Abstract

The potassium salt of E- and Z-2,3-diphenylpropenoic acids prepared in situ could be esterified efficiently in DMSO with the appropriate alkyl halides at room temperature. In this way 10 previously undescribed esters of these acids were synthesised and characterised. Excellent yields were observed for most of the E isomers and the more hindered Z esters were also obtained in good yields, far better than those obtained applying the classical acid-catalysed esterification reaction.

Introduction

According to published accounts, the acid-catalysed esterification reaction can be conveniently used for preparing various esters of E-2,3-diphenylpropenoic acid (E-1), while it is not applicable for the Z isomer (Z-1), due to steric congestion in the transition state [1,2]. For illustration purposes the reactivities of the two isomers were studied under the acid-catalysed esterification conditions and compared to that of the saturated analogue, 2,3-diphenylpropionic acid (Table 1).

Table 1.

Esterification by the CH3OH/H2SO4/reflux method a

| Acid | Reaction time h | Yield %a |

|---|---|---|

| 2,3-Diphenylpropionic acid | 0.5 | 94 |

| E-2,3-Diphenylpropenoic acid | 4 | 77 |

| Z-2,3-Diphenylpropenoic acid | 15 | 17 |

aSee Experimental part

It can be seen that the reactivities of the unsaturated acids were lower than those of the saturated one and for the Z isomer the ester yield was very low, in spite of the prolonged reaction time. Accordingly, the synthesis of the methyl or the ethyl esters of E-2,3-diphenylpropenoic acid by the ROH/H+/reflux method is suggested [3,4], while the methyl ester of the Z isomer can be obtained in another way, through the reaction with diazomethane [5].

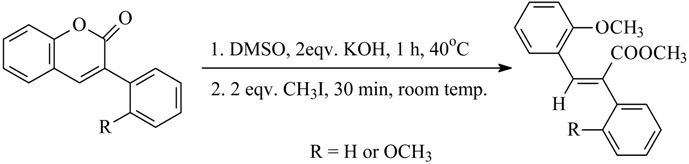

Another important method for producing esters is the reaction of the carboxylate anion with alkylating reagents. Variations in the method are possible: the counter ion (cation), the solvent and the alkylating agent may all be altered [6,7,8,9,10,11,12]. Not long ago we described the preparation of the methyl esters of o-methoxy-substituted Z-2,3-diphenylpropenoic acids from the corresponding 3-phenyl-coumarin using the DMSO/KOH/CH3I system [13]:

Since it is highly probable that the first step in the reaction is the formation of the bis-potassium salt of the phenolic carboxylic acid, which further reacts with methyl iodide, it seemed to be plausible to find out whether the DMSO/KOH/alkyl halide system can be used for the esterification of E- (E-1) and Z-2,3-diphenylpropenoic (Z-1) acids with special emphasis on the latter.

Results and discussion

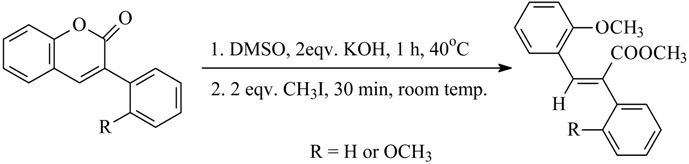

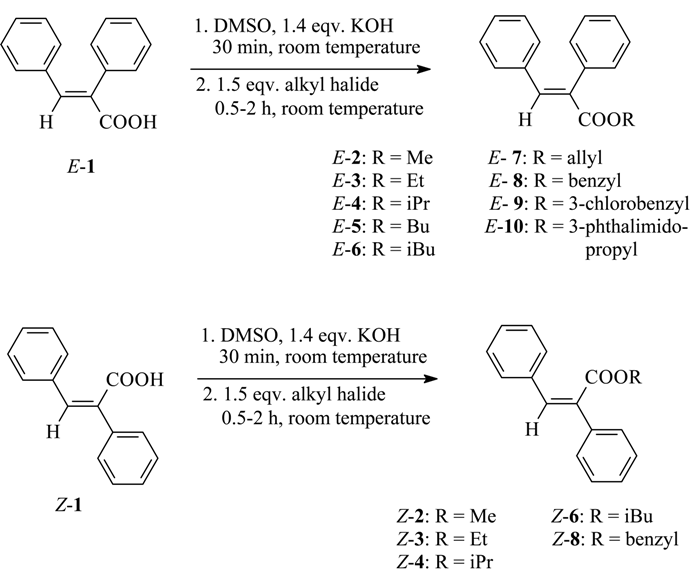

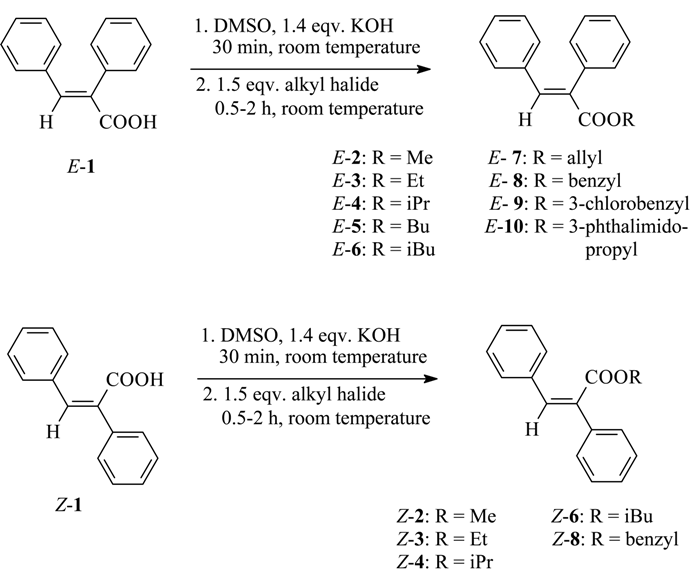

In our procedure 1.4 equivalents of powdered KOH were added to the carboxylic acid dissolved in DMSO. The mixture was stirred for 30 min then it was reacted with 1.5 equivalents of various alkyl halides at room temperature for a preset reaction time and the ester was isolated by pouring it into water. Through application of this method 10 as yet undescribed esters of the two carboxylic acids were prepared, besides the already known E-2 [2], Z-2 [2], E-3 [4], Z-3 [4] and E-4 [14] esters:

The results obtained are summarised in Table 2 and Table 3. The yields depended on the relative reactivities of the corresponding alkyl halides.

Table 2.

Preparation of various esters of E- (E-1) and Z-2,3-diphenylpropenoic acid (Z-1)a

| Entry | Acid | Alkyl halide | Reaction time (h) | Ester Formula | Yielda (%) |

|---|---|---|---|---|---|

| 1 | E-1 | MeI | 0.5 | E-2 C16H14O2 | 95 |

| 2 | Z-1 | MeI | 0.5 | Z-2 C16H14O2 | 91 |

| 3 | E-1 | EtI | 0.5 | E-3 C17H16O2 | 80 |

| 4 | E-1 | EtBr | 1 | E-3 C17H16O2 | 75 |

| 5 | Z-1 | EtI | 0.5 | Z-3 C17H16O2 | 78 |

| 6 | E-1 | iPrBr | 2 | E-4 C18H18O2 | 36 |

| 7 | Z-1 | iPrBr | 2 | Z-4 C18H18O2 | 38 |

| 8 | E-1 | BuI | 1 | E-5 C19H20O2 | 91 |

| 9 | E-1 | BuBr | 1 | E-5 C19H20O2 | 55 |

| 10 | E-1 | BuCl | 1 | E-5 C19H20O2 | 2-3 |

| 11 | E-1 | iBuI | 1 | E-6 C19H20O2 | 31 |

| 12 | Z-1 | iBuI | 1 | Z-6 C19H20O2 | 38 |

| 13 | E-1 | Allyl bromide | 1 | E-7 C18H16O2 | 79 |

| 14 | E-1 | BnBr | 1 | E-8 C22H18O2 | 82 |

| 15 | E-1 | BnCl | 1 | E-8 C22H18O2 | 75 |

| 16 | Z-1 | BnBr | 1 | Z-8 C22H18O2 | 78 |

| 17 | E-1 | 1-Bromo-3-chloropropane | 1 | E-9 C18H17ClO2 | 79 |

| 18 | E-1 | 2-Bromoethyl phenylether | 1 | E-10 C23H19O3 | 83 |

| 19 | E-1 | N-(3-Bromopropyl)-phthalimide | 1 | E-11 C26H21NO4 | 92 |

aSee Experimental part

Conclusions

Ten new propenoic acid esters were synthesized (and characterised) along with some known derivatives, starting from the corresponding acids applying the DMSO/KOH/alkyl halide method. The reactions were simple, the reaction times were shorter and the yields were much higher with regards to the Z isomer than in any of the other known methods.

Experimental

General

The E- and Z-2,3-diphenylpropenoic acids were prepared according to a known procedure [1]. The alkyl halides were Fluka or Aldrich products. The DMSO was dried over a molecular sieve and distilled before use. The purities of the products were checked by thin-layer chromatography (Fluka 60778 Silica gel TLC card, 5% EtOH in benzene). The 1H- (500 MHz) and 13C-NMR (125 MHz) spectra were recorded with a Bruker DRX 500 instrument in CDCl3 solutions. The GC-MS measurements were performed on a HP Model 5890 GC/HP 5970 MS (EI, 70 eV) instrument. Chromatography was done on a 30-m HP-1 capillary column, the heating program was: 100°C for 3 min, then 10°C/min to 250°C. Analytical samples were obtained either by crystallisation from aqueous ethanol or acetone or, for oily products, after column chromatography (silica gel, 1:1 hexane-CH2Cl2). Isolated yields are tabulated in Table 1 and Table 2.

General Procedures

Acid-catalysed esterification

The carboxylic acid (2.5 mmol) was dissolved in methanol (30 mL), then conc. H2SO4 (0.5 mL) was added and the mixture was refluxed. The reaction was followed by thin-layer chromatography. The excess alcohol was evaporated, the residue was dissolved in diethyl ether (30 mL), the ethereal solution was washed free of acid, then dried and the ether was evaporated.

Esterification with the DMSO/KOH/alkyl halide system

The carboxylic acid (10 mmol) was dissolved in DMSO (15 mL), then powdered KOH (0.75 g, 14 mmol) was added and the mixture was stirred for 30 min. Then the alkyl halide (15 mmol) was added under continuous stirring. Stirring was continued for the preset time given in Table 2, then the mixture was poured into cold water (70 mL) and the precipitated product was extracted with diethyl ether. The ethereal solution was washed free of acid, dried and the ether was evaporated. Besides the already described compounds the new molecules prepared by this method were as follows: isopropyl Z-2,3-diphenylpropenoate (Z-4), butyl E-2,3-diphenylpropenoate (E-5), isobutyl E-2,3-diphenylpropenoate (E-6); isobutyl Z-2,3-diphenylpropenoate (Z-6); allyl E-2,3-diphenylpropenoate (E-7); benzyl E-2,3-diphenylpropenoate (E-8); 3-chloropropyl E-2,3-diphenylpropenoate (E-9); 2-phenoxyethyl E-2,3-diphenylpropenoate (E-10); 3-phtalimidopropyl E-2,3-diphenylpropenoate (E-11).

Table 3.

Physical and spectroscopic data of various esters of E- (E-1) and Z-2,3-diphenylpropenoic acid (Z-1)

| Ester | M.p. °C (Lit.) | nD20 | Rf | 1H-NMR δ, ppm, CDCl3 | 13C-NMR δ, ppm, CDCl3 | GC-MS Rt (min) and m/z (rel.int. %) |

|---|---|---|---|---|---|---|

| E-2 | 75-76(75-76 [2]) | – | 0.81 | excellent agreement with literature data [15] | 29.8; 238 (M+, 72), 205 (15), 179 (93), 178 (100), 152 (23), 121 (84) | |

| Z-2 | oil | 1.6198 | 0.83 | excellent agreement with literature data [15] | 31.4; 238 (M+, 66), 205(14), 179 (90), 178 (100), 152 (26), 121 (86) | |

| E-3 | oil | 1.5960 | 0,83 | 1.26-1.29 (t, 3H), 4.23-4.27 (q, 2H), 7.02-7.35 (m, 10H), 7.83 (s, 1H) | 14.2, 61.1, 127.6, 128.1, 128.4, 128.8, 129.7, 130.4, 132.7, 134.6, 135.8, 140.0, 167.7 | 31.2; 252 (M+, 67), 179 (90), 178 (100), 152 (23), 135 (50), 107 (36) |

| Z-3 | oil | 1.6073 | 0.86 | 1.16-1.19 (t, 3H), 4.23-4.27 (q, 2H), 7.02 (s, 1H), 7,30-7,47 (m, 10H) | 13.8, 61.2, 126.4, 128.1, 128.2, 128.3, 128.6, 131.1, 135.3, 135.8, 136.9, 169.5 | 32.9; 252 (M+, 65), 179 (94), 178 (100), 152 (25), 135 (51), 107 (37) |

| E-4 | 68-70(70-71 [14]) | – | 0.89 | 1.26-1.27 (d, 6H), 5.12-5.14 (m, 1H), 7.02-7.35 (m, 10H),7.84 (s, 1H) | 21.8, 68.5, 127.6, 128.1, 128.4, 128.7, 129.8, 130.4, 133.2, 134.7, 135.9, 139.6, 167.2 | 31.4; 266 (M+, 48), 179 (100), 178 (93), 152 (20), 118 (20), 107 (27) |

| Z-4 | 49-51 | – | 0.91 | 1.17-1.19 (d, 6H), 5.17-5.20 (m, 1H), 7.01 (s, 1H),7.28-7.47 (m, 10H) | 21.4, 68.9, 126.3, 128.1, 128.2, 128.3, 128.35, 128.6, 130.6, 135.7, 135.8, 137.0, 169.1 | 33.7; 266 (M+, 48), 179 (100), 178 (92), 152 (21), 118 (20), 107 (27) |

| E-5 | oil | 1.5788 | 0.93 | 0.89-0.92 (t, 3H), 1.32-1.42 (m, 2H), 1.60-1.65 (m, 2H), 4.18-4.21 (t, 2H), 7.03-7.34 (m, 10H), 7.82 (s, 1H) | 13.6, 19.1, 30.6, 64.9, 127.6, 128.1, 128.4, 128.8, 129.7, 130.5, 134.3, 132.7, 136.0, 139.9, 167.8 | 39; 80 (M+, 49), 224 (25), 179 (100), 178 (90), 152 (19), 107 (43) |

| E-6 | oil | 1.5765 | 0.88 | 0.87-0.88 (d, 6H), 1.91-1.94 (m, 1H), 3.97-3.98 (d, 2H), 7.04-7.34 (m, 10H) 7.84 (s, 1H) | 19.1, 27.8, 71.2, 127.7, 128.1, 128.5, 128.9, 129.7, 129.9, 130.6 132.9, 134.7, 136.1, 140.0, 167.8 | 37; 280 (M+, 38), 224 (24), 207 (14), 179 (100), 178 (80), 152 (16), 107 (28) |

| Z-6 | oil | 1.5860 | 0.92 | 0.76-0.77 (d, 6H), 1.83-1.85 (m, 1H), 3.95-3.96 (d, 2H), 7.03 (s, 1H), 7.26-7.47 (m, 10H) | 19.0, 27.4, 71.6, 126.4, 128.2, 128.3, 128.5, 128.7, 132.1, 135.5, 135.9, 136.9, 169.8 | 37.9; 280 (M+, 33), 224 (21), 207 (15), 179 (100), 178 (84), 152 (16), 107 (23) |

| E-7 | oil | 1.6013 | 0.85 | 4.68-4.70 (m, 2H), 5.17-5.26 (m, 2H), 5.89-5.95 (m, 1H), 7.03-7.34 (m, 10H), 7.86 (s, 1H) | 65.5, 117.6, 127.7, 128.1, 128.5, 128.9, 129.7, 130.5, 132.1, 132.5, 134.6, 135.8, 140.4, 167.3 | 34.4; 264 (M+, 56), 179 (82), 178 (100), 152 (25), 105 (26) |

| E-8 | 59-61 | – | 0.88 | 5.24 (s, 2H), 7.02-7.34 (m, 15H), 7.86 (s, 1H) | 66.6, 127.71, 127.74, 127.9, 128.1, 128.4, 128.5, 129.0, 129.7, 130.5, 132.4, 134.5, 135.7, 136.1, 140.5, 167.4 | – |

| Z-8 | 69-71 | – | 0.93 | 5.20 (s, 2H), 7.01 (s, 1H), 7.15-7.43 (m, 15H) | 67.2, 126.5, 128.3, 128.4, 128.5, 128.7, 128.8, 131.7, 135.0, 135.1, 135.7, 136.9, 169.4 | – |

| E-9 | oil | 1.5983 | 0.92 | 2.04-2.10 (m, 2H), 3.473.50 (t, 2H), 4.31-4.33 (t, 2H), 7.03-7.34 (m, 10H), 7.83 (s, 1H) | 31.5, 41.1, 61.7, 127.7, 128.1, 128.5, 129.0, 129.6, 130.5, 132.4, 134.5, 135.8, 140.4, 167.4, | 48.2; 300 (M+, 37), 179 (100), 178 (99), 152 (21), 107 (39) |

| E-10 | 78-80 | – | 0.51 | 4.18-4.19 (t, 2H), 4.52-4.54 (t, 2H), 6.88-7.32 (m, 15H), 7.84 (s, 1H) | 63.7, 66.1, 115.0, 121.3, 128.0, 128.3, 128.7, 129.2, 129.7, 129.8, 130.0, 130.8, 132.5,, 134.7, 135.8, 140.9, 158.8, 167.8 | – |

| E-11 | 77-77.5 | – | 0.75 | 2.04-2.09 (m, 2H), 3.74-3.77 (t, 2H), 4.24-4.27 (t, 2H), 7,0-7.81 (m, 14H), 7.78 (s, 1H) | 27.6, 35.0, 62.4, 123.1, 127.7, 128.0, 128.5, 128.9, 129.7, 130.6, 132.0, 132.4, 133.8, 143.5, 135.7, 140.3, 167.5, 168.2 | – |

Acknowledgements

This work was supported by the National Science Fund of Hungary through grant OTKA T034184. The financial help is highly appreciated.

References

- Fischer, L. F. Experiments in Organic Chemistry; Heath and Co.: Boston, 1957; pp. 182–185. [Google Scholar]

- Geirsson, J. K. F.; Gudmundsson, B. Ö.; Sigurdardottir, R. Unexpected lack of stereoselectivity in the Horner-Wadsworth-Emmond reaction when applied to the synthesis of E- and Z-methyl α-arylcinnamates. Acta Chem. Scand. 1993, 47, 1112–1116. [Google Scholar] [CrossRef]

- Bergens, S. H.; Noheda, P.; Whelan, J.; Bosnich, B. Asymmetric catalysis. Production of chiral diols by enantioselective catalytic intramolecular hydrosililation of olefins. J. Am. Chem. Soc. 1992, 114, 2121–2128. [Google Scholar]

- Newkome, G. R.; Robinson, J. M. Chemistry of heterocyclic compounds. 22. Condensation reactions of 2-substituted pyridines. J. Org. Chem. 1976, 41, 2536–2541. [Google Scholar] [CrossRef]

- Deleux, J. P.; Leroy, G.; Weiler, J. Pyrazoline ring. I. cis- and trans-3,4-diphenyl-3- (methoxycarbonyl)-1-pyrazolines. Tetrahedron 1973, 29, 1135–1144. [Google Scholar] [CrossRef]

- Ogliaruso, M. A.; Wolfe, J. F. Supplement B: The chemistry of acid derivatives, Part 1; (ed. S. Patai); J. Wiley and Sons: New York, 1979; pp. 415–436. [Google Scholar]

- Chakraborti, A. K.; Basak, A.; Grover, V. Chemoselective protection of carboxylic acid as methyl ester: A practical alternative to diazomethane protocol. J. Org. Chem. 1999, 64, 8014–8017. [Google Scholar] [CrossRef]

- Fatope, M. O.; Adeniyi, A. E. Enhanced methylation of sodium carboxylates in methyl ethyl ketone. The effect of quaternary ammonium salt. Synth. Commun. 1985, 15, 307–310. [Google Scholar] [CrossRef]

- Barry, J.; Bram, G.; Decodts, G.; Loupy, A.; Orange, C.; Petit, A.; Sansoulet, J. Solid-liquid phase-transfer catalysis without added solvent. A simple, efficient, and inexpensive synthesis of aromatic carboxylic esters by alkylation of potassium carboxylates. Synthesis 1985, 40–45. [Google Scholar]

- Lee, J. C.; Choi, Y. An improved method for preparation of carboxylic esters using CsF-Celite/alkyl halide/CH3CN. Synth. Commun. 1998, 28, 2021–2026. [Google Scholar]

- Le Bigot, Y.; Delmas, M.; Gorrichon, J.P.; Gaset, A. Synthesis of furoates and furfurylic alcohol esters under very mild conditions using supported base catalysts. A. Synth. Commun. 1982, 12, 327–332. [Google Scholar] [CrossRef]

- Xu, R.; Sim, M-K.; Go, M.-L. Synthesis, antimuscarinic activity and quantitative structure-activity relationship (QSAR) of tropinyl and piperidinyl esters. Chem. Pharm. Bull. 1998, 46, 231–241. [Google Scholar] [CrossRef] [PubMed]

- Felföldi, K.; Sutyinszki, M.; Nagy, N.; Pálinkó, I. Synthesis of E- and Z-o-methoxy-substituted 2,3-diphenyl propenoic acids and its methyl esters. Synth. Commun. 2000, 30, 1543–1553. [Google Scholar] [CrossRef]

- Bordwell, F. G.; Crooks, S.C. Relative rates of cleavage by alkoxide ions of diphenylcyclopropenne and diphenylthiirene 1,1-dioxide. J. Am. Chem. Soc. 1969, 91, 2084–2086. [Google Scholar] [CrossRef]

- Bradley, J. C.; Durst, T. Base-catalyzed ring openings of benzocyclobutenones and -ols. Can. J. Chem. 1995, 73, 1660–1665. [Google Scholar] [CrossRef]

- Sample availability: Contact the authors

© 2004 by MDPI (http:www.mdpi.org). Reproduction is permitted for noncommercial purposes.