Effect of Silane Coupling Agents on Structure and Properties of Carbon Fiber/Silicon Rubber Composites Investigated by Positron Annihilation Spectroscopy

Abstract

1. Introduction

2. Results and Discussion

2.1. Characterization of SCA-Modified CF

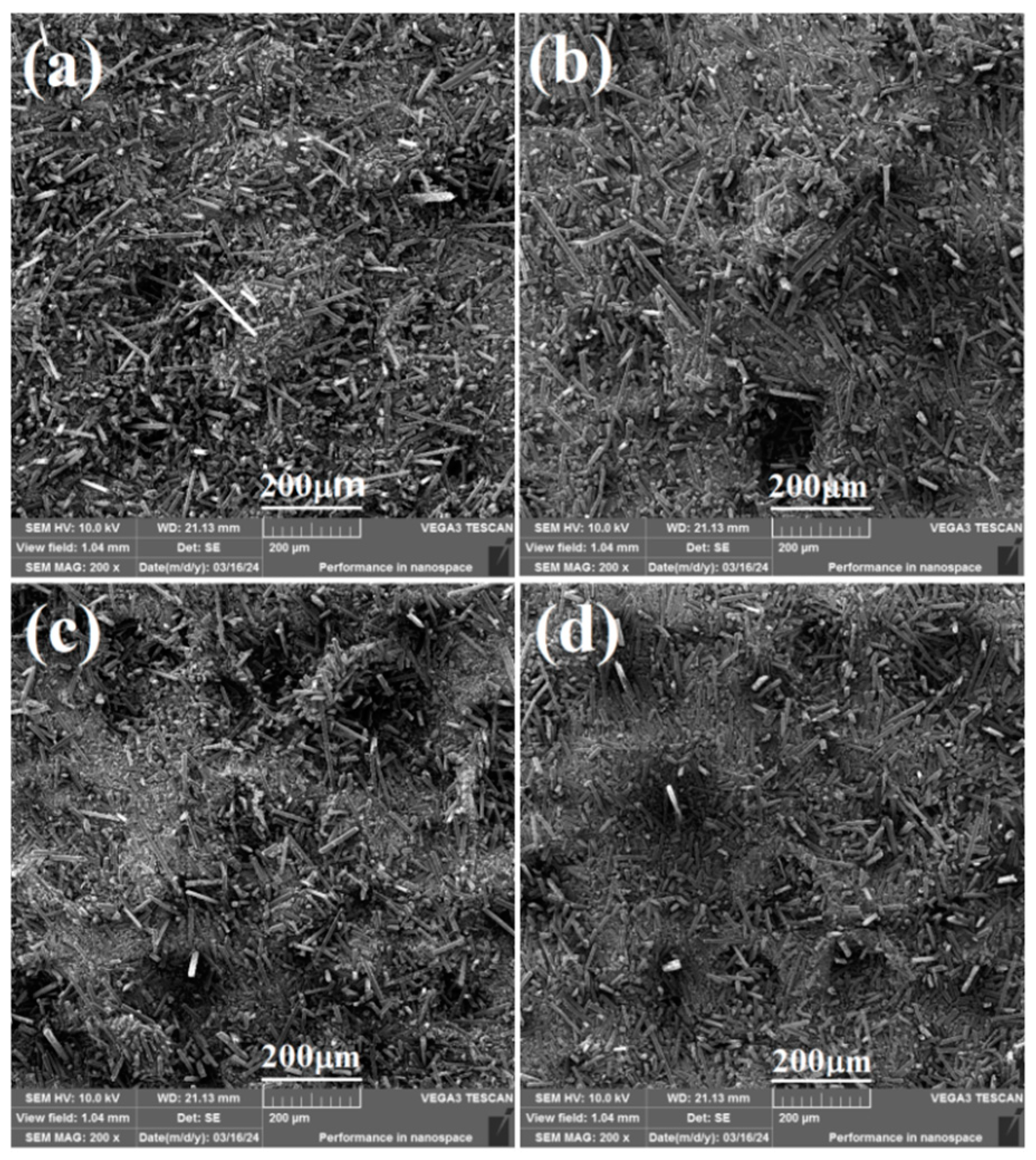

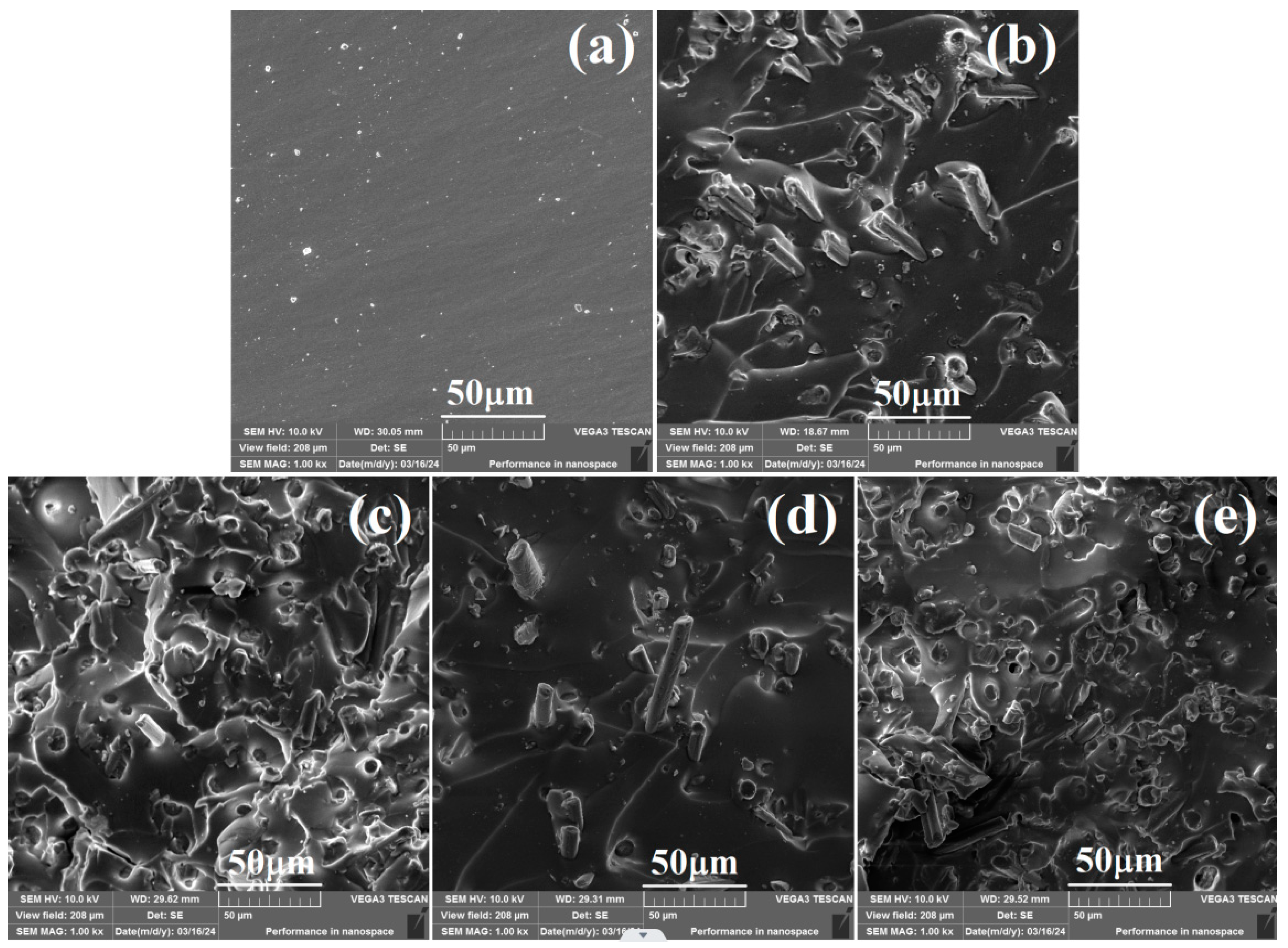

2.1.1. SEM Analysis

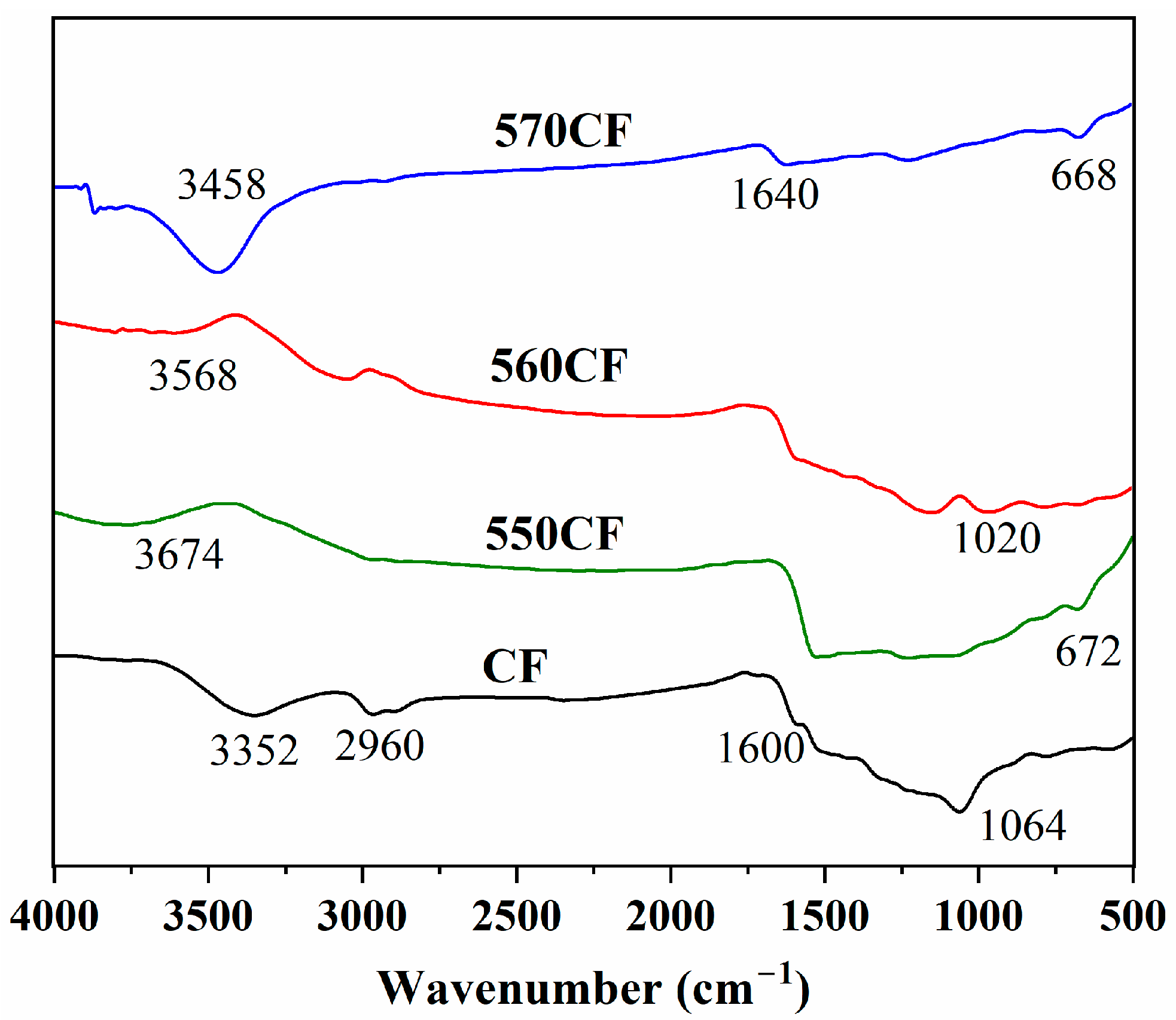

2.1.2. FTIR Analysis

2.2. Characterization of CF/SR Composites

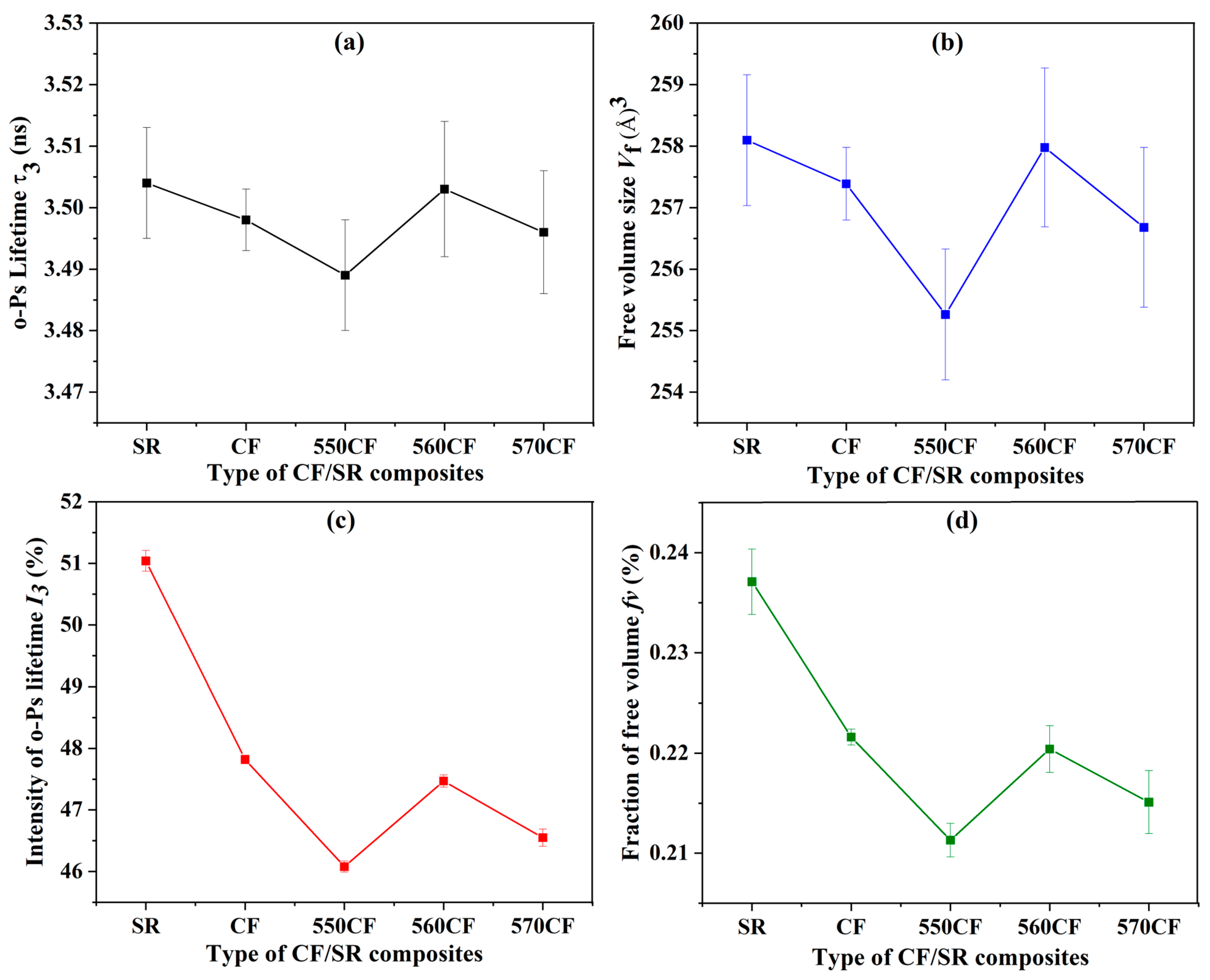

2.2.1. Free Volume Fraction (fv) of the CF/SR Composites

2.2.2. Interfacial Interaction Intensity (β) of the CF/SR Composites

2.3. Properties of Modified CF/SR Composites

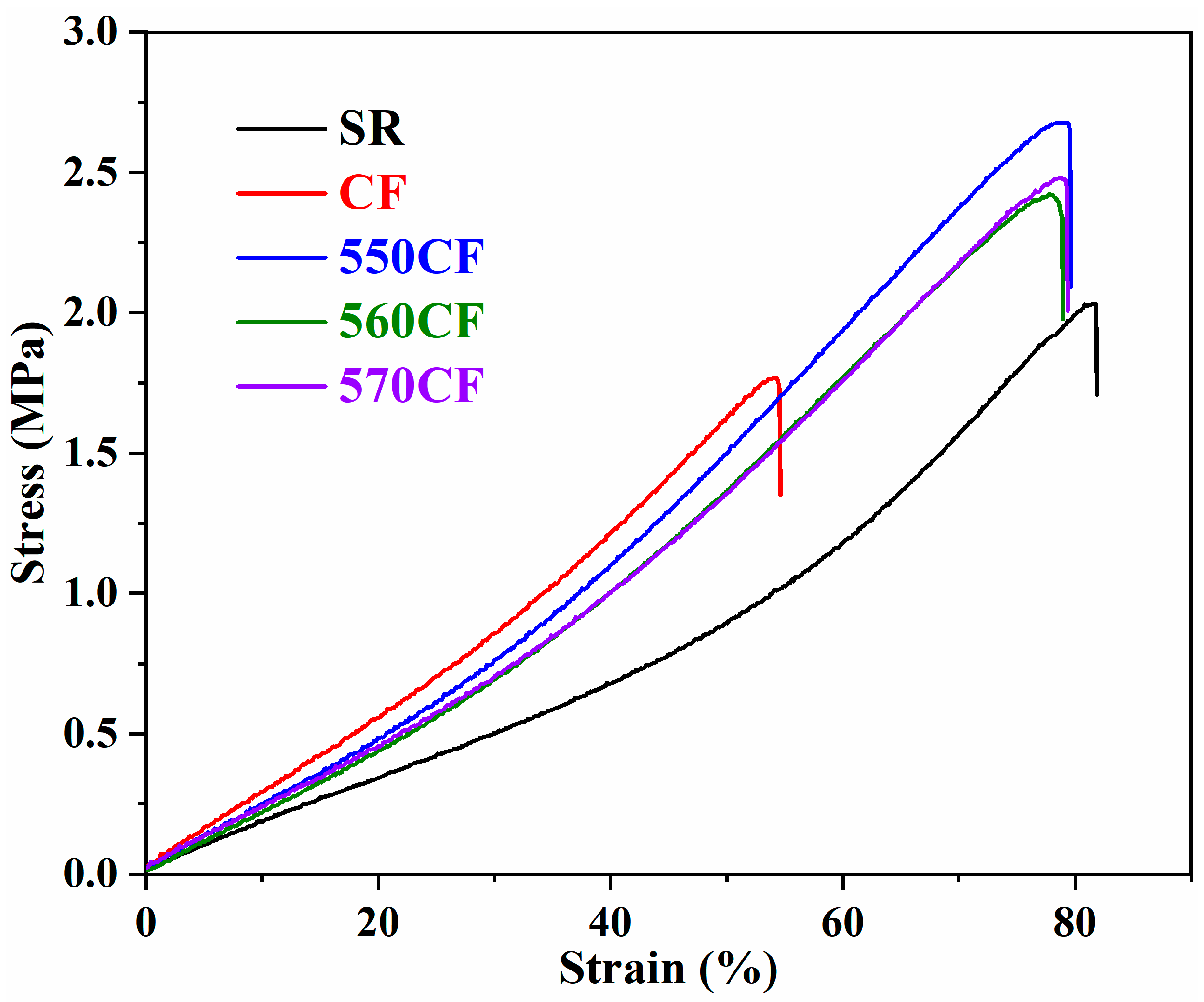

2.3.1. Mechanical Properties

2.3.2. Electric Properties

2.3.3. Thermal Properties

3. Materials and Methods

3.1. Materials

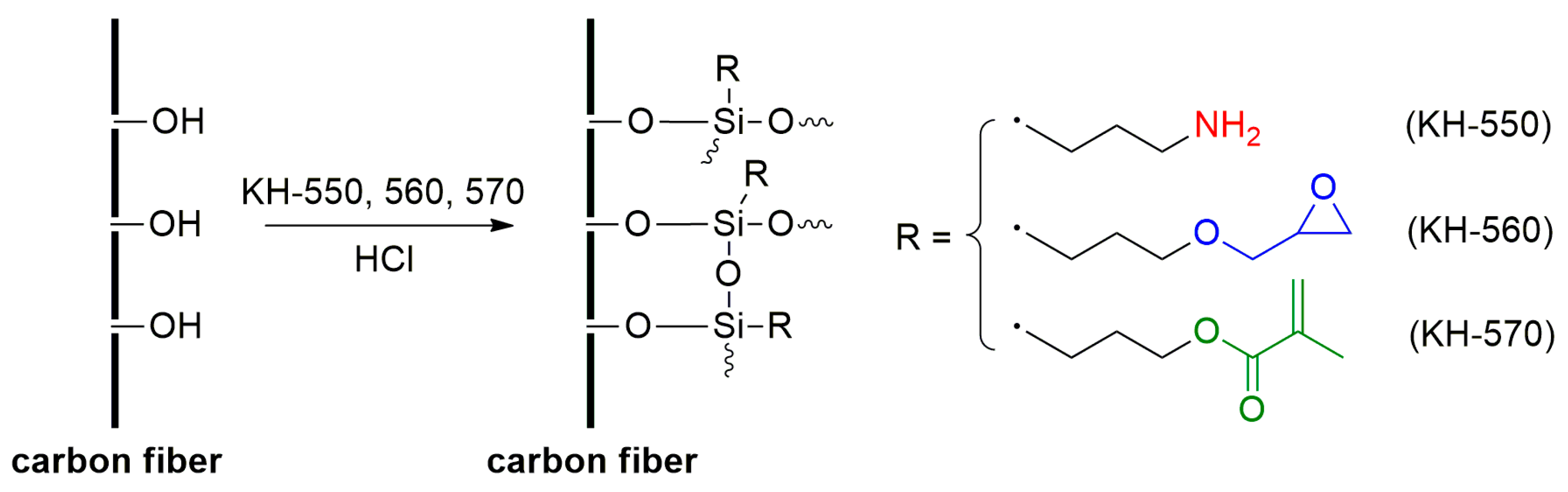

3.2. Preparation of SCA-Modified CF

3.3. Preparation of Modified CF-Incorporated SR Composites

3.4. Characterization of Modified CF and CF/SR Composites

3.5. PALS Characterization of CF/SR Composites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kinloch, I.A.; Suhr, J.; Lou, J.; Young, R.J.; Ajayan, P.M. Composites with carbon nanotubes and graphene: An outlook. Science 2018, 362, 547–553. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Chen, C.J.; Brozena, A.H.; Zhu, J.Y.; Xu, L.X.; Driemeier, C.; Dai, J.Q.; Rojas, O.J.; Isogai, A.; Wagberg, L.; et al. Developing fibrillated cellulose as a sustainable technological material. Nature 2021, 590, 47–56. [Google Scholar] [CrossRef] [PubMed]

- Grootel, A.V.; Chang, J.Y.; Wardle, B.L.; Olivetti, E. Manufacturing variability drives significant environmental and economic impact: The case of carbon fiber reinforced polymer composites in the aerospace industry. J. Clean. Prod. 2020, 261, 121087. [Google Scholar] [CrossRef]

- Liu, Y.P.; Zhang, M.J.; Liu, H.C.; Sun, Y.; Wang, W.X.; Liu, J. The influences of silane coupling agents on the heat and moisture resistance of basalt fibre-reinforced composites. High Volt. 2023, 8, 38–47. [Google Scholar] [CrossRef]

- Chen, F.; Bao, Y.Z.; Zhang, J.M.; Yang, M.; Ruan, M.; Feng, W.; Jiang, Y.F.; Li, M.; Chen, Y. Comparative study on the mechanical and thermal properties of polycarbonate composites reinforced by KH570/SA/SDBS modified wollastonite fibers. Polym. Compos. 2022, 43, 8125–8135. [Google Scholar] [CrossRef]

- Wang, Z.W.; Fang, Z.M.; Wu, H.L.; Liu, Q.F.; Li, Y.; Luo, L.; Wang, K. Effects of interfacial bonding strength on the formation of conductive anodic flament in polyphenylene oxide/glass fiber laminates. Microelectron. Reliab. 2022, 135, 114608. [Google Scholar] [CrossRef]

- Lin, G.Y.; Wang, H.; Yu, B.Q.; Qu, G.K.; Chen, S.W.; Kuang, T.R.; Yu, K.B.; Liang, Z.N. Combined treatments of fber surface etching/silane-coupling for enhanced mechanical strength of aramid fber-reinforced rubber blends. Mater. Chem. Phys. 2020, 255, 123486. [Google Scholar] [CrossRef]

- Zhao, X.L.; Du, J.H.; Yang, H.W.; Jia, C.C.; Wang, Y.L.; Wang, D.F.; Lv, Y.Y. Surface modification of ultra-high molecular weight polyethylene fiber by different kinds of SiO2 nanoparticles. Polym. Compos. 2017, 38, 1928–1936. [Google Scholar] [CrossRef]

- Wang, Q.T.; Zhang, Y.; Liang, W.K.; Wang, J.J.; Chen, Y.X. Effect of silane treatment on mechanical properties and thermal behavior of bamboo fibers reinforced polypropylene composites. J. Eng. Fibre Fabr. 2020, 15, 1–10. [Google Scholar] [CrossRef]

- Eibl, S.; Schuster, T.J. Thermal and principal ablation properties of carbon-fibre-reinforced polymers with out-of-plane fibre orientation. C-J. Carbon Res. 2021, 7, 64. [Google Scholar] [CrossRef]

- Das, T.K.; Ghosh, P.; Das, N.C. Preparation, development, outcomes, and application versatility of carbon fiber-based polymer composites: A review. Adv. Compos. Hybrid Mater. 2019, 2, 214–233. [Google Scholar] [CrossRef]

- Ali, Z.; Gao, Y.; Tang, B.; Wu, X.F.; Wang, Y.; Li, M.H.; Hou, X.; Li, L.H.; Jiang, N.; Yu, J.H. Preparation, properties and mechanisms of carbon fiber/polymer composites for thermal management applications. Polymers 2021, 13, 169. [Google Scholar] [CrossRef] [PubMed]

- Kong, D.Y.; Li, J.; Guo, A.R.; Xiao, X.L. High temperature electromagnetic shielding shape memory polymer composite. Chem. Eng. J. 2021, 408, 127365. [Google Scholar] [CrossRef]

- Guo, Z.W.; Liu, L.; Ao, Y.H. 2D/0D multiscale interfacial engineering of carbon fiber composites for simultaneous achieving high mechanical and electromagnetic interference shielding properties. Polym. Compos. 2024, 45, 7507–7518. [Google Scholar] [CrossRef]

- Li, M.H.; Ali, Z.; Wei, X.Z.; Li, L.H.; Song, G.C.; Hou, X.; Do, H.; Greer, J.G.; Pan, Z.B.; Lin, C.T.; et al. Stress induced carbon fber orientation for enhanced thermal conductivity of epoxy composites. Compos. Part B 2021, 208, 108599. [Google Scholar] [CrossRef]

- Maqsood, N.; Rimasauskas, M. Characterization of carbon fiber reinforced PLA composites manufactured by fused deposition modeling. Compos. Part C 2021, 4, 100112. [Google Scholar] [CrossRef]

- Zeng, C.J.; Liu, L.W.; Bian, W.F.; Liu, Y.J.; Leng, J.S. 4D printed electro-induced continuous carbon fber reinforced shape memory polymer composites with excellent bending resistance. Compos. Part B 2020, 194, 108034. [Google Scholar] [CrossRef]

- Huseynov, O.; Hasanov, S.; Fidan, I. Influence of the matrix material on the thermal properties of the short carbon fber reinforced polymer composites manufactured by material extrusion. J. Manuf. Process. 2023, 92, 521–523. [Google Scholar] [CrossRef]

- Uthaman, A.; Xian, G.J.; Thomas, S.; Wang, Y.J.; Zheng, Q.; Liu, X.L. Durability of an epoxy resin and its carbon fiber-reinforced polymer composite upon immersion in water, acidic, and alkaline solutions. Polymers 2020, 12, 614. [Google Scholar] [CrossRef]

- Memon, H.; Wei, Y.; Zhang, L.Y.; Jiang, Q.R.; Liu, W.S. An imine-containing epoxy vitrimer with versatile recyclability and its application in fully recyclable carbon fber reinforced composites. Compos. Sci. Technol. 2020, 199, 108314. [Google Scholar] [CrossRef]

- Zheng, H.; Zhang, W.J.; Li, B.W.; Zhu, J.J.; Wang, C.H.; Song, G.J.; Wu, G.S.; Yang, X.P.; Huang, Y.D.; Ma, L.C. Recent advances of interphases in carbon fber-reinforced polymer composites: A review. Compos. Part B 2022, 233, 109639. [Google Scholar] [CrossRef]

- Sharma, M.; Gao, S.L.; Mader, E.; Sharma, H.; Wei, L.Y.; Bijwe, J. Carbon fiber surfaces and composite interphases. Compos. Sci. Technol. 2014, 102, 35–50. [Google Scholar] [CrossRef]

- Liu, L.; Jia, C.Y.; He, J.M.; Zhao, F.; Fan, D.P.; Xing, L.X.; Wang, M.Q.; Wang, F.; Jiang, Z.X.; Huang, Y.D. Interfacial characterization, control and modification of carbon fiber reinforced polymer composites. Compos. Sci. Technol. 2015, 121, 56–72. [Google Scholar] [CrossRef]

- Yang, L.N.; Han, P.; Gu, Z. Grafting of a novel hyperbranched polymer onto carbon fiber for interfacial enhancement of carbon fiber reinforced epoxy composites. Mater. Design 2021, 200, 109456. [Google Scholar] [CrossRef]

- Wang, X.K.; Huang, Z.G.; Lai, M.L.; Jiang, L.; Zhang, Y.; Zhou, H.M. Highly enhancing the interfacial strength of CF/PEEK composites by introducing PAIK onto diazonium functionalized carbon fibers. Appl. Surf. Sci. 2020, 510, 145400. [Google Scholar] [CrossRef]

- Jiang, B.; Zhang, T.; Zhao, L.W.; Huang, Y.D. Interfacially reinforced carbon fiber composites by grafting modified methylsilicone resin. Compos. Sci. Technol. 2017, 140, 39–45. [Google Scholar] [CrossRef]

- Yuan, H.; Wang, C.G.; Zhang, S.; Lin, X. Effect of surface modification on carbon fiber and its reinforced phenolic matrix composite. Appl. Surf. Sci. 2012, 259, 288–293. [Google Scholar] [CrossRef]

- Ma, C.R.; Hou, D.W.; Jiang, J.L.; Fan, Y.C.; Li, X.; Li, T.Y.; Ma, Z.F.; Ben, H.X.; Xiong, H. Elucidating the synergic effect in nanoscale MoS2/TiO2 heterointerface for Na-Ion storage. Adv. Sci. 2022, 9, 2204837. [Google Scholar] [CrossRef]

- Shi, Y.J.; Feng, X.; Wang, H.Y.; Lu, X.H. Tribological properties of PTFE composites filled with surfacetreated carbon fiber. J. Mater. Sci. 2007, 42, 8465–8469. [Google Scholar] [CrossRef]

- He, J.M.; Huang, Y.D. Effect of silane-coupling agents on interfacial properties of CF/PI composites. J. Appl. Polym. Sci. 2007, 106, 2231–2237. [Google Scholar] [CrossRef]

- Jiang, Z.X.; Liu, L.; Huang, Y.D.; Ren, H. Influence of coupling agent chain lengths on interfacial performances of carbon fiber and polyarylacetylene resin composites. Surf. Interface Anal. 2009, 41, 624–631. [Google Scholar] [CrossRef]

- Wu, D.L.; Yao, Z.Q.; Sun, X.Y.; Liu, X.D.; Liu, L.; Zhang, R.L.; Wang, C.G. Mussel-tailored carbon fber/carbon nanotubes interface for elevated interfacial properties of carbon fber/epoxy composites. Chem. Eng. J. 2022, 429, 132449. [Google Scholar] [CrossRef]

- Li, H.F.; Liu, C.; Zhu, J.B.; Huan, X.H.; Qi, P.F.; Xu, K.; Geng, H.B.; Guo, X.D.; Wu, H.M.; Zu, L.; et al. Bio-inspired fabrication of “brick-and-mortar” interphase in carbon fiber/epoxy composites with significantly improved high-temperature durability. Adv. Compos. Hybrid Mater. 2024, 7, 72. [Google Scholar] [CrossRef]

- Li, X.Y.; Chen, P.; Sun, X.L.; Almasoud, N.; Wang, C.F.; Alomar, T.S.; Algadi, H.; Sun, B.; Lian, Z.L.; Guo, X.K. Electrophoretically deposited “rigid-flexible” hybrid graphene oxide-polyethyleneimine on carbon fibers for synergistically reinforced epoxy nanocomposites. Adv. Compos. Hybrid Mater. 2023, 6, 152. [Google Scholar] [CrossRef]

- Han, X.B.; Gao, J.; Chen, T.; Qian, L.B.; Xiong, H.H.; Chen, Z.Y. Application progress of PALS in the correlation of structure and properties for graphene/polymer nanocomposites. Nanomaterials 2022, 12, 4161. [Google Scholar] [CrossRef]

- Zhou, W.; Wang, J.J.; Gong, Z.L.; Gong, J.; Qi, N.; Wang, B. Investigation of interfacial interaction and structural transition for epoxy/nanotube composites by positron annihilation lifetime spectroscopy. Appl. Phys. Lett. 2009, 94, 021904. [Google Scholar] [CrossRef]

- Han, X.B.; Chen, T.; Zhao, Y.; Gao, J.; Sang, Y.N.; Xiong, H.H.; Chen, Z.Y. Relationship between the microstructure and performance of graphene/polyethylene composites investigated by positron annihilation lifetime spectroscopy. Nanomaterials 2021, 11, 2990. [Google Scholar] [CrossRef]

- Han, X.B.; Gao, J.; Chen, Z.Y.; Tang, X.Q.; Zhao, Y.; Chen, T. Correlation between microstructure and properties of graphene oxide/waterborne polyurethane composites investigated by positron annihilation spectroscopy. RSC Adv. 2020, 10, 32436–32442. [Google Scholar] [CrossRef]

- Sharma, S.K.; Prakash, J.; Sudarshan, K.; Maheshwari, P.; Sathiyamoorthy, D.; Pujari, P.K. Effect of interfacial interaction on free volumes in phenol-formaldehyde resin-carbon nanotube composites: Positron annihilation lifetime and age momentum correlation studies. Phys. Chem. Chem. Phys. 2012, 14, 10972–10978. [Google Scholar] [CrossRef]

- Patil, P.N.; Sudarshan, K.; Sharma, S.K.; Maheshwari, P.; Rath, S.K.; Patri, M.; Pujari, P.K. Investigation of nanoscopic free volume and interfacial interaction in an epoxy resin/modified clay nanocomposite using positron annihilation spectroscopy. ChemPhysChem 2012, 13, 3916–3922. [Google Scholar] [CrossRef]

- Gao, J.; Xiong, H.H.; Han, X.B.; An, F.; Chen, T. Synergistic effect of aluminum nitride and carbon nanotube-reinforced silicon rubber nanocomposites. Molecules 2024, 29, 2864. [Google Scholar] [CrossRef]

- Wang, G.F.; Li, A.L.; Zhao, W.; Xu, Z.H.; Ma, Y.W.; Zhang, G.Y.; Zhang, Y.B.; Zhou, J.; He, Q. A review on fabrication methods and research progress of superhydrophobic silicone rubber materials. Adv. Mater. Interfaces 2021, 8, 2001460. [Google Scholar] [CrossRef]

- Gao, J.; Bao, F.; Wu, Q.X.; Ma, R.; Han, X.B.; Jin, D.P.; Chen, K.Y.; He, J.Y.; Guo, Z.F.; Yan, C.J. Multifunctional graphene flled silicone encapsulant for high-performance light-emitting diodes. Mater. Today Commun. 2016, 7, 149–154. [Google Scholar] [CrossRef]

- Shinde, A.; Siva, I.; Munde, Y.; Deore, V.; Sultan, M.; Shah, A.U.; Mustapha, F. Testing of silicon rubber/montmorillonite nanocomposite for mechanical and tribological performance. Nanomaterials 2021, 11, 3050. [Google Scholar] [CrossRef]

- Shi, G.; Zhao, Z.H.; Pai, J.H.; Lee, I.; Zhang, L.Q.; Stevenson, C.; Ishara, K.; Zhang, R.J.; Zhu, H.W.; Ma, J. Highly sensitive, wearable, durable strain sensors, and stretchable conductors using graphene/silicon rubber composites. Adv. Funct. Mater. 2016, 26, 7614–7625. [Google Scholar] [CrossRef]

- Li, M.H.; Li, L.H.; Hou, X.; Qin, Y.; Song, G.C.; Wei, X.Z.; Kong, X.D.; Zhang, Z.B.; Do, H.; Greer, J.C.; et al. Synergistic effect of carbon fber and graphite on reducing thermal resistance of thermal interface materials. Compos. Sci. Technol. 2021, 212, 108883. [Google Scholar] [CrossRef]

- Huang, P.; Xia, Z.D.; Cui, S. 3D printing of carbon fiber-filled conductive silicon rubber. Mater. Design 2018, 142, 11–21. [Google Scholar] [CrossRef]

- Wang, L.; Huang, R.H.; Zhou, B.Q.; Zhang, Y.; Dong, Y.W. Carbon fibers modified with silicone peroxide containing vinyl groups for silicone rubber reinforcement. Mater. Lett. 2016, 176, 38–41. [Google Scholar] [CrossRef]

- Kim, E.S.; Lee, T.H.; Kim, E.J.; Yoom, J.S. Surface modification of carbon fiber and the mechanical properties of the silicone rubber/carbon fiber composites. J. Appl. Polym. Sci. 2012, S2, 48207. [Google Scholar] [CrossRef]

- Zhang, M.X.; Zhu, H.X.; Xi, B.D.; Tian, Y.X.; Sun, X.J.; Zhang, H.X.; Wu, B.B. Surface hydrophobic modification of biochar by silane coupling agent KH-570. Processes 2022, 10, 301. [Google Scholar] [CrossRef]

- Zhong, J.; Ding, Y.; Gao, F.; Wen, J.; Zhou, J.; Zheng, W.; Shen, L.; Fu, C.; Wang, B. Free volume correlation with electrical conductivity of polycarbonate/reduced graphene oxide nanocomposites studied by positron annihilation lifetime spectroscopy. J. Appl. Polym. Sci. 2019, 136, 48207. [Google Scholar] [CrossRef]

- Xue, G.; Zhong, J.; Gao, S.; Wang, B. Correlation between the free volume and thermal conductivity of porous poly(vinyl alcohol)/reduced graphene oxide composites studied by positron spectroscopy. Carbon 2016, 96, 871–878. [Google Scholar] [CrossRef]

- Yin, C.S.; He, C.; Liu, Q.; Xiong, B.; Li, J.; Zhou, Y. Effect of the orientation of sulfonated graphene oxide (SG) on the gas-barrier properties and proton conductivity of a SG/Nafion composite membrane. J. Membr. Sci. 2021, 625, 119146. [Google Scholar] [CrossRef]

- Palmeri, M.J.; Putz, K.W.; Brinson, L.C. Sacrificial bonds in stacked-cup carbon nanofibers: Biomimetic toughening mechanisms for composite systems. ACS Nano 2010, 4, 4256–4264. [Google Scholar] [CrossRef]

- Han, X.B.; Zhou, Z.H.; Gao, J.; Zhao, Y.; Chen, T. Effect of carbon nanoparticles morphology on the properties of poly(styrene-b-isoprene-b-styrene) elastomer composites. Polymers 2023, 15, 4415. [Google Scholar] [CrossRef] [PubMed]

- Han, X.B.; Kong, H.; Chen, T.; Gao, J.; Zhao, Y.; Sang, Y.N.; Hu, G.W. Effect of π–π stacking interfacial interaction on the properties of graphene/poly(styrene-b-isoprene-b-styrene) composites. Nanomaterials 2021, 11, 2158. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Zhang, X.; Song, C.C.; Zhang, Y.Y.; Fang, Y.C.; Yang, B.; Wang, X.L. An effective surface modification of carbon fiber for improving the interfacial adhesion of polypropylene composites. Mater. Des. 2015, 88, 810–819. [Google Scholar] [CrossRef]

- Fang, C.Q.; Wu, J.X.; Wang, J.L.; Zhang, T. Modification of carbon fiber surfaces via grafting with Meldrum’s acid. Appl. Surf. Sci. 2015, 356, 9–17. [Google Scholar] [CrossRef]

- Ouyang, Y.G.; Yang, Z.X.; Long, T.Y.; Tian, H.F.; Bai, L.Y.; Li, X.F.; Yuan, F.L. Preparation of branched Al2O3 and its synergistic effect with carbon nanotubes on the enhancement of thermal conductive and electrical insulation properties of silicone rubber composites. Mater. Today Commun. 2023, 34, 105239. [Google Scholar] [CrossRef]

- Ji, X.W.; Lu, Z.Y.; Wang, J.Y.; Ye, N.; Zhang, H.; Zhou, L.T.; Li, J.C.; Lu, Y.L. Construction of micro-nano hybrid structure based on carbon nanotube whisker and alumina for thermally conductive yet electrically insulating silicone rubber composites. Compos. Sci. Technol. 2024, 249, 110495. [Google Scholar] [CrossRef]

- Lee, S.; Hong, J.Y.; Jang, J. Multifunctional graphene sheets embedded in silicone encapsulant for superior performance of light emitting diodes. ACS Nano 2013, 7, 5784–5790. [Google Scholar] [CrossRef] [PubMed]

- GB/T 528-2009; Rubber, Vulcanized or Thermoplastic—Determination of Tensile Stress-Strain Properties. Standardization Administration of China: Beijing, China, 2009.

- GB/T 31838.2-2019; Solid Insulating Materials—Dielectric and Resistive Properties—Part 2: Resistive Properties (DC Methods)—Volume Resistance and Volume Resistivity. Standardization Administration of China: Beijing, China, 2019.

- GB/T 11205-2009; Rubber—Determination of Thermal Conductivity by means of Hot—Wire Method. Standardization Administration of China: Beijing, China, 2009.

| Samples | CF | SR | CF/SR | 550CF/SR | 560CF/SR | 570CF/SR |

|---|---|---|---|---|---|---|

| I2 (%) | 86.21 | 26.86 | 33.43 | 30.79 | 31.52 | 31.45 |

| Deviation | 1.742 | 0.159 | 0.082 | 0.076 | 0.084 | 0.112 |

| Samples | SR | CF/SR | 550CF/SR | 560CF/SR | 570CF/SR |

|---|---|---|---|---|---|

| Tensile strength (MPa) | 2.03 ± 0.05 | 1.76 ± 0.04 | 2.68 ± 0.07 | 2.36 ± 0.04 | 2.52 ± 0.05 |

| Elongation (%) | 81.4 ± 1.1 | 53.9 ± 1.5 | 79.4 ± 0.7 | 77.3 ± 0.6 | 78.5 ± 0.4 |

| Samples | T30% (°C) | R800 (%) |

|---|---|---|

| SR | 486.4 | 8.6 |

| CF/SR | 620.6 | 46.7 |

| 550CF/SR | 648.8 | 53.5 |

| 560CF/SR | 632.9 | 50.4 |

| 570CF/SR | 634.3 | 52.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, J.; Mei, J.; Xiong, H.; Han, X. Effect of Silane Coupling Agents on Structure and Properties of Carbon Fiber/Silicon Rubber Composites Investigated by Positron Annihilation Spectroscopy. Molecules 2025, 30, 1658. https://doi.org/10.3390/molecules30081658

Gao J, Mei J, Xiong H, Han X. Effect of Silane Coupling Agents on Structure and Properties of Carbon Fiber/Silicon Rubber Composites Investigated by Positron Annihilation Spectroscopy. Molecules. 2025; 30(8):1658. https://doi.org/10.3390/molecules30081658

Chicago/Turabian StyleGao, Jie, Jiaming Mei, Houhua Xiong, and Xiaobing Han. 2025. "Effect of Silane Coupling Agents on Structure and Properties of Carbon Fiber/Silicon Rubber Composites Investigated by Positron Annihilation Spectroscopy" Molecules 30, no. 8: 1658. https://doi.org/10.3390/molecules30081658

APA StyleGao, J., Mei, J., Xiong, H., & Han, X. (2025). Effect of Silane Coupling Agents on Structure and Properties of Carbon Fiber/Silicon Rubber Composites Investigated by Positron Annihilation Spectroscopy. Molecules, 30(8), 1658. https://doi.org/10.3390/molecules30081658