2.1. Microstructure and Compositions

Figure 1 depicts the XRD patterns of the chromized layers treated under different chromizing time by both grazing-incidence XRD (GIXRD) and conventional XRD measurements. The chromized layer primarily consists of Cr

23C

6 (PDF#35-0783) and (Cr,Fe)

7C

3 (PDF# 05-0720) phases, accompanied by a minor (Cr,Fe)

2N

1−x (PDF#19-0330) phase. The enhanced intensity of (Cr,Fe)

2N

1−x diffraction peaks in GIXRD indicates that its preferential disperses on the surface of the chromized layer. The nitrogen in the chromized layer is primarily derived from the decomposition of NH

4Cl in the chromizing agent. The decomposed nitrogen atoms react with the surface-adsorbed Cr to form (Cr,Fe)

2N

1−x.

The formation process of the chromized layer primarily involves the inward diffusion of Cr, N atoms from the chromizing agent and the outward diffusion of substrate elements such as Fe and C. In the initial stage, the following reactions (as shown in

Table 1 Equations (1)–(8)) occur in the chromizing agent at high temperatures [

34,

35].

It is known that the growth of the chromized layer involves thermodynamics and kinetics issues. At a low temperature (<1000 °C), the resistance encountered during the coating growth is high and the kinetics dominate the growth process of coating. The Cr atoms/ions spill from the packed powders and diffuse into the substrate at a slow rate [

36]. Cr atoms diffuse inwards and C atoms in the substrate diffuse outwards, meeting at the interface and reacting to form the chromium carbide phase. Theoretically, there would be many different types of chromium carbides including Cr

23C

6, Cr

7C

3 and Cr

3C

2, formed by the reaction. The following equations (as shown in

Table 1 Equations (9)–(11)) show the reaction and the associated Gibbs free energy [

21].

Previous studies indicate that the Gibbs free energy of Cr

23C

6, Cr

7C

3 and Cr

3C

2 remains nearly constant within a certain temperature range. According to the thermodynamic theory, it can be concluded that the formation order of the three kinds of chromium carbides should by Cr

23C

6 first, then Cr

7C

3 and lastly Cr

3C

2 [

37]. Thus, when the ratio between Cr and C is large enough, Cr

23C

6 phase can easily form [

38]. The phase structure of the chromized layer is also closely related to the C content in the substrate. For high-carbon steel, the active chromium atoms first react with the carbon atoms on the surface of the steel substrate to form Cr

23C

6. After the formation of the Cr

23C

6 layer on the surface, surface-adsorbed Cr atoms penetrate through the carbide layer to reach the substrate, which increases the inward diffusion resistance of Cr atoms, while the Cr atoms in the Cr

23C

6 phase near the substrate interface constantly diffuse inward. This results in a continuous decrease in Cr content in the Cr

23C

6 phase at the interface, coupled with the continuous outward diffusion of C atoms from the substrate, which promote the phase transformation from Cr

23C

6 to Cr

7C

3 near the interface [

27]. Additionally, the outward diffusion of Fe from the substrate to replace part of the Cr atoms is more conducive to thermodynamic stability [

39]. So, the (Cr,Fe)

23C

6 phase and the (Cr,Fe)

7C

3 phase are formed in the chromized layer. In

Figure 1b, with the increase in chromizing time, the diffraction peak intensity enhances, indicating that the crystal structure of the chromized layer phase is strengthened, which may be attributed to the grain growth caused by the prolonged chromizing time.

According to the Scherrer equation,

In the formula,

K is a constant, β is a half-height width of the diffraction peak,

θ is an angle corresponding to the diffraction peak, and

λ is a wavelength of the x-ray. Bringing the angle of a single diffraction peak into Equation (12), the grain thickness of the corresponding crystal plane normal is obtained. After taking multiple angles into the calculation, the grain size

D can be obtained by averaging. The calculation results of grain size under different chromizing time are summarized in

Table 2. It can be observed that as the chromizing time increases, the grain size of the Cr

23C

6 phase increases gradually, while the grain size of the (Cr,Fe)

7C

3 phase does not exhibit a significant change. In summary, the grain size of the chromized layer gradually coarsens with extended chromizing time.

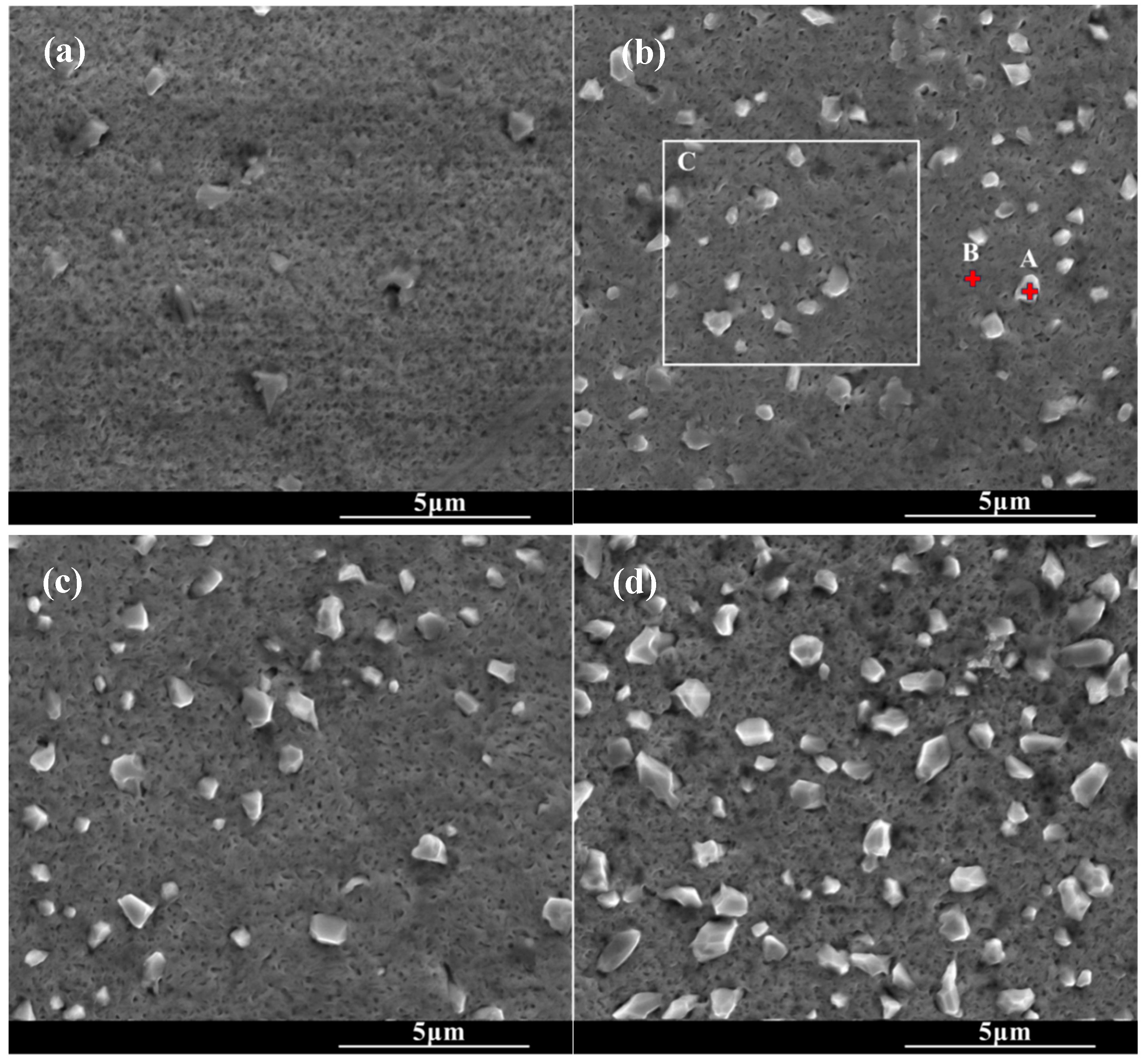

Figure 2 shows the surface morphologies of the chromized layers under the different chromizing time. The surface of the chromized layer exhibits relatively smooth topography, with scattered protruding rhombic grains embedded on the surface. As the chromizing time increases, the number and size of rhombic grains gradually increase. A large number of fine pores are distributed on the chromized layer surface. The formation of these pores may be attributed to the migration of vacancies in the subsurface of substrate, inward diffusion of Cr atoms into the substrate and decomposition of gas atoms from the NH

4Cl activator in the pack mixture [

22,

40]. EDS analysis was performed on different regions of the chromized surface, as shown in

Table 3. It can be found that the protruding rhombic grains are primarily enriched with Cr and N, while the remaining areas consist mainly of Cr and C. This indicates that the chromized layer predominantly comprises chromium carbide phases, while the scattered rhombic grains represent nitrogen-rich compounds. The presence of a small number of nitrogen-rich compounds in the chromized layer is related to active nitrogen atoms decomposed from the activator NH

4Cl in the chromizing agent that produces N

2 and combines with active Cr atoms to form Cr–N compounds [

34]. This is consistent with the result of XRD.

Figure 3 shows the cross-section morphology of the chromized layer under different chromizing times. The microstructure exhibits distinct light–dark contrast, enabling clear differentiation into four distinct layers labeled A, B, C and D (as shown in

Figure 3c). According to the EDS results shown in

Table 4, the Cr content in the chromized layer gradually decreases and the Fe content gradually increases from the surface to the substrate, forming a gradual composition transition structure. The C content is higher than that of the substrate throughout the chromized layer due to the outward diffusion from the substrate. It is known that the diffusion coefficient of C atoms is three or four orders of magnitude greater than that of Cr atoms at high temperature. In the early stage of the chromizing process, Cr atoms first deposit on the surface and then diffuse inward; its penetration inside is stopped by a counter-diffusion of carbon as a result of the vigorous chemical affinity of these elements and formation of a carbide layer [

39]. No N element is detected inside the chromized layer. A small amount of nitrogen atoms from the decomposition of NH

4Cl in the agent combine with Cr on the surface to form the chromium nitride phase sporadically dispersed on the surface.

A certain number of pores distribute at the interface of the chromized layer/steel substrate shown in

Figure 3. According to

Figure 2 and

Figure 3, two types of pores are observed in the chromized layer: surface pores and interfacial pores. Previous studies have shown that the formation of pores on the surface of the chromized layer is caused by the mismatch diffusion of Cr atoms and Fe atoms in the chromized layer and the aggregation of vacancy migration at grain boundaries, as well as gas decomposition from the activator (NH

4Cl in the pack), etc. [

30,

40,

41]. During the chromizing process, Cr atoms diffuse inwards and C atoms in the substrate diffuse outwards, meeting at the interface and reacting to form the chromium carbide phase. Once this carbide layer develops, surface-adsorbed Cr atoms must penetrate it to reach the substrate, significantly hindering inward diffusion and consequently limiting chromized layer growth. The initially formed chromium carbide phase (such as Cr

23C

6) can also serve as a Cr source for further inward diffusion. If the vacancies generated by the inward diffusion of Cr atoms cannot be timely, compensated by the inward diffusion of surface Cr atoms from external medium, a large number of vacancies will migrate and coalesce, leading to the formation of pores on the surface [

22]. Wang H.F. et al. [

30] observed that the formation of pores on the surface was caused by the differential Cr diffusion rates between grain boundaries and intragranular regions in the Cr-rich phase layer. The lower boundaries of most pores are connected to grain boundaries, while the upper boundaries of pores are located within the grains. The diffusion rate of atoms along the grain boundary is much higher than that through intragranular region, resulting in the formation of a large number of vacancies. Vacancies are constantly accumulating, and finally pores are formed. Similarly, the mechanism of pore formation and growth at the chromized layer/steel substrate interface is also the result of this inequality of atom diffusion. Additionally, the stress and relaxation, which are caused by the different specific volumes and coefficients of linear thermal expansion of the carbide layer and the steel substrate and which is accompanied by vacancy coagulation at the interface boundary, may also be causes of porosity at the interface of carbide-layer/steel [

39]. Such interfacial porosity may reduce the bonding strength of the chromized layer to the substrate [

42].

Figure 4 shows the thickness variation in the chromized layer under different chromizing times. As the chromizing time increases from 6 h to 12 h, the layer thickness exhibits a gradual growth from 6.97 μm to 8.67 μm. Previous research has shown that C content in the substrate significantly influences the thickness of the chromized layer. Liu T. et al. [

22] proposed that the carbon content in the substrate of 0.2 wt.% is a cut-off point, which has an apparent influence on the structure and growth mechanism of the chromized layer. When the C content is ≤0.2 wt.%, the thickness of the chromized layer is significantly thicker, although the thickness of the permeable layer decreased slightly with the increase in C content in the substrate (ranging from 51.19 μm to 31.39 μm). In contrast, for substrates with higher carbon content (>0.2 wt.%), the chromized layer remains relatively thin (13.04 μm to 15.60 μm for C content of 0.3~0.45 wt.%) and shows only a slight increase in thickness with further elevation of C content. However, Lee J.W. et al. [

28] indicated that the thickness of the chromized layer obeys the parabolic rate law: X = K✓t and increases with chromizing time and carbon contents in the substrate. The high carbon content (up to 1 wt.%) in GCr15 steel substrate promotes the rapid formation of the chromium carbide layer during the chromizing process. After the chromium carbide layer is formed due to the vigorous chemical affinity on the surface, Cr atoms adsorbed on the surface must pass through the carbides layer to reach the substrate, which increases the difficulty of inward diffusion, hindering the inward diffusion of Cr atoms, and thus limiting the growth rate of the chromized layer. As a result, the thickness of the chromized layer increases slightly with an increase in the chromizing time. Since the diffusion rate of C atoms at a high temperature is much higher than that of Cr, the outward diffusion of C atoms has become the main reason for the growth of the chromized layer. As indicated during chromized plating, about 70% of the thickness of the carbide layer is formed due to its outward growth, and only 30% due to inward growth into the depth of specimen [

39].

2.3. Indentation

Figure 6 shows the SEM morphology of the indentation on the surface of the chromized layer. Numerous cracks exist within and around the indentation, where radial and circumferential cracks are observed inside the indentation zone, while radial cracks dominate the surrounding area. Radial cracks typically initiate inside the indentation, then propagate outward in a radial pattern through the indentation edge. Some radial cracks deflect and then continue to extend outward. Within the indentation zone, circumferential cracks appear to be discontinuous, terminating at radial cracks. That is, numerous discontinuous circumferential cracks exist between radial cracks, with coarser ones appearing at the indentation edge. The presence of circumferential cracks reflects fracture behavior in the material, indicating that the chromized layer inside the indentation has undergone fracturing, with the most severe fracture occurring and leading to the spalling around the indentation edge. Spalling tends to occur in enclosed regions formed by radial and circumferential cracks. The spalling regions surrounding the indention observed for CT6 and CT8 are relatively small, with minimal spalling at the indention edge. In contrast, CT10 and CT12 exhibited obviously larger spalling areas. The spalling zones surrounding the indentations are nearly completely interconnected, forming a continuous spalling circle. Furthermore, spalling at the indentation edge obviously increases and gradually propagates outward, merging with the outer spalling circle to form extensive spalling regions. This indicates that the brittleness of the chromized layer increases with prolonged chromizing time. Burnett P.J. et al. [

43] revealed that the ratio of

Ef/

Es (where

Ef and

Es are the Young’s modulus of coatings and substrate, respectively) significantly influences the indentation-cracking behavior of the coating, primarily depending on the deformation mode of the coating/substrate system. When the elastic modulus of the coating is close to that of the substrate, the coating deformation under stress is obstructed by the substrate, leading to cracking in the coating and typically in radial patterns. If a coating with a higher elastic modulus is deposited onto a relatively softer substrate, the high-hardness coating usually has higher yield stress, and the soft substrate tends to yield first under stress. In this case, the deformation of coating will be affected by the deformation of the substrate; that is, the plastic deformation zone of the substrate beneath the coating will increase the curvature of the coating, thus increasing the cracking displacement and generating frame-like cracks (circumferential cracks). Simulation results confirm that the material beneath the indenter undergoes plastic deformation under compressive stress during the indentation process, being extruded and accumulating/expanding around the indentation. The maximum radial tensile stress exists outside the indentation edge, which is the main reason for the circumferential cracking of the coating. As indentation depth increases, the maximum circumferential tensile stress increases and its position shifts toward the indentation edge [

44,

45].

The chromized layer forms a continuous metallurgical bond with the steel substrate, ensuring excellent bonding strength between them and preventing premature delamination during loading. During stress loading, the chromized layer bears most of the stress due to its high hardness. However, the grain boundaries and defects within the chromized layer are prone to becoming stress concentration points, where cracks first initiate and propagate. As shown in

Figure 2 and

Figure 3, there are many pores on the surface and at the interface of the chromized layer/steel substrate. These pores may accelerate the propagation of cracks and lead to the spalling of layers. Furthermore, with the increase in chromizing time, the grains of the chromized layer are coarsened, causing the increment of the brittleness of the chromized layer and resulting in serious spalling around the indentation.

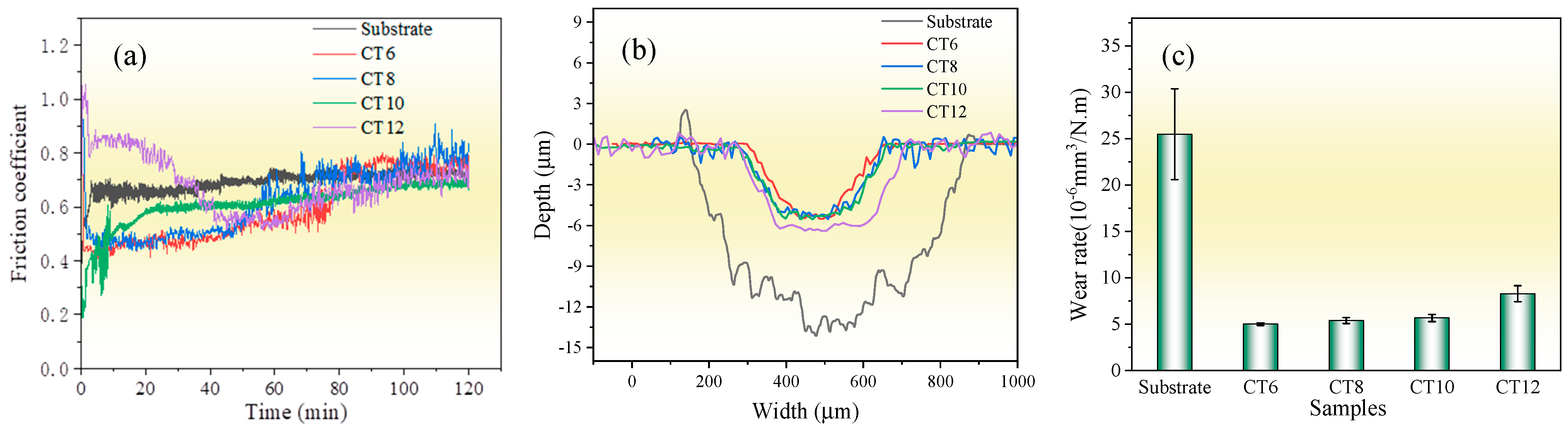

2.4. Tribological Properties

Figure 7 shows the friction and wear properties of the substrate and the chromized layer at room temperature. The average friction coefficients of the substrate, CT6, CT8, CT10 and CT12, are 0.69, 0.59, 0.62, 0.61 and 0.69, respectively. For CT6, CT8 and CT10, the average friction coefficient is lower than that of the substrate. However, with the increase in sliding time, their friction coefficient gradually increases and tends to be the same as the substrate at the end of the friction test. It is known that the main wear form of the GCr15 matrix is severe abrasive wear; thus, the friction coefficient is high, and the wear is serious [

8]. After chromizing treatment, the high-hardness phase of chromium carbide is formed on the surface, and the resistance to abrasive wear is improved, resulting in a lower initial friction coefficient. However, with the increase in sliding time, the friction coefficient of the chromized layer gradually increases due to the continuous accumulation of hard abrasive particles at the friction interface. When the chromizing time is increased to 12 h (CT12 sample), coarse grains are formed on the surface of the chromized layer (see

Figure 2), which can increase the surface roughness, resulting in a larger initial friction coefficient. As the coarse grains are gradually smoothed out with continued sliding, the friction coefficient decreased gradually. After approximately 50 min of wear, the variation trend of friction coefficient of the CT12 sample is similar to that of other chromized layers.

From the wear scar profile, the substrate displays a wear scar dimension with 726 μm in width and 14.29 μm in depth, whereas the chromized layer is markedly reduced in wear scar dimension with smaller width and depth. The wear depths of the chromized layer are lower than their thickness, indicating that the chromized layers have not been worn through.

Figure 7c shows the wear rate, calculated based on the wear scar profile. The wear rate of the substrate is 25.47×10

−6 mm

3·N

−1·m

−1, which is about five times higher than that of the chromized layers. This suggests that the wear rate is reduced greatly by chromizing treatment. This improvement in wear resistance can be attributed to the high hardness of the chromized layer and excellent interface bonding strength between the substrate and coating. The wear rates of CT6, CT8 and CT10 samples exhibited minimal variations, while that of the sample CT12 has increased. This may be related to the larger friction coefficient of CT12 samples.

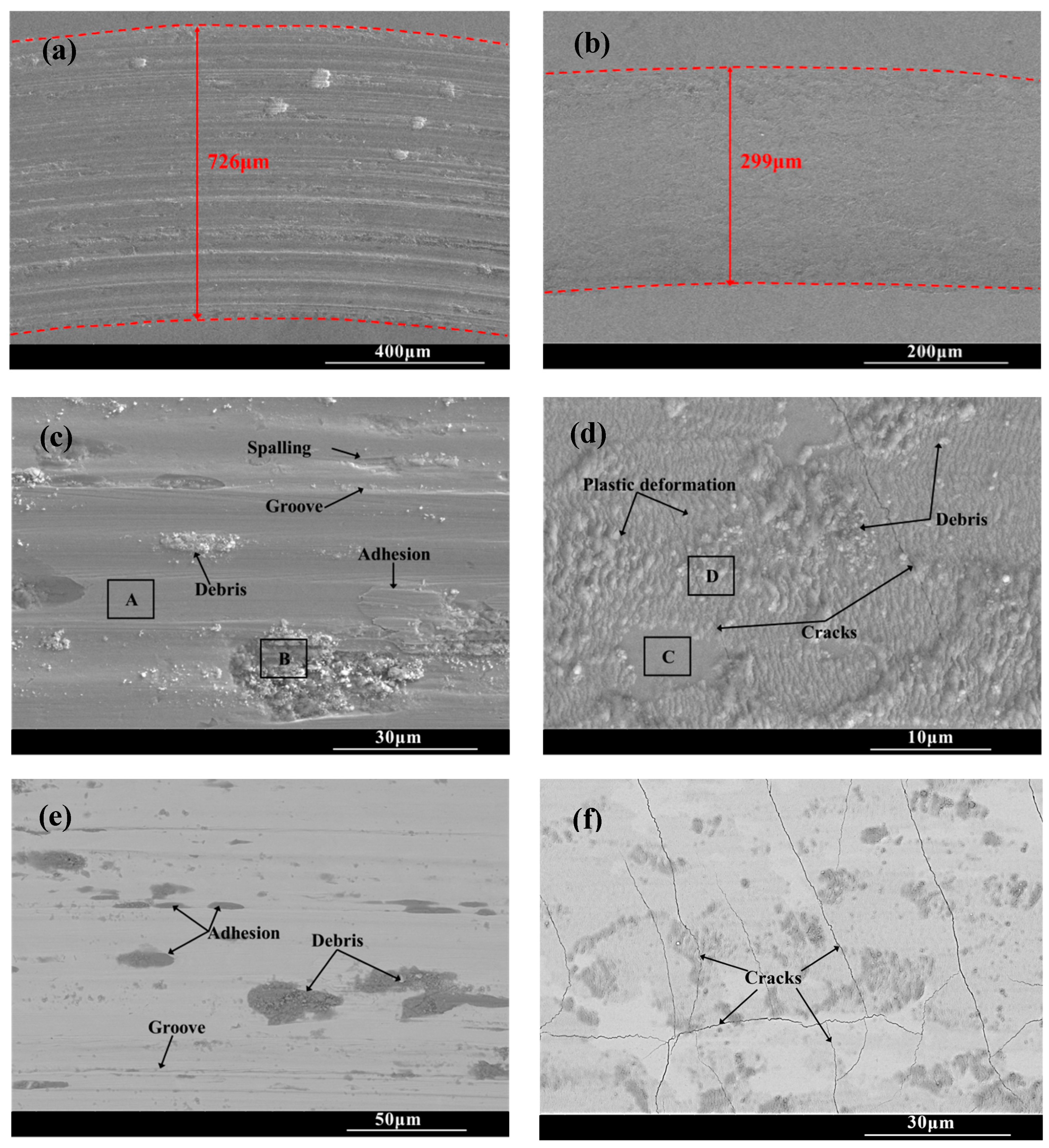

Figure 8 shows the wear scar morphologies of the substrate and CT10 chromized layer after the friction and wear test. There are a large number of scratches, along with torn-wear phenomena within the wear scar of the substrate. Some wear debris adhere in the scar and are crushed to form abrasive particles. The EDS result shown in

Table 3 reveals that oxidation is not obvious in the smooth Area A, but is severe in the abrasive particle’s Area B, which indicates that wear debris undergoes oxidation under repeated sliding of the load and forms hard oxide abrasive particles. The surface of steel substrate, mainly composed of Fe and a small amount of Cr, exhibits high oxygen affinity. During the repeated friction process, the interface temperature increases, causing these metals to combine with oxygen to form hard oxide particles. These hard particles embed in the wear interface, accelerating the abrasion of the soft substrate. Moreover, the affinity between the metal and the counter ball leads to adhesive wear, causing tearing and spalling of the material within the wear scar. Therefore, the wear mechanism of the GCr15 steel substrate is characterized by a combination of abrasive wear, adhesive wear and oxidative wear, collectively contributing to severe material wear.

The wear tracks of the chromized layer shown in

Figure 8b,d,f exhibit relatively shallow profiles with minor superficial scratches, indicating that the superior wear is resistant to the chromized layer. Higher-magnification images (

Figure 8d,f) reveal the presence of microcracks, plastic deformation zones and fine wear debris particles within the wear tracks. During the friction contact process, the material in the wear tracks is subjected to repeated shear stress and compressive stress, leading to plastic deformation as the material flows along the direction of the friction force. The thickness change in the deformation zone is inversely proportional to the hardness of the material. Generally, the material with large plastic deformation has lower hardness, while the material with higher hardness is more resistant to deformation. In the severe deformation zone, intense shear and contact stresses induce pronounced grain slip and flow, resulting in irregular deformation characteristics [

46]. As observed in

Figure 8d, it can be found that the plastic deformation zone within the wear scar of the chromized layer is shallow due to its high hardness. Under the cyclic contact stress and fatigue at the friction interface, micro-cracks nucleate at pores and grain boundary regions in the chromized layer. These micro-cracks gradually propagate under the repeated loading, eventually developing into macroscopic cracks within the wear tracks. As the crack density increases and propagates to form interlaced cracks, material spalling will be triggered.

It can be seen that although the substrate material undergoes extensive plastic deformation within the wear tracks due to its low hardness and high toughness, but no cracks are generated. However, the substrate is heavily ground due to its low hardness, resulting in poor wear resistance. In contrast, despite the presence of numerous cracks, the chromized layer demonstrates significantly enhanced wear resistance owing to its superior hardness and strong metallurgical bonding with the substrate.

Additionally, compared with that of the GCr15 steel substrate, no adhesive wear phenomenon is found within the wear tracks of the chromized layer. The chromized layer is mainly composed of hard ceramic phases: (Cr,Fe)

23C

6 and (Cr,Fe)

7C

3. The ceramic phases exhibit high chemical stability and poor affinity with the counter grinding ball. Therefore, the phenomena of adhesive wear and oxidative wear are significantly suppressed (as shown in

Table 5). Thus, the main wear mechanism of the chromized layer is abrasive wear.