Development of High-Efficiency, Magnetically Separable Palladium-Decorated Manganese-Ferrite Catalyst for Nitrobenzene Hydrogenation

Abstract

:1. Introduction

2. Results and Discussion

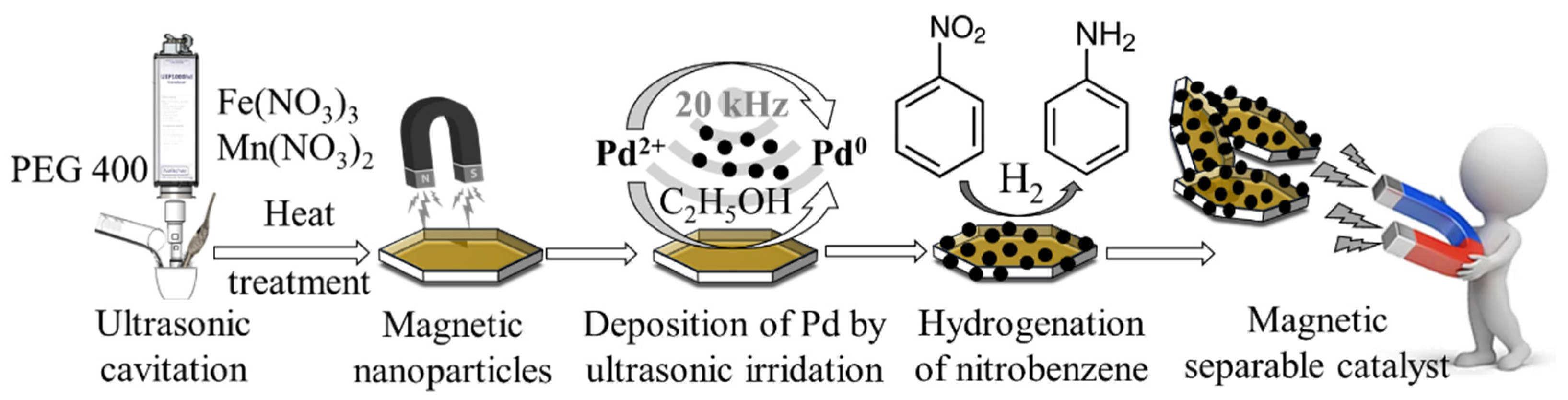

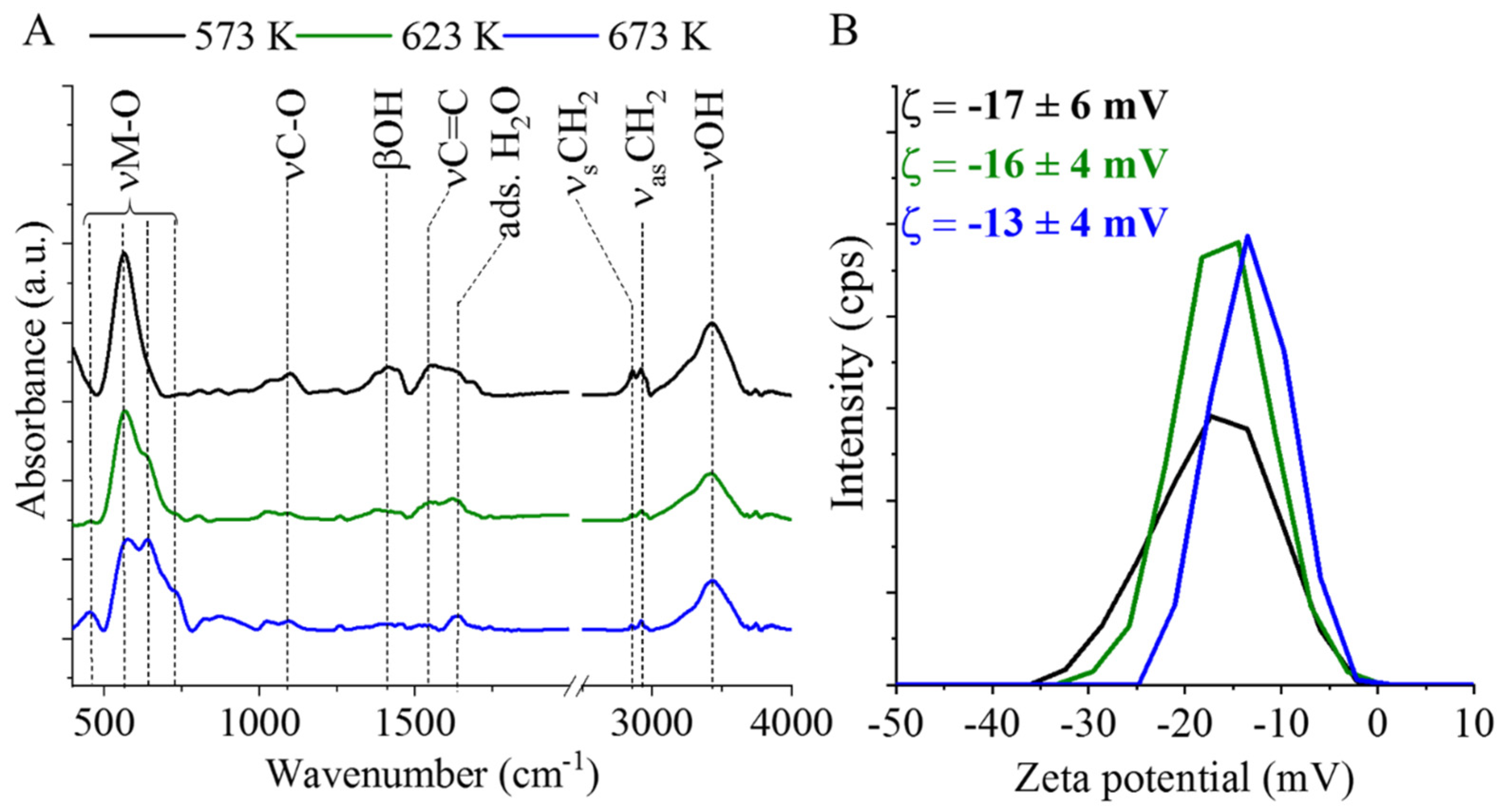

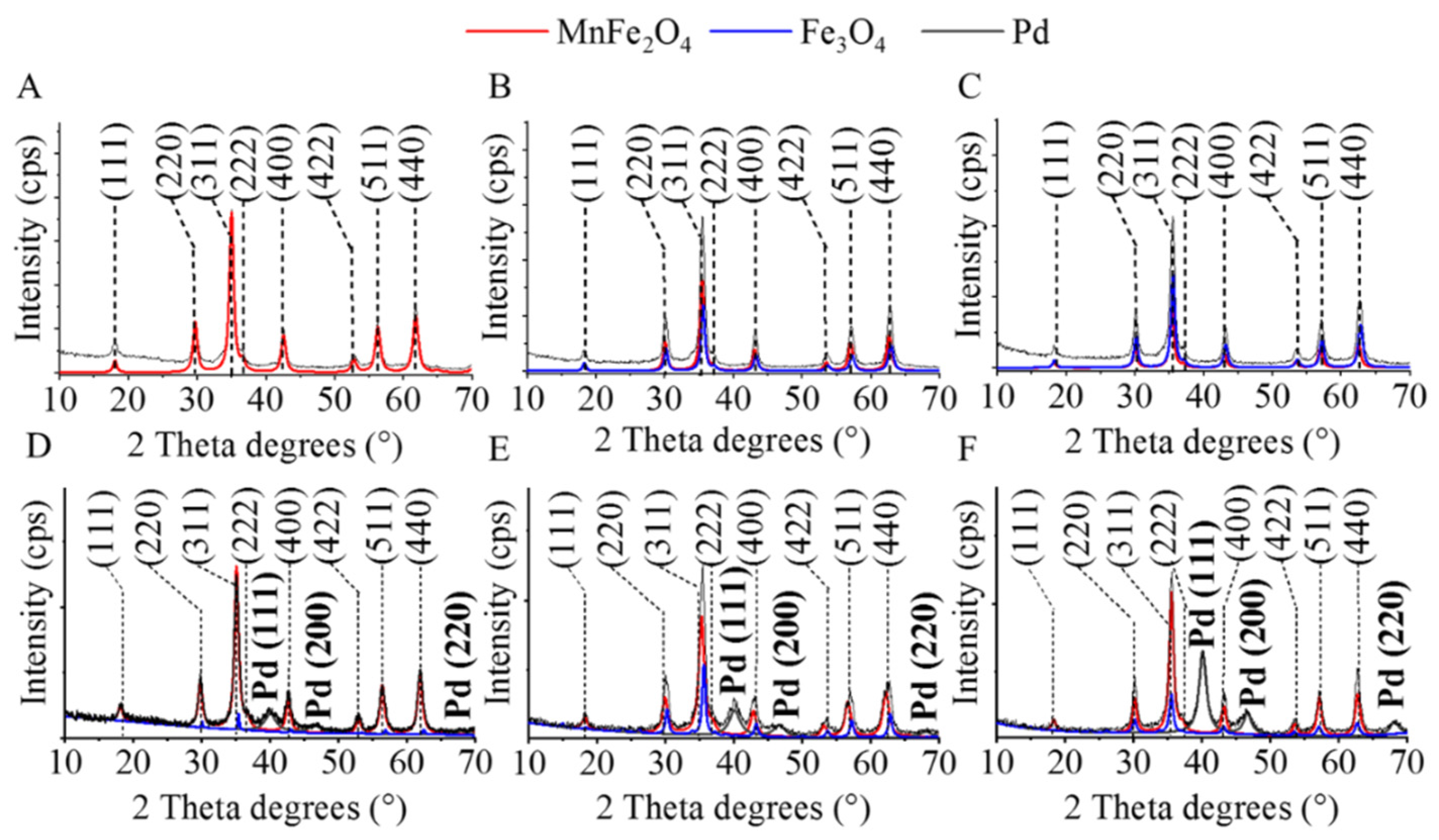

2.1. Synthesis and Characterization of the Developed Magnetic Catalysts

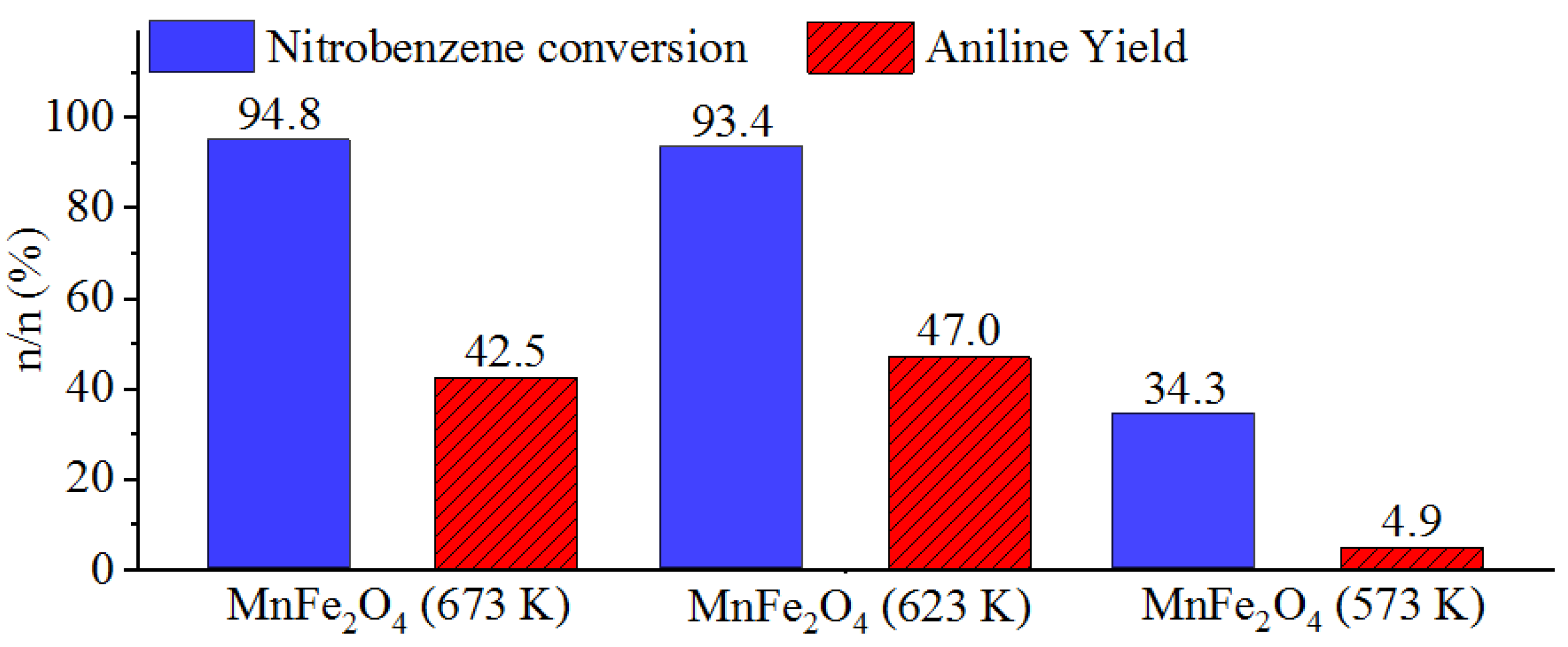

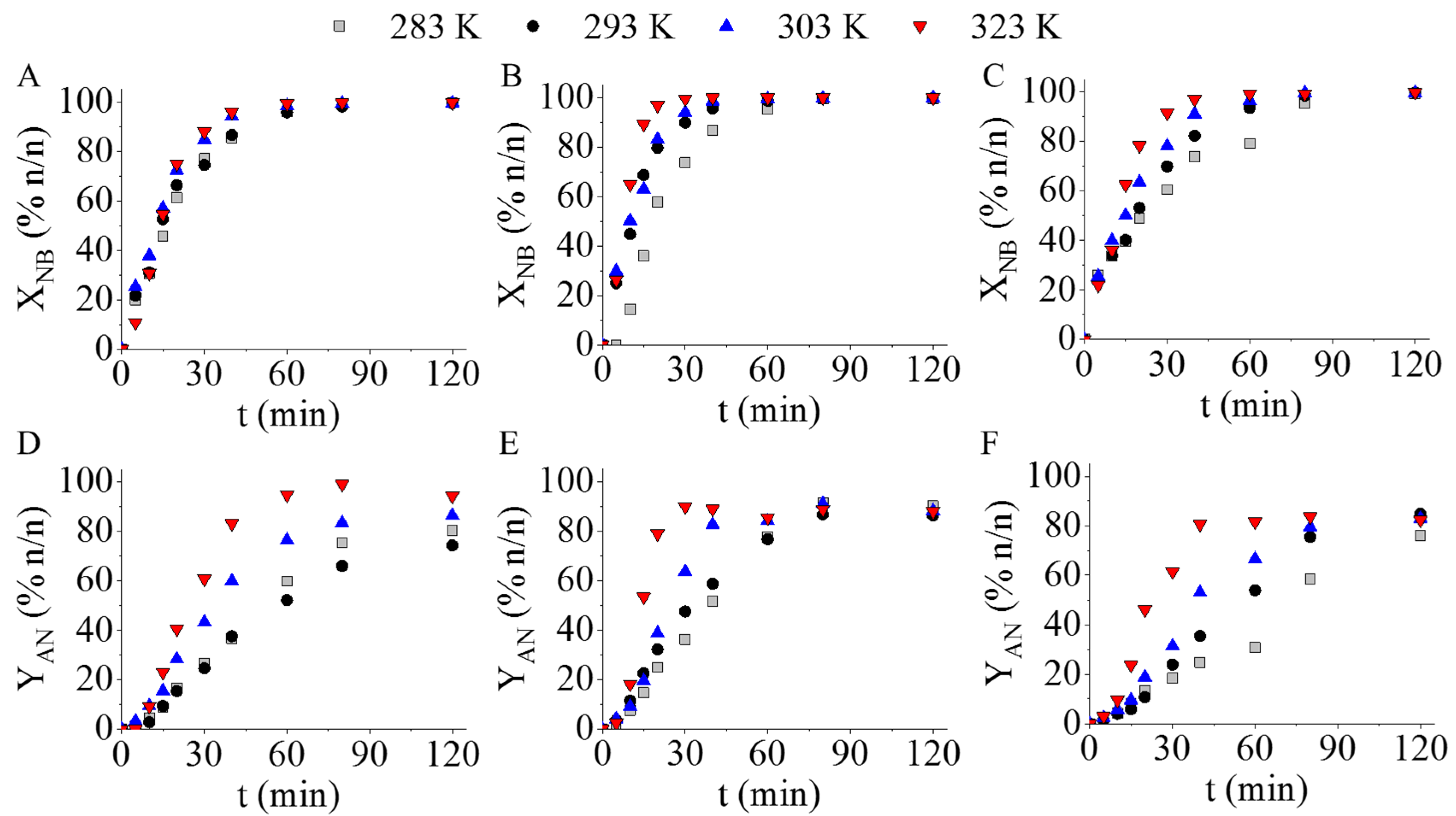

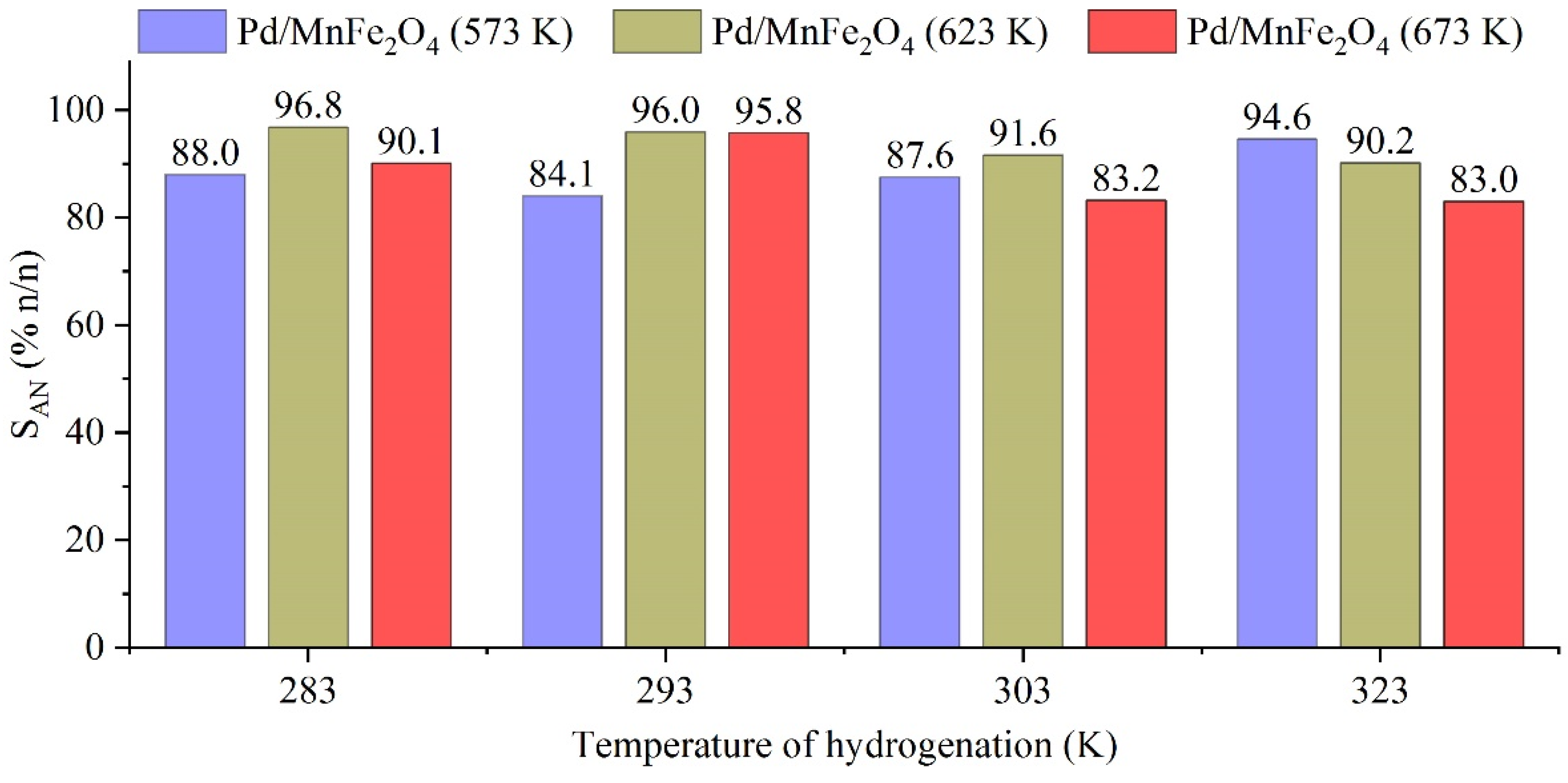

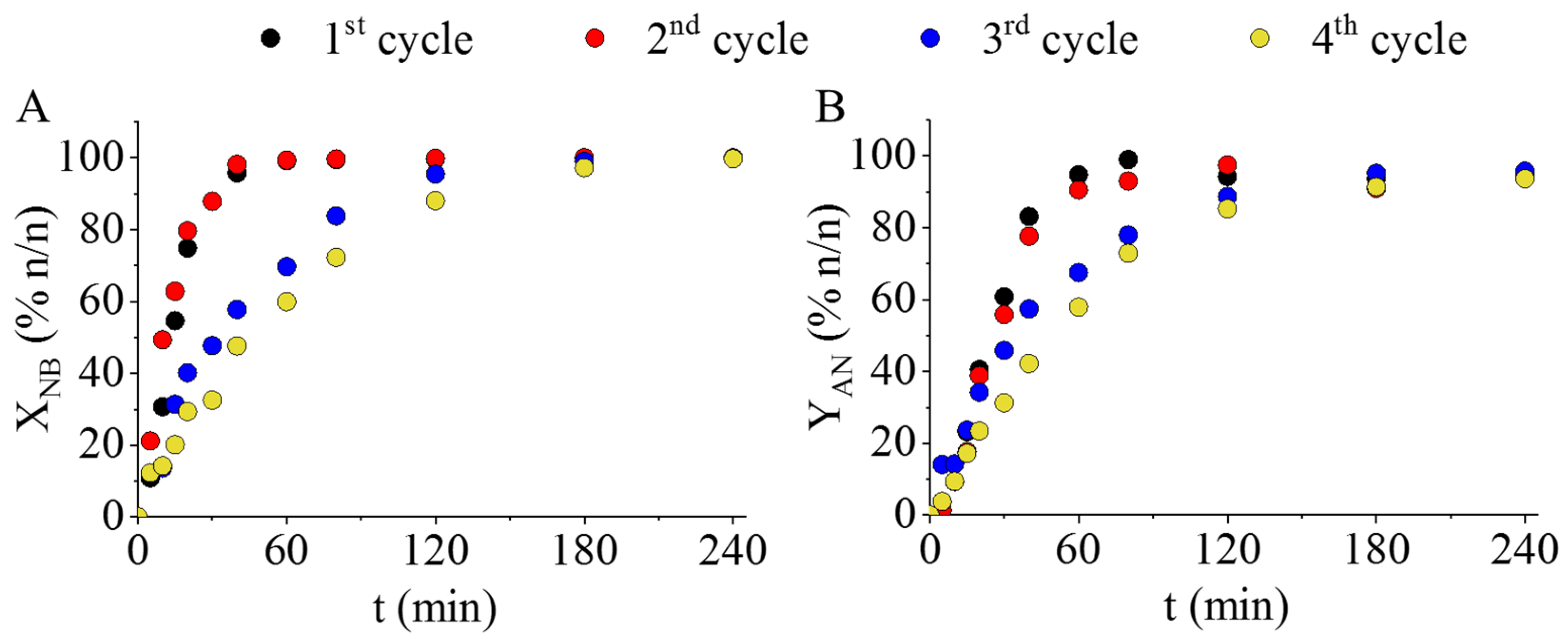

2.2. Catalytic Tests of the Prepared Magnetic Catalysts in Nitrobenzene Hydrogenation

3. Materials and Methods

3.1. Preparation of the Magnetic Spinel Nanoparticles and the Final Pd Catalyst

3.2. Catalytic Tests—Nitrobenzene Hydrogenation

3.3. Characterization Techniques

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Downing, R.S.; Kunkeler, P.J.; Van Bekkum, H. Catalytic syntheses of aromatic amines. Catal. Today 1997, 37, 121–136. [Google Scholar] [CrossRef]

- Grirrane, A.; Corma, A.; Garcia, H. Preparation of symmetric and asymmetric aromatic azo compounds from aromatic amines or nitro compounds using supported gold catalysts. Nat. Protoc. 2010, 5, 429–438. [Google Scholar] [CrossRef] [PubMed]

- Fu, L.; Cai, W.; Wang, A.; Zheng, Y. Photocatalytic hydrogenation of nitrobenzene to aniline over tungsten oxide-silver nanowires. Mater. Lett. 2015, 142, 201–203. [Google Scholar] [CrossRef]

- Xiao, Q.; Sarina, S.; Waclawik, E.R.; Jia, J.; Chang, J.; Riches, J.D.; Wu, H.; Zheng, Z.; Zhu, H. Alloying Gold with Copper Makes for a Highly Selective Visible-Light Photocatalyst for the Reduction of Nitroaromatics to Anilines. ACS Catal. 2016, 6, 1744–1753. [Google Scholar] [CrossRef]

- Sun, X.; Olivos-Suarez, A.I.; Osadchii, D.; Romero, M.J.V.; Kapteijn, F.; Gascon, J. Single cobalt sites in mesoporous N-doped carbon matrix for selective catalytic hydrogenation of nitroarenes. J. Catal. 2018, 357, 20–28. [Google Scholar] [CrossRef]

- Prekob, A.; Hajdu, V.; Muránszky, G.; Fiser, B.; Sycheva, A.; Ferenczi, T.; Viskolcz, B.; Vanyorek, L. Application of carbonized cellulose-based catalyst in nitrobenzene hydrogenation. Mater. Today Chem. 2020, 17, 100337. [Google Scholar] [CrossRef]

- Turek, F.; Geike, R.; Lange, R. Liquid-phase hydrogenation of nitrobenzene in a slurry reactor. Chem. Eng. Process. Process. Intensif. 1986, 20, 213–219. [Google Scholar] [CrossRef]

- Gelder, E.A.; Jackson, S.D.; Lok, C.M. A Study of Nitrobenzene Hydrogenation Over Palladium/Carbon Catalysts. Catal. Lett. 2002, 84, 205–208. [Google Scholar] [CrossRef]

- Mahata, N.; Cunha, A.F.; Órfão, J.J.M.; Figueiredo, J.L. Hydrogenation of nitrobenzene over nickel nanoparticles stabilized by filamentous carbon. Appl. Catal. A Gen. 2008, 351, 204–209. [Google Scholar] [CrossRef]

- Petrov, L.; Kumbilieva, K.; Kirkov, N. Kinetic model of nitrobenzene hydrogenation to aniline over industrial copper catalyst considering the effects of mass transfer and deactivation. Appl. Catal. 1990, 59, 31–43. [Google Scholar] [CrossRef]

- Cano, M.; Villuendas, P.; Benito, A.M.; Urriolabeitia, E.P.; Maser, W.K. Carbon nanotube-supported gold nanoparticles as efficient catalyst for the selective hydrogenation of nitroaromatic derivatives to anilines. Mater. Today Commun. 2015, 3, 104–113. [Google Scholar] [CrossRef]

- Li, C.H.; Yu, Z.X.; Yao, K.F.; Ji, S.F.; Liang, J. Nitrobenzene hydrogenation with carbon nanotube-supported platinum catalyst under mild conditions. J. Mol. Catal. A Chem. 2005, 226, 101–105. [Google Scholar] [CrossRef]

- Couto, C.S.; Madeira, L.M.; Nunes, C.P.; Araújo, P. Hydrogenation of Nitrobenzene over a Pd/Al2O3 Catalyst–Mechanism and Effect of the Main Operating Conditions. Chem. Eng. Technol. 2015, 38, 1625–1636. [Google Scholar] [CrossRef]

- Yu, X.; Wang, M.; Li, H. Study on the nitrobenzene hydrogenation over a Pd-B/SiO2 amorphous catalyst. Appl. Catal. A Gen. 2000, 202, 17–22. [Google Scholar] [CrossRef]

- Sadjadi, S.; Heravi, M.M.; Malmir, M. Pd@HNTs-CDNS-g-C3N4: A novel heterogeneous catalyst for promoting ligand and copper-free Sonogashira and Heck coupling reactions, benefits from halloysite and cyclodextrin chemistry and g-C3N4 contribution to suppress Pd leaching. Carbohydr. Polym. 2018, 186, 25–34. [Google Scholar] [CrossRef]

- Sadjadi, S.; Lazzara, G.; Malmir, M.; Heravi, M.M. Pd nanoparticles immobilized on the poly-dopamine decorated halloysite nanotubes hybridized with N-doped porous carbon monolayer: A versatile catalyst for promoting Pd catalyzed reactions. J. Catal. 2018, 366, 245–257. [Google Scholar] [CrossRef]

- Bahri-Laleh, N.; Sadjadi, S.; Poater, A. Pd immobilized on dendrimer decorated halloysite clay: Computational and experimental study on the effect of dendrimer generation, Pd valance and incorporation of terminal functionality on the catalytic activity. J. Colloid Interface Sci. 2018, 531, 421–432. [Google Scholar] [CrossRef]

- Tabrizi, M.; Sadjadi, S.; Pareras, G.; Nekoomanesh-Haghighi, M.; Bahri-Laleh, N.; Poater, A. Efficient hydro-finishing of polyalfaolefin based lubricants under mild reaction condition using Pd on ligands decorated halloysite. J. Colloid Interface Sci. 2021, 581, 939–953. [Google Scholar] [CrossRef]

- Dehghani, S.; Sadjadi, S.; Bahri-Laleh, N.; Nekoomanesh-Haghighi, M.; Poater, A. Study of the effect of the ligand structure on the catalytic activity of Pd@ligand decorated halloysite: Combination of experimental and computational studies. Appl. Organomet. Chem. 2019, 33, e4891. [Google Scholar] [CrossRef]

- Alleshagh, M.; Sadjadi, S.; Arabi, H.; Bahri-Laleh, N.; Monflier, E. Pd on ligand-decorated chitosan as an efficient catalyst for hydrofinishing polyalphaolefins: Experimental and computational studies. J. Phys. Chem. Solids 2022, 164, 110611. [Google Scholar] [CrossRef]

- Sun, Q.; Guo, C.Z.; Wang, G.H.; Li, W.C.; Bongard, H.J.; Lu, A.H. Fabrication of Magnetic Yolk–Shell Nanocatalysts with Spatially Resolved Functionalities and High Activity for Nitrobenzene Hydrogenation. Chem.–A Eur. J. 2013, 19, 6217–6220. [Google Scholar] [CrossRef] [PubMed]

- Easterday, R.; Sanchez-Felix, O.; Losovyj, Y.; Pink, M.; Stein, B.D.; Morgan, D.G.; Rakitin, M.; Doluda, V.Y.; Sulman, M.G.; Mahmoud, W.E.; et al. Design of ruthenium/iron oxide nanoparticle mixtures for hydrogenation of nitrobenzene. Catal. Sci. Technol. 2015, 5, 1902–1910. [Google Scholar] [CrossRef]

- Hajdu, V.; Prekob, Á.; Muránszky, G.; Kocserha, I.; Kónya, Z.; Fiser, B.; Viskolcz, B.; Vanyorek, L. Catalytic activity of maghemite supported palladium catalyst in nitrobenzene hydrogenation. React. Kinet. Mech. Catal. 2020, 129, 107–116. [Google Scholar] [CrossRef]

- Fronczak, M.; Kasprzak, A.; Bystrzejewski, M. Carbon-encapsulated iron nanoparticles with deposited Pd: A high-performance catalyst for hydrogenation of nitro compounds. J. Environ. Chem. Eng. 2021, 9, 104673. [Google Scholar] [CrossRef]

- Shokouhimehr, M. Magnetically Separable and Sustainable Nanostructured Catalysts for Heterogeneous Reduction of Nitroaromatics. Catalysts 2015, 5, 534–560. [Google Scholar] [CrossRef]

- Peng, Y.; Wang, Z.; Liu, W.; Zhang, H.; Zuo, W.; Tang, H.; Chen, F.; Wang, B. Size- and shape-dependent peroxidase-like catalytic activity of MnFe2O4 Nanoparticles and their applications in highly efficient colorimetric detection of target cancer cells. Dalton Trans. 2015, 44, 12871–12877. [Google Scholar] [CrossRef]

- Kavkhani, R.; Hajalilou, A.; Abouzari-Lotf, E.; Ferreira, L.P.; Cruz, M.M.; Yusefi, M.; Parvini, E.; Ogholbeyg, A.B.; Ismail, U.N. CTAB assisted synthesis of MnFe2O4@SiO2 nanoparticles for magnetic hyperthermia and MRI application. Mater. Today Commun. 2022, 31, 103412. [Google Scholar] [CrossRef]

- Liew, K.H.; Lee, T.K.; Yarmo, M.A.; Loh, K.S.; Peixoto, A.F.; Freire, C.; Yusop, R.M. Ruthenium supported on ionically cross-linked chitosan-carrageenan hybrid MnFe2O4 catalysts for 4-nitrophenol reduction. Catalysts 2019, 9, 254. [Google Scholar] [CrossRef]

- Hazarika, M.; Chinnamuthu, P.; Borah, J.P. MWCNT decorated MnFe2O4 nanoparticles as an efficient photo-catalyst for phenol degradation. J. Mater. Sci. Mater. Electron. 2018, 29, 12231–12240. [Google Scholar] [CrossRef]

- Facile hydrothermal synthesis of cubic spinel AB2O4 type MnFe2O4 nanocrystallites and their electrochemical performance. Appl. Surf. Sci. 2017, 413, 83–91. [CrossRef]

- Chen, G.; Zhang, X.; Gao, Y.; Zhu, G.; Cheng, Q.; Cheng, X. Novel magnetic MnO2/MnFe2O4 nanocomposite as a heterogeneous catalyst for activation of peroxymonosulfate (PMS) toward oxidation of organic pollutants. Sep. Purif. Technol. 2019, 213, 456–464. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, G.; Li, X.; Lu, X. Removal of rare earth elements by MnFe2O4 based mesoporous adsorbents: Synthesis, isotherms, kinetics, thermodynamics. J. Alloys Compd. 2021, 856, 158185. [Google Scholar] [CrossRef]

- Li, Z.; Gao, K.; Han, G.; Wang, R.; Li, H.; Zhao, X.S.; Guo, P. Solvothermal synthesis of MnFe2O4 colloidal nanocrystal assemblies and their magnetic and electrocatalytic properties. New J. Chem. 2014, 39, 361–368. [Google Scholar] [CrossRef]

- Akhtar, M.J.; Younas, M. Structural and transport properties of nanocrystalline MnFe2O4 synthesized by co-precipitation method. Solid State Sci. 2012, 14, 1536–1542. [Google Scholar] [CrossRef]

- Vignesh, V.; Subramani, K.; Sathish, M.; Navamathavan, R. Electrochemical investigation of manganese ferrites prepared via a facile synthesis route for supercapacitor applications. Colloids Surfaces A Physicochem. Eng. Asp. 2018, 538, 668–677. [Google Scholar] [CrossRef]

- Li, J.; Yuan, H.; Li, G.; Liu, Y.; Leng, J. Cation distribution dependence of magnetic properties of sol–gel prepared MnFe2O4 spinel ferrite nanoparticles. J. Magn. Magn. Mater. 2010, 322, 3396–3400. [Google Scholar] [CrossRef]

- Baig, M.M.; Yousuf, M.A.; Agboola, P.O.; Khan, M.A.; Shakir, I.; Warsi, M.F. Optimization of different wet chemical routes and phase evolution studies of MnFe2O4 nanoparticles. Ceram. Int. 2019, 45, 12682–12690. [Google Scholar] [CrossRef]

- Silambarasu, A.; Manikandan, A.; Balakrishnan, K.; Jaganathan, S.K.; Manikandan, E.; Aanand, J.S. Comparative Study of Structural, Morphological, Magneto-Optical and Photo-Catalytic Properties of Magnetically Reusable Spinel MnFe 2O4 Nano-Catalysts. J. Nanosci. Nanotechnol. 2017, 18, 3523–3531. [Google Scholar] [CrossRef]

- Singh Yadav, R.; Kuřitka, I.; Vilcakova, J.; Jamatia, T.; Machovsky, M.; Skoda, D.; Urbánek, P.; Masař, M.; Urbánek, M.; Kalina, L.; et al. Impact of sonochemical synthesis condition on the structural and physical properties of MnFe2O4 spinel ferrite nanoparticles. Ultrason. Sonochem. 2020, 61, 104839. [Google Scholar] [CrossRef]

- Zipare, K.; Dhumal, J.; Bandgar, S.; Mathe, V.; Shahane, G. Superparamagnetic Manganese Ferrite Nanoparticles: Synthesis and Magnetic Properties. J. Nanosci. Nanoeng. 2015, 1, 178–182. [Google Scholar]

| MnFe2O4 | Fe3O4 | Pd | ADA m2/g | Xmax, (t) (%) | Ymax.(t) (%) | Smax.(t) (%) | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| d (nm) | wt% | d (nm) | wt% | d (nm) | wt% | |||||

| MnFe2O4 (573 K) | 11 ± 3 | 100 | ᴓ | ᴓ | ᴓ | ᴓ | ᴓ | 34.3 a | 4.90 a | n/a |

| MnFe2O4 (623 K) | 12 ± 2 | 61.1 | 14 ± 3 | 38.9 | ᴓ | ᴓ | ᴓ | 93.4 a | 47.0 a | n/a |

| MnFe2O4 (673 K) | 13 ± 2 | 41.8 | 12 ± 3 | 48.2 | ᴓ | ᴓ | ᴓ | 94.8 a | 42.5 a | n/a |

| Pd/MnFe2O4 (573 K) | 10 ± 3 | 89.1 | 35 ± 5 | 3.3 | 4 ± 1 | 4.20 | 74 | 99.9 (180 min) (303 K) | 94.8 (60 min) (323 K) | 94.6 (120 min) (323 K) |

| Pd/MnFe2O4 (623 K) | 8 ± 2 | 66.0 | 15 ± 3 | 25.7 | 4 ± 1 | 4.64 | 69 | 99.9 (40 min) (323 K) | 96.7 (240 min) (283 K) | 96.8 (240 min) (283 K) |

| Pd/MnFe2O4 (673 K) | 10 ± 3 | 64.3 | 13 ± 2 | 20.3 | 6 ± 1 | 4.61 | 78 | 99.9 (120 min) (323 K) | 95.7 (180 min) (293 K) | 95.8 (180 min) (293K) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hajdu, V.; Muránszky, G.; Nagy, M.; Kopcsik, E.; Kristály, F.; Fiser, B.; Viskolcz, B.; Vanyorek, L. Development of High-Efficiency, Magnetically Separable Palladium-Decorated Manganese-Ferrite Catalyst for Nitrobenzene Hydrogenation. Int. J. Mol. Sci. 2022, 23, 6535. https://doi.org/10.3390/ijms23126535

Hajdu V, Muránszky G, Nagy M, Kopcsik E, Kristály F, Fiser B, Viskolcz B, Vanyorek L. Development of High-Efficiency, Magnetically Separable Palladium-Decorated Manganese-Ferrite Catalyst for Nitrobenzene Hydrogenation. International Journal of Molecular Sciences. 2022; 23(12):6535. https://doi.org/10.3390/ijms23126535

Chicago/Turabian StyleHajdu, Viktória, Gábor Muránszky, Miklós Nagy, Erika Kopcsik, Ferenc Kristály, Béla Fiser, Béla Viskolcz, and László Vanyorek. 2022. "Development of High-Efficiency, Magnetically Separable Palladium-Decorated Manganese-Ferrite Catalyst for Nitrobenzene Hydrogenation" International Journal of Molecular Sciences 23, no. 12: 6535. https://doi.org/10.3390/ijms23126535

APA StyleHajdu, V., Muránszky, G., Nagy, M., Kopcsik, E., Kristály, F., Fiser, B., Viskolcz, B., & Vanyorek, L. (2022). Development of High-Efficiency, Magnetically Separable Palladium-Decorated Manganese-Ferrite Catalyst for Nitrobenzene Hydrogenation. International Journal of Molecular Sciences, 23(12), 6535. https://doi.org/10.3390/ijms23126535