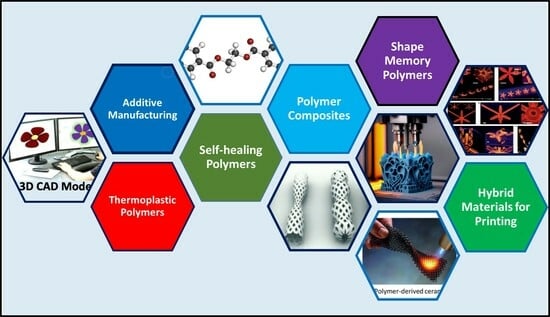

Polymer Composites in 3D/4D Printing: Materials, Advances, and Prospects

Abstract

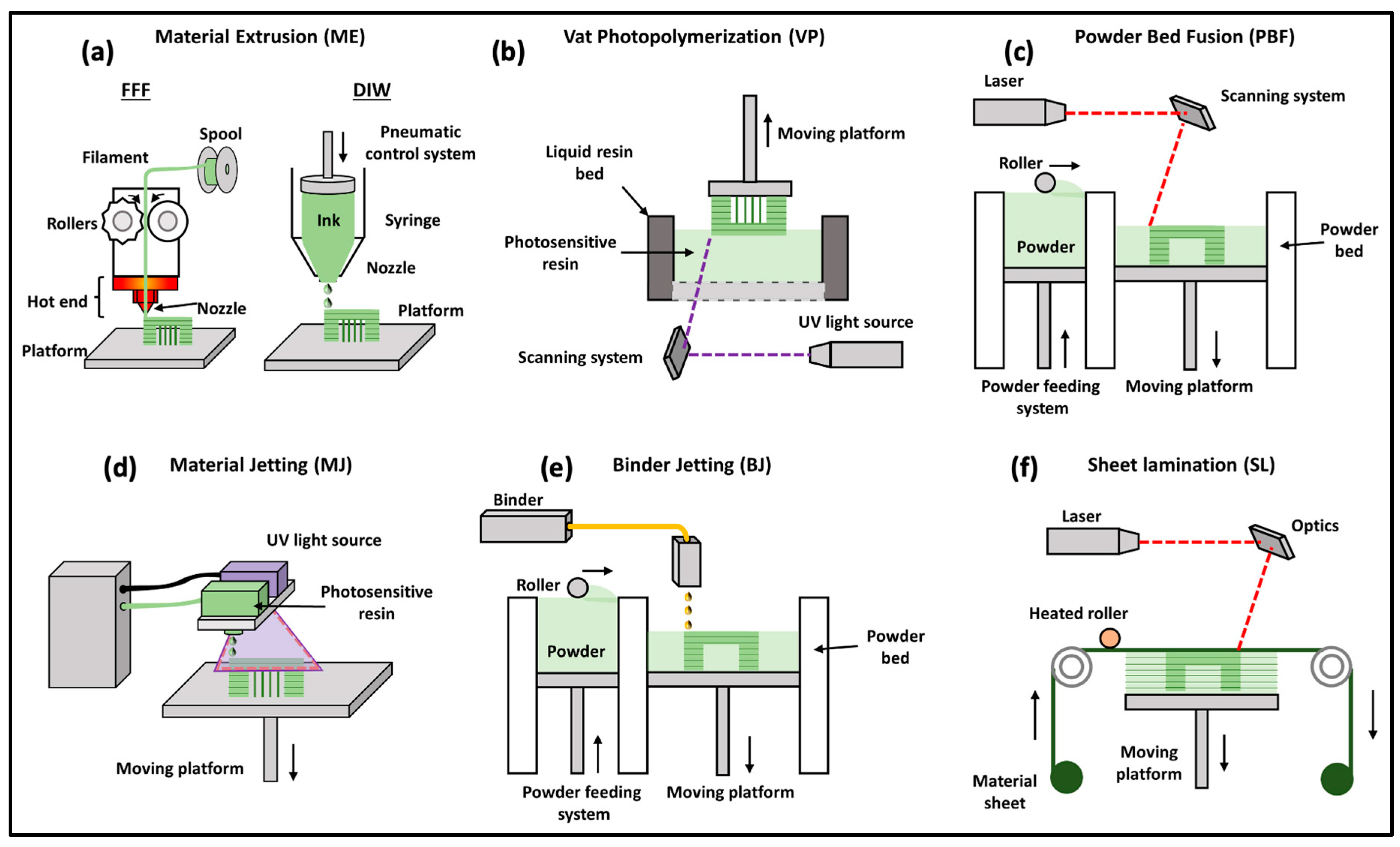

1. Introduction

The Evolution of Polymer 3D Printing: A Journey through Time

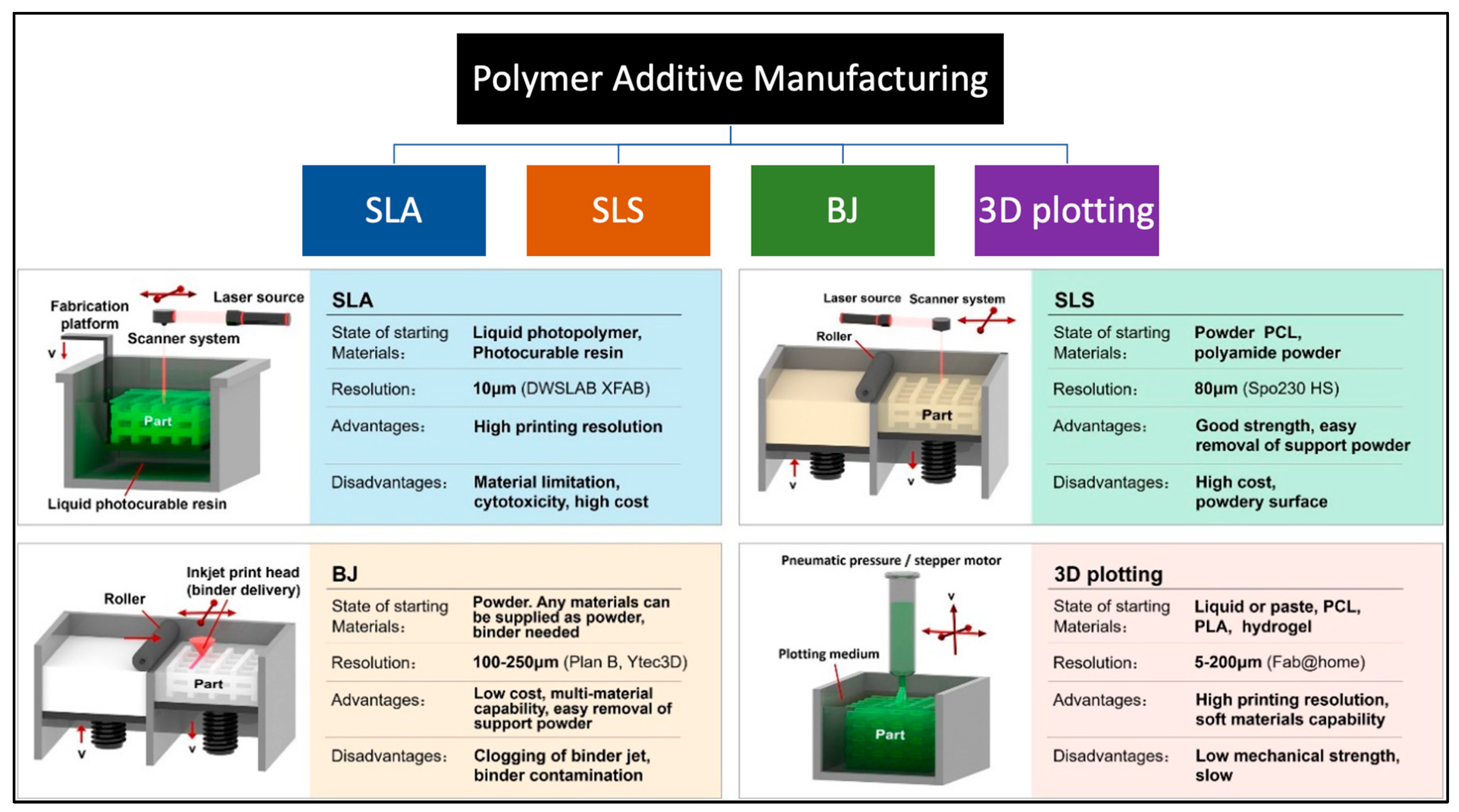

2. Polymer Materials and Design for 3D Printing

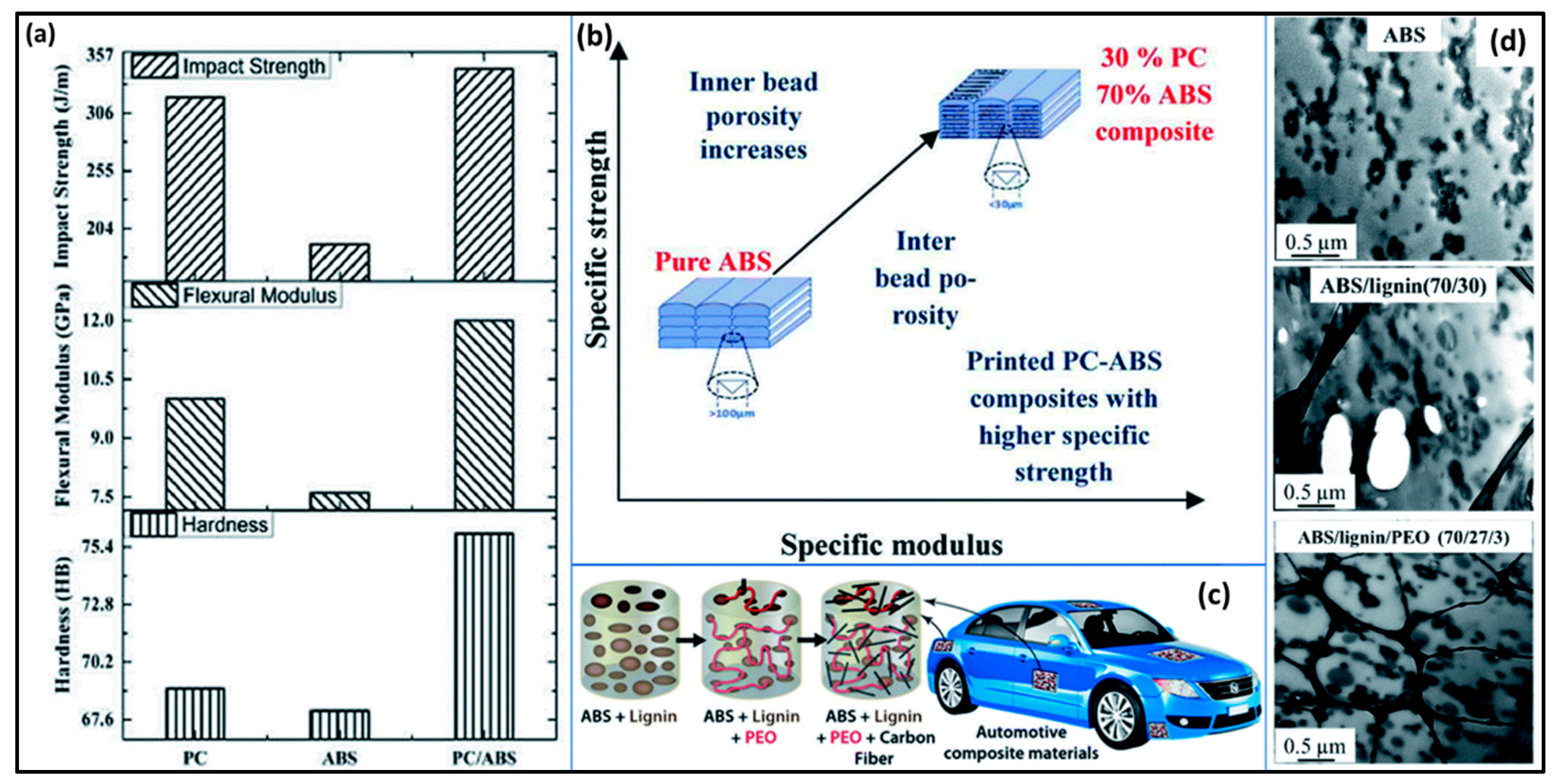

2.1. Thermoplastics

2.2. Thermosetting Polymers

2.3. Hydrogels

2.4. Elastomers

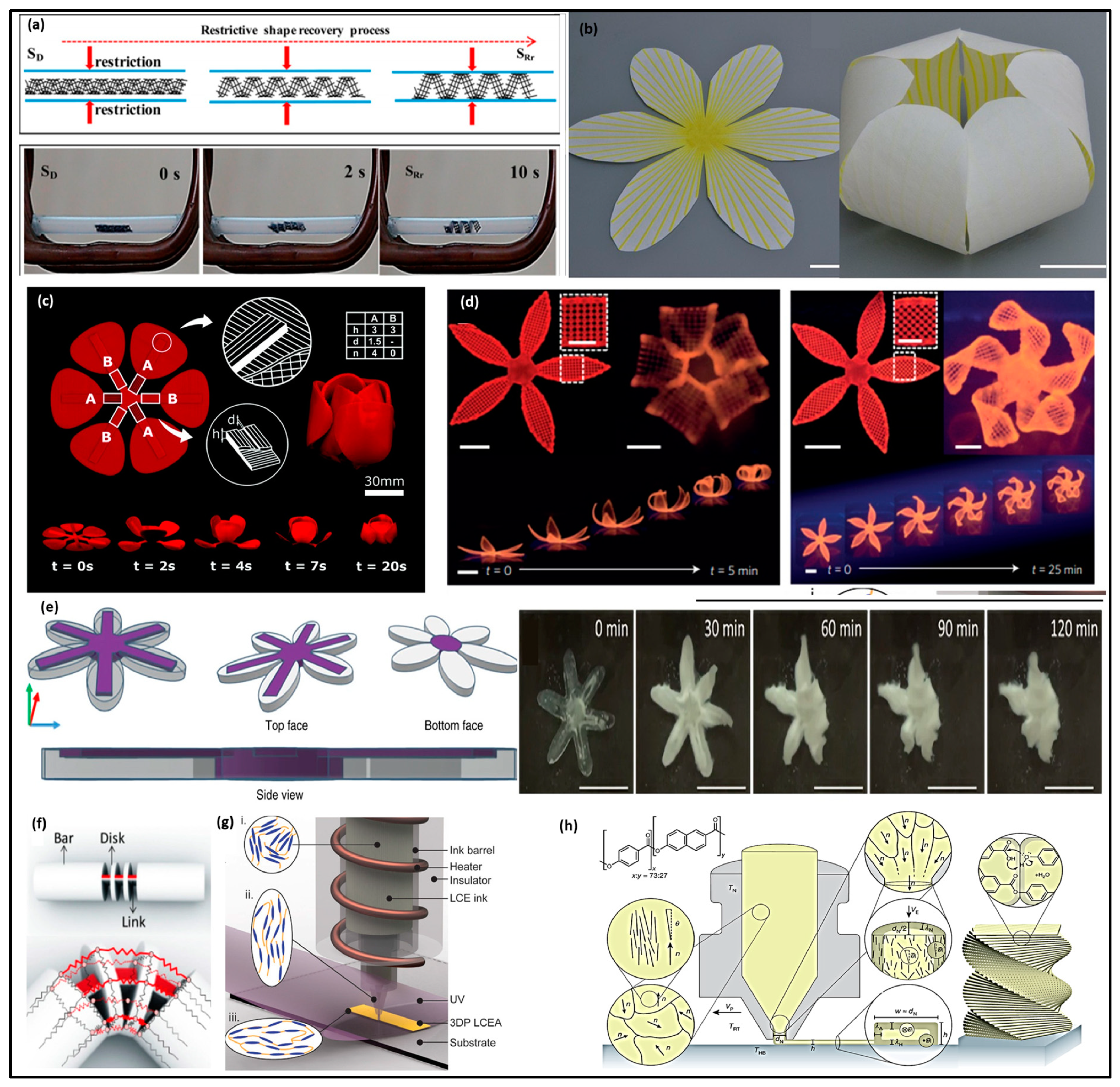

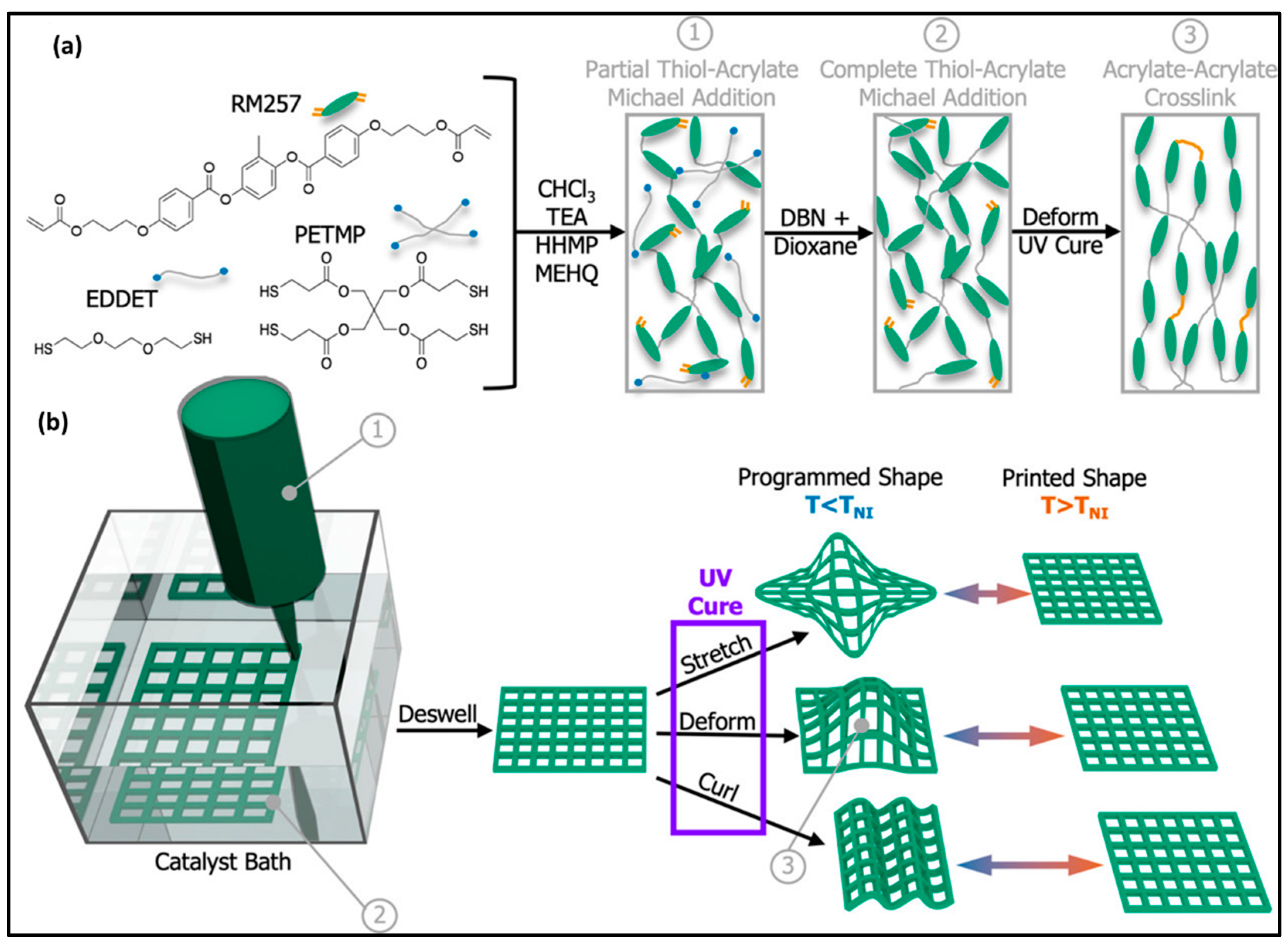

3. Smart Polymer Materials for 4D Printing

3.1. Shape Memory Polymers

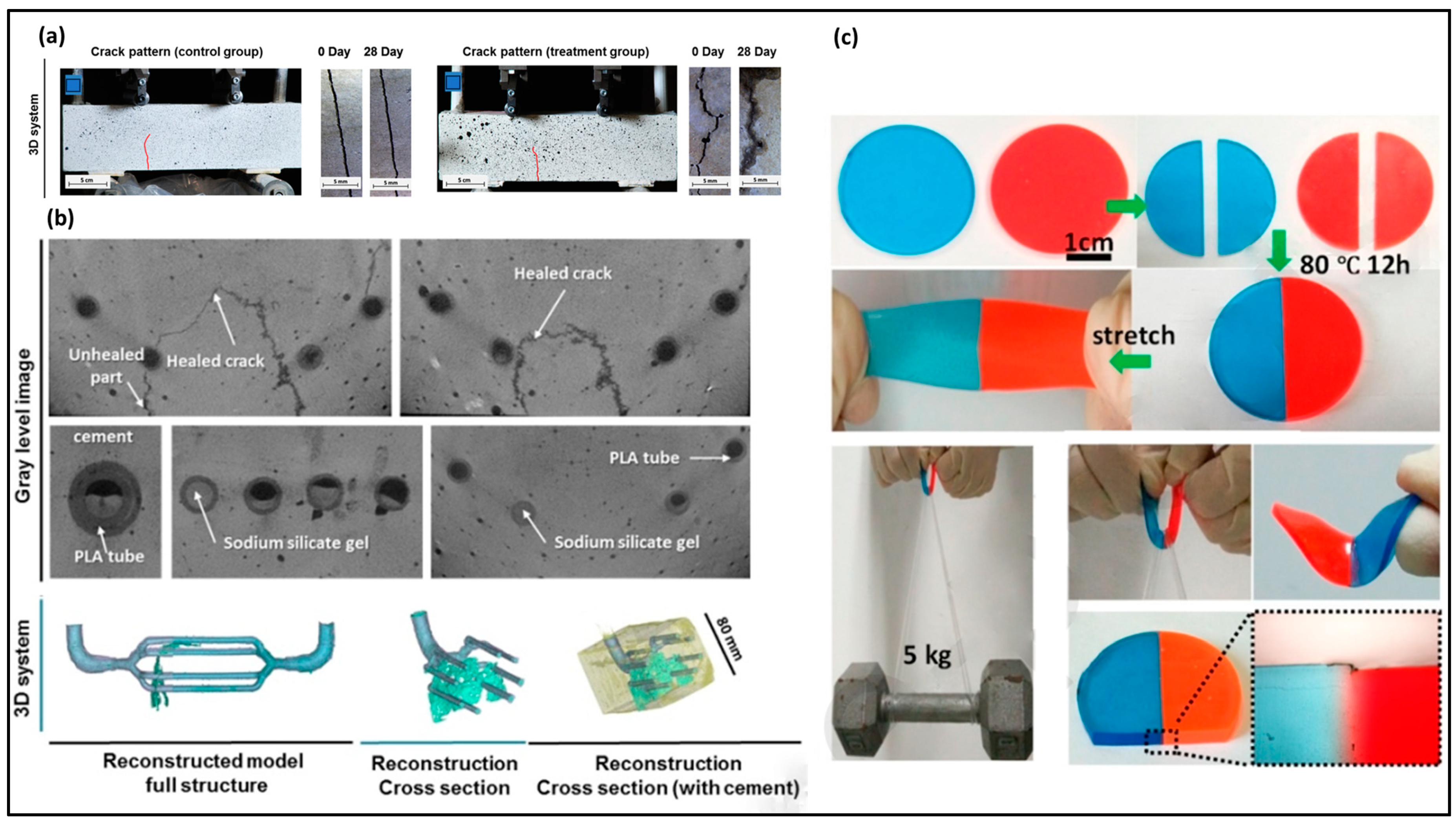

3.2. Self-Healing Polymer Materials

3.2.1. Microvascular Self-Healing Mechanisms

3.2.2. Encapsulation Self-Healing Mechanisms

3.2.3. Autonomous Self-Healing Polymers: Supramolecular Polymers

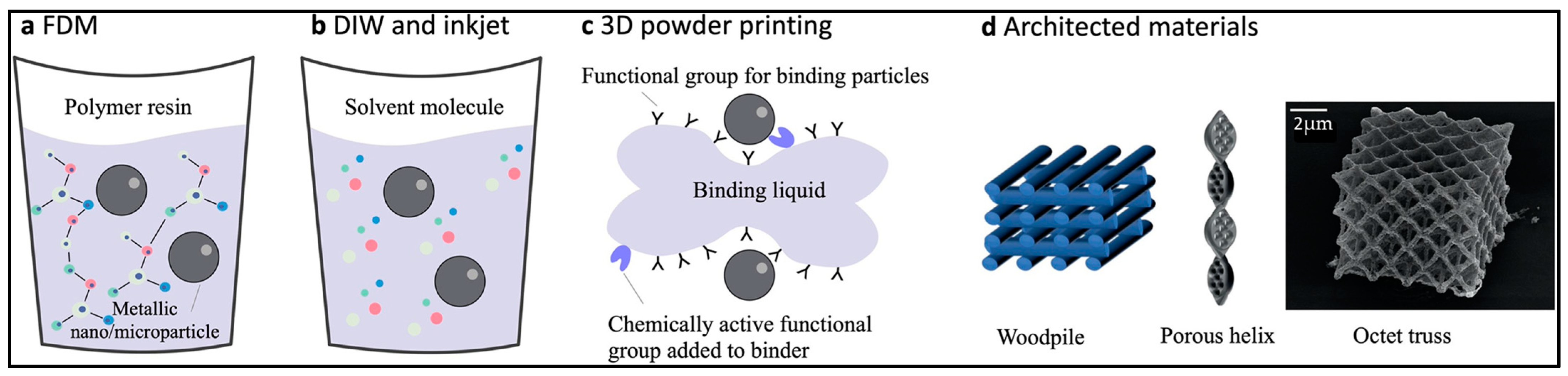

4. Hybrid Materials for Printing

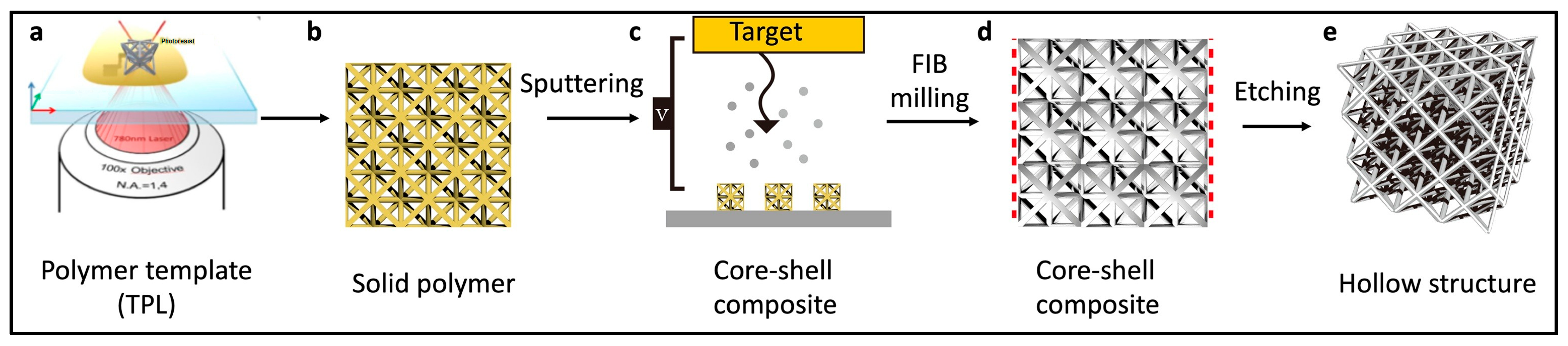

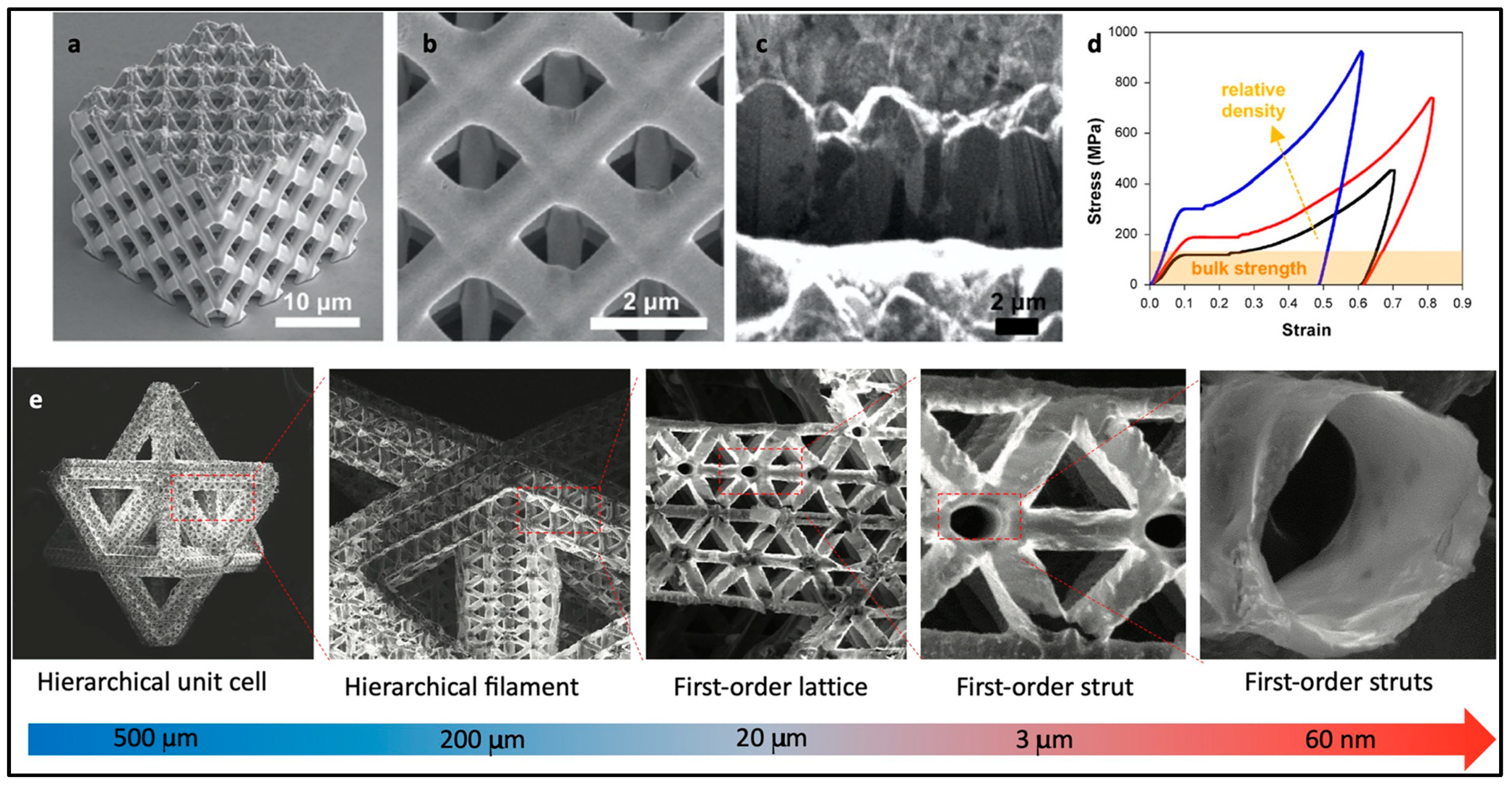

4.1. Polymer–Metal Composites

4.1.1. Three-Dimensional Printing of Polymer–Metal Composite Feedstocks

4.1.2. Surface Coating of Metals on 3D-Printed Polymers

4.2. Polymer–Ceramic Composites

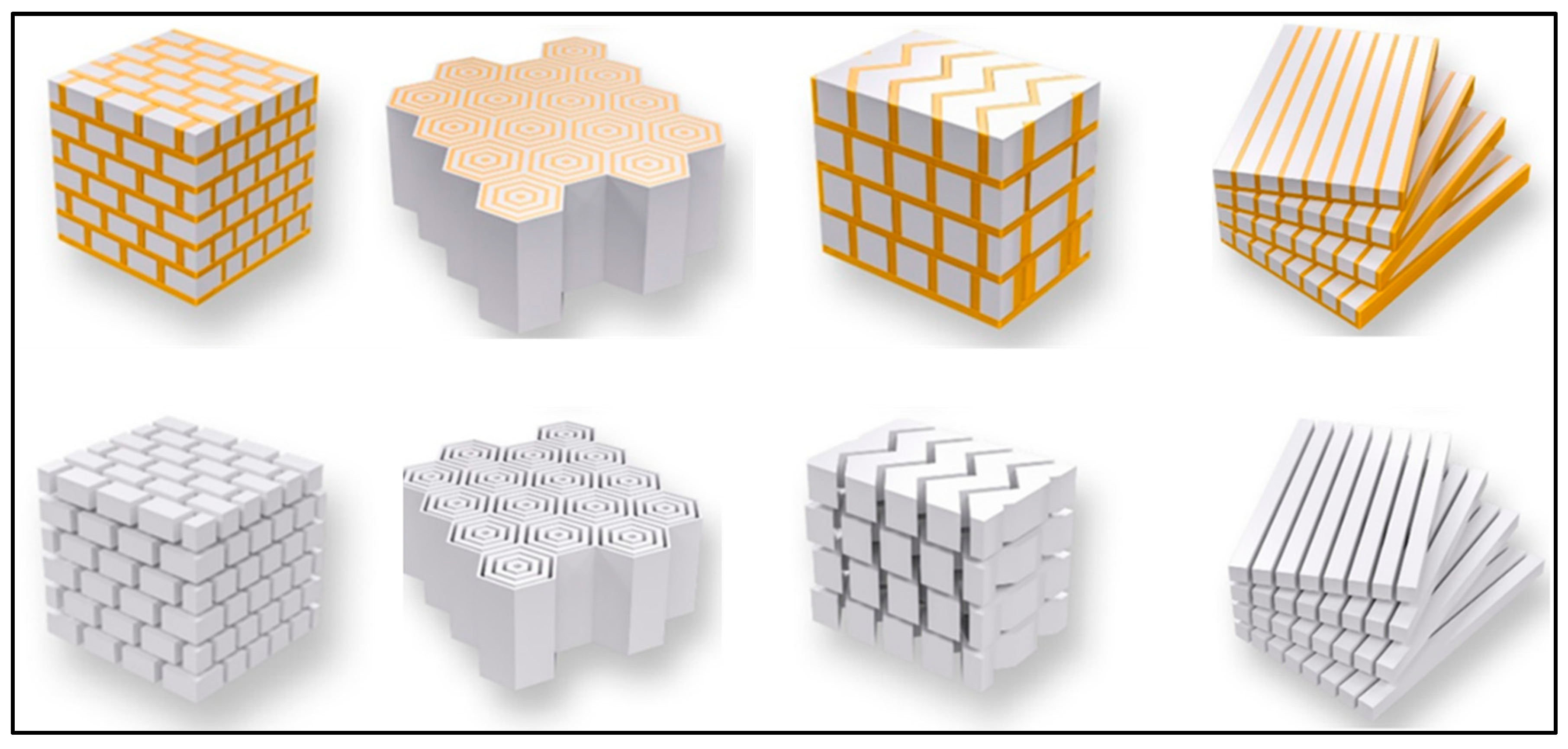

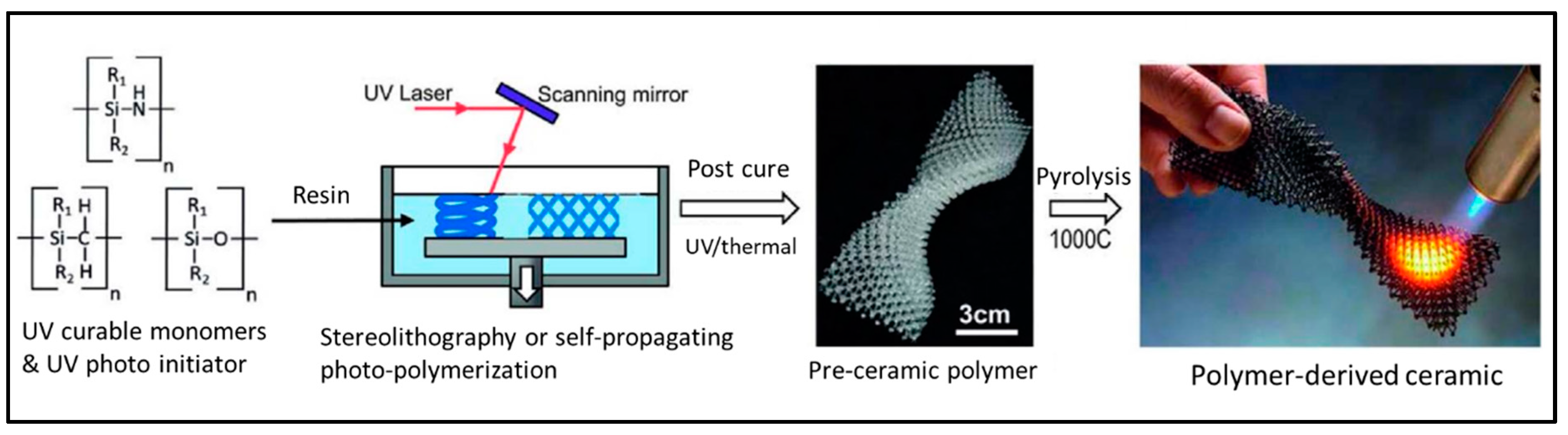

4.2.1. Three-Dimensional Printing of Polymer–Ceramic Composite Feedstocks

4.2.2. Multi-Material Printing of Polymer–Ceramic Composite Structures

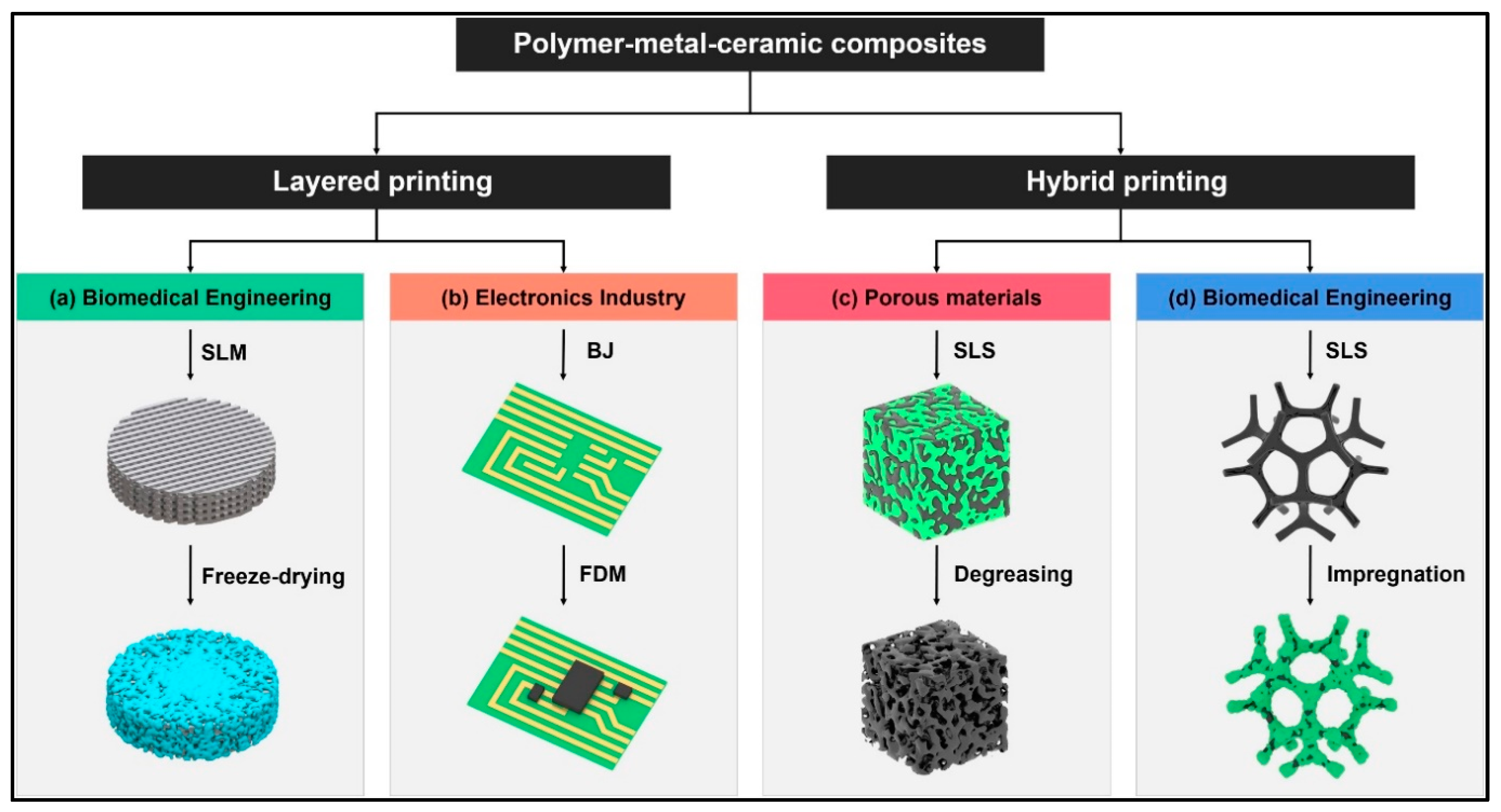

4.3. Polymer–Metal–Ceramic Composites

5. Three-Dimensional/Four-Dimensional Printing and Biomedicine

6. Future Perspectives of Polymer AM and Challenges Ahead

6.1. Material Diversity

6.2. Multi-Material and Multi-Scale AM for Various Applications

6.3. Improving AM Processes for High-Quality Prints

6.4. High-Throughput and Scalable Manufacturing

6.5. Sustainability

6.6. Safety Concerns

Author Contributions

Funding

Conflicts of Interest

References

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing; Springer Science+Business Media: New York, NY, USA, 2015; p. 498. [Google Scholar]

- Jacobs, P.F. Rapid Prototyping & Manufacturing: Fundamentals of Stereolithography; Society of Manufacturing Engineers: Southfield, MI, USA, 1993; ISBN 978-0-87263-425-1. [Google Scholar]

- Azman, A.H.; Vignat, F.; Villeneuve, F. CAD Tools and File Format Performance Evaluation in Designing Lattice Structures for Additive Manufacturing. J. Teknol. 2018, 80, 87–95. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.L.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The Status, Challenges, and Future of Additive Manufacturing in Engineering. Comput.-Aided Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Tibbits, S. 4D Printing: Multi-Material Shape Change. Archit. Des. 2014, 84, 116–121. [Google Scholar] [CrossRef]

- Mallakpour, S.; Tabesh, F.; Hussain, C.M. 3D and 4D Printing: From Innovation to Evolution. Adv. Colloid Interface Sci. 2021, 294, 102482. [Google Scholar] [CrossRef] [PubMed]

- Huang, S.H.; Liu, P.; Mokasdar, A.; Hou, L. Additive Manufacturing and Its Societal Impact: A Literature Review. Int. J. Adv. Manuf. Technol. 2013, 67, 1191–1203. [Google Scholar] [CrossRef]

- Kuang, X.; Roach, D.J.; Wu, J.; Hamel, C.M.; Ding, Z.; Wang, T.; Dunn, M.L.; Qi, H.J. Advances in 4D Printing: Materials and Applications. Adv. Funct. Mater. 2019, 29, 1805290. [Google Scholar] [CrossRef]

- Ryan, K.R.; Down, M.P.; Banks, C.E. Future of Additive Manufacturing: Overview of 4D and 3D Printed Smart and Advanced Materials and Their Applications. Chem. Eng. J. 2021, 403, 126162. [Google Scholar] [CrossRef]

- Imrie, P.; Jin, J. Polymer 4D Printing: Advanced Shape-Change and Beyond. J. Polym. Sci. 2022, 60, 149–174. [Google Scholar] [CrossRef]

- Mitchell, A.; Lafont, U.; Hołyńska, M.; Semprimoschnig, C. Additive Manufacturing—A Review of 4D Printing and Future Applications. Addit. Manuf. 2018, 24, 606–626. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Heer, B. Additive Manufacturing of Multi-Material Structures. Mater. Sci. Eng. R Rep. 2018, 129, 1–16. [Google Scholar] [CrossRef]

- Ambrosi, A.; Pumera, M. 3D-Printing Technologies for Electrochemical Applications. Chem. Soc. Rev. 2016, 45, 2740–2755. [Google Scholar] [CrossRef] [PubMed]

- Capel, A.J.; Rimington, R.P.; Lewis, M.P.; Christie, S.D.R. 3D Printing for Chemical, Pharmaceutical and Biological Applications. Nat. Rev. Chem. 2018, 2, 422–436. [Google Scholar] [CrossRef]

- Bhattacharjee, N.; Urrios, A.; Kang, S.; Folch, A. The Upcoming 3D-Printing Revolution in Microfluidics. Lab Chip 2016, 16, 1720–1742. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.Y.; An, J.; Chua, C.K. Fundamentals and Applications of 3D Printing for Novel Materials. Appl. Mater. Today 2017, 7, 120–133. [Google Scholar] [CrossRef]

- Ahmed, A.; Arya, S.; Gupta, V.; Furukawa, H.; Khosla, A. 4D Printing: Fundamentals, Materials, Applications and Challenges. Polymer 2021, 228, 123926. [Google Scholar] [CrossRef]

- Mahmood, A.; Akram, T.; Chen, H.; Chen, S. On the Evolution of Additive Manufacturing (3D/4D Printing) Technologies: Materials, Applications, and Challenges. Polymers 2022, 14, 4698. [Google Scholar] [CrossRef] [PubMed]

- Mahmood, A.; Akram, T.; Shenggui, C.; Chen, H. Revolutionizing Manufacturing: A Review of 4D Printing Materials, Stimuli, and Cutting-Edge Applications. Compos. Part B Eng. 2023, 266, 110952. [Google Scholar] [CrossRef]

- Feldman, D. Polymer History. Des. Monomers Polym. 2008, 11, 13. [Google Scholar] [CrossRef]

- Park, S.; Shou, W.; Makatura, L.; Matusik, W.; Fu, K.K. 3D Printing of Polymer Composites: Materials, Processes, and Applications. Matter 2022, 5, 43–76. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D Printing of Polymer Matrix Composites: A Review and Prospective. Compos. Part B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Pakkanen, J.; Manfredi, D.; Minetola, P.; Iuliano, L. About the Use of Recycled or Biodegradable Filaments for Sustainability of 3D Printing. In Sustainable Design and Manufacturing 2017; Campana, G., Howlett, R.J., Setchi, R., Cimatti, B., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 776–785. [Google Scholar]

- Wohlers, T.; Gornet, T.; Mostow, N.; Campbell, I.; Diegel, O.; Kowen, J.; Huff, R.; Stucker, B.; Fidan, I.; Doukas, A.; et al. History of Additive Manufacturing; Wohlers Associates, Inc.: Fort Collins, CO, USA, 2016. [Google Scholar]

- Zhang, Q.; Zhang, K.; Hu, G. Smart Three-Dimensional Lightweight Structure Triggered from a Thin Composite Sheet via 3D Printing Technique. Sci. Rep. 2016, 6, 22431. [Google Scholar] [CrossRef] [PubMed]

- van Manen, T.; Janbaz, S.; Zadpoor, A.A. Programming 2D/3D Shape-Shifting with Hobbyist 3D Printers. Mater. Horiz. 2017, 4, 1064–1069. [Google Scholar] [CrossRef] [PubMed]

- Long, K.N.; Scott, T.F.; Jerry Qi, H.; Bowman, C.N.; Dunn, M.L. Photomechanics of Light-Activated Polymers. J. Mech. Phys. Solids 2009, 57, 1103–1121. [Google Scholar] [CrossRef]

- Wei, H.; Zhang, Q.; Yao, Y.; Liu, L.; Liu, Y.; Leng, J. Direct-Write Fabrication of 4D Active Shape-Changing Structures Based on a Shape Memory Polymer and Its Nanocomposite. ACS Appl. Mater. Interfaces 2017, 9, 876–883. [Google Scholar] [CrossRef]

- Sydney Gladman, A.; Matsumoto, E.A.; Nuzzo, R.G.; Mahadevan, L.; Lewis, J.A. Biomimetic 4D Printing. Nat. Mater. 2016, 15, 413–418. [Google Scholar] [CrossRef] [PubMed]

- Schwartz, J.J.; Boydston, A.J. Multimaterial Actinic Spatial Control 3D and 4D Printing. Nat. Commun. 2019, 10, 791. [Google Scholar] [CrossRef]

- Raviv, D.; Zhao, W.; McKnelly, C.; Papadopoulou, A.; Kadambi, A.; Shi, B.; Hirsch, S.; Dikovsky, D.; Zyracki, M.; Olguin, C.; et al. Active Printed Materials for Complex Self-Evolving Deformations. Sci. Rep. 2014, 4, 7422. [Google Scholar] [CrossRef]

- van Oosten, C.L.; Bastiaansen, C.W.M.; Broer, D.J. Printed Artificial Cilia from Liquid-Crystal Network Actuators Modularly Driven by Light. Nat. Mater. 2009, 8, 677–682. [Google Scholar] [CrossRef]

- Yuan, C.; Roach, D.J.; Dunn, C.K.; Mu, Q.; Kuang, X.; Yakacki, C.M.; Wang, T.J.; Yu, K.; Qi, H.J. 3D Printed Reversible Shape Changing Soft Actuators Assisted by Liquid Crystal Elastomers. Soft Matter 2017, 13, 5558–5568. [Google Scholar] [CrossRef]

- Kotikian, A.; Truby, R.L.; Boley, J.W.; White, T.J.; Lewis, J.A. 3D Printing of Liquid Crystal Elastomeric Actuators with Spatially Programed Nematic Order. Adv. Mater. 2018, 30, 1706164. [Google Scholar] [CrossRef]

- Gantenbein, S.; Masania, K.; Woigk, W.; Sesseg, J.P.W.; Tervoort, T.A.; Studart, A.R. Three-Dimensional Printing of Hierarchical Liquid-Crystal-Polymer Structures. Nature 2018, 561, 226–230. [Google Scholar] [CrossRef] [PubMed]

- Rim, Y.S.; Bae, S.-H.; Chen, H.; De Marco, N.; Yang, Y. Recent Progress in Materials and Devices toward Printable and Flexible Sensors. Adv. Mater. 2016, 28, 4415–4440. [Google Scholar] [CrossRef] [PubMed]

- Mao, S.; Dong, E.; Jin, H.; Xu, M.; Low, K.H. Locomotion and Gait Analysis of Multi-Limb Soft Robots Driven by Smart Actuators. In Proceedings of the 2016 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Daejeon, Republic of Korea, 9–14 October 2016; pp. 2438–2443. [Google Scholar]

- Gao, B.; Yang, Q.; Zhao, X.; Jin, G.; Ma, Y.; Xu, F. 4D Bioprinting for Biomedical Applications. Trends Biotechnol. 2016, 34, 746–756. [Google Scholar] [CrossRef] [PubMed]

- Bahnini, I.; Rivette, M.; Rechia, A.; Siadat, A.; Elmesbahi, A. Additive Manufacturing Technology: The Status, Applications, and Prospects. Int. J. Adv. Manuf. Technol. 2018, 97, 147–161. [Google Scholar] [CrossRef]

- Mercado Rivera, F.J.; Rojas Arciniegas, A.J. Additive Manufacturing Methods: Techniques, Materials, and Closed-Loop Control Applications. Int. J. Adv. Manuf. Technol. 2020, 109, 17–31. [Google Scholar] [CrossRef]

- Gebhardt, A.; Hötter, J.-S. (Eds.) Additive Manufacturing; Hanser: Munich, Germany, 2016; pp. I–XX. ISBN 978-1-56990-582-1. [Google Scholar]

- Yuan, S.; Shen, F.; Chua, C.K.; Zhou, K. Polymeric Composites for Powder-Based Additive Manufacturing: Materials and Applications. Prog. Polym. Sci. 2019, 91, 141–168. [Google Scholar] [CrossRef]

- Saha, S.K.; Wang, D.; Nguyen, V.H.; Chang, Y.; Oakdale, J.S.; Chen, S.C. Scalable Submicrometer Additive Manufacturing. Science 2019, 366, 105–109. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Qiu, J.; Wei, J.; Wang, S. Additive Manufacturing of Carbon Fiber Reinforced Thermoplastic Composites Using Fused Deposition Modeling. Compos. Part B Eng. 2015, 80, 369–378. [Google Scholar] [CrossRef]

- Tekinalp, H.L.; Kunc, V.; Velez-Garcia, G.M.; Duty, C.E.; Love, L.J.; Naskar, A.K.; Blue, C.A.; Ozcan, S. Highly Oriented Carbon Fiber–Polymer Composites via Additive Manufacturing. Compos. Sci. Technol. 2014, 105, 144–150. [Google Scholar] [CrossRef]

- Nikzad, M.; Masood, S.H.; Sbarski, I. Thermo-Mechanical Properties of a Highly Filled Polymeric Composites for Fused Deposition Modeling. Mater. Des. 2011, 32, 3448–3456. [Google Scholar] [CrossRef]

- Castles, F.; Isakov, D.; Lui, A.; Lei, Q.; Dancer, C.E.J.; Wang, Y.; Janurudin, J.M.; Speller, S.C.; Grovenor, C.R.M.; Grant, P.S. Microwave Dielectric Characterisation of 3D-Printed BaTiO3/ABS Polymer Composites. Sci. Rep. 2016, 6, 22714. [Google Scholar] [CrossRef] [PubMed]

- Chung, H.; Das, S. Processing and Properties of Glass Bead Particulate-Filled Functionally Graded Nylon-11 Composites Produced by Selective Laser Sintering. Mater. Sci. Eng. A 2006, 437, 226–234. [Google Scholar] [CrossRef]

- Tian, X.; Liu, T.; Yang, C.; Wang, Q.; Li, D. Interface and Performance of 3D Printed Continuous Carbon Fiber Reinforced PLA Composites. Compos. Part A Appl. Sci. Manuf. 2016, 88, 198–205. [Google Scholar] [CrossRef]

- Compton, B.G.; Lewis, J.A. 3D-Printing of Lightweight Cellular Composites. Adv. Mater. 2014, 26, 5930–5935. [Google Scholar] [CrossRef]

- Klift, F.V.D.; Koga, Y.; Todoroki, A.; Ueda, M.; Hirano, Y.; Matsuzaki, R. 3D Printing of Continuous Carbon Fibre Reinforced Thermo-Plastic (CFRTP) Tensile Test Specimens. Open J. Compos. Mater. 2015, 6, 18–27. [Google Scholar] [CrossRef]

- Lin, D.; Jin, S.; Zhang, F.; Wang, C.; Wang, Y.; Zhou, C.; Cheng, G.J. 3D Stereolithography Printing of Graphene Oxide Reinforced Complex Architectures. Nanotechnology 2015, 26, 434003. [Google Scholar] [CrossRef] [PubMed]

- Wei, X.; Li, D.; Jiang, W.; Gu, Z.; Wang, X.; Zhang, Z.; Sun, Z. 3D Printable Graphene Composite. Sci. Rep. 2015, 5, 11181. [Google Scholar] [CrossRef]

- Fantino, E.; Chiappone, A.; Calignano, F.; Fontana, M.; Pirri, F.; Roppolo, I. In Situ Thermal Generation of Silver Nanoparticles in 3D Printed Polymeric Structures. Materials 2016, 9, 589. [Google Scholar] [CrossRef]

- Eutionnat-Diffo, P.A.; Chen, Y.; Guan, J.; Cayla, A.; Campagne, C.; Zeng, X.; Nierstrasz, V. Stress, Strain and Deformation of Poly-Lactic Acid Filament Deposited onto Polyethylene Terephthalate Woven Fabric through 3D Printing Process. Sci. Rep. 2019, 9, 14333. [Google Scholar] [CrossRef]

- Rocha, C.R.; Perez, A.R.T.; Roberson, D.A.; Shemelya, C.M.; MacDonald, E.; Wicker, R.B. Novel ABS-Based Binary and Ternary Polymer Blends for Material Extrusion 3D Printing. J. Mater. Res. 2014, 29, 1859–1866. [Google Scholar] [CrossRef]

- Weng, Z.; Wang, J.; Senthil, T.; Wu, L. Mechanical and Thermal Properties of ABS/Montmorillonite Nanocomposites for Fused Deposition Modeling 3D Printing. Mater. Des. 2016, 102, 276–283. [Google Scholar] [CrossRef]

- Alexandre, M.; Dubois, P. Polymer-Layered Silicate Nanocomposites: Preparation, Properties and Uses of a New Class of Materials. Mater. Sci. Eng. R Rep. 2000, 28, 1–63. [Google Scholar] [CrossRef]

- Pasanen, T.P.; von Gastrow, G.; Heikkinen, I.T.S.; Vähänissi, V.; Savin, H.; Pearce, J.M. Compatibility of 3-D Printed Devices in Cleanroom Environments for Semiconductor Processing. Mater. Sci. Semicond. Process. 2019, 89, 59–67. [Google Scholar] [CrossRef]

- Cardoso, R.M.; Mendonça, D.M.H.; Silva, W.P.; Silva, M.N.T.; Nossol, E.; da Silva, R.A.B.; Richter, E.M.; Muñoz, R.A.A. 3D Printing for Electroanalysis: From Multiuse Electrochemical Cells to Sensors. Anal. Chim. Acta 2018, 1033, 49–57. [Google Scholar] [CrossRef] [PubMed]

- Arulmozhi, R.S.; Vaidya, M.; Poojalakshmi, M.G.; Ashok Kumar, D.; Anuraag, K. 3d Design and Printing of Custom-Fit Finger Splint. Biomed. Eng. Appl. Basis Commun. 2018, 30, 1850032. [Google Scholar] [CrossRef]

- Singh, R.; Singh, H.; Farina, I.; Colangelo, F.; Fraternali, F. On the Additive Manufacturing of an Energy Storage Device from Recycled Material. Compos. Part B Eng. 2019, 156, 259–265. [Google Scholar] [CrossRef]

- Bible, M.; Sefa, M.; Fedchak, J.A.; Scherschligt, J.; Natarajan, B.; Ahmed, Z.; Hartings, M.R. 3D-Printed Acrylonitrile Butadiene Styrene-Metal Organic Framework Composite Materials and Their Gas Storage Properties. 3D Print. Addit. Manuf. 2018, 5, 63–72. [Google Scholar] [CrossRef]

- Provaggi, E.; Capelli, C.; Rahmani, B.; Burriesci, G.; Kalaskar, D.M. 3D Printing Assisted Finite Element Analysis for Optimising the Manufacturing Parameters of a Lumbar Fusion Cage. Mater. Des. 2019, 163, 107540. [Google Scholar] [CrossRef]

- Dawoud, M.; Taha, I.; Ebeid, S.J. Strain Sensing Behaviour of 3D Printed Carbon Black Filled ABS. J. Manuf. Process. 2018, 35, 337–342. [Google Scholar] [CrossRef]

- Haque, R.I.; Chandran, O.; Lani, S.; Briand, D. Self-Powered Triboelectric Touch Sensor Made of 3D Printed Materials. Nano Energy 2018, 52, 54–62. [Google Scholar] [CrossRef]

- Khatri, B.; Lappe, K.; Habedank, M.; Mueller, T.; Megnin, C.; Hanemann, T. Fused Deposition Modeling of ABS-Barium Titanate Composites: A Simple Route towards Tailored Dielectric Devices. Polymers 2018, 10, 666. [Google Scholar] [CrossRef] [PubMed]

- Kumar, M.; Ramakrishnan, R.; Omarbekova, A. 3D Printed Polycarbonate Reinforced Acrylonitrile–Butadiene–Styrene Composites: Composition Effects on Mechanical Properties, Micro-Structure and Void Formation Study. J. Mech. Sci. Technol. 2019, 33, 5219–5226. [Google Scholar] [CrossRef]

- Chen, S.; Lu, J.; Feng, J. 3D-Printable ABS Blends with Improved Scratch Resistance and Balanced Mechanical Performance. Ind. Eng. Chem. Res. 2018, 57, 3923–3931. [Google Scholar] [CrossRef]

- Akato, K.; Tran, C.D.; Chen, J.; Naskar, A.K. Poly(Ethylene Oxide)-Assisted Macromolecular Self-Assembly of Lignin in ABS Matrix for Sustainable Composite Applications. ACS Sustain. Chem. Eng. 2015, 3, 3070–3076. [Google Scholar] [CrossRef]

- Shim, J.S.; Kim, J.-E.; Jeong, S.H.; Choi, Y.J.; Ryu, J.J. Printing Accuracy, Mechanical Properties, Surface Characteristics, and Microbial Adhesion of 3D-Printed Resins with Various Printing Orientations. J. Prosthet. Dent. 2020, 124, 468–475. [Google Scholar] [CrossRef] [PubMed]

- Bîrcă, A.; Gherasim, O.; Grumezescu, V.; Grumezescu, A.M. Chapter 1—Introduction in Thermoplastic and Thermosetting Polymers. In Materials for Biomedical Engineering; Grumezescu, V., Grumezescu, A.M., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–28. ISBN 978-0-12-816874-5. [Google Scholar]

- Fu, S.; Hu, H.; Chen, J.; Zhu, Y.; Zhao, S. Silicone Resin Derived Larnite/C Scaffolds via 3D Printing for Potential Tumor Therapy and Bone Regeneration. Chem. Eng. J. 2020, 382, 122928. [Google Scholar] [CrossRef]

- Lin, C.-H.; Lin, Y.-M.; Lai, Y.-L.; Lee, S.-Y. Mechanical Properties, Accuracy, and Cytotoxicity of UV-Polymerized 3D Printing Resins Composed of Bis-EMA, UDMA, and TEGDMA. J. Prosthet. Dent. 2020, 123, 349–354. [Google Scholar] [CrossRef]

- Hmeidat, N.S.; Kemp, J.W.; Compton, B.G. High-Strength Epoxy Nanocomposites for 3D Printing. Compos. Sci. Technol. 2018, 160, 9–20. [Google Scholar] [CrossRef]

- Li, J.; Wu, C.; Chu, P.K.; Gelinsky, M. 3D Printing of Hydrogels: Rational Design Strategies and Emerging Biomedical Applications. Mater. Sci. Eng. R Rep. 2020, 140, 100543. [Google Scholar] [CrossRef]

- Bahram, M.; Mohseni, N.; Moghtader, M.; Bahram, M.; Mohseni, N.; Moghtader, M. An Introduction to Hydrogels and Some Recent Applications. In Emerging Concepts in Analysis and Applications of Hydrogels; IntechOpen: Rijeka, Croatia, 2016; ISBN 978-953-51-2510-5. [Google Scholar]

- Ahmed, E.M. Hydrogel: Preparation, Characterization, and Applications: A Review. J. Adv. Res. 2015, 6, 105–121. [Google Scholar] [CrossRef]

- Holländer, J.; Hakala, R.; Suominen, J.; Moritz, N.; Yliruusi, J.; Sandler, N. 3D Printed UV Light Cured Polydimethylsiloxane Devices for Drug Delivery. Int. J. Pharm. 2018, 544, 433–442. [Google Scholar] [CrossRef] [PubMed]

- Xiang, H.; Wang, X.; Ou, Z.; Lin, G.; Yin, J.; Liu, Z.; Zhang, L.; Liu, X. UV-Curable, 3D Printable and Biocompatible Silicone Elastomers. Prog. Org. Coat. 2019, 137, 105372. [Google Scholar] [CrossRef]

- Khoo, Z.X.; Teoh, J.E.M.; Liu, Y.; Chua, C.K.; Yang, S.; An, J.; Leong, K.F.; Yeong, W.Y. 3D Printing of Smart Materials: A Review on Recent Progresses in 4D Printing. Virtual Phys. Prototyp. 2015, 10, 103–122. [Google Scholar] [CrossRef]

- Mondal, S.; Hu, J.L. Temperature Stimulating Shape Memory Polyurethane for Smart Clothing. Indian J. Fibre Text. Res. (IJFTR) 2006, 31, 66–71. [Google Scholar]

- Campbell, D.; Lake, M.; Scherbarth, M.; Nelson, E.; Six, R. Elastic Memory Composite Material: An Enabling Technology for Future Furlable Space Structures. In Proceedings of the 46th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Austin, TX, USA, 18–21 April 2005; American Institute of Aeronautics and Astronautics: Reston VA, USA, 2005. [Google Scholar]

- Wache, H.M.; Tartakowska, D.J.; Hentrich, A.; Wagner, M.H. Development of a Polymer Stent with Shape Memory Effect as a Drug Delivery System. J. Mater. Sci. Mater. Med. 2003, 14, 109–112. [Google Scholar] [CrossRef]

- Singh, M.; Haverinen, H.M.; Dhagat, P.; Jabbour, G.E. Inkjet Printing—Process and Its Applications. Adv. Mater. 2010, 22, 673–685. [Google Scholar] [CrossRef]

- Cutkosky, M.R.; Kim, S. Design and Fabrication of Multi-Material Structures for Bioinspired Robots. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2009, 367, 1799–1813. [Google Scholar] [CrossRef]

- Peng, W.; Zhang, G.; Liu, J.; Nie, S.; Wu, Y.; Deng, S.; Fang, G.; Zhou, J.; Song, J.; Qian, J.; et al. Light-Coded Digital Crystallinity Patterns Toward Bioinspired 4D Transformation of Shape-Memory Polymers. Adv. Funct. Mater. 2020, 30, 2000522. [Google Scholar] [CrossRef]

- Wong, Y.S.; Venkatraman, S.S. Recovery as a Measure of Oriented Crystalline Structure in Poly(l-Lactide) Used as Shape Memory Polymer. Acta Mater. 2010, 58, 49–58. [Google Scholar] [CrossRef]

- Vashist, A.; Vashist, A.; Gupta, Y.K.; Ahmad, S. Recent Advances in Hydrogel Based Drug Delivery Systems for the Human Body. J. Mater. Chem. B 2013, 2, 147–166. [Google Scholar] [CrossRef]

- Bassil, M.; Davenas, J.; EL Tahchi, M. Electrochemical Properties and Actuation Mechanisms of Polyacrylamide Hydrogel for Artificial Muscle Application. Sens. Actuators B Chem. 2008, 134, 496–501. [Google Scholar] [CrossRef]

- Azeem, M.K.; Islam, A.; Khan, R.U.; Rasool, A.; Qureshi, M.A.u.R.; Rizwan, M.; Sher, F.; Rasheed, T. Eco-Friendly Three-Dimensional Hydrogels for Sustainable Agricultural Applications: Current and Future Scenarios. Polym. Adv. Technol. 2023, 34, 3046–3062. [Google Scholar] [CrossRef]

- Palanivelu, S.D.; Armir, N.A.Z.; Zulkifli, A.; Hair, A.H.A.; Salleh, K.M.; Lindsey, K.; Che-Othman, M.H.; Zakaria, S. Hydrogel Application in Urban Farming: Potentials and Limitations—A Review. Polymers 2022, 14, 2590. [Google Scholar] [CrossRef] [PubMed]

- Roach, D.J.; Kuang, X.; Yuan, C.; Chen, K.; Qi, H.J. Novel Ink for Ambient Condition Printing of Liquid Crystal Elastomers for 4D Printing. Smart Mater. Struct. 2018, 27, 125011. [Google Scholar] [CrossRef]

- Ambulo, C.P.; Burroughs, J.J.; Boothby, J.M.; Kim, H.; Shankar, M.R.; Ware, T.H. Four-Dimensional Printing of Liquid Crystal Elastomers. ACS Appl. Mater. Interfaces 2017, 9, 37332–37339. [Google Scholar] [CrossRef] [PubMed]

- Pei, Z.; Yang, Y.; Chen, Q.; Terentjev, E.M.; Wei, Y.; Ji, Y. Mouldable Liquid-Crystalline Elastomer Actuators with Exchangeable Covalent Bonds. Nat. Mater. 2014, 13, 36–41. [Google Scholar] [CrossRef] [PubMed]

- Guin, T.; Settle, M.J.; Kowalski, B.A.; Auguste, A.D.; Beblo, R.V.; Reich, G.W.; White, T.J. Layered Liquid Crystal Elastomer Actuators. Nat. Commun. 2018, 9, 2531. [Google Scholar] [CrossRef]

- Kirton, J. The Physics of Liquid Crystals. Opt. Acta Int. J. Opt. 1975, 22, 158. [Google Scholar] [CrossRef]

- López-Valdeolivas, M.; Liu, D.; Broer, D.J.; Sánchez-Somolinos, C. 4D Printed Actuators with Soft-Robotic Functions. Macromol. Rapid Commun. 2018, 39, 1700710. [Google Scholar] [CrossRef]

- Yang, Y.; Pei, Z.; Li, Z.; Wei, Y.; Ji, Y. Making and Remaking Dynamic 3D Structures by Shining Light on Flat Liquid Crystalline Vitrimer Films without a Mold. J. Am. Chem. Soc. 2016, 138, 2118–2121. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, H.; Wang, H.; Chan, J.Y.E.; Liu, H.; Zhang, B.; Zhang, Y.-F.; Agarwal, K.; Yang, X.; Ranganath, A.S.; et al. Structural Multi-Colour Invisible Inks with Submicron 4D Printing of Shape Memory Polymers. Nat. Commun. 2021, 12, 112. [Google Scholar] [CrossRef] [PubMed]

- Barnes, M.; Sajadi, S.M.; Parekh, S.; Rahman, M.M.; Ajayan, P.M.; Verduzco, R. Reactive 3D Printing of Shape-Programmable Liquid Crystal Elastomer Actuators. ACS Appl. Mater. Interfaces 2020, 12, 28692–28699. [Google Scholar] [CrossRef] [PubMed]

- Hagaman, D.E.; Leist, S.; Zhou, J.; Ji, H.-F. Photoactivated Polymeric Bilayer Actuators Fabricated via 3D Printing. ACS Appl. Mater. Interfaces 2018, 10, 27308–27315. [Google Scholar] [CrossRef] [PubMed]

- Ceamanos, L.; Kahveci, Z.; López-Valdeolivas, M.; Liu, D.; Broer, D.J.; Sánchez-Somolinos, C. Four-Dimensional Printed Liquid Crystalline Elastomer Actuators with Fast Photoinduced Mechanical Response toward Light-Driven Robotic Functions. ACS Appl. Mater. Interfaces 2020, 12, 44195–44204. [Google Scholar] [CrossRef]

- Lu, X.; Ambulo, C.P.; Wang, S.; Rivera-Tarazona, L.K.; Kim, H.; Searles, K.; Ware, T.H. 4D-Printing of Photoswitchable Actuators. Angew. Chem. Int. Ed. 2021, 60, 5536–5543. [Google Scholar] [CrossRef] [PubMed]

- Hager, M.D.; Greil, P.; Leyens, C.; Van Der Zwaag, S.; Schubert, U.S. Self-Healing Materials. Adv. Mater. 2010, 22, 5424–5430. [Google Scholar] [CrossRef]

- Blaiszik, B.J.; Kramer, S.L.B.; Olugebefola, S.C.; Moore, J.S.; Sottos, N.R.; White, S.R. Self-Healing Polymers and Composites. Annu. Rev. Mater. Res. 2010, 40, 179–211. [Google Scholar] [CrossRef]

- De Nardi, C.; Gardner, D.; Jefferson, A.D. Development of 3D Printed Networks in Self-Healing Concrete. Materials 2020, 13, 1328. [Google Scholar] [CrossRef]

- Postiglione, G.; Alberini, M.; Leigh, S.; Levi, M.; Turri, S. Effect of 3D-Printed Microvascular Network Design on the Self-Healing Behavior of Cross-Linked Polymers. ACS Appl. Mater. Interfaces 2017, 9, 14371–14378. [Google Scholar] [CrossRef]

- Li, Z.; de Souza, L.R.; Litina, C.; Markaki, A.E.; Al-Tabbaa, A. A Novel Biomimetic Design of a 3D Vascular Structure for Self-Healing in Cementitious Materials Using Murray’s Law. Mater. Des. 2020, 190, 108572. [Google Scholar] [CrossRef]

- Wu, W.; DeConinck, A.; Lewis, J.A. Omnidirectional Printing of 3D Microvascular Networks. Adv. Mater. 2011, 23, H178–H183. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Yu, R.; He, Y.; Zhang, Y.; Yang, X.; Zhao, X.; Huang, W. Self-Healing Polyurethane Elastomers Based on a Disulfide Bond by Digital Light Processing 3D Printing. ACS Macro Lett. 2019, 8, 1511–1516. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, S.K. Self-Healing Materials: Fundamentals, Design Strategies, and Applications. In Self-Healing Materials; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2008; pp. 1–28. ISBN 978-3-527-62537-6. [Google Scholar]

- Davami, K.; Mohsenizadeh, M.; Mitcham, M.; Damasus, P.; Williams, Q.; Munther, M. Additively Manufactured Self-Healing Structures with Embedded Healing Agent Reservoirs. Sci. Rep. 2019, 9, 7474. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Ding, X.; Urban, M.W. Chemical and Physical Aspects of Self-Healing Materials. Prog. Polym. Sci. 2015, 49–50, 34–59. [Google Scholar] [CrossRef]

- Hartings, M.R.; Ahmed, Z. Chemistry from 3D Printed Objects. Nat. Rev. Chem. 2019, 3, 305–314. [Google Scholar] [CrossRef]

- Vyatskikh, A.; Delalande, S.; Kudo, A.; Zhang, X.; Portela, C.M.; Greer, J.R. Additive Manufacturing of 3D Nano-Architected Metals. Nat. Commun. 2018, 9, 593. [Google Scholar] [CrossRef]

- Li, T.; Chen, Y.; Wang, L. Enhanced Fracture Toughness in Architected Interpenetrating Phase Composites by 3D Printing. Compos. Sci. Technol. 2018, 167, 251–259. [Google Scholar] [CrossRef]

- Bapari, S.; Chokshi, A.H. The Role of the Soft Phase in Rigidity Enhancements in a Particulate Composite. Compos. Part A Appl. Sci. Manuf. 2019, 123, 114–122. [Google Scholar] [CrossRef]

- Li, X.; Tan, Y.H.; Wang, P.; Su, X.; Willy, H.J.; Herng, T.S.; Ding, J. Metallic Microlattice and Epoxy Interpenetrating Phase Composites: Experimental and Simulation Studies on Superior Mechanical Properties and Their Mechanisms. Compos. Part A Appl. Sci. Manuf. 2020, 135, 105934. [Google Scholar] [CrossRef]

- Fafenrot, S.; Grimmelsmann, N.; Wortmann, M.; Ehrmann, A. Three-Dimensional (3D) Printing of Polymer-Metal Hybrid Materials by Fused Deposition Modeling. Materials 2017, 10, 1199. [Google Scholar] [CrossRef]

- Gu, X.W.; Greer, J.R. Ultra-Strong Architected Cu Meso-Lattices. Extrem. Mech. Lett. 2015, 2, 7–14. [Google Scholar] [CrossRef]

- Zheng, X.; Smith, W.; Jackson, J.; Moran, B.; Cui, H.; Chen, D.; Ye, J.; Fang, N.; Rodriguez, N.; Weisgraber, T.; et al. Multiscale Metallic Metamaterials. Nat. Mater. 2016, 15, 1100–1106. [Google Scholar] [CrossRef] [PubMed]

- Mieszala, M.; Hasegawa, M.; Guillonneau, G.; Bauer, J.; Raghavan, R.; Frantz, C.; Kraft, O.; Mischler, S.; Michler, J.; Philippe, L. Micromechanics of Amorphous Metal/Polymer Hybrid Structures with 3D Cellular Architectures: Size Effects, Buckling Behavior, and Energy Absorption Capability. Small 2017, 13, 1602514. [Google Scholar] [CrossRef]

- Zhang, X.; Yao, J.; Liu, B.; Yan, J.; Lu, L.; Li, Y.; Gao, H.; Li, X. Three-Dimensional High-Entropy Alloy-Polymer Composite Nanolattices That Overcome the Strength-Recoverability Trade-Off. Nano Lett. 2018, 18, 4247–4256. [Google Scholar] [CrossRef] [PubMed]

- Meza, L.R.; Das, S.; Greer, J.R. Strong, Lightweight, and Recoverable Three-Dimensional Ceramic Nanolattices. Science 2014, 345, 1322–1326. [Google Scholar] [CrossRef] [PubMed]

- Wu, B.M.; Borland, S.W.; Giordano, R.A.; Cima, L.G.; Sachs, E.M.; Cima, M.J. Solid Free-Form Fabrication of Drug Delivery Devices. J. Control. Release 1996, 40, 77–87. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D Printing of Ceramics: A Review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Ritchie, R.O. The Conflicts between Strength and Toughness. Nat. Mater. 2011, 10, 817–822. [Google Scholar] [CrossRef]

- Mirkhalaf, M.; Dastjerdi, A.K.; Barthelat, F. Overcoming the Brittleness of Glass through Bio-Inspiration and Micro-Architecture. Nat. Commun. 2014, 5, 3166. [Google Scholar] [CrossRef]

- Yahyazadehfar, M.; Bajaj, D.; Arola, D.D. Hidden Contributions of the Enamel Rods on the Fracture Resistance of Human Teeth. Acta Biomater. 2013, 9, 4806–4814. [Google Scholar] [CrossRef]

- Currey, J.D.; Taylor, J.D. The Mechanical Behaviour of Some Molluscan Hard Tissues. J. Zool. 1974, 173, 395–406. [Google Scholar] [CrossRef]

- Munch, E.; Launey, M.E.; Alsem, D.H.; Saiz, E.; Tomsia, A.P.; Ritchie, R.O. Tough, Bio-Inspired Hybrid Materials. Science 2008, 322, 1516–1520. [Google Scholar] [CrossRef] [PubMed]

- Bonderer, L.J.; Studart, A.R.; Gauckler, L.J. Bioinspired Design and Assembly of Platelet Reinforced Polymer Films. Science 2008, 319, 1069–1073. [Google Scholar] [CrossRef] [PubMed]

- Podsiadlo, P.; Kaushik, A.K.; Arruda, E.M.; Waas, A.M.; Shim, B.S.; Xu, J.; Nandivada, H.; Pumplin, B.G.; Lahann, J.; Ramamoorthy, A.; et al. Ultrastrong and Stiff Layered Polymer Nanocomposites. Science 2007, 318, 80–83. [Google Scholar] [CrossRef]

- Martin, J.H.; Yahata, B.D.; Hundley, J.M.; Mayer, J.A.; Schaedler, T.A.; Pollock, T.M. 3D Printing of High-Strength Aluminium Alloys. Nature 2017, 549, 365–369. [Google Scholar] [CrossRef]

- Dimas, L.S.; Bratzel, G.H.; Eylon, I.; Buehler, M.J. Tough Composites Inspired by Mineralized Natural Materials: Computation, 3D Printing, and Testing. Adv. Funct. Mater. 2013, 23, 4629–4638. [Google Scholar] [CrossRef]

- Wang, L.; Lau, J.; Thomas, E.L.; Boyce, M.C. Co-Continuous Composite Materials for Stiffness, Strength, and Energy Dissipation. Adv. Mater. 2011, 23, 1524–1529. [Google Scholar] [CrossRef]

- Wegst, U.G.K.; Bai, H.; Saiz, E.; Tomsia, A.P.; Ritchie, R.O. Bioinspired Structural Materials. Nat. Mater. 2014, 14, 23–36. [Google Scholar] [CrossRef]

- Li, H.; Shen, J.; Wei, Q.; Li, X. Dynamic Self-Strengthening of a Bio-Nanostructured Armor—Conch Shell. Mater. Sci. Eng. C 2019, 103, 109820. [Google Scholar] [CrossRef]

- Grunenfelder, L.K.; Suksangpanya, N.; Salinas, C.; Milliron, G.; Yaraghi, N.; Herrera, S.; Evans-Lutterodt, K.; Nutt, S.R.; Zavattieri, P.; Kisailus, D. Bio-Inspired Impact-Resistant Composites. Acta Biomater. 2014, 10, 3997–4008. [Google Scholar] [CrossRef]

- Barthelat, F.; Tang, H.; Zavattieri, P.D.; Li, C.-M.; Espinosa, H.D. On the Mechanics of Mother-of-Pearl: A Key Feature in the Material Hierarchical Structure. J. Mech. Phys. Solids 2007, 55, 306–337. [Google Scholar] [CrossRef]

- Jia, Z.; Wang, L. 3D Printing of Biomimetic Composites with Improved Fracture Toughness. Acta Mater. 2019, 173, 61–73. [Google Scholar] [CrossRef]

- Eckel, Z.C.; Zhou, C.; Martin, J.H.; Jacobsen, A.J.; Carter, W.B.; Schaedler, T.A. Additive Manufacturing of Polymer-Derived Ceramics. Science 2016, 351, 58–62. [Google Scholar] [CrossRef] [PubMed]

- Travitzky, N.; Bonet, A.; Dermeik, B.; Fey, T.; Filbert-Demut, I.; Schlier, L.; Schlordt, T.; Greil, P. Additive Manufacturing of Ceramic-Based Materials. Adv. Eng. Mater. 2014, 16, 729–754. [Google Scholar] [CrossRef]

- Saroia, J.; Wang, Y.; Wei, Q.; Lei, M.; Li, X.; Guo, Y.; Zhang, K. A Review on 3D Printed Matrix Polymer Composites: Its Potential and Future Challenges. Int. J. Adv. Manuf. Technol. 2020, 106, 1695–1721. [Google Scholar] [CrossRef]

- Ma, X.-Y.; Feng, Y.-F.; Ma, Z.-S.; Li, X.; Wang, J.; Wang, L.; Lei, W. The Promotion of Osteointegration under Diabetic Conditions Using Chitosan/Hydroxyapatite Composite Coating on Porous Titanium Surfaces. Biomaterials 2014, 35, 7259–7270. [Google Scholar] [CrossRef] [PubMed]

- Backes, E.H.; Pires, L.D.N.; Beatrice, C.A.G.; Costa, L.C.; Passador, F.R.; Pessan, L.A. Fabrication of Biocompatible Composites of Poly(Lactic Acid)/Hydroxyapatite Envisioning Medical Applications. Polym. Eng. Sci. 2020, 60, 636–644. [Google Scholar] [CrossRef]

- Li, C.; Lai, Y.; Li, L.; Cao, H.; Long, J.; Wang, X.; Qin, L. The in Vitro Biocompatibility and Osteoinductive Activity Study of Magnesium Composed PLGA/TCP Porous Scaffold for Bone Regeneration. J. Orthop. Transl. 2016, 7, 78. [Google Scholar] [CrossRef]

- Noroozi, R.; Arif, Z.U.; Taghvaei, H.; Khalid, M.Y.; Sahbafar, H.; Hadi, A.; Sadeghianmaryan, A.; Chen, X. 3D and 4D Bioprinting Technologies: A Game Changer for the Biomedical Sector? Ann. Biomed. Eng. 2023, 51, 1683–1712. [Google Scholar] [CrossRef]

- Willemen, N.G.A.; Morsink, M.A.J.; Veerman, D.; da Silva, C.F.; Cardoso, J.C.; Souto, E.B.; Severino, P. From Oral Formulations to Drug-Eluting Implants: Using 3D and 4D Printing to Develop Drug Delivery Systems and Personalized Medicine. Bio-Des. Manuf. 2022, 5, 85–106. [Google Scholar] [CrossRef]

- Awad, A.; Basit, A.W. 3D and 4D Printing in Digital Healthcare. In 3D & 4D Printing Methods for Pharmaceutical Manufacturing and Personalised Drug Delivery: Opportunities and Challenges; Lamprou, D., Ed.; AAPS Introductions in the Pharmaceutical Sciences; Springer International Publishing: Cham, Switzerland, 2023; pp. 1–23. ISBN 978-3-031-34119-9. [Google Scholar]

- Agarwal, T.; Hann, S.Y.; Chiesa, I.; Cui, H.; Celikkin, N.; Micalizzi, S.; Barbetta, A.; Costantini, M.; Esworthy, T.; Zhang, L.G.; et al. 4D Printing in Biomedical Applications: Emerging Trends and Technologies. J. Mater. Chem. B 2021, 9, 7608–7632. [Google Scholar] [CrossRef] [PubMed]

- Muhindo, D.; Elkanayati, R.; Srinivasan, P.; Repka, M.A.; Ashour, E.A. Recent Advances in the Applications of Additive Manufacturing (3D Printing) in Drug Delivery: A Comprehensive Review. AAPS PharmSciTech 2023, 24, 57. [Google Scholar] [CrossRef] [PubMed]

- Tran, T.S.; Balu, R.; Mettu, S.; Roy Choudhury, N.; Dutta, N.K. 4D Printing of Hydrogels: Innovation in Material Design and Emerging Smart Systems for Drug Delivery. Pharmaceuticals 2022, 15, 1282. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.-J.; Tsai, Y.-L.; Lin, S.-H.; Hsu, S. Smart Polymers for Cell Therapy and Precision Medicine. J. Biomed. Sci. 2019, 26, 73. [Google Scholar] [CrossRef] [PubMed]

- Pineda-Castillo, S.A.; Stiles, A.M.; Bohnstedt, B.N.; Lee, H.; Liu, Y.; Lee, C.-H. Shape Memory Polymer-Based Endovascular Devices: Design Criteria and Future Perspective. Polymers 2022, 14, 2526. [Google Scholar] [CrossRef] [PubMed]

- Uboldi, M.; Melocchi, A.; Moutaharrik, S.; Cerea, M.; Gazzaniga, A.; Zema, L. Dataset on a Small-Scale Film-Coating Process Developed for Self-Expanding 4D Printed Drug Delivery Devices. Coatings 2021, 11, 1252. [Google Scholar] [CrossRef]

- Afzali Naniz, M.; Askari, M.; Zolfagharian, A.; Afzali Naniz, M.; Bodaghi, M. 4D Printing: A Cutting-Edge Platform for Biomedical Applications. Biomed. Mater. 2022, 17, 062001. [Google Scholar] [CrossRef]

- Pruksawan, S.; Lin, Z.; Lee, Y.L.; Chee, H.L.; Wang, F. 4D-Printed Hydrogel Actuators through Diffusion-Path Architecture Design. ACS Appl. Mater. Interfaces 2023, 15, 46388–46399. [Google Scholar] [CrossRef]

- Xiong, W.; Liu, Y.; Jiang, L.J.; Zhou, Y.S.; Li, D.W.; Jiang, L.; Silvain, J.-F.; Lu, Y.F. Laser-Directed Assembly of Aligned Carbon Nanotubes in Three Dimensions for Multifunctional Device Fabrication. Adv. Mater. 2016, 28, 2002–2009. [Google Scholar] [CrossRef]

- Choi, J.-W.; Kim, H.-C.; Wicker, R. Multi-Material Stereolithography. J. Mater. Process. Technol. 2011, 211, 318–328. [Google Scholar] [CrossRef]

- Kelly, B.E.; Bhattacharya, I.; Heidari, H.; Shusteff, M.; Spadaccini, C.M.; Taylor, H.K. Volumetric Additive Manufacturing via Tomographic Reconstruction. Science 2019, 363, 1075–1079. [Google Scholar] [CrossRef] [PubMed]

- Walker, D.A.; Hedrick, J.L.; Mirkin, C.A. Rapid, Large-Volume, Thermally Controlled 3D Printing Using a Mobile Liquid Interface. Science 2019, 366, 360–364. [Google Scholar] [CrossRef] [PubMed]

- Sitthi-Amorn, P.; Ramos, J.E.; Wangy, Y.; Kwan, J.; Lan, J.; Wang, W.; Matusik, W. MultiFab: A Machine Vision Assisted Platform for Multi-Material 3D Printing. ACM Trans. Graph. 2015, 34, 129:1–129:11. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Lambeth, R.H. Recycled Polyethylene Terephthalate as a New FFF Feedstock Material. Addit. Manuf. 2018, 21, 174–182. [Google Scholar] [CrossRef]

- Stephens, B.; Azimi, P.; El Orch, Z.; Ramos, T. Ultrafine Particle Emissions from Desktop 3D Printers. Atmos. Environ. 2013, 79, 334–339. [Google Scholar] [CrossRef]

- Kim, Y.; Yoon, C.; Ham, S.; Park, J.; Kim, S.; Kwon, O.; Tsai, P.-J. Emissions of Nanoparticles and Gaseous Material from 3D Printer Operation. Environ. Sci. Technol. 2015, 49, 12044–12053. [Google Scholar] [CrossRef]

- Yang, Y.; Li, L. Total Volatile Organic Compound Emission Evaluation and Control for Stereolithography Additive Manufacturing Process. J. Clean. Prod. 2018, 170, 1268–1278. [Google Scholar] [CrossRef]

- Davis, A.Y.; Zhang, Q.; Wong, J.P.S.; Weber, R.J.; Black, M.S. Characterization of Volatile Organic Compound Emissions from Consumer Level Material Extrusion 3D Printers. Build. Environ. 2019, 160, 106209. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahmood, A.; Perveen, F.; Chen, S.; Akram, T.; Irfan, A. Polymer Composites in 3D/4D Printing: Materials, Advances, and Prospects. Molecules 2024, 29, 319. https://doi.org/10.3390/molecules29020319

Mahmood A, Perveen F, Chen S, Akram T, Irfan A. Polymer Composites in 3D/4D Printing: Materials, Advances, and Prospects. Molecules. 2024; 29(2):319. https://doi.org/10.3390/molecules29020319

Chicago/Turabian StyleMahmood, Ayyaz, Fouzia Perveen, Shenggui Chen, Tayyaba Akram, and Ahmad Irfan. 2024. "Polymer Composites in 3D/4D Printing: Materials, Advances, and Prospects" Molecules 29, no. 2: 319. https://doi.org/10.3390/molecules29020319

APA StyleMahmood, A., Perveen, F., Chen, S., Akram, T., & Irfan, A. (2024). Polymer Composites in 3D/4D Printing: Materials, Advances, and Prospects. Molecules, 29(2), 319. https://doi.org/10.3390/molecules29020319