Application of Argon Ion Implantation to Improve the Surface Properties of Materials Based on PLA and Lignocellulosic Particles

Abstract

1. Introduction

2. Results and Discussion

2.1. Visual Characteristics of the Fabricated Composite

2.2. Modeling and Ion Implantation Results

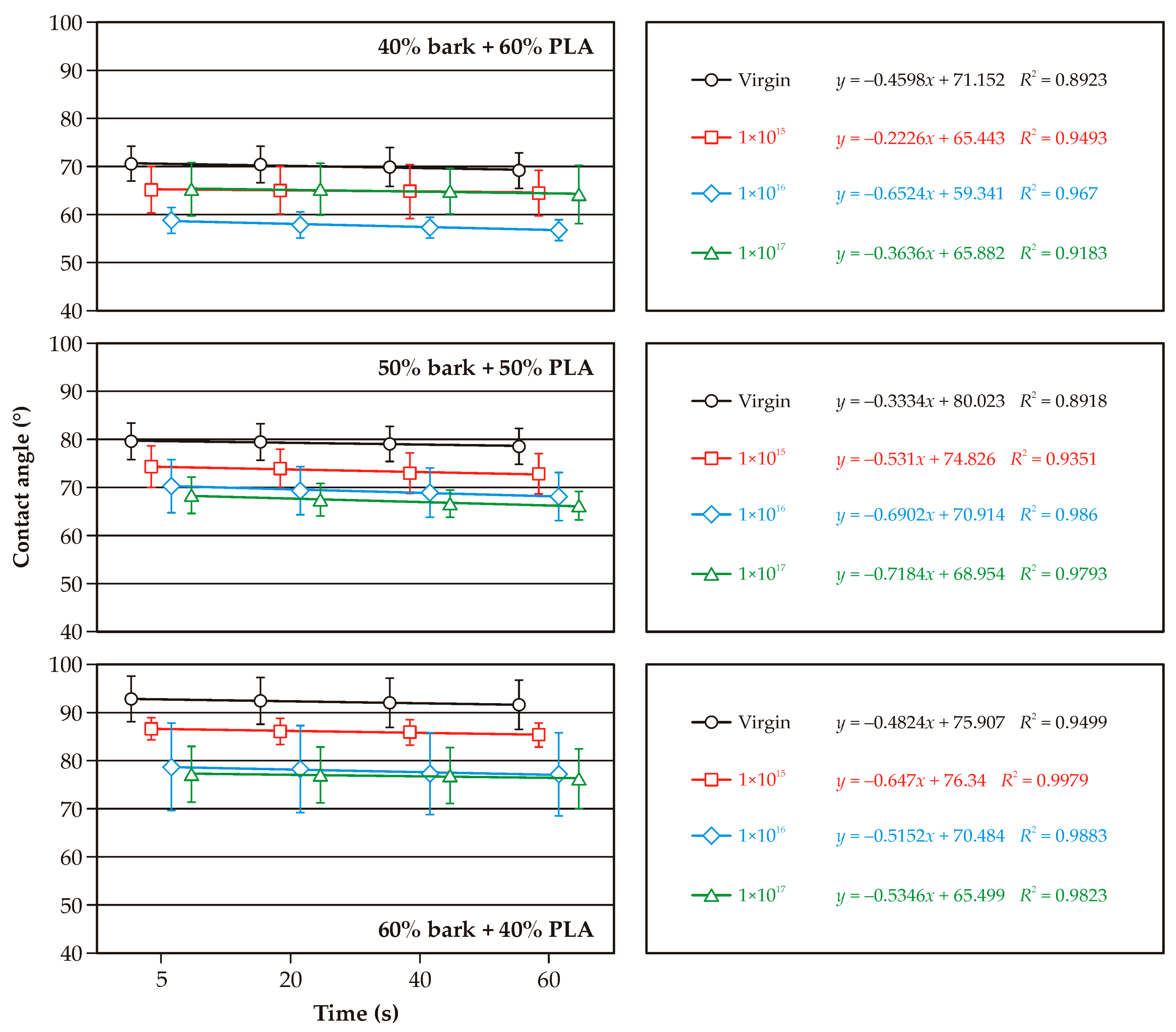

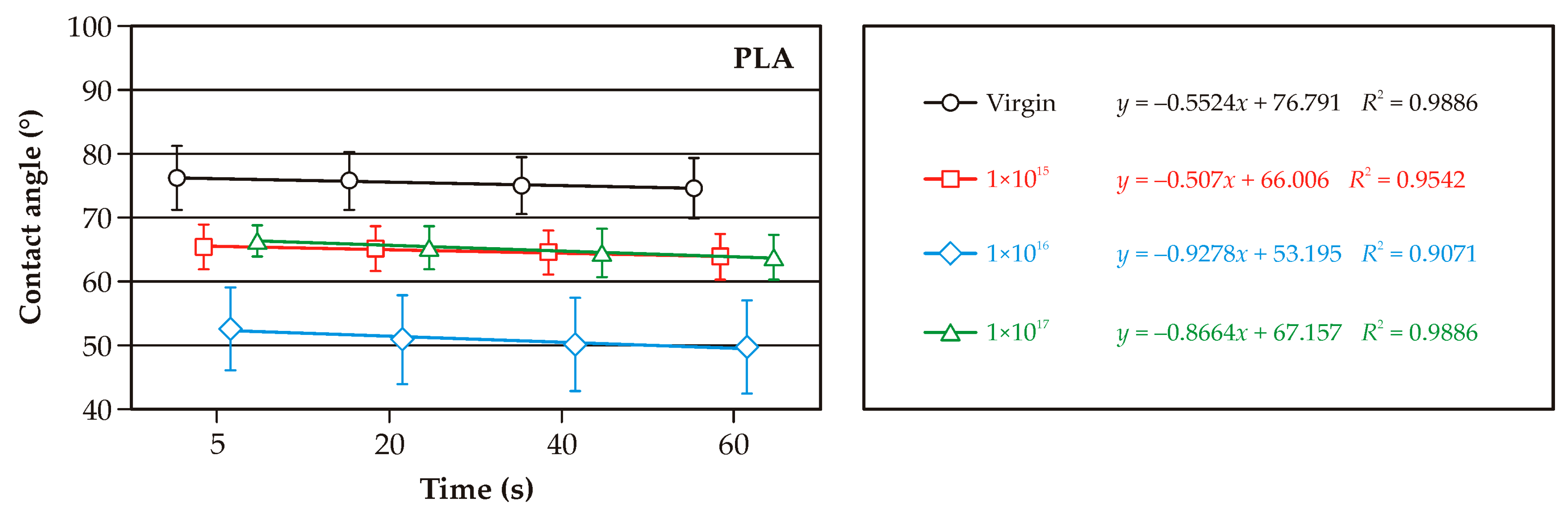

2.3. Results of Changes in Surface Wettability and Surface Free Energy

2.4. Results of the Influence of Implantation on Surface Color Changes

2.5. Statistical Analysis of Results

3. Materials and Methods

3.1. Preparation of Composites

- (1)

- producing granules of the appropriate formulation using an extruder (Leistritz Extrusionstechnik GmbH, Nürnberg, Germany). The extrusion process took place at a temperature of 170–180 °C, and the resulting continuous strip of the composite was ground using a hammer mill.

- (2)

- producing a composite of 300 mm × 300 mm × 0.5 mm in the process of flat pressing. The pressing was carried out in a single-shelf press (AB AK Eriksson, Mariannelund, Sweden) with the following parameters: pressing temperature 200 °C, maximum unit pressing pressure pmax = 1.25 MPa, and pressing time 6 min.

3.2. Ion Implantation and Modeling

- -

- 100% polylactide (PLA),

- -

- 40% sawdust + 60% PLA,

- -

- 50% sawdust + 50% PLA,

- -

- 60% sawdust + 40% PLA.

3.3. Wetting Angle Measurement and Surface Free Energy

3.4. Assessment of the Surface Color of the Composites

- 0 < ΔE ≤ 1—unnoticeable difference

- 1 < ΔE ≤ 2—difference noticed by an experienced observer

- 2 < ΔE ≤ 3.5—difference noticed by an inexperienced observer

- 3.5 < ΔE ≤ 5—noticeable difference

- 5 < ΔE—significant color change

3.5. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jian, B.; Mohrmann, S.; Li, H.; Li, Y.; Ashraf, M.; Zhou, J.; Zheng, X. A Review on Flexural Properties of Wood-Plastic Composites. Polymers 2022, 14, 3942. [Google Scholar] [CrossRef] [PubMed]

- Siddiqui, M.N.; Redhwi, H.H.; Andrady, A.L.; Furquan, S.A.; Hussain, S. Effect of Extensive Solar Ultra-Violet Irradiation on the Durability of High-Density Polyethylene- and Polypropylene-Based Wood–Plastic Composites. Polymers 2025, 17, 74. [Google Scholar] [CrossRef]

- Bengtsson, M.; Oksman, K. Silane crosslinked wood plastic composites: Processing and properties. Compos. Sci. Technol. 2006, 66, 2177–2186. [Google Scholar] [CrossRef]

- Karumuri, S.; Hiziroglu, S.; Kalkan, A.K. Thermoset-Cross-Linked Lignocellulose: A Moldable Plant Biomass. ACS Appl. Mater. Interfaces 2015, 7, 6596–6604. [Google Scholar] [CrossRef]

- Zhang, W.; Lu, Q.; Liu, S.; Zhao, B. Study on properties and interfacial treatment of PLA wood-plastic composites. Eng. Plast. Appl. 2020, 48, 39–43. [Google Scholar]

- Friedrich, D. Additive manufacturing of post-process thermoformed wood-plastic composite cladding. Autom. Constr. 2022, 139, 104322. [Google Scholar] [CrossRef]

- Cosse, R.L.; van der Most, T.; Voet, V.S.D.; Folkersma, R.; Loos, K. Improving the Long-Term Mechanical Properties of Thermoplastic Short Natural Fiber Compounds by Using Alternative Matrices. Biomimetics 2025, 10, 46. [Google Scholar] [CrossRef]

- Pérez-Fonseca, A.A.; Robledo-Ortíz, J.R.; González-Núñez, R.; Rodrigue, D. Effect of Thermal Annealing on the Mechanical and Thermal Properties of Polylactic Acid–Cellulosic Fiber Biocomposites. J. Appl. Polym. Sci. 2016, 133, 43750. [Google Scholar] [CrossRef]

- Lee, C.Y.; Kil, J.K. Hydrophilic property by contact angle change of ion implanted polycarbonate. Rev. Sci. Instrum. 2008, 79, 02C508. [Google Scholar] [CrossRef]

- Mohamed, M.R.; Naguib, H.M.; El-Ghazawy, R.A.; Shaker, N.O.; Amer, A.A.; Soliman, A.M.; Kandil, U.F. Surface activation of wood plastic composites (WPC) for enhanced adhesion with epoxy coating. Mater. Perform. Charact. 2019, 8, 22–40. [Google Scholar] [CrossRef]

- Laput, O.A.; Zuza, D.A.; Vasenina, I.V.; Savkin, K.P.; Kurzina, I.A. Effect of silver ion implantation on surface physicochemical properties of composite materials based on polylactic acid and hydroxyapatite. Vacuum 2020, 175, 109251. [Google Scholar] [CrossRef]

- Cajzl, J.; Nekvindová, P.; Macková, A.; Vargade, M.; Kromka, A. Erbium ion implantation into LiNbO3, Al2O3, ZnO and diamond—Measurement and modelling—An overview. Phys. Chem. Chem. Phys. 2022, 24, 19052–19072. [Google Scholar] [CrossRef]

- Zheng, C.; Gentils, A.; Ribis, J.; Borodin, V.A.; Kaïtasov, O.; Garrido, F. Metal-oxide nanoclusters in Fe–10%Cr alloy by ion implantation. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2015, 365, 319–324. [Google Scholar] [CrossRef]

- Mikšová, R.; Nekvindová, P.; Aubrecht, P.; Macková, A. Optical response of channel waveguides in silicate glass created via ion implantation with optical barriers of varying thickness. Opt. Laser Technol. 2025, 183, 112333. [Google Scholar] [CrossRef]

- Feng, Q.; Li, B.; Luo, W.; Xiang, X.; Zu, X. Regulations of oxygen-silicon ratio and microstructure to enhance laser damage resistance of fused silica via oxygen ion implantation. Opt. Mater. 2024, 157, 116430. [Google Scholar] [CrossRef]

- Tsuji, H.; Sasaki, H.; Utsumi, Y.; Sato, H.; Gotoh, Y.; Ishikawa, J. Extracellular matrix absorption properties of negative ion-implanted polystyrene, polydimethylsiloxane and poly-lactic acid. Surf. Coat. Technol. 2002, 158, 620–623. [Google Scholar] [CrossRef]

- Park, C.; Seong, Y.-J.; Kang, I.-G.; Song, E.-H.; Lee, H.; Kim, J.; Jung, H.-D.; Kim, H.-E.; Jang, T.-S. Enhanced Osseointegration Ability of Poly(lactic acid) via Tantalum Sputtering-Based Plasma Immersion Ion Implantation. ACS Appl. Mater. Interfaces 2019, 11, 10492–10504. [Google Scholar] [CrossRef]

- Migneault, S.; Koubaa, A.; Perré, P.; Riedl, B. Effects of wood fiber surface chemistry on strength of wood–plastic composites. Appl. Surf. Sci. 2015, 343, 11–18. [Google Scholar] [CrossRef]

- Betlej, I.; Barlak, M.; Lipska, K.; Borysiuk, P.; Boruszewski, P. Argon Ion Implantation as a Method of Modifying the Surface Properties of Wood–Plastic Composites. Materials 2024, 17, 5347. [Google Scholar] [CrossRef]

- Tümer, E.H.; Erbil, H.Y.; Akdoǧan, N. Wetting of Superhydrophobic Polylactic Acid Micropillared Patterns. Langmuir 2022, 38, 10052–10064. [Google Scholar] [CrossRef]

- Slepička, P.; Trostová, S.; Slepičková Kasálková, N.; Kolská, Z.; Sajdl, P.; Švorčík, V. Surface Modification of Biopolymers by Argon Plasma and Thermal Treatment. Plasma Process. Polym. 2012, 9, 197–206. [Google Scholar] [CrossRef]

- Nakao, A.; Iwaki, M.; Yokoyama, Y. Potassium ion implantation into glassy carbon. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2003, 206, 211–214. [Google Scholar] [CrossRef]

- Vendamani, V.S.; Kanjilal, D.; Venugopal Rao, S. Controlled wetting properties of proton beam irradiated silicon nanowires. Chem. Phys. 2021, 548, 111242. [Google Scholar] [CrossRef]

- Wang, M.; Yang, C.; Yang, Z.; Tian, Y. The effects of carbon ion implantation on wettability, abrasion, thermal and anti-corrosion stabilities of laser ablated super-hydrophobic Nitinol surface. J. Mater. Res. Technol. 2024, 28, 1784–1793. [Google Scholar] [CrossRef]

- Guzman, L.; Celva, R.; Miotello, A.; Voltolini, E.; Ferrari, F.; Adami, M. Polymer surface modification by ion implantation and reactive deposition of transparent films. Surf. Coat. Technol. 1998, 103–104, 375–379. [Google Scholar] [CrossRef]

- Chen, X.; Yin, X.; Jin, J. A Study on the Wettability of Ion-Implanted Stainless and Bearing Steels. Metals 2019, 9, 208. [Google Scholar] [CrossRef]

- Tencio, D.; Baldi-Sevilla, A.; Aguiar-Moya, J. Surface energy and wetting behavior on high-conditioned aggregates. Int. J. Adhes. Adhes. 2022, 118, 103218. [Google Scholar] [CrossRef]

- Jordá-Vilaplana, A.; Fombuena, V.; García-García, D.; Samper, M.D.; Sánchez-Nácher, L. Surface modification of polylactic acid (PLA) by air atmospheric plasma treatment. Eur. Polym. J. 2014, 58, 23–33. [Google Scholar] [CrossRef]

- SRIM. Available online: http://www.srim.org/ (accessed on 28 February 2025).

- Barlak, M.; Wilkowski, J.; Szymanowski, K.; Czarniak, P.; Podziewski, P.; Werner, Z.; Zagórski, J.; Staszkiewicz, B. Influence of the ion implantation of nitrogen and selected metals on the lifetime of WC-Co indexable knives during MDF machining. Ann. Wars. Univ. Life Sci. SGGW For. Wood Technol. 2019, 108, 45–52. [Google Scholar] [CrossRef]

- Wilkowski, J.; Barlak, M. Wpływ chropowatości powierzchni narzędzi WC-Co do obróbki materiałów drzewnych na modelowane parametry głębokościowych profili implantowanego azotu. Biul. Inf. OB-RPPD 2021, 3–4, 157–169. [Google Scholar]

- Otwarta Encyklopedia Leśna. Available online: https://www.encyklopedia.lasypolskie.pl/doku.php?id=b:budowa-i-skladchemiczny-drewna.products (accessed on 28 February 2025).

- Barette, J.P.; Hazard, C.; Mayer, J. Mémotech—Bois et Matériaux Associés; Éditions Casteilla: Paris, France, 1996; p. 22. ISBN 978-2-7135-1645-0. [Google Scholar]

- Kraszkiewicz, A. Analiza wybranych właściwości chemicznych drewna i kory robinii akacjowej (Robinia pseudoacacia L.). Inżynieria Rol. 2009, 117, 69–75. [Google Scholar]

- ISO 7724-3:2003; Paints and Varnishes—Colorimetry—Part 3: Calculation of Colour Differences. Polish Committee for Standardization: Warsaw, Poland, 2003.

| Parameter | PLA | 40% Sawdust + 60% PLA | 50% Sawdust + 50% PLA | 60% Sawdust + 40% PLA |

|---|---|---|---|---|

| SRIMmax | 1.26 × 105 | 1.34 × 105 | 1.33 × 105 | 1.38 × 105 |

| (atoms/cm3)/(atoms/cm2) | (5.99%) | (5.51%) | (9.63%) | |

| Nmax (cm−3) | 1.26 × 1020 | 1.34 × 1020 | 1.33 × 1020 | 1.38 × 1020 |

| (5.99%) | (5.51%) | (9.63%) | ||

| 1.26 × 1021 | 1.34 × 1021 | 1.33 × 1021 | 1.38 × 1021 | |

| (5.99%) | (5.51%) | (9.63%) | ||

| 1.347 × 1022 | 1.33 × 1022 | 1.38 × 1022 | ||

| 1.26 × 1022 | (5.99%) | (5.51%) | (9.63%) | |

| Rp (nm) | 109 | 105.2 | 105.2 | 104.4 |

| (−3.49%) | (−3.49%) | (−4.22%) | ||

| ΔRp (nm) | 62 | 59 | 58.6 | 57.8 |

| (−4.84%) | (−5.48%) | (−6.77%) | ||

| Skewness | 0.0024 | −0.0415 | −0.0446 | −0.0502 |

| (−1829.17%) | (−1958.33%) | (−2191.67%) | ||

| Kurtosis | 2.7169 | 2.6974 | 2.7059 | 2.7073 |

| (−0.72%) | (−0.4%) | (−0.35%) | ||

| YC (atoms/ion) | 0.3558 | 0.3145 | 0.304 | 0.3006 |

| (−11.61%) | (−14.56%) | (−15.51%) | ||

| YH (atoms/ion) | 0.5627 | 0.7191 | 0.7606 | 0.809 |

| (27.79%) | (35.17%) | (43.77%) | ||

| YO (atoms/ion) | 0.5637 | 0.5098 | 0.4931 | 0.4837 |

| (−9.56%) | (−12.52%) | (−14.19%) | ||

| YN (atoms/ion) | 0.00078 | 0.00044 | 0.0008 | |

| Ytotal (atoms/ion) | 1.4822 | 1.54418 | 1.55814 | 1.5941 |

| (4.18%) | (5.12%) | (7.55%) |

| Filler Type | Filler Amount (%) | Fluence (cm−2) | |||

|---|---|---|---|---|---|

| 0 | 1 × 1015 | 1 × 1016 | 1 × 1017 | ||

| Surface Free Energy (mJ/m2) | |||||

| Bark | 0 | 46.3 | 52.4 | 58.2 | 51.9 |

| 40 | 48.7 | 53.0 | 57.0 | 52.4 | |

| 50 | 42.7 | 47.5 | 49.6 | 50.4 | |

| 60 | 39.0 | 42.2 | 46.0 | 46.9 | |

| Sawdust | 0 | 46.3 | 52.4 | 58.2 | 51.9 |

| 40 | 47.3 | 49.1 | 52.5 | 51.5 | |

| 50 | 42.4 | 47.2 | 49.7 | 52.2 | |

| 60 | 46.3 | 50.5 | 54.3 | 51.9 | |

| Filler Type | Filler Amount (%) | Fluence (cm−2) | L* | a* | b* | ΔE |

|---|---|---|---|---|---|---|

| Bark | 0 | 0 | 67.578 | 2.678 | −4.500 | |

| 40 | 23.760 | 1.357 | 1.342 | |||

| 50 | 22.743 | 1.083 | 1.378 | |||

| 60 | 24.870 | 1.565 | 1.448 | |||

| Sawdust | 0 | 0 | 67.578 | 2.678 | −4.500 | |

| 40 | 38.800 | 9.125 | 19.356 | |||

| 50 | 38.086 | 9.535 | 18.375 | |||

| 60 | 30.488 | 4.481 | 8.529 | |||

| Bark | 0 | 1 × 1015 | 58.565 | 2.679 | 9.309 | 16.490 |

| 40 | 34.141 | 0.590 | 4.003 | 10.744 | ||

| 50 | 31.180 | 1.326 | 2.724 | 8.547 | ||

| 60 | 33.654 | 0.671 | 2.217 | 8.863 | ||

| Sawdust | 0 | 1 × 1015 | 58.565 | 2.679 | 9.309 | 16.490 |

| 40 | 41.312 | 7.761 | 16.742 | 3.873 | ||

| 50 | 42.763 | 8.080 | 16.757 | 5.158 | ||

| 60 | 39.224 | 4.322 | 9.234 | 8.766 | ||

| Bark | 0 | 1 × 1016 | 44.992 | 3.226 | 1.371 | 23.343 |

| 40 | 38.160 | 2.506 | −0.736 | 14.594 | ||

| 50 | 36.663 | 0.490 | 1.230 | 13.933 | ||

| 60 | 38.546 | 0.346 | 0.891 | 13.742 | ||

| Sawdust | 0 | 1 × 1016 | 44.992 | 3.226 | 1.371 | 23.343 |

| 40 | 40.552 | 3.509 | 4.350 | 16.118 | ||

| 50 | 39.855 | 3.321 | 4.074 | 15.693 | ||

| 60 | 40.659 | 1.760 | 2.050 | 12.362 | ||

| Bark | 0 | 1 × 1017 | 38.128 | −0.910 | 1.564 | 30.281 |

| 40 | 41.801 | 0.932 | 1.774 | 18.051 | ||

| 50 | 40.439 | 0.925 | 2.715 | 17.747 | ||

| 60 | 41.614 | 0.093 | 2.608 | 16.849 | ||

| Sawdust | 0 | 1 × 1017 | 38.128 | −0.910 | 1.564 | 30.281 |

| 40 | 41.408 | 1.730 | 4.290 | 16.984 | ||

| 50 | 39.922 | −1.998 | 7.614 | 15.880 | ||

| 60 | 41.263 | 0.926 | 3.238 | 12.519 |

| Factors | p | X (%) |

|---|---|---|

| Filler type (A) | 1.57 × 10−1 | 0.06 |

| Filler amount (B) | <1.00 × 10−17 | 43.27 |

| Implanted fluencies of ions (C) | <1.00 × 10−17 | 28.58 |

| Time after placing a droplet (D) | 7.34 × 10−3 | 0.38 |

| A × B | <1.00 × 10−17 | 2.66 |

| A × C | 1.08 × 10−2 | 0.35 |

| B × C | <1.00 × 10−17 | 8.03 |

| A × D | 9.96 × 10−1 | <0.01 |

| B × D | 1.00 | 0.01 |

| C × D | 1.00 | 0.02 |

| A × B × C | 2.87 × 10−3 | 0.79 |

| A × B × D | 1.00 | <0.01 |

| A × C × D | 1.00 | <0.01 |

| B × C × D | 1.00 | 0.01 |

| A × B × C × D | 1.00 | 0.01 |

| Error | 15.82 |

| Samples | PLA (%) | Sawdust (%) | Bark (%) |

|---|---|---|---|

| 40% bark + 60% PLA | 60 | - | 40 |

| 40% sawdust + 60% PLA | 60 | 40 | - |

| 50% bark + 50% PLA | 50 | - | 50 |

| 50% sawdust + 50% PLA | 50 | 50 | - |

| 60% bark + 40% PLA | 40 | - | 60 |

| 60% sawdust + 40% PLA | 40 | 60 | - |

| PLA | 100 | - | - |

| Substrate | at.% C | at.% H | at.% O | at.% N | Density (g/cm3) |

|---|---|---|---|---|---|

| PLA | 42.44 | 29.13 | 28.43 | - | 1.134 |

| 40% sawdust + 60% PLA | 38.03 | 36.5 | 25.44 | 0.03 | 1.152 |

| 50% sawdust + 50% PLA | 36.93 | 38.34 | 24.7 | 0.03 | 1.146 |

| 60% sawdust + 40% PLA | 35.83 | 40.18 | 23.95 | 0.04 | 1.148 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Betlej, I.; Barlak, M.; Lipska, K.; Boruszewski, P.; Borysiuk, P. Application of Argon Ion Implantation to Improve the Surface Properties of Materials Based on PLA and Lignocellulosic Particles. Molecules 2025, 30, 1948. https://doi.org/10.3390/molecules30091948

Betlej I, Barlak M, Lipska K, Boruszewski P, Borysiuk P. Application of Argon Ion Implantation to Improve the Surface Properties of Materials Based on PLA and Lignocellulosic Particles. Molecules. 2025; 30(9):1948. https://doi.org/10.3390/molecules30091948

Chicago/Turabian StyleBetlej, Izabela, Marek Barlak, Karolina Lipska, Piotr Boruszewski, and Piotr Borysiuk. 2025. "Application of Argon Ion Implantation to Improve the Surface Properties of Materials Based on PLA and Lignocellulosic Particles" Molecules 30, no. 9: 1948. https://doi.org/10.3390/molecules30091948

APA StyleBetlej, I., Barlak, M., Lipska, K., Boruszewski, P., & Borysiuk, P. (2025). Application of Argon Ion Implantation to Improve the Surface Properties of Materials Based on PLA and Lignocellulosic Particles. Molecules, 30(9), 1948. https://doi.org/10.3390/molecules30091948