Unlocking the Potential of Thermal Post-Treatments: A Study on Odor Emission Control in Eucalyptus Wood Particleboard

Abstract

1. Introduction

2. Results

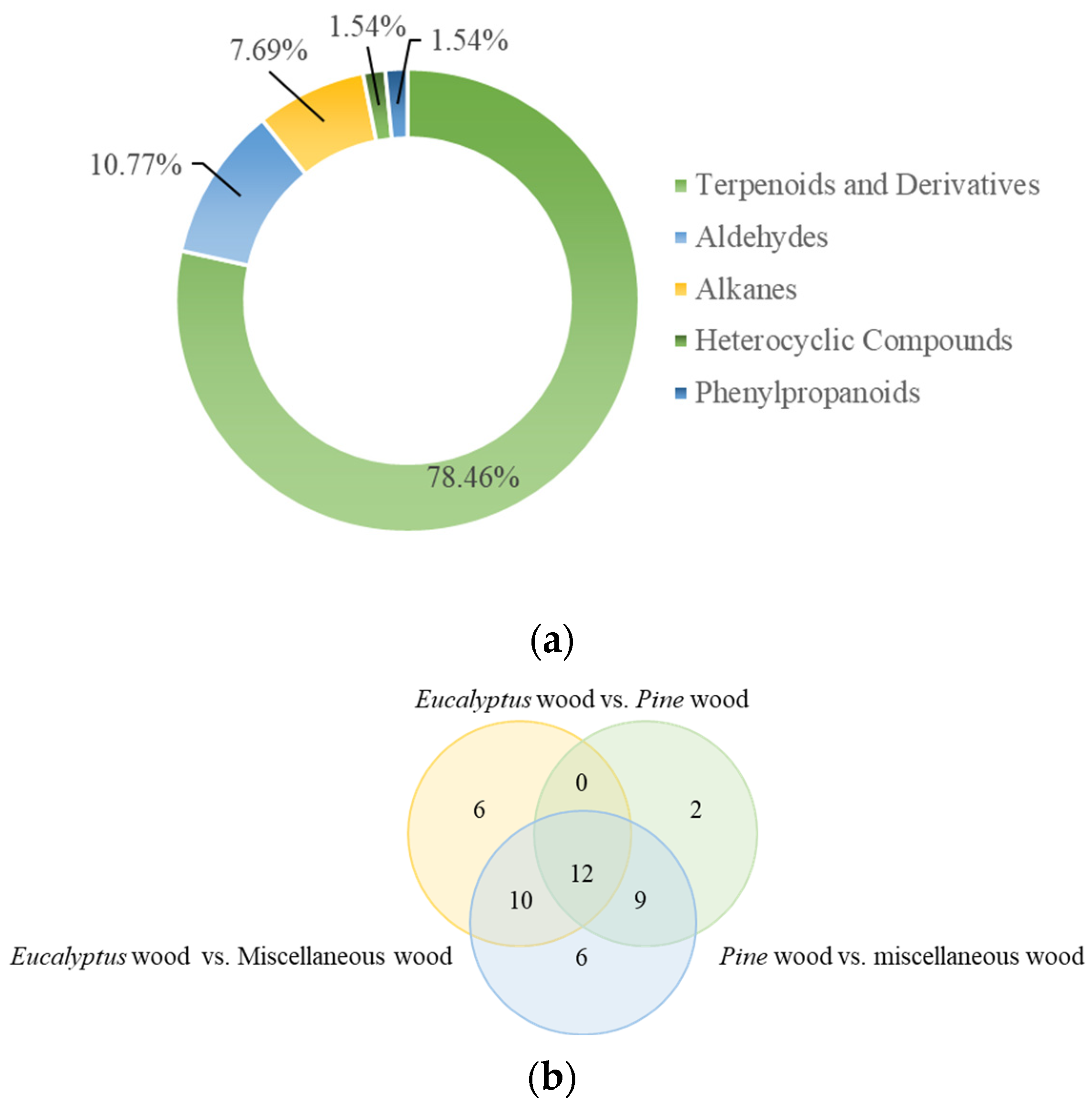

2.1. Identification of VOCs

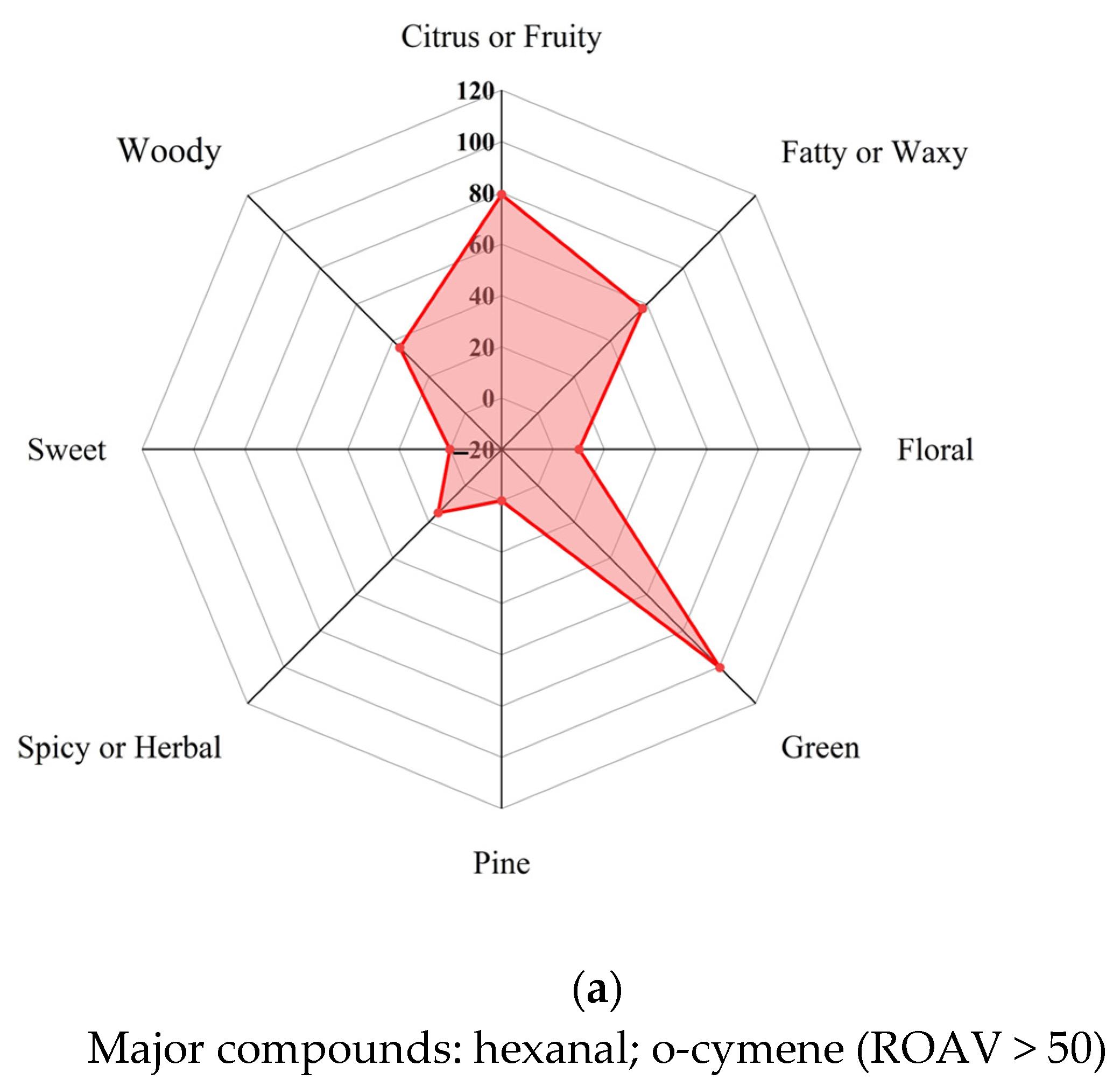

2.2. Analysis of KOCs

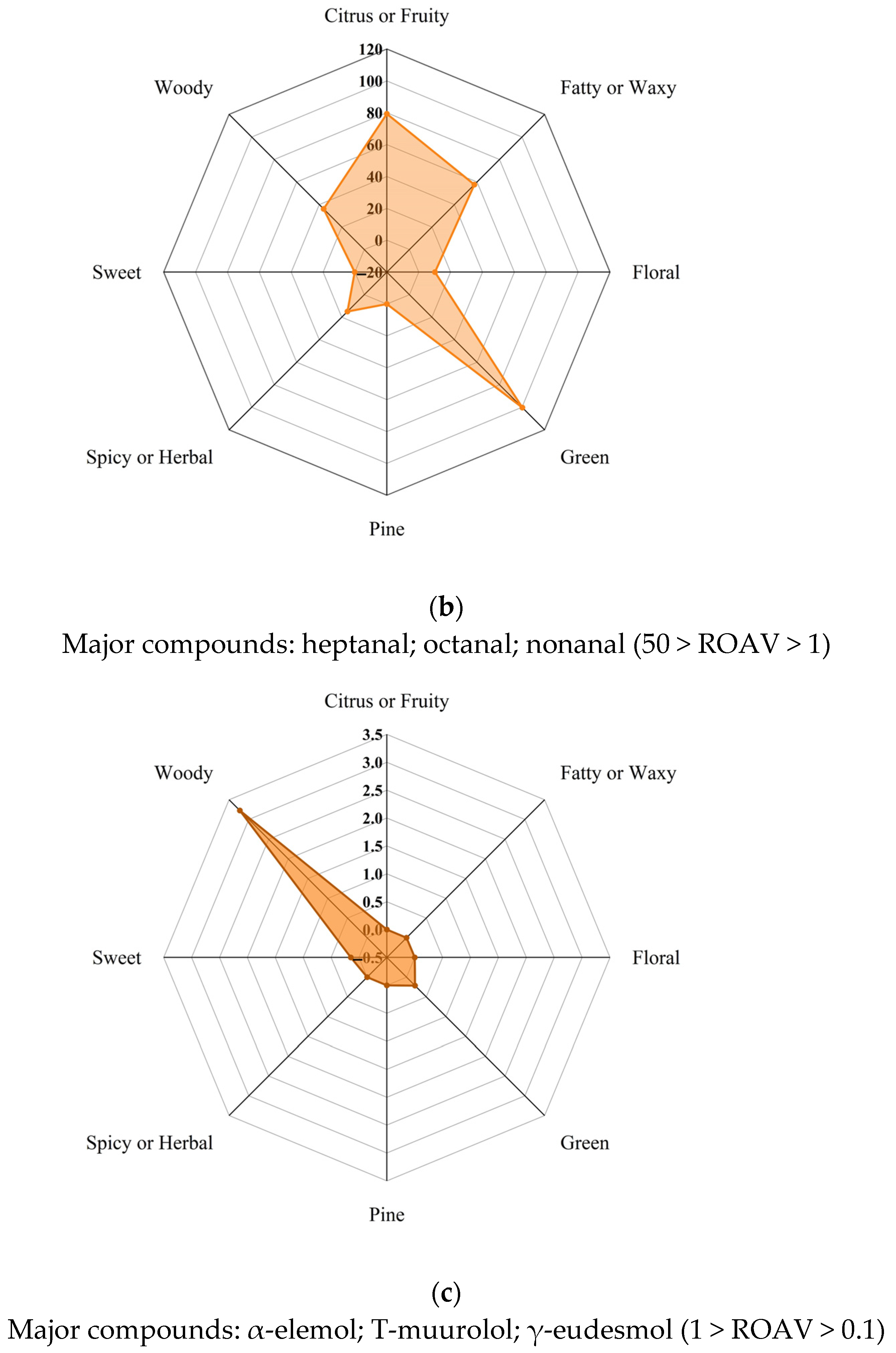

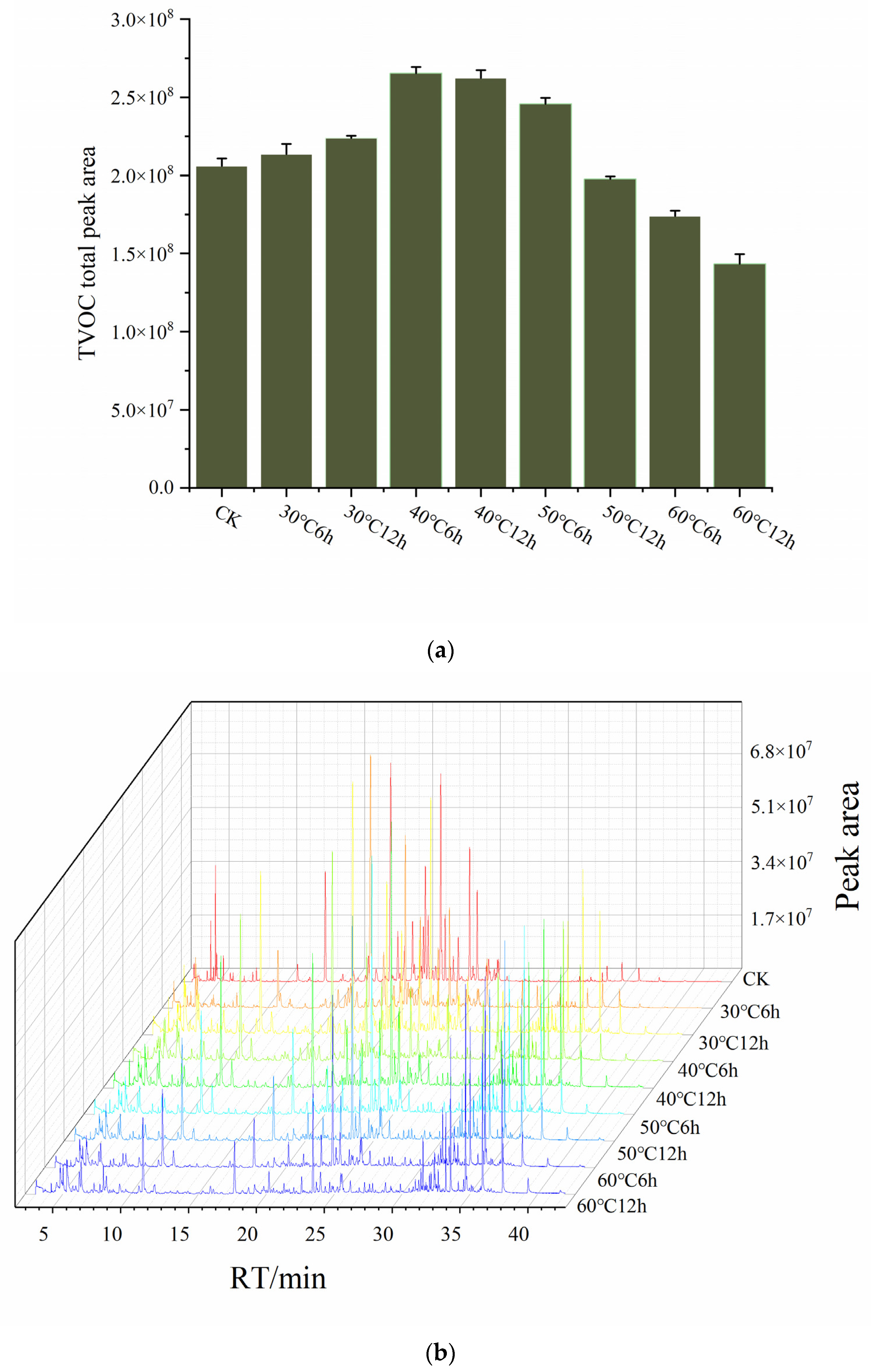

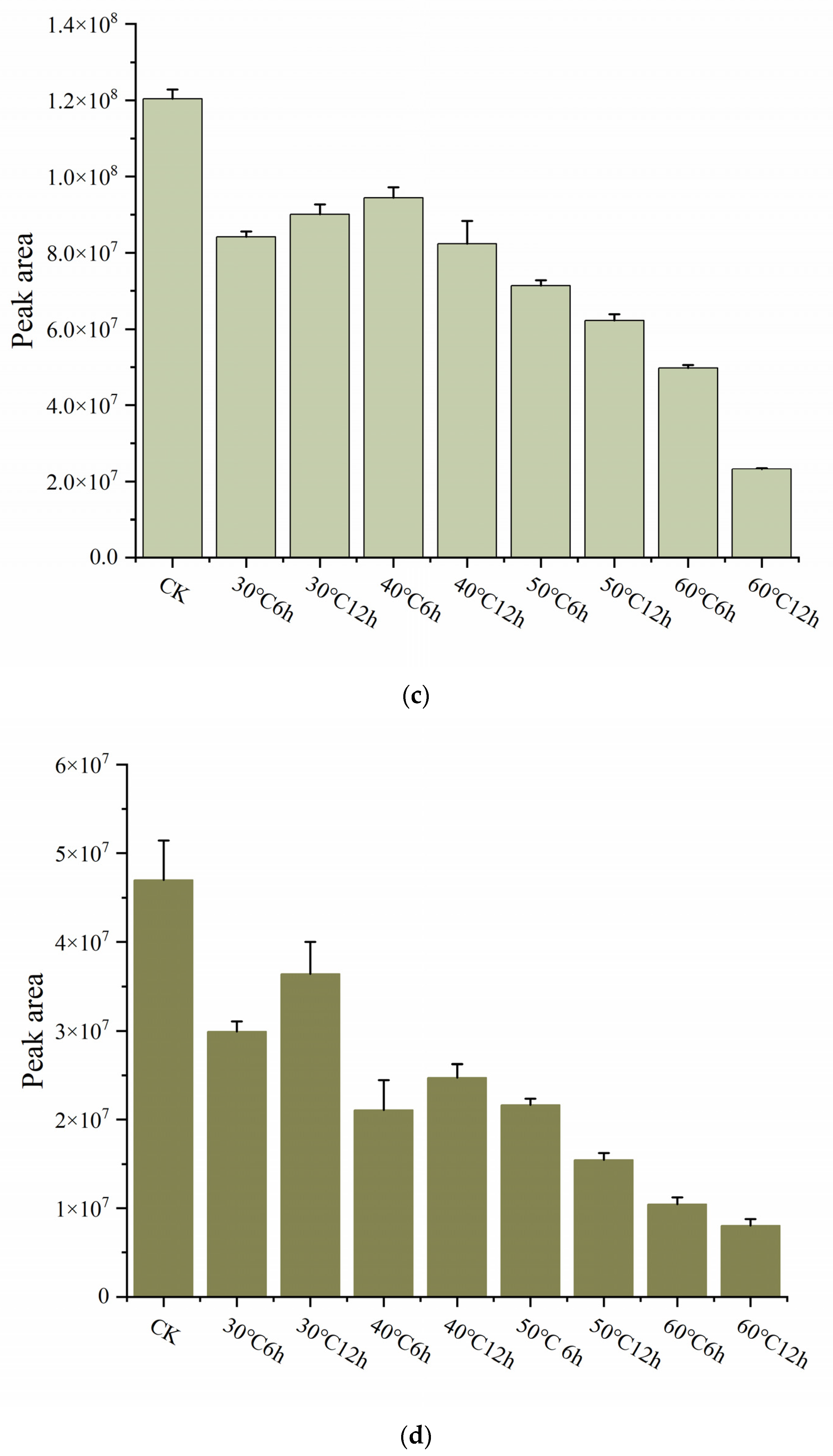

2.3. Comparison of VOCs After Thermal Post-Treatment Under Different Conditions

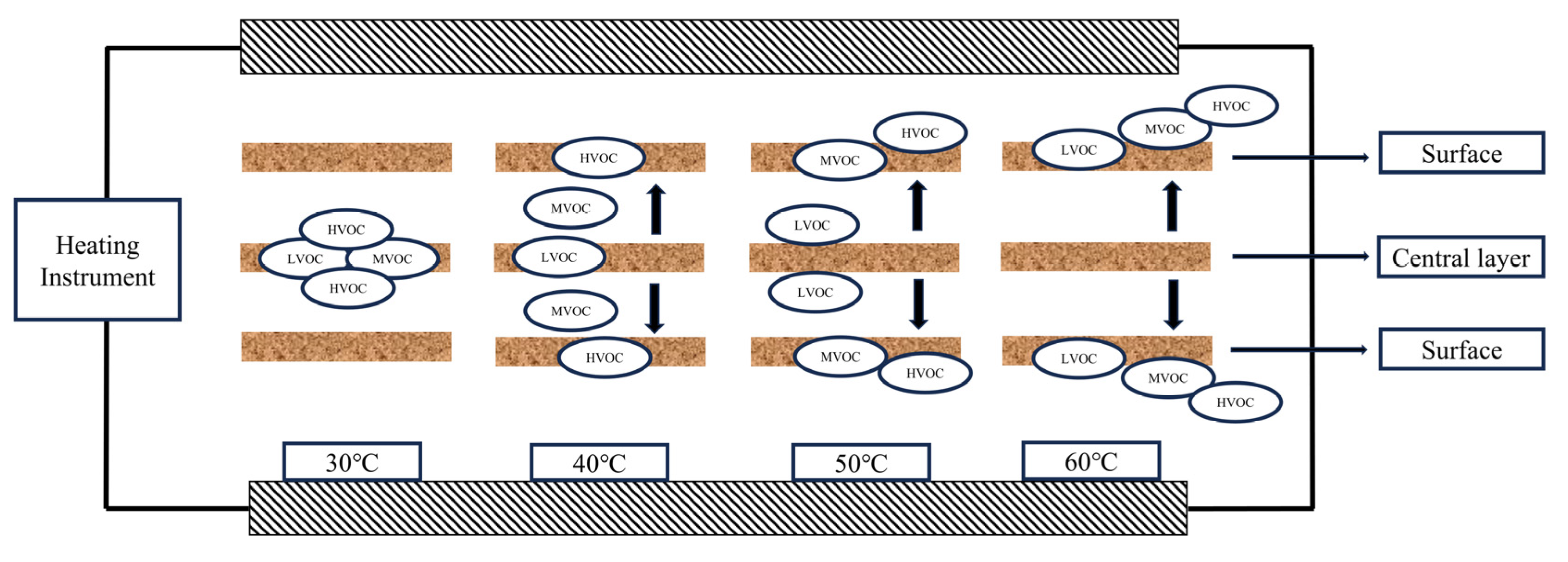

2.4. Mechanisms of VOC Removal Through Thermal Post-Treatment

3. Discussion

4. Materials and Methods

4.1. Materials

4.2. Thermal Post-Treatment

4.3. Enrichment of VOCs and Component Analysis

4.4. Analysis of KOCs

4.5. Data Processing

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fiedler, C.E.; Arno, S.F.; Keegan, C.E.; Blatner, K.A. Overcoming America’s Wood Deficit: An Overlooked Option. BioScience 2001, 51, 53–58. [Google Scholar] [CrossRef]

- Matsui, K.; Akhapov, Y.; Kussainova, M.; Funakawa, S. Management of wood resources: A dilemma between conservation and livelihoods in a rural district in the Aral region. Energy. Sustain. Dev. 2017, 41, 121–127. [Google Scholar] [CrossRef]

- Pramreiter, M.; Nenning, T.; Malzl, L.; Konnerth, J. A plea for the efficient use of wood in construction. Nat. Rev. Mater. 2023, 8, 217–218. [Google Scholar] [CrossRef]

- Wang, J.B.; Deng, N.; Cao, N.; Li, J.J.; Sun, J. Life cycle analysis of a novel treatment method for recycling wood processing residues into the core material of wooden doors. J. Clean. Prod. 2023, 415, 137798. [Google Scholar] [CrossRef]

- Zhang, M.; Xiong, X.Q.; Yue, X.Y.; Xu, X.T. Status of China’s wooden-door industry and challenges lying ahead. Wood Mater. Sci. Eng. 2023, 19, 485–498. [Google Scholar] [CrossRef]

- Khojasteh-Khosro, S.; Shalbafan, A.; Thoemen, H. Preferences of furniture manufacturers for using lightweight wood-based panels as eco-friendly products. Eur. J. Wood Wood Prod. 2020, 78, 593–603. [Google Scholar] [CrossRef]

- Khojasteh-Khosro, S.; Shalbafan, A.; Thoemen, H. Consumer behavior assessment regarding lightweight furniture as an environmentally-friendly product. Wood Mater. Sci. Eng. 2020, 17, 192–201. [Google Scholar] [CrossRef]

- Iswanto, A.H.; Tarigan, I.G.; Nuryawan, A.; Oktaviani, F. The properties of particleboards made from corn stalks and bagasse at various compositions. IOP Conf. Ser. Earth Environ. Sci. 2020, 713, 012033. [Google Scholar] [CrossRef]

- Taha, I.; Elkafafy, M.S.; Mously, H.E. Potential of utilizing tomato stalk as raw material for particleboards. Ain Shams Eng. J. 2018, 9, 1457–1464. [Google Scholar] [CrossRef]

- Derikvand, M.; Kotlarewski, N.; Lee, M.; Jiao, H.; Chan, A.; Nolan, G. Short-term and long-term bending properties of nail-laminated timber constructed of fast-grown plantation eucalypt. Constr. Build. Mater. 2019, 211, 952–964. [Google Scholar] [CrossRef]

- Maissupova, I.K.; Sarsekova, D.N.; Weger, J.; Bubeník, J. Comparison of the growth of fast-growing poplar and willow in two sites of Central Kazakhstan. J. Sci. 2017, 65, 239–244. [Google Scholar] [CrossRef]

- Aravanopoulos, F.A. Breeding of fast growing forest tree species for biomass production in Greece. Biomass Bioenerg. 2010, 34, 1531–1537. [Google Scholar] [CrossRef]

- Yin, W.H.; Wu, B.X.; Yang, Z.J.; Guo, Z.H.; Liu, Y.; He, Y.K.; Xu, W.X.; Huang, H.M.; Du, G.B.; Zhao, P. VOCs Analyses and odor characteristics of Eucalyptus wood particleboard and its dried strands. J. Southwest. For. Univ. 2024, 45, 1–8. [Google Scholar] [CrossRef]

- World Health Organization. Indoor air quality: Organic pollutants. Environ. Technol. 1989, 1, 855–858. [Google Scholar] [CrossRef]

- Molhave, L.; Liu, Z.; Jorgensen, A.H.; Pedersen, O.F.; Kjægaard, S.K. Sensory and physiological effects on humans of combined exposures to air temperatures and volatile organic compounds. Indoor Air. 1993, 3, 155–169. [Google Scholar] [CrossRef]

- Kim, K.; Jahan, S.A.; Lee, J. Exposure to formaldehyde and its potential human health hazards. J. Environ. Sci. Health C-Tox. 2011, 29, 277–299. [Google Scholar] [CrossRef]

- Dongni, Y.; Mitchel, K.; Howard, H.C.; Jeremy, A.S.; James, A.M.; Eric, S.E.; Andrea, W.; Paige, E.T.; Stefanie Ebelt, S. Estimating Acute Cardiorespiratory Effects of Ambient Volatile Organic Compound. Epidemiology 2017, 28, 197–206. [Google Scholar] [CrossRef]

- Kagi, N.; Fujii, S.; Tamura, H.; Namiki, N. Secondary VOC emissions from flooring material surfaces exposed to ozone or UV irradiation. Build. Environ. 2009, 44, 1199–1205. [Google Scholar] [CrossRef]

- Knudsen, H.N.; Clausen, P.A.; Wilkins, C.K.; Wolkoff, P. Sensory and chemical evaluation of odorous emissions from building products with and without linseed oil. Build. Environ. 2007, 42, 4059–4067. [Google Scholar] [CrossRef]

- Kim, S.; Kim, J.; An, J.; Kim, H.; Kim, S.D.; Park, J.C. TVOC and formaldehyde emission behaviors from flooring materials bonded with environmental-friendly MF/PVAc hybrid resins. Indoor Air. 2007, 17, 404–415. [Google Scholar] [CrossRef]

- Tran, H.M.; Bui, H.T.M.; Thoumsang, S.; Ngo, N.T.B.; Nguyen, N.P.T.; Nguyen, H.T.M.; Nguyen, S.M.; Hara, K.; Wangwongwatana, S. Occupational symptoms due to exposure to volatile organic compounds among female Vietnamese nail salon workers in Danang city. J. Occup. Health 2020, 62, e12160. [Google Scholar] [CrossRef] [PubMed]

- McGwin, G., Jr.; Lienert, J.; Kennedy, J.I., Jr. Formaldehyde Exposure and Asthma in Children: A Systematic Review. Environ. Health Persp. 2010, 118, 313–317. [Google Scholar] [CrossRef] [PubMed]

- Landrigan, P.J.; Fuller, R.; Acosta, N.J.R.; Adeyi, O.; Arnold, R.; Basu, N.; Baldé, A.B.; Bertollini, R.; Bose-O’Reilly, S.; Boufford, J.I.; et al. The Lancet Commission on pollution and health. Lancet 2018, 391, 462–512. [Google Scholar] [CrossRef]

- An, J.; Kim, S.; Kim, H.; Seo, J. Emission behavior of formaldehyde and TVOC from engineered flooring in under heating and air circulation systems. Build. Environ. 2010, 45, 1826–1833. [Google Scholar] [CrossRef]

- Li, D.D. Research on the Identification and Control of Pollutants Released from Wood-Based Panel; Tsinghua University: Beijing, China, 2016. [Google Scholar]

- Ayrilmis, N.; Lee, Y.; Kwon, J.H.; Han, T.; Kim, H. Formaldehyde emission and VOCs from LVLs produced with three grades of urea-formaldehyde resin modified with nanocellulose. Build. Environ. 2016, 97, 82–87. [Google Scholar] [CrossRef]

- Li, J.J.; Hu, Z.J.; Xu, M.; Wang, Z.C.; He, Z.; Wang, Z.L. Emission characteristics of volatile organic compounds in fiberboard industry and control measures. J. Cellul. Sci. Technol. 2017, 25, 58–64. [Google Scholar]

- Hong, W. Study on the Releasing Characteristics of Formaldehyde from Surface Decorated Wood-Based Panel and Formaldehyde Treatment Method; Guangxi Normal University: Guilin, China, 2017. [Google Scholar]

- Chen, F.; Xia, X.H.; Shen, J. Study on the release characteristics of the VOCs from veneered particleboard for panel furniture. Shandong For. Sci. Technol. 2018, 48, 11–14+18. [Google Scholar]

- Tong, R.P.; Zhang, L.; Yang, X.Y.; Liu, J.F.; Zhou, P.N.; Li, J.F. Emission characteristics and probabilistic health risk of volatile organic compounds from solvents in wooden furniture manufacturing. J. Clean. Prod. 2019, 208, 1096–1108. [Google Scholar] [CrossRef]

- Jiang, L.Q.; Shen, J.; Zhao, Z.; Dong, H.J.; Li, Y.B. Study on film properties and VOCs of nano-TiO2 and ZnO modified waterborne paints. J. For. Eng. 2019, 4, 148–155. [Google Scholar]

- Yan, S. Study on Volatile Organic Compounds Emitted from Wooden Furniture and Optimization of Furniture Production Technology; Beijing Forestry University: Beijing, China, 2020. [Google Scholar]

- Wang, Z.P. Research on VOCs Evaluation and Treatment Technology of Wood Based Panels and Relative Products; China Academy of Forestry Sciences: Beijing, China, 2021. [Google Scholar]

- Liu, Y.; Zhu, X.D.; Qin, X.; Wang, W.C.; Hu, Y.B.; Yuan, D.L. Identification and characterization of odorous volatile organic compounds emitted from wood-based panels. Environ. Monit. Assess. 2020, 192, 348. [Google Scholar] [CrossRef]

- Adamová, T.; Hradecký, J.; Pánek, M. Volatile Organic Compounds (VOCs) from Wood and Wood-Based Panels: Methods for Evaluation, Potential Health Risks, and Mitigation. Polymers 2020, 12, 2289. [Google Scholar] [CrossRef] [PubMed]

- Eid, A.M.; Hawash, M. Biological evaluation of Safrole oil and Safrole oil Nanoemulgel as antioxidant, antidiabetic, antibacterial, antifungal and anticancer. BMC Complement. Med. 2021, 21, 159. [Google Scholar] [CrossRef]

- Khaya, M.T.; Mohammad, K.A.; Omar, A.M.; Mohamed, G.A.; Ibrahim, S.R.M. Fungal Bergamotane Sesquiterpenoids-Potential Metabolites: Sources Bioactivities, and Biosynthesis. Mar. Drugs 2022, 20, 771. [Google Scholar] [CrossRef]

- Zhang, H.; Sun, R.R.; Liu, Y.F.; Guo, X.; Li, C.L.; Nan, Z.D.; Jiang, Z.B. Research Progress on Sesquiterpenes from the Genus Ainsliaea. Molecules 2024, 29, 5483. [Google Scholar] [CrossRef] [PubMed]

- Verma, R.S.; Verma, R.K.; Padalia, R.C.; Chauhan, A.; Singh, A.; Singh, H.P. Chemical diversity in the essential oil of Indian valerian (Valeriana jatamansi Jones). Chem. Biodivers. 2011, 8, 1921–1929. [Google Scholar] [CrossRef] [PubMed]

- Pandey, S.K.; Baruah, J.; Paw, M.; Sarma, N.; Begum, T.; Saikia, S.; Lal, M. Molecular Diversity and Chemical Composition Among Induced Mutation Lines of Pogostemon cablin (Blanco) Benth. Using RAPD and ISSR Marker. J. Essent. Oil Bear. Pl. 2022, 25, 234–249. [Google Scholar] [CrossRef]

- EI-Gawad, A.A.; Elshamy, A.; Gendy, A.E.E.; Gaara, A.; Assaeed, A. Volatiles Profiling, Allelopathic Activity, and Antioxidant Potentiality of Xanthium Strumarium Leaves Essential Oil from Egypt: Evidence from Chemometrics Analysis. Molecules 2019, 24, 584. [Google Scholar] [CrossRef]

- Manninen, A.; Pasanen, P.; Holopainen, K.J. Comparing the VOC emissions between air-dried and heat-treated Scots pine wood. Atmos. Environ. 2002, 36, 1763–1768. [Google Scholar] [CrossRef]

- Jiang, C.J.; Li, D.D.; Zhang, P.Y.; Li, J.G.; Wang, J.; Yu, J.G. Formaldehyde and volatile organic compound (VOC) emissions from particleboard: Identification of odorous compounds and effects of heat treatment. Build. Environ. 2017, 117, 118–126. [Google Scholar] [CrossRef]

- Wu, L.; Zhou, C.C.; Zhang, B.Q.; Lei, H.Y.; Wang, W.Z.; Pu, X.B.; Liu, L.; Liang, J.; Fan, Y.J.; Zhang, X.D. Construction of Biomimetic Natural Wood Hierarchical Porous-Structure Bioceramic with Micro/Nanowhisker Coating to Modulate Cellular Behavior and Osteoinductive Activity. ACS Appl. Mater. Interfaces 2020, 12, 48395–48407. [Google Scholar] [CrossRef]

- Xiong, J.Y.; Yao, Y.; Zhang, Y.P. C-history method: Rapid measurement of the initial emittable concentration, diffusion and partition coefficients for formaldehyde and VOCs in building materials. Environ. Sci. Technol. 2011, 45, 3584–3590. [Google Scholar] [CrossRef] [PubMed]

- Castillo, R.A.; Biard, P.; Guihéneuf, S.; Paquin, L.; Amranem, A.; Couvert, A. Assessment of VOC absorption in hydrophobic ionic liquids: Measurement of partition and diffusion coefficients and simulation of a packed column. Chem. Eng. J. 2019, 360, 1416–1426. [Google Scholar] [CrossRef]

- Zhou, X.J.; Fang, W.P.; Dong, X.J.; Li, W.J.; Liu, J.L.; Wang, X.K. Advancing Characterization of VOC Diffusion in Indoor Fabrics: A Dual-Porosity Modeling Approach. Environ. Pollut. 2024, 363, 125245. [Google Scholar] [CrossRef] [PubMed]

- Wu, B.X.; Wang, J.M.; Wan, H.; Li, Y.; Chu, J.J.; Wen, T.G.; Yang, Z.J.; Du, G.B.; Zhao, P. Optimization of Headspace Solid-phase Microextraction of VOCs in Eucalyptus Particleboard. J. Southwest. For. Univ. 2023, 43, 163–171. [Google Scholar] [CrossRef]

- Xu, Y.; Bi, S.; Xiong, C.H.; Dai, Y.X.; Zhou, Q.; Liu, Y. Identification of aroma active compounds in walnut oil by monolithic material adsorption extraction of RSC18 combined with gas chromatography-olfactory-mass spectrometry. Food Chem. 2023, 402, 134303. [Google Scholar] [CrossRef]

- Zhu, Y.F.; Chen, J.; Chen, X.J.; Chen, D.Z.; Deng, S.G. Use of relative odor activity value (ROAV) to link aroma profiles to volatile compounds: Application to fresh and dried eel (Muraenesoxcinereus). Int. J. Food Prop. 2020, 23, 2257–2270. [Google Scholar] [CrossRef]

- Lan, Y.B.; Xiang, X.F.; Qian, X.; Wang, J.M.; Ling, M.Q.; Zhu, B.Q.; Liu, T.; Sun, L.B.; Shi, Y.; Reynolds, A.G.; et al. Characterization and differentiation of key odor-active compounds of ‘Beibinghong’ icewine and dry wine by gas chromatography-olfactometry and aroma recomstitution. Food Chem. 2019, 287, 186–196. [Google Scholar] [CrossRef]

- Gemert, L.J.V. Compilation of Threshold Values for Compound Odors; Science Press: Beijing, China, 2018. [Google Scholar]

- Revah, S.; Morgan-Sagastume, J.M. Methods of Odor and VOC Control; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar] [CrossRef]

- Aldrich, R.L. Environmental Laws and Regulations Related to Odor and Waste Gas Contaminants; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar] [CrossRef]

| No. | Sample Name | Group | Sample Information |

|---|---|---|---|

| 1 | CK-1 | Untreated | Blank control |

| 2 | CK-2 | ||

| 3 | CK-3 | ||

| 4 | 30 °C 6 h-1 | 30 °C 6 h | Heated at 30 °C for 6 h |

| 5 | 30 °C 6 h-2 | ||

| 6 | 30 °C 6 h-3 | ||

| 7 | 30 °C 12 h-1 | 30 °C 12 h | Heated at 30 °C for 12 h |

| 8 | 30 °C 12 h-2 | ||

| 9 | 30 °C 12 h-3 | ||

| 10 | 40 °C 6 h-1 | 40 °C 6 h | Heated at 40 °C for 6 h |

| 11 | 40 °C 6 h-2 | ||

| 12 | 40 °C 6 h-3 | ||

| 13 | 40 °C 12 h-1 | 40 °C 12 h | Heated at 40 °C for 12 h |

| 14 | 40 °C 12 h-2 | ||

| 15 | 40 °C 12 h-3 | ||

| 16 | 50 °C 6 h-1 | 50 °C 6 h | Heated at 50 °C for 6 h |

| 17 | 50 °C 6 h-2 | ||

| 18 | 50 °C 6 h-3 | ||

| 19 | 50 °C 12 h-1 | 50 °C 12 h | Heated at 50 °C for 12 h |

| 20 | 50 °C 12 h-2 | ||

| 21 | 50 °C 12 h-3 | ||

| 22 | 60 °C 6 h-1 | 60 °C 6 h | Heated at 60 °C for 6 h |

| 23 | 60 °C 6 h-2 | ||

| 24 | 60 °C 6 h-3 | ||

| 25 | 60 °C 12 h-1 | 60 °C 12 h | Heated at 60 °C for 12 h |

| 26 | 60 °C 12 h-2 | ||

| 27 | 60 °C 12 h-3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, W.; Zhang, Y.; Li, C.; Wu, B.; Yang, Z.; Huang, H.; Luo, B.; Du, G.; Zhao, P.; Yang, X. Unlocking the Potential of Thermal Post-Treatments: A Study on Odor Emission Control in Eucalyptus Wood Particleboard. Molecules 2025, 30, 1949. https://doi.org/10.3390/molecules30091949

Yin W, Zhang Y, Li C, Wu B, Yang Z, Huang H, Luo B, Du G, Zhao P, Yang X. Unlocking the Potential of Thermal Post-Treatments: A Study on Odor Emission Control in Eucalyptus Wood Particleboard. Molecules. 2025; 30(9):1949. https://doi.org/10.3390/molecules30091949

Chicago/Turabian StyleYin, Wenhang, Yueyun Zhang, Churan Li, Boxiao Wu, Zhaojin Yang, Heming Huang, Bangrui Luo, Guanben Du, Ping Zhao, and Xiaoqin Yang. 2025. "Unlocking the Potential of Thermal Post-Treatments: A Study on Odor Emission Control in Eucalyptus Wood Particleboard" Molecules 30, no. 9: 1949. https://doi.org/10.3390/molecules30091949

APA StyleYin, W., Zhang, Y., Li, C., Wu, B., Yang, Z., Huang, H., Luo, B., Du, G., Zhao, P., & Yang, X. (2025). Unlocking the Potential of Thermal Post-Treatments: A Study on Odor Emission Control in Eucalyptus Wood Particleboard. Molecules, 30(9), 1949. https://doi.org/10.3390/molecules30091949