Chromium Catalysts for Selective Ethylene Oligomerization Featuring Binuclear PNP Ligands

Abstract

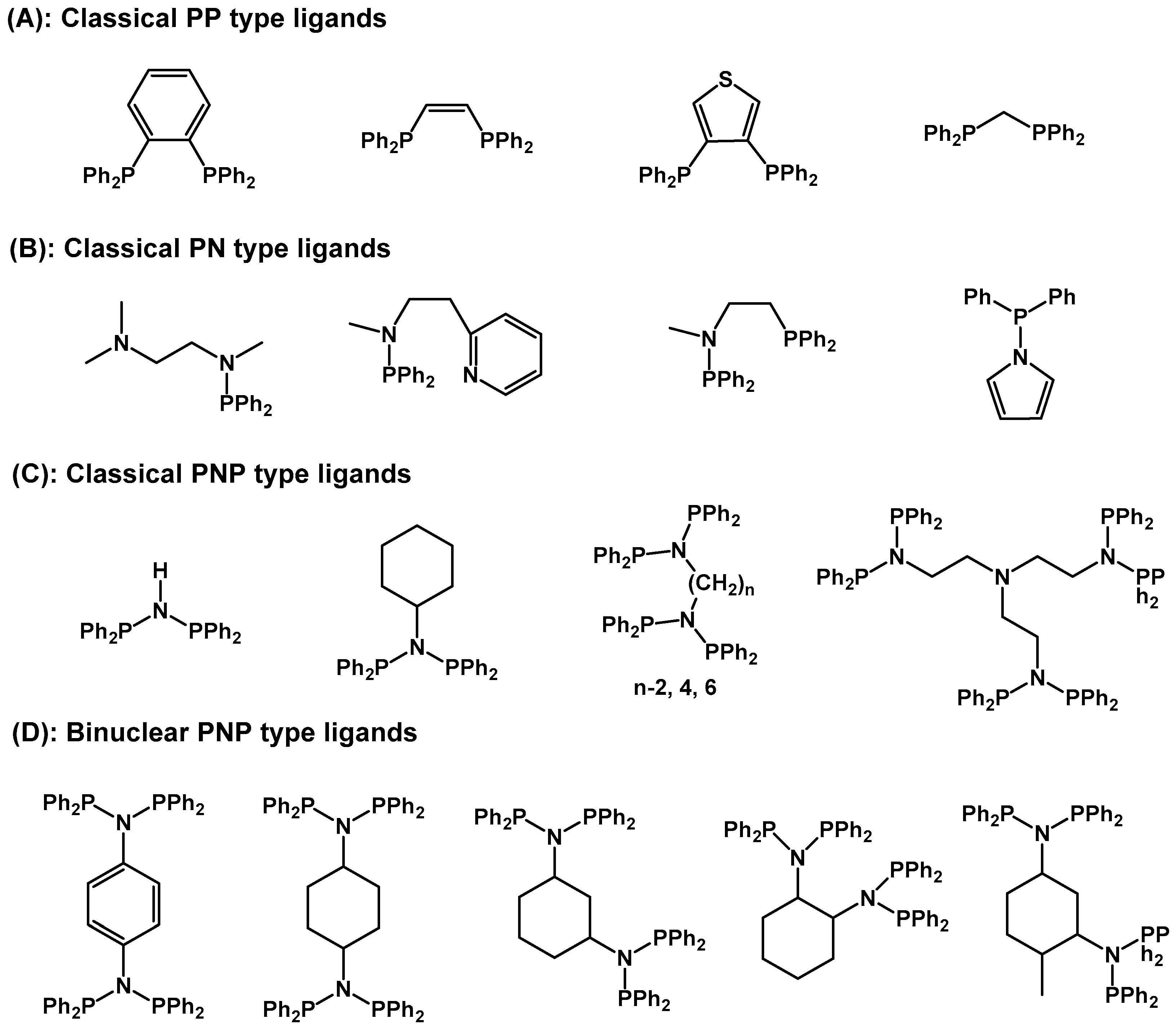

1. Introduction

2. Results and Discussion

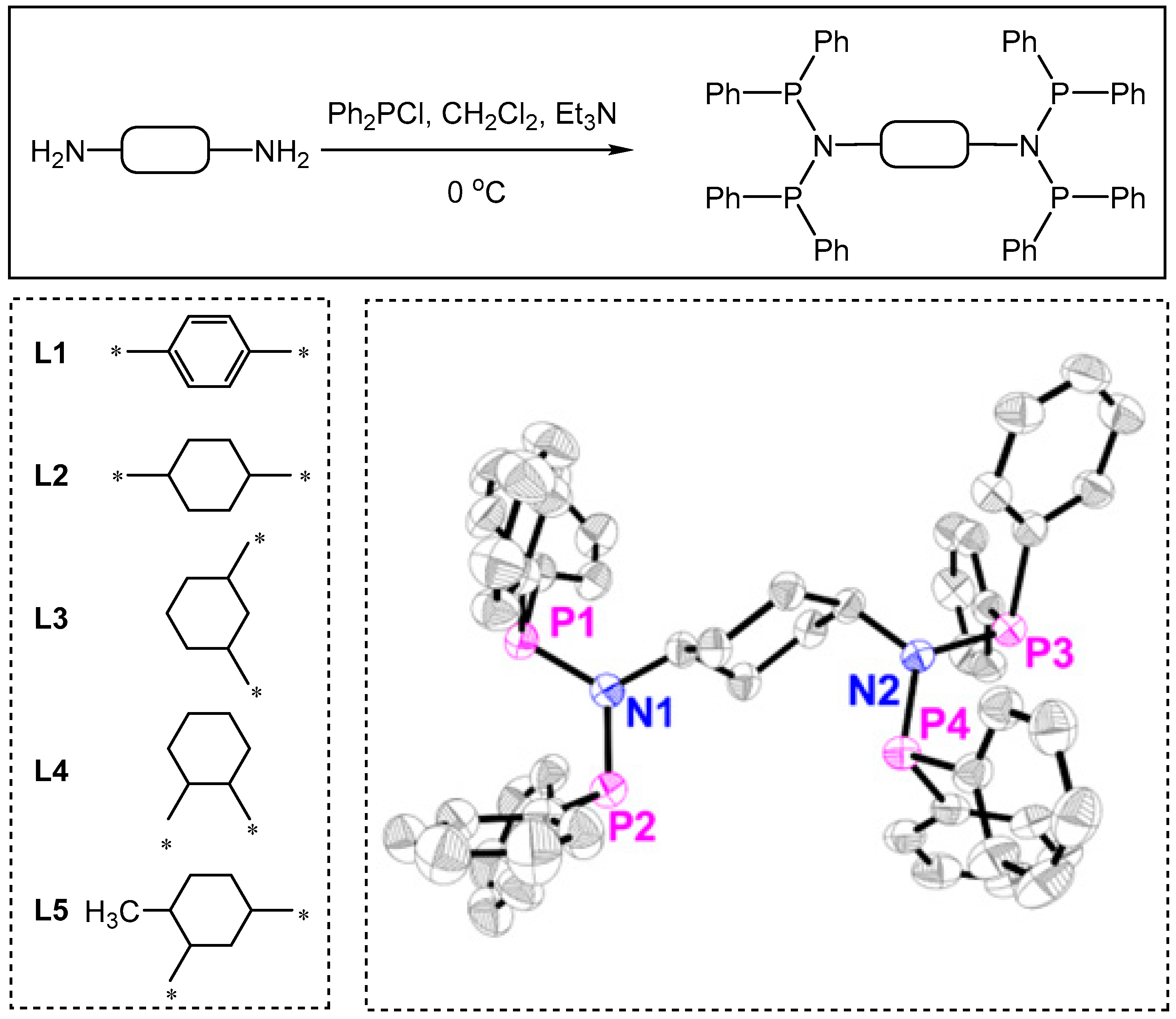

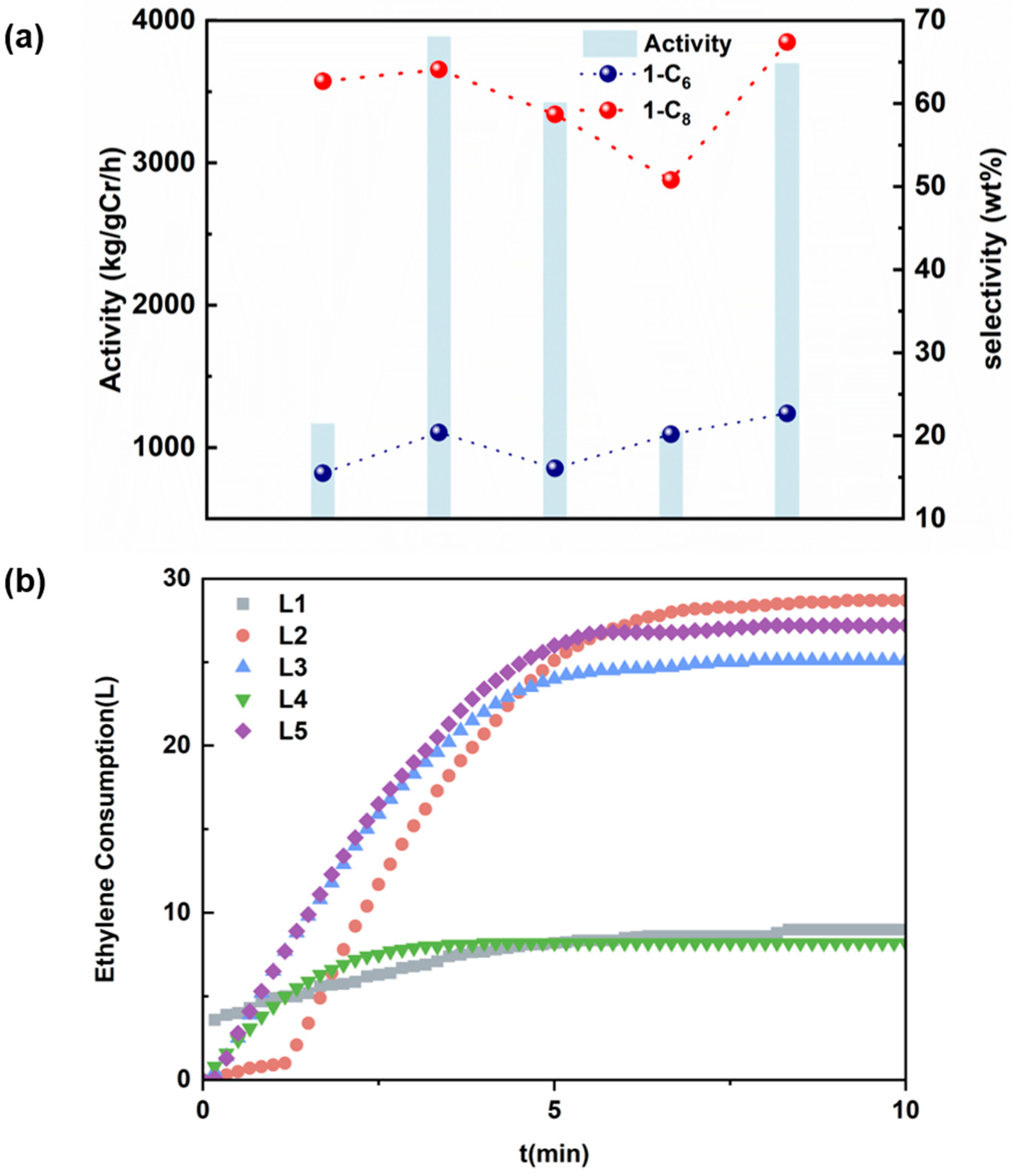

2.1. Optimization of Ligands

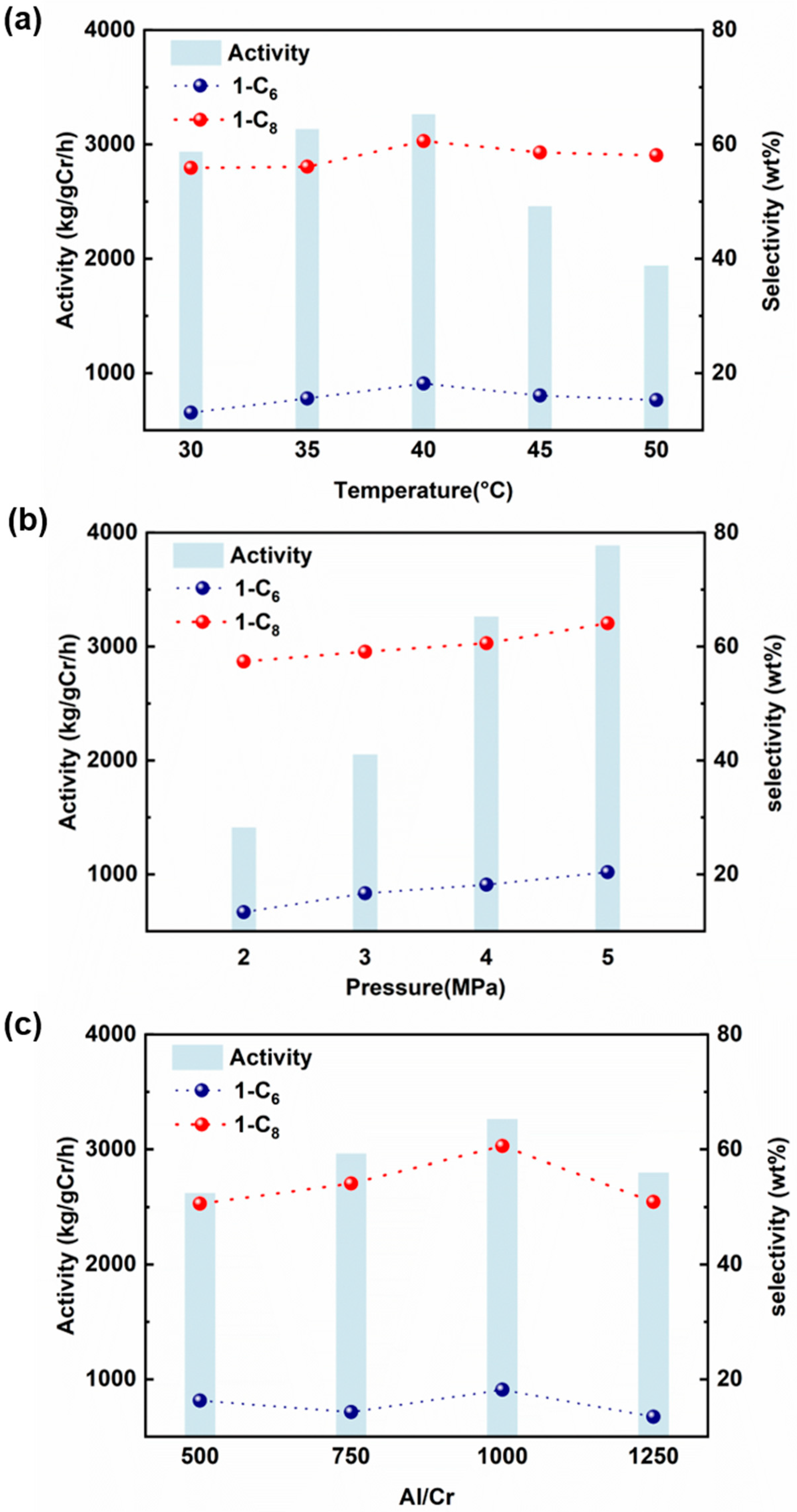

2.2. The Impact of Temperature on Ethylene Oligomerization

2.3. The Impact of Ethylene Pressures on Ethylene Oligomerization

2.4. The Impact of Al/Cr Molar Ratios on Ethylene Oligomerization

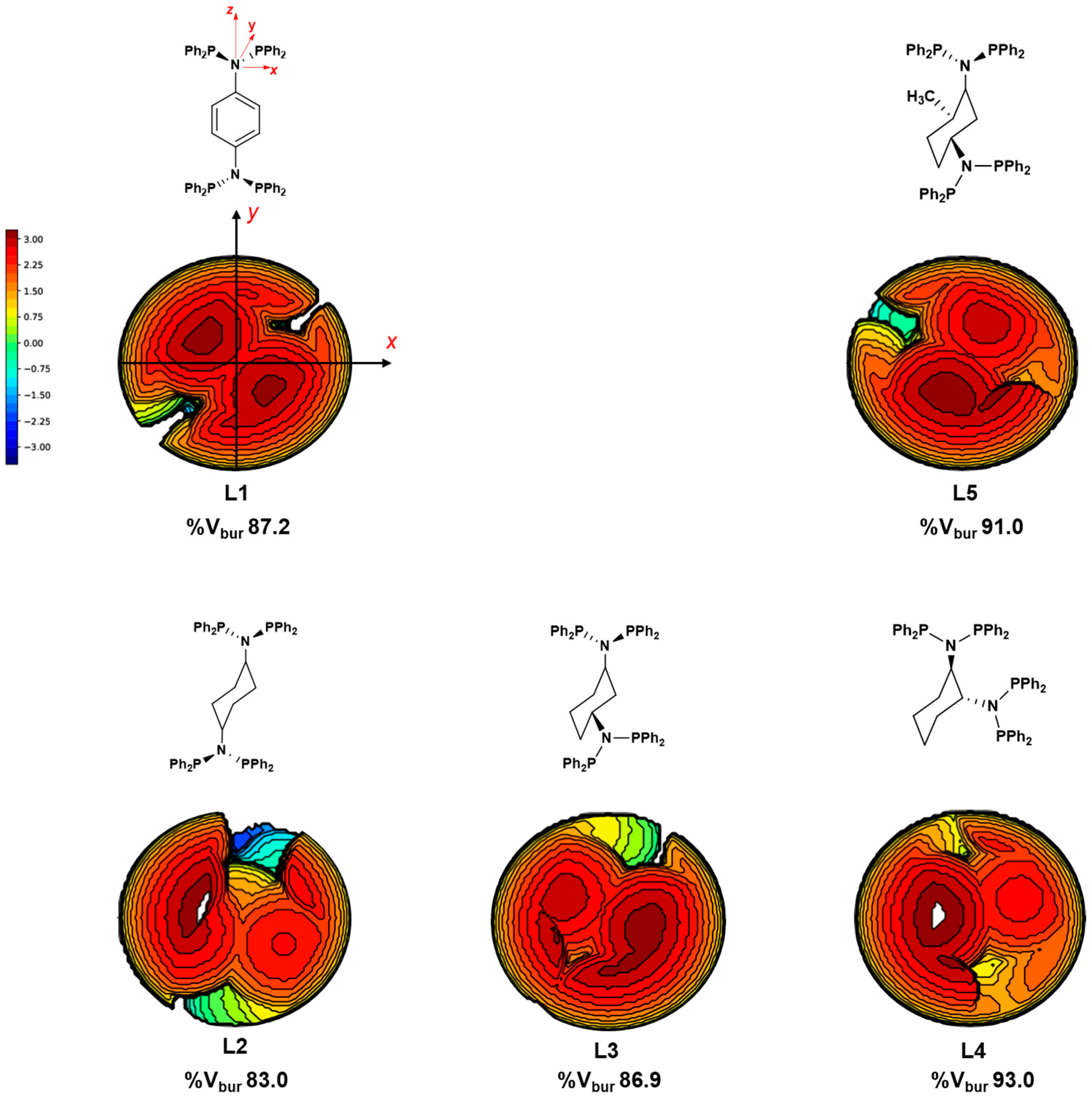

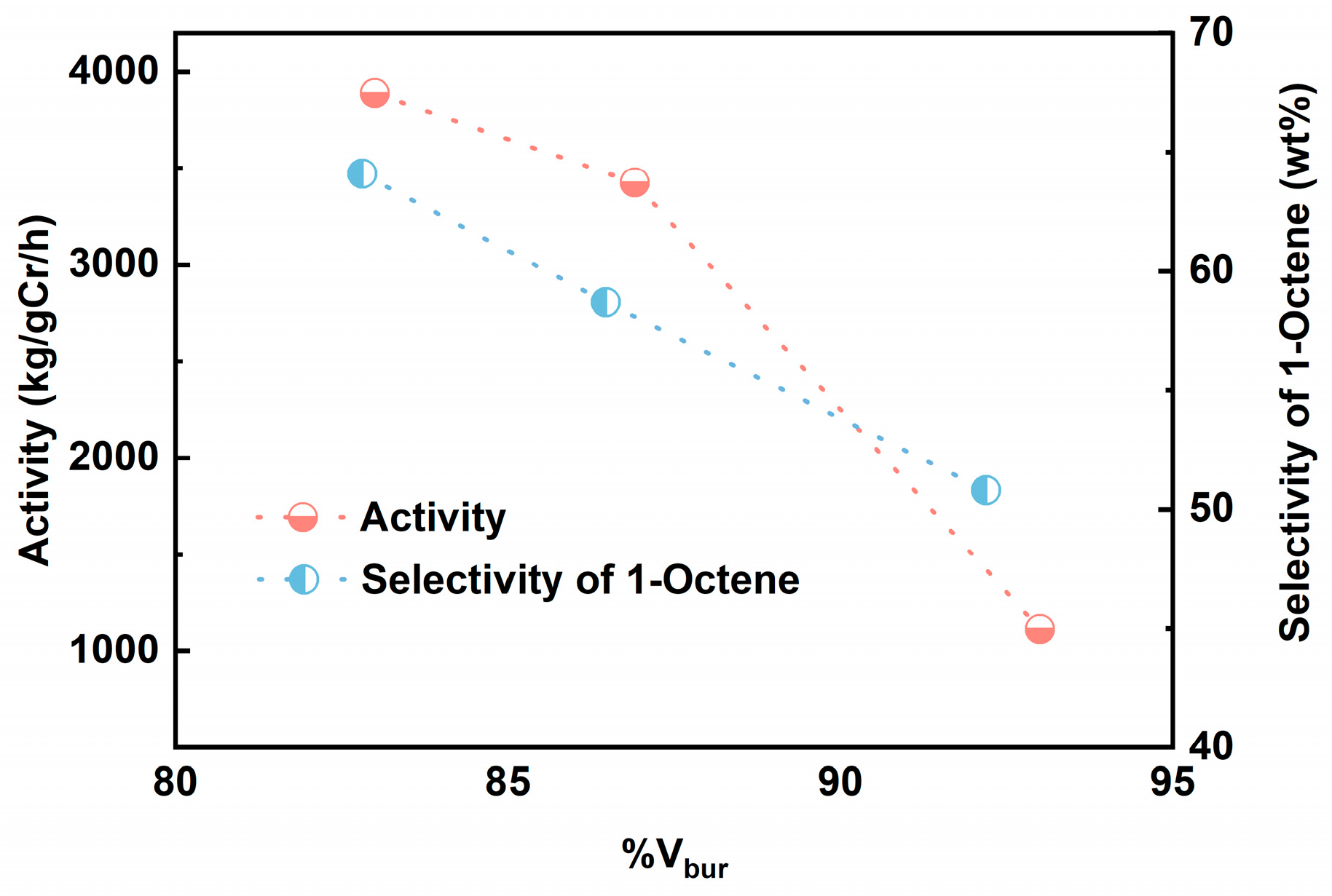

2.5. Relationship between Ligand Structure and Performance in Catalysts

3. Materials and Methods

3.1. Materials

3.2. Methods

3.3. Synthesis of Ligands

3.3.1. N,N′-1,4-Phenylenebis [N-(diphenylphosphino)-P,P-diphenylphosphinous Amide](L1)

3.3.2. N,N′-1,4-Cyclohexyl [N-(diphenylphosphino)-P,P-diphenylphosphinous Amide](L2)

3.3.3. N,N′-1,3-Cyclohexyl [N-(diphenylphosphino)-P,P-diphenylphosphinous Amide](L3)

3.3.4. N,N′-1,2-Cyclohexyl [N-(diphenylphosphino)-P,P-diphenylphosphinous Amide](L4)

3.3.5. N,N′-1,3-Cyclohexyl [N-(diphenylphosphino)-P,P-diphenylphosphinous Amide](L5)

3.4. Ethylene Oligomerization

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Forestière, A.; Olivier-Bourbigou, H.; Saussine, L. Oligomerization of monoolefins by homogeneous catalysts. Oil Gas Sci. Technol. 2009, 64, 649–667. [Google Scholar] [CrossRef]

- Belov, G.P.; Matkovsky, P.E. Processes for the production of higher linear α-olefins. Pet. Chem. 2010, 50, 283–289. [Google Scholar] [CrossRef]

- Olivier-Bourbigou, H.; Forestière, A.; Saussine, L.; Magna, L.; Favre, F.; Hugues, F.J.O. Olefin oligomerization for the production of fuels and petrochemicals. Oil Gas-Eur. Mag. 2010, 36, 97–102. Available online: https://www.osti.gov/etdeweb/biblio/21327984 (accessed on 5 February 2024).

- Speiser, F.; Braunstein, P.; Saussine, L. New nickel ethylene oligomerization catalysts bearing bidentate P, N-phosphinopyridine ligands with different substituents α to phosphorus. Organometallics 2004, 23, 2625–2632. [Google Scholar] [CrossRef]

- Breuil, P.-A.R.; Magna, L.; Olivier-Bourbigou, H.J.C.L. Role of homogeneous catalysis in oligomerization of olefins: Focus on selected examples based on group 4 to group 10 transition metal complexes. Catal. Lett. 2015, 145, 173–192. [Google Scholar] [CrossRef]

- Pierro, I.; Leone, G.; Zanchin, G.; Canetti, M.; Ricci, G.; Bertini, F. Polyolefin thermoplastic elastomers from 1-octene copolymerization with 1-decene and cyclopentene. Eur. Polym. J. 2017, 93, 200–211. [Google Scholar] [CrossRef]

- Alferov, K.A.; Belov, G.P.; Meng, Y. Chromium catalysts for selective ethylene oligomerization to 1-hexene and 1-octene: Recent results. Appl. Catal. A-Gen. 2017, 542, 71–124. [Google Scholar] [CrossRef]

- Zhang, K.; Liu, P.; Wang, W.-J.; Li, B.-G.; Liu, W.; Zhu, S. Preparation of Comb-Shaped Polyolefin Elastomers Having Ethylene/1-Octene Copolymer Backbone and Long Chain Polyethylene Branches via a Tandem Metallocene Catalyst System. Macromolecules 2018, 51, 8790–8799. [Google Scholar] [CrossRef]

- Maynard, L.A.; DeButts, B.L.; Barone, J.R. Mechanical and thermal properties of polyolefin thermoplastic elastomer blends. Plast. Rubber Compos. 2019, 48, 338–346. [Google Scholar] [CrossRef]

- Bariashir, C.; Huang, C.; Solan, G.A.; Sun, W.-H. Recent advances in homogeneous chromium catalyst design for ethylene tri-, tetra-, oligo- and polymerization. Coord. Chem. Rev. 2019, 385, 208–229. [Google Scholar] [CrossRef]

- Mohite, A.S.; Rajpurkar, Y.D.; More, A.P. Bridging the gap between rubbers and plastics: A review on thermoplastic polyolefin elastomers. Polym. Bull. 2021, 79, 1309–1343. [Google Scholar] [CrossRef]

- Zhu, L.; Yu, H.; Wang, L.; Xing, Y.; Amin, B.U. Advances in the Synthesis of Polyolefin Elastomers with “Chain-walking” Catalysts and Electron Spin Resonance Research of Related Catalytic Systems. Curr. Org. Chem. 2021, 25, 935–949. [Google Scholar] [CrossRef]

- Ruan, S.-X.; Zhang, X.-B.; Luo, Z.-H. Investigation and optimization of polyolefin elastomers polymerization processes using multi-objective genetic algorithm. Chem. Eng. Res. Des. 2023, 193, 383–393. [Google Scholar] [CrossRef]

- Sun, M.; Xiao, Y.; Liu, K.; Yang, X.; Liu, P.; Jie, S.; Hu, J.; Shi, S.; Wang, Q.; Lim, K.H.; et al. Synthesis and characterization of polyolefin thermoplastic elastomers: A review. Can. J. Chem. Eng. 2023, 101, 4886–4906. [Google Scholar] [CrossRef]

- Yang, Y.; Liu, Z.; Zhong, L.; Qiu, P.; Dong, Q.; Cheng, R.; Vanderbilt, J.; Liu, B. Spin Surface Crossing between Chromium(I)/Sextet and Chromium(III)/Quartet without Deprotonation in SNS-Cr Mediated Ethylene Trimerization. Organometallics 2011, 30, 5297–5302. [Google Scholar] [CrossRef]

- McGuinness, D.S. Olefin oligomerization via metallacycles: Dimerization, trimerization, tetramerization, and beyond. Chem. Rev. 2011, 111, 2321–2341. [Google Scholar] [CrossRef]

- Härzschel, S.; Kühn, F.E.; Wöhl, A.; Müller, W.; Al-Hazmi, M.H.; Alqahtani, A.M.; Müller, B.H.; Peulecke, N.; Rosenthal, U. Comparative study of new chromium-based catalysts for the selective tri- and tetramerization of ethylene. Catal. Sci. Technol. 2015, 5, 1678–1682. [Google Scholar] [CrossRef]

- Kim, Y.-E.; Im, H.B.; Jung, U.H.; Park, J.C.; Youn, M.H.; Jeong, H.-D.; Lee, D.-W.; Rhim, G.B.; Chun, D.H.; Lee, K.B.; et al. Production of linear α-olefin 1-octene via dehydration of 1-octanol over Al2O3 catalyst. Fuel 2019, 256, 115957. [Google Scholar] [CrossRef]

- Bollmann, A.; Blann, K.; Dixon, J.T.; Hess, F.M.; Killian, E.; Maumela, H.; McGuinness, D.S.; Morgan, D.H.; Neveling, A.; Otto, S.; et al. Ethylene tetramerization: A new route to produce 1-octene in exceptionally high selectivities. J. Am. Chem. Soc. 2004, 126, 14712–14713. [Google Scholar] [CrossRef]

- Overett, M.J.; Blann, K.; Bollmann, A.; de Villiers, R.; Dixon, J.T.; Killian, E.; Maumela, M.C.; Maumela, H.; McGuinness, D.S.; Morgan, D.H.; et al. Carbon-bridged diphosphine ligands for chromium-catalysed ethylene tetramerisation and trimerisation reactions. J. Mol. Catal. A Chem. 2008, 283, 114–119. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, X.; Zhang, X.; Wu, W.; Zhang, G.; Xu, S.; Shi, M. Switchable Ethylene Tri-/Tetramerization with High Activity: Subtle Effect Presented by Backbone-Substituent of Carbon-Bridged Diphosphine Ligands. ACS Catal. 2013, 3, 2311–2317. [Google Scholar] [CrossRef]

- Zhang, C.; Song, L.; Wu, H.; Ji, X.; Jiao, J.; Zhang, J. Ethylene tri-/tetramerization catalysts supported by diphosphinothiophene ligands. Dalton Trans. 2017, 46, 8399–8404. [Google Scholar] [CrossRef] [PubMed]

- Klemps, C.; Payet, E.; Magna, L.; Saussine, L.; Le Goff, X.F.; Le Floch, P. PCNCP ligands in the chromium-catalyzed oligomerization of ethylene: Tri- versus tetramerization. Chemistry 2009, 15, 8259–8268. [Google Scholar] [CrossRef]

- Shaikh, Y.; Gurnham, J.; Albahily, K.; Gambarotta, S.; Korobkov, I. Aminophosphine-Based Chromium Catalysts for Selective Ethylene Tetramerization. Organometallics 2012, 31, 7427–7433. [Google Scholar] [CrossRef]

- Sydora, O.L.; Jones, T.C.; Small, B.L.; Nett, A.J.; Fischer, A.A.; Carney, M.J. Selective Ethylene Tri-/Tetramerization Catalysts. ACS Catal. 2012, 2, 2452–2455. [Google Scholar] [CrossRef]

- Radcliffe, J.E.; Batsanov, A.S.; Smith, D.M.; Scott, J.A.; Dyer, P.W.; Hanton, M.J. Phosphanyl Methanimine (PCN) Ligands for the Selective Trimerization/Tetramerization of Ethylene with Chromium. ACS Catal. 2015, 5, 7095–7098. [Google Scholar] [CrossRef]

- Blann, K.; Bollmann, A.; Debod, H.; Dixon, J.; Killian, E.; Nongodlwana, P.; Maumela, M.; Maumela, H.; McConnell, A.; Morgan, D. Ethylene tetramerisation: Subtle effects exhibited by N-substituted diphosphinoamine ligands. J. Catal. 2007, 249, 244–249. [Google Scholar] [CrossRef]

- Kuhlmann, S.; Blann, K.; Bollmann, A.; Dixon, J.; Killian, E.; Maumela, M.; Maumela, H.; Morgan, D.; Pretorius, M.; Taccardi, N. N-substituted diphosphinoamines: Toward rational ligand design for the efficient tetramerization of ethylene. J. Catal. 2007, 245, 279–284. [Google Scholar] [CrossRef]

- Killian, E.; Blann, K.; Bollmann, A.; Dixon, J.T.; Kuhlmann, S.; Maumela, M.C.; Maumela, H.; Morgan, D.H.; Nongodlwana, P.; Overett, M.J.; et al. The use of bis(diphenylphosphino)amines with N-aryl functionalities in selective ethylene tri- and tetramerisation. J. Mol. Catal. A Chem. 2007, 270, 214–218. [Google Scholar] [CrossRef]

- Barman, S.; Jaseer, E.A.; Garcia, N.; Elanany, M.; Khawaji, M.; Xu, W.; Lin, S.; Alasiri, H.; Akhtar, M.N.; Theravalappil, R. A rational approach towards selective ethylene oligomerization via PNP-ligand design with an N-triptycene functionality. Chem. Commun. 2022, 58, 10044–10047. [Google Scholar] [CrossRef]

- Jiang, T.; Zhang, S.; Jiang, X.; Yang, C.; Niu, B.; Ning, Y. The effect of N-aryl bisphosphineamine ligands on the selective ethylene tetramerization. J. Mol. Catal. A Chem. 2008, 279, 90–93. [Google Scholar] [CrossRef]

- Blann, K.; Bollmann, A.; Dixon, J.T.; Hess, F.M.; Killian, E.; Maumela, H.; Morgan, D.H.; Neveling, A.; Otto, S.; Overett, M.J. Highly selective chromium-based ethylene trimerisation catalysts with bulky diphosphinoamine ligands. Chem. Commun. 2005, 620–621. [Google Scholar] [CrossRef] [PubMed]

- Kim, T.H.; Lee, H.M.; Park, H.S.; Kim, S.D.; Kwon, S.J.; Tahara, A.; Nagashima, H.; Lee, B.Y. MAO-free and extremely active catalytic system for ethylene tetramerization. Appl. Organomet. Chem. 2019, 33, e4829. [Google Scholar] [CrossRef]

- Lee, D.G.; Baek, J.W.; Lee, J.H.; Lee, H.J.; Seo, Y.H.; Lee, J.; Lee, C.G.; Lee, B.Y. Replacement of the Common Chromium Source CrCl3(thf)3 with Well-Defined [CrCl2(mu-Cl)(thf)2]2. Molecules 2021, 26, 1167. [Google Scholar] [CrossRef]

- Lee, J.H.; Baek, J.W.; Lee, D.G.; Ko, J.H.; Lee, D.G.; Cho, K.S.; Lee, J.W.; Lee, B.Y. Preparation of Extremely Active Ethylene Tetramerization Catalyst [iPrN(PAr2)2−CrCl2]+[B(C6F5)4]− (Ar = −C6H4-p-SiR3). Catalysts 2021, 11, 1122. [Google Scholar] [CrossRef]

- Zhou, Y.; Wu, H.; Xu, S.; Zhang, X.; Shi, M.; Zhang, J. Highly active chromium-based selective ethylene tri-/tetramerization catalysts supported by PNPO phosphazane ligands. Dalton Trans. 2015, 44, 9545–9550. [Google Scholar] [CrossRef]

- Alam, F.; Fan, H.; Dong, C.; Zhang, J.; Ma, J.; Chen, Y.; Jiang, T. Chromium catalysts stabilized by alkylphosphanyl PNP ligands for selective ethylene tri-/tetramerization. J. Catal. 2021, 404, 163–173. [Google Scholar] [CrossRef]

- Zhang, J.; Alam, F.; Fan, H.; Ma, J.; Jiang, T. Chromium catalysts based on PNP(NR2)2 ligands for selective ethylene oligomerization. Appl. Organomet. Chem. 2021, 36, e6454. [Google Scholar] [CrossRef]

- Jiang, T.; Chen, H.; Ning, Y.; Chen, W. Preparation of 1-octene by ethylene tetramerization with high selectivity. Chin. Sci. Bull. 2006, 51, 521–523. [Google Scholar] [CrossRef]

- Mao, G.; Ning, Y.; Hu, W.; Li, S.; Song, X.; Niu, B.; Jiang, T. Synthesis of a novel triple-site diphosphinoamine (PNP) ligand and its applications in ethylene tetramerization. Chin. Sci. Bull. 2008, 53, 3511–3515. [Google Scholar] [CrossRef][Green Version]

- Britovsek, G.J.P.; McGuinness, D.S.; Tomov, A.K. Mechanistic study of ethylene tri- and tetramerisation with Cr/PNP catalysts: Effects of additional donors. Catal. Sci. Technol. 2016, 6, 8234–8241. [Google Scholar] [CrossRef]

- Falivene, L.; Credendino, R.; Poater, A.; Petta, A.; Serra, L.; Oliva, R.; Scarano, V.; Cavallo, L. SambVca 2. A Web Tool for Analyzing Catalytic Pockets with Topographic Steric Maps. Organometallics 2016, 35, 2286–2293. [Google Scholar] [CrossRef]

- Falivene, L.; Cao, Z.; Petta, A.; Serra, L.; Poater, A.; Oliva, R.; Scarano, V.; Cavallo, L. Towards the online computer-aided design of catalytic pockets. Nat. Chem. 2019, 11, 872–879. [Google Scholar] [CrossRef] [PubMed]

- Escayola, S.; Bahri-Laleh, N.; Poater, A. %V(Bur) index and steric maps: From predictive catalysis to machine learning. Chem. Soc. Rev. 2024, 53, 853–882. [Google Scholar] [CrossRef]

- Britovsek, G.J.; McGuinness, D.S. A DFT Mechanistic Study on Ethylene Tri- and Tetramerization with Cr/PNP Catalysts: Single versus Double Insertion Pathways. Chemistry 2016, 22, 16891–16896. [Google Scholar] [CrossRef]

- Chabbra, S.; Smith, D.; Bell, N.L.; Watson, A.J.B.; Buehl, M.; Cole-Hamilton, D.J.; Bode, B.E. First experimental evidence for a bis-ethene chromium (I) complex forming from an activated ethene oligomerization catalyst. Sci. Adv. 2020, 6, eabd7057. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Liu, Z.; Tang, S.; Cheng, R.; He, X.; Liu, B. What Triggered the Switching from Ethylene-Selective Trimerization into Tetramerization over the Cr/(2,2′-Dipicolylamine) Catalysts? ACS Catal. 2019, 9, 10519–10527. [Google Scholar] [CrossRef]

- Dolomanov, O.V.; Bourhis, L.J.; Gildea, R.J.; Howard, J.A.K.; Puschmann, H.J.J.o.A.C. OLEX2: A complete structure solution, refinement and analysis program. J. Appl. Cryst. 2009, 42, 339–341. [Google Scholar] [CrossRef]

- Sheldrick, G.M. SHELXT–Integrated space-group and crystal-structure determination. Acta Crystallogr. Sect. A 2015, 71, 3–8. [Google Scholar] [CrossRef]

- Sheldrick, G.M. Crystal structure refinement with SHELXL. Acta Crystallogr. Sect. C Struct. Chem. 2015, 71, 3–8. [Google Scholar] [CrossRef]

- Frisch, M.J.; Schlegel, H.B.; Scuseria, G.E.; Robb, M.A.; Cheeseman, J.R.; Scalmani, G.; Barone, V.; Mennucci, B.; Petersson, G.A.; Nakatsuji, H.; et al. Gaussian 09, Revision E.01; Gaussian, Inc.: Wallingford, CT, USA, 2013. Available online: https://gaussian.com/g09citation/ (accessed on 29 April 2024).

| Entry a | Ligand | Activity [kg/(g·h)] | Product Selectivity (%) | ||||

|---|---|---|---|---|---|---|---|

| 1-C6 b (wt%) | 1-C8 b (wt%) | (1-C6 + 1-C8) b (wt%) | C10+ b (wt%) | PE c (wt%) | |||

| 1 | 1 | 1168.8 | 15.5 | 62.7 | 78.2 | 10.3 | 1.4 |

| 2 | 2 | 3887.7 | 20.4 | 64.1 | 84.5 | 9.8 | 1.7 |

| 3 | 3 | 3425.5 | 16.0 | 58.6 | 74.6 | 11.2 | 3.0 |

| 4 | 4 | 1114.7 | 20.2 | 50.8 | 71.0 | 13.9 | 10.1 |

| 5 | 5 | 3697.4 | 22.7 | 67.4 | 90.1 | 8.8 | 4.8 |

| 6 d | 2 | 3262.4 | 18.2 | 60.6 | 78.8 | 9.6 | 1.5 |

| 7 e | 2 | 2677.9 | 17.3 | 59.8 | 77.1 | 13.3 | 0.4 |

| 8 f | 2 | 2215.9 | 16.9 | 56.1 | 76.0 | 14.8 | 0.2 |

| Entry a | T/°C | P/bar | Activity [kg/(g·h)] | Product Selectivity (%) | ||||

|---|---|---|---|---|---|---|---|---|

| 1-C6 b (wt%) | 1-C8 b (wt%) | (1-C6 + 1-C8) b (wt%) | C10+ b (wt%) | PE c (wt%) | ||||

| 1 | 30 | 40 | 2936.9 | 13.1 | 55.9 | 69.0 | 10.7 | 0.9 |

| 2 | 35 | 40 | 3134.1 | 15.6 | 56.1 | 71.1 | 10.3 | 1.1 |

| 3 | 40 | 40 | 3264.4 | 18.2 | 60.6 | 78.8 | 9.6 | 1.5 |

| 4 | 45 | 40 | 2460.4 | 16.1 | 58.6 | 74.7 | 12.3 | 1.2 |

| 5 | 50 | 40 | 1938.4 | 15.3 | 58.1 | 73.4 | 11.8 | 0.7 |

| 6 | 40 | 20 | 1413.7 | 13.4 | 57.4 | 70.8 | 13.4 | 0.4 |

| 7 | 40 | 30 | 2052.6 | 16.7 | 59.1 | 75.8 | 10.6 | 0.9 |

| 8 | 40 | 50 | 3887.7 | 20.4 | 64.1 | 84.5 | 6.8 | 1.7 |

| Entry a | Al/Cr | Activity [kg/(g·h)] | Product Selectivity (%) | ||||

|---|---|---|---|---|---|---|---|

| 1-C6 b (wt%) | 1-C8 b (wt%) | (1-C6 + 1-C8) b (wt%) | C10+ b (wt%) | PE c (wt%) | |||

| 1 | 500 | 2623.5 | 16.3 | 50.6 | 66.9 | 15.7 | 1.4 |

| 2 | 750 | 2963.4 | 14.3 | 54.1 | 68.4 | 16.4 | 2.4 |

| 3 | 1000 | 3264.4 | 18.2 | 60.6 | 78.8 | 9.6 | 1.5 |

| 4 | 1250 | 2800.2 | 13.5 | 50.9 | 64.4 | 14.3 | 2.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, X.; Ding, Z.; Gao, H.; Ma, Z.; Pan, L.; Wang, B.; Li, Y. Chromium Catalysts for Selective Ethylene Oligomerization Featuring Binuclear PNP Ligands. Molecules 2024, 29, 2158. https://doi.org/10.3390/molecules29092158

Meng X, Ding Z, Gao H, Ma Z, Pan L, Wang B, Li Y. Chromium Catalysts for Selective Ethylene Oligomerization Featuring Binuclear PNP Ligands. Molecules. 2024; 29(9):2158. https://doi.org/10.3390/molecules29092158

Chicago/Turabian StyleMeng, Xiangyang, Zhiqiang Ding, Huan Gao, Zhe Ma, Li Pan, Bin Wang, and Yuesheng Li. 2024. "Chromium Catalysts for Selective Ethylene Oligomerization Featuring Binuclear PNP Ligands" Molecules 29, no. 9: 2158. https://doi.org/10.3390/molecules29092158

APA StyleMeng, X., Ding, Z., Gao, H., Ma, Z., Pan, L., Wang, B., & Li, Y. (2024). Chromium Catalysts for Selective Ethylene Oligomerization Featuring Binuclear PNP Ligands. Molecules, 29(9), 2158. https://doi.org/10.3390/molecules29092158