Surfaces with Adjustable Features—Effective and Durable Materials for Water Desalination

Abstract

:1. Introduction

2. Results and Discussion

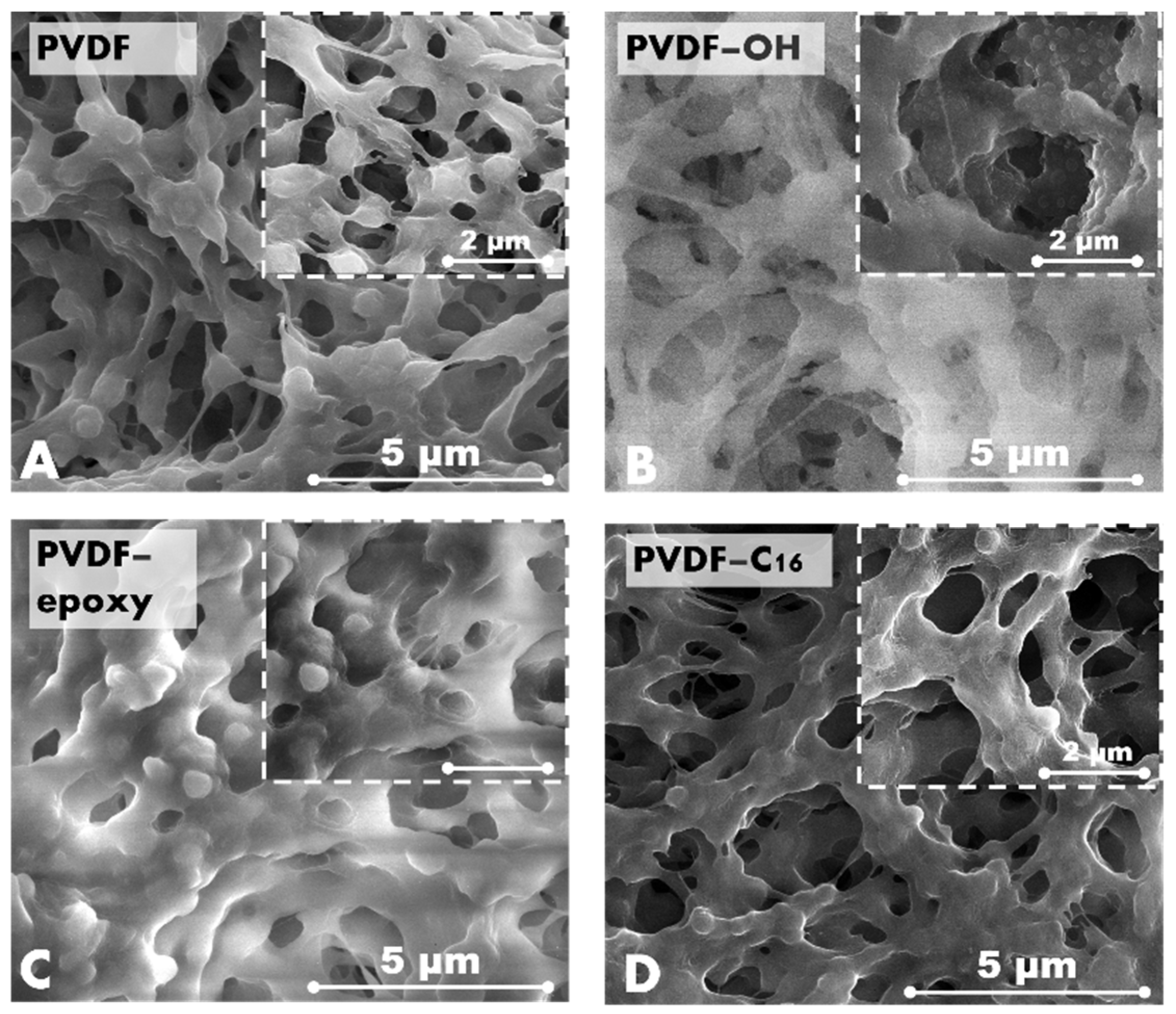

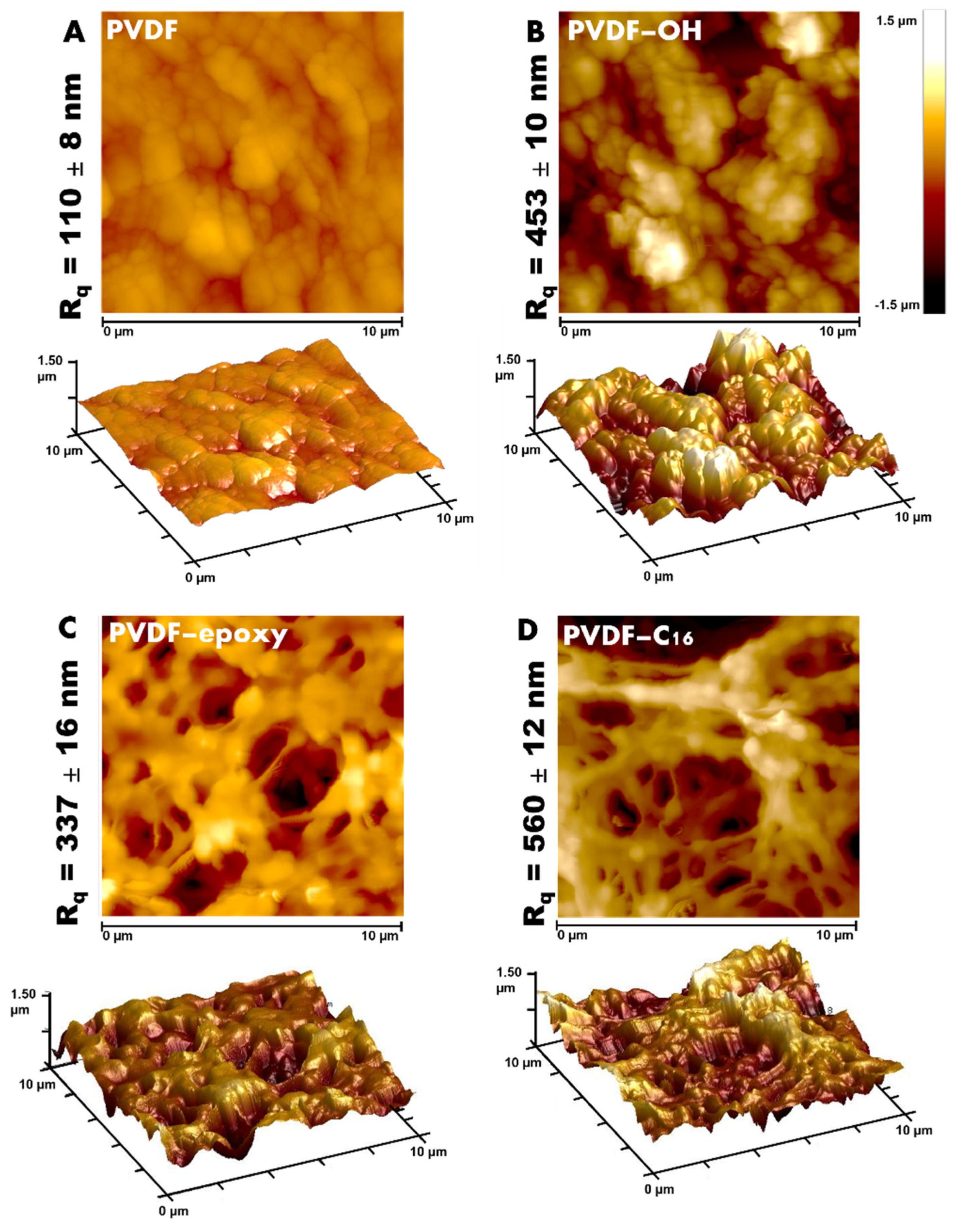

2.1. Impact on Morphology

2.2. Impact on Material Structure

2.3. Impact on Thermal Properties

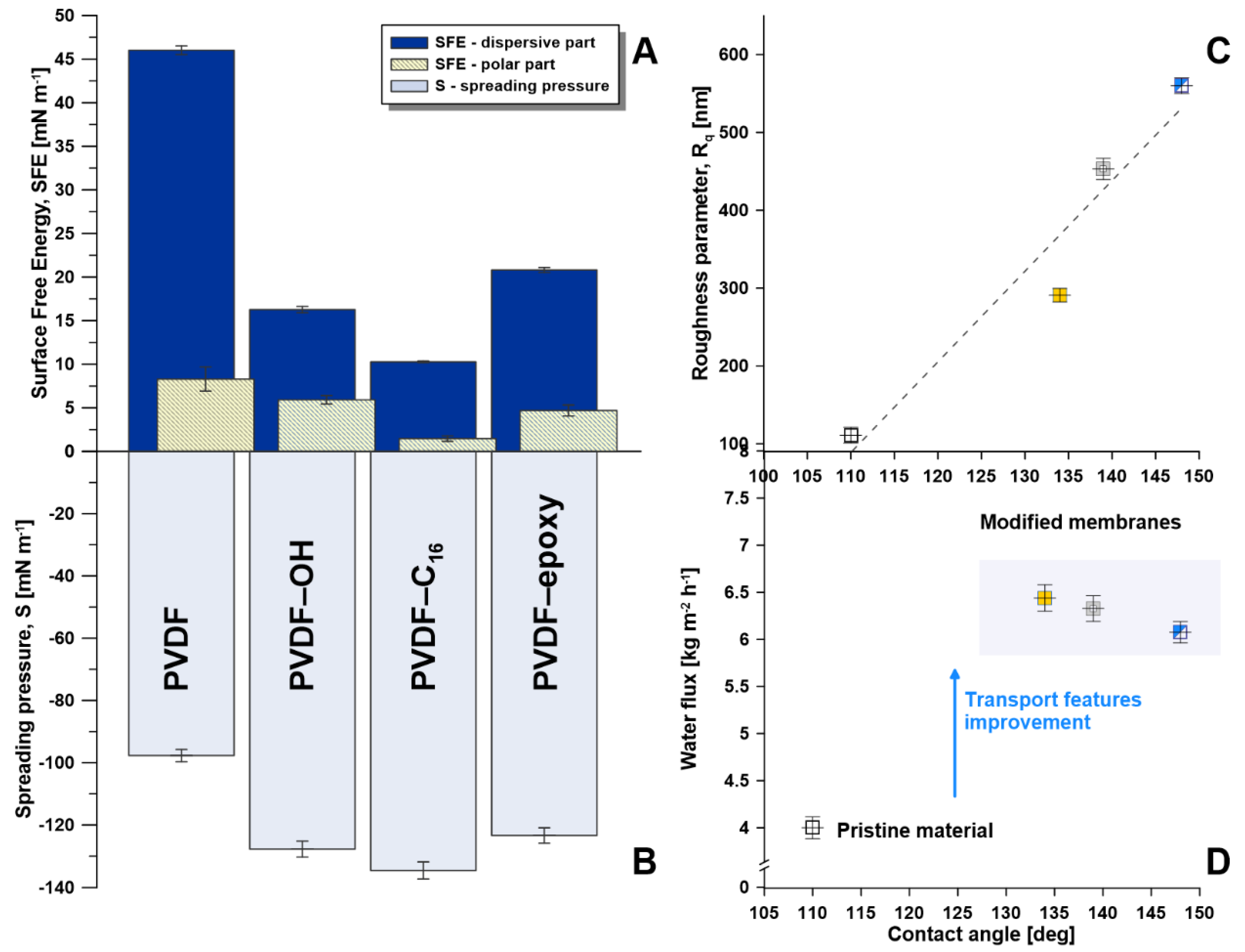

2.4. Impact on Wettability

2.5. Impact on Mechanical Features

2.6. Transport and Separation in Membrane Distillation

2.6.1. Water Transport

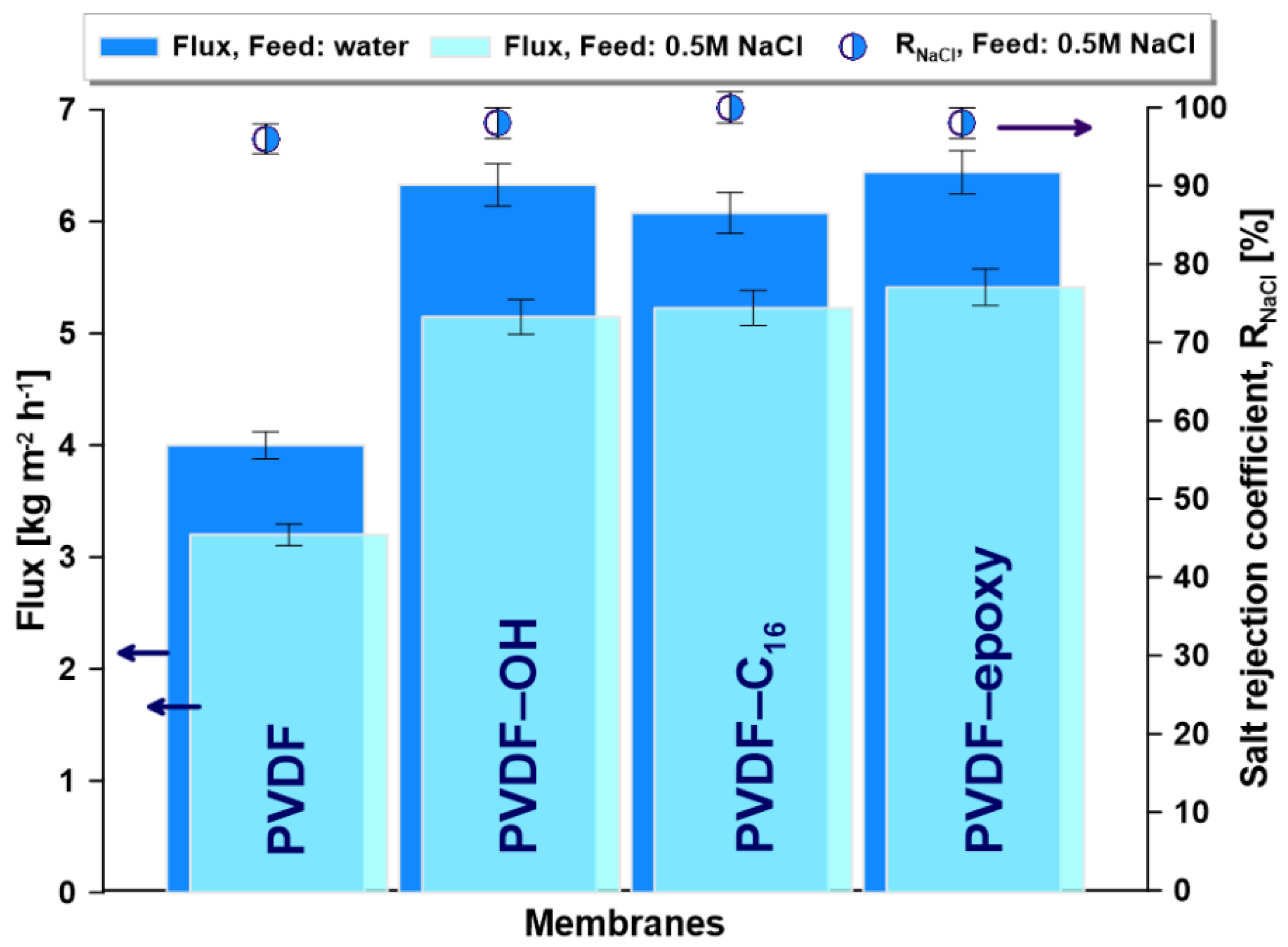

2.6.2. Desalination

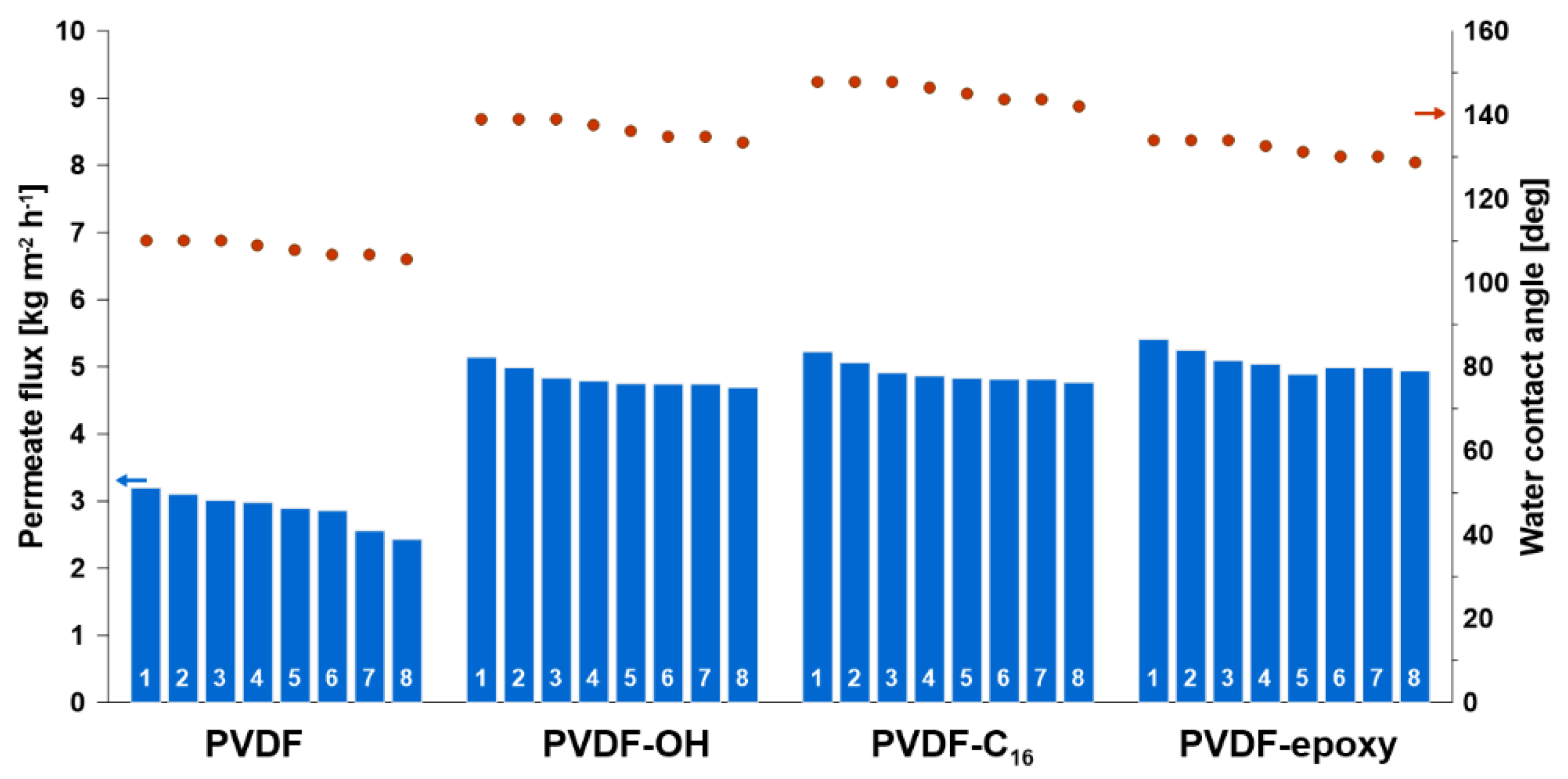

2.7. Stability

3. Materials and Methods

3.1. Materials

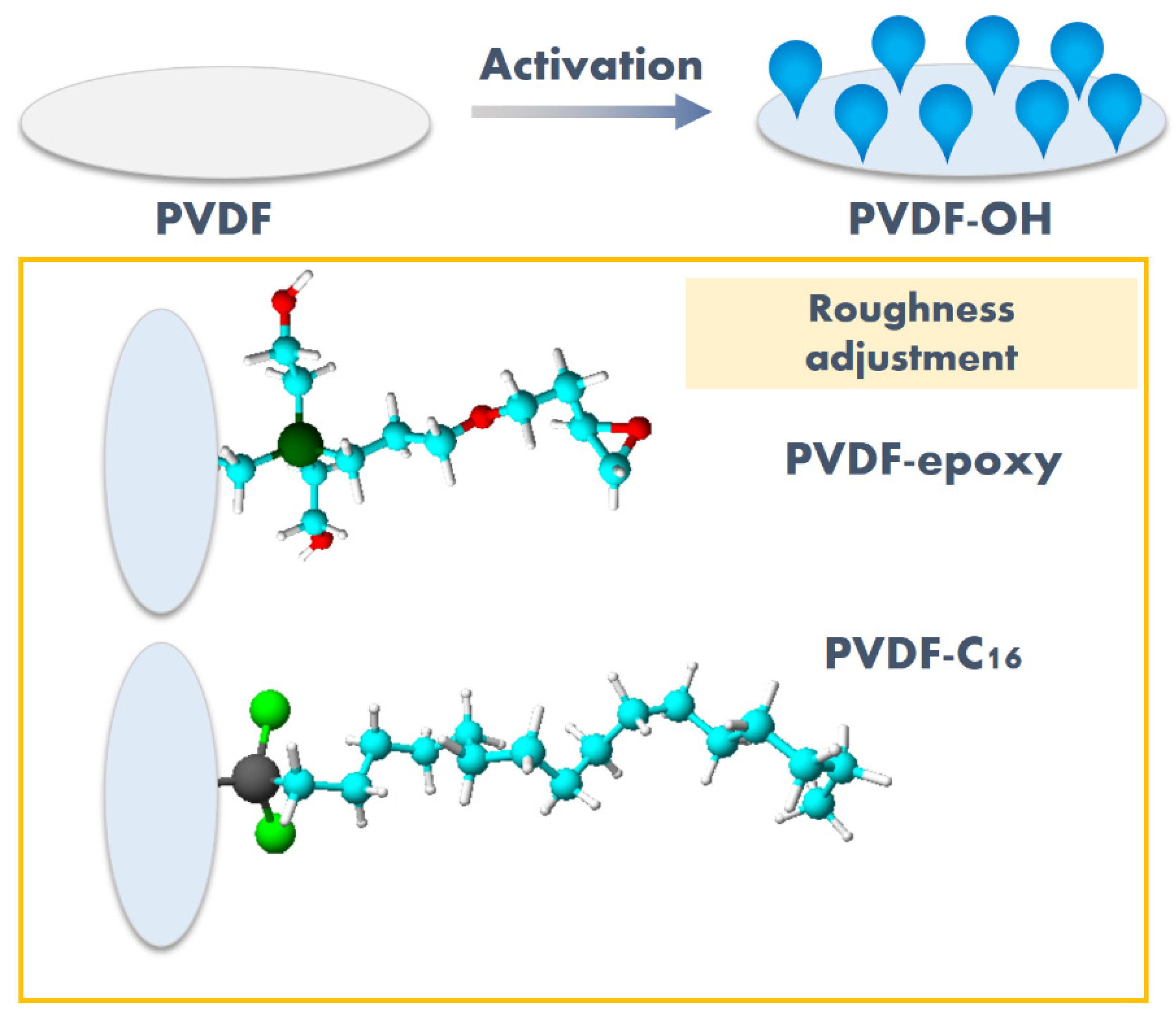

3.2. Membrane Modification Protocol

3.2.1. Activation Process

3.2.2. Material Functionalization

3.3. Membrane Characterization

3.4. Desalination Process

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Qing, W.; Wang, J.; Ma, X.; Yao, Z.; Feng, Y.; Shi, X.; Liu, F.; Wang, P.; Tang, C.Y. One-step tailoring surface roughness and surface chemistry to prepare superhydrophobic polyvinylidene fluoride (PVDF) membranes for enhanced membrane distillation performances. J. Colloid Interface Sci. 2019, 553, 99–107. [Google Scholar] [CrossRef]

- Mekonnen, M.M.; Hoekstra, A.Y. Four billion people facing severe water scarcity. Sci. Adv. 2016, 2, e1500323. [Google Scholar] [CrossRef] [Green Version]

- Dudchenko, A.V.; Chen, C.; Cardenas, A.; Rolf, J.; Jassby, D. Frequency-dependent stability of CNT Joule heaters in ionizable media and desalination processes. Nat. Nanotechnol. 2017, 12, 557–563. [Google Scholar] [CrossRef] [PubMed]

- Eryildiz, B.; Yuksekdag, A.; Korkut, S.; Koyuncu, I. Performance evaluation of boron removal from wastewater containing high boron content according to operating parameters by air gap membrane distillation. Environ. Technol. Innov. 2021, 22, 101493. [Google Scholar] [CrossRef]

- Alawad, S.M.; Khalifa, A.E. Performance and energy evaluation of compact multistage air gap membrane distillation system: An experimental investigation. Sep. Purif. Technol. 2021, 268, 118594. [Google Scholar] [CrossRef]

- Eang, C.; Opaprakasit, P. Electrospun Nanofibers with Superhydrophobicity Derived from Degradable Polylactide for Oil/Water Separation Applications. J. Polym. Environ. 2020, 28, 1484–1491. [Google Scholar] [CrossRef]

- Deka, B.J.; Lee, E.-J.; Guo, J.; Kharraz, J.; An, A.K. Electrospun Nanofiber Membranes Incorporating PDMS-Aerogel Superhydrophobic Coating with Enhanced Flux and Improved Antiwettability in Membrane Distillation. Environ. Sci. Technol. 2019, 53, 4948–4958. [Google Scholar] [CrossRef]

- Yan, K.-K.; Jiao, L.; Lin, S.; Ji, X.; Lu, Y.; Zhang, L. Superhydrophobic electrospun nanofiber membrane coated by carbon nanotubes network for membrane distillation. Desalination 2018, 437, 26–33. [Google Scholar] [CrossRef]

- Tian, M.; Zhu, J.; Yuan, S.; Zhang, Y.; Van der Bruggen, B. A co-casting route enables the formation of skinless, hydrophobic poly(vinylidene fluoride) membranes for DCMD. J. Membr. Sci. 2021, 630, 119299. [Google Scholar] [CrossRef]

- Xia, Q.-C.; Liu, M.-L.; Cao, X.-L.; Wang, Y.; Xing, W.; Sun, S.-P. Structure design and applications of dual-layer polymeric membranes. J. Membr. Sci. 2018, 562, 85–111. [Google Scholar] [CrossRef]

- Yang, J.; Li, H.-N.; Chen, Z.-X.; He, A.; Zhong, Q.-Z.; Xu, Z.-K. Janus membranes with controllable asymmetric configurations for highly efficient separation of oil-in-water emulsions. J. Mater. Chem. A 2019, 7, 7907–7917. [Google Scholar] [CrossRef]

- Afsari, M.; Shon, H.K.; Tijing, L.D. Janus membranes for membrane distillation: Recent advances and challenges. Adv. Colloid Interface Sci. 2021, 289, 102362. [Google Scholar] [CrossRef] [PubMed]

- Al-Gharabli, S.; Kujawa, J. Molecular activation of fluoropolymer membranes via base piranha treatment to enhance transport and mitigate fouling—New materials for water purification. J. Membr. Sci. 2021, 624, 119105. [Google Scholar] [CrossRef]

- Yuan, Y.; Tian, C.; Liu, J. PEDOT surface modified PVDF filtration membrane for conductive membrane preparation and fouling mitigation. J. Environ. Chem. Eng. 2021, 9, 105212. [Google Scholar] [CrossRef]

- Feng, Y.; Chen, P.; Zhu, Q.; Qin, B.; Li, Y.; Deng, Q.; Li, X.; Li, X.; Peng, C. Boron nitride nanosheet-induced low dielectric loss and conductivity in PVDF-based high-k ternary composites bearing ionic liquid. Mater. Today Commun. 2020, 26, 101896. [Google Scholar] [CrossRef]

- Zhong, X.; Han, J.; Chen, L.; Liu, W.; Jiao, F.; Zhu, H.; Qin, W. Binding mechanisms of PVDF in lithium ion batteries. Appl. Surf. Sci. 2021, 553, 149564. [Google Scholar] [CrossRef]

- Silva, A.J.D.J.; Contreras, M.M.; Nascimento, C.R.; da Costa, M.F. Kinetics of thermal degradation and lifetime study of poly(vinylidene fluoride) (PVDF) subjected to bioethanol fuel accelerated aging. Heliyon 2020, 6, e04573. [Google Scholar] [CrossRef]

- Wu, Y.; Li, Y.; Wang, Y.; Liu, Q.; Chen, Q.; Chen, M. Advances and prospects of PVDF based polymer electrolytes. J. Energy Chem. 2022, 64, 62–84. [Google Scholar] [CrossRef]

- Pascariu, P.; Cojocaru, C.; Samoila, P.; Olaru, N.; Bele, A.; Airinei, A. Novel electrospun membranes based on PVDF fibers embedding lanthanide doped ZnO for adsorption and photocatalytic degradation of dye organic pollutants. Mater. Res. Bull. 2021, 141, 111376. [Google Scholar] [CrossRef]

- Liu, Y.; Xiao, T.; Bao, C.; Fu, Y.; Yang, X. Fabrication of novel Janus membrane by nonsolvent thermally induced phase separation (NTIPS) for enhanced performance in membrane distillation. J. Membr. Sci. 2018, 563, 298–308. [Google Scholar] [CrossRef]

- Qing, W.; Shi, X.; Zhang, W.; Wang, J.; Wu, Y.; Wang, P.; Tang, C.Y. Solvent-thermal induced roughening: A novel and versatile method to prepare superhydrophobic membranes. J. Membr. Sci. 2018, 564, 465–472. [Google Scholar] [CrossRef]

- Xiong, B.; Li, J.; He, C.; Tang, X.; Lv, Z.; Li, X.; Yan, X. Effect of pore morphology and surface roughness on wettability of porous titania films. Mater. Res. Express 2020, 7, 115013. [Google Scholar] [CrossRef]

- Al-Gharabli, S.; Kujawski, W.; Arafat, H.; Kujawa, J. Tunable separation via chemical functionalization of polyvinylidenefluoride membranes using piranha reagent. J. Membr. Sci. 2017, 541, 567–579. [Google Scholar] [CrossRef]

- Haponska, M.; Trojanowska, A.; Nogalska, A.; Jastrzab, R.; Gumi, T.; Tylkowski, B. PVDF Membrane Morphology—Influence of Polymer Molecular Weight and Preparation Temperature. Polymers 2017, 9, 718. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Arahman, N.; Mulyati, S.; Fahrina, A. Morphology and performance of pvdf membranes composed of triethylphospate and dimethyl sulfoxide solvents. Mater. Res. Express 2019, 6, 66419. [Google Scholar] [CrossRef]

- Muthukumar, K.; Kaleekkal, N.J.; Lakshmi, D.S.; Srivastava, S.; Bajaj, H. Tuning the morphology of PVDF membranes using inorganic clusters for oil/water separation. J. Appl. Polym. Sci. 2019, 136, 47641. [Google Scholar] [CrossRef]

- Lovinger, A.J. Annealing of poly(vinylidene fluoride) and formation of a fifth phase. Macromolecules 1982, 15, 40–44. [Google Scholar] [CrossRef]

- Hasegawa, R.; Takahashi, Y.; Chatani, Y.; Tadokoro, H. Crystal Structures of Three Crystalline Forms of Poly(vinylidene fluoride). Polym. J. 1972, 3, 600–610. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, J.; Monteiro, T.; Lopes, A.C.; Costa, C.M.; Silva, M.M.; Machado, A.; Lanceros-Mendez, S. Variation of the physicochemical and morphological characteristics of solvent casted poly(vinylidene fluoride) along its binary phase diagram with dimethylformamide. J. Non-Cryst. Solids 2015, 412, 16–23. [Google Scholar] [CrossRef]

- Das, A.K.; Bhowmik, R.; Meikap, A.K. Surface functionalized carbon nanotube with polyvinylidene fluoride: Preparation, characterization, current-voltage and ferroelectric hysteresis behaviour of polymer nanocomposite films. AIP Adv. 2017, 7, 45110. [Google Scholar] [CrossRef] [Green Version]

- Eggedi, O.; Valiyaneerilakkal, U.; Darla, M.R.; Varghese, S. Nanoindentation and thermal characterization of poly (vinylidenefluoride)/MWCNT nanocomposites. AIP Adv. 2014, 4, 47102. [Google Scholar] [CrossRef] [Green Version]

- Kujawa, J.; Kujawski, W.; Cerneaux, S.; Li, G.; Al-Gharabli, S. Zirconium dioxide membranes decorated by silanes based-modifiers for membrane distillation—Material chemistry approach. J. Membr. Sci. 2019, 596, 117597. [Google Scholar] [CrossRef]

- Lipatov, Y.; Feinerman, A. Surface tension and surface free energy of polymers. Adv. Colloid Interface Sci. 1979, 11, 195–233. [Google Scholar] [CrossRef]

- Bartenev, G.M.; Akopyan, L.A. Surface free energy of polymers. Mater. Sci. 1972, 5, 560–565. [Google Scholar] [CrossRef]

- Korczeniewski, E.; Bryk, P.; Koter, S.; Kowalczyk, P.; Kujawski, W.; Kujawa, J.; Terzyk, A.P. Revisiting Wetting, Freezing, and Evaporation Mechanisms of Water on Copper. ACS Appl. Mater. Interfaces 2021, 13, 37893–37903. [Google Scholar] [CrossRef]

- Rudawska, A.; Jacniacka, E. Evaluating uncertainty of surface free energy measurement by the van Oss-Chaudhury-Good method. Int. J. Adhes. Adhes. 2018, 82, 139–145. [Google Scholar] [CrossRef]

- Park, S.-J.; Seo, M.-K. Chapter 2—Solid-gas interaction. In Interface Science and Technology; Park, S.-J., Seo, M.-K., Eds.; Elsevier: Amsterdam, The Netherlands, 2011; pp. 59–145. [Google Scholar]

- Kraus, E.; Orf, L.; Heilig, M.; Baudrit, B.; Starostina, I.; Stoyanov, O. Characterization of Polymer Surfaces by the Use of Different Wetting Theories Regarding Acid-Base Properties. Int. J. Polym. Sci. 2017, 2017, 4350470. [Google Scholar] [CrossRef] [Green Version]

- Starostina, I.A.; Makhrova, N.V.; Stoyanov, O.V.; Aristov, I.V. On the Evaluation of the Acidity and Basicity Parameters of the Surface Free Energy of Polymers. J. Adhes. 2012, 88, 751–765. [Google Scholar] [CrossRef]

- Della Volpe, C.; Siboni, S. Acid-base surface free energies of solids and the definition of scales in the Good-van Oss-Chaudhury theory. In Apparent and Microscopic Contact Angles; CRC Press: Boca Raton, FL, USA, 2014; pp. 181–218. [Google Scholar]

- Good, R.J. Spreading pressure and contact angle. J. Colloid Interface Sci. 1975, 52, 308–313. [Google Scholar] [CrossRef]

- Dorrer, C.; Rühe, J. Some thoughts on superhydrophobic wetting. Soft Matter 2008, 5, 51–61. [Google Scholar] [CrossRef]

- Moradi, R.; Karimi-Sabet, J.; Shariaty-Niassar, M.; Koochaki, A. Preparation and Characterization of Polyvinylidene Fluoride/Graphene Superhydrophobic Fibrous Films. Polymers 2015, 7, 1444–1463. [Google Scholar] [CrossRef] [Green Version]

- Miracle, D.; Wilks, G.; Dahlman, A.; Dahlman, J. The strength of chemical bonds in solids and liquids. Acta Mater. 2011, 59, 7840–7854. [Google Scholar] [CrossRef]

- Kwon, S.; Kim, T.-H. The effect of adjusting the hydrophilic–hydrophobic block length in densely sulfonated poly(fluorenyl ether sulfone) block copolymer membranes. Int. J. Hydrogen Energy 2017, 42, 11845–11856. [Google Scholar] [CrossRef]

- Erbil, H.Y.; Cansoy, C.E. Range of Applicability of the Wenzel and Cassie−Baxter Equations for Superhydrophobic Surfaces. Langmuir 2009, 25, 14135–14145. [Google Scholar] [CrossRef] [PubMed]

- Dalal, E.N. Calculation of solid surface tensions. Langmuir 1987, 3, 1009–1015. [Google Scholar] [CrossRef]

- Wu, S. Calculation of interfacial tension in polymer systems. J. Polym. Sci. Part C Polym. Symp. 1971, 34, 19–30. [Google Scholar] [CrossRef]

- Yonemoto, Y.; Kunugi, T. Estimating critical surface tension from droplet spreading area. Phys. Lett. A 2020, 384, 126218. [Google Scholar] [CrossRef]

- Goujon, F.; Ghoufi, A.; Malfreyt, P. Size-effects on the surface tension near the critical point: Monte Carlo simulations of the Lennard-Jones fluid. Chem. Phys. Lett. 2018, 694, 60–64. [Google Scholar] [CrossRef] [Green Version]

- Kebria, M.R.S.; Rahimpour, A.; Salestan, S.K.; Seyedpour, S.F.; Jafari, A.; Banisheykholeslami, F.; Kiadeh, N.T.H. Hyper-branched dendritic structure modified PVDF electrospun membranes for air gap membrane distillation. Desalination 2020, 479, 114307. [Google Scholar] [CrossRef]

- Ravi, J.; Othman, M.H.D.; Matsuura, T.; Bilad, M.R.; El-Badawy, T.; Aziz, F.; Ismail, A.; Rahman, M.A.; Jaafar, J. Polymeric membranes for desalination using membrane distillation: A review. Desalination 2020, 490, 114530. [Google Scholar] [CrossRef]

- Attia, H.; Alexander, S.; Wright, C.J.; Hilal, N. Superhydrophobic electrospun membrane for heavy metals removal by air gap membrane distillation (AGMD). Desalination 2017, 420, 318–329. [Google Scholar] [CrossRef] [Green Version]

- Liao, Y.; Wang, R.; Fane, A.G. Engineering superhydrophobic surface on poly(vinylidene fluoride) nanofiber membranes for direct contact membrane distillation. J. Membr. Sci. 2013, 440, 77–87. [Google Scholar] [CrossRef]

- Liao, Y.; Wang, R.; Fane, A.G. Fabrication of Bioinspired Composite Nanofiber Membranes with Robust Superhydrophobicity for Direct Contact Membrane Distillation. Environ. Sci. Technol. 2014, 48, 6335–6341. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Z.; Liu, Y.; Hou, H.; Shi, W.; Qu, F.; Cui, F.; Wang, W. Dual-Bioinspired Design for Constructing Membranes with Superhydrophobicity for Direct Contact Membrane Distillation. Environ. Sci. Technol. 2018, 52, 3027–3036. [Google Scholar] [CrossRef]

- Deka, B.J.; Guo, J.; Khanzada, N.K.; An, A.K. Omniphobic re-entrant PVDF membrane with ZnO nanoparticles composite for desalination of low surface tension oily seawater. Water Res. 2019, 165, 114982. [Google Scholar] [CrossRef] [PubMed]

- Xiao, Z.; Guo, H.; He, H.; Liu, Y.; Li, X.; Zhang, Y.; Yin, H.; Volkov, A.V.; He, T. Unprecedented scaling/fouling resistance of omniphobic polyvinylidene fluoride membrane with silica nanoparticle coated micropillars in direct contact membrane distillation. J. Membr. Sci. 2020, 599, 117819. [Google Scholar] [CrossRef]

- Zhao, D.; Zuo, J.; Lu, K.-J.; Chung, T.-S. Fluorographite modified PVDF membranes for seawater desalination via direct contact membrane distillation. Desalination 2017, 413, 119–126. [Google Scholar] [CrossRef]

- Ghorabi, S.; Ashtiani, F.Z.; Karimi, M.; Fouladitajar, A.; Yousefi, B.; Dorkalam, F. Development of a novel dual-bioinspired method for synthesis of a hydrophobic/hydrophilic polyethersulfone coated membrane for membrane distillation. Desalination 2021, 517, 115242. [Google Scholar] [CrossRef]

- Kharraz, J.; An, A.K. Patterned superhydrophobic polyvinylidene fluoride (PVDF) membranes for membrane distillation: Enhanced flux with improved fouling and wetting resistance. J. Membr. Sci. 2019, 595, 117596. [Google Scholar] [CrossRef]

- Kujawski, W.; Adamczak, P.; Narebska, A. A Fully Automated System for the Determination of Pore Size Distribution in Microfiltration and Ultrafiltration Membranes. Sep. Sci. Technol. 1989, 24, 495–506. [Google Scholar] [CrossRef]

- Kujawski, W.; Kujawa, J.; Wierzbowska, E.; Cerneaux, S.; Bryjak, M.; Kujawski, J. Influence of hydrophobization conditions and ceramic membranes pore size on their properties in vacuum membrane distillation of water–organic solvent mixtures. J. Membr. Sci. 2015, 499, 442–451. [Google Scholar] [CrossRef]

- Bharathidasan, T.; Narayanan, T.N.; Sathyanaryanan, S.; Sreejakumari, S. Above 170° water contact angle and oleophobicity of fluorinated graphene oxide based transparent polymeric films. Carbon 2015, 84, 207–213. [Google Scholar] [CrossRef]

- Zisman, W.A. Relation of the Equilibrium Contact Angle to Liquid and Solid Constitution. Adv. Chem. 1964, 43, 1–51. [Google Scholar] [CrossRef]

| Sample | Pore Size [µm] | Effect of Activation—Difference Referred to PVDF [%] | Effect of Functionalization—Difference Referred to PVDF-OH [%] | ||

|---|---|---|---|---|---|

| Min | Max | Aver | |||

| PVDF | 0.429 | 0.662 | 0.551 | - | - |

| PVDF-OH | 0.571 | 0.837 | 0.747 | +35.5 | - |

| PVDF-epoxy | 0.515 | 0.755 | 0.703 | +27.6 | −5.9 |

| PVDF-C16 | 0.530 | 0.782 | 0.681 | +23.6 | −8.8 |

| Sample | LEP [kPa] | γcr [mN m−1] | Fa [nN] | E [GPa] | H [GPa] |

|---|---|---|---|---|---|

| PVDF | 74.40 | 32.3 ± 1.1 | 24.8 ± 1.1 | 2.11 ± 0.06 | 0.132 ± 0.010 |

| PVDF-OH | 129.84 | 28.3 ± 1.0 | 35.0 ± 1.1 | 2.23 ± 0.06 | 0.222 ± 0.013 |

| PVDF-C16 | 161.24 | 25.4 ± 1.1 | 31.7 ± 1.0 | 2.33 ± 0.06 | 0.231 ± 0.016 |

| PVDF-epoxy | 132.49 | 27.6 ± 1.1 | 36.2 ± 1.2 | 2.33 ± 0.06 | 0.224 ± 0.013 |

| Sample | (pi/L) [kg m−2 h−1 bar−1] | K [kg m−2 s−1 Pa−1] |

|---|---|---|

| PVDF | 27.23 | 0.75 × 10−8 |

| PVDF-OH | 43.06 | 1.20 × 10−8 |

| PVDF-C16 | 41.36 | 1.15 × 10−8 |

| PVDF-epoxy | 43.84 | 1.22 × 10−8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Gharabli, S.; Abu El-Rub, Z.; Hamad, E.; Kujawski, W.; Flanc, Z.; Pianka, K.; Kujawa, J. Surfaces with Adjustable Features—Effective and Durable Materials for Water Desalination. Int. J. Mol. Sci. 2021, 22, 11743. https://doi.org/10.3390/ijms222111743

Al-Gharabli S, Abu El-Rub Z, Hamad E, Kujawski W, Flanc Z, Pianka K, Kujawa J. Surfaces with Adjustable Features—Effective and Durable Materials for Water Desalination. International Journal of Molecular Sciences. 2021; 22(21):11743. https://doi.org/10.3390/ijms222111743

Chicago/Turabian StyleAl-Gharabli, Samer, Ziad Abu El-Rub, Eyad Hamad, Wojciech Kujawski, Zuzanna Flanc, Katarzyna Pianka, and Joanna Kujawa. 2021. "Surfaces with Adjustable Features—Effective and Durable Materials for Water Desalination" International Journal of Molecular Sciences 22, no. 21: 11743. https://doi.org/10.3390/ijms222111743

APA StyleAl-Gharabli, S., Abu El-Rub, Z., Hamad, E., Kujawski, W., Flanc, Z., Pianka, K., & Kujawa, J. (2021). Surfaces with Adjustable Features—Effective and Durable Materials for Water Desalination. International Journal of Molecular Sciences, 22(21), 11743. https://doi.org/10.3390/ijms222111743