Synergistic Effect of Aluminum Nitride and Carbon Nanotube-Reinforced Silicon Rubber Nanocomposites

Abstract

1. Introduction

2. Results and Discussion

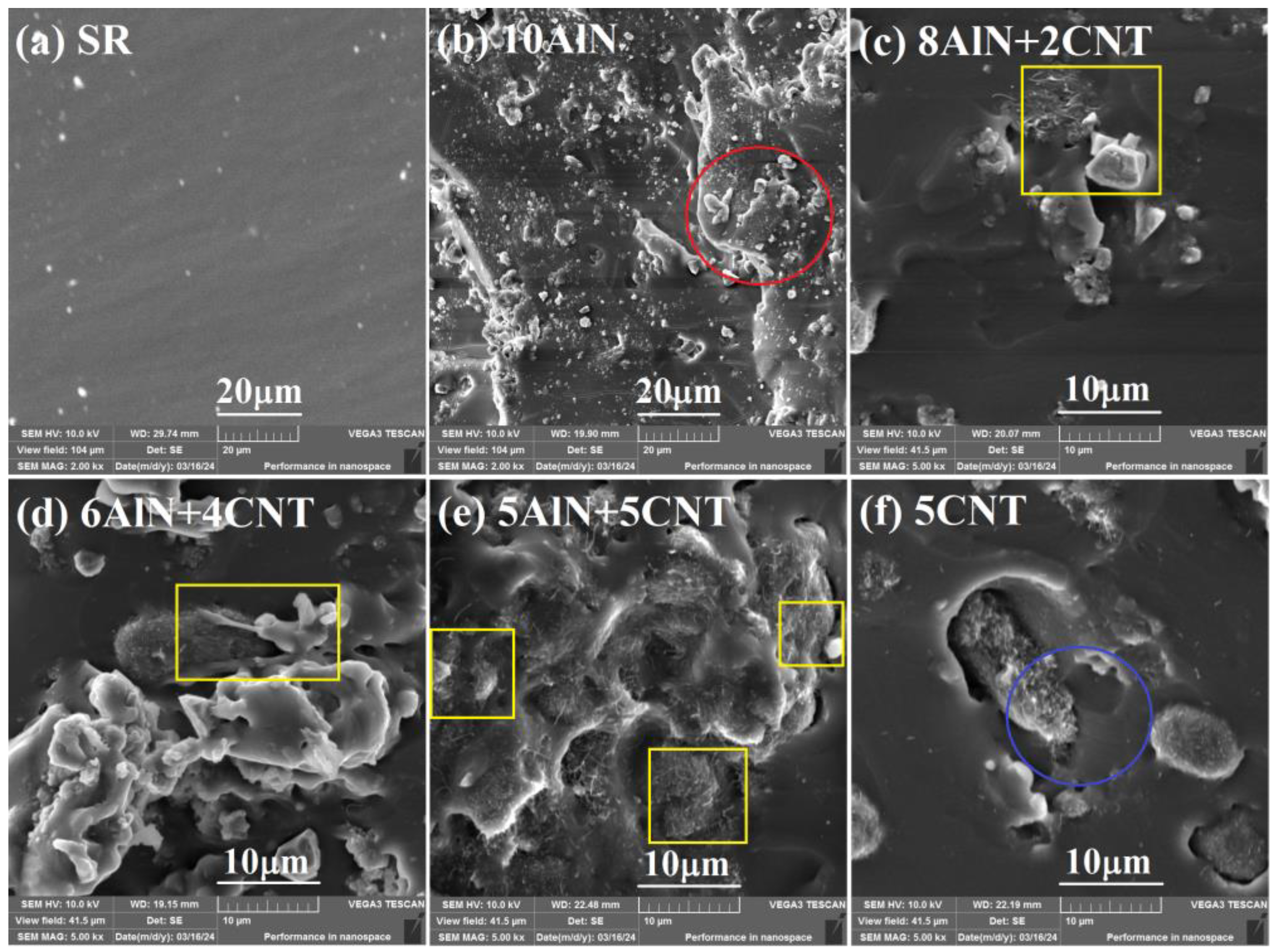

2.1. Morphology of Nanofillers

2.2. Mechanical Properties of AlN/CNT/SR Nanocomposites

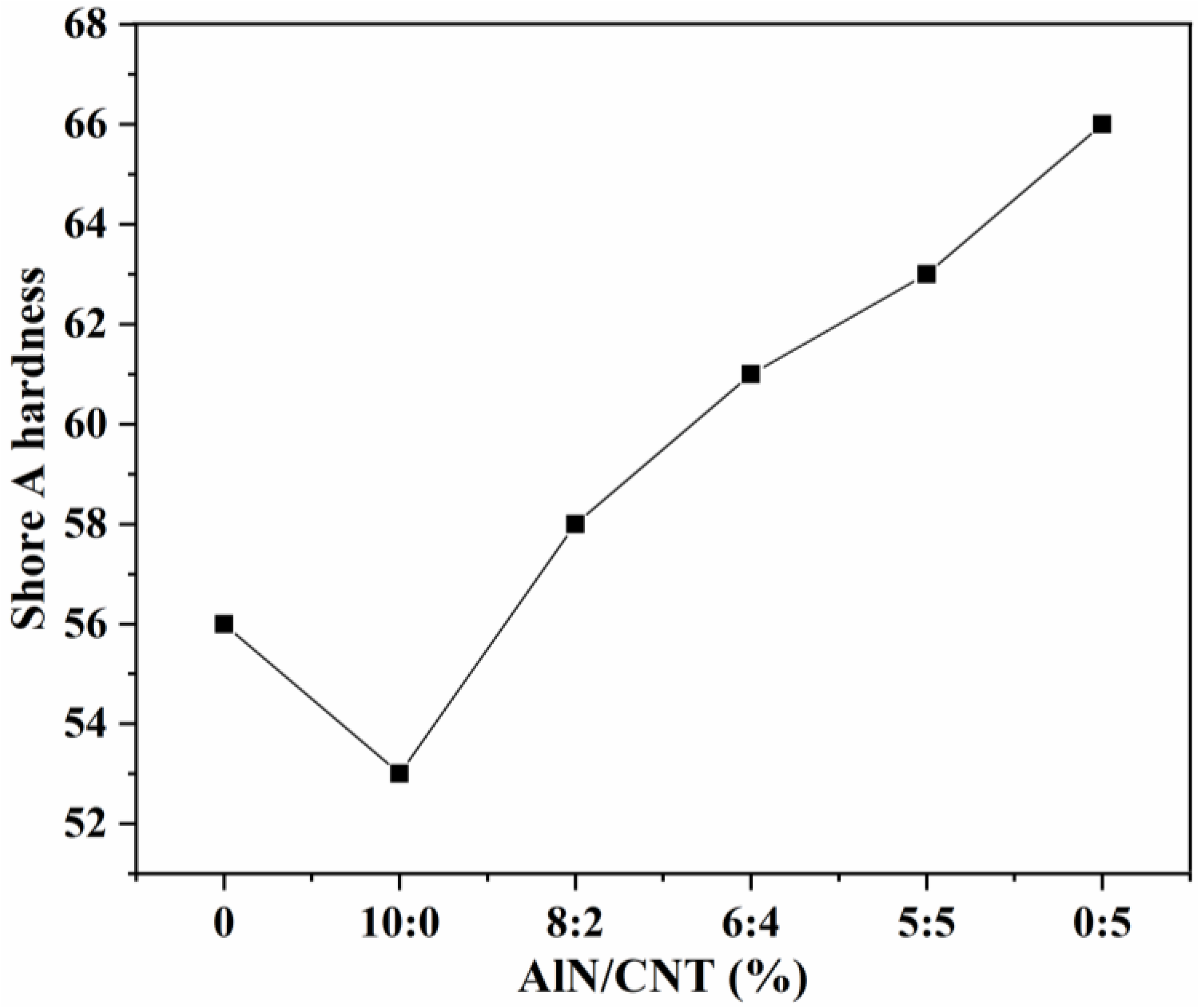

2.2.1. Hardness

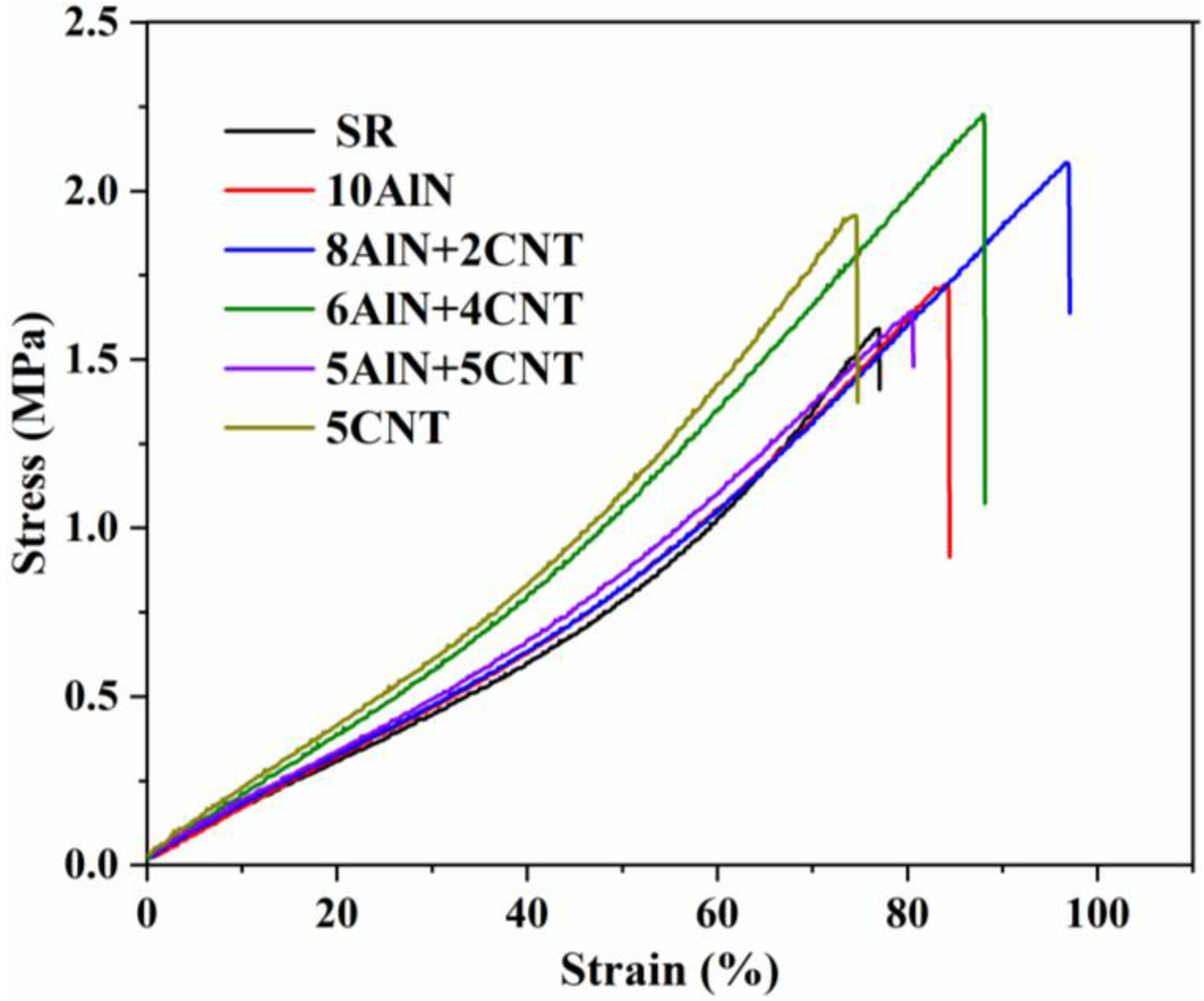

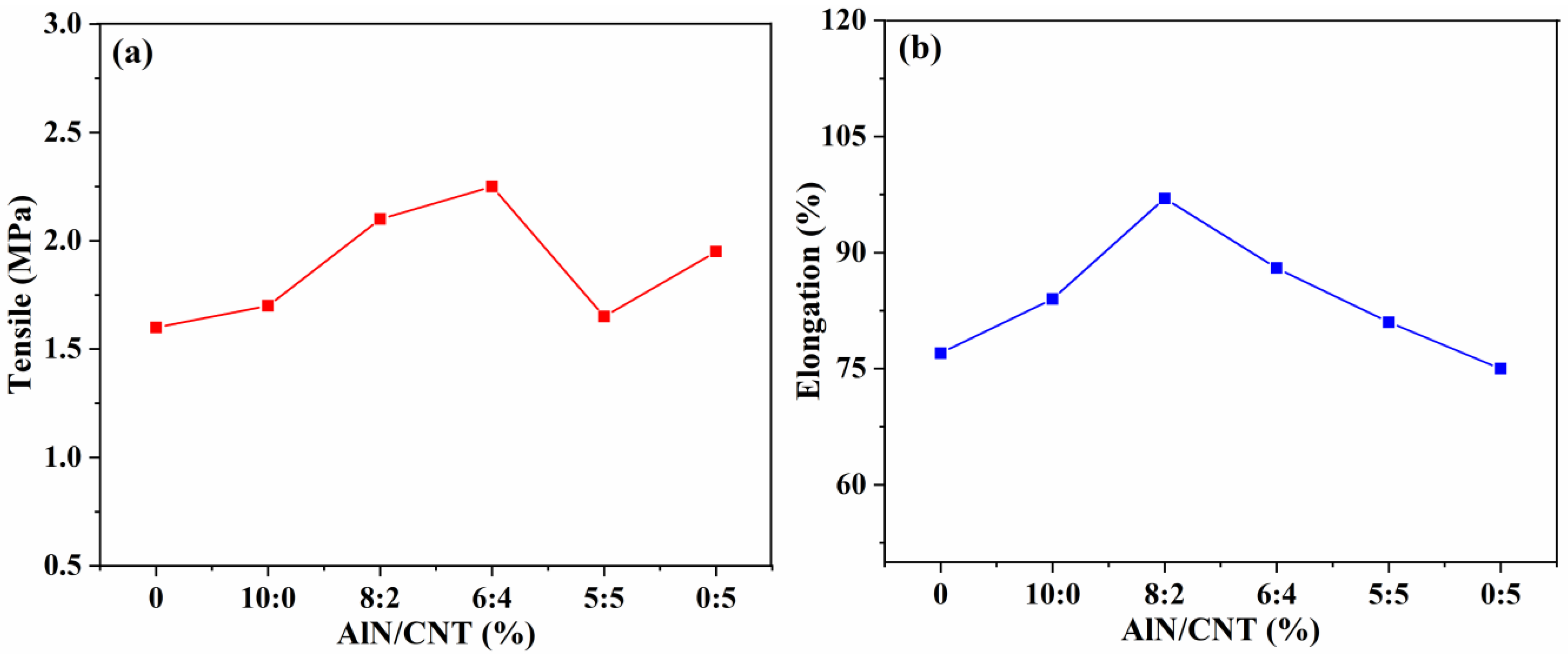

2.2.2. Tensile Strength and Elongation

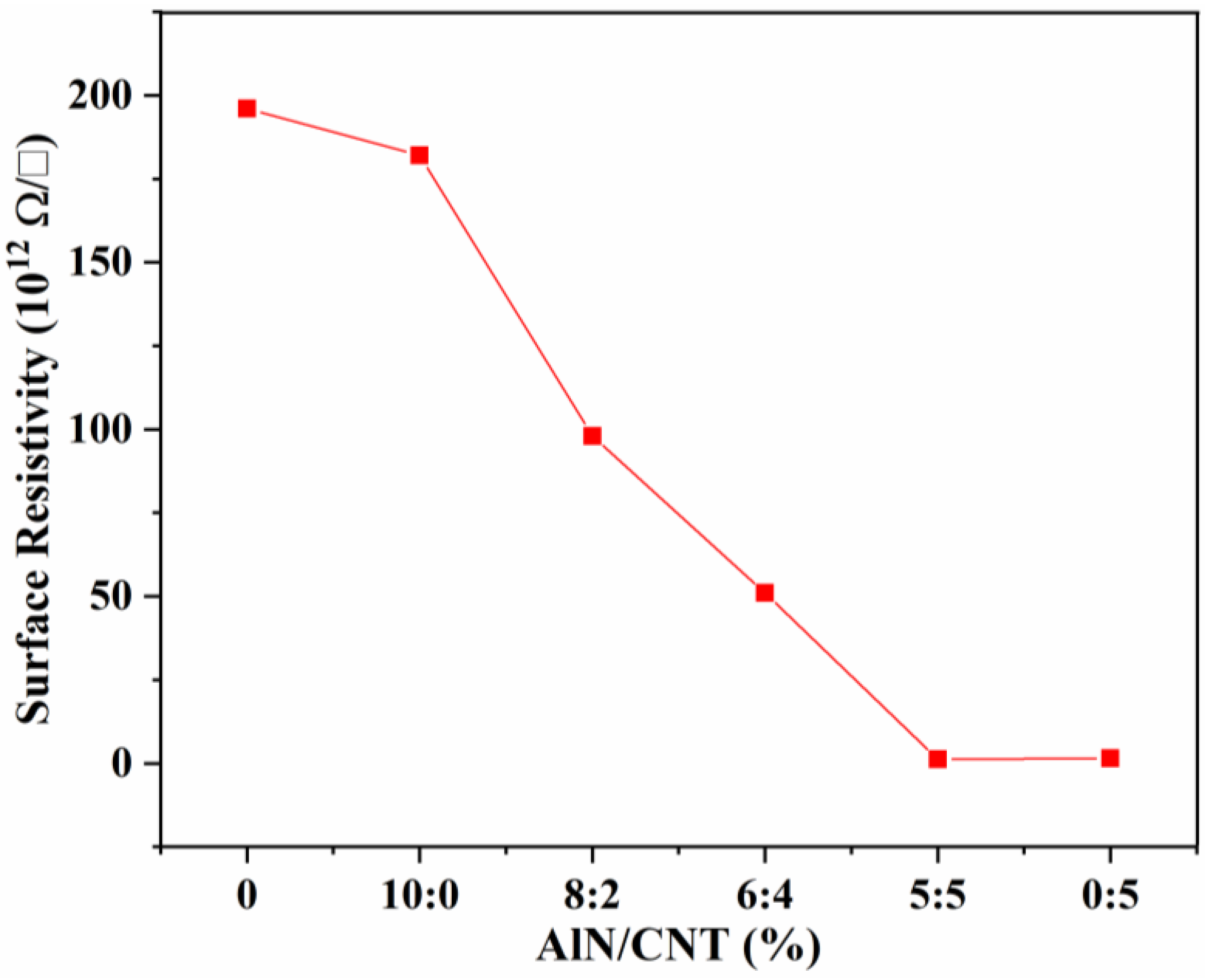

2.3. Electronic Properties of AlN/CNT/SR Nanocomposites

2.4. Thermal Properties of AlN/CNT/SR Nanocomposites

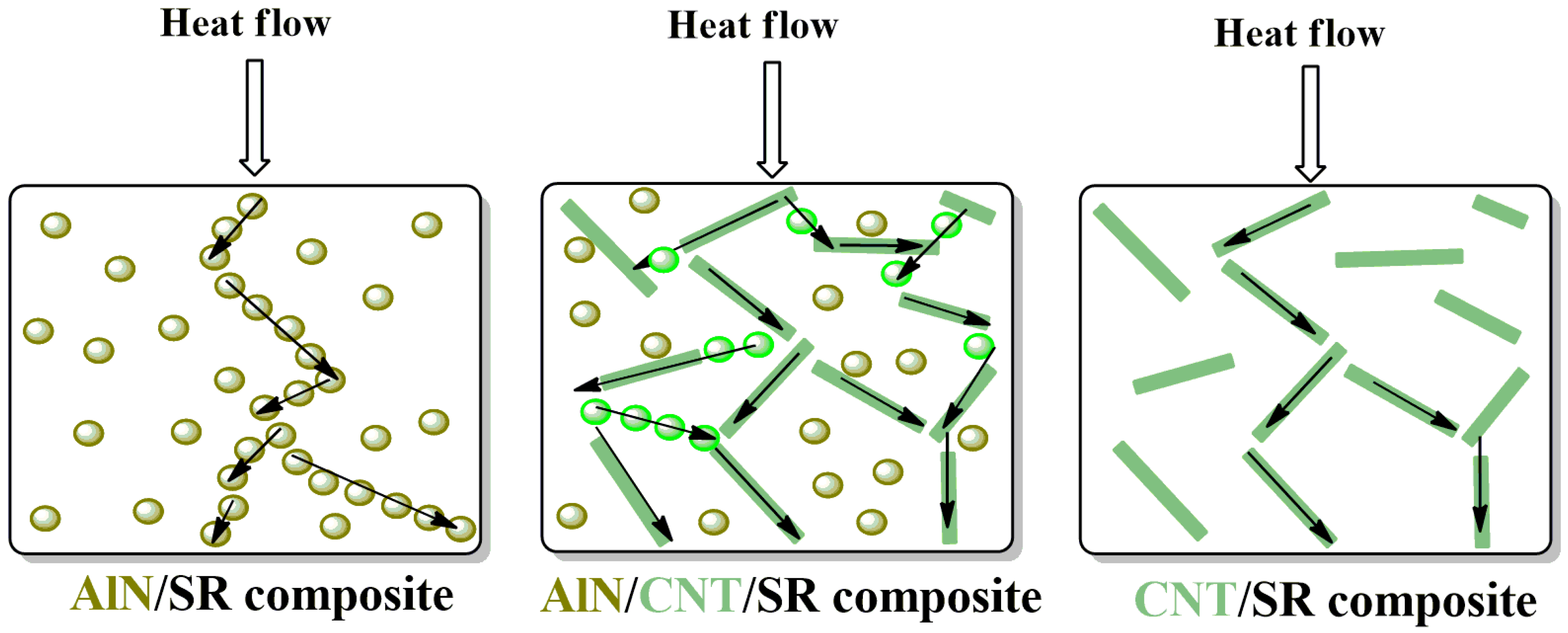

2.4.1. Thermal Conductivity

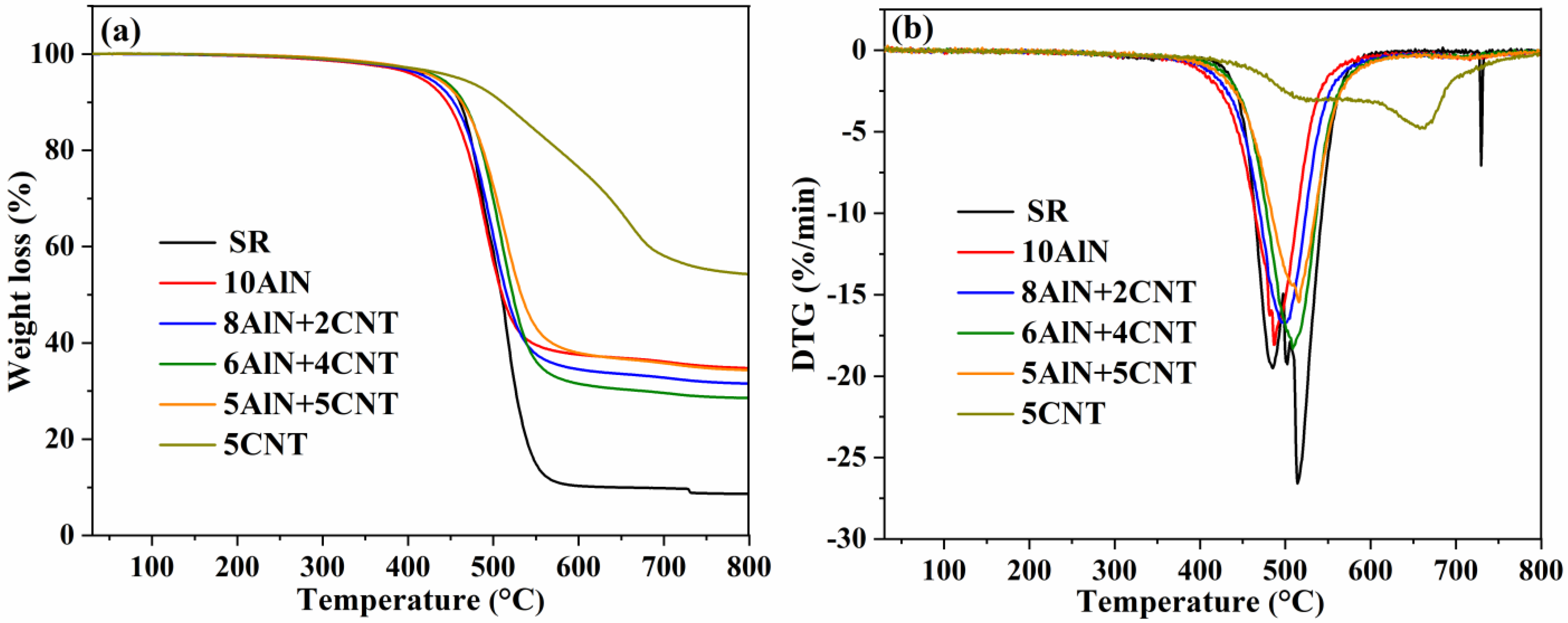

2.4.2. Thermogravimetric Analysis

2.5. Comparison Study of Hybrid Filler Incorporation

3. Materials and Methods

3.1. Materials

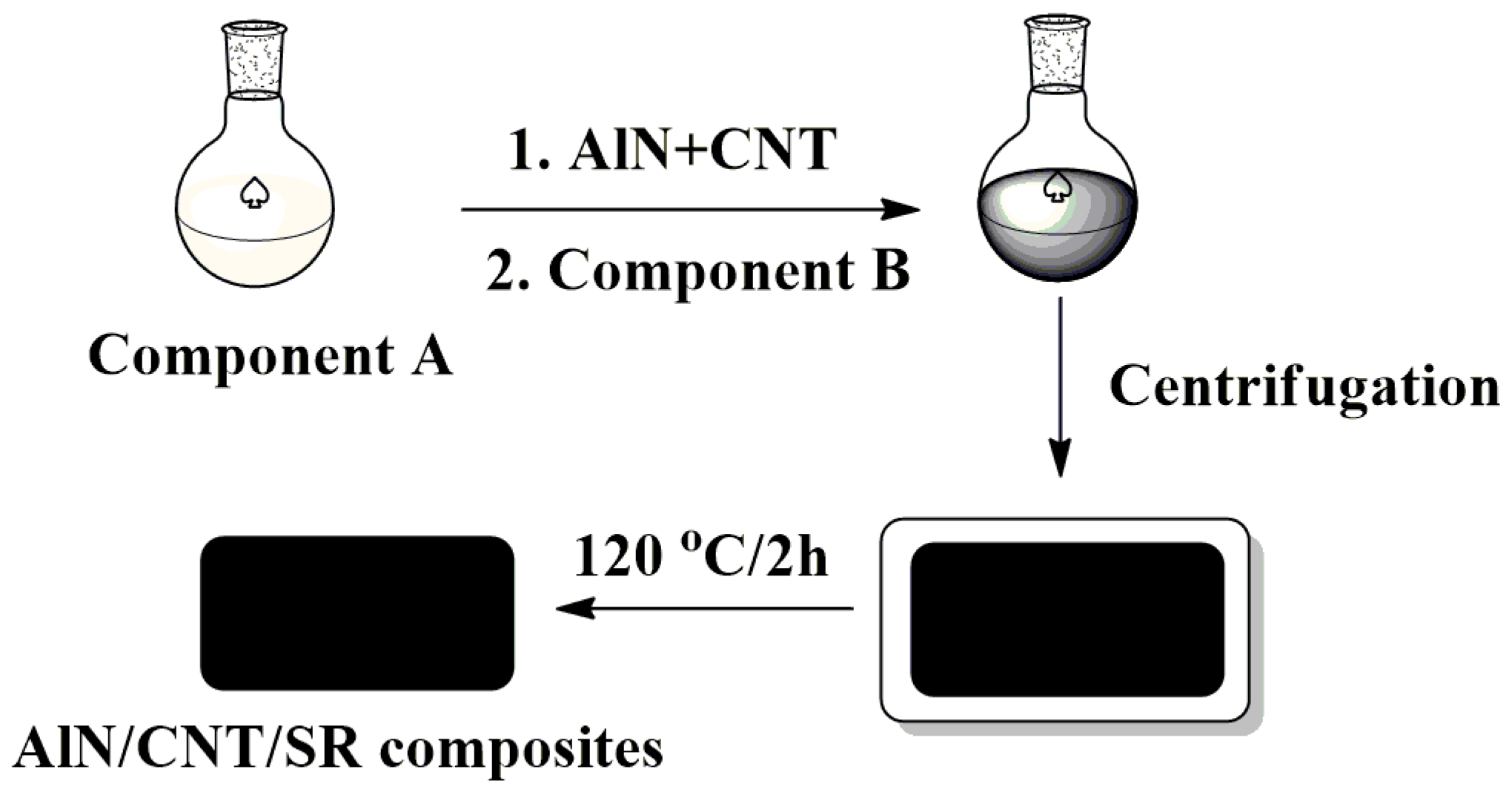

3.2. Preparation of AlN/CNT/SR Nanocomposites

3.3. Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, S.M.; Liu, S.Q.; Wang, Q.; Zuo, Z.; Wei, L.; Chen, Z.; Liang, X.D. Improving surface performance of silicone rubber for composite insulators by multifunctional Nano-coating. Chem. Eng. J. 2022, 451, 138679. [Google Scholar] [CrossRef]

- Wang, G.F.; Li, A.L.; Zhao, W.; Xu, Z.H.; Ma, Y.W.; Zhang, G.Y.; Zhang, Y.B.; Zhou, J.; He, Q. A review on fabrication methods and research progress of superhydrophobic silicone rubber materials. Adv. Mater. Interfaces 2021, 8, 2001460. [Google Scholar] [CrossRef]

- Chen, Q.Y.; Zhao, J.Y.; Ren, J.B.; Rong, L.H.; Cao, P.F.; Advincula, R.C. 3D printed multifunctional, hyperelastic silicone rubber foam. Adv. Funct. Mater. 2019, 29, 1900469. [Google Scholar] [CrossRef]

- Sarath, P.; Biswal, M.; Mohanty, S.; Nayak, S.K. Effect of silicone rubber based impact modifier on mechanical and flammability properties of plastics recovered from waste mobile phones. J. Clean. Prod. 2018, 171, 209–219. [Google Scholar] [CrossRef]

- Shi, G.; Zhao, Z.H.; Pai, J.H.; Lee, I.; Zhang, L.Q.; Stevenson, C.; Ishara, K.; Zhang, R.J.; Zhu, H.W.; Ma, J. Highly sensitive, wearable, durable strain sensors, and stretchable conductors using graphene/silicon rubber composites. Adv. Funct. Mater. 2016, 26, 7614–7625. [Google Scholar] [CrossRef]

- Gao, J.; Bao, F.; Wu, Q.X.; Ma, R.; Han, X.B.; Jin, D.P.; Chen, K.Y.; He, J.Y.; Guo, Z.F.; Yan, C.J. Multifunctional graphene filled silicone encapsulant for high-performance light-emitting diodes. Mater. Today Commun. 2016, 7, 149–154. [Google Scholar] [CrossRef]

- Kumar, V.; Alam, M.N.; Manikkavel, A.; Song, M.; Lee, D.J.; Park, S.S. Silicone rubber composites reinforced by carbon nanofillers and their hybrids for various applications: A review. Polymers 2021, 13, 2322. [Google Scholar] [CrossRef]

- Baranovskii, E.M.; Khistiaeva, V.V.; Deriabin, K.V.; Petrovskii, S.K.; Koshevoy, I.O.; Kolesnikov, I.E.; Grachova, E.V.; Islamova, R.M. Re(I) complexes as backbone substituents and cross-linking agents for hybrid luminescent polysiloxanes and silicone rubbers. Molecules 2021, 26, 6866. [Google Scholar] [CrossRef]

- Yu, N.; Zhang, S.F.; Tang, B.T.; Ma, W.; Qiu, J.J. Synthesis of novel reactive disperse silicon-containing dyes and their coloring properties on silicone rubbers. Molecules 2018, 23, 127. [Google Scholar] [CrossRef]

- Liang, Y.; Gao, T.; Wang, X.N.; Sun, M.T.; Gao, L.J. Electric field intensity effects on the microstructural characteristics evolution of methyl vinyl silicone rubber via molecular simulation. Molecules 2018, 23, 1861. [Google Scholar] [CrossRef]

- Farahani, A.; Jamshidi, M.; Foroutan, M. Effects of functionalization and silane modifcation of hexagonal boron nitride on thermal/mechanical/morphological properties of silicon rubber nanocomposite. Sci. Rep. 2023, 13, 11915. [Google Scholar] [CrossRef] [PubMed]

- Shinde, A.; Siva, I.; Munde, Y.; Deore, V.; Sultan, M.; Shah, A.U.; Mustapha, F. Testing of silicon rubber/montmorillonite nanocomposite for mechanical and tribological performance. Nanomaterials 2021, 11, 3050. [Google Scholar] [CrossRef]

- Huang, T.Q.; Wang, T.; Jin, J.; Chen, M.; Wu, L.M. Design of silicon rubber/BN film with high through-plane thermal conductivity and ultra-low contact resistance. Chem. Eng. J. 2023, 469, 143874. [Google Scholar] [CrossRef]

- Li, M.; Li, Y.; Hong, T.; Zhao, Y.H.; Wang, S.J.; Jing, X.L. High ablation-resistant silicone rubber composites via nanoscale phenolic resin dispersion. Chem. Eng. J. 2023, 472, 145132. [Google Scholar] [CrossRef]

- Huang, P.; Xia, Z.D.; Cui, S. 3D printing of carbon fiber-filled conductive silicon rubber. Mater. Design 2018, 142, 11–21. [Google Scholar] [CrossRef]

- Li, Y.C.; Huang, X.R.; Zeng, L.J.; Li, R.F.; Tian, H.F.; Fu, X.W.; Wang, Y.; Zhong, W.H. A review of the electrical and mechanical properties of carbon nanofiller-reinforced polymer composites. J. Mater. Sci. 2019, 54, 1036–1076. [Google Scholar] [CrossRef]

- Han, X.B.; Zhou, Z.Z.; Gao, J.; Zhao, Y.; Chen, T. Effect of carbon nanoparticles morphology on the properties of poly(styrene-b-isoprene-b-styrene) elastomer composites. Polymers 2023, 15, 4415. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, F.M.; Ezquerra, T.A.; Denchev, Z.Z. Broadband electrical conductivity of metal/carbon nanotubes polyamide 6 composites fabricated by reactive encapsulation. J. Mater. Sci. 2024, 59, 1348–1363. [Google Scholar] [CrossRef]

- Han, X.B.; Gao, J.; Chen, T.; Qian, L.; Xiong, H.H.; Chen, Z.Y. Application progress of PALS in the correlation of structure and properties for graphene/polymer nanocomposites. Nanomaterials 2022, 12, 4161. [Google Scholar] [CrossRef]

- Siriwas, T.; Pichaiyut, S.; Susoff, M.; Petersen, S.; Nakason, C. Enhancing curing, mechanical and electrical properties of epoxidized natural rubber nanocomposites with graphene and carbon nanotubes hybrid fillers. J. Mater. Sci. 2023, 58, 15676–15695. [Google Scholar] [CrossRef]

- Han, X.B.; Chen, T.; Zhao, Y.; Gao, J.; Sang, Y.N.; Xiong, H.H.; Chen, Z.Y. Relationship between the microstructure and performance of graphene/polyethylene composites investigated by positron annihilation lifetime spectroscopy. Nanomaterials 2021, 11, 2990. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.L.; Fu, Y.; Meng, Z.P.; Wan, B.L.; Han, B.G. Experimental study and piezoresistive mechanism of electrostatic self-assembly of carbon nanotubes-carbon black/epoxy nanocomposites for structural health monitoring. J. Mater. Sci. 2022, 57, 12416–12437. [Google Scholar] [CrossRef]

- Velentini, L.; Bon, S.B.; Manchado, M.A.; Verdejo, R.; Pappalardo, L.; Bolognini, A.; Alvino, A.; Berardo, A.; Pugno, N.M. Synergistic effect of graphene nanoplatelets and carbon black in multifunctional EPDM nanocomposites. Compos. Sci. Technol. 2016, 128, 123–130. [Google Scholar] [CrossRef]

- Dong, B.; Liu, C.; Lu, Y.L.; Wu, Y.P. Synergistic effects of carbon nanotubes and carbon black on the fracture and fatigue resistance of natural rubber composites. J. Appl. Polym. Sci. 2015, 132, 42075. [Google Scholar] [CrossRef]

- Che, J.J.; Wu, K.; Lin, Y.J.; Wang, K.; Fu, Q. Largely improved thermal conductivity of HDPE/expanded graphite/carbon nanotubes ternary composites via filler network-network synergy. Compos. Part A 2017, 99, 32–40. [Google Scholar] [CrossRef]

- Shtein, M.; Nadiv, R.; Buzalglo, M.; Kahil, K.; Regev, O. Thermally conductive graphene-polymer composites: Size, percolation, and synergy effects. Chem. Mater. 2015, 27, 2100–2106. [Google Scholar] [CrossRef]

- Teng, C.C.; Ma, C.C.; Chiou, K.C.; Lee, T.M. Synergetic effect of thermal conductive properties of epoxy composites containing functionalized multi-walled carbon nanotubes and aluminum nitride. Compos. Part B 2012, 43, 265–271. [Google Scholar] [CrossRef]

- Kim, M.; Park, S.; Park, J. Effect of the grafting reaction of aluminum nitride on the multi-walled carbon nanotubes on the thermal properties of the poly(phenylene sulfide) composites. Polymers 2017, 9, 452. [Google Scholar] [CrossRef]

- Choi, S.; Im, H.; Kim, J. The thermal conductivity of embedded nano-aluminum nitride-doped multi-walled carbon nanotubes in epoxy composites containing micro-aluminum nitride particles. Nanotechnology 2012, 23, 065303. [Google Scholar] [CrossRef]

- Du, F.P.; Li, J.J.; Fu, P.; Wu, Y.G.; Liao, G.Y.; Zhang, Y.F.; Luo, S. Enhanced thermal conductivity of poly(L-lactide) composites with synergistic effect of aluminum nitride and modified multi-walled carbon nanotubes. Fuller. Nanotub. Carbon Nanostruct. 2016, 24, 667–673. [Google Scholar] [CrossRef]

- Mi, Y.N.; Liang, G.Z.; Gu, A.J.; Zhao, F.P.; Yuan, L. Thermally conductive aluminum nitride-multiwalled carbon nanotube/cyanate ester composites with high flame retardancy and low dielectric loss. Ind. Eng. Chem. Res. 2013, 52, 3342–3353. [Google Scholar] [CrossRef]

- Jiao, J.; Cui, Y.H.; Xia, Y. Improved thermal conductivity of epoxy composites prepared with a mixed filler of multiwalled carbon nanotubes and aluminum nitride particles. High Perform. Polym. 2016, 29, 484–492. [Google Scholar] [CrossRef]

- Chen, C.; He, Y.; Liu, C.Q.; Xie, H.Q.; Yu, W. Comprehensive excellent performance for silicone-based thermal interface materials through the synergistic effect between graphene and spherical alumina. J. Mater. Sci. Mater. Electron. 2020, 31, 4642–4649. [Google Scholar] [CrossRef]

- Zhang, Y.C.; Yu, W.; Zhang, L.Y.; Jin, J.S.; Wang, J.K.; Xie, H.Q. Thermal conductivity and mechanical properties of low-density silicone rubber filled with Al2O3 and graphene nanoplatelets. J. Therm. Sci. Eng. Appl. 2018, 10, 011014. [Google Scholar] [CrossRef]

- Zhou, W.Y.; Wang, C.F.; An, Q.L.; Ou, H.Y. Thermal properties of heat conductive silicone rubber filled with hybrid fillers. J. Compos. Mater. 2008, 42, 173–187. [Google Scholar] [CrossRef]

- Ji, X.W.; Lu, Z.Y.; Wang, J.Y.; Ye, N.; Zhang, H.; Zhou, L.T.; Li, J.C.; Lu, Y.L. Construction of micro-nano hybrid structure based on carbon nanotube whisker and alumina for thermally conductive yet electrically insulating silicone rubber composites. Compos. Sci. Technol. 2024, 249, 110495. [Google Scholar] [CrossRef]

- Yu, W.; Xie, H.Q.; Yin, L.Q.; Zhao, J.C.; Xia, L.G.; Chen, L.F. Exceptionally high thermal conductivity of thermal grease: Synergistic effects of graphene and alumina. Int. J. Therm. Sci. 2015, 91, 76–82. [Google Scholar] [CrossRef]

- Wei, Q.G.; Ni, Y.F.; Yang, D.; Yu, L.Y.; Zhang, L.Q. Enhanced thermal conductivity of silicone rubber via synergistic effects of polydopamine modification and silver deposition on boron nitride. Compos. Commun. 2022, 30, 101082. [Google Scholar] [CrossRef]

- Wei, Q.G.; Yang, D. Formation of thermally conductive network accompanied by reduction of interface resistance for thermal conductivity enhancement of silicone rubber. ACS Appl. Electron. Mater. 2022, 4, 3503–3511. [Google Scholar] [CrossRef]

- Lin, J.L.; Su, S.M.; He, Y.B.; Kang, F.Y. Improving thermal and mechanical properties of the alumina filled silicone rubber composite by incorporating carbon nanotubes. New Carbon Mater. 2020, 35, 66–72. [Google Scholar] [CrossRef]

- Ouyang, Y.G.; Yang, Z.X.; Long, T.Y.; Tian, H.F.; Bai, L.Y.; Li, X.F.; Yuan, F.L. Preparation of branched Al2O3 and its synergistic effect with carbon nanotubes on the enhancement of thermal conductive and electrical insulation properties of silicone rubber composites. Mater. Today Commun. 2023, 34, 105239. [Google Scholar] [CrossRef]

- Chio, S.; Im, H.; Kim, J. Flexible and high thermal conductivity thin films based on polymer: Aminated multi-walled carbon nanotubes/micro-aluminum nitride hybrid composites. Compos. Part A 2012, 43, 1860–1868. [Google Scholar] [CrossRef]

- Han, X.B.; Kong, H.; Chen, T.; Gao, J.; Zhao, Y.; Sang, Y.N.; Hu, G.W. Effect of π–π stacking interfacial interaction on the properties of graphene/poly(styrene-b-isoprene-b-styrene) composites. Nanomaterials 2021, 11, 2158. [Google Scholar] [CrossRef]

- Gomez, J.; Villaro, E.; Karagiannidis, P.G.; Elmarakbi, A. Effects of chemical structure and morphology of graphene-related materials (GRMs) on melt processing and properties of GRM/polyamide-6 nanocomposites. Results Mater. 2020, 7, 100105. [Google Scholar] [CrossRef]

- Suresha, B.; Hemanth, G.; Hemanth, R.; Lalla, N.P. Role of graphene nanoplatelets and carbon fiber on mechanical properties of PA66/thermoplastic copolyester elastomer composites. Mater. Res. Express 2020, 7, 015325. [Google Scholar] [CrossRef]

- Mondal, S.; Khastgir, D. Elastomer reinforcement by graphene nanoplatelets and synergistic improvements of electrical and mechanical properties of composites by hybrid nano fillers of graphene-carbon black & graphene-MWCNT. Compos. Part A 2017, 102, 154–165. [Google Scholar] [CrossRef]

- Han, X.B.; Gao, J.; Chen, T.; Zhao, Y. Interfacial interaction and steric repulsion in polymer-assisted liquid exfoliation to produce high-quality graphene. Chem. Pap. 2020, 74, 757–765. [Google Scholar] [CrossRef]

- Jiang, S.; He, Z.L.; Li, Q.F.; Wang, J.W.; Wu, G.P.; Zhao, Y.H.; Kang, M.Q. Effect of carbon fiber-graphene oxide multiscale reinforcements on the thermo-mechanical properties of polyurethane elastomer. Polym. Compos. 2019, 40, e953–e961. [Google Scholar] [CrossRef]

- Tarawneh, M.A.; Ahmad, S.; Chen, R.S. Mechanical, thermal, and electrical properties of graphene oxide-multiwalled carbon nanotubes-filled thermoplastic elastomer nanocomposite. J. Elastom. Plast. 2017, 49, 345–355. [Google Scholar] [CrossRef]

- Wang, L.W.; Hong, J.B.; Chen, G.H. Comparison study of graphite nanosheets and carbon black as fillers for high density polyethylene. Polym. Eng. Sci. 2010, 50, 2176–2181. [Google Scholar] [CrossRef]

- Li, J.Y.; Lu, Y.C.; Jiang, S.B.; Zhong, Y.L.; Yeh, J.M. Phase diagram of hopping conduction mechanisms in polymer nanofiber network. J. Appl. Phys. 2015, 118, 215104. [Google Scholar] [CrossRef]

- Guo, J.Y.; Wang, X.L.; Jia, Z.D.; Wang, J.; Chen, C. Nonlinear electrical properties and field dependency of BST and nano-ZnO-doped silicone rubber composites. Molecules 2018, 23, 3153. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.F.; Wu, Z.J.; Almasoud, N.; Weng, L.; Alomar, T.S.; EI-Bahy, Z.M.; He, M.P.; Yang, C.J.; Sun, M.Q.; Wasnik, P.; et al. Effective three-dimensional thermal conductivity networks in polystyrene/multi-walled carbon nanotubes/aluminum oxide@hexagonal boron nitride composites based on synergistic effects and isolated structures. Adv. Compos. Hybrid Mater. 2023, 6, 125. [Google Scholar] [CrossRef]

- Badakhsh, A.; Lee, Y.M.; Rhee, K.Y.; Park, C.W.; An, K.H.; Kim, B.J. Improvement of thermal, electrical and mechanical properties of composites using a synergistic network of length controlled-CNTs and graphene nanoplatelets. Compos. Part B 2019, 175, 107075. [Google Scholar] [CrossRef]

- Han, X.B.; Gao, J.; Chen, Z.Y.; Tang, X.Q.; Zhao, Y.; Chen, T. Correlation between microstructure and properties of graphene oxide/waterborne polyurethane composites investigated by positron annihilation spectroscopy. RSC Adv. 2020, 10, 32436–32442. [Google Scholar] [CrossRef] [PubMed]

- Liu, P.J.; Yao, Z.J.; Li, L.; Zhou, J.T. In situ Synthesis and mechanical, thermal properties of polyimide nanocomposite film by addition of functionalized graphene oxide. Polym. Compos. 2016, 37, 907. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Zhang, Y.F.; Wu, Z.K.; Bai, S.L. Synergic enhancement of thermal properties of polymer composites by graphene foam and carbon black. Compos. Part B 2016, 84, 52–58. [Google Scholar] [CrossRef]

- Lee, S.; Hong, J.Y.; Jang, J. Multifunctional graphene sheets embedded in silicone encapsulant for superior performance of light emitting diodes. ACS Nano 2013, 7, 5784–5790. [Google Scholar] [CrossRef]

- Kim, Y.H.; Bae, J.Y.; Jin, J.; Bae, B.S. Sol-gel derived transparent zirconium-phenyl siloxane hybrid for robust high refractive index LED encapsulant. ACS Appl. Mater. Interfaces 2014, 6, 3115–3121. [Google Scholar] [CrossRef]

- Yang, S.C.; Kwak, S.Y.; Jin, J.; Kim, J.S.; Choi, Y.; Paik, K.W.; Bae, S.B. Thermally resistant UV-curable epoxy-siloxane hybrid materials for light emitting diode (LED) encapsulation. J. Mater. Chem. 2012, 22, 8874–8880. [Google Scholar] [CrossRef]

| Sample | T5% (°C) | TH (°C) | R800 (%) |

|---|---|---|---|

| SR | 436.4 | 485.4 | 8.6 |

| 10AlN | 414.6 | 486.6 | 34.8 |

| 8AlN+2CNT | 425.0 | 499.0 | 28.6 |

| 6AlN+4CNT | 433.9 | 508.6 | 31.6 |

| 5AlN+5CNT | 438.6 | 515.9 | 34.3 |

| 5CNT | 458.8 | 661.8 | 54.3 |

| Hybrid Fillers | Parameters | Polymer (TC) | Preparation Method | Properties | Application | Ref. | ||

|---|---|---|---|---|---|---|---|---|

| Mechanical | Electrical | Thermal | ||||||

| 25 vol.%AlN/1 vol.%CNT | Zirconate-coupling Agent-modified AlN, GMA-grafted CNT | EP (~0.3) | Thermal curing | / | / | 1.21 W/m·K | Microelectronic devices | [27] |

| 20 wt.%AlN/1 wt.%CNT | GPTMS-grafted AlN-g-CNT | PPS (0.28) | Melt blending | / | / | 0.85 W/m·K, T5% 472 °C | Engineering plastic | [28] |

| 57.4 vol.%AlN/2 wt.%CNT | APTES-grafted AlN-g-CNT | EP (~0.2) | Thermal curing | / | / | 6.25 W/m·K | Electronic packages | [29] |

| 50 wt.%AlN/3 wt.%CNT | AlN: 1 μm, PEG-grafted CNT | PLA (0.1967) | Solution blending | / | / | 0.773 W/m·K, | Electronic devices | [30] |

| 47.5 wt.%AlN/2.5 wt.%CNT | KH-550-grafted AlN, E51-modified CNT | CE (~0.4) | Thermal curing | / | Dielectric constants (~5) | ~2.3 W/m·K, | Microelectronics | [31] |

| 3.4 vol.%AlN/0.6 vol.%CNT | Commercial, AlN: 0.5 μm, CNT: Φ 10 nm, length 20–30 μm | EP(~0.25) | Thermal curing | / | 1.8–2.6 × 1012 Ω·m | 0.53 W/m·K, T5% 368 °C | Microelectronics | [32] |

| 70 wt.%AlN/3 wt.%CNT | Ethylenediamine-grafted CNT | SR (~0.15) | Thermal curing (addition) | / | / | 3.81 W/m·K | Electronic devices | [42] |

| 6 wt.%AlN/4 wt.%CNT | Commercial, AlN: 2–5 μm, CNT: Φ 30 nm, length 1–5 μm | SR (0.104) | Thermal curing (addition) | Shore 61 A, 2.25 Mpa, elongation 88% | 51 × 1012 Ω/☐ | 0.162 W/m·K, T5% 434 °C, R800 31.6% | Electronic packaging | This work |

| 5 wt.%Al2O3/5 wt.%CNT | KH-304-grafted Al2O3 | SR (~0.13) | Thermal curing (addition) | Shore 28 A | / | 0.26 W/m·K | Electronic packaging | [40] |

| 36 vol.%Al2O3/2 wt.%CNT | APTES-grafted Al2O3, CNT electrostatic self-assembly Al2O3 | SR (~0.2) | Vulcanization (peroxide) | 2.5 Mpa, 50% | 1.323 × 109 Ω·cm | 1.137 W/m·K | Electronic packaging | [36] |

| 20 vol.%Al2O3/0.5 wt.%CNT | Sintering Al2O3 to form a branched one | SR (~0.18) | Vulcanization (peroxide) | 4.47 MPa, 206.9% | 1.1 × 1015 Ω·cm | 1.307 W/m·K | Electronic packaging | [41] |

| 71.5 wt.%Al2O3/0.5 wt.%graphene | Graphene: 1–3 layers, 7–12 μm | Silicone grease | Blending | / | / | 4.38 W/m·K | Thermal interface materials | [33] |

| 89 wt.%Al2O3/1 wt.%graphene | Al2O3: 5 μm, Graphene: RGO | SR (~0.2) | Vulcanization (peroxide) | ~0.3 MPa | / | ~3.4 W/m·K | Heat dissipation | [34] |

| 63 vol.%Al2O3/1 wt.%graphene | Al2O3: 0.7 μm, Graphene: RGO | Silicone grease | Blending | / | / | 3.45 W/m·K | Thermal interface materials | [37] |

| 30 vol.%BN-Ag | PDA-grafted BN-g-Ag | SR (~0.2) | Vulcanization (peroxide) | ~2.0 Mpa, elongation 50% | 1.89 × 10−11 S/cm | 0.75 W/m·K | Electronic equipment | [38] |

| 30 vol.%CNT-Ag | PDA -rafted CNT-g-Ag | SR (~0.2) | Vulcanization (peroxide) | / | / | 0.655 W/m·K | Electronic equipment | [38] |

| 5 vol.%SiC/45 vol.%Si3N4 | SiC: 2 μm, Si3N4: Φ 100 nm, length 20 μm | SR (~0.2) | Vulcanization (peroxide) | 2.81 Mpa | / | 1.48 W/m·K, T5% 551 °C | Heat dissipation | [35] |

| Sample | AlN (g) | CNT (g) |

|---|---|---|

| SR | - | - |

| 10AlN | 0.60 | - |

| 8AlN+2CNT | 0.48 | 0.12 |

| 6AlN+4CNT | 0.36 | 0.24 |

| 5AlN+5CNT | 0.30 | 0.30 |

| 5CNT | - | 0.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, J.; Xiong, H.; Han, X.; An, F.; Chen, T. Synergistic Effect of Aluminum Nitride and Carbon Nanotube-Reinforced Silicon Rubber Nanocomposites. Molecules 2024, 29, 2864. https://doi.org/10.3390/molecules29122864

Gao J, Xiong H, Han X, An F, Chen T. Synergistic Effect of Aluminum Nitride and Carbon Nanotube-Reinforced Silicon Rubber Nanocomposites. Molecules. 2024; 29(12):2864. https://doi.org/10.3390/molecules29122864

Chicago/Turabian StyleGao, Jie, Houhua Xiong, Xiaobing Han, Fei An, and Tao Chen. 2024. "Synergistic Effect of Aluminum Nitride and Carbon Nanotube-Reinforced Silicon Rubber Nanocomposites" Molecules 29, no. 12: 2864. https://doi.org/10.3390/molecules29122864

APA StyleGao, J., Xiong, H., Han, X., An, F., & Chen, T. (2024). Synergistic Effect of Aluminum Nitride and Carbon Nanotube-Reinforced Silicon Rubber Nanocomposites. Molecules, 29(12), 2864. https://doi.org/10.3390/molecules29122864