Poly(Butylene Adipate/Terephthalate-Co-Glycolate) Copolyester Synthesis Based on Methyl Glycolate with Improved Barrier Properties: From Synthesis to Structure-Property

Abstract

:1. Introduction

2. Results and Discussion

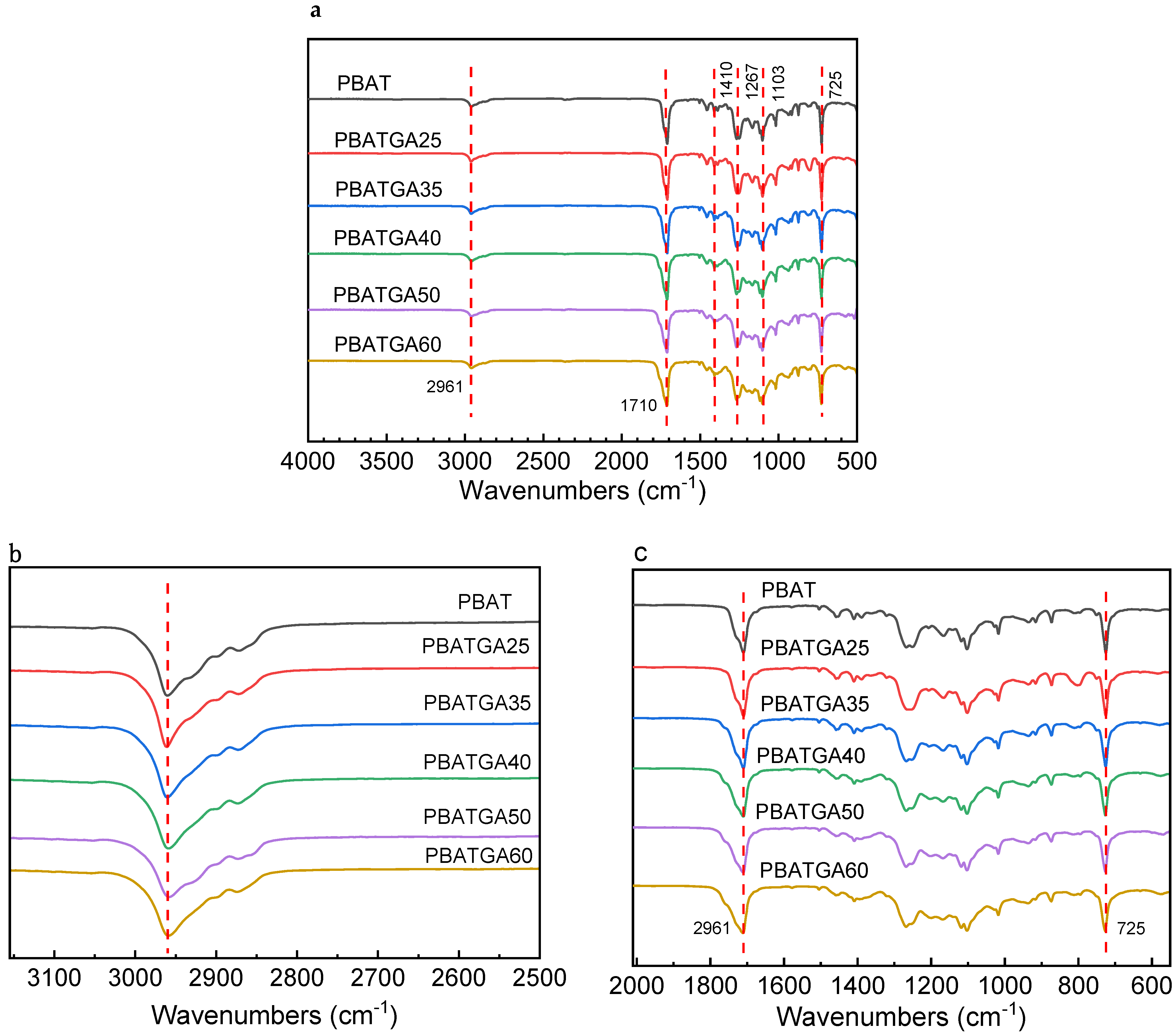

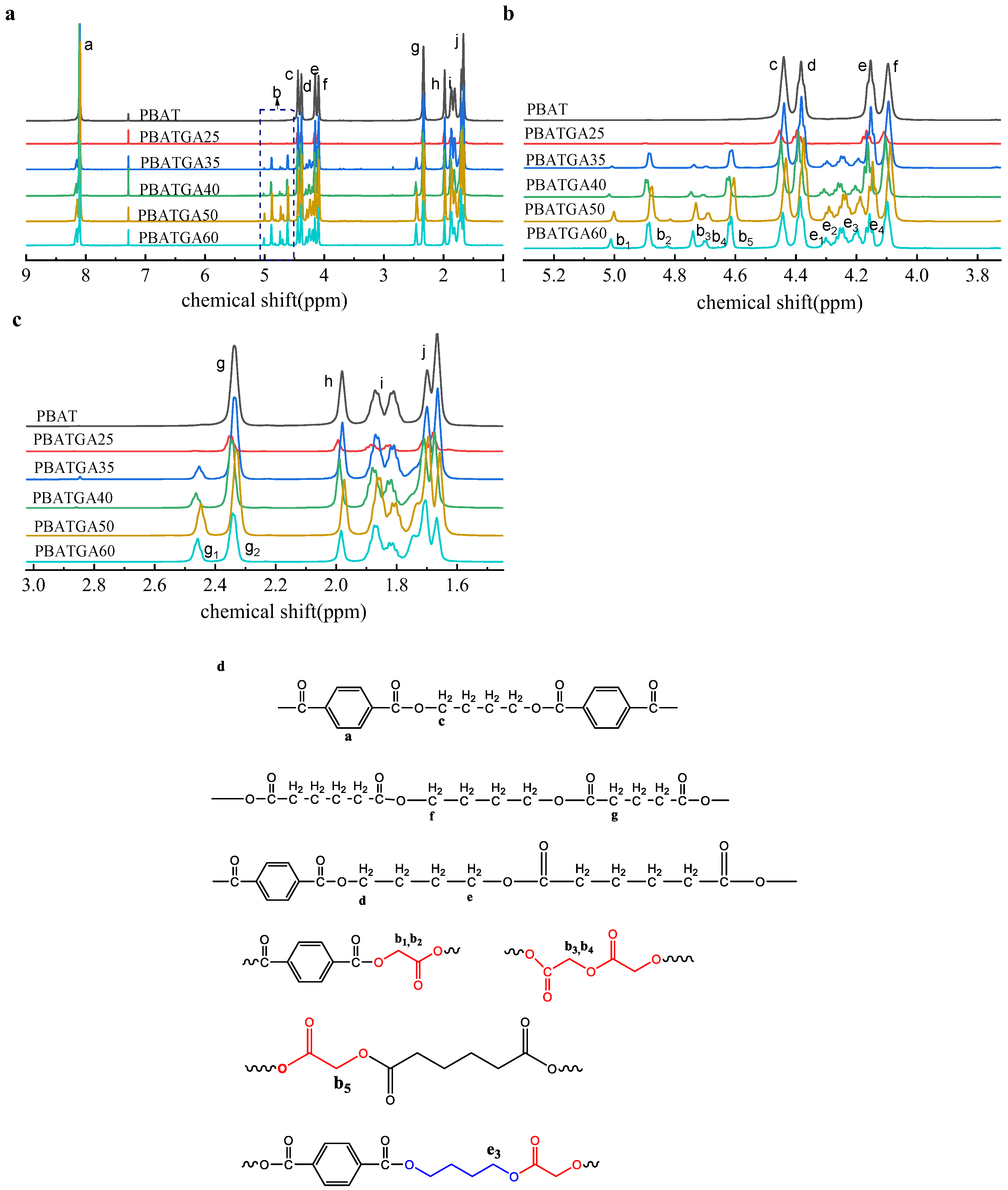

2.1. FTIR and 1H NMR Characterization of PBATGAs

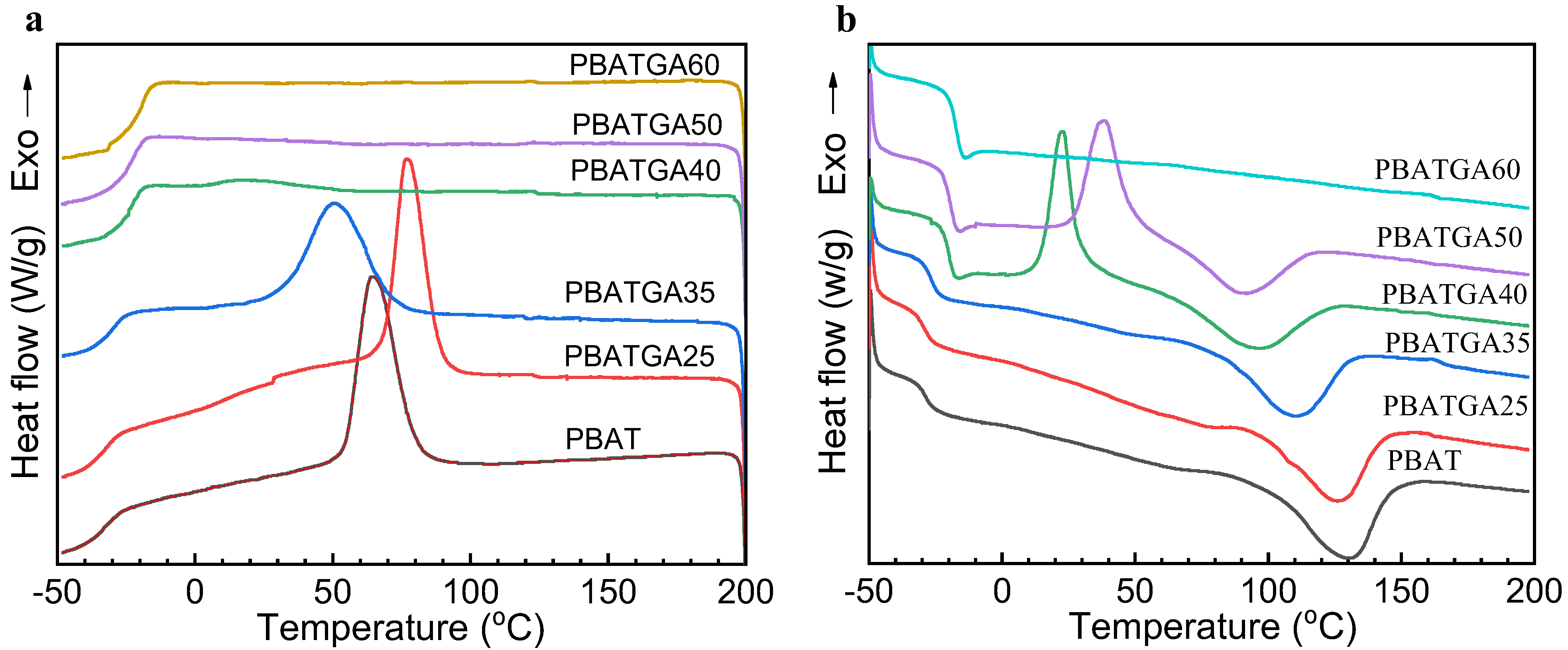

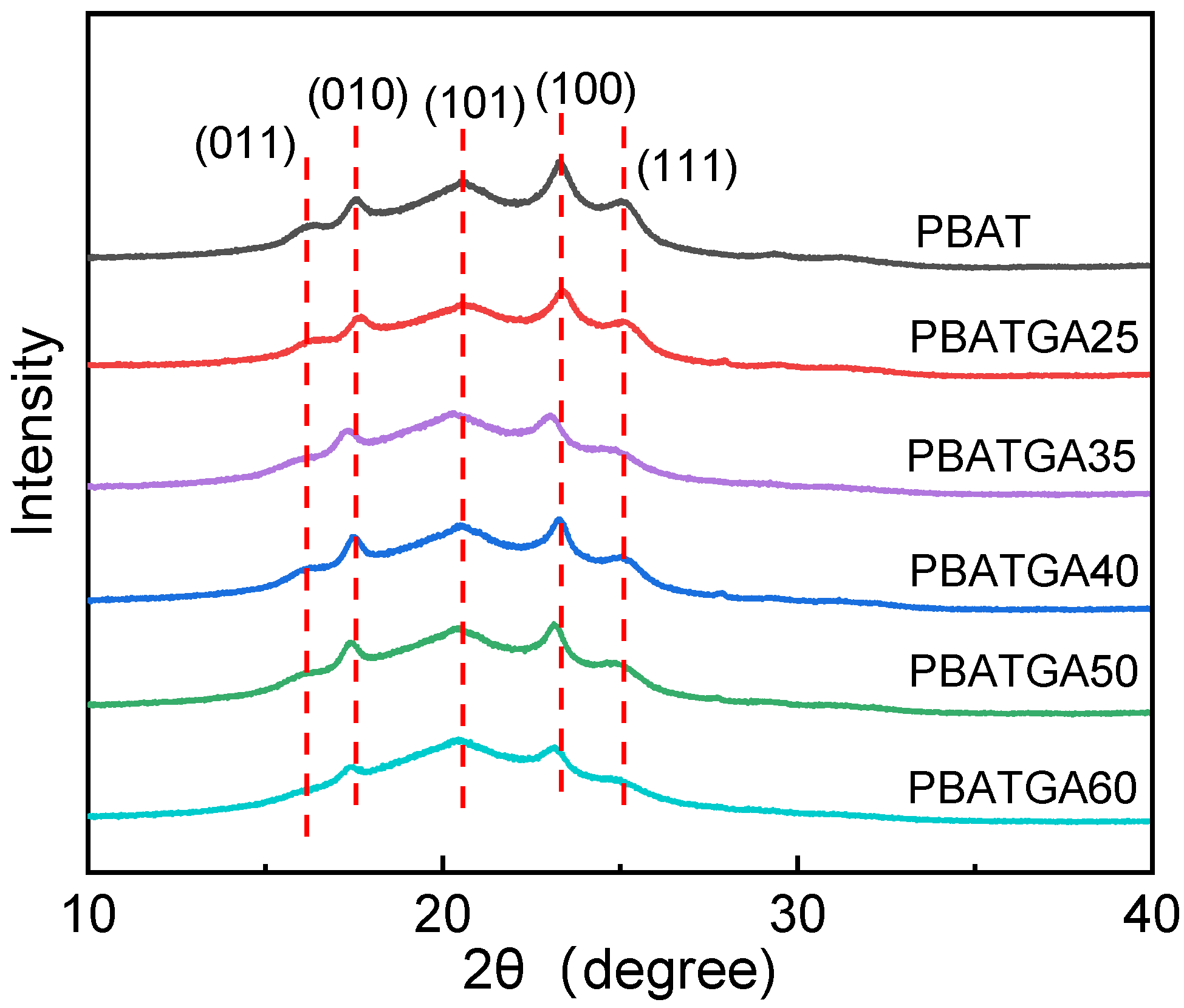

2.2. Crystallization Behavior and Crystal Structure

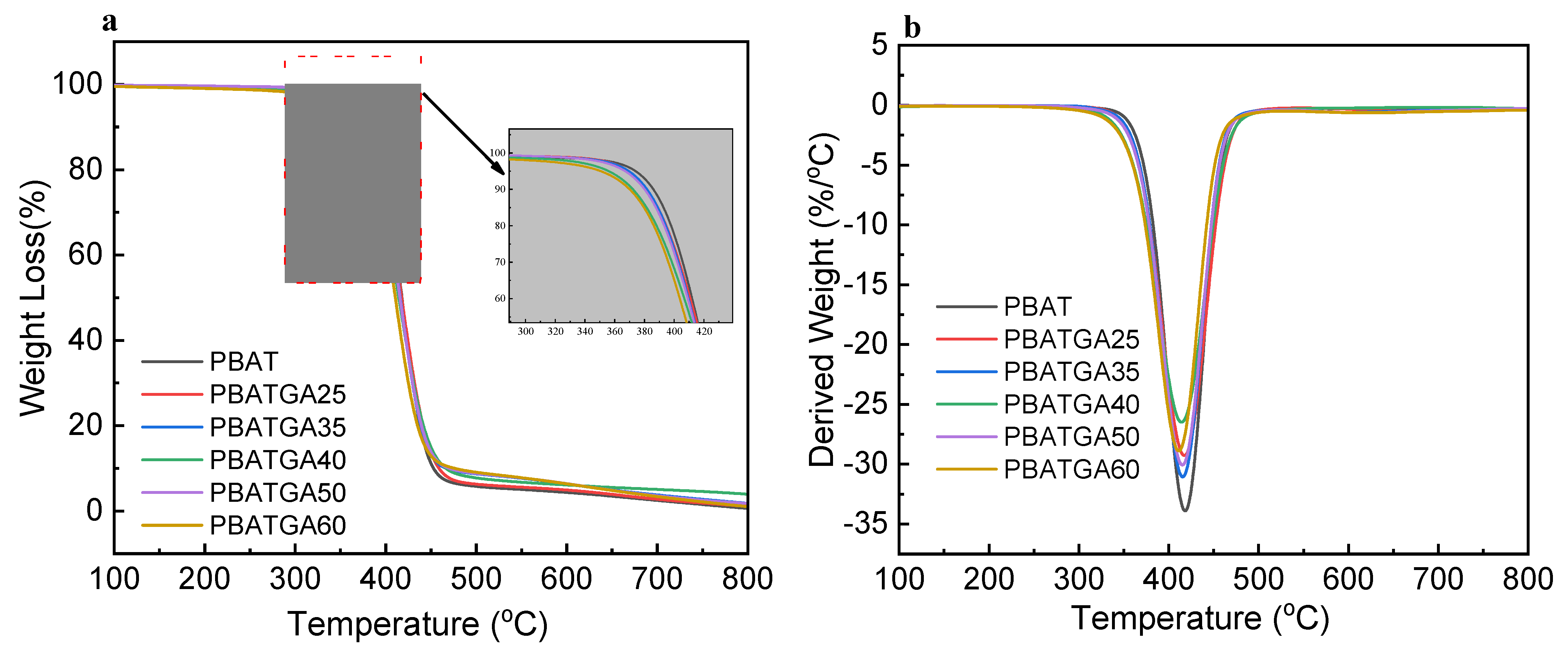

2.3. Thermogravimetric Analysis

2.4. Barrier Properties

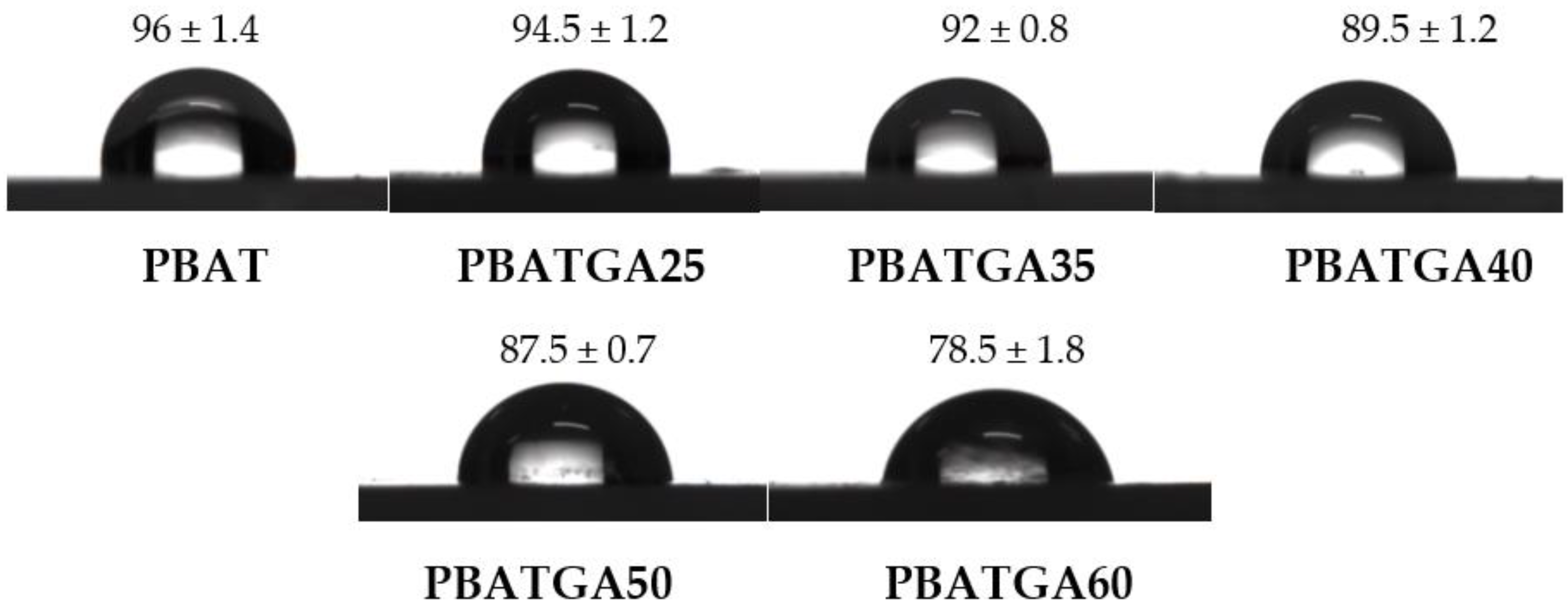

2.5. Surface Hydrophilicity

2.6. Heat Resistance Analysis

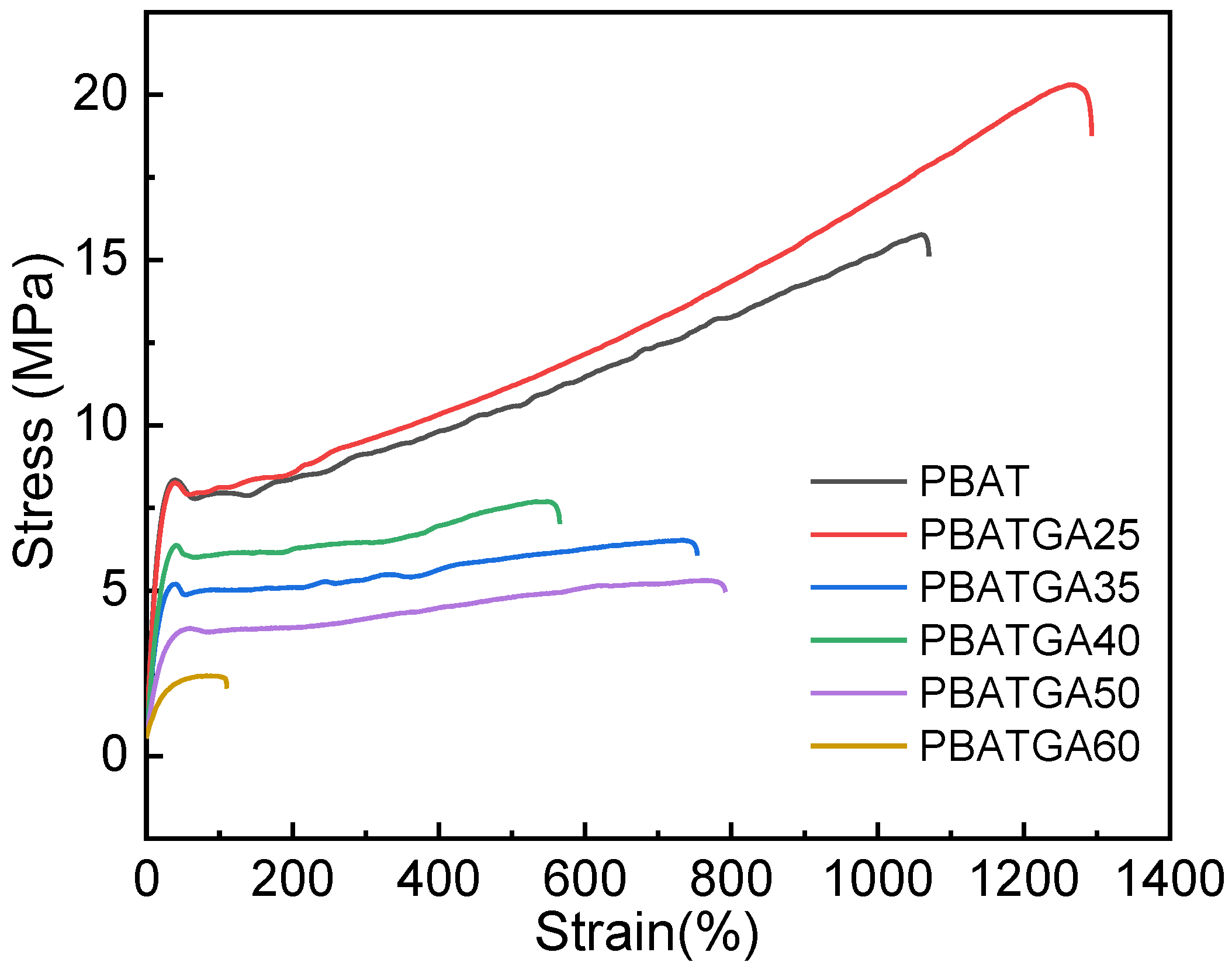

2.7. Mechanical Properties

3. Materials and Methods

3.1. Materials

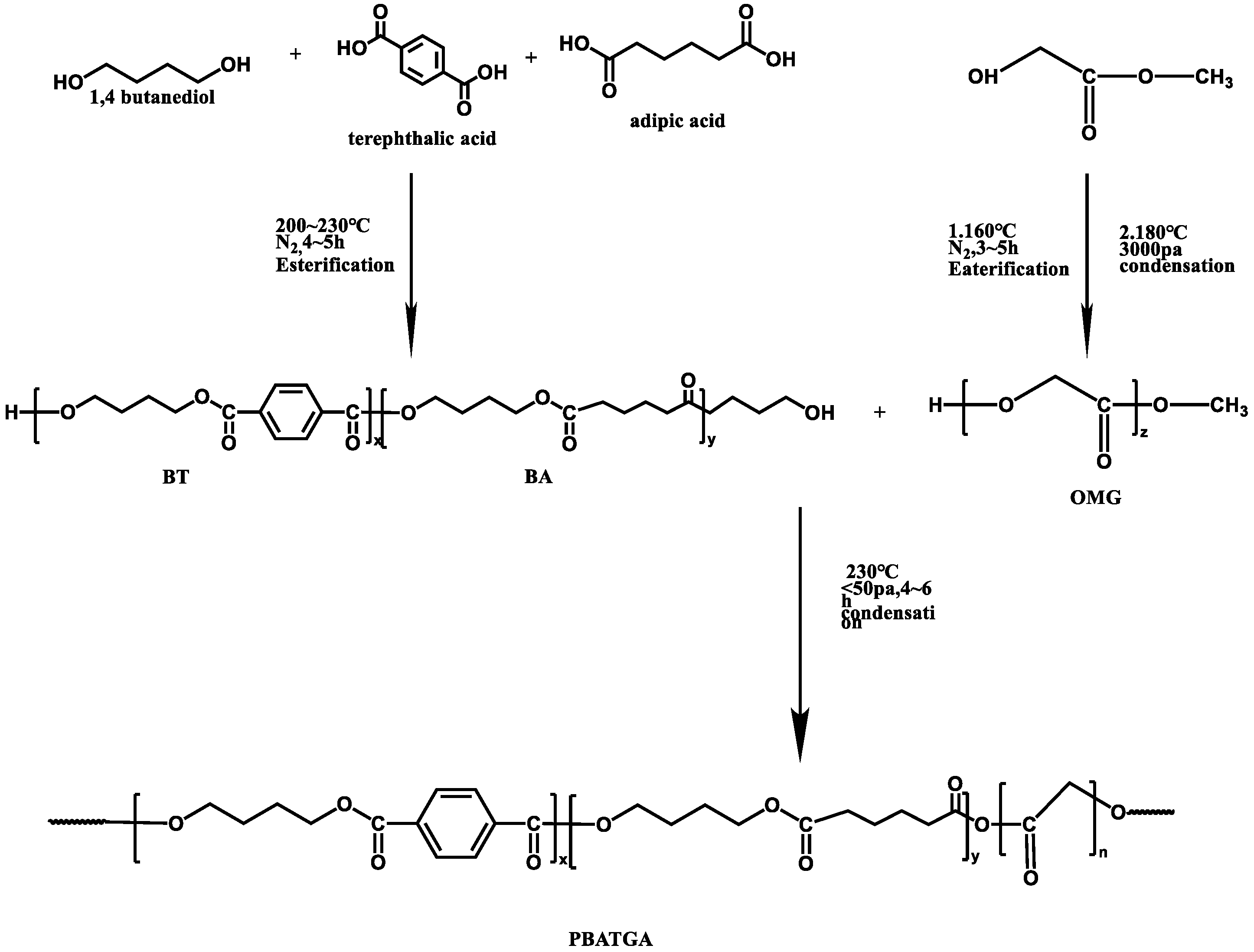

3.2. Synthesis

3.2.1. Synthesis of Oligo(Methyl Glycolate) (OMG)

3.2.2. Synthesis of PBATGAs

3.3. Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sera, J.; Kadleckova, M.; Fayyazbakhsh, A.; Kucabova, V.; Koutny, M. Occurrence and Analysis of Thermophilic Poly(butylene adipate-co-terephthalate)-Degrading Microorganisms in Temperate Zone Soils. Int. J. Mol. Sci. 2020, 21, 7857. [Google Scholar] [CrossRef] [PubMed]

- Xie, J.; Yan, Y.; Fan, S.; Min, X.; Wang, L.; You, X.; Jia, X.; Waterhouse, G.I.N.; Wang, J.; Xu, J. Prediction Model of Photodegradation for PBAT/PLA Mulch Films: Strategy to Fast Evaluate Service Life. Environ. Sci. Technol. 2022, 56, 9041–9051. [Google Scholar] [CrossRef] [PubMed]

- Meereboer, K.W.; Misra, M.; Mohanty, A.K. Review of recent advances in the biodegradability of polyhydroxyalkanoate (PHA) bioplastics and their composites. Green Chem. 2020, 22, 5519–5558. [Google Scholar] [CrossRef]

- Sid, S.; Mor, R.S.; Kishore, A.; Sharanagat, V.S. Bio-sourced polymers as alternatives to conventional food packaging materials: A review. Trends Food Sci. Technol. 2021, 115, 87–104. [Google Scholar] [CrossRef]

- Zhao, X.; Cornish, K.; Vodovotz, Y. Narrowing the Gap for Bioplastic Use in Food Packaging: An Update. Environ. Sci. Technol. 2020, 54, 4712–4732. [Google Scholar] [CrossRef]

- Feng, S.; Wu, D.; Liu, H.; Chen, C.; Liu, J.; Yao, Z.; Xu, J.; Zhang, M. Crystallization and creep of the graphite nanosheets based poly(butylene adipate-co-terephthalate) biocomposites. Thermochim. Acta 2014, 587, 72–80. [Google Scholar] [CrossRef]

- Chaves, R.P.; Fechine, G.J.M. Thermo stabilisation of poly (butylene adipate-co-terephthalate). Polímeros 2016, 26, 102–105. [Google Scholar] [CrossRef]

- Roy, S.; Rhim, J.-W. Curcumin Incorporated Poly(Butylene Adipate-co-Terephthalate) Film with Improved Water Vapor Barrier and Antioxidant Properties. Materials 2020, 13, 4369. [Google Scholar] [CrossRef]

- Huang, F.; Wu, L.; Li, B.-G. Sulfonated biodegradable PBAT copolyesters with improved gas barrier properties and excellent water dispersibility: From synthesis to structure-property. Polym. Degrad. Stab. 2020, 182, 109391. [Google Scholar] [CrossRef]

- Qin, P.; Wu, L.; Li, B.; Li, N.; Pan, X.; Dai, J. Superior Gas Barrier Properties of Biodegradable PBST vs. PBAT Copolyesters: A Comparative Study. Polymers 2021, 13, 3449. [Google Scholar] [CrossRef]

- Poulose, S.; Toriseva, J.; Lahti, J.; Jönkkäri, I.; Hedenqvist, M.S.; Kuusipalo, J. A Green High Barrier Solution for Paperboard Packaging based on Potato Fruit Juice, Poly(lactic acid), and Poly(butylene adipate terephthalate). ACS Appl. Polym. Mater. 2022, 4, 4179–4188. [Google Scholar] [CrossRef]

- Yeh, J.-T.; Tsou, C.-H.; Huang, C.-Y.; Chen, K.-N.; Wu, C.-S.; Chai, W.-L. Compatible and crystallization properties of poly(lactic acid)/poly(butylene adipate-co-terephthalate) blends. J. Appl. Polym. Sci. 2010, 116, 680–687. [Google Scholar] [CrossRef]

- Zhou, Y.; Qiu, S.; Waterhouse, G.I.N.; Zhang, K.; Xu, J. Enhancing the properties of PBAT/PLA composites with novel phosphorus-based ionic liquid compatibilizers. Mater. Today Commun. 2021, 27, 102407. [Google Scholar] [CrossRef]

- Su, S. Prediction of the Miscibility of PBAT/PLA Blends. Polymers 2021, 13, 2339. [Google Scholar] [CrossRef] [PubMed]

- Kilic, N.T.; Can, B.N.; Kodal, M.; Ozkoc, G. Compatibilization of PLA/PBAT blends by using Epoxy-POSS. J. Appl. Polym. Sci. 2019, 136, 47217. [Google Scholar] [CrossRef]

- Aversa, C.; Barletta, M.; Cappiello, G.; Gisario, A. Compatibilization strategies and analysis of morphological features of poly(butylene adipate-co-terephthalate) (PBAT)/poly(lactic acid) PLA blends: A state-of-art review. Eur. Polym. J. 2022, 173, 111304. [Google Scholar] [CrossRef]

- Lyu, Y.; Chen, Y.; Lin, Z.; Zhang, J.; Shi, X. Manipulating phase structure of biodegradable PLA/PBAT system: Effects on dynamic rheological responses and 3D printing. Compos. Sci. Technol. 2020, 200, 108399. [Google Scholar] [CrossRef]

- Shi, L.; Kang, L.; Gong, J.; Zhang, X.; Liao, J.; Mo, L.; Li, J. Cellulose nanofibrils reinforced films without chemical modification, hydrophobic, high elongation, and foldability. Ind. Crops Prod. 2022, 180, 114742. [Google Scholar] [CrossRef]

- Xiang, S.; Feng, L.; Bian, X.; Li, G.; Chen, X. Evaluation of PLA content in PLA/PBAT blends using TGA. Polym. Test. 2020, 81, 106211. [Google Scholar] [CrossRef]

- Hu, D.; Xue, K.; Liu, Z.; Xu, Z.; Zhao, L. The essential role of PBS on PBAT foaming under supercritical CO2 toward green engineering. J. CO2 Util. 2022, 60, 101965. [Google Scholar] [CrossRef]

- Zhang, Z.; He, F.; Wang, B.; Zhao, Y.; Wei, Z.; Zhang, H.; Sang, L. Biodegradable PGA/PBAT Blends for 3D Printing: Material Performance and Periodic Minimal Surface Structures. Polymers 2021, 13, 3757. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.; Sun, X.; Chen, L.; Liang, W. Morphological and mechanical properties of biodegradable poly(glycolic acid)/poly(butylene adipate-co-terephthalate) blends with in situ compatibilization. RSC Adv. 2021, 11, 1241–1249. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Huang, Y.; Wang, X.-Y.; Wu, Z.-Y.; Weng, Y.-X. Kinetic analysis of PGA/PBAT plastic films for strawberry fruit preservation quality and enzyme activity. J. Food Compos. Anal. 2022, 108, 104439. [Google Scholar] [CrossRef]

- Shen, J.; Wang, K.; Ma, Z.; Xu, N.; Pang, S.; Pan, L. Biodegradable blends of poly(butylene adipate-co-terephthalate) and polyglycolic acid with enhanced mechanical, rheological and barrier performances. J. Appl. Polym. Sci. 2021, 138, 51285. [Google Scholar] [CrossRef]

- Samantaray, P.K.; Ellingford, C.; Farris, S.; O’Sullivan, D.; Tan, B.; Sun, Z.; McNally, T.; Wan, C. Electron Beam-Mediated Cross-Linking of Blown Film-Extruded Biodegradable PGA/PBAT Blends toward High Toughness and Low Oxygen Permeation. ACS Sustain. Chem. Eng. 2022, 10, 1267–1276. [Google Scholar] [CrossRef]

- Yang, F.; Zhang, C.; Ma, Z.; Weng, Y. In Situ Formation of Microfibrillar PBAT in PGA Films: An Effective Way to Robust Barrier and Mechanical Properties for Fully Biodegradable Packaging Films. ACS Omega 2022, 7, 21280–21290. [Google Scholar] [CrossRef]

- Niu, D.; Xu, P.; Sun, Z.; Yang, W.; Dong, W.; Ji, Y.; Liu, T.; Du, M.; Lemstra, P.J.; Ma, P. Superior toughened bio-compostable Poly(glycolic acid)-based blends with enhanced melt strength via selective interfacial localization of in-situ grafted copolymers. Polymer 2021, 235, 124269. [Google Scholar] [CrossRef]

- Sousa, F.M.; Costa, A.R.M.; Reul, L.T.A.; Cavalcanti, F.B.; Carvalho, L.H.; Almeida, T.G.; Canedo, E.L. Rheological and thermal characterization of PCL/PBAT blends. Polym. Bull. 2018, 76, 1573–1593. [Google Scholar] [CrossRef]

- Sousa, F.M.; Cavalcanti, F.B.; Marinho, V.A.D.; Morais, D.D.S.; Almeida, T.G.; Carvalho, L.H. Effect of composition on permeability, mechanical properties and biodegradation of PBAT/PCL blends films. Polym. Bull. 2021, 79, 5327–5338. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, Y.; Xie, D.; Chen, J. Effect of chain extrender on the compatibility, mechanical and gas barrier properties of poly(butylene adipate-co-terephthalate)/poly(propylene carbonate) bio-composites. J. Appl. Polym. Sci. 2021, 138, 50487. [Google Scholar] [CrossRef]

- Tian, H.-L.; Wang, Z.-P.; Jia, S.-L.; Pan, H.-W.; Han, L.-J.; Bian, J.-J.; Li, Y.; Yang, H.-L.; Zhang, H.-L. Biodegradable Foaming Material of Poly(butylene adipate-co-terephthalate) (PBAT)/Poly(propylene carbonate) (PPC). Chin. J. Polym. Sci. 2021, 40, 208–219. [Google Scholar] [CrossRef]

- Jiang, G.; Wang, F.; Zhang, S.; Huang, H. Structure and improved properties of PPC/PBAT blends via controlling phase morphology based on melt viscosity. J. Appl. Polym. Sci. 2020, 137, 48924. [Google Scholar] [CrossRef]

- Jiang, G.; Li, H.; Wang, F. Structure of PBAT/PPC blends prepared by in-situ reactive compatibilization and properties of their blowing films. Mater. Today Commun. 2021, 27, 102215. [Google Scholar] [CrossRef]

- Elhamnia, M.; Motlagh, G.H.; Jafari, S.H. A multiple approach in determination of interfacial tension of biodegradable melt-mixed PBAT/EVOH blends: Correlation of morphology, rheology and mechanical properties. Polym. Test. 2020, 82, 106301. [Google Scholar] [CrossRef]

- Wei, X.Y.; Ren, L.; Sun, Y.N.; Zhang, X.Y.; Guan, X.F.; Zhang, M.Y.; Zhang, H.X. Sustainable composites from biodegradable poly(butylene succinate) modified with thermoplastic starch and poly(butylene adipate-co-terephthalate): Preparation and performance. New J. Chem. 2021, 45, 17384–17397. [Google Scholar] [CrossRef]

- Chang, C.C.; Trinh, B.M.; Mekonnen, T.H. Robust multiphase and multilayer starch/polymer (TPS/PBAT) film with simultaneous oxygen/moisture barrier properties. J. Colloid Interface Sci. 2021, 593, 290–303. [Google Scholar] [CrossRef]

- Zhang, T.; Zhang, C.; Yang, Y.; Yang, F.; Zhao, M.; Weng, Y. Improved properties of poly(butylene adipate-co-terephthalate)/calcium carbonate films through silane modification. J. Appl. Polym. Sci. 2021, 138, 50970. [Google Scholar] [CrossRef]

- Diao, X.; Zhang, C.; Weng, Y. Properties and Degradability of Poly(Butylene Adipate-Co-Terephthalate)/Calcium Carbonate Films Modified by Polyethylene Glycol. Polymers 2022, 14, 484. [Google Scholar] [CrossRef]

- Iwakura, Y.; Li, Y.; Nakayama, K.; Shimizu, H. Strengthening of poly(butylene adipate-co-terephthalate) by melt blending with a liquid crystalline polymer. J. Appl. Polym. Sci. 2008, 109, 333–339. [Google Scholar] [CrossRef]

- Zhao, H.; Li, L.; Zhang, Q.; Xia, Z.; Yang, E.; Wang, Y.; Chen, W.; Meng, L.; Wang, D.; Li, L. Manipulation of Chain Entanglement and Crystal Networks of Biodegradable Poly(butylene adipate-co-butylene terephthalate) During Film Blowing through the Addition of a Chain Extender: An In Situ Synchrotron Radiation X-ray Scattering Study. Biomacromolecules 2019, 20, 3895–3907. [Google Scholar] [CrossRef]

- Budak, K.; Sogut, O.; Aydemir Sezer, U. A review on synthesis and biomedical applications of polyglycolic acid. J. Polym. Res. 2020, 27, 208. [Google Scholar] [CrossRef]

- Samantaray, P.K.; Little, A.; Haddleton, D.M.; McNally, T.; Tan, B.; Sun, Z.; Huang, W.; Ji, Y.; Wan, C. Poly(glycolic acid) (PGA): A versatile building block expanding high performance and sustainable bioplastic applications. Green Chem. 2020, 22, 4055–4081. [Google Scholar] [CrossRef]

- Yamane, K.; Sato, H.; Ichikawa, Y.; Sunagawa, K.; Shigaki, Y. Development of an industrial production technology for high-molecular-weight polyglycolic acid. Polym. J. 2014, 46, 769–775. [Google Scholar] [CrossRef]

- Kim, B.N.; Ko, Y.G.; Yeo, T.; Kim, E.J.; Kwon, O.K.; Kwon, O.H. Guided Regeneration of Rabbit Calvarial Defects Using Silk Fibroin Nanofiber-Poly(glycolic acid) Hybrid Scaffolds. ACS Biomater. Sci. Eng. 2019, 5, 5266–5272. [Google Scholar] [CrossRef] [PubMed]

- Hu, H.; Zhang, R.; Wang, J.; Ying, W.B.; Shi, L.; Yao, C.; Kong, Z.; Wang, K.; Zhu, J. A mild method to prepare high molecular weight poly(butylene furandicarboxylate-co-glycolate) copolyesters: Effects of the glycolate content on thermal, mechanical, and barrier properties and biodegradability. Green Chem. 2019, 21, 3013–3022. [Google Scholar] [CrossRef]

- Hu, H.; Li, J.; Tian, Y.; Chen, C.; Li, F.; Ying, W.B.; Zhang, R.; Zhu, J. Experimental and Theoretical Study on Glycolic Acid Provided Fast Bio/Seawater-Degradable Poly(Butylene Succinate-co-Glycolate). ACS Sustain. Chem. Eng. 2021, 9, 3850–3859. [Google Scholar] [CrossRef]

- Ding, Y.; Huang, D.; Ai, T.; Zhang, C.; Chen, Y.; Luo, C.; Zhou, Y.; Yao, B.; Dong, L.; Du, X.; et al. Bio-Based Poly(butylene furandicarboxylate-co-glycolate) Copolyesters: Synthesis, Properties, and Hydrolysis in Different Aquatic Environments for Water Degradation Application. ACS Sustain. Chem. Eng. 2021, 9, 1254–1263. [Google Scholar] [CrossRef]

- Nishimura, F.; Hoshina, H.; Ozaki, Y.; Sato, H. Isothermal crystallization of poly(glycolic acid) studied by terahertz and infrared spectroscopy and SAXS/WAXD simultaneous measurements. Polym. J. 2018, 51, 237–245. [Google Scholar] [CrossRef]

- Ding, Y.; Wang, J.; Luo, C.; Yao, B.; Dong, L.; Du, X.; Ji, J. Modification of poly(butylene succinate) with biodegradable glycolic acid: Significantly improved hydrolysis rate retaining high toughness property. J. Appl. Polym. Sci. 2021, 139, 52106. [Google Scholar] [CrossRef]

- Chen, L.; Qin, Y.; Wang, X.; Zhao, X.; Wang, F. Plasticizing while toughening and reinforcing poly(propylene carbonate) using low molecular weight urethane: Role of hydrogen-bonding interaction. Polymer 2011, 52, 4873–4880. [Google Scholar] [CrossRef]

- Neng, W.-B.; Xie, W.-G.; Lu, B.; Zhen, Z.-C.; Zhao, J.-L.; Wang, G.-X.; Ji, J.-H. Biodegradable thermoplastic copolyester elastomers: Methyl branched PBAmT. e-Polymers 2021, 21, 336–345. [Google Scholar] [CrossRef]

| Sample | nGA (mol %) | m(PBAT):m(OMG) | Ln,BA | Ln,BT | Ln,GA | R | Mn (g/mol) | Mw (g/mol) | PDI |

|---|---|---|---|---|---|---|---|---|---|

| PBAT | — | — | 1.91 | 2.13 | 0 | 0.99 | 39,058 | 66,496 | 1.70 |

| PBATGA25 | 25.19 | 45:1 | 5.67 | 18.96 | 1.50 | 0.90 | 37,943 | 68,740 | 1.81 |

| PBATGA35 | 34.21 | 10:1 | 2.33 | 6.52 | 1.99 | 1.09 | 30,377 | 54,749 | 1.80 |

| PBATGA40 | 41.18 | 6:1 | 1.91 | 5.00 | 2.15 | 1.19 | 61,847 | 109,126 | 1.76 |

| PBATGA50 | 50.50 | 5:1 | 1.55 | 3.31 | 1.54 | 1.60 | 35,967 | 64,852 | 1.8 |

| PBATGA60 | 57.62 | 3:1 | 1.27 | 2.47 | 1.65 | 1.80 | 31,010 | 59,341 | 1.91 |

| Sample | Cooling Scan | Second Heating Scan | TGA | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Tonset-Tc (°C) | Tc (°C) | ΔHc (J/g) | Xc (%) | Tg (°C) | Tm (°C) | ΔHm (J/g) | T5% (°C) | Tdmax (°C) | |

| PBAT | 15.55 | 64.41 | 24.19 | 21.22 | −27.02 | 129.4 | 31.57 | 376 | 418 |

| PBATGA25 | 11.98 | 76.87 | 21.63 | 18.97 | −28.73 | 125.9 | 13.03 | 371 | 417 |

| PBATGA35 | 19.88 | 50.52 | 20.49 | 17.97 | −26.02 | 109.9 | 22.87 | 369 | 416 |

| PBATGA40 | 25.69 | 21.04 | 1.50 | 1.32 | −20.32 | 92.93 | 15.34 | 359 | 414 |

| PBATGA50 | — | — | — | — | −20.10 | 90.29 | 13.07 | 368 | 415 |

| PBATGA60 | — | — | — | — | −18.05 | — | — | 352 | 411 |

| Sample | PO2 a | BIFO2 | Pwv b | BIFwv |

|---|---|---|---|---|

| PBAT | 196 | 1 | 1.11 | 1 |

| PBATGA25 | 2.05 | 95.61 | 0.62 | 1.79 |

| PBATGA35 | 602 | 0.33 | 1.29 | 0.86 |

| PBATGA40 | 2.13 | 92.02 | 0.91 | 1.23 |

| PBATGA50 | 637 | 0.31 | 0.82 | 1.35 |

| PBATGA60 | 518 | 0.38 | 1.10 | 1.01 |

| Sample | Strength (MPa) | Elongation at Break (%) |

|---|---|---|

| PBAT | 16 ± 1.6 | 1070 ± 148 |

| PBATGA25 | 21 ± 1.0 | 1304 ± 92.4 |

| PBATGA35 | 7 ± 0.1 | 752 ± 92.8 |

| PBATGA40 | 7 ± 0.9 | 601 ± 216 |

| PBATGA50 | 5 ± 0.2 | 800 ± 92 |

| PBATGA60 | 2 ± 0.1 | 109 ± 13 |

| PPC [50] | 6.57 ± 0.41 | 837.26 ± 43.21 |

| PBAmT55 [51] | 20.8 ± 0.5 | 1071 ± 70 |

| PBSGA25 [46] | 24.5 ± 1.0 | 408 ± 7 |

| PBFGA20 [45] | 37.5 ± 2.3 | 332 ± 13 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Yang, H.; Li, B.; Liu, S.; He, M.; Chen, Q.; Li, J. Poly(Butylene Adipate/Terephthalate-Co-Glycolate) Copolyester Synthesis Based on Methyl Glycolate with Improved Barrier Properties: From Synthesis to Structure-Property. Int. J. Mol. Sci. 2022, 23, 11074. https://doi.org/10.3390/ijms231911074

Wang Y, Yang H, Li B, Liu S, He M, Chen Q, Li J. Poly(Butylene Adipate/Terephthalate-Co-Glycolate) Copolyester Synthesis Based on Methyl Glycolate with Improved Barrier Properties: From Synthesis to Structure-Property. International Journal of Molecular Sciences. 2022; 23(19):11074. https://doi.org/10.3390/ijms231911074

Chicago/Turabian StyleWang, Yanning, Haicun Yang, Bingjian Li, Shi Liu, Mingyang He, Qun Chen, and Jinchun Li. 2022. "Poly(Butylene Adipate/Terephthalate-Co-Glycolate) Copolyester Synthesis Based on Methyl Glycolate with Improved Barrier Properties: From Synthesis to Structure-Property" International Journal of Molecular Sciences 23, no. 19: 11074. https://doi.org/10.3390/ijms231911074

APA StyleWang, Y., Yang, H., Li, B., Liu, S., He, M., Chen, Q., & Li, J. (2022). Poly(Butylene Adipate/Terephthalate-Co-Glycolate) Copolyester Synthesis Based on Methyl Glycolate with Improved Barrier Properties: From Synthesis to Structure-Property. International Journal of Molecular Sciences, 23(19), 11074. https://doi.org/10.3390/ijms231911074