Energy-Related Assessment of a Hemicellulose-First Concept—Debottlenecking of a Hydrothermal Wheat Straw Biorefinery

Abstract

1. Introduction

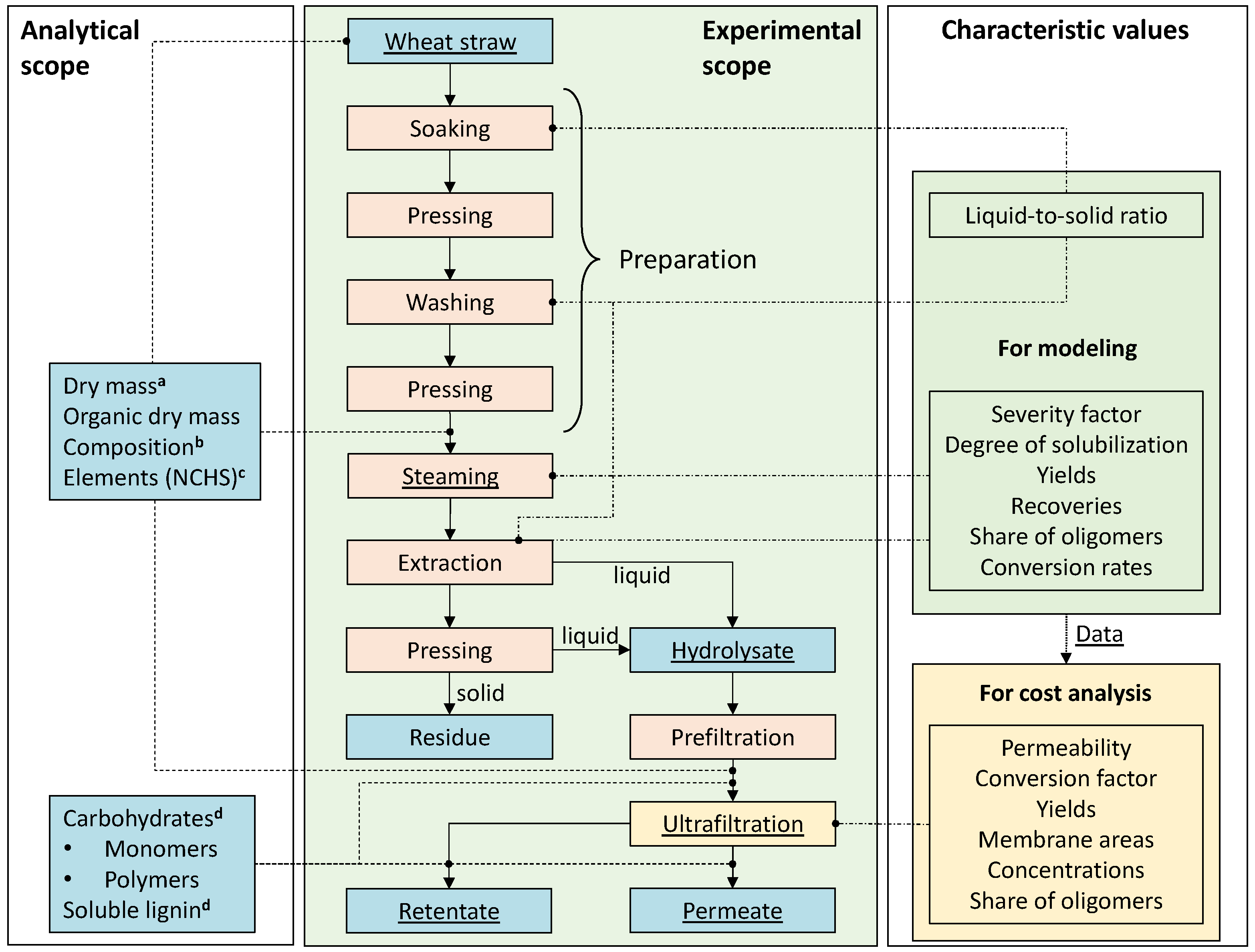

- In the first part, a process model is developed based on experimentally determined data for the proposed hemicellulose-first concept scaled to a size of 30,000 t/a (30 kt/a) of wheat straw dry mass [29]. This process approach (reference case) includes a multi-effect evaporator within the (thermal only) downstream processing.

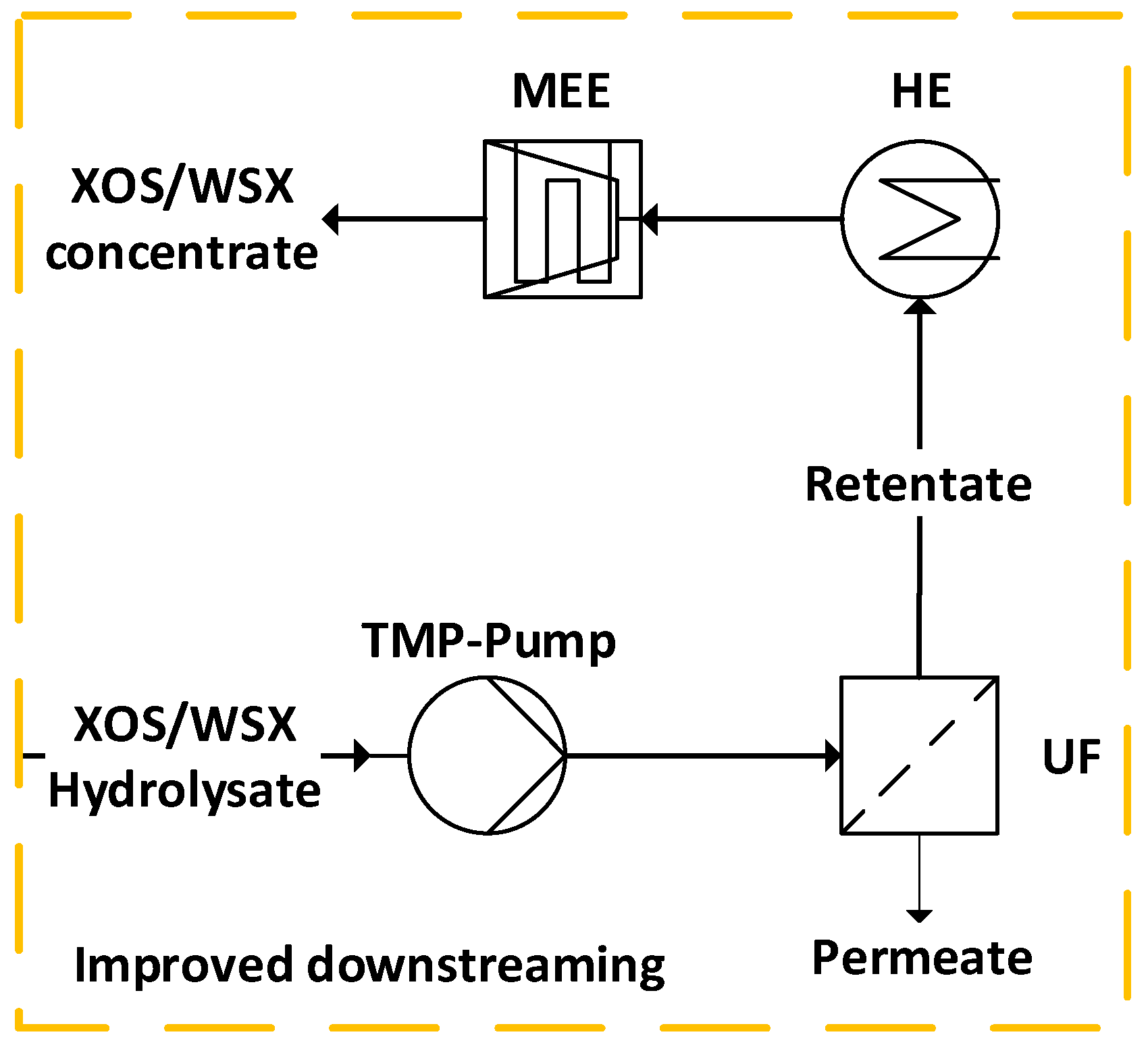

- In the second part, the downstream processing section is extended to include an ultrafiltration step for the hemicellulose hydrolysate before the evaporator (improved process, alternative case). The impact on product separation and energy requirements is examined in order to be compared with the reference case. Additionally, the equipment cost factors for various investigated membranes are examined, as they need to be weighed against the potential energy savings in the improved downstream processing.

2. Process Analysis (Reference Case)

2.1. Process Modeling—Reference Case

2.1.1. Process Definition—Reference Case

- A continuous process in steady state with 7500 h/a (full load hours per year) was assumed.

- Heat was provided as high-pressure steam at 250 °C and low-pressure steam at 125 °C.

- Cooling water was supplied at 20 °C and heated to a maximum of 25 °C.

- The efficiencies of the pumps and the drivers were assumed as 80% and as 90%, respectively [33].

- For the preparation, the temperature of the soaking/washing water was assumed to be 90 °C.

- For the extraction, a continuous countercurrent-suspension extraction with a yield of 94% for the target fraction (XOS/WSX) was assumed [37].

- Further processing of the solid lignin and the cellulose (solid residue in Figure 1) was not considered as both fractions can be used for established applications after hydrothermal pretreatment.

- The multi-effect evaporator (MEE) was designed as a three-stage flash at 1 bar, 0.4 bar and 0.2 bar. The first two condenser stages of the three-stage (multi-effect) evaporator were not considered in heat integration, as they supply the next stage with heat.

- The final dry mass content in the concentrate after the multi-effect evaporator was 50%.

2.1.2. Flowsheet Simulation—Reference Case

2.2. Results and Discussion—Reference Case

3. Process Improvement (Alternative Case)

3.1. Experimental Procedure—Alternative Case

3.2. Process Modeling—Alternative Case

3.2.1. Process Definition—Alternative Case

3.2.2. Flowsheet Simulation—Alternative Case

3.3. Cost Analysis—Alternative Case

3.4. Results and Discussion—Alternative Case

3.4.1. Experimental Data

- The smaller the pore size (Molecular Weight Cut-Off, MWCO), the lower the absolute reduction in permeability (i.e., difference in permeability at CF = 0% and CF = 50%).

- The permeability compared to deionized water is significantly reduced from the beginning in all cases investigated and falls sharply in the initial phase of filtration (up to a conversion factor of roughly CF = 20%).

- The regressions follow a second-order polynomial.

3.4.2. Process Data

3.4.3. Cost Evaluation

4. Overall Discussion

- A major part of the arabinoxylan (63.1 ± 3.1%) in the feedstock is solubilized during primary hydrolysis and is mainly present as non-monomeric xylose (about 87%) (Table 1).

- The majority of the cellulose (over 90%) and lignin (over 70%) remain in the solid residue, which can be utilized for other applications [29].

- The specific (0.28 MWh/tDM (1 GJ/tDM) wheat straw) (Section 3.4.2) energy requirement for feedstock preparation and primary hydrolysis is relatively low [8,16], as no energy intensive preparation is necessary and only the arabinoxylan needs to be solubilized. A low liquid-to-solid ratio, the recovery of excess steam and effective heat integration further reduce the energy requirements (Table 2 and Table 4).

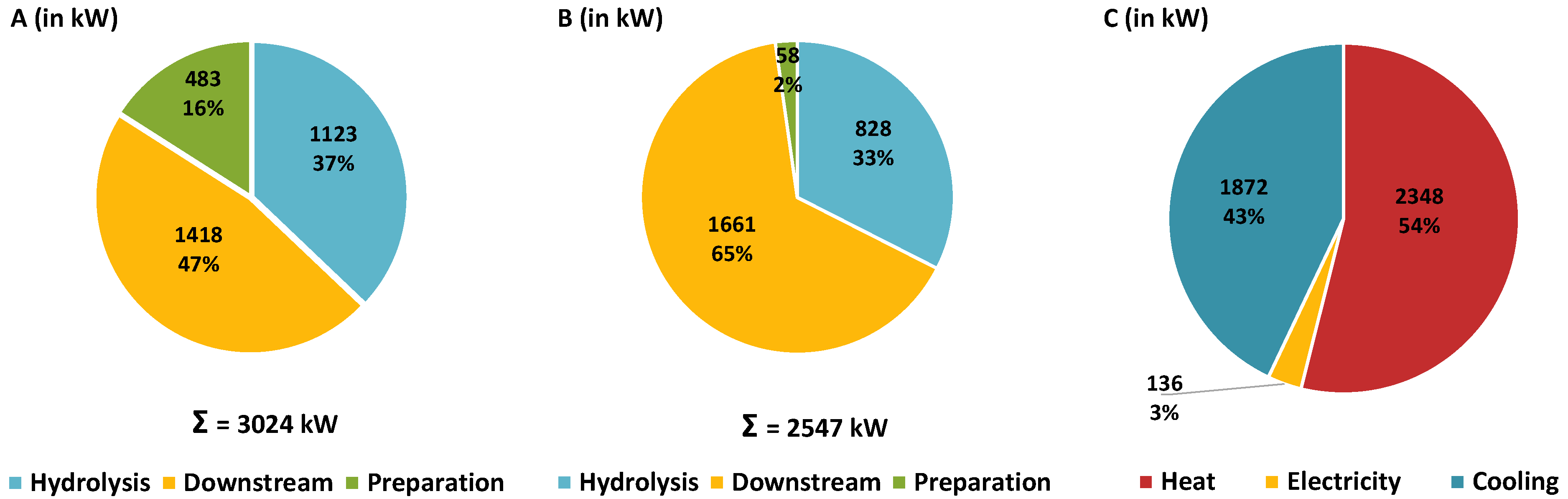

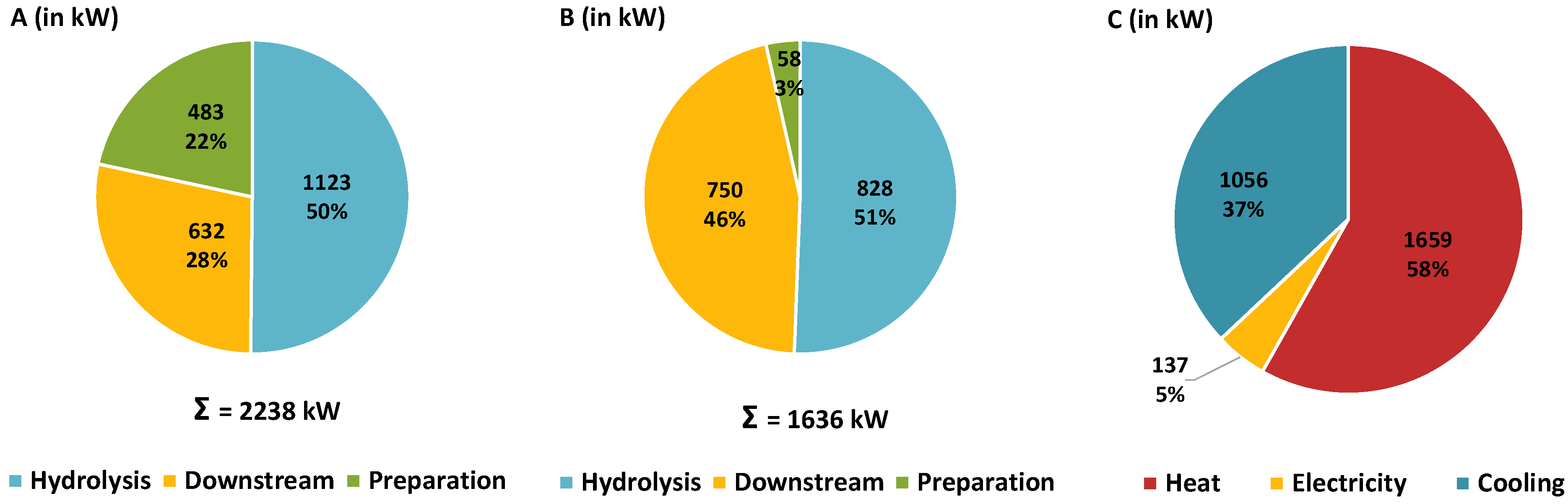

- If the hydrolysate properties enable effective ultrafiltration, substantial amounts of thermal energy can be saved compared to exclusively thermal downstream processing, with reductions of 29% in heating and 44% in cooling energy (Figure 2 and Figure 6). This results in a comparatively low specific energy requirement for downstream processing of 0.13 MWh/tDM (468 MJ/tDM) of wheat straw.

- The low turbidity of the hydrolysate (approx. 50 to 100 NTU after steaming) indicates a low particle load and lignin content. This leads to a low fouling potential, higher flow rates, reduced membrane area requirements and, finally, lower module and membrane costs, even under moderate filtration conditions (Section 3.4).

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Singh, N.; Singhania, R.R.; Nigam, P.S.; Dong, C.-D.; Patel, A.K.; Puri, M. Global status of lignocellulosic biorefinery: Challenges and perspectives. Bioresour. Technol. 2022, 344, 126415. [Google Scholar] [CrossRef] [PubMed]

- Neuling, U.; Kaltschmitt, M. Review of biofuel production—Feedstock, processes and markets. J. Oil Palm Res. 2017, 29, 137–167. [Google Scholar] [CrossRef]

- Buchspies, B.; Kaltschmitt, M. Life cycle assessment of bioethanol from wheat and sugar beet discussing environmental impacts of multiple concepts of co-product processing in the context of the European Renewable Energy Directive. Biofuels 2016, 7, 141–153. [Google Scholar] [CrossRef]

- Mujtaba, M.; Fernandes Fraceto, L.; Fazeli, M.; Mukherjee, S.; Savassa, S.M.; Araujo de Medeiros, G.; do Espírito Santo Pereira, A.; Mancini, S.D.; Lipponen, J.; Vilaplana, F. Lignocellulosic biomass from agricultural waste to the circular economy: A review with focus on biofuels, biocomposites and bioplastics. J. Clean. Prod. 2023, 402, 136815. [Google Scholar] [CrossRef]

- Andersen, L.F.; Parsin, S.; Lüdtke, O.; Kaltschmitt, M. Biogas production from straw—The challenge feedstock pretreatment. Biomass Convers. Biorefin. 2020, 12, 379–402. [Google Scholar] [CrossRef]

- Carvalheiro, F.; Duarte, L.C.; Gírio, F.M. Hemicellulose biorefineries: A review on biomass pretreatments. J. Sci. Ind. Res. 2008, 67, 849–864. [Google Scholar]

- Lassmann, T.; Kravanja, P.; Friedl, A. Simulation of the downstream processing in the ethanol production from lignocellulosic biomass with ASPEN Plus® and IPSEpro. Energy Sustain. Soc. 2014, 4, 27. [Google Scholar] [CrossRef]

- Zhu, J.Y.; Pan, X.J. Woody biomass pretreatment for cellulosic ethanol production: Technology and energy consumption evaluation. Bioresour. Technol. 2010, 101, 4992–5002. [Google Scholar] [CrossRef]

- Cheah, W.Y.; Sankaran, R.; Show, P.L.; Ibrahim, T.N.B.T.; Chew, K.W.; Culaba, A.; Chang, J.-S. Pretreatment methods for lignocellulosic biofuels production: Current advances, challenges and future prospects. Biofuel Res. J. 2020, 7, 1115–1127. [Google Scholar] [CrossRef]

- Usmani, Z.; Sharma, M.; Awasthi, A.K.; Lukk, T.; Tuohy, M.G.; Gong, L.; Nguyen-Tri, P.; Goddard, A.D.; Bill, R.M.; Nayak, S.; et al. Lignocellulosic biorefineries: The current state of challenges and strategies for efficient commercialization. Renew. Sustain. Energy Rev. 2021, 148, 111258. [Google Scholar] [CrossRef]

- Mankar, A.R.; Pandey, A.; Modak, A.; Pant, K.K. Pretreatment of lignocellulosic biomass: A review on recent advances. Bioresour. Technol. 2021, 334, 125235. [Google Scholar] [CrossRef] [PubMed]

- Kumar, R.; Kim, T.H.; Basak, B.; Patil, S.M.; Kim, H.H.; Ahn, Y.; Yadav, K.K.; Cabral-Pinto, M.M.; Jeon, B.-H. Emerging approaches in lignocellulosic biomass pretreatment and anaerobic bioprocesses for sustainable biofuels production. J. Clean. Prod. 2022, 333, 130180. [Google Scholar] [CrossRef]

- Bhutto, A.W.; Qureshi, K.; Harijan, K.; Abro, R.; Abbas, T.; Bazmi, A.A.; Karim, S.; Yu, G. Insight into progress in pre-treatment of lignocellulosic biomass. Energy 2017, 122, 724–745. [Google Scholar] [CrossRef]

- Haldar, D.; Purkait, M.K. A review on the environment-friendly emerging techniques for pretreatment of lignocellulosic biomass: Mechanistic insight and advancements. Chemosphere 2021, 264, 128523. [Google Scholar] [CrossRef]

- Ruiz, H.A.; Conrad, M.; Sun, S.-N.; Sanchez, A.; Rocha, G.J.M.; Romaní, A.; Castro, E.; Torres, A.; Rodríguez-Jasso, R.M.; Andrade, L.P.; et al. Engineering aspects of hydrothermal pretreatment: From batch to continuous operation, scale-up and pilot reactor under biorefinery concept. Bioresour. Technol. 2020, 299, 122685. [Google Scholar] [CrossRef]

- Ruiz, H.A.; Sganzerla, W.G.; Larnaudie, V.; Veersma, R.J.; van Erven, G.; Shiva; Ríos-González, L.J.; Rodríguez-Jasso, R.M.; Rosero-Chasoy, G.; Ferrari, M.D.; et al. Advances in process design, techno-economic assessment and environmental aspects for hydrothermal pretreatment in the fractionation of biomass under biorefinery concept. Bioresour. Technol. 2023, 369, 128469. [Google Scholar] [CrossRef]

- Hammond, G.P.; Mansell, R.V. A comparative thermodynamic evaluation of bioethanol processing from wheat straw. Appl. Energy 2018, 224, 136–146. [Google Scholar] [CrossRef]

- Font Palma, C. Modelling of tar formation and evolution for biomass gasification: A review. Appl. Energy 2013, 111, 129–141. [Google Scholar] [CrossRef]

- Scherzinger, M.; Kaltschmitt, M. Thermal pre-treatment options to enhance anaerobic digestibility—A review. Renew. Sustain. Energy Rev. 2021, 137, 110627. [Google Scholar] [CrossRef]

- Abu-Omar, M.M.; Barta, K.; Beckham, G.T.; Luterbacher, J.S.; Ralph, J.; Rinaldi, R.; Román-Leshkov, Y.; Samec, J.S.M.; Sels, B.F.; Wang, F. Guidelines for performing lignin-first biorefining. Energy Environ. Sci. 2021, 14, 262–292. [Google Scholar] [CrossRef]

- Arts, W.; van Aelst, K.; Cooreman, E.; van Aelst, J.; van den Bosch, S.; Sels, B.F. Stepping away from purified solvents in reductive catalytic fractionation: A step forward towards a disruptive wood biorefinery process. Energy Environ. Sci. 2023, 16, 2518–2539. [Google Scholar] [CrossRef]

- Santibáñez, L.; Henríquez, C.; Corro-Tejeda, R.; Bernal, S.; Armijo, B.; Salazar, O. Xylooligosaccharides from lignocellulosic biomass: A comprehensive review. Carbohydr. Polym. 2021, 251, 117118. [Google Scholar] [CrossRef] [PubMed]

- Carvalheiro, F. Production of oligosaccharides by autohydrolysis of brewery’s spent grain. Bioresour. Technol. 2004, 91, 93–100. [Google Scholar] [CrossRef] [PubMed]

- Naidu, D.S.; Hlangothi, S.P.; John, M.J. Bio-based products from xylan: A review. Carbohydr. Polym. 2018, 179, 28–41. [Google Scholar] [CrossRef]

- Qaseem, M.F.; Shaheen, H.; Wu, A.-M. Cell wall hemicellulose for sustainable industrial utilization. Renew. Sustain. Energy Rev. 2021, 144, 110996. [Google Scholar] [CrossRef]

- Yue, P.; Hu, Y.; Tian, R.; Bian, J.; Peng, F. Hydrothermal pretreatment for the production of oligosaccharides: A review. Bioresour. Technol. 2022, 343, 126075. [Google Scholar] [CrossRef]

- Amorim, C.; Silvério, S.C.; Prather, K.L.J.; Rodrigues, L.R. From lignocellulosic residues to market: Production and commercial potential of xylooligosaccharides. Biotechnol. Adv. 2019, 37, 107397. [Google Scholar] [CrossRef]

- Gomes, D.G.; Teixeira, J.A.; Domingues, L. Economic determinants on the implementation of a Eucalyptus wood biorefinery producing biofuels, energy and high added-value compounds. Appl. Energy 2021, 303, 117662. [Google Scholar] [CrossRef]

- Parsin, S.; Kaltschmitt, M. Processing of hemicellulose in wheat straw by steaming and ultrafiltration—A novel approach. Bioresour. Technol. 2023, 393, 130071. [Google Scholar] [CrossRef]

- Scapini, T.; Dos Santos, M.S.N.; Bonatto, C.; Wancura, J.H.C.; Mulinari, J.; Camargo, A.F.; Klanovicz, N.; Zabot, G.L.; Tres, M.V.; Fongaro, G.; et al. Hydrothermal pretreatment of lignocellulosic biomass for hemicellulose recovery. Bioresour. Technol. 2021, 342, 126033. [Google Scholar] [CrossRef]

- Nitzsche, R.; Etzold, H.; Verges, M.; Gröngröft, A.; Kraume, M. Demonstration and Assessment of Purification Cascades for the Separation and Valorization of Hemicellulose from Organosolv Beechwood Hydrolyzates. Membranes 2022, 12, 82. [Google Scholar] [CrossRef] [PubMed]

- Valério, R.; Crespo, J.G.; Galinha, C.F.; Brazinha, C. Effect of Ultrafiltration Operating Conditions for Separation of Ferulic Acid from Arabinoxylans in Corn Fibre Alkaline Extract. Sustainability 2021, 13, 4682. [Google Scholar] [CrossRef]

- Peters, M.S.; Timmerhaus, K.D.; West, R.E. Plant Design and Economics for Chemical Engineers, 5th ed.; internat. ed.; [Nachdr.]; McGraw-Hill: Boston, MA, USA, 2006; ISBN 0071198725. [Google Scholar]

- Tumuluru, J.S.; Tabil, L.G.; Song, Y.; Iroba, K.L.; Meda, V. Grinding energy and physical properties of chopped and hammer-milled barley, wheat, oat, and canola straws. Biomass Bioenergy 2014, 60, 58–67. [Google Scholar] [CrossRef]

- Mani, S.; Tabil, L.G.; Sokhansanj, S. Grinding performance and physical properties of wheat and barley straws, corn stover and switchgrass. Biomass Bioenergy 2004, 27, 339–352. [Google Scholar] [CrossRef]

- Kratky, L.; Jirout, T. Biomass Size Reduction Machines for Enhancing Biogas Production. Chem. Eng. Technol. 2011, 34, 391–399. [Google Scholar] [CrossRef]

- Conrad, M.; Smirnova, I. Counter-Current Suspension Extraction Process of Lignocellulose in Biorefineries to Reach Low Water Consumption, High Extraction Yields, and Extract Concentrations. Processes 2021, 9, 1585. [Google Scholar] [CrossRef]

- Renon, H.; Prausnitz, J.M. Local compositions in thermodynamic excess functions for liquid mixtures. AIChE J. 1968, 14, 135–144. [Google Scholar] [CrossRef]

- DDBST GmbH. Dortmund Data Bank (DDB). Available online: https://www.ddbst.com/ (accessed on 14 October 2024).

- Humbird, D.; Davis, R.; Tao, L.; Kinchin, C.; Hsu, D.; Aden, A.; Schoen, P.; Lukas, J.; Olthof, B.; Worley, M.; et al. Process Design and Economics for Biochemical Conversion of Lignocellulosic Biomass to Ethanol: Dilute-Acid Pretreatment and Enzymatic Hydrolysis of Corn Stover; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2011. [Google Scholar] [CrossRef]

- Sarker, T.R.; Pattnaik, F.; Nanda, S.; Dalai, A.K.; Meda, V.; Naik, S. Hydrothermal pretreatment technologies for lignocellulosic biomass: A review of steam explosion and subcritical water hydrolysis. Chemosphere 2021, 284, 131372. [Google Scholar] [CrossRef]

- Ruiz, H.A.; Ruzene, D.S.; Silva, D.P.; Da Silva, F.F.M.; Vicente, A.A.; Teixeira, J.A. Development and characterization of an environmentally friendly process sequence (autohydrolysis and organosolv) for wheat straw delignification. Appl. Biochem. Biotechnol. 2011, 164, 629–641. [Google Scholar] [CrossRef]

- Leppänen, K.; Spetz, P.; Pranovich, A.; Hartonen, K.; Kitunen, V.; Ilvesniemi, H. Pressurized hot water extraction of Norway spruce hemicelluloses using a flow-through system. Wood Sci. Technol. 2011, 45, 223–236. [Google Scholar] [CrossRef]

- Lawther, J.M.; Sun, R.; Banks, W.B. Extraction, fractionation, and characterization of structural polysaccharides from wheat straw. J. Agric. Food Chem. 1995, 43, 667–675. [Google Scholar] [CrossRef]

- Campuzano, F.; Brown, R.C.; Martínez, J.D. Auger reactors for pyrolysis of biomass and wastes. Renew. Sustain. Energy Rev. 2019, 102, 372–409. [Google Scholar] [CrossRef]

- Moser, K.; Wopienka, E.; Pfeifer, C.; Schwarz, M.; Sedlmayer, I.; Haslinger, W. Screw reactors and rotary kilns in biochar production—A comparative review. J. Anal. Appl. Pyrolysis 2023, 174, 106112. [Google Scholar] [CrossRef]

- Diedrich, H.; Stahl, A.; Frerichs, H. NCHS-Elementaranalyse: M02.001. Available online: https://www.tuhh.de/zentrallabor/methoden/ac-methoden/m02001.html (accessed on 14 October 2024).

- Choi, H.; Zhang, K.; Dionysiou, D.D.; Oerther, D.B.; Sorial, G.A. Influence of cross-flow velocity on membrane performance during filtration of biological suspension. J. Membr. Sci. 2005, 248, 189–199. [Google Scholar] [CrossRef]

- Shamsuddin, N.; Das, D.B.; Starov, V.M. Filtration of natural organic matter using ultrafiltration membranes for drinking water purposes: Circular cross-flow compared with stirred dead end flow. Chem. Eng. J. 2015, 276, 331–339. [Google Scholar] [CrossRef]

- Massé, A.; Thi, H.N.; Legentilhomme, P.; Jaouen, P. Dead-end and tangential ultrafiltration of natural salted water: Influence of operating parameters on specific energy consumption. J. Membr. Sci. 2011, 380, 192–198. [Google Scholar] [CrossRef]

- Judd, S.J. Membrane technology costs and me. Water Res. 2017, 122, 1–9. [Google Scholar] [CrossRef]

- Schäfer, A.I.; Fane, A.G.; Waite, T.D. Cost factors and chemical pretreatment effects in the membrane filtration of waters containing natural organic matter. Water Res. 2001, 35, 1509–1517. [Google Scholar] [CrossRef]

- Eurostat. Natural Gas Price Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Natural_gas_price_statistics#Natural_gas_prices_for_non-household_consumers (accessed on 14 October 2024).

- Vegas, R.; Alonso, J.L.; Domínguez, H.; Parajó, J.C. Processing of rice husk autohydrolysis liquors for obtaining food ingredients. J. Agric. Food Chem. 2004, 52, 7311–7317. [Google Scholar] [CrossRef]

- Vázquez, M.J.; Garrote, G.; Alonso, J.L.; Domínguez, H.; Parajó, J.C. Refining of autohydrolysis liquors for manufacturing xylooligosaccharides: Evaluation of operational strategies. Bioresour. Technol. 2005, 96, 889–896. [Google Scholar] [CrossRef]

- Wiesner, M.R.; Hackney, J.; Sethi, S.; Jacangelo, J.G.; Laîé, J.-M. Cost estimates for membrane filtration and conventional treatment. J. AWWA 1994, 86, 33–41. [Google Scholar] [CrossRef]

- Hliavitskaya, T.; Plisko, T.; Pratsenko, S.; Bildyukevich, A.; Lipnizki, F.; Rodrigues, G.; Sjölin, M. Development of antifouling ultrafiltration PES membranes for concentration of hemicellulose. J. Appl. Polym. Sci. 2021, 138, 50316. [Google Scholar] [CrossRef]

- S&P Global. Molasses and Feed Ingredients Market Analysis. Available online: https://www.spglobal.com/commodityinsights/en/ci/products/food-commodities-food-manufacturing-softs-molasses-feed-ingredients.html (accessed on 14 October 2024).

| Fraction | DM | oDM | Glucan | Arabino-xylan | Lignin | Acetate | Ash | Protein | Rest |

|---|---|---|---|---|---|---|---|---|---|

| Unit | wt%FM | wt%DM | wt%DM | wt%DM | wt%DM | wt%DM | wt%DM | wt%DM | wt%DM |

| Hydrolysate | 4.5 | 93.0 | 5.5 | 57.9 | 6.8 | 7.1 | 7.0 | 2.3 | 13.3 |

| STD | 0.1 | 0.3 | 0.2 | 1.2 | 0.1 | 0.2 | 0.3 | 0.3 | 1.3 |

| Component | CB | Glucose | Xylose | Arabinose | Formic Acid | Acetic Acid | HMF c | Furfural | Ara/Xyl |

| Unit | g/L | g/L | g/L | g/L | g/L | g/L | g/L | g/L | |

| Total concentrations b | |||||||||

| Hydrolysate | 0.82 | 1.75 | 26.11 | 2.06 | 0.80 | 3.28 | 0.11 | 0.92 | 7.9% |

| STD | 0.01 | 0.06 | 0.08 | 0.02 | 0.00 | 0.02 | 0.01 | 0.03 | 0.07% |

| Released from oligomers | |||||||||

| Hydrolysate | 0.82 | 1.67 | 22.75 | 0.62 | 0.00 | 0.87 | 0.01 | 0.42 | 2.7% |

| STD | 0.01 | 0.06 | 0.07 | 0.01 | 0.00 | 0.02 | 0.00 | 0.03 | 0.06% |

| Sol (%) a | -- | 95 | 87 | 30 | 0 | 26 | 8 | 46 | -- |

| Unit | Conventional Process a | |

|---|---|---|

| Heating Preparation Hydrolysis Downstream processing | MWh/a (%) MWh/a (%) MWh/a (%) MWh/a (%) | 17,610 (100) 0 (0) 8453 (48) 9157 (52) |

| High Pressure steam Low Pressure steam | MWh/a (%) t/a MWh/a (%) t/a | 8075 (46) 17,070 9538 (54) 15,630 |

| Cooling Preparation Hydrolysis Downstream prodessing | MWh/a (%) MWh/a (%) MWh/a (%) MWh/a (%) | 14,040 (100) 421 (3) 1123 (8) 12,496 (89) |

| Electricity | MWh/a (%) | 1020 (100) |

| XOS/WSX concentrate Dry mass (DM) XOS/WSX content | t/a wt% %DM | 10,172 50 61 |

| Solid residue Dry mass (DM) Cellulose Lignin | t/a wt% %DM %DM | 47,733 50 46 34 |

| Membrane Type | MWCO a kDa | Material b | Supplier | pH | T °C | p bar | Permeability c L/(m2 h bar) |

|---|---|---|---|---|---|---|---|

| UH050 | 50 | Hydrophilic PES | Microdyn Nadir | 0–14 | 5–95 | ≥ 85 | |

| UH030 | 30 | Hydrophilic PES | Microdyn Nadir | 0–14 | 5–95 | ≥ 35 | |

| UP020 | 20 | PES | Microdyn Nadir | 0–14 | 5–95 | ≥ 70 | |

| UP010 | 10 | PES | Microdyn Nadir | 0–14 | 5–95 | ≥ 50 | |

| UP005 | 5 | PES | Microdyn Nadir | 0–14 | 5–95 | ≥ 10 | |

| UH004P | 4 | Hydrophilic PES | Microdyn Nadir | 0–14 | 5–95 | ≥ 7.0 | |

| UF10 | 10 | PES | Microdyn Nadir | 2–11 | 5–45 | 1–21 | ≥ 74 |

| UF5 | 5 | PES | Microdyn Nadir | 2–11 | 5–45 | 1–21 | ≥ 8.3 |

| PS (GR61PP) | 20 | PS | Alfa Laval | 1–13 | 5–75 | 1–10 | |

| PES (GR80PP) | 10 | PES | Alfa Laval | 1–13 | 5–75 | 1–10 | |

| PES (GR90PP) | 5 | PES | Alfa Laval | 1–13 | 5–75 | 1–10 |

| Unit | Improved Process | Change to Reference Case b | |

|---|---|---|---|

| Heating Preparation Hydrolysis Downstream processing | MWh/a (%) MWh/a (%) MWh/a (%) MWh/a (%) | 12,443 (100) 0 (0) 8461 (68) 3982 (32) | −29.3% (+41.7%) (−38.5%) |

| High Pressure steam Low Pressure steam | MWh/a (%) t/a MWh/a (%) t/a | 8075 (65) 17,070 4369 (35) 7163 | 0% 0% −54.2% −54.2% |

| Cooling Preparation Hydrolysis Downstream processing | MWh/a (%) MWh/a (%) MWh/a (%) MWh/a (%) | 7920 (100) 396 (5) 1901 (24) 5623 (71) | −43.6% (+66.7%) (+200.0%) (−20.2%) |

| Electricity | MWh/a (%) | 1028 (100) | +0.9% |

| XOS/WSX concentrate Dry mass (DM) XOS/WSX content | t/a wt% %DM | 7698 a 50 71 a | −24.3% 0% +16.4% |

| Solid residue Dry mass (DM) Cellulose Lignin | t/a wt% %DM %DM | 47,733 50 46 34 | 0% 0% 0% 0% |

| Type b MWCO | Unit | UH 50 | UH 30 | UP 20 | UP 10 | UP 5 | UH 4 | UF 10 | UF 5 | PS 20 | PES 10 | PES 5 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| l/(m2 h bar) | 111 | 7.4 | 3.9 | 2.7 | 1.1 | 1.4 | 2.3 | 0.8 | 5.6 | 2.3 | 2.3 | |

| c | m2 bar | 66 | 986 | 1854 | 2725 | 6904 | 5069 | 3138 | 8840 | 1306 | 3138 | 3208 |

| g/L | 48 | 68 | 75 | 77 | 87 | 85 | 79 | 87 | 62 | 80 | 82 | |

| g/L | 44 | 30 | 25 | 21 | 9 | 13 | 17 | 9 | 33 | 16 | 16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Parsin, S.; Scherzinger, M.; Kaltschmitt, M. Energy-Related Assessment of a Hemicellulose-First Concept—Debottlenecking of a Hydrothermal Wheat Straw Biorefinery. Molecules 2025, 30, 602. https://doi.org/10.3390/molecules30030602

Parsin S, Scherzinger M, Kaltschmitt M. Energy-Related Assessment of a Hemicellulose-First Concept—Debottlenecking of a Hydrothermal Wheat Straw Biorefinery. Molecules. 2025; 30(3):602. https://doi.org/10.3390/molecules30030602

Chicago/Turabian StyleParsin, Stanislav, Marvin Scherzinger, and Martin Kaltschmitt. 2025. "Energy-Related Assessment of a Hemicellulose-First Concept—Debottlenecking of a Hydrothermal Wheat Straw Biorefinery" Molecules 30, no. 3: 602. https://doi.org/10.3390/molecules30030602

APA StyleParsin, S., Scherzinger, M., & Kaltschmitt, M. (2025). Energy-Related Assessment of a Hemicellulose-First Concept—Debottlenecking of a Hydrothermal Wheat Straw Biorefinery. Molecules, 30(3), 602. https://doi.org/10.3390/molecules30030602