Application of Bio-Waste Modified by Ionic Liquids in Epoxy Composites—From Preparation to Biodegradation

Abstract

1. Introduction

2. Results and Discussion

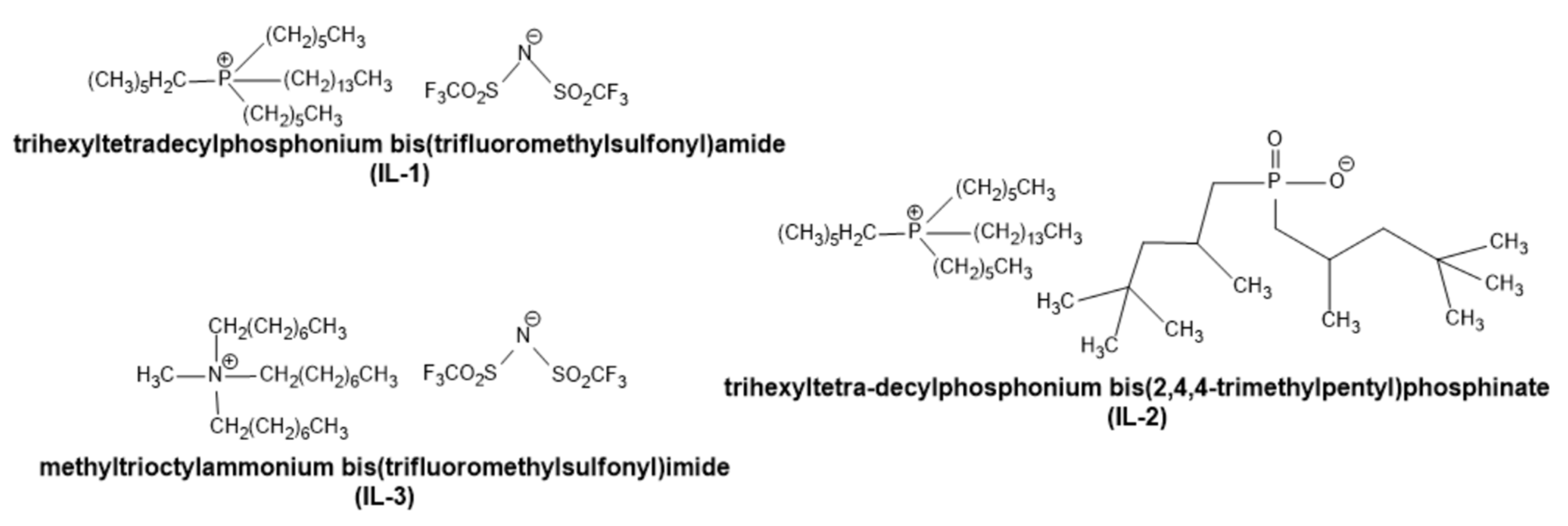

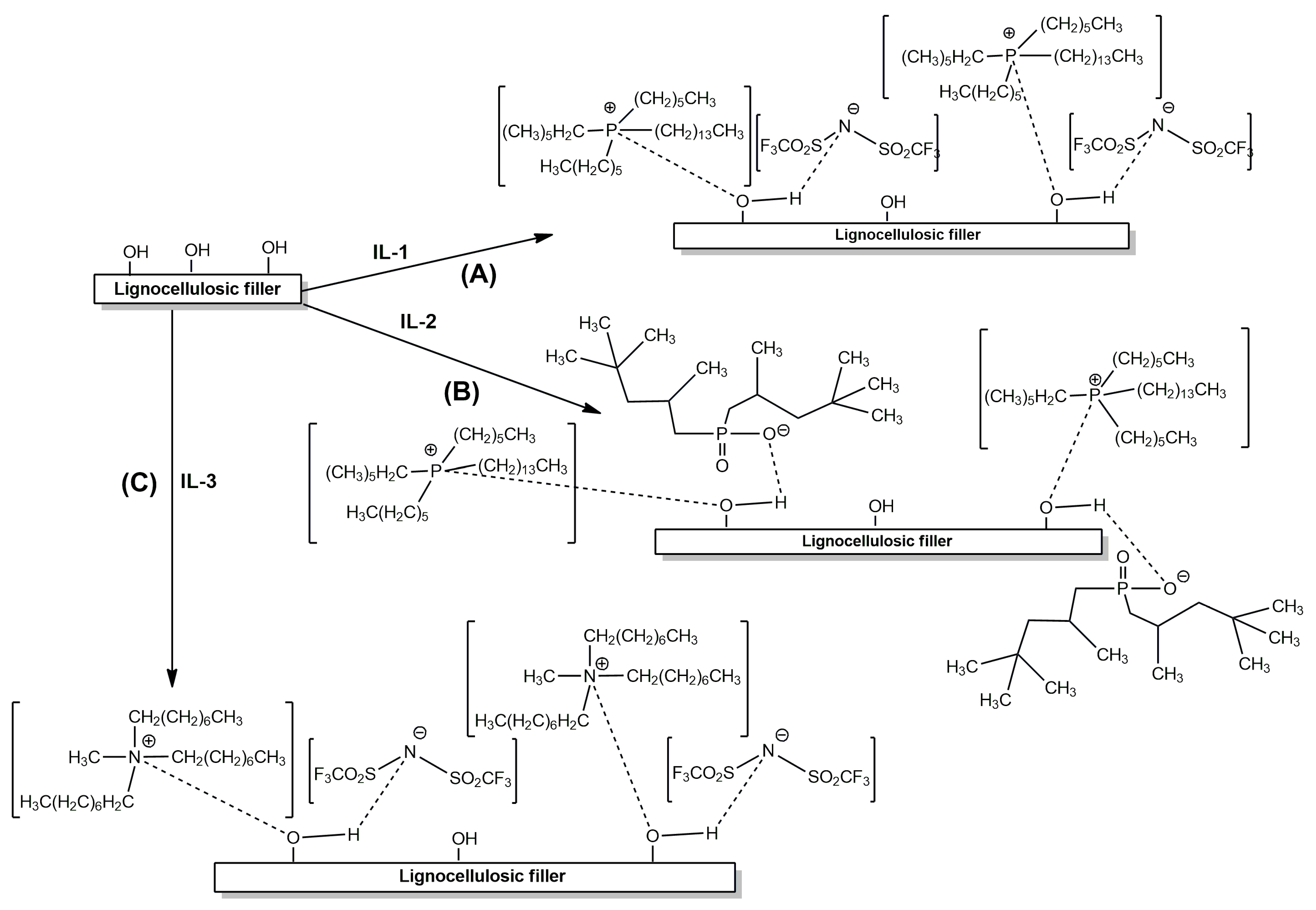

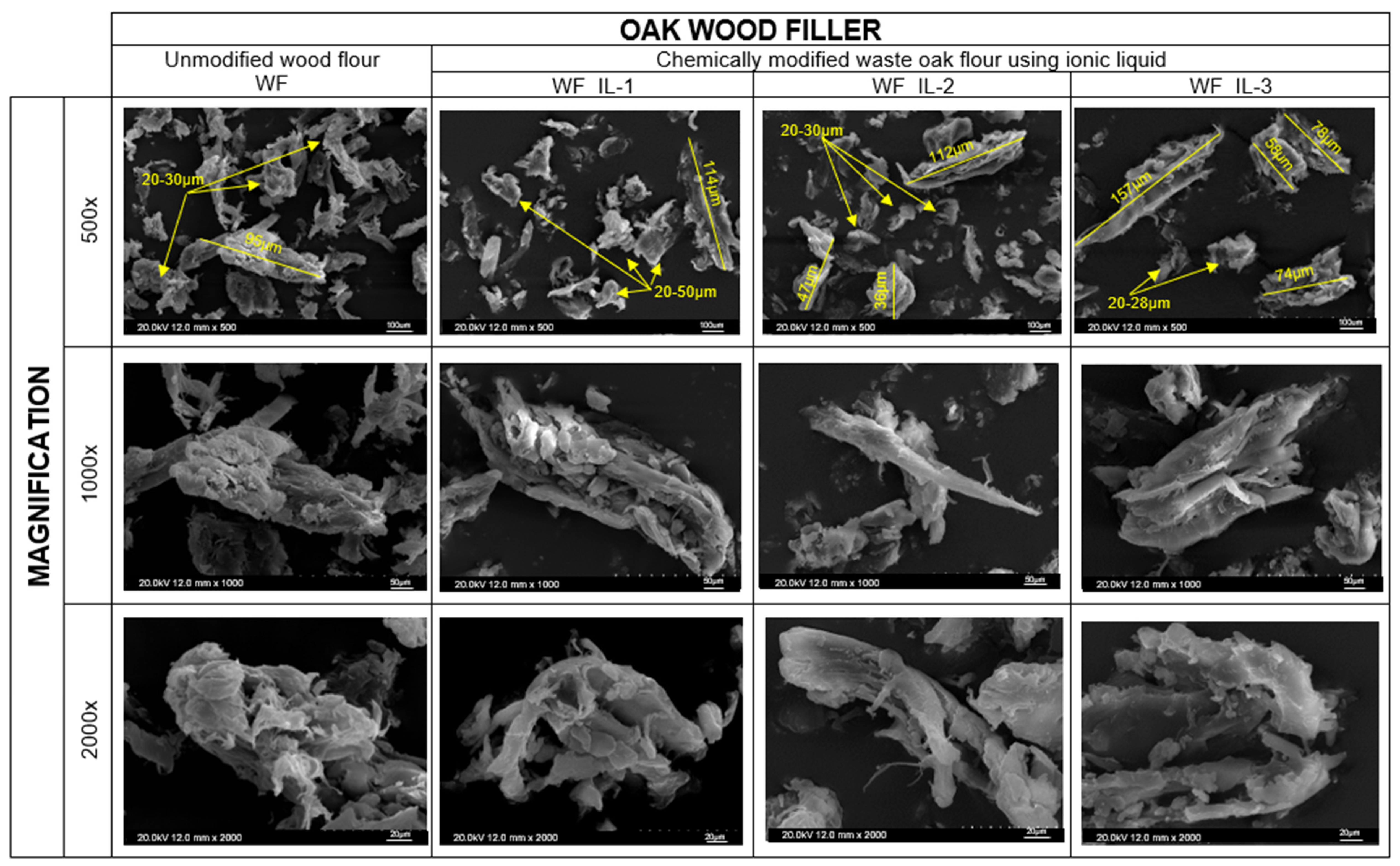

2.1. Chemical Modification of Waste Wood Flour

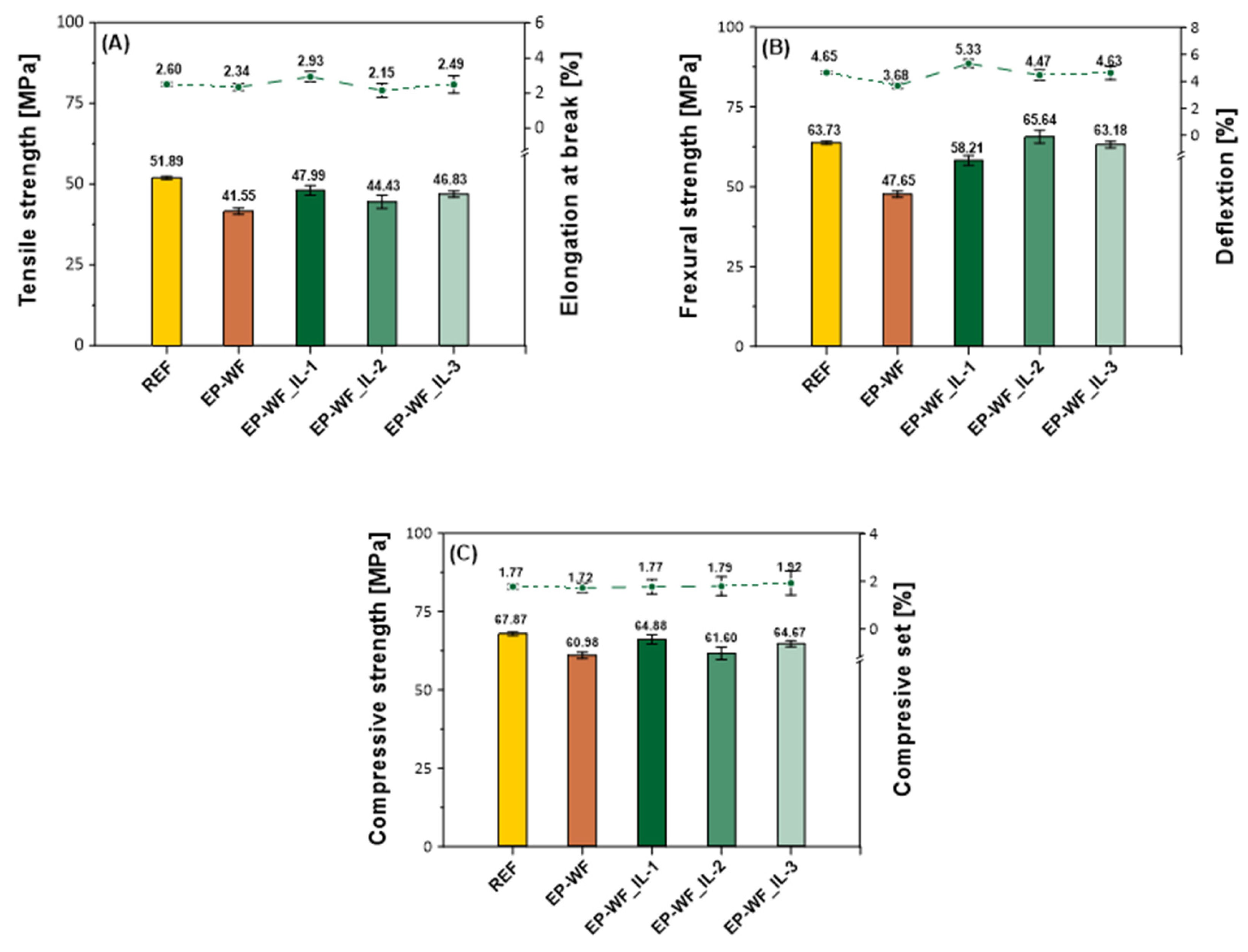

2.2. Obtaining and Testing the Selected Properties of Epoxy Composites with Wood Waste Flour Modified by Ionic Liquids

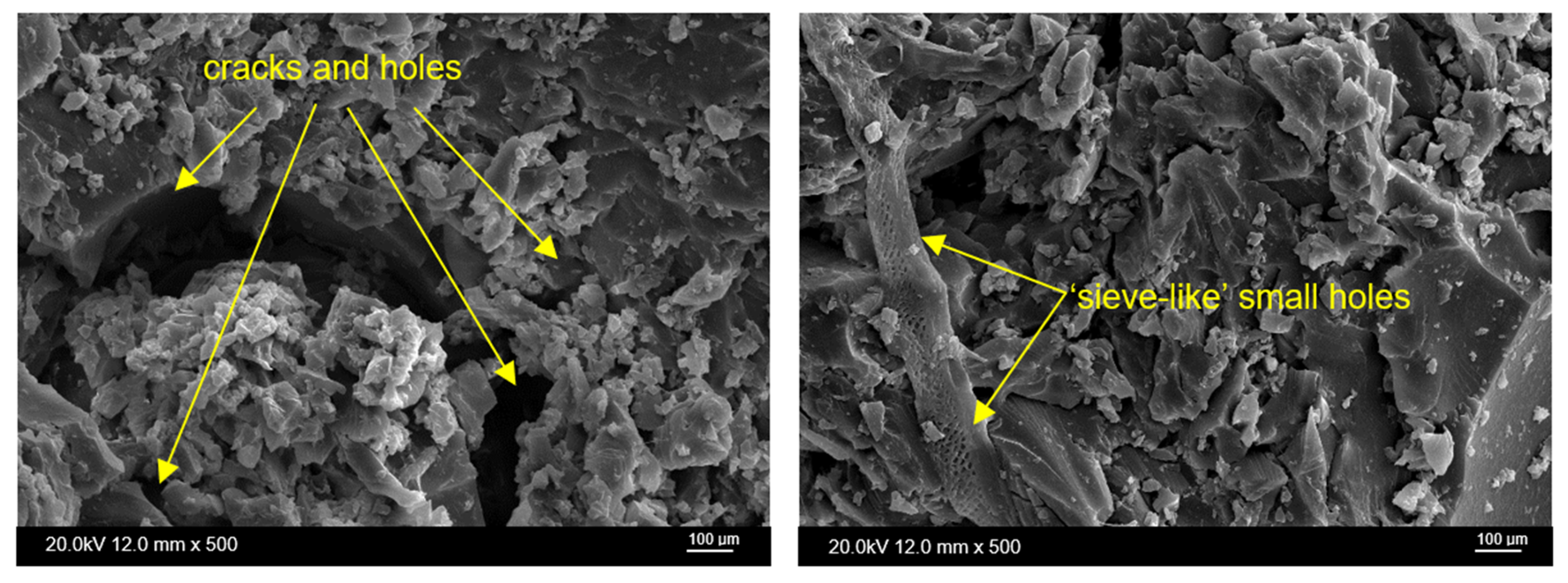

2.3. Enzymatic Degradation of Epoxy Composites Containing Bio-Waste Modified by Ionic Liquids

3. Materials and Methods

3.1. Preparation of Waste Wood Filler

3.2. Preparation of Epoxy-Waste Wood Composites

3.3. Biodegradation of Epoxy-Wood Composites

3.4. Composite Materials’ Characteristics

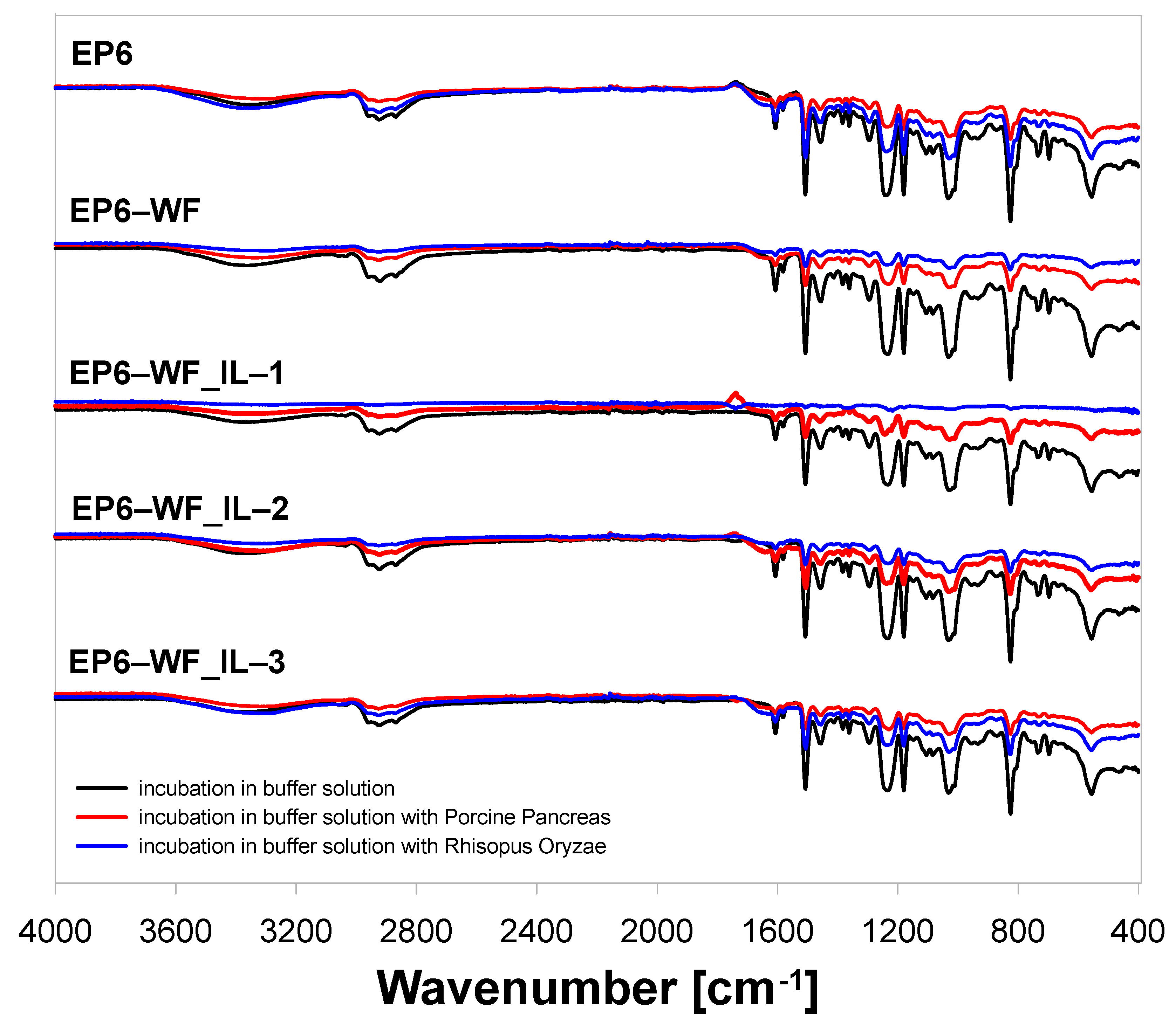

3.4.1. Spectroscopic Analysis (ATR/FT-IR)

3.4.2. The Mechanical Properties of Epoxy-Wood Composites

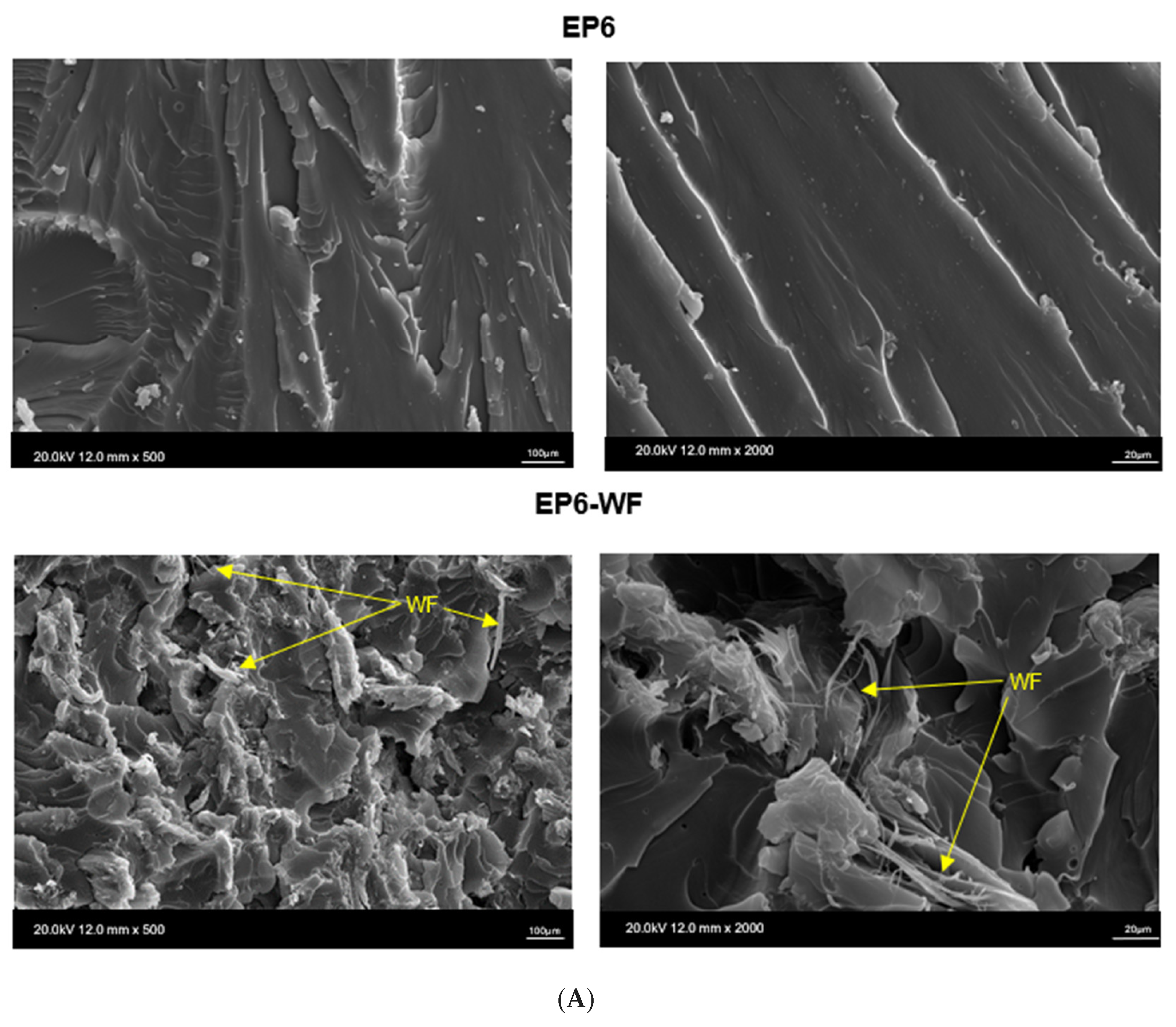

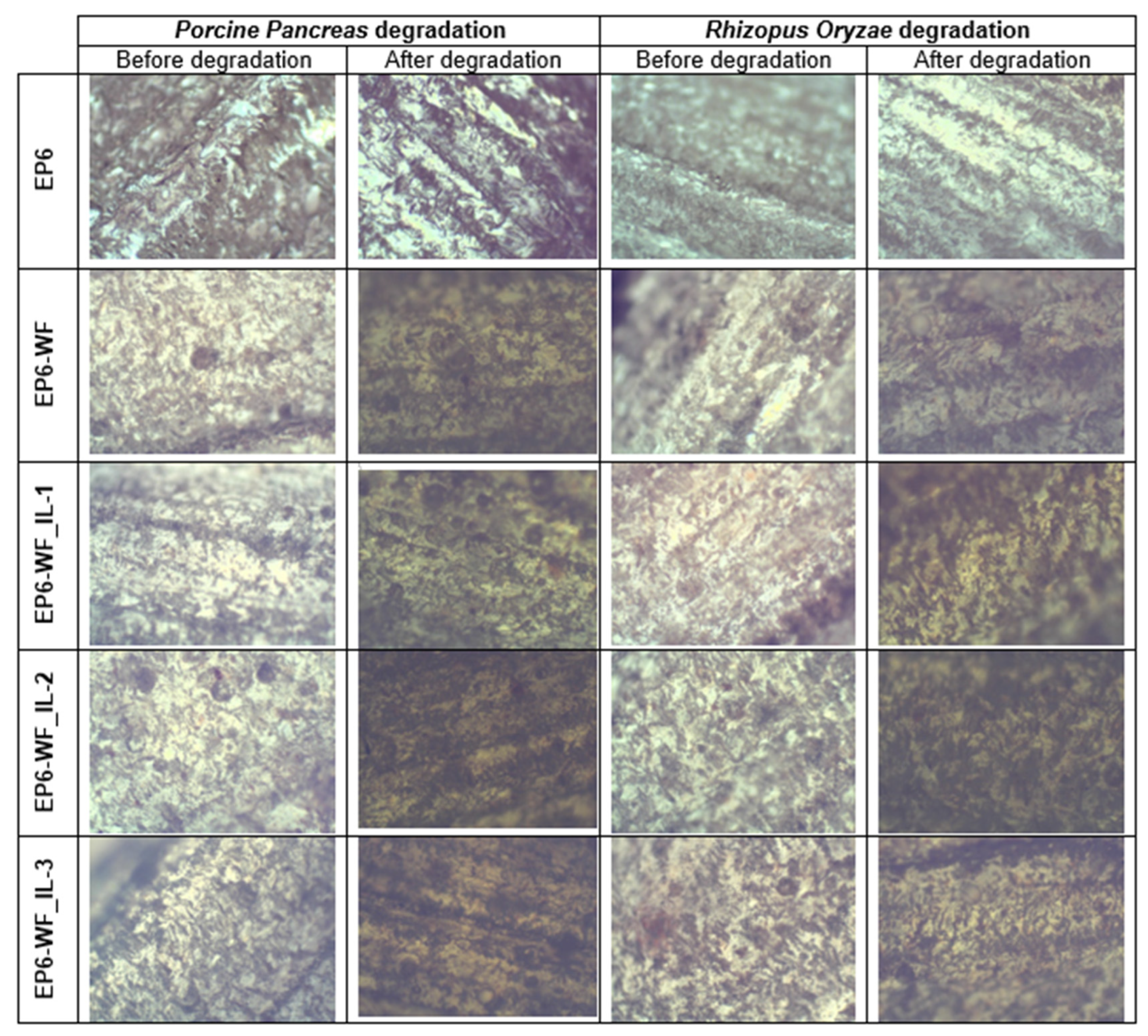

3.4.3. Morphological Analysis

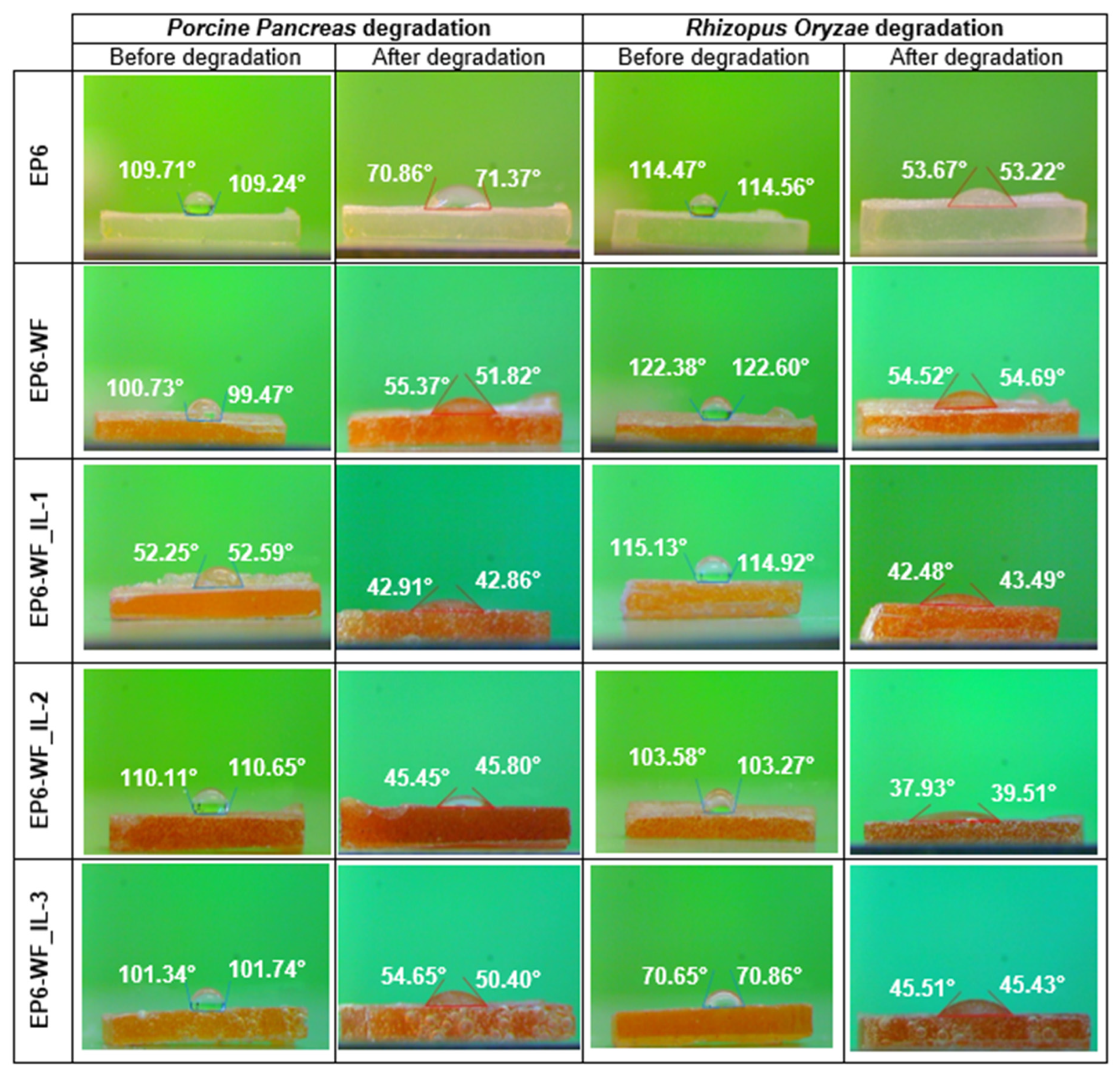

3.4.4. Contact Angle Measurements

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| IL-1 | trihexyltetradecylphosphonium bis(trifluoromethylsulfonyl)amide |

| IL-2 | trihexyltetradecylphosphonium bis(2,4,4-trimethyl-pentyl)phosphinate |

| IL-3 | methyltrioctylammonium bis(trifluoromethylsulfonyl)imide |

| PP | Porcine Pancreas lipase |

| RO | Rhizopus Oryzae enzyme |

| REF | Cured epoxy composition based on low-molecular-weight epoxy resin Epidian 6 |

| WF | Cured epoxy composite based on low-molecular-weight epoxy resin Epidian 6 filled with 5 wt.% of unmodified wood flour |

| EP-WF_IL-1 | Cured epoxy composite based on low-molecular-weight epoxy resin Epidian 6 filled with 5 wt.% of wood flour modified with trihexyltetra-decylphosphonium bis(trifluoromethyl-sulfonyl)amide |

| EP-WF_IL-2 | Cured epoxy composite based on low-molecular-weight epoxy resin Epidian 6 filled with 5 wt.% of wood flour modified with trihexyltetradecylphosphonium bis(2,4,4tri-methyl)pentylphosphinate |

| EP-WF_IL-3 | Cured epoxy composite based on low-molecular-weight epoxy resin Epidian 6 filled with 5 wt.% of wood flour modified with methyltrioctylammonium bis(trifluoromethyl-sulfonyl)imide |

References

- Pham, H.Q.; Marks, M.J. Epoxy resins. In Ullmann’s Encyclopedia of Industrial Chemistry; John Wiley & Sons: Hoboken, NJ, USA, 2000. [Google Scholar]

- Dallaev, R.; Pisarenko, T.; Papež, N.; Sadovský, P.; Holcman, V. A brief overview on epoxies in electronics: Properties, applications, and modifications. Polymers 2023, 15, 3964. [Google Scholar] [CrossRef]

- Gonçalves, F.A.; Santos, M.; Cernadas, T.; Alves, P.; Ferreira, P. Influence of fillers on epoxy resins properties: A review. J. Mater. Sci. 2022, 57, 15183–15212. [Google Scholar] [CrossRef]

- Rahman, M.M.; Akhtarul Islam, M. Application of epoxy resins in building materials: Progress and prospects. Polym. Bull. 2022, 79, 1949–1975. [Google Scholar] [CrossRef]

- Shundo, A.; Yamamoto, S.; Tanaka, K. Network formation and physical properties of epoxy resins for future practical applications. JACS Au 2022, 2, 1522–1542. [Google Scholar] [CrossRef]

- Müller-Pabel, M.; Agudo, J.A.R.; Gude, M. Measuring and understanding cure-dependent viscoelastic properties of epoxy resin: A review. Polym. Test. 2022, 114, 107701. [Google Scholar] [CrossRef]

- Tian, Z.S.; Wang, Y.Q.; Hou, X.L. Review of chemical recycling and reuse of carbon fiber reinforced epoxy resin composites. New Carbon Mater. 2022, 37, 1021–1041. [Google Scholar] [CrossRef]

- Bai, T.; Wang, D.; Yan, J.; Cheng, W.; Cheng, H.; Shi, S.Q.; Han, G. Wetting mechanism and interfacial bonding performance of bamboo fiber reinforced epoxy resin composites. Compos. Sci. Technol. 2021, 213, 108951. [Google Scholar] [CrossRef]

- Praveenkumara, J.; Madhu, P.; Yashas Gowda, T.G.; Sanjay, M.R.; Siengchin, S. A comprehensive review on the effect of synthetic filler materials on fiber-reinforced hybrid polymer composites. J. Text. Inst. 2022, 113, 1231–1239. [Google Scholar] [CrossRef]

- Sienkiewicz, N.; Dominic, M.; Parameswaranpillai, J. Natural fillers as potential modifying agents for epoxy composition: A review. Polymers 2022, 14, 265. [Google Scholar] [CrossRef]

- Khan, F.M.; Shah, A.H.; Wang, S.; Mehmood, S.; Wang, J.; Liu, W.; Xu, X. A comprehensive review on epoxy biocomposites based on natural fibers and bio-fillers: Challenges, recent developments and applications. Adv. Fiber Mater. 2022, 4, 683–704. [Google Scholar] [CrossRef]

- Ramesh, M.; Rajeshkumar, L.N.; Srinivasan, N.; Kumar, D.V.; Balaji, D. Influence of filler material on properties of fiber-reinforced polymer composites: A review. e-Polymers 2022, 22, 898–916. [Google Scholar] [CrossRef]

- Jeyapragash, R.; Srinivasan, V.; Sathiyamurthy, S.J. Mechanical properties of natural fiber/particulate reinforced epoxy composites—A review of the literature. Mater. Today Proc. 2020, 22, 1223–1227. [Google Scholar] [CrossRef]

- Zwawi, M. A review on natural fiber bio-composites, surface modifications and applications. Molecules 2021, 26, 404. [Google Scholar] [CrossRef] [PubMed]

- Hemmati, F.; Farizeh, T.; Mohammadi-Roshandeh, J. Lignocellulosic fiber-reinforced PLA green composites: Effects of chemical fiber treatment. In Biocomposite Materials: Design and Mechanical Properties Characterization; Springer: Singapore, 2021; pp. 97–204. [Google Scholar]

- Mohammed, M.; Rahman, R.; Mohammed, A.M.; Adam, T.; Betar, B.O.; Osman, A.F.; Dahham, O.S. Surface treatment to improve water repellence and compatibility of natural fiber with polymer matrix: Recent advancement. Polym. Test. 2022, 115, 107707. [Google Scholar] [CrossRef]

- Vladkova, T.G.; Dineff, P.D.; Gospodinova, D.N. Wood flour: A new filler for the rubber processing industry. II. Cure characteristics and mechanical properties of NBR compounds filled with corona-treated wood flour. J. Appl. Polym. Sci. 2004, 91, 883–889. [Google Scholar] [CrossRef]

- Saerova, K.V.; Safin, R.R.; Galyavetdinov, N.R. High Frequency Low-Temperature Plasma Treatment of Thermally Modified Wood Filler and Its Effect on the Properties of Filled Polymers. Fibre Chem. 2025, 56, 334–339. [Google Scholar] [CrossRef]

- Majeed, S.S.; Mydin, M.A.O.; Omar, R.; Razak, R.A.; Al Bakri Abdullah, M.M.; Ishak, S. Effect of Fibre Mercerization on Strength Properties of Agave Cantula Roxb. Strengthen Foamed Concrete. Arch. Metall. Mater. 2024, 69, 1175–1182. [Google Scholar] [CrossRef]

- Mahakur, V.K.; Bhowmik, S.; Patowari, P.K. Impact of silanization on the characterization of Corchorus olitorius particle-based composites for sustainable applications. Polym. Int. 2024, 73, 270–279. [Google Scholar] [CrossRef]

- Sienkiewicz, A.; Czub, P. Modification of Epoxy Compositions by the Application of Various Fillers of Natural Origin. Materials 2023, 16, 3149. [Google Scholar] [CrossRef] [PubMed]

- Kawalerczyk, J.; Walkiewicz, J.; Sedliačik, J.; Dukarska, D.; Woźniak, M.; Mirski, R. Modified Buckwheat Husk as a Filler for Urea-Formaldehyde Resin in Plywood Production. Polymers 2024, 16, 1350. [Google Scholar] [CrossRef]

- Jiyas, N.; Sasidharan, I.; Bindu Kumar, K.; Senthamaraikannan, P.; Kumar, R. Characterization of Potassium Permanganate Treated Natural Fibers and Its Eco-Friendly Friction Composites. J. Nat. Fibers 2025, 22, 2502647. [Google Scholar] [CrossRef]

- Ayana, K.D.; Ha, C.S.; Ali, A.Y. Comprehensive overview of wood polymer composite: Formulation and technology, properties, interphase modification, and characterization. Sustain. Mater. Technol. 2024, 40, e00983. [Google Scholar] [CrossRef]

- Brandt, A.; Gräsvik, J.; Hallett, J.P.; Welton, T. Deconstruction of lignocellulosic biomass with ionic liquids. Green Chem. 2013, 15, 550–583. [Google Scholar] [CrossRef]

- Sharma, P.; Sharma, S.; Kumar, H. Introduction to ionic liquids, applications and micellization behaviour in presence of different additives. J. Mol. Liq. 2024, 393, 123447. [Google Scholar] [CrossRef]

- Berga, L.; Bruce, I.; Nicol, T.W.J. Cellulose dissolution and regeneration using a non-aqueous, non-stoichiometric protic ionic liquid system. Cellulose 2020, 27, 9593–9603. [Google Scholar] [CrossRef]

- Hinner, L.P.; Wissner, J.L.; Beurer, A.; Nebel, B.A.; Hauer, B. Homogeneous vinyl ester-based synthesis of different cellulose derivatives in 1-ethyl-3-methyl-imidazolium acetate. Green Chem. 2016, 18, 6099–6107. [Google Scholar] [CrossRef]

- Taokaew, S.; Kriangkrai, W. Recent progress in processing cellulose using ionic liquids as solvents. Polysaccharides 2022, 3, 671–691. [Google Scholar] [CrossRef]

- Shamsuri, A.A.; Jamil, S.N.A.M.; Abdan, K. The influence of ionic liquid pretreatment on the physicomechanical properties of polymer biocomposites: A mini-review. e-Polymers 2022, 22, 809–820. [Google Scholar] [CrossRef]

- Keating, M.Y.; Gao, F.; Ramsey, J.B. TGA-MS study of the decomposition of phosphorus containing liquids trihexyl (tetradecyl) phosphonium decanoate and trihexyltetradecylphosphonium bis[(trifluoromethyl)sulfonyl] amide. J. Therm. Anal. Calorim. 2011, 106, 207–211. [Google Scholar] [CrossRef]

- Dharaskar, S.A.; Sillanpaa, M. Trihexyl (tetradecyl) phosphonium hexafluorophosphate as an promising extractant for extractive desulfurization from liquid fuels. Sep. Sci. Technol. 2018, 53, 2044–2054. [Google Scholar] [CrossRef]

- Assenine, M.A.; Haddad, B.; Paolone, A.; Brandán, S.A.; Goussem, M.; Villemin, D.; Bresson, S. Synthesis, thermal properties, vibrational spectra and computational studies of Trioctylmethylammonium bis(trifluoromethylsulfonyl)imide ionic liquid. J. Mol. Struct. 2021, 1232, 130085. [Google Scholar] [CrossRef]

- Paiva, M.C.; Ammar, I.; Campos, A.R.; Cheikh, R.B.; Cunha, A.M. Alfa fibres: Mechanical, morphological and interfacial characterization. Compos. Sci. Technol. 2007, 67, 1132–1138. [Google Scholar] [CrossRef]

- Alawar, A.; Hamed, A.M.; Al-Kaabi, K. Characterization of treated date palm tree fiber as composite reinforcement. Compos. Part B Eng. 2009, 40, 601–606. [Google Scholar] [CrossRef]

- Sgriccia, N.; Hawley, M.C.; Misra, M. Characterization of natural fiber surfaces and natural fiber composites. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1632–1637. [Google Scholar] [CrossRef]

- Le Troedec, M.; Sedan, D.; Peyratout, C.; Bonnet, J.P.; Smith, A.; Guinebretiere, R.; Krausz, P. Influence of various chemical treatments on the composition and structure of hemp fibres. Compos. Part A Appl. Sci. Manuf. 2008, 39, 514–522. [Google Scholar] [CrossRef]

- Mathew, L.; Joseph, K.U.; Joseph, R. Isora fibre: Morphology, chemical composition, surface modification, physical, mechanical and thermal properties–A potential natural reinforcement. J. Nat. Fibers 2007, 3, 13–27. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Nicoletti, F.; Vitale, G.; Prestipino, M.; Valenza, A. A new eco-friendly chemical treatment of natural fibres: Effect of sodium bicarbonate on properties of sisal fibre and its epoxy composites. Compos. Part B Eng. 2016, 85, 150–160. [Google Scholar] [CrossRef]

- Mallakpour, S.; Zadehnazari, A. Molten salt-supported polycondensation of optically active diacid monomers with an aromatic thiazole-bearing diamine using microwave irradiation. J. Adv. Res. 2014, 5, 311–318. [Google Scholar] [CrossRef]

- Economou, C.N.; Bertozzi, S.M.; Nardi, M.; Paul, U.C.; Fiorentini, F.; Ferrari, G.; Athanassiou, A. Enhanced biodegradation of polylactic acid by Aspergillus oryzae lipase: Toward sustainable plastic end-of-life solutions. Bioresour. Technol. 2025, 434, 132807. [Google Scholar] [CrossRef]

- Charusheela, A.; Arvind, L. Enzyme catalyzed hydrolysis of esters using reversibly soluble polymer conjugated lipases. Enzyme Microb. Technol. 2002, 30, 19–25. [Google Scholar] [CrossRef]

- Mendes, A.A.; Oliveira, P.C.; de Castro, H.F. Properties and biotechnological applications of porcine pancreatic lipase. J. Mol. Catal. B Enzym. 2012, 78, 119–134. [Google Scholar] [CrossRef]

- Helal, S.E.; Abdelhady, H.M.; Abou-Taleb, K.A.; Hassan, M.G.; Amer, M.M. Lipase from Rhizopus oryzae R1: In-depth characterization, immobilization, and evaluation in biodiesel production. J. Genet. Eng. Biotechnol. 2021, 19, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Akram, M.A.; Savitha, R.; Kinsella, G.K.; Nolan, K.; Ryan, B.J.; Henehan, G.T. Microbial and enzymatic biodegradation of plastic waste for a circular economy. Appl. Sci. 2024, 14, 11942. [Google Scholar] [CrossRef]

- Suresh, V.; Shams, R.; Dash, K.K.; Shaikh, A.M.; Béla, K. Comprehensive review on enzymatic polymer degradation: A sustainable solution for plastics. J. Agric. Food Res. 2025, 20, 101788. [Google Scholar] [CrossRef]

- Ashori, A.; Sheshmani, S. Hybrid composites made from recycled materials: Moisture absorption and thickness swelling behavior. Biores. Technol. 2010, 101, 4717–4720. [Google Scholar] [CrossRef] [PubMed]

- Masoodi, R.; Pillai, K.M. A study on moisture absorption and swelling in bio-based jute epoxy composites. J. Reinf. Plast. Compos. 2012, 31, 285–294. [Google Scholar] [CrossRef]

- Gajowy, J.; Bednarz, P.; Laska, J. Degradacja mieszanin polimerowych poliuretanu z polilaktydem w symulowanym środowisku biologicznym. Eng. Biomater. 2009, 12, 214–217. [Google Scholar]

- Dhakal, H.N.; Zhang, Z.A.; Richardson, M.O. Effect of water absorption on the mechanical properties of hemp fibre reinforced unsaturated polyester composites. Compos. Sci. Technol. 2007, 67, 1674–1683. [Google Scholar] [CrossRef]

- Azevedo, H.S.; Reis, R.L. Understanding the enzymatic degradation of biodegradable polymers and strategies to control their degradation rate. In Biodegradable Systems in Tissue Engineering and Regenerative Medicine; Reis, R.L., Roman, J., Eds.; SCRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Lee, S.H.; Song, W.S. Hydrolysis of polylactic acid fiber by lipase from porcine pancreas. J. Korean Soc. Cloth. Text. 2011, 35, 670–677. [Google Scholar] [CrossRef][Green Version]

- Faiza, W.; Firouzi, A.; Islam, M.R.; Sumdani, G.; Taher, A. Degradation analysis of epoxy resin composites reinforced with bioprotein: Effects of hydrolysis using papain and bromelain. Polym. Compos. 2021, 42, 2717–2727. [Google Scholar] [CrossRef]

- PN-EN ISO 527-1:2012; Plastics-Determination of Tensile Properties-Part 1: General Principles. ISO: Geneva, Switzerland, 2012.

- PN-EN ISO 178:2011; Plastics-Determination of Flexural Properties. ISO: Geneva, Switzerland, 2011.

- PN-EN ISO 604:2006; Plastics-Determination of Compressive Properties. ISO: Geneva, Switzerland, 2006.

- PN-EN ISO 179-2:2001; Plastics-Determination of Charpy Impact Properties-Part 2: Instrumented Impact Test. ISO: Geneva, Switzerland, 2001.

| Signal | Frequency [cm−1] | Associated Band | |||

|---|---|---|---|---|---|

| Unmodified Wood Flour WF | Wood Flour Chemically Modified with Ionic Liquids | ||||

| WF_IL-1 | WF_IL-2 | WF_IL-3 | |||

| 1 | 3100–3570 | 3095–3575 | valence stretching -OH and/or -N-H | ||

| 2 | 2899 | 2915, 2845 | 2865 | 2935, 2850 | valence stretching -C-H |

| 3 | 1724 | 1722 | 1722 | 1718 | valence stretching -C=O |

| 4 | 1592, 1470 | 1590, 1467 | stretching C=C of the ring, skeletal vibrations in the plane of the ring | ||

| 5 | 1417 | 1418 | 1420 | 1420 | symmetrical bending -CH2 |

| 6 | 1363, 1314 | 1328, 1320 | 1363, 1312 | 1354, 1322 | bending -C-H and -C-O groups of the aromatic ring/stretching -C-N of the imide group |

| 7 | 1227 | - | 1227 | - | stretching -C-O of the acetyl group |

| 8 | - | 1199 | - | - | stretching -C-O-C of the amide group |

| 9 | - | - | - | 1185 | bending H-C-C and H-C-N of the imide ring |

| 10 | 1080 | 1085, 1045 | 1085 | 1080, 1040 | stretching -C-O-C |

| 11 | 1022 | 1025 | stretching -C-O ether group | ||

| 12 | 888 | 891 | β-glycosidic bonds between monosaccharides | ||

| 13 | - | 620–500 | - | 620–500 | deformation of the amide/imide ring |

| 14 | 560 | 556 | 552 | 556 | bending -C-OH |

| Epoxy Composition | Epoxy Resin | Hardener | Deaerator [1 wt.%] | Filler [5 wt.%] |

|---|---|---|---|---|

| REF | Epidian 6 | IDA hardener | BYK A530 | - |

| EP6-WF | Unmodified wood flour | |||

| EP6-WF_IL-1 | Wood flour modified with IL-1 | |||

| EP6-WF_IL-2 | Wood flour modified with IL-2 | |||

| EP6-WF_IL-3 | Wood flour modified with IL-3 |

| Mechanical Properties | Epoxy Compositions Based on Low Molecular Epoxy Resin Epidian 6 | ||||

|---|---|---|---|---|---|

| Epoxy Composition Without the Filler | Epoxy Composites with Unmodified Wood Flour | Epoxy Composites with Wood Flour Modified with Ionic Liquids | |||

| REF | EP6_WF | EP6-WF_IL-1 | EP6-WF_IL-2 | EP6-WF_IL-3 | |

| Modulus of elasticity (MPa) | 2441.18 ± 227.55 | 839.45 ± 121.90 | 814.97 ± 60.22 | 698.90± 114.00 | 951.90 ± 47.94 |

| Elasticity flexural modulus (MPa) | 1628.0 ± 59.1 | 1744.0 ± 82.0 | 1825.3 ± 92.7 | 1855.3 ± 140.5 | 1551.0 ± 142.8 |

| Rockwell Hardness (MPa) | 72.0 ± 0.02 | 69.40 ± 0.03 | 90.70 ± 0.01 | 77.80 ± 0.01 | 69.40 ± 0.01 |

| Impact toughness (kJ/m2) | 9.15 ± 0.94 | 10.26 ± 3.48 | 12.02 ± 2.12 | 9.21 ± 0.92 | 7.13 ± 1.71 |

| Parameter | Conditions of Enzymatic Degradation | |

|---|---|---|

| Temperature | 30 °C | |

| pH | 7.24 | |

| Time of degradation | 30 days | |

| Type of enzyme | Porcine Pancreas | Rhizopus Oryzae |

| Concentration of the enzyme | 0.5 mg/week | 0.5 mg/week |

| Buffer solution | NH4Cl—1.0 g/L MgSO4·7H2O—0.25 g/L Na2HPO4—7.0 g/L NaCl—0.5 g/L H3BO3—0.5 µg/L CuSO4·5H2O—40.0 µg/L FeCl3·6H2O—0.2 µg/L ZnCl2—0.4 µg/L MnSO4·5H2O—0.4 µg/L (NH4)5Mo7O24·7H2O—0.2 µg/L | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sienkiewicz, A.; Czub, P. Application of Bio-Waste Modified by Ionic Liquids in Epoxy Composites—From Preparation to Biodegradation. Molecules 2025, 30, 3714. https://doi.org/10.3390/molecules30183714

Sienkiewicz A, Czub P. Application of Bio-Waste Modified by Ionic Liquids in Epoxy Composites—From Preparation to Biodegradation. Molecules. 2025; 30(18):3714. https://doi.org/10.3390/molecules30183714

Chicago/Turabian StyleSienkiewicz, Anna, and Piotr Czub. 2025. "Application of Bio-Waste Modified by Ionic Liquids in Epoxy Composites—From Preparation to Biodegradation" Molecules 30, no. 18: 3714. https://doi.org/10.3390/molecules30183714

APA StyleSienkiewicz, A., & Czub, P. (2025). Application of Bio-Waste Modified by Ionic Liquids in Epoxy Composites—From Preparation to Biodegradation. Molecules, 30(18), 3714. https://doi.org/10.3390/molecules30183714