Regulation of Interface Compatibility and Performance in Soft Magnetic Composites with Inorganic Insulation Layers by FePO4 Intermediate Transition Layer

Abstract

1. Introduction

2. Results and Discussion

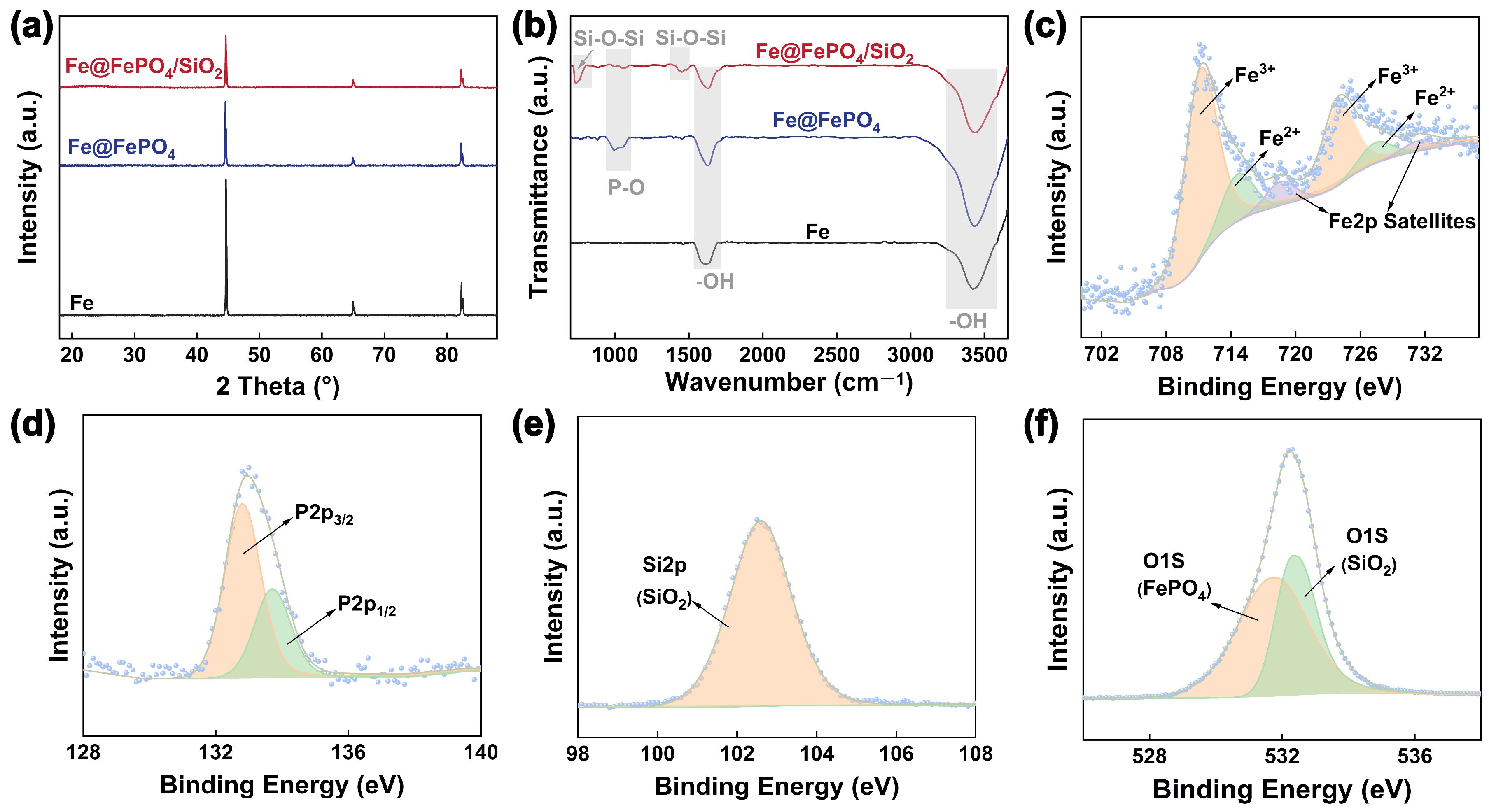

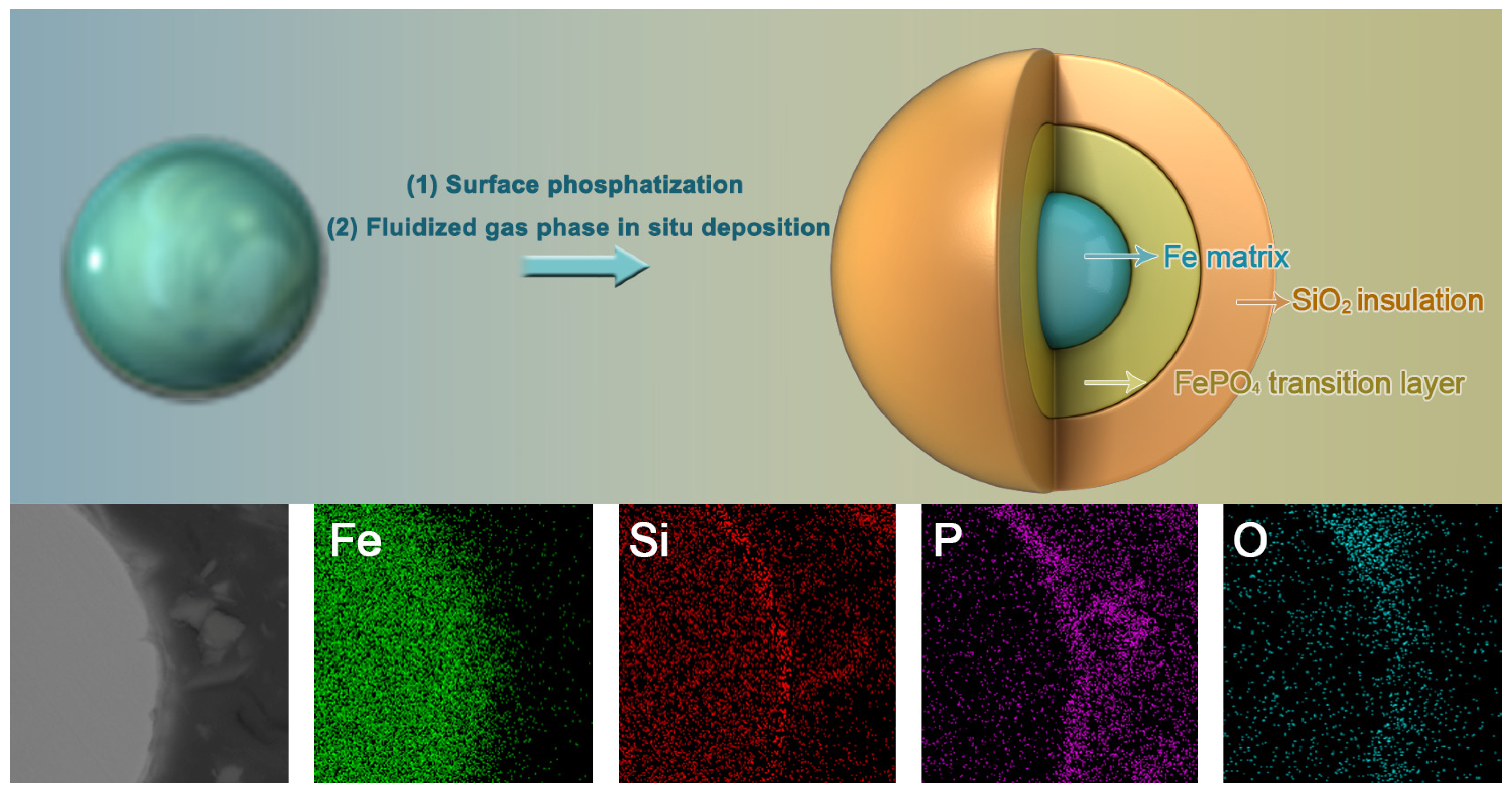

2.1. Formation Process of FePO4 Intermediate Transition Layer and SiO2 Insulation Layer on Surface of Fe Powder

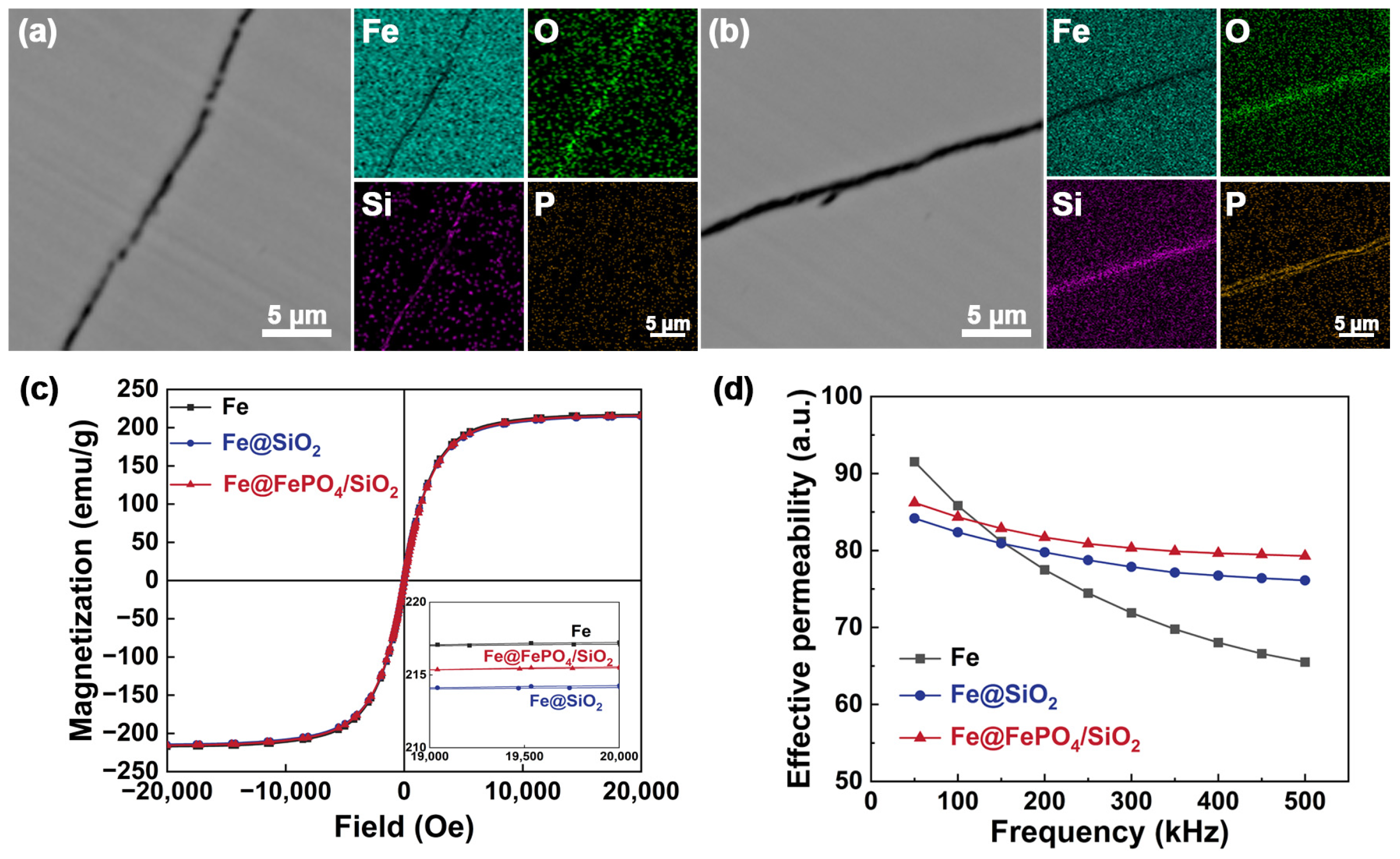

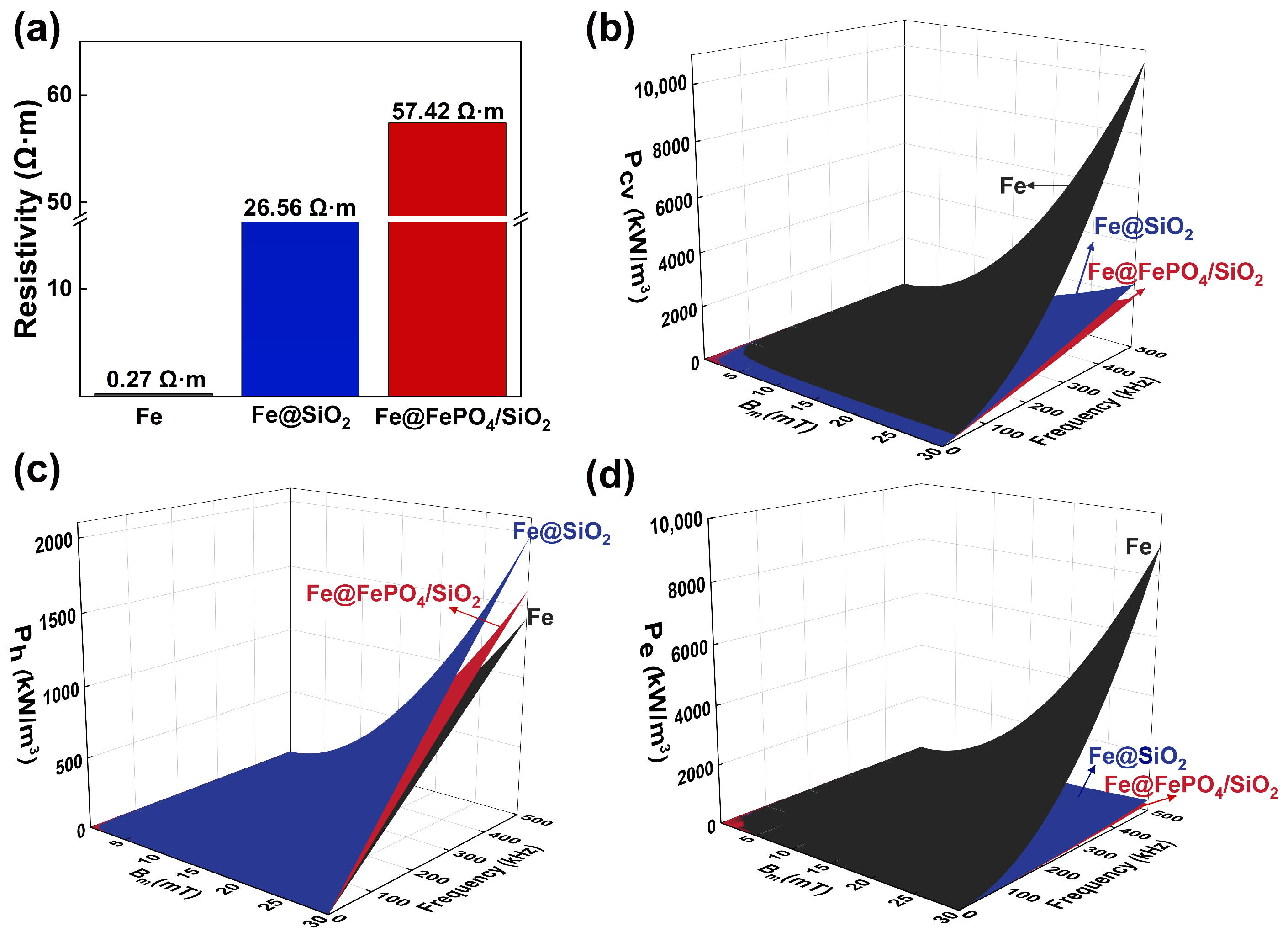

2.2. Impact of FePO4 Intermediate Transition Layer on Properties of Soft Magnetic Composites

2.3. Impact of H3PO4 Concentration on Structural and Magnetic Characteristics of SMCs

3. Materials and Methods

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Perigo, E.A.; Weidenfeller, B.; Kollar, P.; Fuzer, J. Past, present, and future of soft magnetic composites. Appl. Phys. Rev. 2018, 5, 031301. [Google Scholar] [CrossRef]

- Wu, Z.Y.; Jiang, Z.; Fan, X.A.; Zhou, L.J.; Wang, W.L.; Xu, K. Facile synthesis of Fe-6.5wt%Si/SiO2 soft magnetic composites as an efficient soft magnetic composite material at medium and high frequencies. J. Alloys Compd. 2018, 742, 90–98. [Google Scholar] [CrossRef]

- Li, W.; Cai, H.; Kang, Y.; Ying, Y.; Yu, J.; Zheng, J.; Qiao, L.; Jiang, Y.; Che, S. High permeability and low loss bioinspired soft magnetic composites with nacre-like structure for high frequency applications. Acta Mater. 2019, 167, 267–274. [Google Scholar] [CrossRef]

- Ba, X.; Guo, Y.; Zhu, J.; Zhang, C. An Equivalent Circuit Model for Predicting the Core Loss in a Claw-Pole Permanent Magnet Motor With Soft Magnetic Composite Core. IEEE Trans. Magn. 2018, 54, 1–6. [Google Scholar] [CrossRef]

- Guo, Y.; Zhu, J.; Lu, H.; Lin, Z.; Li, Y. Core Loss Calculation for Soft Magnetic Composite Electrical Machines. IEEE Trans. Magn. 2012, 48, 3112–3115. [Google Scholar] [CrossRef]

- Jang, P. Core Loss Measurement of dc-Biased Soft Magnetic Composite Cores. J. Korean Magnet. Soc. 2018, 28, 5–9. [Google Scholar] [CrossRef]

- Wang, R.; Li, Y.; Li, K.; Qiu, Y.; Wu, Z.; Kong, H. Augmenting magnetic properties: Ectopic reconstruction of insulation layer in soft magnetic composites via coating-doping method. J. Mater. Res. Technol. JMRT 2024, 30, 101–109. [Google Scholar] [CrossRef]

- Poskovic, E.; Franchini, F.; Ferraris, L.; Fracchia, E.; Bidulska, J.; Carosio, F.; Bidulsky, R.; Actis Grande, M. Recent Advances in Multi-Functional Coatings for Soft Magnetic Composites. Materials 2021, 14, 6844. [Google Scholar] [CrossRef]

- Wang, J.; Liu, X.; Zheng, Z.; Qiu, Z.; Li, K.; Xu, J.; Lu, K.; Zeng, D. Reduction of core loss for FeSi soft magnetic composites prepared using atomic layer deposition-based coating and high-temperature annealing. J. Alloys Compd. 2022, 909, 164655. [Google Scholar] [CrossRef]

- Streckova, M.; Bures, R.; Faberova, M.; Medvecky, L.; Fuzer, J.; Kollar, P. A comparison of soft magnetic composites designed from different ferromagnetic powders and phenolic resins. Chin. J. Chem. Eng. 2015, 23, 736–743. [Google Scholar] [CrossRef]

- Lucarini, S.; Hossain, M.; Garcia-Gonzalez, D. Recent advances in hard-magnetic soft composites: Synthesis, characterisation, computational modelling, and applications. Compos. Struct. 2022, 279, 114800. [Google Scholar] [CrossRef]

- Park, J.E.; Kwon, S.H.; Lu, Q.; Choi, H.J.; Wie, J.J. Synergistic Inclusion Effects of Hard Magnetic Nanorods on the Magnetomechanical Actuation of Soft Magnetic Microsphere-Based Polymer Composites. Small 2024, 20, 2305272. [Google Scholar] [CrossRef] [PubMed]

- Huang, M.; Wu, C.; Jiang, Y.; Yan, M. Evolution of phosphate coatings during high-temperature annealing and its influence on the Fe and FeSiAl soft magnetic composites. J. Alloys Compd. 2015, 644, 124–130. [Google Scholar] [CrossRef]

- Li, H.; Huang, Z.; Li, G.; Lin, J. Review of soft magnetic composite permanent magnet motor. In Proceedings of the International Symposium on Big Data and Artificial Intelligence (ISBDAI), Hong Kong, China, 29–30 December 2018; pp. 294–298. [Google Scholar]

- Li, W.; Yan, H.; Ying, Y.; Yu, J.; Zheng, J.; Qiao, L.; Li, J.; Che, S. Analysis of the magnetic properties of a silicate-coated spherical FeSiAl-based soft magnetic composite for high-frequency power-applications. Appl. Phys. Lett. 2019, 115, 212401. [Google Scholar] [CrossRef]

- Mei, C.; Li, J.; Zhang, B.; Zhu, X.; Hu, F.; Liu, W.; Su, H.; Zou, Z.; Du, Y. Synthesis of FeNi@kaolin soft magnetic composites with adjustable magnetic properties under different DC bias fields. J. Magn. Magn. Mater. 2023, 587, 171350. [Google Scholar] [CrossRef]

- Zhu, S.; Wang, Z.; Kan, X.; Feng, S.; Liu, X. FeNi/Glass Soft Magnetic Composites with High Magnetic Properties. J. Supercond. Nov. Magn. 2022, 35, 1165–1172. [Google Scholar] [CrossRef]

- Huang, H.; Wang, R.; Li, K.; Dai, B.; Wu, Z.; Lyu, P. Fabrication of high-performance FeSiCr-based soft magnetic composites using thermal decomposition of salt compounds. J. Mater. Res. Technol. JMRT 2024, 29, 3291–3302. [Google Scholar] [CrossRef]

- Wang, R.; He, Y.H.; Kong, H.; Wang, J.; Wu, Z.Y.; Wang, H.C. Influence of sintering temperature on heterogeneous-interface structural evolution and magnetic properties of Fe-Si soft magnetic powder cores. Ceram. Int. 2022, 48, 29854–29861. [Google Scholar] [CrossRef]

- Luo, Z.; Jin, Q.; Wang, R.; Yang, Z.; Wu, Z.; Li, G.; Fan, X.a. High-performance FeSiAl/(Al2O3-Ni)soft magnetic composites prepared by in situ synthesis method. Adv. Powder Technol. 2024, 35, 104624. [Google Scholar] [CrossRef]

- Zhang, J.; Dong, Y.; Li, Y.; Yang, L.; Jia, X.; Zhang, L.; Cai, L.; He, A.; Li, J.; Liu, X.; et al. The effect of phosphate/TiO2 composite insulating layer on the high frequency magnetic properties of FeSiBPCNbCu nanocrystalline soft magnetic powder cores. Mater. Today Commun. 2024, 38, 107809. [Google Scholar] [CrossRef]

- Huang, H.; Wang, J.; Cui, Z.; Gao, Z.; Huang, Z.; Wu, Z. Selective oxidation of rare metal oxide insulation layers on particle substrates for optimizing the performance of FeSiCr-based soft magnetic composites. Mater. Des. 2023, 230, 111984. [Google Scholar] [CrossRef]

- Luo, Z.G.; Fan, X.A.; Zhang, Y.L.; Yang, Z.J.; Wang, J.; Wu, Z.Y.; Liu, X.; Li, G.Q.; Li, Y.W. Formation mechanism and magnetic performance of Fe-Si soft magnetic composites coated with MnO-SiO2 composite coatings. Adv. Powder Technol. 2021, 32, 3364–3371. [Google Scholar] [CrossRef]

- Wang, J.; Xue, Z.; Song, S.; Sun, H. Magnetic properties and loss separation mechanism of FeSi soft magnetic composites with in situ NiZn-ferrite coating. J. Mater. Sci. Mater. Electron. 2021, 32, 20410–20421. [Google Scholar] [CrossRef]

- Yang, T.; Lu, K.; Wang, J.; Xu, J.; Zheng, Z.; Liu, X. Fe-6.5 wt%Si soft magnetic composites with significant improvement of magnetic properties by compositing nano-MnZn ferrites. J. Alloys Compd. 2022, 909, 164660. [Google Scholar] [CrossRef]

- Gao, Z.; Jia, J.; Zhao, Q.; Kong, H.; Wu, Z.; Li, J. Determination of a quantitative relationship between deposition duration and magnetic performance of soft ferromagnetic composites via data-analysis and theoretical models. J. Magn. Magn. Mater. 2022, 549, 168891. [Google Scholar] [CrossRef]

- Wu, Z.; Gao, Z.; Zhao, Q.; Kong, H.; Li, M.; Jia, J. Mechanism and Effect of the Dilution Gas Flow Rate on Various Fe-Si/SiO Soft Magnetic Composites during Fluidised Bed Chemical Vapour Deposition. Crystals 2021, 11, 963. [Google Scholar] [CrossRef]

- Wang, J.; Liu, X.; Li, L.; Mao, X.-H. Performance improvement of Fe-6.5 Si soft magnetic composites with hybrid phosphate-silica insulation coatings. J. Cent. South Univ. 2021, 28, 1266–1278. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, L.; Sun, H.; Chen, F.; Zhang, P.; Qu, X.; Fan, E. Enhanced magnetic properties of iron-based soft magnetic composites with phosphate-polyimide insulating layer. J. Alloys Compd. 2020, 813, 152205. [Google Scholar] [CrossRef]

- Hsiang, H.-I.; Fan, L.-F.; Hung, J.-J. Phosphoric acid addition effect on the microstructure and magnetic properties of iron-based soft magnetic composites. J. Magn. Magn. Mater. 2018, 447, 1–8. [Google Scholar] [CrossRef]

- Fujii, T.; De Groot, F.; Sawatzky, G.; Voogt, F.C.; Hibma, T.; Okada, K. In situ XPS Analysis of Various Iron Oxide Films Grown by NO2-Assisted Molecular-Beam Epitaxy. Phys. Rev. B 1999, 59, 3195. [Google Scholar] [CrossRef]

- Dietrich, P.M.; Glamsch, S.; Ehlert, C.; Lippitz, A.; Kulak, N.; Unger, W.E.S. Synchrotron-radiation XPS analysis of ultra-thin silane films: Specifying the organic silicon. Appl. Surf. Sci. 2016, 363, 406–411. [Google Scholar] [CrossRef]

- Liu, L.; Yue, Q.; Li, G.Q.; Xu, K.; Wang, J.; Wu, Z.Y.; Fan, X.A. Influence of SiO insulation layers thickness distribution on magnetic behaviors of Fe-Si@SiO soft magnetic composites. J. Phys. Chem. Solids 2019, 132, 76–82. [Google Scholar] [CrossRef]

- Lu, K.; Liu, X.; Wang, J.; Yang, T.; Xu, J. Simultaneous improvements of effective magnetic permeability, core losses and temperature characteristics of Fe-Si soft magnetic composites induced by annealing treatment. J. Alloys Compd. 2022, 892, 162100. [Google Scholar] [CrossRef]

- Dobak, S.; Fuezer, J.; Kollar, P.; Faberova, M.; Bures, R. Interplay of domain walls and magnetization rotation on dynamic magnetization process in iron/polymer-matrix soft magnetic composites. J. Magn. Magn. Mater. 2017, 426, 320–327. [Google Scholar] [CrossRef]

- Gao, Y.; Araki, Y.; Dozono, H.; Muramatsu, K.; Guan, W.; Yuan, J.; Tian, C.; Chen, B. Modeling of Anomalous Eddy Current Losses Due to Movement of Domain Walls in Particles of a Soft Magnetic Composite. IEEE Trans. Magn. 2020, 56, 1–4. [Google Scholar] [CrossRef]

- Luo, G.; Li, X.; Zhu, Y.; Wang, X. Performance optimization of FeSiCr/ZnO soft magnetic composites by highly orientation and domain wall engineering. J. Magn. Magn. Mater. 2024, 604, 172319. [Google Scholar] [CrossRef]

- Nie, M.; Jiang, C.; Song, W.; Chen, M.; He, J.; Chen, Z.; Li, Z.; Jia, G.; Guo, H. Magnetic domain structure and electromagnetic performance of amorphous and nanocrystalline soft magnetic composites treated by magnetic field assisted annealing. J. Alloys Compd. 2024, 1005, 175995. [Google Scholar] [CrossRef]

- Wu, S.; Sun, A.; Lu, Z.; Cheng, C.; Gao, X. Magnetic properties of iron-based soft magnetic composites with SiO<sub>2</sub> coating obtained by reverse microemulsion method. J. Magn. Magn. Mater. 2015, 381, 451–456. [Google Scholar] [CrossRef]

- Lee, S.; Choi, M.; Kim, J. Magnetic Properties of Pure Iron Soft Magnetic Composites Coated by Manganese Phosphates. IEEE Trans. Magn. 2017, 53, 1–4. [Google Scholar] [CrossRef]

- He, H.; Liu, Y.; Cui, Z.; Huang, Z.; Wu, Z.; Hou, Q. High-performance Fe-6.5wt.%Si/CaCO3 soft magnetic composites prepared via The thermal decomposition of calcium acetate. J. Phys. Chem. Solids 2024, 190, 112012. [Google Scholar] [CrossRef]

- Shokrollahi, H.; Janghorban, K. Soft magnetic composite materials (SMCs). J. Mater. Process. Technol. 2007, 189, 1–12. [Google Scholar] [CrossRef]

- Zhao, L.; Wang, Y.; Wu, S.; Yang, Y.; Liu, C.; Huo, C. Core Loss Analysis of Soft Magnetic Composites Based on 3D Modeling under Non-sinusoidal Excitation. In Proceedings of the 20th Biennial IEEE Conference on Electromagnetic Field Computation (CEFC), Electr Network, Denver, CO, USA, 24–26 October 2022. [Google Scholar]

- Vesa, J.; Hyvarinen, L.; Rasilo, P. Eddy-Current Loss Model for Soft Magnetic Composite Materials Considering Particle Size Distribution. IEEE Trans. Magn. 2023, 59, 1–8. [Google Scholar] [CrossRef]

- Kollár, P.; Birčáková, Z.; Füzer, J.; Bureš, R.; Fáberová, M. Power loss separation in Fe-based composite materials. J. Magn. Magn. Mater. 2013, 327, 146–150. [Google Scholar] [CrossRef]

- Jing, Y.; Zhang, Y.; Zhang, D.; Zhu, J. Calculation of Iron Loss in Soft Magnetic Composites Using Neural Network-Based Dynamic Hysteresis Model Under SVPWM Excitation. In Proceedings of the IEEE 21st Biennial Conference on Electromagnetic Field Computation (IEEE CEFC), Jeju, Republic of Korea, 2–5 June 2024. [Google Scholar]

- Wang, R.; Huang, H.; Li, K.; Yang, J.; Wu, Z.; Kong, H. Design and evolution of Fe-Si-Al soft magnetic composites doped with carbonyl iron powders: Overcoming the restrictive relation between permeability and core loss. Ceram. Int. 2024, 50, 17861–17872. [Google Scholar] [CrossRef]

| H3PO4 Concentration | Radial Compressive Strength (Kgf) | Ms (emu/g) | μe (300 kHz) | ρ (Ω·m) | Pcv (kW/m3) | ||

|---|---|---|---|---|---|---|---|

| 10 mT, 100 kHz | 10 mT, 300 kHz | 10 mT, 500 kHz | |||||

| 0.25 wt% | 10.13 | 216.13 | 79.1 | 41.35 | 65.73 | 214.09 | 462.93 |

| 0.50 wt% | 12.22 | 215.96 | 80.8 | 47.13 | 459.04 | 183.95 | 313.56 |

| 0.75 wt% | 13.87 | 215.77 | 81.4 | 51.68 | 51.41 | 161.92 | 285.24 |

| 1.00 wt% | 15.95 | 215.60 | 83.2 | 57.42 | 43.69 | 138.64 | 243.08 |

| 1.25 wt% | 13.57 | 210.69 | 78.3 | 50.86 | 47.80 | 159.41 | 279.36 |

| 1.50 wt% | 11.72 | 209.18 | 71.6 | 42.98 | 51.33 | 173.29 | 345.17 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, S.; Ma, J.; Liu, Y.; He, H.; Lyu, P.; Huang, H.; Dai, B. Regulation of Interface Compatibility and Performance in Soft Magnetic Composites with Inorganic Insulation Layers by FePO4 Intermediate Transition Layer. Molecules 2024, 29, 5281. https://doi.org/10.3390/molecules29225281

Huang S, Ma J, Liu Y, He H, Lyu P, Huang H, Dai B. Regulation of Interface Compatibility and Performance in Soft Magnetic Composites with Inorganic Insulation Layers by FePO4 Intermediate Transition Layer. Molecules. 2024; 29(22):5281. https://doi.org/10.3390/molecules29225281

Chicago/Turabian StyleHuang, Sanao, Junjie Ma, Yang Liu, Hao He, Peisheng Lyu, Huaqin Huang, and Bing Dai. 2024. "Regulation of Interface Compatibility and Performance in Soft Magnetic Composites with Inorganic Insulation Layers by FePO4 Intermediate Transition Layer" Molecules 29, no. 22: 5281. https://doi.org/10.3390/molecules29225281

APA StyleHuang, S., Ma, J., Liu, Y., He, H., Lyu, P., Huang, H., & Dai, B. (2024). Regulation of Interface Compatibility and Performance in Soft Magnetic Composites with Inorganic Insulation Layers by FePO4 Intermediate Transition Layer. Molecules, 29(22), 5281. https://doi.org/10.3390/molecules29225281