Characterization of Volatilized Compounds in Conventional and Organic Vegetable-Source Alternative Meat-Curing Ingredients

Abstract

1. Introduction

2. Results

2.1. Physicochemical Properties of Commercially Available Pre-Converted Vegetable Curing Powders

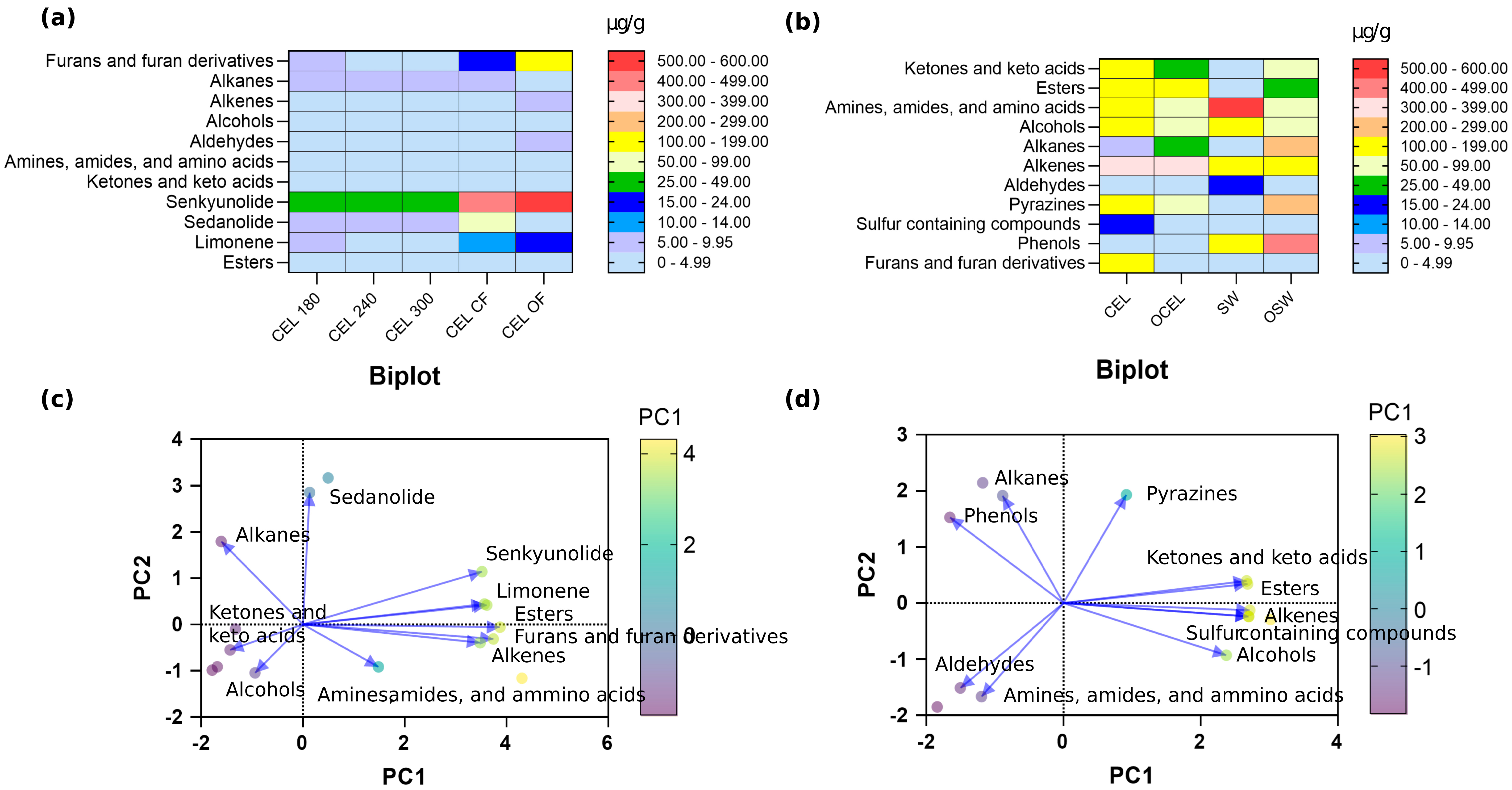

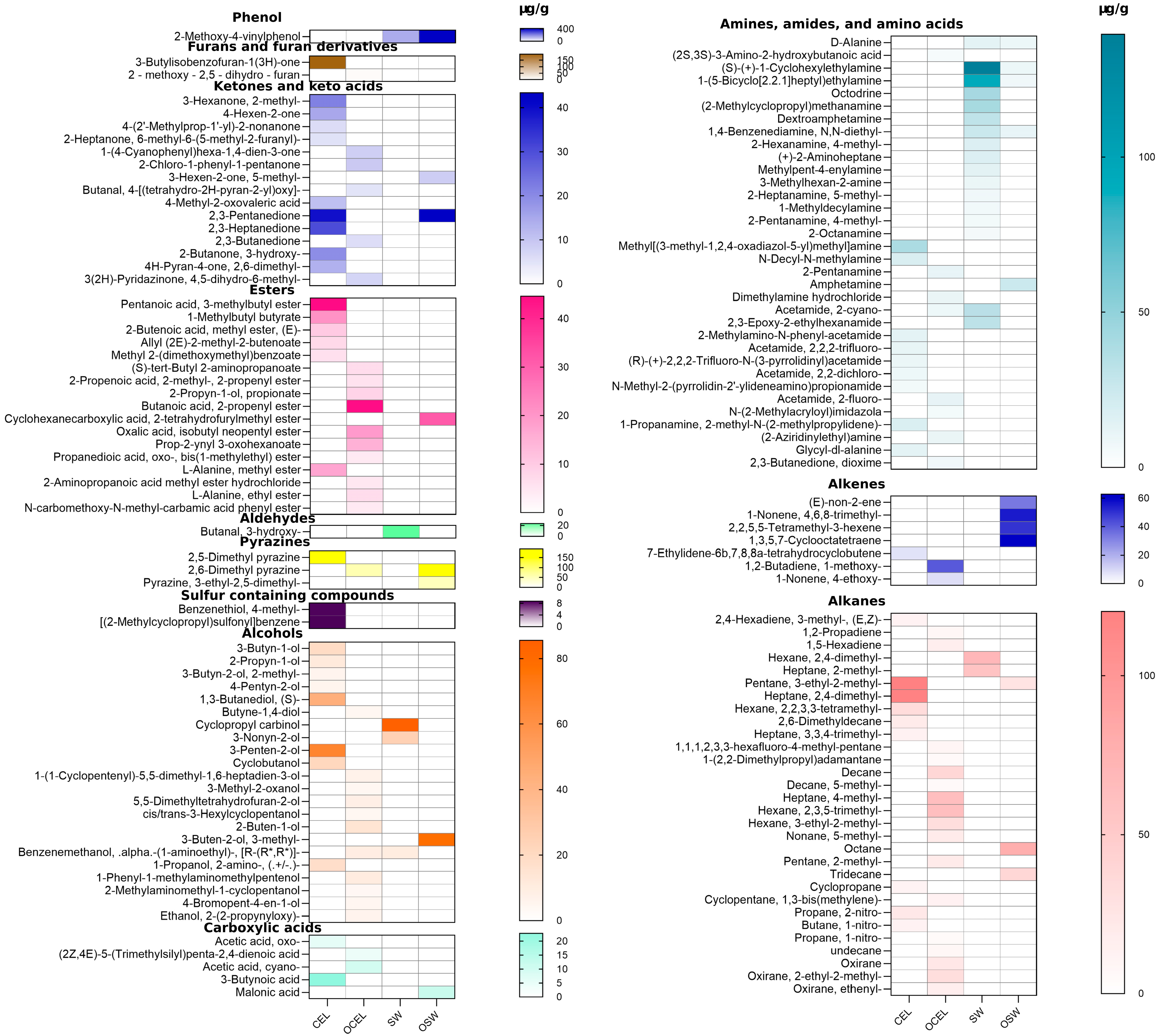

2.2. Comparison of Commercially Available Conventional and Organic Pre-Converted Vegetable Curing Powders

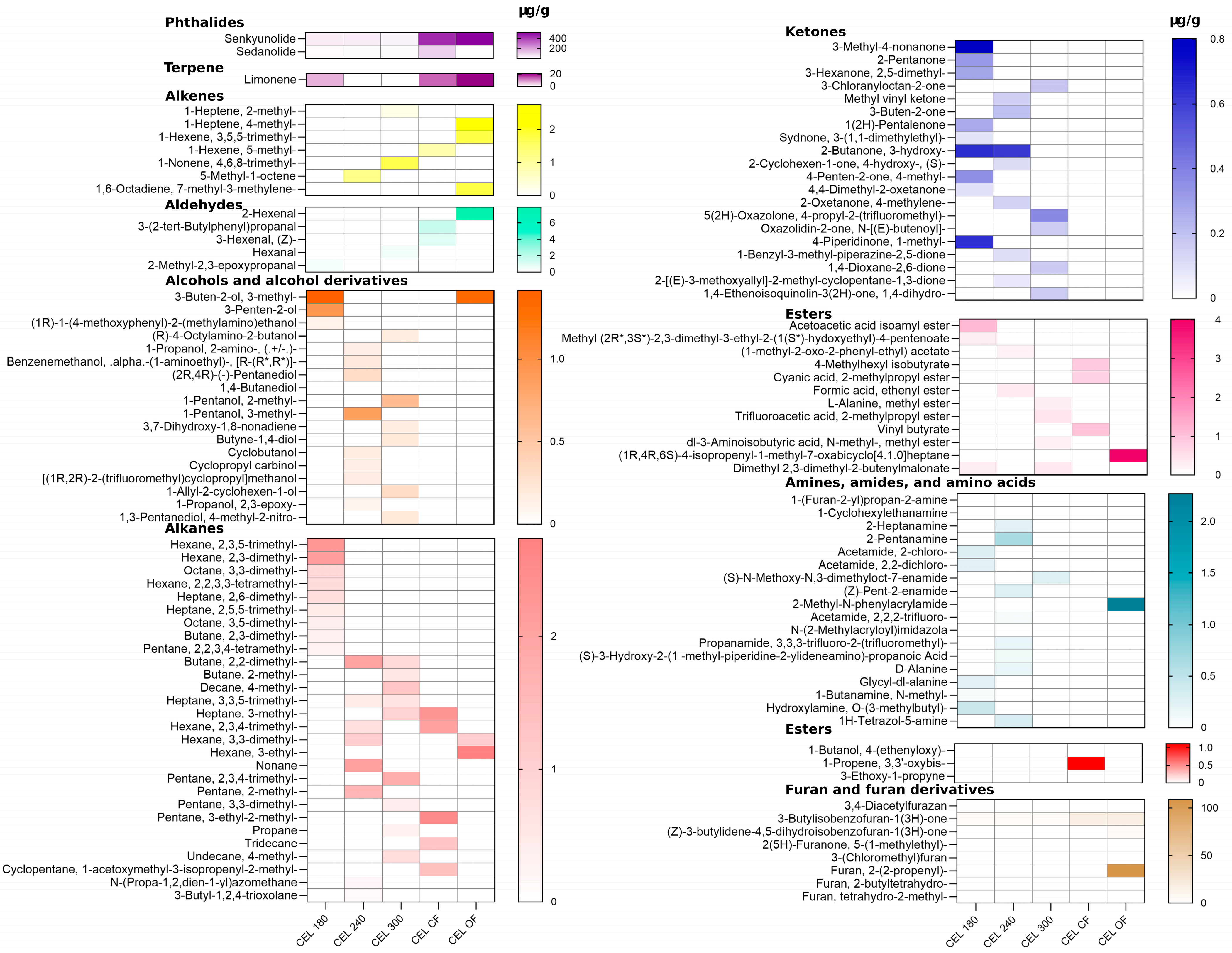

2.3. Comparison of Non-Converted and Pre-Converted Organic Celery Juices

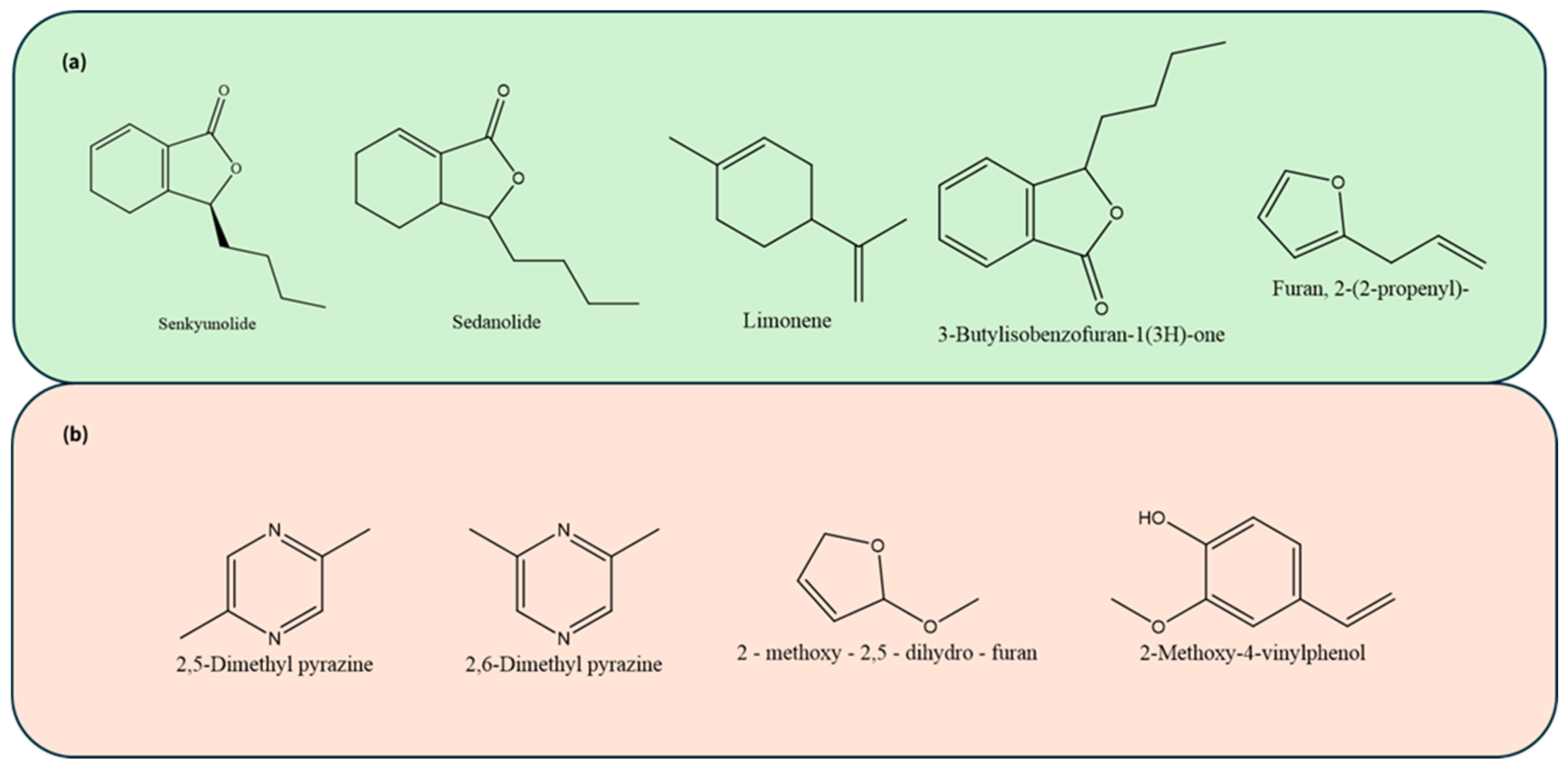

2.4. Chemical Composition Differences in Pre-Converted Vegetable Powder and Juices

3. Discussion

4. Materials and Methods

4.1. Plant-Source Meat-Curing Materials

4.2. Extraction of VOCs

4.3. Detection of VOCs Using a GC-MS/MS System

4.4. Qualitative and Quantitative Analysis of VOCs

4.5. Residual Nitrite and Nitrate Measurements

4.6. pH Measurement

4.7. Data Analysis

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| USDA | U.S. Department of Agriculture |

| HPLC | High-pressure liquid chromatography |

| GC | Gas chromatography |

| VOC | Volatile compounds |

| MS/MS | Tandem mass spectrometry |

| PCA | Principal component analysis |

References

- Keenan, D.F. Pork Meat Quality, Production and Processing on. In Encyclopedia of Food and Health; Caballero, B., Finglas, P.M., Toldrá, F., Eds.; Academic Press: Oxford, UK, 2016; pp. 419–431. [Google Scholar]

- Karwowska, M.; Kononiuk, A.; Wójciak, K.M. Impact of sodium nitrite reduction on lipid oxidation and antioxidant properties of cooked meat products. Antioxidants 2019, 9, 9. [Google Scholar] [CrossRef] [PubMed]

- Froehlich, D.A.; Gullett, E.; Usborne, W. Effect of nitrite and salt on the color, flavor and overall acceptability of ham. J. Food Sci. 1983, 48, 152–154. [Google Scholar] [CrossRef]

- Pierson, M.D.; Smoot, L.A.; Robach, M.C. Nitrite, nitrite alternatives, and the control of Clostridium Botulinum in cured meats. CRC Crit. Rev. Food Sci. Nutr. 1983, 17, 141–187. [Google Scholar] [CrossRef] [PubMed]

- USDA, 7 CFR 205.606. In U.S.A. 2024. Available online: https://www.ecfr.gov/current/title-7/section-205.606 (accessed on 20 November 2024).

- Organic Trade Association. RE: Celery Powder—Handling Subcommittee 2026 Sunset Reviews. 2024. Available online: https://ota.com/sites/default/files/indexed_files/OTA_HS_CeleryPowder_NOSBSpring2024_AMS-NOP-23-0075_FINAL.pdf (accessed on 24 November 2024).

- Santamaria, P.; Elia, A.; Serio, F.; Gonnella, M.; Parente, A. Comparison between nitrate and ammonium nutrition in fennel, celery, and swiss chard. J. Plant Nutr. 1999, 22, 1091–1106. [Google Scholar] [CrossRef]

- Ballmer-Weber, B.; Hoffmann, A.; Wüthrich, B.; Lüttkopf, D.; Pompei, C.; Wangorsch, A.; Kästner, M.; Vieths, S. Influence of food processing on the allergenicity of celery: DBPCFC with celery spice and cooked celery in patients with celery allergy. Allergy 2002, 57, 228–235. [Google Scholar] [CrossRef]

- USDA, 9 CFR 317.17. In U.S.A. 1979. Available online: https://www.ecfr.gov/current/title-9/section-317.17 (accessed on 20 November 2024).

- Grand View Research. Organic Meat Market Size, Share & Trends Analysis Report by Meat Type (Poultry, Pork), by Product (Chilled, Preserved), by Distribution Channel (Natural Food Stores, Retailers, Hypermarkets), by Region, and Segment Forecasts, 2023 to 2030; Grand View Research: San Francisco, CA, USA, 2023. [Google Scholar]

- Mordor Intelligence. Organic Meat Market Size & Share Analysis-Growth Trends & Forecasts (2024–2029); Mordor Intelligence: Hyderabad, India, 2024. [Google Scholar]

- NOSB. National Organic Standards Board Meeting; NOSB: Atlanta, GA, USA, 2023; pp. 104–105. [Google Scholar]

- Matallana Gonzalez, M.; Martinez-Tome, M.; Torija Isasa, M. Nitrate and nitrite content in organically cultivated vegetables. Food Addit. Contam. Part B 2010, 3, 19–29. [Google Scholar] [CrossRef]

- Ibrahim, M.H.; Jaafar, H.Z.E.; Karimi, E.; Ghasemzadeh, A. Impact of organic and inorganic fertilizers application on the phytochemical and antioxidant activity of Kacip Fatimah (Labisia pumila Benth). Molecules 2013, 18, 10973–10988. [Google Scholar] [CrossRef] [PubMed]

- Klimankova, E.; Holadová, K.; Hajšlová, J.; Čajka, T.; Poustka, J.; Koudela, M. Aroma Profiles of Five Basil (Ocimum basilicum L.) cultivars grown under conventional and organic conditions. Food Chem. 2008, 107, 464–472. [Google Scholar] [CrossRef]

- Ruan, S.; Luo, H.; Wu, F.; He, L.; Lai, R.; Tang, X. Organic cultivation induced regulation in yield formation, grain quality attributes, and volatile organic compounds of fragrant rice. Food Chem. 2023, 405, 134845. [Google Scholar] [CrossRef] [PubMed]

- Dong, T.; Chen, X.; Wang, M.; Huang, Y.; Yi, G. Comparison of volatile aroma compounds in Dwarf Cavendish banana (Musa spp. AAA) grown under organic or traditional cultivation. J. Hortic. Sci. Biotechnol. 2014, 89, 441–447. [Google Scholar] [CrossRef]

- Sun, Y.; Li, M.; Li, X.; Du, J.; Li, W.; Lin, Y.; Zhang, Y.; Wang, Y.; He, W.; Chen, Q.; et al. Characterization of Volatile Organic Compounds in Five Celery (Apium graveolens L.) Cultivars with Different Petiole Colors by HS-SPME-GC-MS. Int. J. Mol. Sci. 2023, 24, 13343. [Google Scholar] [CrossRef] [PubMed]

- Glass, C.; Silverstein, J. Denitrification kinetics of high nitrate concentration water: pH effect on inhibition and nitrite accumulation. Water Res. 1998, 32, 831–839. [Google Scholar] [CrossRef]

- Fors, S.M.; Olofsson, B.K. Alkylpyrazines, volatiles formed in the Maillard reaction. I. Determination of odour detection thresholds and odour intensity functions by dynamic olfactometry. Chem. Senses 1985, 10, 287–296. [Google Scholar] [CrossRef]

- Hou, L.; Zhang, Y.; Wang, X. Characterization of the volatile compounds and taste attributes of sesame pastes processed at different temperatures. J. Oleo Sci. 2019, 68, 551–558. [Google Scholar] [CrossRef] [PubMed]

- Miao, Y.-h.; Hu, Y.-h.; Yang, J.; Liu, T.; Sun, J.; Wang, X.-J. Natural source, bioactivity and synthesis of benzofuran derivatives. RSC Adv. 2019, 9, 27510–27540. [Google Scholar] [CrossRef]

- Sunao, M.; Ito, T.; Hiroshima, K.; Sato, M.; Uehara, T.; Ohno, T.; Watanabe, S.; Takahashi, H.; Hashizume, K. Analysis of volatile phenolic compounds responsible for 4-vinylguaiacol-like odor characteristics of sake. Food Sci. Technol. Res. 2016, 22, 111–116. [Google Scholar] [CrossRef]

- Wang, K.; Liu, X.; Cai, G.; Gong, J.; Guo, Y.; Gao, W. Chemical Composition Analysis of Angelica Sinensis (Oliv.) Diels and its four processed products by ultra-high-performance liquid chromatography coupled with quadrupole-orbitrap mass spectrometry combining with nontargeted metabolomics. J. Sep. Sci. 2023, 46, 2300473. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Cheng, M.; Xue, Y.; Lin, L.; Wang, Y.; Li, B. Volatile flavour identification and odour complexity of Radix Angelicae Sinensis by electronic nose, integrated gas chromatography–mass spectrometry/olfactometry and comprehensive two-dimensional gas chromatography-time-of-flight-mass spectrometry. Phytochem. Anal. 2023, 34, 329–346. [Google Scholar] [CrossRef]

- Kurobayashi, Y.; Kouno, E.; Fujita, A.; Morimitsu, Y.; Kubota, K. Potent odorants characterize the aroma quality of leaves and stalks in raw and boiled celery. Biosci. Biotechnol. Biochem. 2006, 70, 958–965. [Google Scholar] [CrossRef]

- Oguro, D.; Watanabe, H. Asymmetric synthesis and sensory evaluation of sedanenolide. Biosci. Biotechnol. Biochem. 2011, 75, 1502–1505. [Google Scholar] [CrossRef] [PubMed]

- Jongedijk, E.; Cankar, K.; Buchhaupt, M.; Schrader, J.; Bouwmeester, H.; Beekwilder, J. Biotechnological production of limonene in microorganisms. Appl. Microbiol. Biotechnol. 2016, 100, 2927–2938. [Google Scholar] [CrossRef] [PubMed]

- Wailzer, B.; Kocker, J.; Wolschann, P.; Buchbauer, G. Structural features for furan-derived fruity and meaty aroma impressions. Nat. Prod. Commun. 2016, 11, 1475–1479. [Google Scholar] [CrossRef]

- Young, J.E.; Zhao, X.; Carey, E.E.; Welti, R.; Yang, S.S.; Wang, W. Phytochemical phenolics in organically grown vegetables. Mol. Nutr. Food Res. 2005, 49, 1136–1142. [Google Scholar] [CrossRef]

- de Oliveira Pereira, F.; dos Santos Pereira, R.; de Souza Rosa, L.; Teodoro, A.J. Organic and conventional vegetables: Comparison of the physical and chemical characteristics and antioxidant activity. Afr. J. Biotechnol. 2016, 15, 1746–1754. [Google Scholar]

- Ferreira, V.B.; da Silva, T.T.C.; Couto, S.R.M.; Srur, A.U.O.S. Total phenolic compounds and antioxidant activity of organic vegetables consumed in Brazil. Food Nutr. Sci. 2015, 6, 798–804. [Google Scholar] [CrossRef]

- Kelly, D.; Zerihun, A. The effect of phenol composition on the sensory profile of smoke affected wines. Molecules 2015, 20, 9536–9549. [Google Scholar] [CrossRef] [PubMed]

- Doraghi, F.; Morshedsolouk, M.H.; Zahedi, N.A.; Larijani, B.; Mahdavi, M. Phthalimides: Developments in synthesis and functionalization. RSC Adv. 2024, 14, 22809–22827. [Google Scholar] [CrossRef]

- Hong, Y.S.; Son, J.H.; Jeong, J.Y.; Song, O.Y.; Lee, J.H.; Kim, K.S. Comparison of volatile flavor compounds of Artemisia annua L. extracted by simultaneous steam distillation extraction and solid-phase micro extraction. Korean J. Food Preserv. 2018, 25, 321–329. [Google Scholar] [CrossRef]

- Abbas, A.A.; Dawood, K.M. Anticancer therapeutic potential of benzofuran scaffolds. RSC Adv. 2023, 13, 11096–11120. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Wu, Y.; Yin, H.; Du, L.; Chen, C. Senkyunolide I: A review of its phytochemistry, pharmacology, pharmacokinetics, and drug-likeness. Molecules 2023, 28, 3636. [Google Scholar] [CrossRef]

- Li, Q.; Wan, J.-B.; Zhao, L. Research progress on the pharmacological activities of senkyunolides. Acupunct. Herb. Med. 2023, 3, 180–188. [Google Scholar] [CrossRef]

- Qi, H.; Siu, S.O.; Chen, Y.; Han, Y.; Chu, I.K.; Tong, Y.; Lau, A.S.; Rong, J. Senkyunolides reduce hydrogen peroxide-induced oxidative damage in human liver HepG2 cells via induction of heme oxygenase-1. Chem.-Biol. Interact. 2010, 183, 380–389. [Google Scholar] [CrossRef] [PubMed]

- Woods, J.; Jewell, C.; O’Brien, N. Sedanolide, A natural phthalide from celery seed oil: Effect on hydrogen peroxide and tert-butyl hydroperoxide-induced toxicity in Hepg2 and Caco-2 human cell lines. Vitr. Mol. Toxicol. A J. Basic Appl. Res. 2001, 14, 233–240. [Google Scholar] [CrossRef]

- Hussain, M.; Sabri, R.; Zia-Ul-Haq, M.; Riaz, M. Celery. In Essentials of Medicinal and Aromatic Crops; Zia-Ul-Haq, M., Abdulkreem Al-Huqail, A., Riaz, M., Farooq Gohar, U., Eds.; Springer International Publishing: Cham, Switzerland, 2023; pp. 1165–1190. [Google Scholar]

- Xie, R.; Tu, M.; Elder, T. Substituent effect of phenolic aldehyde inhibition on alcoholic fermentation by Saccharomyces cerevisiae. Energy Fuels 2016, 30, 3078–3084. [Google Scholar] [CrossRef]

- Shu, C.-K. Pyrazine formation from amino acids and reducing sugars, a pathway other than Strecker degradation. J. Agric. Food Chem. 1998, 46, 1515–1517. [Google Scholar] [CrossRef]

- Sheng, J.-P.; Liu, C.; Shen, L. Comparative study of minerals and some nutrients in organic celery and traditional celery. Spectrosc. Spectr. Anal. 2009, 29, 247–249. [Google Scholar]

- Gąstoł, M.; Domagała-Świątkiewicz, I.; Krośniak, M. Organic versus conventional–a comparative study on quality and nutritional value of fruit and vegetable juices. Biol. Agric. Hortic. 2011, 27, 310–319. [Google Scholar] [CrossRef]

- Colonia, B.S.O.; de Melo Pereira, G.V.; de Carvalho, J.C.; Karp, S.G.; Rodrigues, C.; Soccol, V.T.; Fanka, L.S.; Soccol, C.R. Deodorization of algae biomass to overcome off-flavors and odor issues for developing new food products: Innovations, Trends, and Applications. Food Chem. Adv. 2023, 2, 100270. [Google Scholar] [CrossRef]

- Hong, J.; Kim, M.-J.; Oh, W.Y.; Lee, J. Evaluation of deodorization techniques using cyclodextrins on the headspace volatiles and antioxidant properties of onion. Food Chem. 2023, 410, 135416. [Google Scholar] [CrossRef] [PubMed]

- Feng, S.; Tian, Y.; Sheng, J.; Yu, J.; Lin, Y.; Hileuskaya, K.; Kraskouski, A.; Li, H.; Lin, Z.; Shao, P. Enhancing high-temperature stability of limonene-loaded nanostructured lipid carriers with various solid lipids. Food Bioeng. 2024, 3, 323–336. [Google Scholar] [CrossRef]

- Ahmed, E.M.; Dennison, R.A.; Dougherty, R.H.; Shaw, P.E. Effect of nonvolatile orange juice components, acid, sugar, and pectin on the flavor threshold of D-limonene in water. J. Agric. Food Chem. 1978, 26, 192–194. [Google Scholar] [CrossRef]

- Vieira, A.J.; Beserra, F.P.; Souza, M.C.; Totti, B.M.; Rozza, A.L. Limonene: Aroma of innovation in health and disease. Chem.-Biol. Interact. 2018, 283, 97–106. [Google Scholar] [CrossRef]

- Bai, J.; Guenther, A.; Turnipseed, A.; Duhl, T.; Yu, S.; Wang, B. Seasonal variations in whole-ecosystem BVOC emissions from a subtropical bamboo plantation in China. Atmos. Environ. 2016, 124, 12–21. [Google Scholar] [CrossRef]

- Wettasinghe, M.; Vasanthan, T.; Temelli, F.; Swallow, K. Volatile flavour composition of cooked by-product blends of chicken, beef and pork: A quantitative GC–MS investigation. Food Res. Int. 2001, 34, 149–158. [Google Scholar] [CrossRef]

- Xie, Y.; He, Z.; Zhang, E.; Li, H. Characterization of key volatile odorants in rabbit meat using gas chromatography mass spectrometry with simultaneous distillation extraction. World Rabbit Sci. 2016, 24, 313–320. [Google Scholar] [CrossRef]

- Madruga, M.S.; Elmore, J.S.; Dodson, A.T.; Mottram, D.S. Volatile flavour profile of goat meat extracted by three widely used techniques. Food Chem. 2009, 115, 1081–1087. [Google Scholar] [CrossRef]

- Watkins, P.; Rose, G.; Warner, R.; Dunshea, F.; Pethick, D. A comparison of solid-phase microextraction (SPME) with simultaneous distillation–extraction (SDE) for the analysis of volatile compounds in heated beef and sheep fats. Meat Sci. 2012, 91, 99–107. [Google Scholar] [CrossRef]

- Li, J.; Zhang, Q.; Peng, B.; Hu, M.; Zhong, B.; Yu, C.-w.; Tu, Z. Exploration on the quality changes and flavour characteristics of freshwater crayfish (Procambarus clarkia) during steaming and boiling. LWT 2023, 190, 115582. [Google Scholar] [CrossRef]

- De González, M.T.N.; Osburn, W.N.; Hardin, M.D.; Longnecker, M.; Garg, H.K.; Bryan, N.S.; Keeton, J.T. Survey of Residual Nitrite and Nitrate in Conventional and Organic/Natural/Uncured/Indirectly Cured Meats Available at Retail in the United States. J. Agric. Food Chem. 2012, 60, 3981–3990. [Google Scholar] [CrossRef] [PubMed]

- Korkeala, H.; Mäki-Petäys, O.; Alanko, T.; Sorvettula, O. Determination of pH in meat. Meat Sci. 1986, 18, 121–132. [Google Scholar] [CrossRef]

| Product 1,2 | Appearance | Ingredient | pH | Nitrite Content on Label 3 | Measured Nitrite Content 3,4 |

|---|---|---|---|---|---|

| CEL | Tan to brown free-flowing powder | Cultured celery powder, sea salt | 7.88 | 22,500 | 22,487 |

| SW | Tan to brown free-flowing powder | Cultured Swiss chard powder, sea salt | 8.63 | 22,500 | 24,531 |

| OSW | Tan to brown free-flowing powder | Organic Swiss chard powder, sea salt | 8.89 | 22,500 | 27,711 |

| OCEL | Yellow-brown flowing powder | Sea salt, cultured organic celery juice powder | 7.49 | 20,250–24,750 | 17,262 |

| Compounds | Commercially Available Alternative Curing Powder 1 | CAS # | Notes Description | |||

|---|---|---|---|---|---|---|

| CEL | OCEL | SW | OSW | |||

| 2,5-Dimethyl pyrazine | 165.91 ± 0.87 | - | - | - | 123-32-0 | earthy and roasted [20] |

| 2,6-Dimethyl pyrazine | - | 54.65 ± 0.24 | - | 191.41 ± 1.14 | 108-50-9 | nutty, coffee-like, and roasted [20,21] |

| 3-Butylisobenzofuran-1(3H)-one | 196.17 ± 1.01 | - | - | 6066-49-5 | woody, spicy, and slightly floral scent [22] | |

| 2-methoxy-2,5-dihydro-furan | - | 4.93 ± 0.02 | - | - | 332-77-4 | slightly fruity [22] |

| 2-Methoxy-4-vinylphenol | - | - | 139.65 ± 1.76 | 420.46 ± 2.57 | 7786-61-0 | apple, spicy, peanut, wine-like aroma [23] |

| Compounds | Organic Pre-Converted Celery Juice 1 | Non-Converted Celery Juice 2 | CAS # | Notes Description | |||

|---|---|---|---|---|---|---|---|

| CEL 180 | CEL 240 | CEL 300 | CEL CF | CEL OF | |||

| Senkyunolide | 45.16 ± 0.24 a | 42.71 ± 0.47 a | 30.72 ± 0.58 b | 434.00 ± 2.01 a | 518.71 ± 2.41 a | 94596-27-7 | celery-like aroma [24,25] |

| Sedanolide | 9.26 ± 0.11 a | 9.94 ± 0.21 a | 7.35 ± 0.17 b | 97.55 ± 0.46 a | 2.11 ± 0.01 b | 6415-59-4 | fresh, green, and slightly spicy aroma of celery [26,27] |

| Limonene | 6.55 ± 0.01 a | - | - | 12.87 ± 0.14 b | 21.00 ± 0.23 a | 138-86-3 | fresh, citrusy aroma [28] |

| 3-Butylisobenzofuran-1(3H)-one | 4.70 ± 0.47 a | 4.52 ± 0.11 a | 3.27 ± 0.03 b | 17.87 ± 0.25 a | 18.21 ± 0.17 a | 6066-49-5 | woody, spicy, and slightly floral scent [22] |

| Furan, 2-(2-propenyl)- | - | - | - | - | 108.92 ± 0.87 | 75135-41-0 | sweet, green, and slightly fruity aroma [29]. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sheng, S.; Silva, E.M.; Ricke, S.C.; Claus, J.R. Characterization of Volatilized Compounds in Conventional and Organic Vegetable-Source Alternative Meat-Curing Ingredients. Molecules 2025, 30, 835. https://doi.org/10.3390/molecules30040835

Sheng S, Silva EM, Ricke SC, Claus JR. Characterization of Volatilized Compounds in Conventional and Organic Vegetable-Source Alternative Meat-Curing Ingredients. Molecules. 2025; 30(4):835. https://doi.org/10.3390/molecules30040835

Chicago/Turabian StyleSheng, Siyuan, Erin M. Silva, Steven C. Ricke, and James R. Claus. 2025. "Characterization of Volatilized Compounds in Conventional and Organic Vegetable-Source Alternative Meat-Curing Ingredients" Molecules 30, no. 4: 835. https://doi.org/10.3390/molecules30040835

APA StyleSheng, S., Silva, E. M., Ricke, S. C., & Claus, J. R. (2025). Characterization of Volatilized Compounds in Conventional and Organic Vegetable-Source Alternative Meat-Curing Ingredients. Molecules, 30(4), 835. https://doi.org/10.3390/molecules30040835