2.1. Equilibrium Electron Transmission

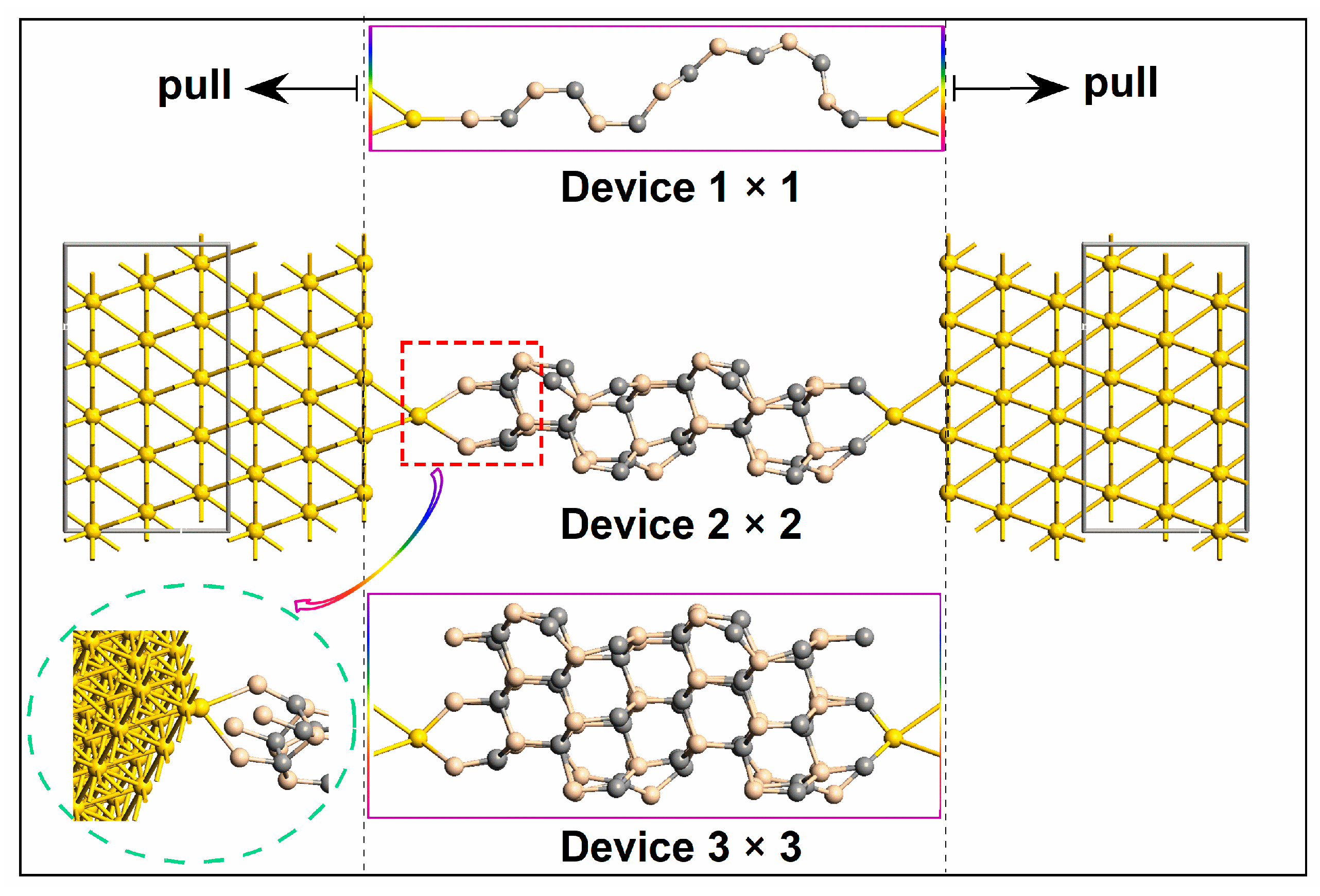

Firstly, we calculated the equilibrium electron transmission spectrum of three devices at representative strains which can reflect their electron transport capacity, shown in

Figure 2,

Figure 3 and

Figure 4. Furthermore, the equilibrium electron transmission at the Fermi level (E

F) under representative strains is also given in these figures. By diagonalizing the transmission matrix, we can obtain the transmission eigenvalues, and then by summing the transmission eigenvalues of all the electron transmission orbitals at E

F, we can obtain the electron transmission at E

F [

33]. When the device is at zero bias, the electron transmission around E

F, especially at E

F, is higher for devices with strong electron transmission capacity [

34]. For the electron transmission spectrum of the probe device, the number, width, position, and peak value of the transmission peaks are all factors that cannot be ignored.

Figure 2 shows the electron transmission spectrum of Device 1 × 1 around E

F under various representative strains. For the number of transmission peaks, as the tensile process begins, the number of transmission peaks of Device 1 × 1 appears to change firstly from a small amount (initial-stage) to multi-volume (middle and late stages), and finally to 0. Next is the width of the transmission peak. Similar to the change in the number of peaks, the change in transmission peak width with the tensile process shows a shift from narrower peaks (initial-stage) to wider peaks (middle and late stages), and finally the transmission peaks no longer appear. This is followed by a discussion of peak values, and in order to provide a more comprehensive analysis of the peak changes, we select the closest transmission peaks to the Fermi energy level (including transmission peaks at E

F) named Category I peaks. The peaks with the highest peaks in the entire [−3.5 eV, 3.5 eV] energy range are named Category II peaks. When Wire 1 × 1 is unstretched, the summit of Category I peak is at E

F. At the beginning of the stretching, the Category I peak gradually moves away from E

F and the values of the Category I and II peaks decrease. The transmission efficient at E

F also falls off rapidly. When the strain reaches 0.5408 or over but does not fracture, the Category I peak is very close to E

F and the Category II peak elevates greatly. The number of high transmission peaks surges. When Wire 1 × 1 breaks, no transmission can be observed.

Based on this discussion, it can be found that the trend of the peak value of the first type of peak with the strain is similar to the trend of the electron transmission coefficient at E

F (shown in

Figure 2h). But the maximum peak of the first type of peak occurs late at the strain of 0.7136, which is different from the E

F, where the maximum electron transmission coefficient appears in the initial state (strain 0). The changing trend of the second type of peak is similar to that of the first category, with the largest peaks occurring late at the strain of 0.7136. In all, the maximum peaks of both the first and second peaks occur late in the stretch (strain 0.7136). From

Figure 2h, the good transmission possibility at E

F clearly appears in the un-tensile wire and the stretching wire at the middle and late stages.

Figure 3 shows an electron transmission spectrum of Device 2 × 2 around E

F under various representative strains. Similar to Device 1 × 1, we analyze the number of peaks, the width of the peaks, and the peak value. Device 2 × 2 obviously shows many more transmission peaks than Device 1 × 1 does, whatever the strain is. As the SiC nanowires are stretched, the number of transmission peaks increases initially. When the strain reaches 0.5, the number of peaks drops obviously until Wire 2 × 2 breaks. For the transmission peak width, the transmission peak width of Device 2 × 2 remains basically the same throughout the rest of the stretch, except for the larger peak width in the initial state and the narrow peak width at the end of the stretch. The peak analysis, similar to the Device 1 analysis, is discussed in the Category I peak and Category II peak. When the strain does not exceed 0.5, the Category I peak is very close to E

F, with an increased peak value, and the summit of the Category II peak fluctuates. When the strain reaches to 0.5, the Category I peak stays a little farther away from E

F but with a much lower peak value, and the summit of the Category II peak drops fast. As the strain continue to rise without fracture, the peak value of Category II peak increases again.

Since the first type of peak is close to E

F, the trend of its peak value with tensile change is similar to the trend of the electron projection coefficient at E

F with tensile change in

Figure 3h. But for the second type of peak, the change in the peak value with the strain is very different from the trend of the first type of peak. Although the second type of maximum peak still occurs in the middle of the stretch, there is also a larger Type II peak in the initial stage, At the end of the stretch, the peak of the second category also rises before falling. It differs from the Class Platform Phase presented late in the stretch at the first peaks and at E

F. From

Figure 3h, the strongest electron transmission at E

F appears in the middle stage (at strain of 0.3168). When the strain reaches 0.5 and above, Device 2 × 2 presents weaker electron transport. Thus, by applying the appropriate stress, the electron transmission of Device 2 × 2 can be improved significantly. A large degree of stretching would suppress the electron transport for Wire 2 × 2.

Figure 4 gives the electron transmission spectrum of Device 3 × 3 around E

F under various representative strains. In quantity, the number of transmission peaks in Device 3 × 3 is significantly greater than in the first two, and as the stretch progresses, the number of peaks is presented by a small number in the initial stage, multi-vector in the middle stage, and a gradual transition from multiple to zero in the late stage. In addition to the larger transmission peak width in the initial stage, the width of the transmission peak during the rest of the tensile process is basically the same. The Category I peak stays very close to E

F, influenced by the tensile strain. Split peak occurs closest to E

F in the initial and middle stages. When the strain exceeds 0.568, most of the transmission peaks present obviously lower peak transmission, especially Category I peak. Furthermore, the peak value of the Category II peak is very high under most of the strains, except when it is about to break.

Similar to Device 2 × 2, the changing trend of the peak value of the first class is similar to that of the transmission electron coefficient at E

F (shown in

Figure 3e). For the peaks of the second category, the maximum peaks of the second category of Device 3 × 3 occur in the middle of the stretch (at strain 0.4752). In addition, large peaks and those numerically close to the maximum peaks of the second category occur repeatedly in the initial state (strain to 0) and middle of the stretch. At the late stage of tensile (strain 0.8472), there is also a large peak value of the second type, which is very different from the trend of the electron transmission coefficient at E

F changing with the tensile strain.

Finally, a longitudinal comparison is made of the cross-sectional atomic area of nanowires as an argument. As the cross-sectional area of SiC NWs becomes larger, the number of peaks gradually increases, the average width of peaks gradually increases, and the maximum electron transmission coefficient at E

F gradually increases. From

Figure 3e, the electron transmission coefficient at E

F waves in the initial and middle stretching stages, where stronger electron transmission appears. Device 3 × 3 presents the great electron transport at the strain of 0.568. In the late stage, the electron transport stays weak.

Therefore, for SiC nanowires with cross-sectional areas that are not single atoms (i.e., Device 2 × 2 and Device 3 × 3), the ultra-thin SiC NWs that remain in the initial state always show fewer transmission peaks and wider transmission peaks, compared with the NWs that undergo tensile strain, at the scales of their respective size. This shows that for SiC nanowires with large cross-sectional areas, a certain stretching strain can make the electronic transition of the device easy. As a result, the electronic transport performance of the device can be improved to some extent.

From the relationship between the equilibrium electron transmission and strain at EF, it is not hard to see that the SiC nanowires of various sizes have certain similarities caused by the destruction of their original structure. The reduction in the equilibrium electron transmission of the nanowires is affected by tensile strain. However, when the strain increases, the electron transmission of the ultra-thin 3C-SiC NWs can be somewhat adjusted due to some specific structures. This suggests that tensile strain can also affect the equilibrium electron transmission of these NWs.

2.2. Electronic Structures

The device density of states (DDOSs) represents the electronic structure of the device [

35]. In general, the higher the state density value around E

F, the more electrons around E

F. To some extent, there will be more electrons crossing the energy gap. However, the actual situation remains constrained by other factors.

Figure 5a–g exhibits the DDOS of Device 1 × 1 around E

F. In the [−3.5 eV, 3.5 eV] range of energy levels, the number of DDOSs peaks throughout the stretch of Device 1 × 1 remains from three to four peaks. When not stretched, a significant DDOS peak is exactly at E

F. As the stretch progresses, the peak gradually deviates from E

F, and the peak decreases. In the middle of the stretch, the peak of DDOS becomes not very obvious. However, after the stretch, the peak becomes apparent again, but the DDOS peak closest to E

F is not yet at E

F. It is visible that for Device 1 × 1, the DDOS values of the stretched devices are lower than the unstretched device. Different from the electron transmission, the DDOS of Device 1 × 1 still shows certain values around E

F when it is broken. However, the tensile strain will cause a large deformation of the entire nanowire throughout the tensile process, but it has little effect on the electronic structure of the device.

To give a quantitative relation more clearly,

Figure 5h presents the changing trend of the DDOS value at E

F with strain. It can be found that when Device 1 × 1 is not stretched, the DDOS value at E

F. is largest. The DDOS value at E

F is minimized in the beginning of the stretch. The corresponding DDOS value is minimum at strain 0.2112. As the stretch progresses, the DDOS value picks up slightly in the middle and late stages of the stretch and stabilizes, but the DDOS value is much smaller than that before the stretch. The stretching would reduce the DDOS at E

F of Device 1 × 1. Comparing

Figure 2 with

Figure 5, the DDOS curves are similar with the transmission curves in shape under the influence of the strain. Moreover, the prominent DDOS peaks basically correspond to the transmission peaks. By comparing

Figure 2h with

Figure 5h, for Device 1 × 1, the trend of the electron transmission coefficient changing with strain in the initial stage is consistent with that of the DDOS values with strain. The structure of SiC NWs with a cross-sectional area of one atom is relatively simple, so the DDOS can fully reflect the electronic structure of Device 1 × 1, which also directly determines the electronic transport performance of Device 1 × 1.

Based on this,

Figure 5(i-j) gives the distribution of the electron states at the two maxima of DDOSs. It can be found that when the DDOS value is greatest, the electronic state of the device is distributed uniformly along the nanowires and is in an extended state. When the DDOS value is minimal, the electronic state of the device is localized, and the nanowire near the leakage electrode is fuller than the source electrode. The delocalization of electronic states results in an increase in the SiC NWs’ charge transfer ability, which indicates that the coupling of the SiC NWs and electrodes has a small barrier that enhances the device’s electron transmission [

36]. This also shows that the extended electronic states distribution makes the DDOS value of nanowires higher, while the distribution of the local electronic states makes the DDOS value smaller. When a SiC NW is a single atomic chain, the tensile strain applied to both ends of the nanowire changes the electronic state distribution and the electronic structure of the device.

Figure 6a–g shows a DDOSs map of Device 2 × 2 around E

F under representative strain. In terms of the number of peaks, Device 2 × 2 generally has more state density peaks than Device 1 × 1 in the same energy range, and the maximum peak is also larger than Device 1 × 1. This shows that the electronic structure of the SiC NWs with a cross-sectional area of four atoms is more complex than that of the SiC NW with single atomic chains. Unlike Device 1 × 1, Device 2 × 2 presents a gentle distribution of DDOSs near E

F when not stretched. When the tensile stress is applied, the DDOSs peak increases significantly. Especially, in the early stretch period, the DDOSs peak increases significantly and is just at E

F. As the stretch progresses, the peak decreases and deviates from E

F. But the peaks are much higher than when not stretched. At the end of the stretch, when the nanowire is just pulled off, the obvious DDOS peak is mainly distributed on the left side of E

F. Affected by the tensile stress, Device 2 × 2 shows not many obvious DDOS peaks around E

F, only presenting one or two prominent DDOS peaks at strains of 0.1584 and 0.3168. It should be noted that different from the electron transmission spectrum, the DDOS of Device 2 × 2 still shows certain values around E

F when it is broken.

Comparing

Figure 3 with

Figure 6, the DDOS curves of Device 2 × 2 are similar with the transmission curves in shape under the influence of the strain and the prominent DDOSs peaks basically correspond to transmission peaks, which is similar with Device 1 × 1.

Figure 6h shows how the DDOS values of Device 2 × 2 at E

F vary with strain. It can be found that the maximum DDOS value of Device 2 × 2 occurs during the entire stretch (strain 0.1584), with the lowest value in the late stretch (strain 0.8232). At other strains, the DDOS values of Device 2 × 2 at E

F are not much different from when not stretched.

Combined with the distribution of electronic states (see

Figure 6(i-j) for analysis, it can be found that the electronic states of Device 2 × 2 present a uniform distribution over the nanowires at the strain of 0.1584. In the case of strain 0.8112, the electronic states of the device are quite localized, are mainly concentrated near the leakage electrode of the device, and there is almost no electron state distribution near the source electrode. This also shows that the DDOS value at E

F is closely related to the electronic states near E

F. In addition, the maximum DDOS value of the device occurs in the pre-stretching phase and the value of the maximum DDOS differs greatly from the initial state. For SiC NWs with a cross-sectional area of four atoms, slight tensile strain can make the electronic states distribution and electronic structure of the device more complex. To some extent, it may be helpful to improve the electronic transport capability of devices.

Figure 7 gives the DDOSs map of Device 3 × 3 near E

F under various representative strains. Not surprisingly, SiC nanowire devices with a cross-sectional area of nine atoms have more peaks than the previous two. And the peak has grown to more than 500 eV

−1. This shows that the electronic structure of the device is more complex than in the first two cases. When not stretched, the only peaks in the entire interval are more pronounced and near E

F. At the beginning of tensile period, the number of DDOS peaks increases, especially the obvious peaks, but the peaks are not high compared with the unstretched one. As the stretch progresses, the number of peaks changes little, but gradually highlights the single peak. However, when the strain exceeds 0.5, until it breaks, the summit of the DDOSs peak decreases and a gentle trend occurs. And the DDOS hardly changes in the middle and late stretch, which shows gentle and similar distributions starting from the strain of 0.5112, characterized by low multi-peaks. Comparing

Figure 4 with

Figure 7, the DDOS peaks approximate the transmission peaks in quantity but differ in the height of peak for Device 3 × 3. Similar to other sizes of devices, the freshly broken Device 3 × 3 also show certain values of DDOSs around E

F.

Figure 7o gives the DDOS values of the three devices at E

F under each typical strain. Obviously, when the strain is 0.3992, Device 3 × 3 has the largest DDOS value, while DDOS is the smallest when the strain is 1.0136. During other strains, the DDOS varies little. On this basis, we combine the distribution of electronic states (

Figure 7(p-q)) to analyze. It can be found that the electronic states of Device 3 × 3 are uniformly distributed at the maximum DDOS value, whether near the source electrode, near the leakage electrode, or in the middle of the nanowire. Inversely, when the DDOS value is minimal, small and discrete electronic states are distributed locally around the source and leakage electrodes due to the tensile fracture of the nanowires. This phenomenon proves again that the DDOS value at E

F of the device can reflect the electronic states and the electronic structure of the device near E

F.

In addition, the maximum DDOS value of Device 3 × 3 appears in the middle of the stretch and the minimum DDOS value appears later in the stretch. Both the maximum and minimum values differ significantly from the DDOS values near EF in the initial state of Device 3 × 3. This shows that for SiC NWs with a cross-sectional area of nine atoms, a certain amount of tensile strain can effectively increase the DDOS value of the device and improve the electronic distribution and electronic structure of devices. But excessive tensile strain can also have counterproductive effects and makes the electronic states distribution of the device discrete.

For Device 2 × 2 and Device 3 × 3, the trend of DDOS changing with strain during the pre-stretch and late-stretch periods is not fully matched with the trend of electron transmission with strain, based on the contrast of

Figure 3h and

Figure 6h, as well as

Figure 4o and

Figure 7o. This is due to the large cross-sectional area of the SiC NWs, unlike the simple Device 1 × 1. The devices with larger cross-sectional SiC NWs contain more Si atoms and C atoms, which have more influence on each other, so the DDOS values do not appear to be more consistent with the electron transmission than Device 1 × 1.

We can see that as the cross-sectional area becomes larger, the number of peaks in the state density map of the SiC NWs increases and the peaks increase. This shows that the cross-sectional area of the SiC NWs gradually increases from one atom to nine atoms, thus increasing the influence between the Si atoms and the C atoms in the devices, and the overall electronic structure of the devices becomes more complex. From the contrast of DDOS at E

F among the three devices (

Figure 7o), Device 1 × 1 presents lower DDOS values than Device 2 × 2 under various strains. Device 1 × 1 in an unstretched state shows very similar DDOS values with Device 2 × 2 at most strains, except the strain of 0.1584 with the maximum. As the diameter increases, the DDOS fluctuates with the strain, not showing the changing trend as well as the devices with thinner SiC NWs. Device 3 × 3 displays several local optimal points, which are higher than the DDOS values of the devices with thinner SiC NWs at all strains except the maximum of Device 2 × 2. Noticeably, the maximum DDOS of Device 3 × 3 is significantly greater than other devices, which is about two times the maximum DDOS of Device 2 × 2 and more than six times the DDOS of thinner devices at most strains.

It is worth noting that the devices with large cross-sectional areas or smaller cross-sectional areas tend to have similar trend of DDOS values with strain to electron transmission coefficients with strain in the late stage of the stretch. This is because at this point the nanowire stretch basically ends and the complete structure of the NW has been destroyed. This reduces the interaction between atoms and atoms and the factors that constrain electrons from crossing the energy gap. The electronic states near EF determine the electronic transport capability of the device again, so the trend of the DDOS value at EF with strain is similar to that of the electron transmission coefficient with strain.

In order to investigate thoroughly the internal mechanism of electron transport properties, we studied the electron distributions of the devices with these stretched SiC NWs by calculating their electron localization functions (ELFs), which are given in

Figure 8. The ELFs can be described in the form of a contour plot in real space with values ranging from 0 to 1, and a large value denotes a high degree of electron localization. Generally, values of 1 or 0.5 represent the fully localized or fully delocalized electrons, respectively, while a value near 0 refers to a very low electron density. The colors of red and blue refer to the highest (1) and lowest (0) values of ELF, indicating accumulation and depletion of electrons at different colored regions, respectively.

From

Figure 8, it can be seen that the electrode extension part of each device almost has the same distribution of electrons. On the whole, the red color can be found in the surroundings of many Si and C atoms for each SiC NW, revealing that the electrons around these atoms possess stubborn localization, denoting strong covalent electron states which can electronically stabilize the frame of SiC NWs. More interestingly, a green color can be seen around many red areas, demonstrating that the homogeneous electron gas is widely distributed in outskirts where these electrons are free and can transfer flexibly. Such distribution of electronic states would provide bases for electron transport. A blue color can be observed in the areas far away from the SiC NWs and the parts with larger tensile deformations (the ELF value is 0), which testifies to the electron deficiency.

In detail, for Wire 1 × 1, the unstretched state possesses the continuous green area from the left to the right that forms the whole electron transfer path, together with the shortest length and less tortuous degree, contributing stronger electron transmission than other stretched states. Wire 1 × 1 at strains of 0.5408 and 0.7136 shows the most stretchable and straightest green strips (distribution of electronic states), which facilitates the electron transferring. So, the two tensile states also display stronger electron transmission. When Wire 1 × 1 breaks, the electron distribution area appears to be divided into two parts with a continuous blue area, leading to weaker electron transport. As the diameter increases, several small blue patches also appear in the electronic distribution inside the SiC NWs. For Wire 2 × 2, the stretched state at the strain of 0.3168 presents the least small blue patches and the biggest green areas in the electronic distribution inside the SiC NWs, bringing about the strongest electron transport. Larger strains initiate continuous blue areas inside the NWs and smaller strains cause more small blue patches and less green areas in electronic distribution inside the SiC NWs, which are not conducive to the electron transport. Similarly, the electronic distributions inside the SiC NWs are also important for Wire 3 × 3.