Synthesis of Polyethylene Terephthalate (PET) with High Crystallization and Mechanical Properties via Functionalized Graphene Oxide as Nucleation Agent

Abstract

1. Introduction

2. Results and Discussion

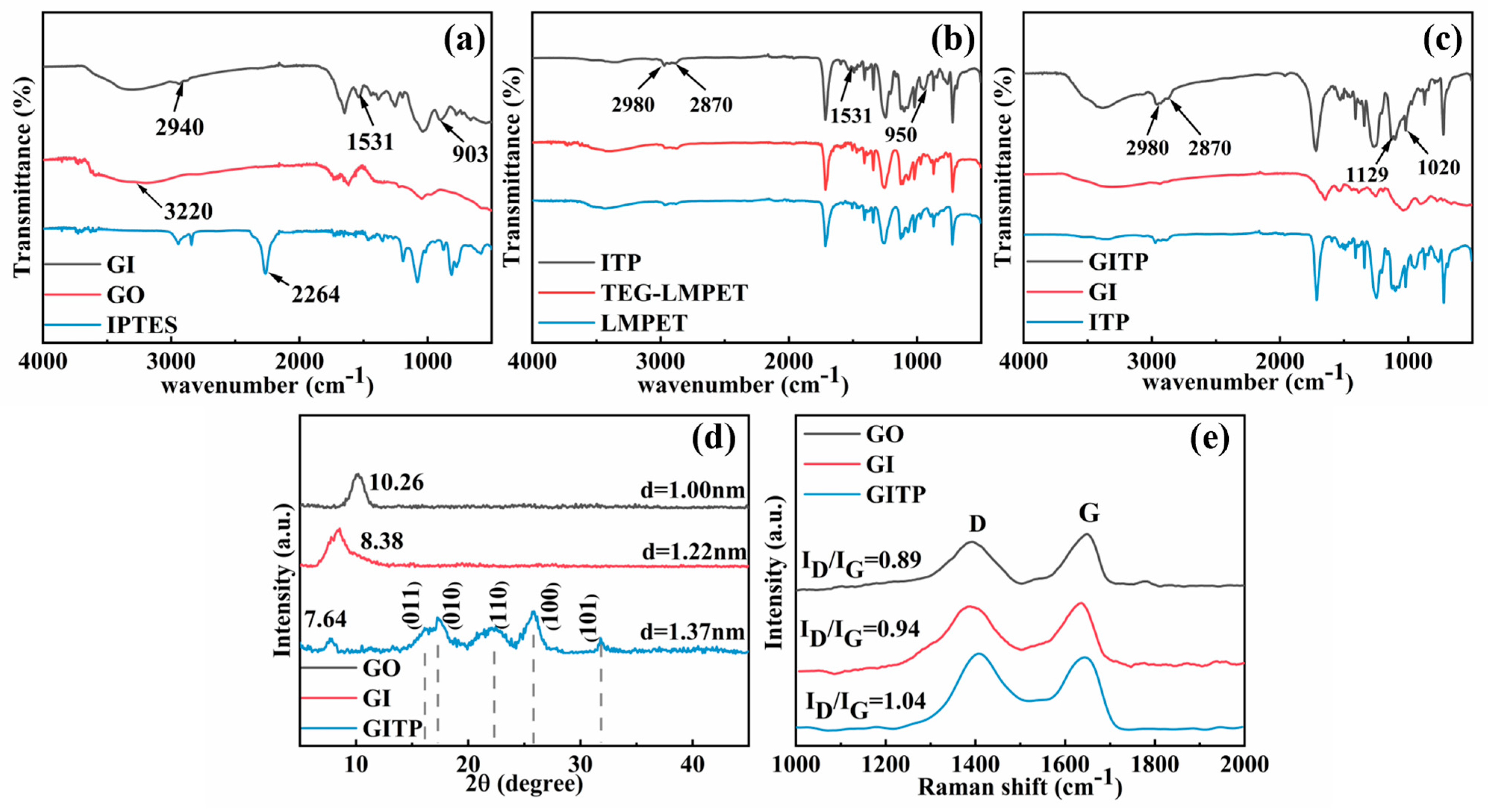

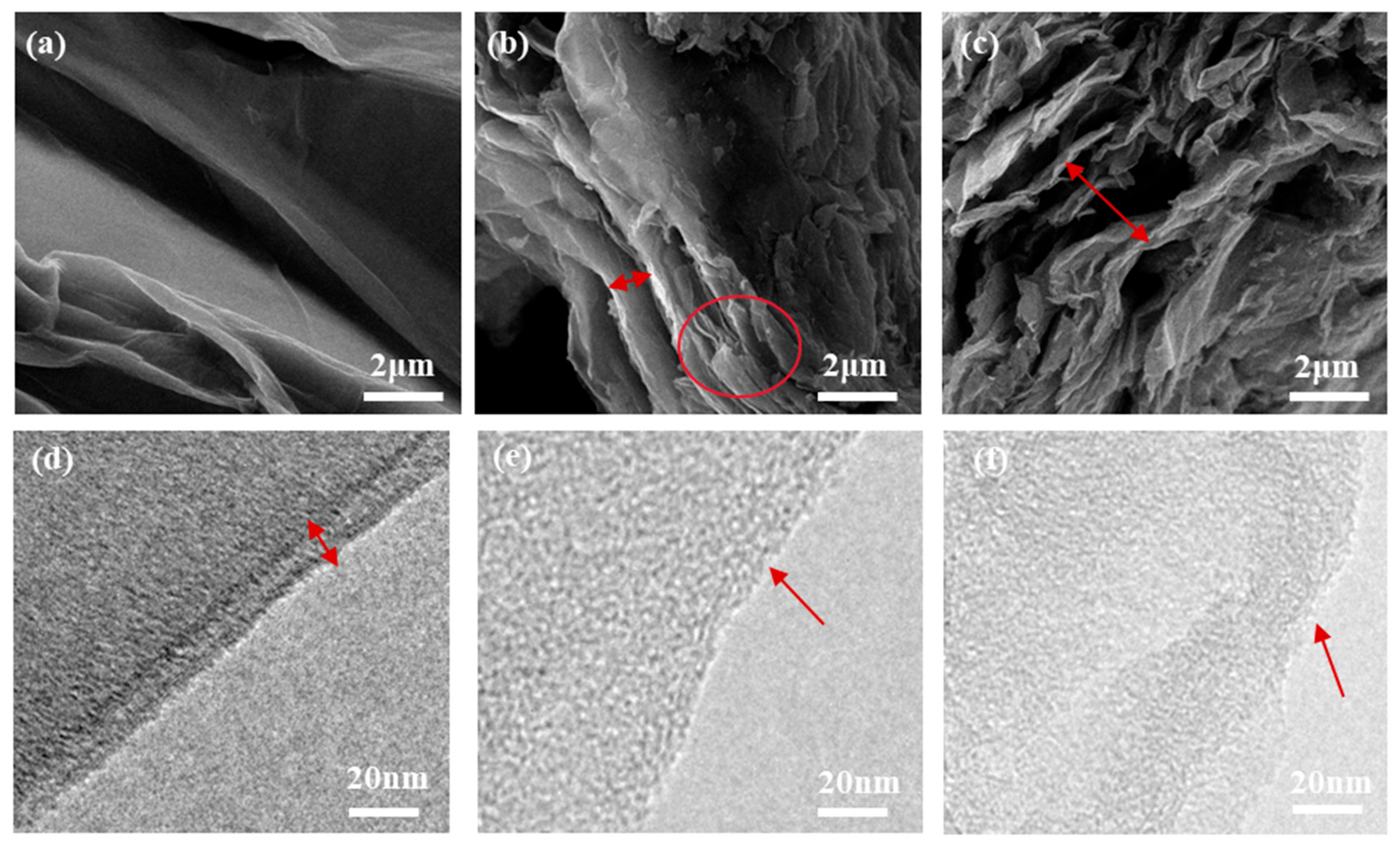

2.1. Characterization of GITP Nanocomposites

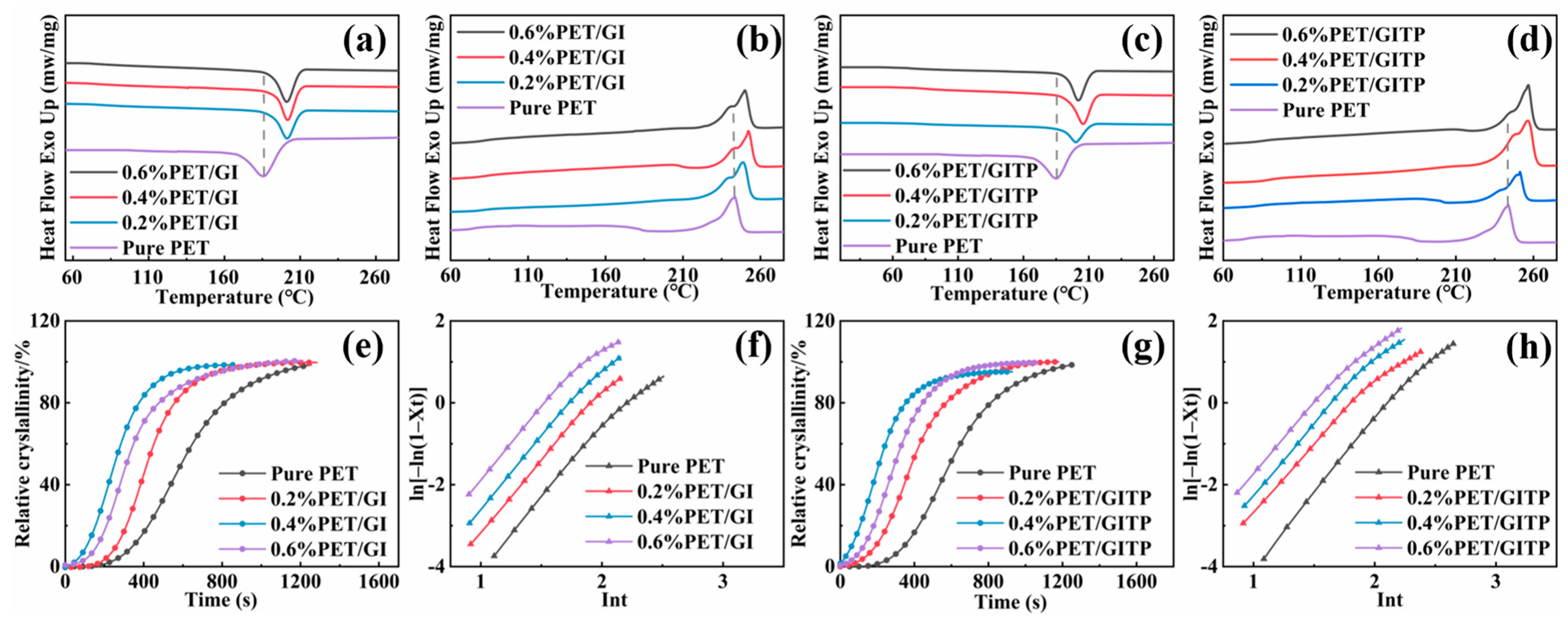

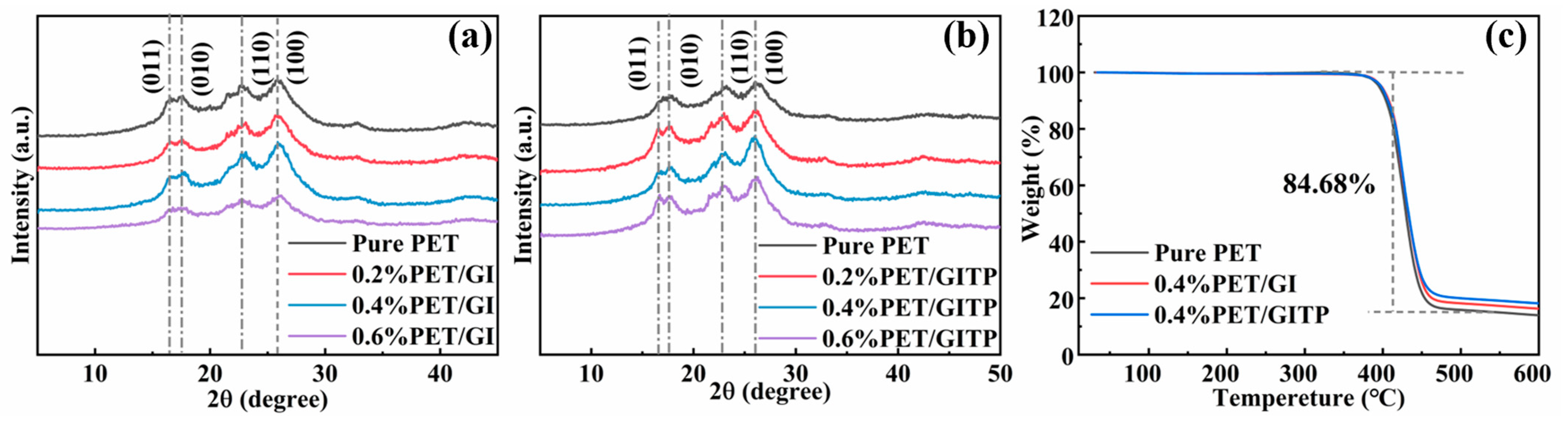

2.2. Crystallization Properties and Thermal Stability of PET Matrix Composites

2.3. Mechanical Properties of PET Matrix Composites

3. Experimental Section

3.1. Materials

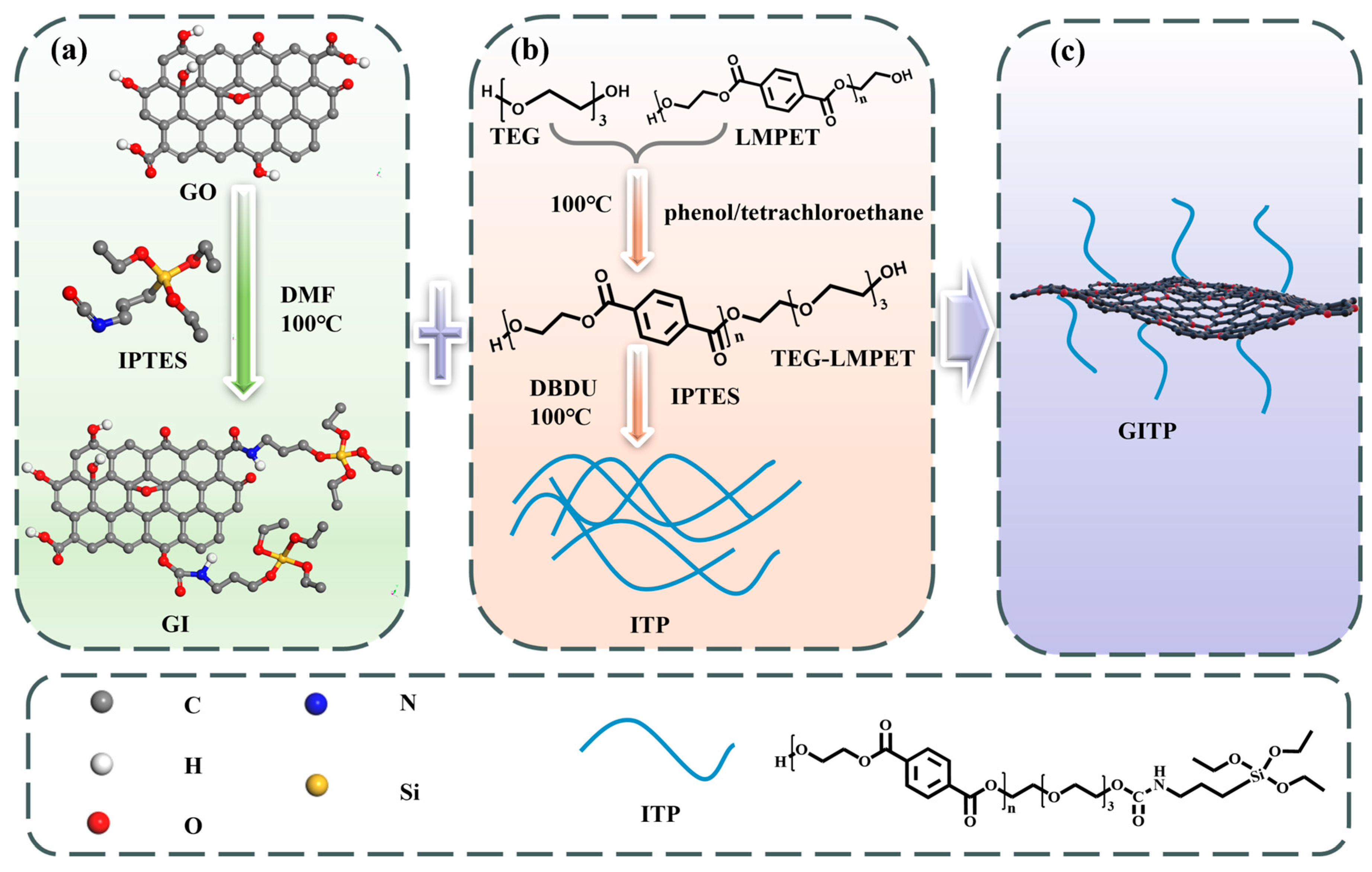

3.2. Synthesis of GI Nanocomposites

3.3. Synthesis of Low Molecular Block Polymers (ITP)

3.4. Synthesis of GITP Nanocomposites

3.5. Preparation of PET/GI and PET/GITP Nanocomposites

3.6. Characterization

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dhaka, V.; Singh, S.; Anil, A.G.; Sunil Kumar Naik, T.S.; Garg, S.; Samuel, J.; Kumar, M.; Ramamurthy, P.C.; Singh, J. Occurrence, toxicity and remediation of polyethylene terephthalate plastics. A review. Environ. Chem. Lett. 2022, 20, 1777–1800. [Google Scholar] [CrossRef] [PubMed]

- Ge, Y.; Liu, T. Numerical simulation on bubble wall shape evolution and uniformity in poly(ethylene terephthalate) foaming process. Chem. Eng. Sci. 2021, 230, 116213. [Google Scholar] [CrossRef]

- Peng, C.; Huang, A.; Ma, X.; Zhong, J.; Chen, G.; Luo, W.; Zeng, B.; Yuan, C.; Xu, Y.; Dai, L. Transparent and flame-retardant hybrid protective coating with high surface hardness, yet foldability. Prog. Org. Coat. 2023, 175, 107346. [Google Scholar] [CrossRef]

- Zimmermann, W. Biocatalytic recycling of polyethylene terephthalate plastic. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2020, 378, 20190273. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Wirasaputra, A.; Jiang, Z.; Liu, S.; Zhao, J.; Fu, Y. Fabrication of improved overall properties of poly (ethylene terephthalate) by simultaneous chain extension and crystallization promotion. J. Therm. Anal. Calorim. 2018, 133, 1447–1454. [Google Scholar] [CrossRef]

- Ren, Q.; Fan, J.; Zhang, Q.; Yi, J.; Feng, J. Toughened polypropylene random copolymer with olefin block copolymer. Mater. Des. 2016, 107, 295–301. [Google Scholar] [CrossRef]

- Naz, F.; Ciprian, M.; Mousavi, B.; Chaemchuen, S.; Zhu, M.; Yan, S.; Verpoort, F. Solvent-free synthesis of cyclic polycaprolactone catalysed by MOF-derived ZnO/NCs catalysts. Eur. Polym. J. 2021, 142, 110127. [Google Scholar] [CrossRef]

- Majka, T.M.; Bartyzel, O.; Raftopoulos, K.N.; Pagacz, J.; Leszczyńska, A.; Pielichowski, K. Recycling of polypropylene/montmorillonite nanocomposites by pyrolysis. J. Anal. Appl. Pyrolysis 2016, 119, 1–7. [Google Scholar] [CrossRef]

- Demir, T.; Wei, L.; Nitta, N.; Yushin, G.; Brown, P.J.; Luzinov, I. Toward a Long-Chain Perfluoroalkyl Replacement: Water and Oil Repellency of Polyethylene Terephthalate (PET) Films Modified with Perfluoropolyether-Based Polyesters. ACS Appl. Mater. Interfaces 2017, 9, 24318–24330. [Google Scholar] [CrossRef]

- Wang, P.; Tang, S.; Sheng, F.; Cai, J.; Fei, P.; Nawaz, A.; Walayat, N.; Javaid, A.B.; Xiong, H. Crystallization, thermal stability, barrier property, and aging resistance application of multi-functionalized graphene oxide/poly(lactide)/starch nanocomposites. Int. J. Biol. Macromol. 2019, 132, 1208–1220. [Google Scholar] [CrossRef]

- Han, X.; Han, Y.; Jin, Y.; Tian, H.; Wang, Z.; Huang, J.; Men, S.; Kumar, R. Tailoring compatibility and toughness of microbial poly(3-hydroxybutyrate-co-3-hydroxyvalerate)/bio-based polyester elastomer blends by epoxy-terminated hyperbranched polyester. Int. J. Biol. Macromol. 2022, 220, 1163–1176. [Google Scholar] [CrossRef]

- Roy, S.; Petrova, R.S.; Mitra, S. Effect of carbon nanotube (CNT) functionalization in epoxy-CNT composites. Nanotechnol. Rev. 2018, 7, 475–485. [Google Scholar] [CrossRef]

- Chen, H.; Liu, Z.; Cebe, P. Chain confinement in electrospun nanofibers of PET with carbon nanotubes. Polymer 2009, 50, 872–880. [Google Scholar] [CrossRef]

- Xie, L.; Duan, G.; Wang, W.; Wang, M.; Wu, Q.; Zhou, X.; Ge, X. Effect of γ-Ray-Radiation-Modified Graphene Oxide on the Integrated Mechanical Properties of PET Blends. Ind. Eng. Chem. Res. 2016, 55, 8123–8132. [Google Scholar] [CrossRef]

- Rajasekar, R.; Kim, N.H.; Jung, D.; Kuila, T.; Lim, J.K.; Park, M.J.; Lee, J.H. Electrostatically assembled layer-by-layer composites containing graphene oxide for enhanced hydrogen gas barrier application. Compos. Sci. Technol. 2013, 89, 167–174. [Google Scholar] [CrossRef]

- Kuilla, T.; Bhadra, S.; Yao, D.; Kim, N.H.; Bose, S.; Lee, J.H. Recent advances in graphene based polymer composites. Prog. Polym. Sci. 2010, 35, 1350–1375. [Google Scholar] [CrossRef]

- Dreyer, D.R.; Park, S.; Bielawski, C.W.; Ruoff, R.S. The chemistry of graphene oxide. Chem. Soc. Rev. 2010, 39, 228–240. [Google Scholar] [CrossRef]

- Gao, W.; Li, Y.; Zhao, J.; Tang, W.; Zhang, Z.; Wang, J.; Wu, Z.; Li, M. Nucleation and thermal stability enhancements in poly(ethylene terephthalate) composites influenced by graphene oxide. J. Therm. Anal. Calorim. 2023, 148, 2401–2415. [Google Scholar] [CrossRef]

- Jing, L.; Yang, H.; Wang, H.; Zhang, J.; Liu, S.; Liu, X.; Liu, W.; Zhang, L.; Niu, M.; Chen, J. Toughness Enhancement in Polyactide Nanocomposites with Swallow-Tailed Graphene Oxide. Polym. Sci. Ser. B 2020, 62, 560–571. [Google Scholar] [CrossRef]

- Dehghani, Z.; Sedghi-Asl, M.; Ghaedi, M.; Sabzehmeidani, M.M.; Adhami, E. Ultrasound-assisted adsorption of paraquat herbicide from aqueous solution by graphene oxide/ mesoporous silica. J. Environ. Chem. Eng. 2021, 9, 105043. [Google Scholar] [CrossRef]

- Pourhashem, S.; Rashidi, A.; Vaezi, M.R.; Bagherzadeh, M.R. Excellent corrosion protection performance of epoxy composite coatings filled with amino-silane functionalized graphene oxide. Surf. Coat. Technol. 2017, 317, 1–9. [Google Scholar] [CrossRef]

- Khodabakhshi, J.; Mahdavi, H.; Najafi, F. Investigation of viscoelastic and active corrosion protection properties of inhibitor modified silica nanoparticles/epoxy nanocomposite coatings on carbon steel. Corros. Sci. 2019, 147, 128–140. [Google Scholar] [CrossRef]

- Ji, W.; Cheng, X.; Chen, H.; Li, L.; Li, Y.; Liu, Z. Efficient synthesis of regular spherical GO/SiO2@Solar Salt microcapsules to enhance heat-storage capacity and cycle stability. Energy Convers. Manag. 2021, 245, 114637. [Google Scholar] [CrossRef]

- Lu, C.; Hao, Z.; Chu, H.; Lu, Z. Investigation on performance of engineered cementitious composites (ECC) based on surface modification of PET fibers using graphene oxide (GO) and polydopamine (PDA). Constr. Build. Mater. 2023, 368, 130343. [Google Scholar] [CrossRef]

- Yang, Y.; Guo, Y.-F.; Fu, C.; Zhang, R.-H.; Zhan, W.; Wang, P.; Zhang, X.; Wang, Q.; Zhou, X.-W. In-situ loading synthesis of graphene supported PtCu nanocube and its high activity and stability for methanol oxidation reaction. J. Colloid Interface Sci. 2021, 595, 107–117. [Google Scholar] [CrossRef] [PubMed]

- Lee, A.S.; Jeon, H.; Choi, S.-S.; Park, J.; Hwang, S.Y.; Jegal, J.; Oh, D.X.; Kim, B.C.; Hwang, S.S. Crystallization derivation of amine functionalized T 12 polyhedral oligomeric silsesquioxane-conjugated poly(ethylene terephthalate). Compos. Sci. Technol. 2017, 146, 42–48. [Google Scholar] [CrossRef]

- Naguib, H.M.; Zhang, X.H. Advanced recycled polyester based on PET and oleic acid. Polym. Test. 2018, 69, 450–455. [Google Scholar] [CrossRef]

- Ji, R.; Zhang, Q.; Zhou, F.; Xu, F.; Wang, X.; Huang, C.; Zhu, Y.; Zhang, H.; Sun, L.; Xia, Y.; et al. Electrospinning fabricated novel poly (ethylene glycol)/graphene oxide composite phase-change nano-fibers with good shape stability for thermal regulation. J. Energy Storage 2021, 40, 102687. [Google Scholar] [CrossRef]

- Abbas, S.S.; Rees, G.J.; Kelly, N.L.; Dancer, C.E.J.; Hanna, J.V.; McNally, T. Facile silane functionalization of graphene oxide. Nanoscale 2018, 10, 16231–16242. [Google Scholar] [CrossRef]

- Kaspar, P.; Sobola, D.; Částková, K.; Knápek, A.; Burda, D.; Orudzhev, F.; Dallaev, R.; Tofel, P.; Trčka, T.; Grmela, L.; et al. Characterization of Polyvinylidene Fluoride (PVDF) Electrospun Fibers Doped by Carbon Flakes. Polymers 2020, 12, 2766. [Google Scholar] [CrossRef]

- Wang, J.; Chen, S.; Wang, W.; Zhao, F.; Xu, K. Energetic properties of new nanothermites based on in situ MgWO4-rGO, CoWO4-rGO and Bi2WO6-rGO. Chem. Eng. J. 2022, 431, 133491. [Google Scholar] [CrossRef]

- Li, S.; Liu, Y.; Liu, Y.; Wang, Q. Synergistic effect of piperazine pyrophosphate and epoxy-octavinyl silsesquioxane on flame retardancy and mechanical properties of epoxy resin. Compos. Part B Eng. 2021, 223, 109115. [Google Scholar] [CrossRef]

- Ghaseminezhad, S.M.; Barikani, M.; Salehirad, M. Development of graphene oxide-cellulose acetate nanocomposite reverse osmosis membrane for seawater desalination. Compos. Part B Eng. 2019, 161, 320–327. [Google Scholar] [CrossRef]

- Ghazi Moradi, L.; Ganjaee Sari, M.; Ramezanzadeh, B. Polyester-amide hyperbranched polymer as an interfacial modifier for graphene oxide nanosheets: Mechanistic approach in an epoxy nanocomposite coating. Prog. Org. Coat. 2020, 142, 105573. [Google Scholar] [CrossRef]

- Zhang, J.-X.; Liang, Y.-X.; Wang, X.; Zhou, H.-J.; Li, S.-Y.; Zhang, J.; Feng, Y.; Lu, N.; Wang, Q.; Guo, Z. Strengthened epoxy resin with hyperbranched polyamine-ester anchored graphene oxide via novel phase transfer approach. Adv. Compos. Hybrid Mater. 2018, 1, 300–309. [Google Scholar] [CrossRef]

- Wang, S.; Wen, B. Effect of functional filler morphology on the crystallization behavior and thermal conductivity of PET resin: A comparative study of three different shapes of BN as heterogeneous nucleating agents. Compos. Sci. Technol. 2022, 222, 109346. [Google Scholar] [CrossRef]

- Pöllänen, M.; Suvanto, M.; Pakkanen, T.T. Cellulose reinforced high density polyethylene composites—Morphology, mechanical and thermal expansion properties. Compos. Sci. Technol. 2013, 76, 21–28. [Google Scholar] [CrossRef]

- Codou, A.; Guigo, N.; van Berkel, J.G.; de Jong, E.; Sbirrazzuoli, N. Preparation and crystallization behavior of poly(ethylene 2,5-furandicarboxylate)/cellulose composites by twin screw extrusion. Carbohydr. Polym. 2017, 174, 1026–1033. [Google Scholar] [CrossRef]

- Yang, H.; Du, J. Composites made of Ginkgo biloba fibers and polylactic acid exhibit non-isothermal crystallization kinetics. Int. J. Biol. Macromol. 2023, 253, 127232. [Google Scholar] [CrossRef]

- Ye, D.-z.; Zhang, X.; Gu, S.; Zhou, Y.; Xu, W. Non-isothermal crystallization kinetics of eucalyptus lignosulfonate/polyvinyl alcohol composite. Int. J. Biol. Macromol. 2017, 97, 249–257. [Google Scholar] [CrossRef]

- Um, H.-J.; Hwang, Y.-T.; Choi, K.-H.; Kim, H.-S. Effect of crystallinity on the mechanical behavior of carbon fiber reinforced polyethylene-terephthalate (CF/PET) composites considering temperature conditions. Compos. Sci. Technol. 2021, 207, 108745. [Google Scholar] [CrossRef]

- Lee, T.-H.; Yu, H.; Forrester, M.; Wang, T.-p.; Shen, L.; Liu, H.; Li, J.; Li, W.; Kraus, G.; Cochran, E. Next-Generation High-Performance Bio-Based Naphthalate Polymers Derived from Malic Acid for Sustainable Food Packaging. ACS Sustain. Chem. Eng. 2022, 10, 2624–2633. [Google Scholar] [CrossRef]

- Chen, Y.; Wu, L.; Li, B.-G. Poly(1,5-pentylene-co-2,2,4,4-tetramethyl cyclobutylene terephthalate) copolyesters with high Tg and improved ductility and thermal stability. Polymer 2021, 232, 124152. [Google Scholar] [CrossRef]

- Ding, L.; Liu, L.; Chen, Y.; Du, Y.; Guan, S.; Bai, Y.; Huang, Y. Modification of poly(ethylene terephthalate) by copolymerization of plant-derived α-truxillic acid with excellent ultraviolet shielding and mechanical properties. Chem. Eng. J. 2019, 374, 1317–1325. [Google Scholar] [CrossRef]

- Majumdar, A.; Shukla, S.; Singh, A.A.; Arora, S. Circular fashion: Properties of fabrics made from mechanically recycled poly-ethylene terephthalate (PET) bottles. Resour. Conserv. Recycl. 2020, 161, 104915. [Google Scholar] [CrossRef]

- Xing, L.; Wang, Y.; Wang, S.; Zhang, Y.; Mao, S.; Wang, G.; Liu, J.; Huang, L.; Li, H.; Belfiore, L.A.; et al. Effects of Modified Graphene Oxide on Thermal and Crystallization Properties of PET. Polymers 2018, 10, 613. [Google Scholar] [CrossRef]

| Content (%) | Tc (°C) | Tm (°C) | Tg (°C) | ΔHm (J/g) | ΔHc (J/g) | Xt (%) | T1/2 (s) | n |

|---|---|---|---|---|---|---|---|---|

| 0 | 185.1 | 244.1 | 73.63 | 23.4 | 21.04 | 16.1 | 595 | 2.7 |

| 0.2%PET/GI | 196.9 | 249.1 | 74.9 | 36.65 | 28.36 | 26.2 | 415 | 2.63 |

| 0.2%PET/GITP | 201.13 | 251 | 75.2 | 33.89 | 26.24 | 24.2 | 388 | 2.57 |

| 0.4%PET/GI | 202.3 | 252.5 | 75.82 | 42.87 | 40.64 | 30.6 | 250 | 2.52 |

| 0.4PET/GITP | 207.5 | 257.1 | 78.32 | 46.35 | 42.01 | 33.1 | 201 | 2.45 |

| 0.6%PET/GI | 199.1 | 250.2 | 73.97 | 38.7 | 30.89 | 27.7 | 314 | 2.66 |

| 0.6%PET/GITP | 203.6 | 355.8 | 74.01 | 42.09 | 33.99 | 30.1 | 299 | 2.60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dan, Y.; Wang, Y.; Zhang, M.; Huang, L.; Sun, Q.; Zhang, P.; Li, Z.; Wang, W.; Tang, J. Synthesis of Polyethylene Terephthalate (PET) with High Crystallization and Mechanical Properties via Functionalized Graphene Oxide as Nucleation Agent. Molecules 2024, 29, 1953. https://doi.org/10.3390/molecules29091953

Dan Y, Wang Y, Zhang M, Huang L, Sun Q, Zhang P, Li Z, Wang W, Tang J. Synthesis of Polyethylene Terephthalate (PET) with High Crystallization and Mechanical Properties via Functionalized Graphene Oxide as Nucleation Agent. Molecules. 2024; 29(9):1953. https://doi.org/10.3390/molecules29091953

Chicago/Turabian StyleDan, Yingdi, Yao Wang, Miaorong Zhang, Linjun Huang, Quankai Sun, Pengwei Zhang, Zengkun Li, Wei Wang, and Jiangguo Tang. 2024. "Synthesis of Polyethylene Terephthalate (PET) with High Crystallization and Mechanical Properties via Functionalized Graphene Oxide as Nucleation Agent" Molecules 29, no. 9: 1953. https://doi.org/10.3390/molecules29091953

APA StyleDan, Y., Wang, Y., Zhang, M., Huang, L., Sun, Q., Zhang, P., Li, Z., Wang, W., & Tang, J. (2024). Synthesis of Polyethylene Terephthalate (PET) with High Crystallization and Mechanical Properties via Functionalized Graphene Oxide as Nucleation Agent. Molecules, 29(9), 1953. https://doi.org/10.3390/molecules29091953