An Explorative Study on Using Carbon Nanotube-Based Superhydrophobic Self-Heating Coatings for UAV Icing Protection

Abstract

1. Introduction

2. Results and Discussion

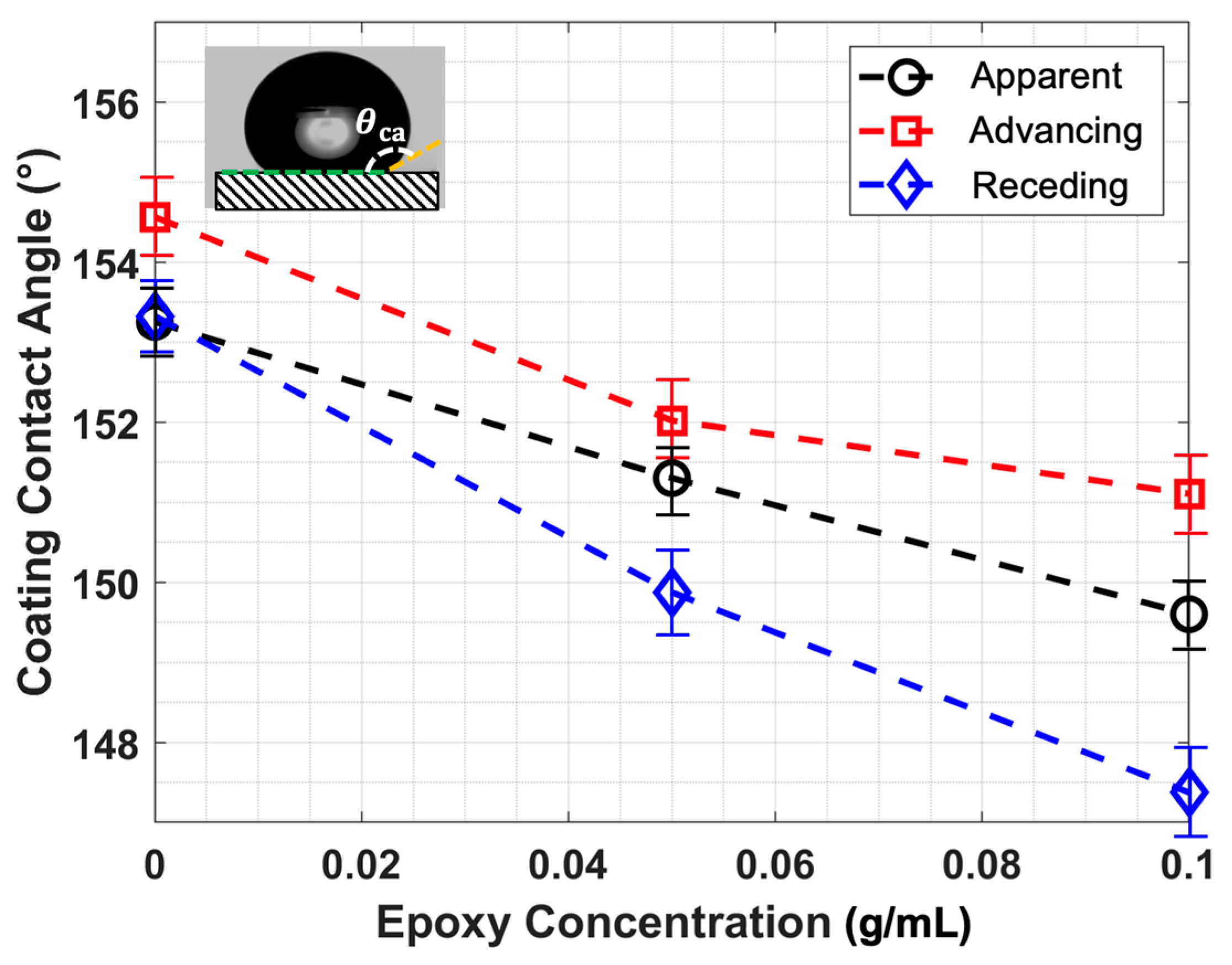

2.1. Effect of the Concentration of the Epoxy on Hydrophobicity

2.2. Effect of the Concentration of the CNT on Electrical Resistance of FM-CNT Coating

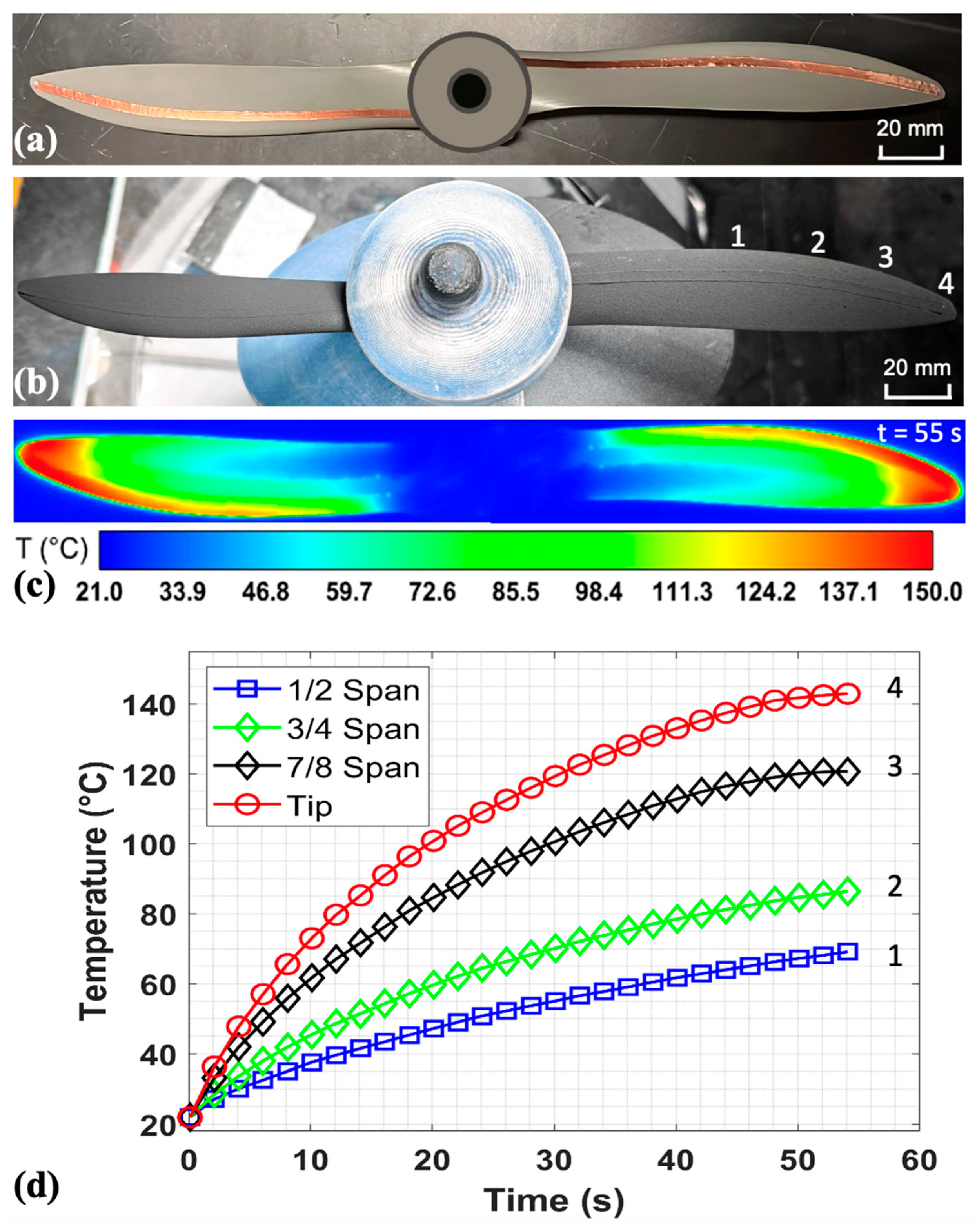

2.3. Heating Efficiency of the FM-CNT Coating

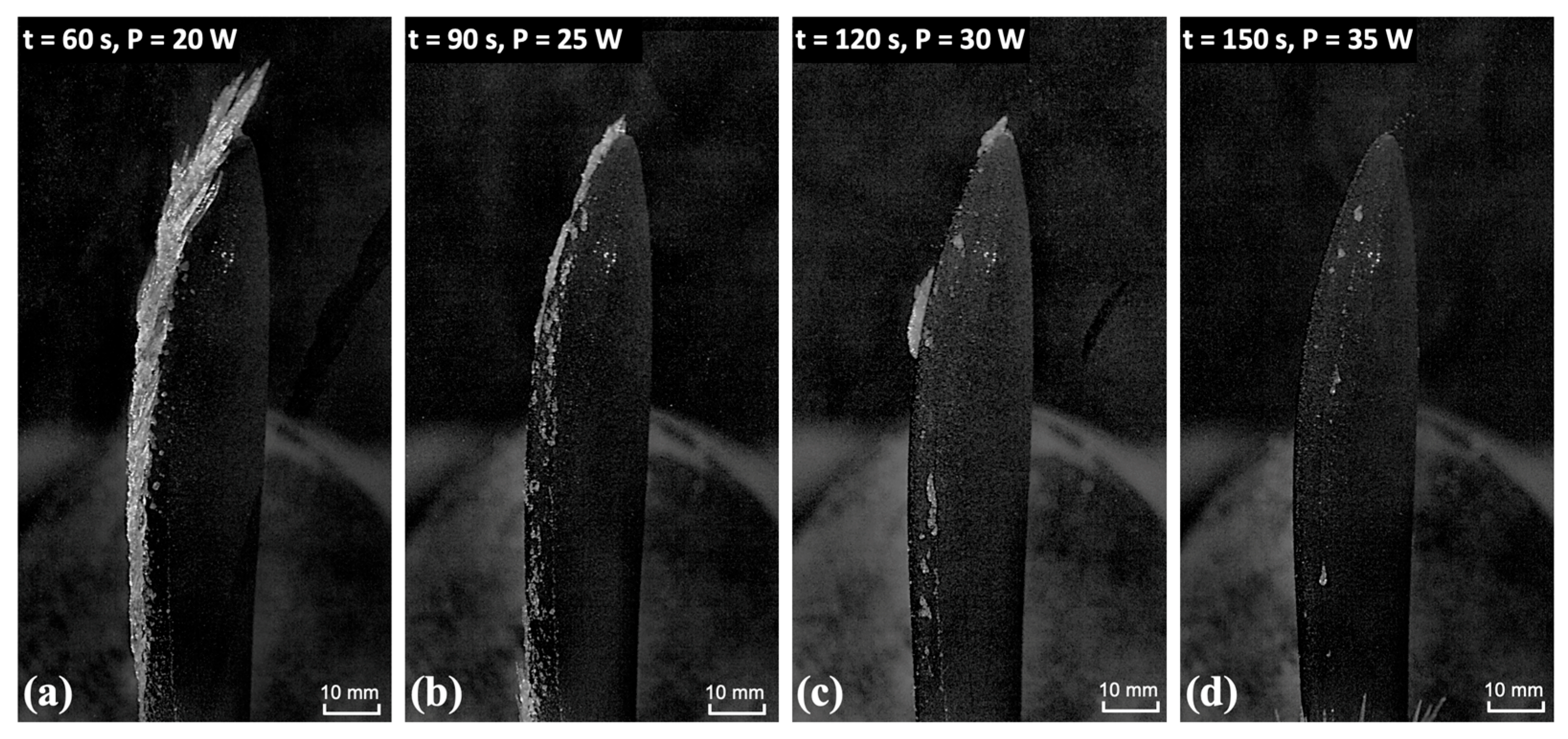

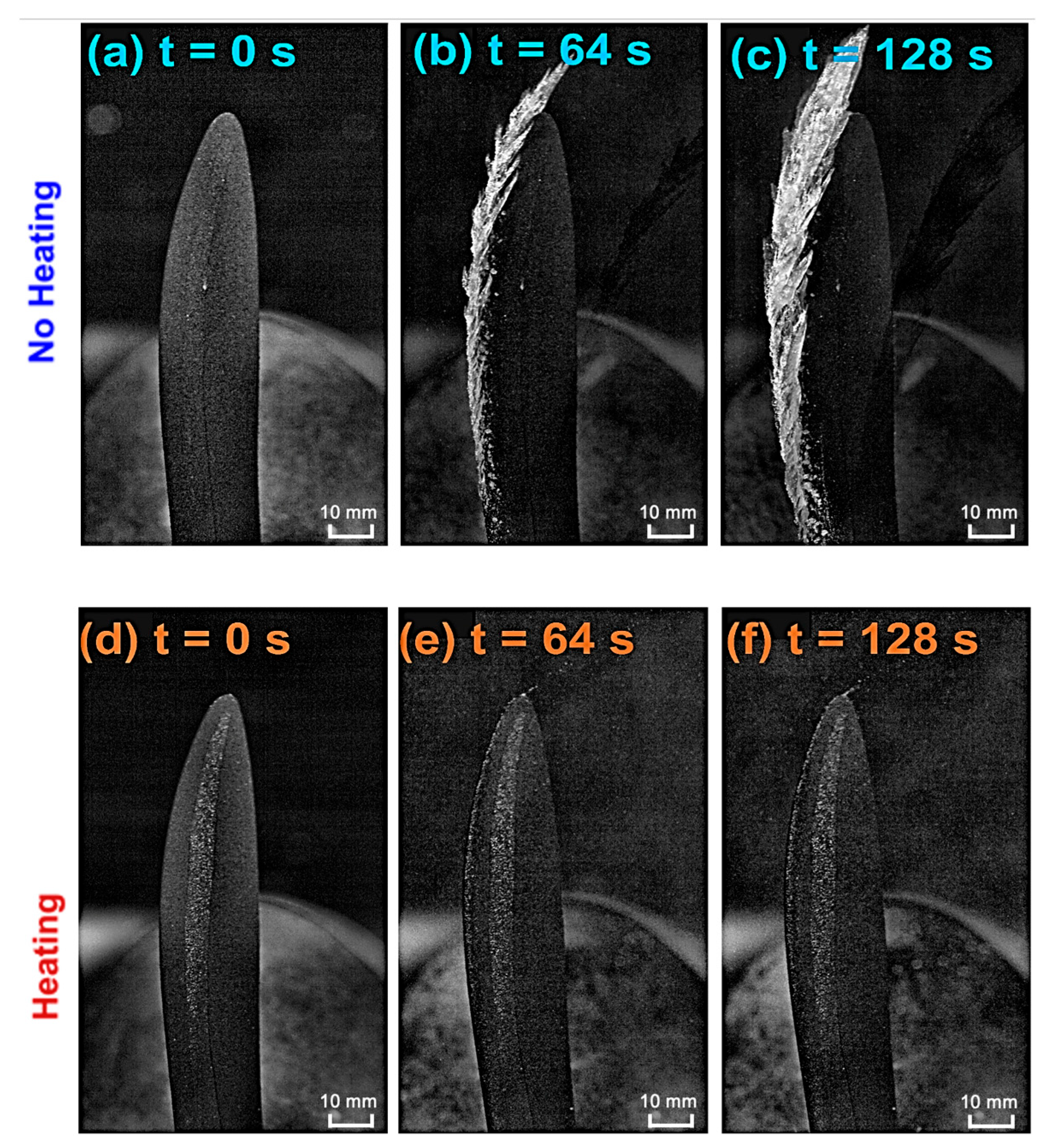

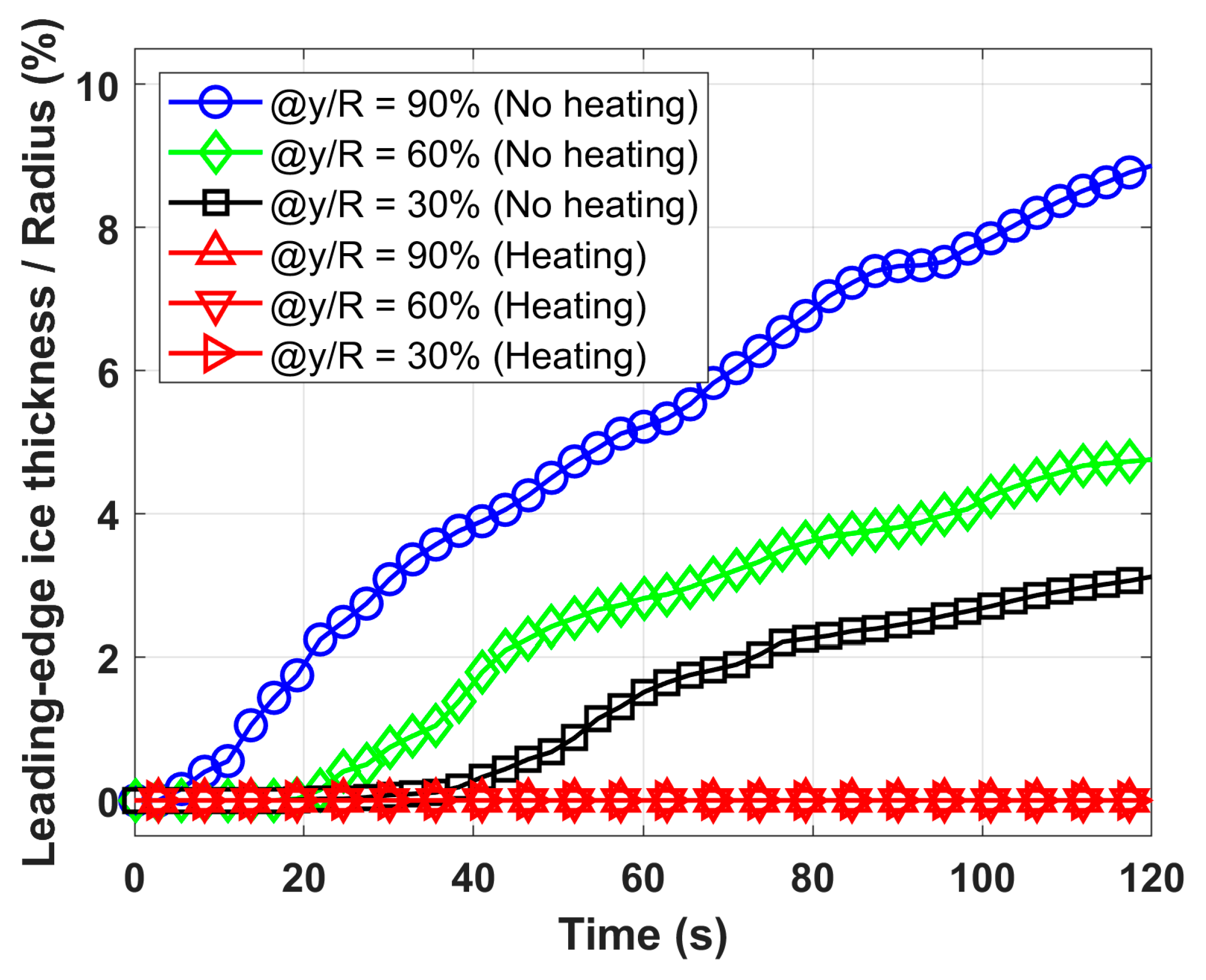

2.4. Anti-/De-Icing Test for a Rotating UAV Propeller Coated with FM-CNT Coating in the Icing Research Tunnel

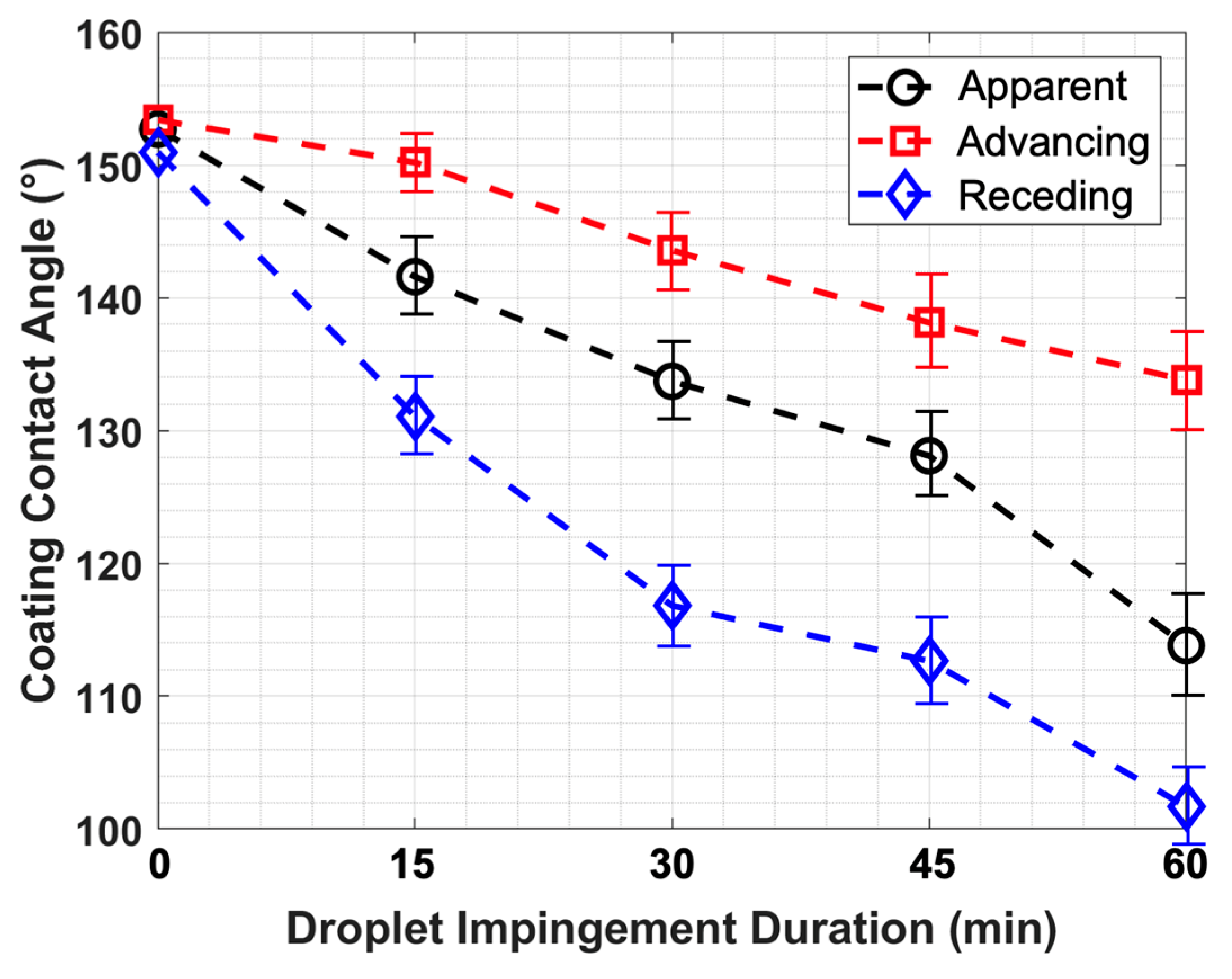

2.5. Durability Test of the FM-CNT Coating by High-Speed Droplet Impingement

3. Materials and Methods

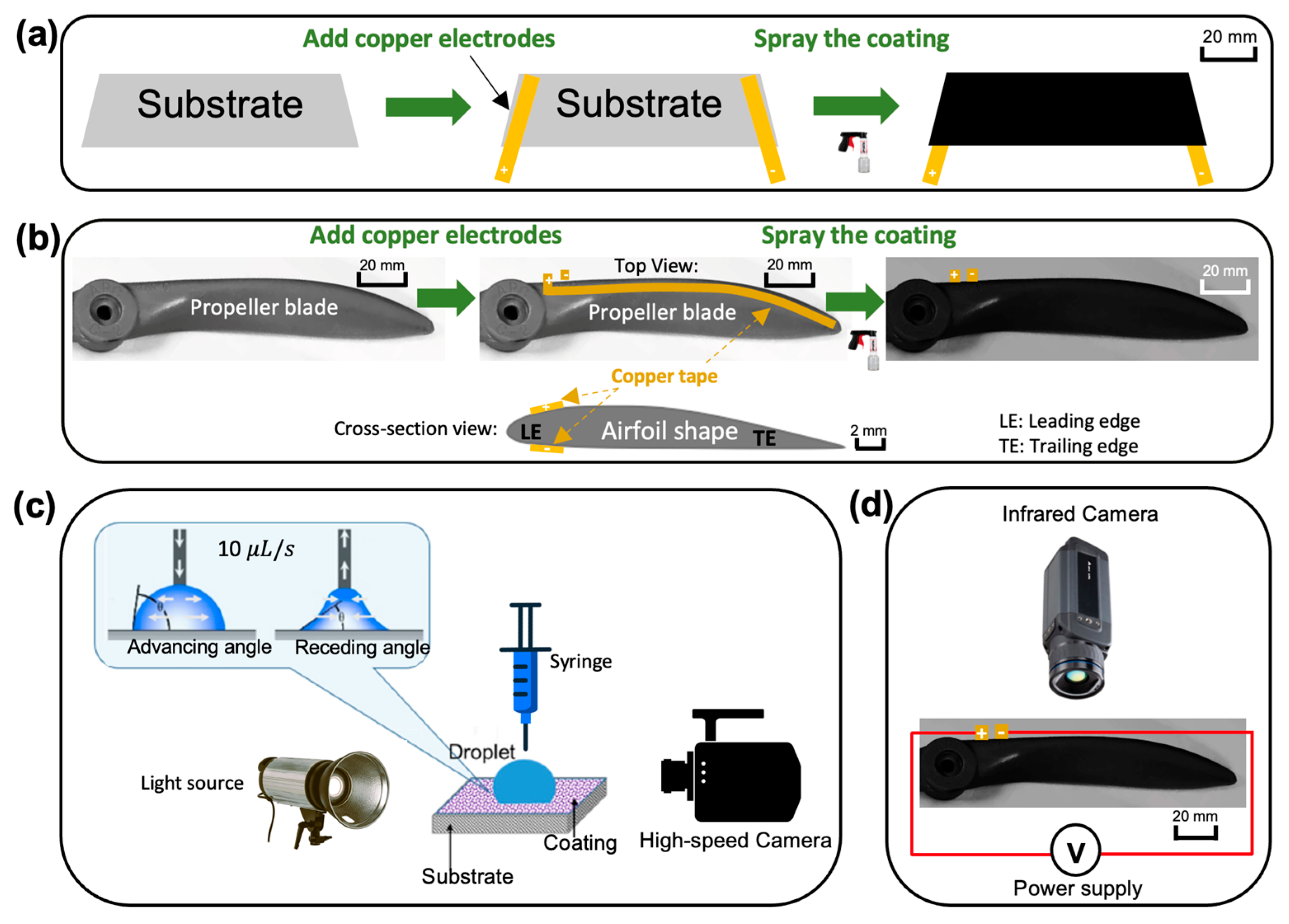

3.1. Fabrication of the FM-CNT Coating

3.2. Measurement Systems for the Coating’s Wettability and Heating Characterization

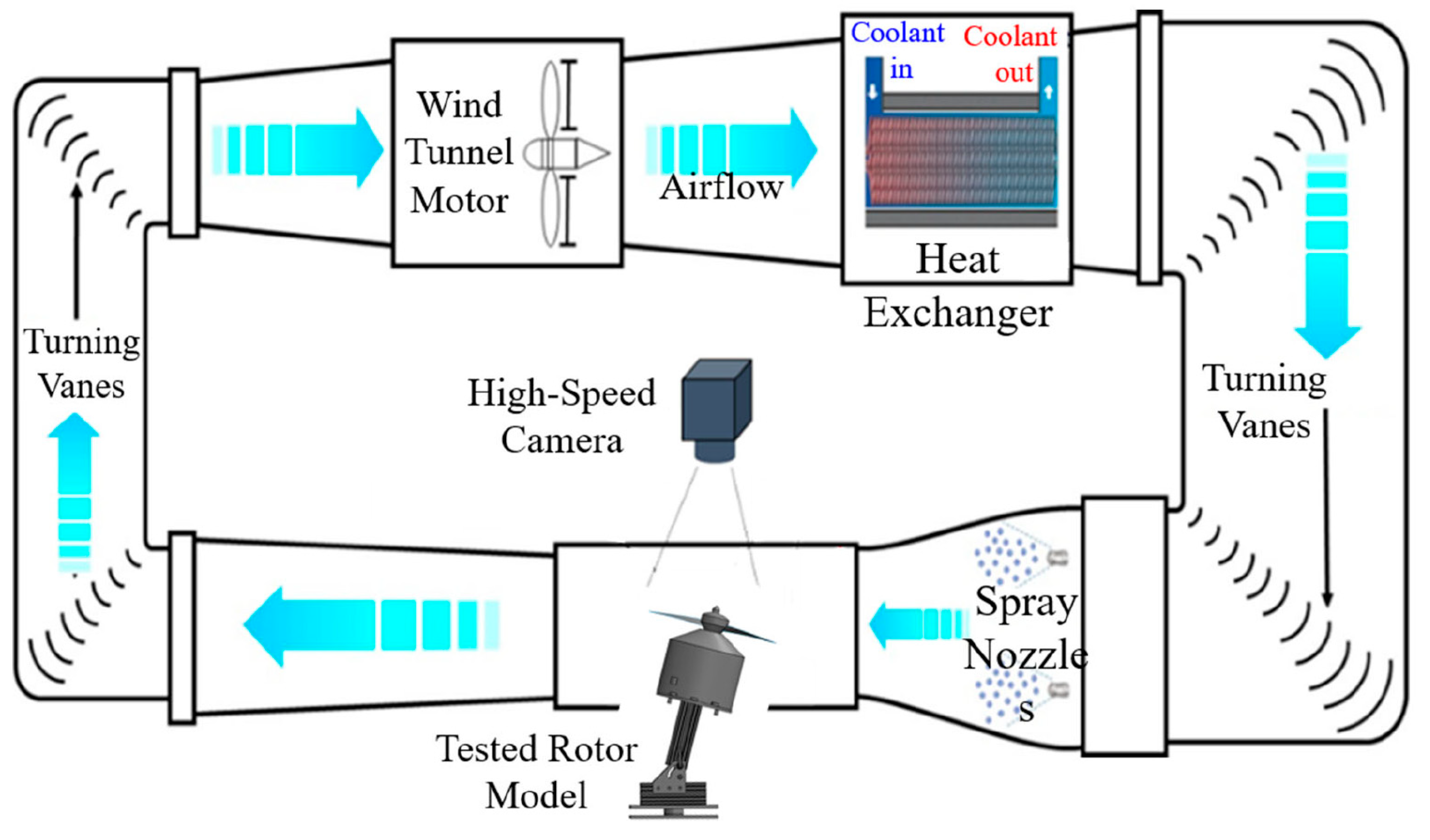

3.3. Icing Research Tunnel for an Anti-/De-Icing Test of the FM-CNT Coating

3.4. Slip-Ring Rotor Propeller System

3.5. Phase-Lock Imaging System for the Rotating Propeller

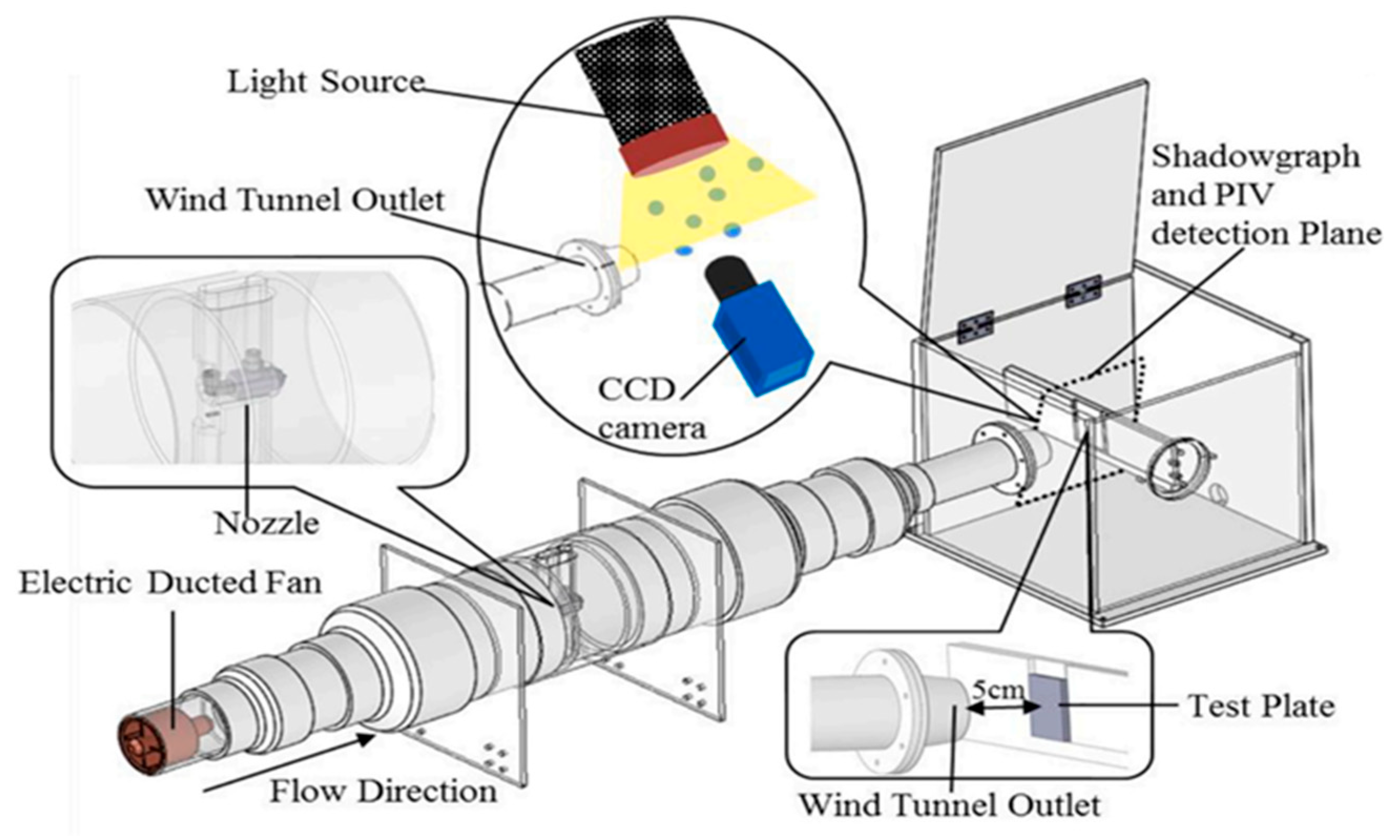

3.6. High-Speed Droplet Impingement Wind Tunnel for Durability Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Miziński, B.; Niedzielski, T. Fully-Automated Estimation of Snow Depth in near Real Time with the Use of Unmanned Aerial Vehicles without Utilizing Ground Control Points. Cold Reg. Sci. Technol. 2017, 138, 63–72. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, H. An Experimental Investigation on the Unsteady Heat Transfer Process over an Ice Accreting Airfoil Surface. Int. J. Heat Mass Transf. 2018, 122, 707–718. [Google Scholar] [CrossRef]

- Wang, J.; Hu, H.; He, P.; Hu, H. A Machine Learning Study to Predict Wind-Driven Water Runback Characteristics. Phys. of Fluids 2023, 35, 102104. [Google Scholar] [CrossRef]

- Waldman, R.M.; Hu, H. High-Speed Imaging to Quantify Transient Ice Accretion Process over an Airfoil. J. Aircr. 2016, 53, 369–377. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, K.; Tian, W.; Hu, H. An Experimental Investigation on the Dynamic Ice Accretion and Unsteady Heat Transfer over an Airfoil Surface with Embedded Initial Ice Roughness. Int. J. Heat Mass Transf. 2020, 146, 118900. [Google Scholar] [CrossRef]

- Wang, J.; Chumbley, E.; Shyam Kumar, M.; Hong, J.; Hu, H. Development of a Digital Inline Holographic System for Aircraft Icing Studies. Appl. Opt. 2025, 64, 95–102. [Google Scholar] [CrossRef]

- Cao, Y.; Tan, W.; Wu, Z. Aircraft Icing: An Ongoing Threat to Aviation Safety. Aerosp. Sci. Technol. 2018, 75, 353–385. [Google Scholar] [CrossRef]

- Han, N.; Siddique, M.A.; Zhang, Z.; Tian, L.; Hu, H.; Hu, H. A Flight-Testing Campaign to Examine Inflight Icing Characteristics and Its Effects on the Flight Performance of an Unmanned-Aerial-Vehicle. Cold Reg. Sci. Technol. 2023, 207, 103775. [Google Scholar] [CrossRef]

- Wang, J.; Dhulipalla, A.; Zhao, Y.; Bunes, A.; Hu, H. An Experimental Investigation on Dynamic Water Runback Process Over the Blade Surface of a Rotating Drone Propeller. In Proceedings of the AIAA AVIATION FORUM AND ASCEND 2025, Las Vegas, NV, USA, 22 July 2025. AIAA-2025-3164. [Google Scholar]

- Botura, G.; Fahrner, A. Icing Detection System—Conception, Development, Testing and Applicability to UAVs. In Proceedings of the 2nd AIAA Unmanned Unlimited Conference and Workshop & Exhibit, San Diego, CA, USA, 15–18 September 2003. [Google Scholar]

- Brown, J.M.; Raghunathan, S.; Watterson, J.K.; Linton, A.J.; Riordon, D. Heat Transfer Correlation for Anti-Icing Systems. J. Aircr. 2002, 39, 65–70. [Google Scholar] [CrossRef]

- Liu, Y.; Li, L.; Li, H.; Hu, H. An Experimental Study of Surface Wettability Effects on Dynamic Ice Accretion Process over an UAS Propeller Model. Aerosp. Sci. Technol. 2018, 73, 164–172. [Google Scholar] [CrossRef]

- Li, Q.; Yao, R.; Tan, V.B.C.; He, F.; Zhao, H.; Bai, T. A Review of Efficient Thermal Application for Ice Detection and Anti/de-Icing Technology. Appl. Therm. Eng. 2025, 263, 125366. [Google Scholar] [CrossRef]

- He, Z.; Xie, H.; Jamil, M.I.; Li, T.; Zhang, Q. Electro-/Photo-Thermal Promoted Anti-Icing Materials: A New Strategy Combined with Passive Anti-Icing and Active De-Icing. Adv. Mater. Interfaces. 2022, 9, 2200275. [Google Scholar] [CrossRef]

- Karpen, N.; Diebald, S.; Dezitter, F.; Bonaccurso, E. Propeller-Integrated Airfoil Heater System for Small Multirotor Drones in Icing Environments: Anti-Icing Feasibility Study. Cold Reg. Sci. Technol. 2022, 201, 103616. [Google Scholar] [CrossRef]

- Lv, J.; Song, Y.; Jiang, L.; Wang, J. Bio-Inspired Strategies for Anti-Icing. ACS Nano 2014, 8, 3152–3169. [Google Scholar] [CrossRef]

- Li, Z.; Cao, M.; Li, P.; Zhao, Y.; Bai, H.; Wu, Y.; Jiang, L. Surface-Embedding of Functional Micro-/Nanoparticles for Achieving Versatile Superhydrophobic Interfaces. Matter 2019, 1, 661–673. [Google Scholar] [CrossRef]

- Wang, Z.; Guo, P.; Heng, L.; Jiang, L. Nano/Submicrometer-Emulsion Oily Wastewater Treatment Inspired by Plant Transpiration. Matter 2021, 4, 1274–1286. [Google Scholar] [CrossRef]

- Wang, F.; Tay, T.E.; Sun, Y.; Liang, W.; Yang, B. Low-Voltage and -Surface Energy SWCNT/Poly(Dimethylsiloxane) (PDMS) Nanocomposite Film: Surface Wettability for Passive Anti-Icing and Surface-Skin Heating for Active Deicing. Compos. Sci. Technol. 2019, 184, 107872. [Google Scholar] [CrossRef]

- Wu, Q.; Zhao, Z.; Li, P.; Ren, X.; Wang, X.; Zhou, F.; Wang, S. Fluorine-Modified CNT@epoxy Electrothermal Coating for Long-Term Anti-Icing at Low Pulse Voltage. Colloids. Sur.f A. Physicochem. Eng. Asp. 2023, 666, 131332. [Google Scholar] [CrossRef]

- Marmur, A.; Della Volpe, C.; Siboni, S.; Amirfazli, A.; Drelich, J.W. Contact Angles and Wettability: Towards Common and Accurate Terminology. Surf. Innov. 2017, 5, 3–8. [Google Scholar] [CrossRef]

- Byczyński, Ł.; Dutkiewicz, M.; Januszewski, R.; Wrona, P.; Pilch-Pitera, B. Epoxy Coatings with Increased Hydrophobicity Modified by Isocyanurate Containing Siloxane. Mater. Today Commun. 2020, 24, 101001. [Google Scholar] [CrossRef]

- Zhi, D.; Wang, H.; Jiang, D.; Parkin, I.P.; Zhang, X. Reactive Silica Nanoparticles Turn Epoxy Coating from Hydrophilic to Super-Robust Superhydrophobic. RSC Adv. 2019, 9, 12547–12554. [Google Scholar] [CrossRef] [PubMed]

- Samad, A.; Dhulipalla, A.; Hu, H. Comparative Study of Various Strategies for Multirotor UAV Propeller Icing Mitigation. AIAA J. 2025, 63, 2892–2907. [Google Scholar] [CrossRef]

- Adrian, R.J.; Westerweel, J. Particle Image Velocimetry; Cambridge Aerospace Series; Cambridge University Press: Cambridge, UK, 2011. [Google Scholar]

- Zhang, Z.; Ma, L.; Liu, Y.; Ren, J.; Hu, H. An Experimental Study of Rain Erosion Effects on a Hydro-/Ice-Phobic Coating Pertinent to Unmanned-Arial-System (UAS) Inflight Icing Mitigation. Cold Reg. Sci. Technol. 2021, 181, 103196. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Frantz, J.; Chumbley, E.; Samad, A.; Hu, H. An Explorative Study on Using Carbon Nanotube-Based Superhydrophobic Self-Heating Coatings for UAV Icing Protection. Molecules 2025, 30, 3472. https://doi.org/10.3390/molecules30173472

Wang J, Frantz J, Chumbley E, Samad A, Hu H. An Explorative Study on Using Carbon Nanotube-Based Superhydrophobic Self-Heating Coatings for UAV Icing Protection. Molecules. 2025; 30(17):3472. https://doi.org/10.3390/molecules30173472

Chicago/Turabian StyleWang, Jincheng, James Frantz, Edward Chumbley, Abdallah Samad, and Hui Hu. 2025. "An Explorative Study on Using Carbon Nanotube-Based Superhydrophobic Self-Heating Coatings for UAV Icing Protection" Molecules 30, no. 17: 3472. https://doi.org/10.3390/molecules30173472

APA StyleWang, J., Frantz, J., Chumbley, E., Samad, A., & Hu, H. (2025). An Explorative Study on Using Carbon Nanotube-Based Superhydrophobic Self-Heating Coatings for UAV Icing Protection. Molecules, 30(17), 3472. https://doi.org/10.3390/molecules30173472