Mechanism and Characterization of Bicomponent-Filler-Reinforced Natural Rubber Latex Composites: Experiment and Molecular Dynamics (MD)

Abstract

1. Introduction

2. Results

2.1. Mechanical Properties

2.2. Rheological Properties

2.3. Analysis of Interfacial Interaction Using the Lorenz–Park Method

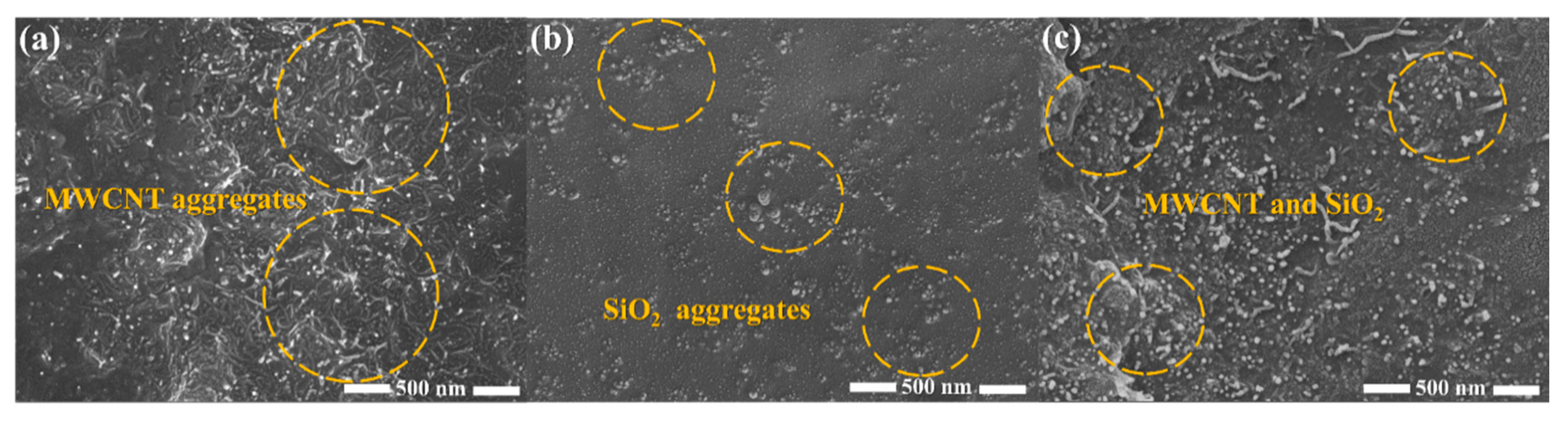

2.4. Microscopic Morphology

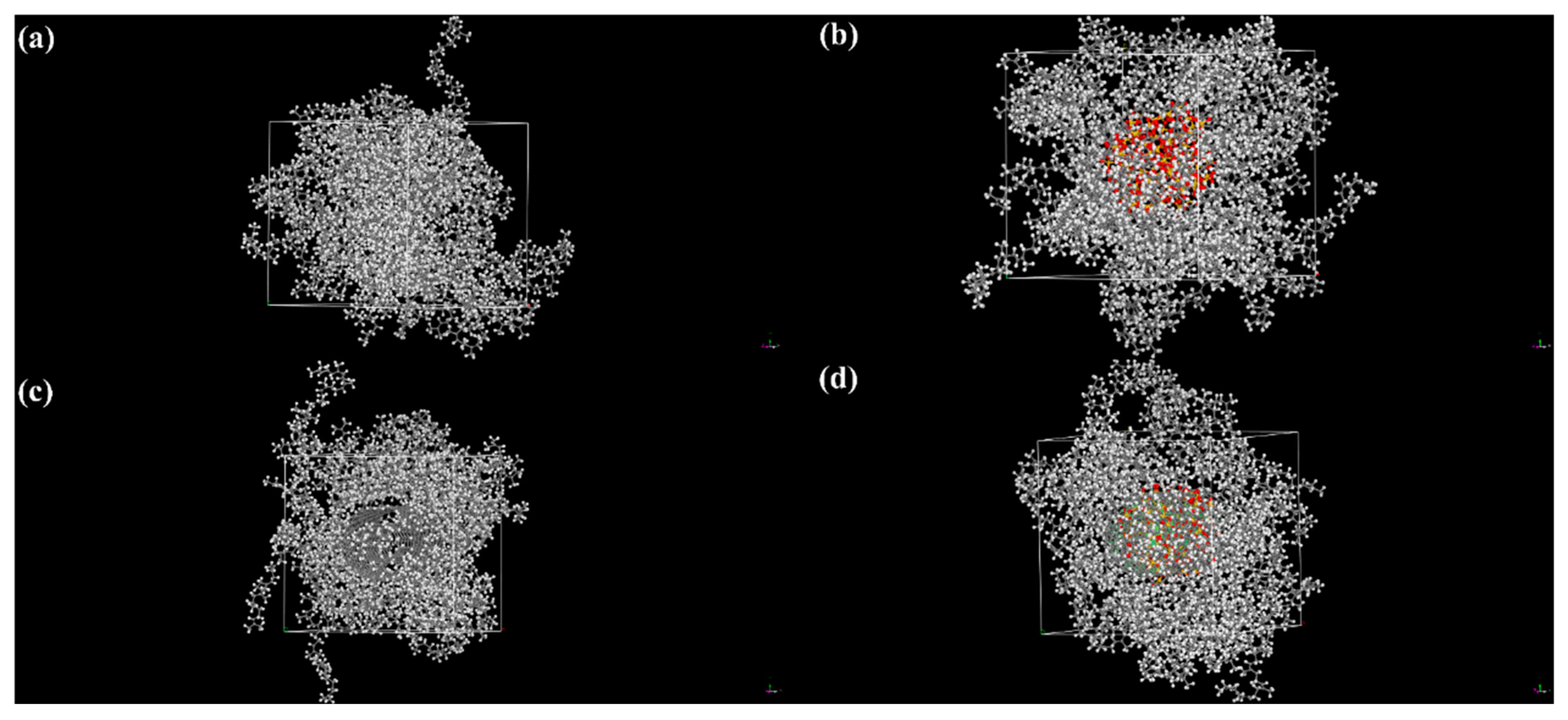

2.5. Molecular Dynamics

2.5.1. Mean Square Displacement (MSD, Section S2.1)

2.5.2. Fractional Free Volume (FFV, Section S2.2)

2.5.3. Binding Energy (Section S2.3)

3. Materials and Methods

3.1. Materials

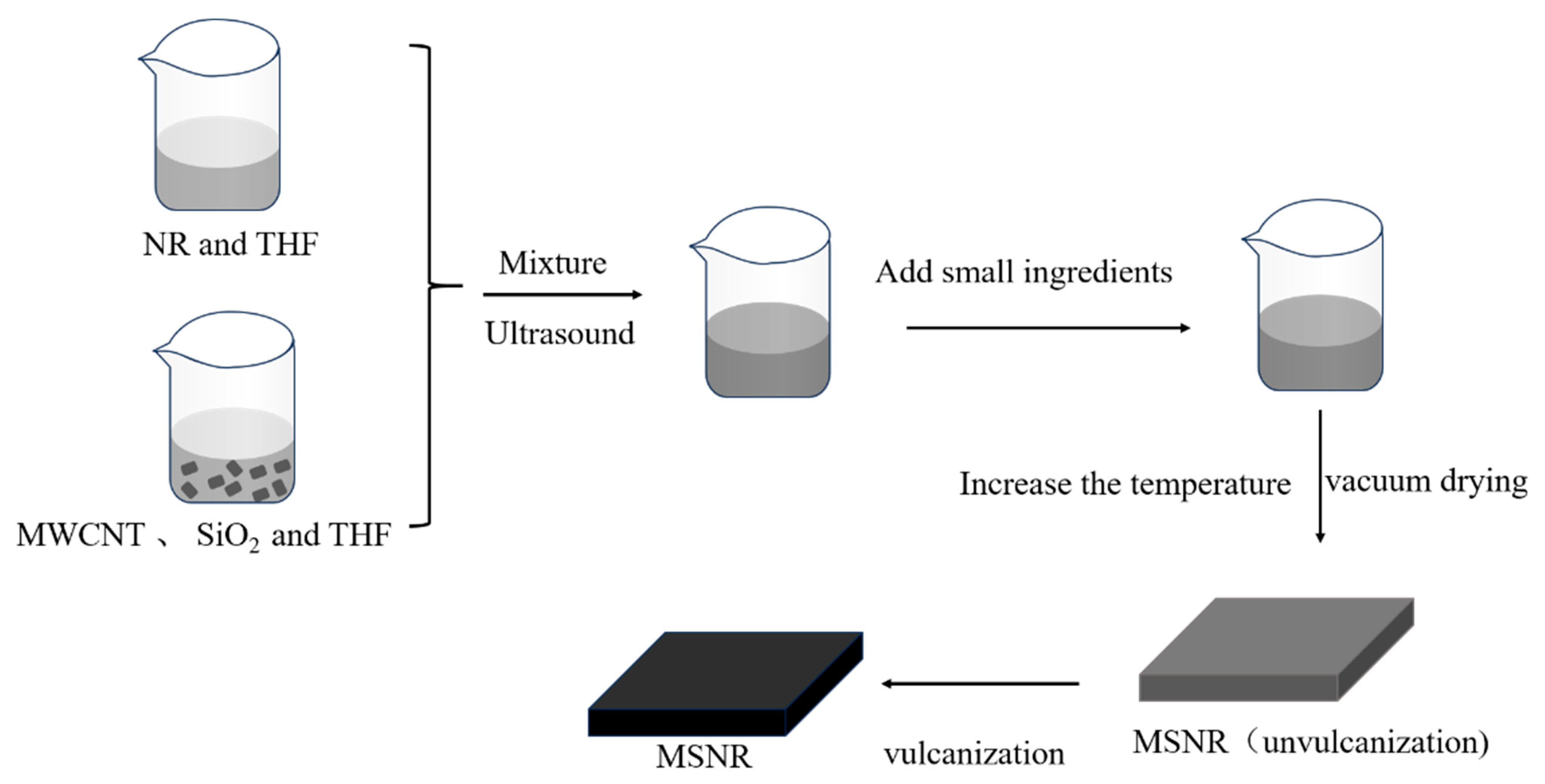

3.2. Sample Preparation

3.3. Characterization Method

3.3.1. Mechanical Property Tests

3.3.2. Dispersion Performance Test

3.3.3. Analysis of the Interfacial Interaction Between the MWCNTs and the Matrix (Via the Lorenz–Park Method)

3.4. Molecular Dynamics Simulation Methods

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, L.; Liu, L.; Gao, J.; Zhang, L. The structure and properties of bis(γ-triethoxysilylpropyl) tetrasulfide modified silica/epoxidized natural rubber nanocomposites as tire tread. Polymer 2024, 311, 127550. [Google Scholar] [CrossRef]

- Miao, X.; Duan, X.; Cheng, H.; Duan, H.; Zhang, Z.; Liu, Y.; Cheng, S. Green and energy-saving tread rubber by constructing chemical cross-linking interface between graphene oxide and natural rubber. Compos. Commun. 2024, 51, 102067. [Google Scholar] [CrossRef]

- Wong, D.; Fabito, G.; Debnath, S.; Anwar, M.; Davies, I.J. A critical review: Recent developments of natural fiber/rubber reinforced polymer composites. Clean. Mater. 2024, 13, 100261. [Google Scholar] [CrossRef]

- Hancharoen, K.; Kamhangrittirong, P.; Suwanna, P. Improvement of natural fiber cement composite for roofing applications through addition of waste tire rubber: An investigation of the physical, mechanical, thermal, and acoustic properties. Clean. Mater. 2024, 13, 100265. [Google Scholar] [CrossRef]

- Guchait, A.; Pramanik, S.; Goswami, D.K.; Chattopadhyay, S.; Mondal, T. Elastomeric Ionic Hydrogel-Based Flexible Moisture-Electric Generator for Next-Generation Wearable Electronics. ACS Appl. Mater. Interfaces 2024, 16, 46844–46857. [Google Scholar] [CrossRef]

- Sun, C.; Li, L.; Ji, H.; Yang, H.; Jin, G.; Jiang, C.; Guo, P.; Zhang, L.; Yu, P.; Wang, R. The use of crude carbon dots as green, low-cost and multifunctional additives to improve the curing, mechanical, antioxidative and fluorescence properties of epoxy natural rubber/silica composites. Compos. Part A Appl. Sci. Manuf. 2024, 182, 108177. [Google Scholar] [CrossRef]

- Mouslih, Y.; Le Cam, J.-B.; Ruellan, B.; Jeanneau, I.; Canevet, F. Temperature effects on the lifetime reinforcement due to strain-induced crystallization in carbon black filled natural rubber under non-relaxing torsion: Comparison with non-relaxing tensile loadings. Mech. Mater. 2024, 196, 105045. [Google Scholar] [CrossRef]

- Li, Q.; Meng, H.; Song, Y.; Zheng, Q. Performance enhancement of silica filled natural rubber nanocomposites using organic deep eutectic solvent. Compos. Sci. Technol. 2024, 256, 110744. [Google Scholar] [CrossRef]

- Sermsook, N.; Thummarungsan, N.; Rotjanasuworapong, K.; Lerdwijitjarud, W.; Sirivat, A. Fabrication and testing of functionalized multi-walled carbon nanotubes/deproteinized natural rubber composites for bending actuation under electric field. Sens. Actuators A Phys. 2022, 344, 113762. [Google Scholar] [CrossRef]

- Yi Xuan, Y.; Ridzuan, M.J.M.; Abdul Majid, M.S.; Rahman, M.T.A.; Yudhanto, F.; Khasri, A.; Ismail, M.S. Influence of multi-walled carbon nanotubes on thermal behaviour and mechanical properties of pineapple leaf fibre-based natural rubber composites. J. Mater. Res. Technol. 2024, 30, 8608–8619. [Google Scholar] [CrossRef]

- Banerjee, S.S.; Arief, I.; Berthold, R.; Wiese, M.; Bartholdt, M.; Ganguli, D.; Mitra, S.; Mandal, S.; Wallaschek, J.; Raatz, A.; et al. Super-elastic ultrasoft natural rubber-based piezoresistive sensors for active sensing interface embedded on soft robotic actuator. Appl. Mater. Today 2021, 25, 101219. [Google Scholar] [CrossRef]

- Liu, H.; Yang, L.; Liu, X.; Cao, J.-P.; Zhang, J.; Luo, Z.; Gao, Z. Silicon dioxide nanoparticle decorated graphene with excellent dispersibility in natural rubber composites via physical mixing for application in green tires. Compos. Part B Eng. 2023, 258, 110700. [Google Scholar] [CrossRef]

- Phumnok, E.; Saetiao, P.; Bumphenkiattikul, P.; Rattanawilai, S.; Khongprom, P. CFD simulation of silica dispersion/natural rubber latex mixing for high silica content rubber composite production. RSC Adv. 2024, 14, 12612–12623. [Google Scholar] [CrossRef] [PubMed]

- Prajitha, V.; Jibin, K.P.; Abitha, V.K.; Sisanth, K.S.; Huskic, M.; Meera, A.P.; George, J.S.; Thomas, S. Advancing mechanical performance in sustainable engineering: Synergistic effects of graphene oxide/nano-silica hybrid nanofiller via latex coagulation in natural rubber composites. Polym. Compos. 2024, 45, 5980–5991. [Google Scholar] [CrossRef]

- Afsharirad, F.; Mousanezhad, S.; Biglari, H.; Rahmani, O. Molecular dynamics of axial interwall van der Waals force and mechanical vibration of double-walled carbon nanotubes. Mater. Today Commun. 2021, 28, 102708. [Google Scholar] [CrossRef]

- You, B.; Jin, S. Preparation of Hydrophobic Modified Silica with Si69 and Its Reinforcing Mechanical Properties in Natural Rubber. Materials 2024, 17, 3131. [Google Scholar] [CrossRef]

- Zhou, J.; Wang, W.; Song, Y.; Zheng, Q. Effect of ionic liquid on structure and properties of carbon black filled natural rubber vulcanizates. Compos. Part A Appl. Sci. Manuf. 2023, 167, 107432. [Google Scholar] [CrossRef]

- Xue, J.; Hao, Y.; Qu, S.; Wang, C.; Li, L. Exploring the reinforcement and conductivity mechanism of K2FeO4-modified multiwalled carbon nanotubes in carbon black/natural rubber composites. Polym. Compos. 2024, 45, 6252–6263. [Google Scholar] [CrossRef]

- Mohd Khairuddin, F.A.; Rashid, A.A.; Leo, C.P.; Lim, G.K.; Ahmad, A.L.; Lim, H.M.; Tan, I.C.S. Recent progress in superhydrophobic rubber coatings. Prog. Org. Coat. 2022, 171, 107024. [Google Scholar] [CrossRef]

- Shahamatifard, F.; Rodrigue, D.; Park, K.W.; Frikha, S.; Mighri, F. Natural rubber nanocomposites: Effect of carbon black/multi-walled carbon nanotubes hybrid fillers on the mechanical properties and thermal conductivity. Polym. Plast. Technol. Mater. 2021, 60, 1930044. [Google Scholar] [CrossRef]

- Sun, C.-Y.; Ji, H.-J.; Li, L.-W.; Yang, H.; An, X.-P.; Chen, Y.-P.; Han, M.-J.; Jiang, C.; Zhang, L.-Q.; Yu, P.; et al. Simultaneously Improved Curing, Mechanical, Antioxidative Properties and Reduced ZnO Loading of Silica Filled NR Composites by Incorporation of Low-cost Crude Carbon Dots via Conventional Melt-milling Method. Chin. J. Polym. Sci. 2024, 42, 815–825. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, W.; Zhu, S.; Yang, G.; Zhang, Z.; Li, P. The evolution of the thermodynamic property of graphene oxide nanofiber coated poly(vinyl alcohol) resin surface by the molecular dynamic simulations. J. Mol. Liq. 2020, 316, 113723. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Q.; Wang, S. A review on enhancement of mechanical and tribological properties of polymer composites reinforced by carbon nanotubes and graphene sheet: Molecular dynamics simulations. Compos. Part B Eng. 2019, 160, 348–361. [Google Scholar] [CrossRef]

- Yang, B.; Li, Y.; Wang, S.; Nie, R.; Wang, Q. Aminosilane modified graphene oxide for reinforcing nitrile butadiene rubber: Experiments and molecular dynamic simulations. Compos. Sci. Technol. 2023, 235, 109956. [Google Scholar] [CrossRef]

- Sepay, N.; Chakrabarti, S.; Afzal, M.; Alarifi, A.; Mal, D. Identification of 4-acrylamido-N-(pyridazin-3-yl)benzamide as anti-COVID-19 compound: A DFTB, molecular docking, and molecular dynamics study. RSC Adv. 2022, 12, 24178–24186. [Google Scholar] [CrossRef]

- Allec, S.I.; Sun, Y.; Sun, J.; Chang, C.A.; Wong, B.M. Heterogeneous CPU+GPU-Enabled Simulations for DFTB Molecular Dynamics of Large Chemical and Biological Systems. J. Chem. Theory Comput. 2019, 15, 2807–2815. [Google Scholar] [CrossRef] [PubMed]

- Xu, F.; Deng, J.; Liu, Y.; Xie, H.; Long, Z.; Dai, B.; Yang, H.; You, L.; Zhu, C.; Jin, D. Multiscale revelation of asphalt morphology and adhesion performance evolution during stress relaxation process. Fuel 2024, 380, 133244. [Google Scholar] [CrossRef]

- Kong, J.; Sun, J.; Tong, Y.; Dou, Q.; Wei, Y.; Thitsartarn, W.; Chee Chuan Yeo, J.; He, C. Carbon nanotubes-bridged-fumed silica as an effective binary nanofillers for reinforcement of silicone elastomers. Compos. Sci. Technol. 2019, 169, 232–241. [Google Scholar] [CrossRef]

- Xu, Z.; Jerrams, S.; Guo, H.; Zhou, Y.; Jiang, L.; Gao, Y.; Zhang, L.; Liu, L.; Wen, S. Influence of graphene oxide and carbon nanotubes on the fatigue properties of silica/styrene-butadiene rubber composites under uniaxial and multiaxial cyclic loading. Int. J. Fatigue 2020, 131, 105388. [Google Scholar] [CrossRef]

- Pan, Q.; Zhao, G.; Deng, H.; Fu, Q. Balanced physical properties for thermoplastic silicone vulcanizate-based polymer composites containing functional filler. Polym. Compos. 2020, 41, 4307–4317. [Google Scholar] [CrossRef]

- Rasana, N.; Jayanarayanan, K.; Mohan, H.T.; Keller, T. Static and dynamic mechanical properties of nanosilica and multiwalled carbon nanotube reinforced acrylonitrile butadiene styrene composites: Theoretical mechanism of nanofiller reinforcement. Iran. Polym. J. 2021, 30, 1211–1225. [Google Scholar] [CrossRef]

- Grunert, F.; Wehmeier, A.; Blume, A. New Insights into the Morphology of Silica and Carbon Black Based on Their Different Dispersion Behavior. Polymers 2020, 12, 567. [Google Scholar] [CrossRef]

- Santos, R.J.; Hiranobe, C.T.; Dognani, G.; Silva, M.J.; Paim, L.L.; Cabrera, F.C.; Torres, G.B.; Job, A.E. Using the Lorenz–Park, Mooney–Rivlin, and dynamic mechanical analysis relationship on natural rubber/leather shavings composites. J. Appl. Polym. Sci. 2021, 139, 51880. [Google Scholar] [CrossRef]

- Wu, J.; Teng, F.; Su, B.; Wang, Y. Molecular dynamics study on tribological properties of EUG/NR composites. Comput. Mater. Sci. 2021, 199, 110732. [Google Scholar] [CrossRef]

- Liu, X.; Song, M.; Wang, H.; Chen, S.; Zheng, W.; Wang, X. Hydrogen bond networks and wrinkles in graphene oxide/nitrile butadiene rubber composites for enhancement of damping capability: Molecular simulation and experimental study. Compos. Sci. Technol. 2023, 240, 110083. [Google Scholar] [CrossRef]

- Teng, F.; Wu, J.; Su, B.; Wang, Y. Enhanced Tribological Properties of Vulcanized Natural Rubber Composites by Applications of Carbon Nanotube: A Molecular Dynamics Study. Nanomaterials 2021, 11, 2464. [Google Scholar] [CrossRef] [PubMed]

- Reil, M.; Hoffman, J.; Predecki, P.; Kumosa, M. Graphene and graphene oxide energetic interactions with polymers through molecular dynamics simulations. Comput. Mater. Sci. 2022, 211, 111548. [Google Scholar] [CrossRef]

- Lorenz, O.; Parks, C.R. The crosslinking efficiency of some vulcanizing agents in natural rubber. J. Polym. Sci. 2003, 50, 299–312. [Google Scholar] [CrossRef]

- Ma, C.; Li, Z.; Duan, X.; Cheng, B.; Cao, H.; Liao, M. Molecular dynamics simulation and performance analysis of polyimide/aramid blends. J. Mol. Model. 2024, 30, 19. [Google Scholar] [CrossRef] [PubMed]

- Qu, Z.; Wang, W.; Hua, Y.; Cang, S. Effect of High-Temperature Paraffin Impregnation on the Properties of the Amorphous Cellulose Region Based on Molecular Dynamics Simulation. Forests 2023, 14, 1068. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, Z.; Zhu, H.; Hu, B.; Chen, H.; Yan, Y. Mechanism and Characterization of Bicomponent-Filler-Reinforced Natural Rubber Latex Composites: Experiment and Molecular Dynamics (MD). Molecules 2025, 30, 349. https://doi.org/10.3390/molecules30020349

Feng Z, Zhu H, Hu B, Chen H, Yan Y. Mechanism and Characterization of Bicomponent-Filler-Reinforced Natural Rubber Latex Composites: Experiment and Molecular Dynamics (MD). Molecules. 2025; 30(2):349. https://doi.org/10.3390/molecules30020349

Chicago/Turabian StyleFeng, Zhipeng, Hongzhou Zhu, Bo Hu, Huabin Chen, and Yong Yan. 2025. "Mechanism and Characterization of Bicomponent-Filler-Reinforced Natural Rubber Latex Composites: Experiment and Molecular Dynamics (MD)" Molecules 30, no. 2: 349. https://doi.org/10.3390/molecules30020349

APA StyleFeng, Z., Zhu, H., Hu, B., Chen, H., & Yan, Y. (2025). Mechanism and Characterization of Bicomponent-Filler-Reinforced Natural Rubber Latex Composites: Experiment and Molecular Dynamics (MD). Molecules, 30(2), 349. https://doi.org/10.3390/molecules30020349