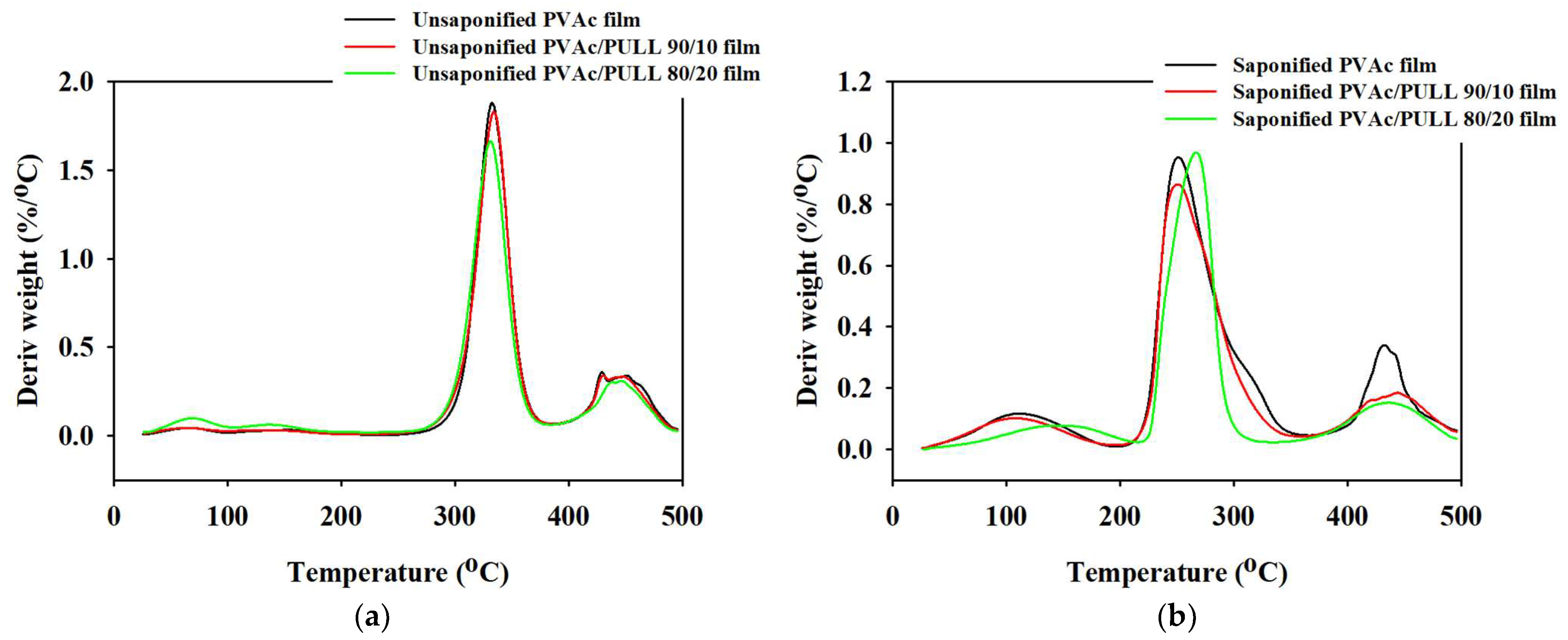

2.8. TGA

2.9. Stress–Strain Curves

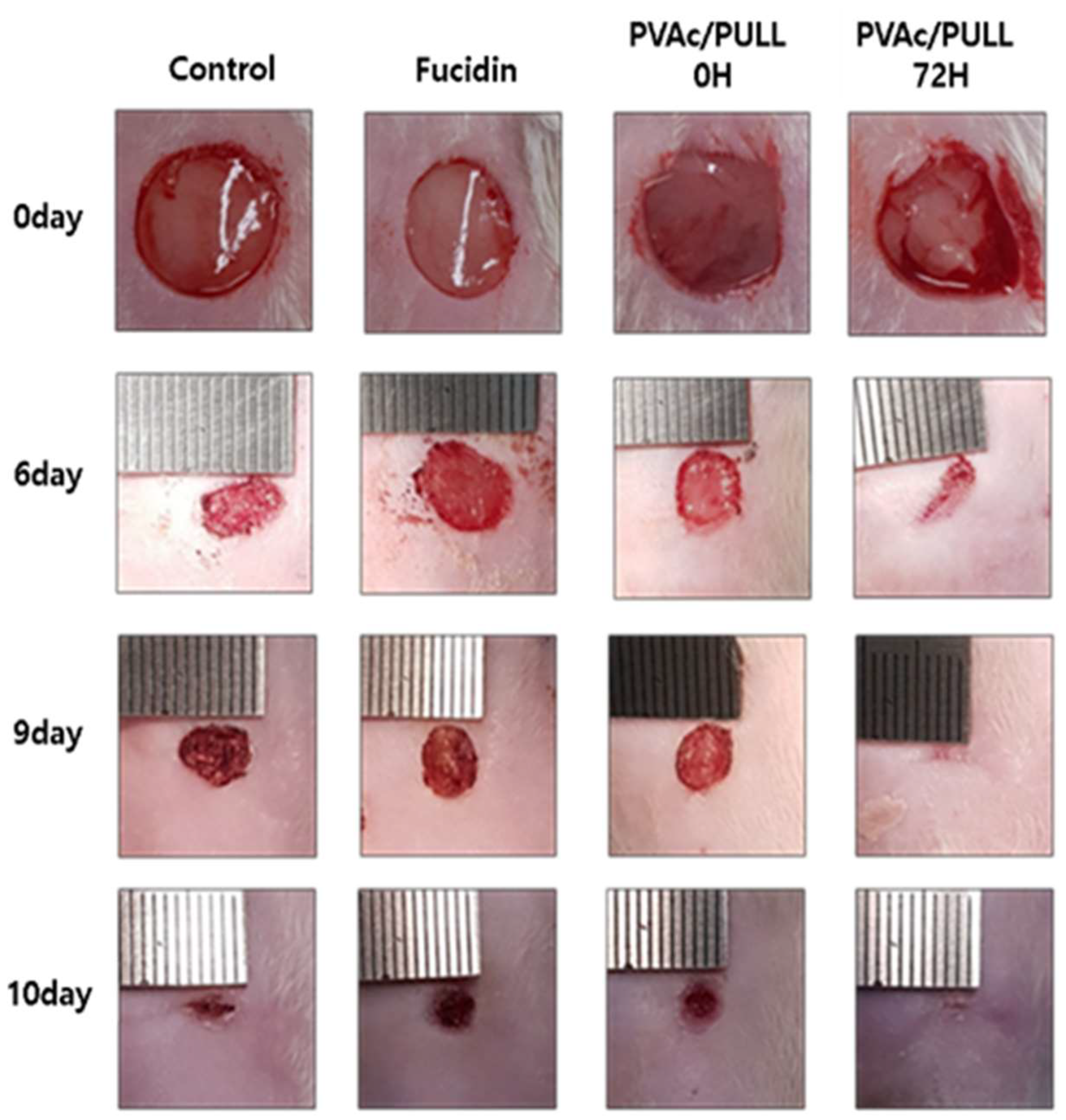

2.10. Wound-Healing Properties of Saponified PVAc/PULL Film

3. Materials and Methods

3.1. Materials

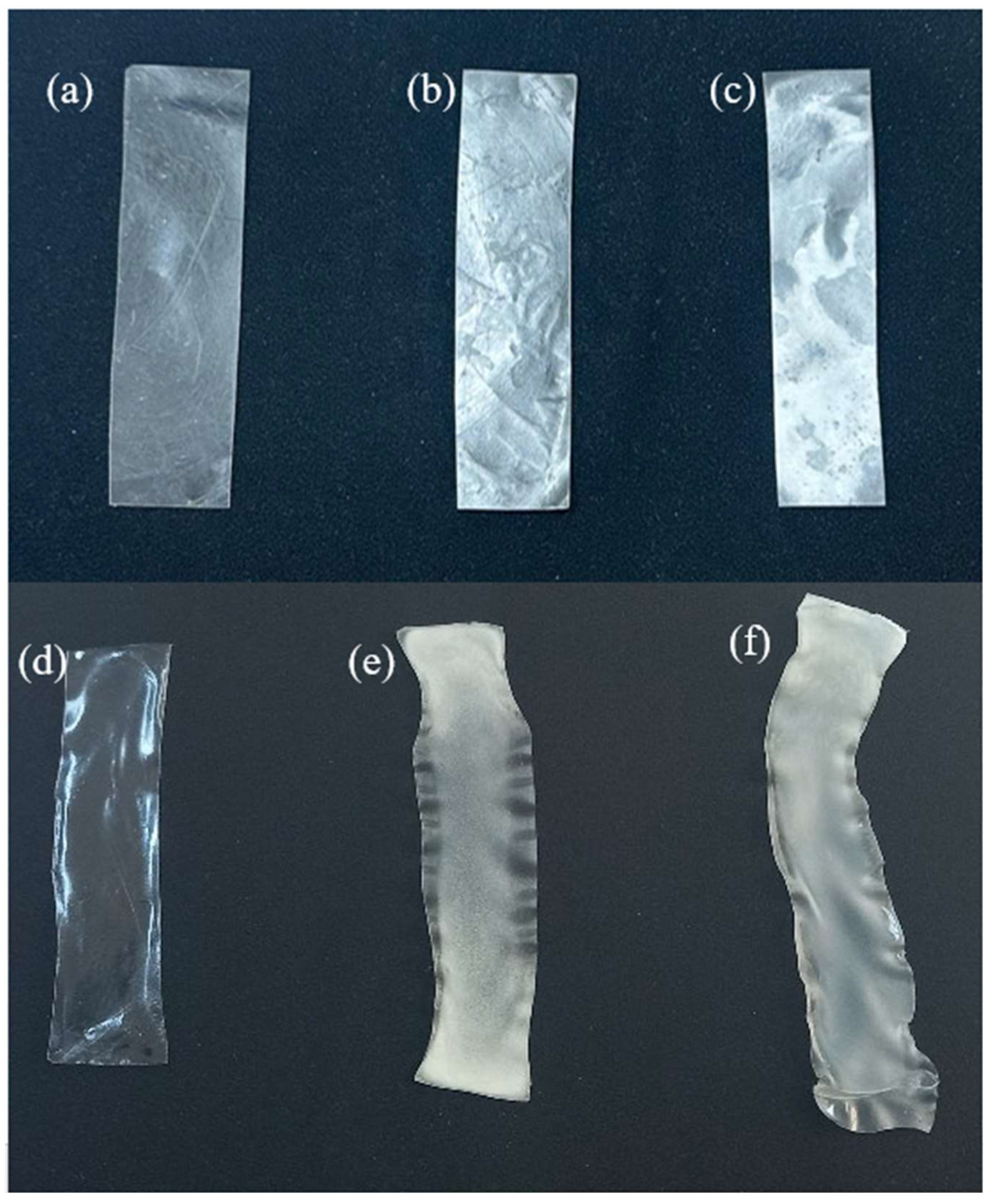

3.2. Fabrication of PVAc/PULL Blend Film and Heterogenous Saponified PVA/PULL Film

3.3. Mechanical Properties

3.4. Characterization

3.5. Assessment of In Vivo Wound-Healing Efficiency

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lazaridou, A.; Biliaderis, C.G.; Kontogiorgos, V. Molecular weight effects on solution rheology of pullulan and mechanical properties of its films. Carbohydr. Polym. 2003, 52, 151–166. [Google Scholar] [CrossRef]

- Yasuda, K.; Ogushi, M.; Nakashima, A.; Nakano, Y.; Suzuki, K. Accelerated Wound Healing on the Skin Using a Film Dressing with beta-Glucan Paramylon. In Vivo 2018, 32, 799–805. [Google Scholar] [CrossRef] [PubMed]

- Deshpande, M.S.; Rale, V.B.; Lynch, J.M. Aureobasidium-Pullulans in Applied Microbiology—A Status-Report. Enzym. Microb. Technol. 1992, 14, 514–527. [Google Scholar] [CrossRef]

- Singh, R.S.; Saini, G.K.; Kennedy, J.F. Pullulan: Microbial sources, production and applications. Carbohydr. Polym. 2008, 73, 515–531. [Google Scholar] [CrossRef]

- Kristo, E.; Biliaderis, C.G.; Zampraka, A. Water vapour barrier and tensile properties of composite caseinate-pullulan films: Biopolymer composition effects and impact of beeswax lamination. Food Chem. 2007, 101, 753–764. [Google Scholar] [CrossRef]

- Li, H.N.; Yang, J.; Hu, X.N.; Liang, J.; Fan, Y.J.; Zhang, X.D. Superabsorbent polysaccharide hydrogels based on pullulan derivate as antibacterial release wound dressing. J. Biomed. Mater. Res. Part A 2011, 98a, 31–39. [Google Scholar] [CrossRef]

- Elangwe, C.N.; Morozkina, S.N.; Olekhnovich, R.O.; Polyakova, V.O.; Krasichkov, A.; Yablonskiy, P.K.; Uspenskaya, M.V. Pullulan-based hydrogels in wound healing and skin tissue engineering applications: A review. Int. J. Mol. Sci. 2023, 24, 4962. [Google Scholar] [CrossRef]

- Cui, R.; Zhang, L.; Ou, R.; Xu, Y.; Xu, L.; Zhan, X.-Y.; Li, D. Polysaccharide-based hydrogels for wound dressing: Design considerations and clinical applications. Front. Bioeng. Biotechnol. 2022, 10, 845735. [Google Scholar] [CrossRef]

- Tang, N.; Zhang, R.; Zheng, Y.; Wang, J.; Khatib, M.; Jiang, X.; Zhou, C.; Omar, R.; Saliba, W.; Wu, W.; et al. Highly Efficient Self-Healing Multifunctional Dressing with Antibacterial Activity for Sutureless Wound Closure and Infected Wound Monitoring. Adv. Mater. 2022, 34, 2106842. [Google Scholar] [CrossRef]

- Wu, J.; Zhong, F.; Li, Y.; Shoemaker, C.F.; Xia, W.S. Preparation and characterization of pullulan-chitosan and pullu-lan-carboxymethyl chitosan blended films. Food Hydrocoll. 2013, 30, 82–91. [Google Scholar] [CrossRef]

- Tong, Q.Y.; Xiao, Q.; Lim, L.T. Preparation and properties of pullulan-alginate-carboxymethylcellulose blend films. Food Res. Int. 2008, 41, 1007–1014. [Google Scholar] [CrossRef]

- Meedecha, P.; Srisang, N.; Eawsakul, K.; Ongtanasup, T.; Tambunlertchai, S.; Sokjabok, S.; Chungcharoen, T.; Srisang, S.; Limmun, W. Preparation and evaluation of blend polymer films for wound dressing using vancomycin-loaded polycaprolactone and carboxymethyl cellulose via crosslinking methods: Effect of mechanical strength, antibacterial activity, and cytotoxicity. J. Mech. Behav. Biomed. Mater. 2023, 151, 106339. [Google Scholar] [CrossRef]

- Plugariu, I.A.; Bercea, M.; Gradinaru, L.M.; Rusu, D.; Lupu, A. Poly (vinyl alcohol)/Pullulan Composite Hydrogels as a Potential Platform for Wound Dressing Applications. Gels 2023, 9, 580. [Google Scholar] [CrossRef] [PubMed]

- Park, J.Y.; Lee, I.H.; Bea, G.N. Optimization of the electrospinning conditions for preparation of nanofibers from polyvinylacetate (PVAc) in ethanol solvent. J. Ind. Eng. Chem. 2008, 14, 707–713. [Google Scholar] [CrossRef]

- Kim, J.O.; Park, J.K.; Kim, J.H.; Jin, S.G.; Yong, C.S.; Li, D.X.; Choi, J.Y.; Woo, J.S.; Yoo, B.K.; Lyoo, W.S.; et al. Development of polyvinyl alcohol-sodium alginate gel-matrix-based wound dressing system containing nitrofurazone. Int. J. Pharm. 2008, 359, 79–86. [Google Scholar] [CrossRef] [PubMed]

- Tripathi, S.; Mehrotra, G.K.; Dutta, P.K. Preparation and physicochemical evaluation of chitosan/poly(vinyl alcohol)/pectin ternary film for food-packaging applications. Carbohydr. Polym. 2010, 79, 711–716. [Google Scholar] [CrossRef]

- Lyoo, W.S.; Han, S.S.; Choi, J.H.; Ghim, H.D.; Yoo, S.W.; Lee, J.; Hong, S.; Ha, W.S. Preparation of high molecular weight poly(vinyl alcohol) with high yield using low-temperature solution polymerization of vinyl acetate. J. Appl. Polym. Sci. 2001, 80, 1003–1012. [Google Scholar] [CrossRef]

- Lee, S.G.; Kim, J.P.; Lyoo, W.S.; Kwak, J.W.; Noh, S.K.; Park, C.S.; Kim, J.H. Preparation of novel syndiotactic poly(vinyl alcohol) microspheres through the low-temperature suspension copolymerization of vinyl pivalate and vinyl acetate and heterogeneous saponification. J. Appl. Polym. Sci. 2005, 95, 1539–1548. [Google Scholar] [CrossRef]

- Yang, S.B.; Lee, H.J.; Sabina, Y.; Kim, J.W.; Yeum, J.H. Novel poly(vinyl alcohol) nanofibers prepared by heterogeneous saponification of electrospun poly(vinyl acetate). Colloids Surf. A 2016, 497, 265–270. [Google Scholar] [CrossRef]

- Yang, S.B.; Yoo, S.H.; Lee, J.S.; Kim, J.W.; Yeum, J.H. Surface Properties of a Novel Poly(vinyl alcohol) Film Prepared by Heterogeneous Saponification of Poly(vinyl acetate) Film. Polymers 2017, 9, 493. [Google Scholar] [CrossRef]

- Gaaz, T.S.; Sulong, A.B.; Akhtar, M.N.; Kadhum, A.A.H.; Mohamad, A.B.; Al-Amiery, A.A. Properties and applications of polyvinyl alcohol, halloysite nanotubes and their nanocomposites. Molecules 2015, 20, 22833–22847. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.B.; Karim, M.R.; Lee, J.; Yeum, J.H.; Yeasmin, S. Alkaline treatment variables to characterize poly (vinyl alcohol)/poly (vinyl butyral/vinyl alcohol) blend films. Polymers 2022, 14, 3916. [Google Scholar] [CrossRef]

- Li, M.; Li, J.; Zhou, M.; Xian, Y.; Shui, Y.; Wu, M.; Yao, Y. Super-hydrophilic electrospun PVDF/PVA-blended nanofiber membrane for microfiltration with ultrahigh water flux. J. Appl. Polym. Sci. 2020, 137, 48416. [Google Scholar] [CrossRef]

- Sun, K.; Xia, Y.; Ouyang, J. Improvement in the photovoltaic efficiency of polymer solar cells by treating the poly (3, 4-ethylenedioxythiophene): Poly (styrenesulfonate) buffer layer with co-solvents of hydrophilic organic solvents and hydrophobic 1, 2-dichlorobenzene. Sol. Energy Mater. Sol. Cells 2012, 97, 89–96. [Google Scholar] [CrossRef]

- Dhivya, S.; Padma, V.V.; Santhini, E. Wound dressings—A review. BioMedicine 2015, 5, 24–28. [Google Scholar] [CrossRef] [PubMed]

- Jančič, U.; Bozic, M.; Hribernik, S.; Mohan, T.; Kargl, R.; Kleinschek, K.S.; Gorgieva, S. High oxygen barrier chitosan films neutralized by alkaline Nanoparticles. Cellulose 2021, 28, 10457–10475. [Google Scholar] [CrossRef]

- Yang, S.B.; Park, S.M.; Kwon, D.J.; Shin, J.C.; Sabina, Y.; Yeum, J.H. Novel Poly(vinyl alcohol)/Clay Nanocomposite Film Prepared by the Heterogeneous Saponification of Poly(vinyl acetate)/Clay Nanocomposite Film. Sci. Adv. Mater. 2020, 12, 319–325. [Google Scholar] [CrossRef]

- Oliveiraa, V.R.L.; Coelhob, V.V.; Sérvuloa, E.F.C.; Caladoa, V.M.A. Study of the Molecular Weight of Pullulan Produced by Aureobasidium pullulans from Industrial Waste. Mater. Res. 2023, 26, e20230060. [Google Scholar] [CrossRef]

- Roe, K.D.; Labuza, T.P. Glass transition and crystallization of amorphous trehalose-sucrose mixtures. Int. J. Food Prop. 2005, 8, 559–574. [Google Scholar] [CrossRef]

- Jia, X.W.; Qin, Z.Y.; Xu, J.X.; Kong, B.H.; Liu, Q.; Wang, H. Preparation and characterization of pea protein isolate-pullulan blend electrospun nanofiber films. Int. J. Biol. Macromol. 2020, 157, 641–647. [Google Scholar] [CrossRef]

- Hu, D.Y.; Wang, H.X.; Wang, L.J. Physical properties and antibacterial activity of quaternized chitosan/carboxymethyl cellulose blend films. LWT-Food Sci. Technol. 2016, 65, 398–405. [Google Scholar] [CrossRef]

- Yin, M.L.; Chen, X.L.; Li, R.; Huang, D.; Fan, X.Y.; Ren, X.H.; Huang, T.S. Preparation and characterization of antimicrobial PVA hybrid films with N-halamine modified chitosan nanospheres. J. Appl. Polym. Sci. 2016, 133, 44204. [Google Scholar] [CrossRef]

- Lewandowska, K. Miscibility and thermal stability of poly(vinyl alcohol)/chitosan mixtures. Thermochim. Acta 2009, 493, 42–48. [Google Scholar] [CrossRef]

- Lotfipour, F.; Alami-Milani, M.; Salatin, S.; Hadavi, A.; Jelyehgari, M. Freeze-thaw-induced cross-linked PVA/chitosan for oxytetracycline-loaded wound dressing: The experimental design and optimization. Res. Pharm. Sci. 2019, 14, 175–189. [Google Scholar] [CrossRef]

- Kamedulski, P.; Wekwejt, M.; Zasada, L.; Ronowska, A.; Michno, A.; Chmielniak, D.; Binkowski, P.; Łukaszewicz, J.P.; Naska, K.-S. Evaluating Gelatin-Based Films with Graphene Nanoparticles for Wound Healing Applications. Nanomaterials 2023, 13, 3068. [Google Scholar] [CrossRef]

- Chiulan, I.; Frone, A.N.; Panaitescu, D.M.; Nicolae, C.A.; Trusca, R. Surface properties, thermal, and mechanical characteristics of poly(vinyl alcohol)-starch-bacterial cellulose composite films. J. Appl. Polym. Sci. 2018, 135, 45800. [Google Scholar] [CrossRef]

| Samples | Weight (mg) | Thickness (µm) | Contact Angle (°) |

|---|---|---|---|

| PVAc film | 88 ± 7 | 80 ± 9 | 85.96 ± 1.76 |

| Saponified PVAc film | 39 ± 9 | 90 ± 6 | 13.13 ± 0.65 |

| PVAc/PULL 90/10 film | 90 ± 5 | 130 ± 15 | 81.67 ± 1.98 |

| Saponified PVAc/PULL 90/10 film | 62.3 ± 6 | 90 ± 9 | 6.73 ± 0. 66 |

| PVAc/PULL 80/20 film | 97 ± 16 | 140 ± 18 | 62.79 ± 1.44 |

| Saponified PVAc/PULL 80/20 film | 58.4 ± 8 | 97 ±11 | 4.4 ± 0.44 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yeasmin, S.; Jung, J.H.; Lee, J.; Kim, T.Y.; Yang, S.B.; Kwon, D.-J.; Kim, M.O.; Yeum, J.H. A Novel Fabrication of Heterogeneous Saponified Poly(Vinyl Alcohol)/Pullulan Blend Film for Improved Wound Healing Application. Int. J. Mol. Sci. 2024, 25, 1026. https://doi.org/10.3390/ijms25021026

Yeasmin S, Jung JH, Lee J, Kim TY, Yang SB, Kwon D-J, Kim MO, Yeum JH. A Novel Fabrication of Heterogeneous Saponified Poly(Vinyl Alcohol)/Pullulan Blend Film for Improved Wound Healing Application. International Journal of Molecular Sciences. 2024; 25(2):1026. https://doi.org/10.3390/ijms25021026

Chicago/Turabian StyleYeasmin, Sabina, Jae Hoon Jung, Jungeon Lee, Tae Young Kim, Seong Baek Yang, Dong-Jun Kwon, Myoung Ok Kim, and Jeong Hyun Yeum. 2024. "A Novel Fabrication of Heterogeneous Saponified Poly(Vinyl Alcohol)/Pullulan Blend Film for Improved Wound Healing Application" International Journal of Molecular Sciences 25, no. 2: 1026. https://doi.org/10.3390/ijms25021026

APA StyleYeasmin, S., Jung, J. H., Lee, J., Kim, T. Y., Yang, S. B., Kwon, D.-J., Kim, M. O., & Yeum, J. H. (2024). A Novel Fabrication of Heterogeneous Saponified Poly(Vinyl Alcohol)/Pullulan Blend Film for Improved Wound Healing Application. International Journal of Molecular Sciences, 25(2), 1026. https://doi.org/10.3390/ijms25021026