Polyether-Thiourea-Siloxane Copolymer Based on H-Bonding Interaction for Marine Antifouling

Abstract

1. Introduction

2. Results and Discussion

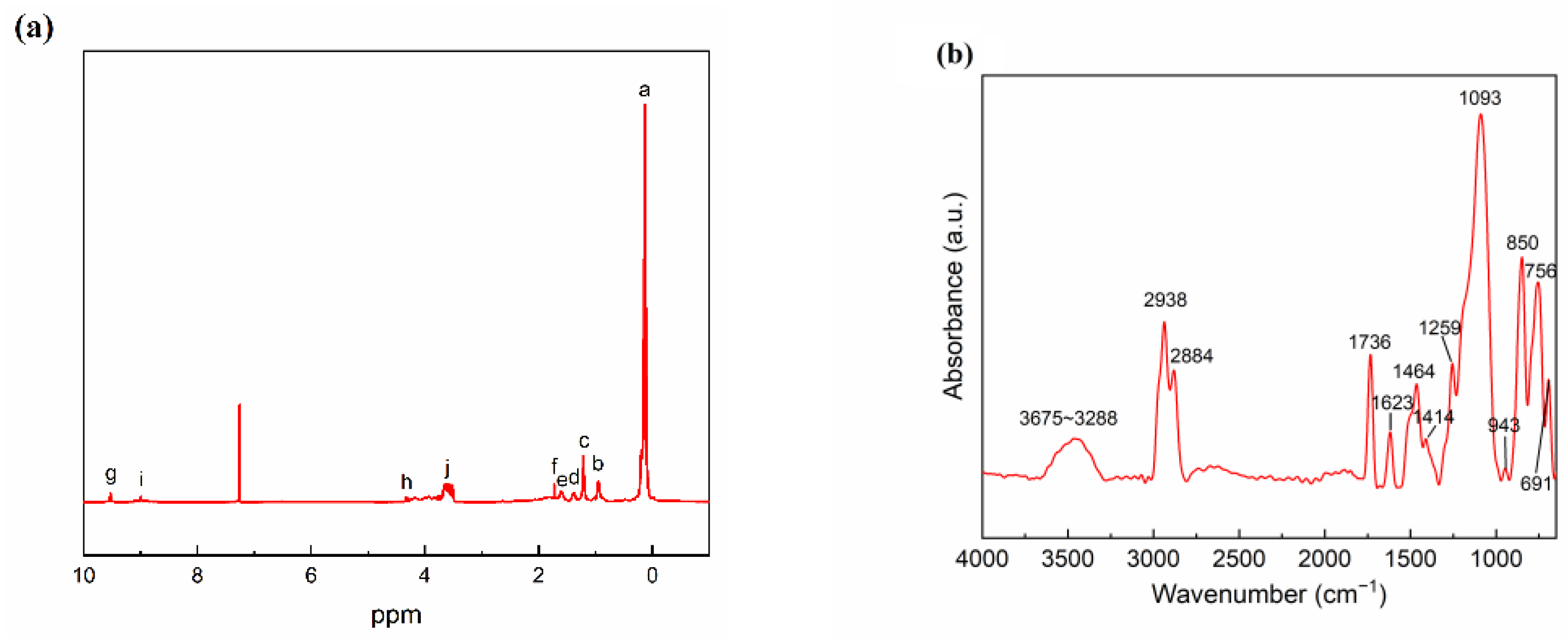

2.1. Synthesis of PTS

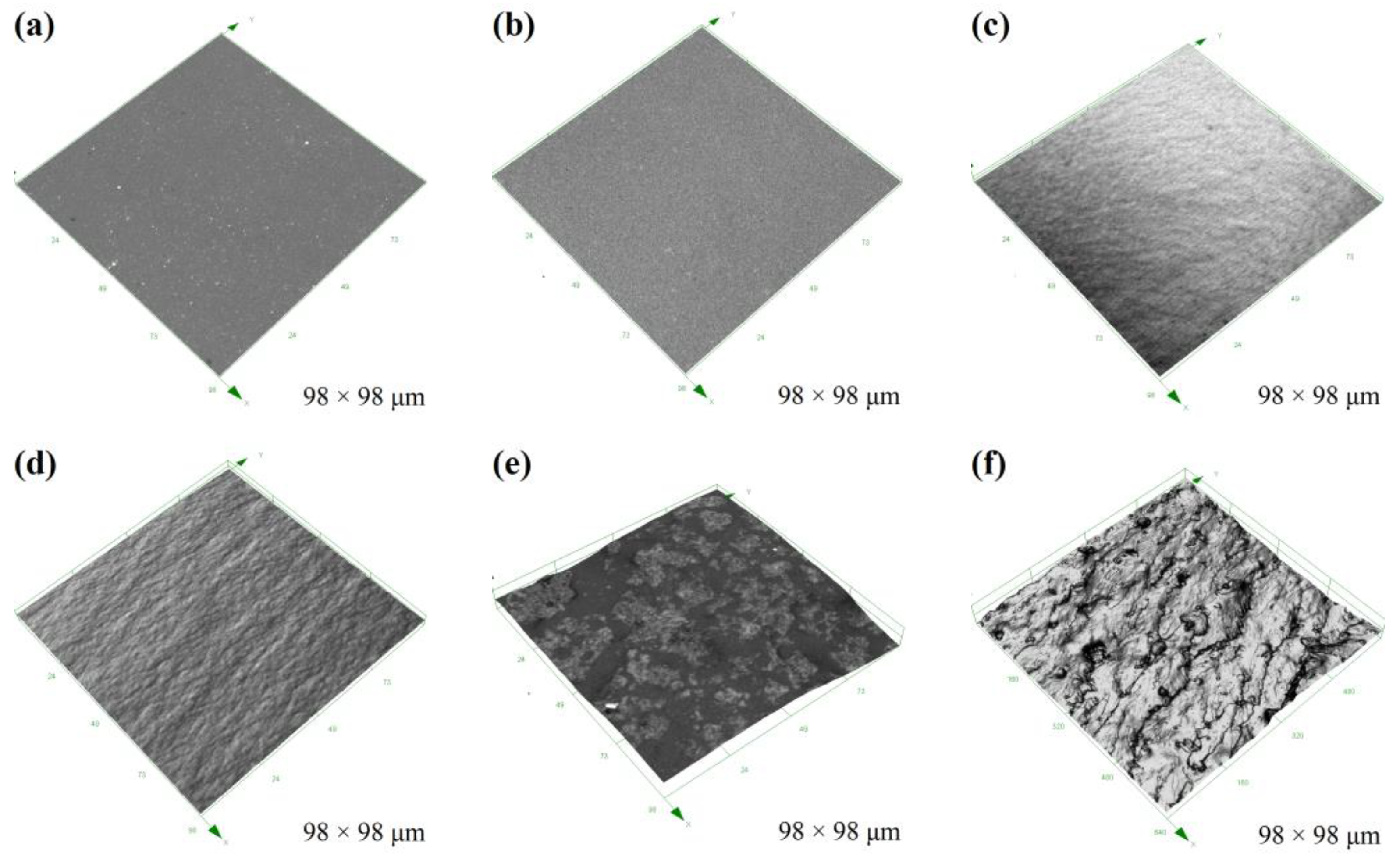

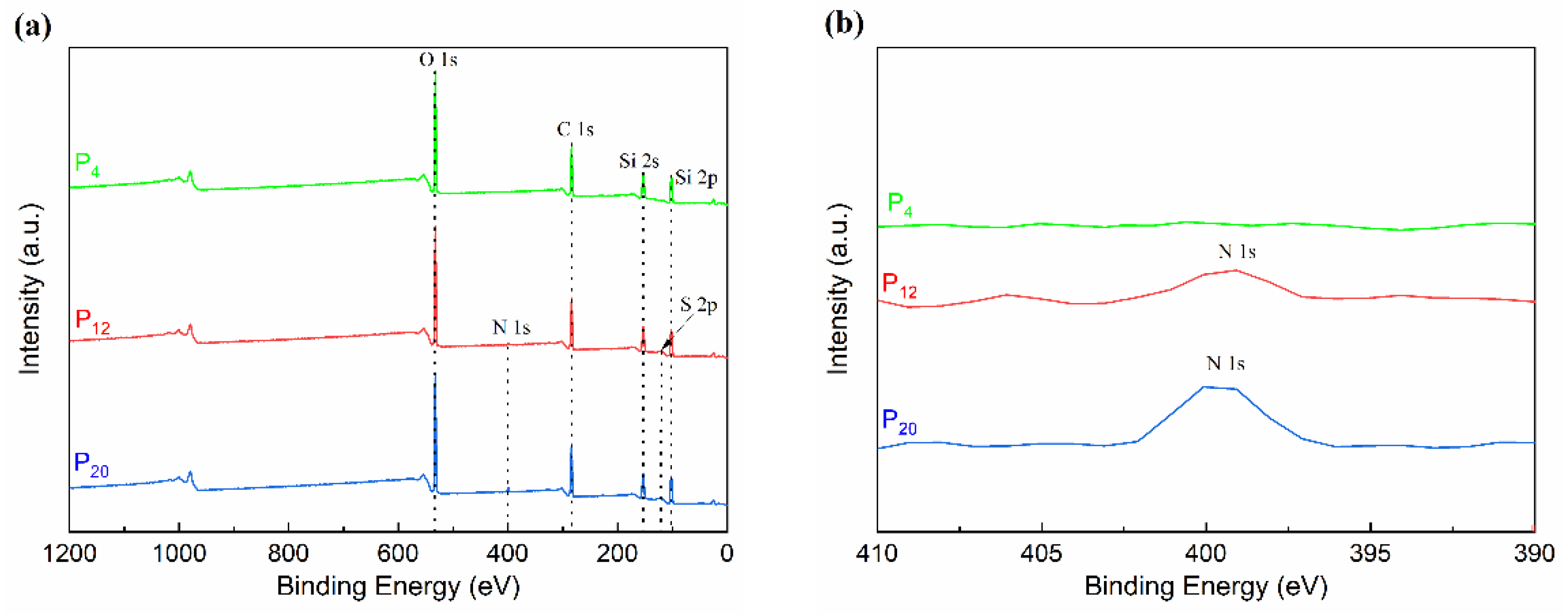

2.2. Surface Properties of the Prepared Coatings

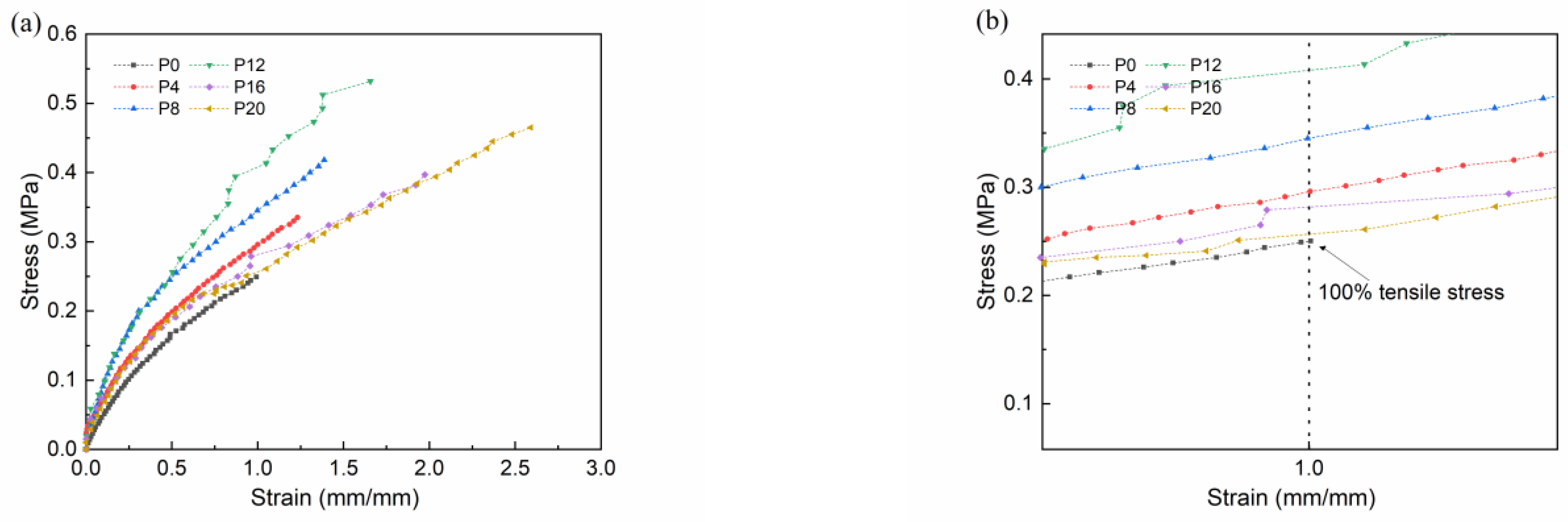

2.3. The Mechanical Properties of the Prepared Coatings

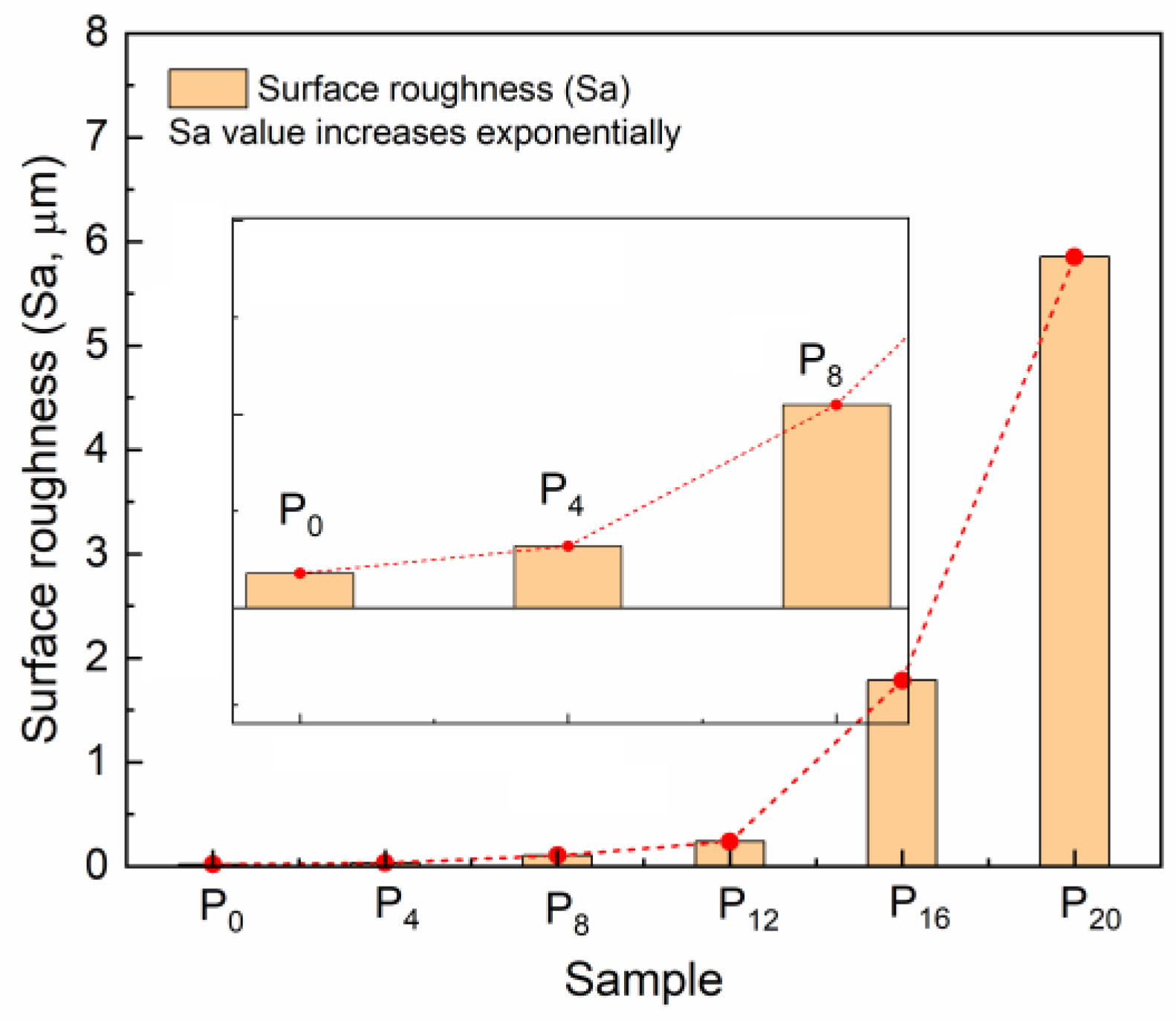

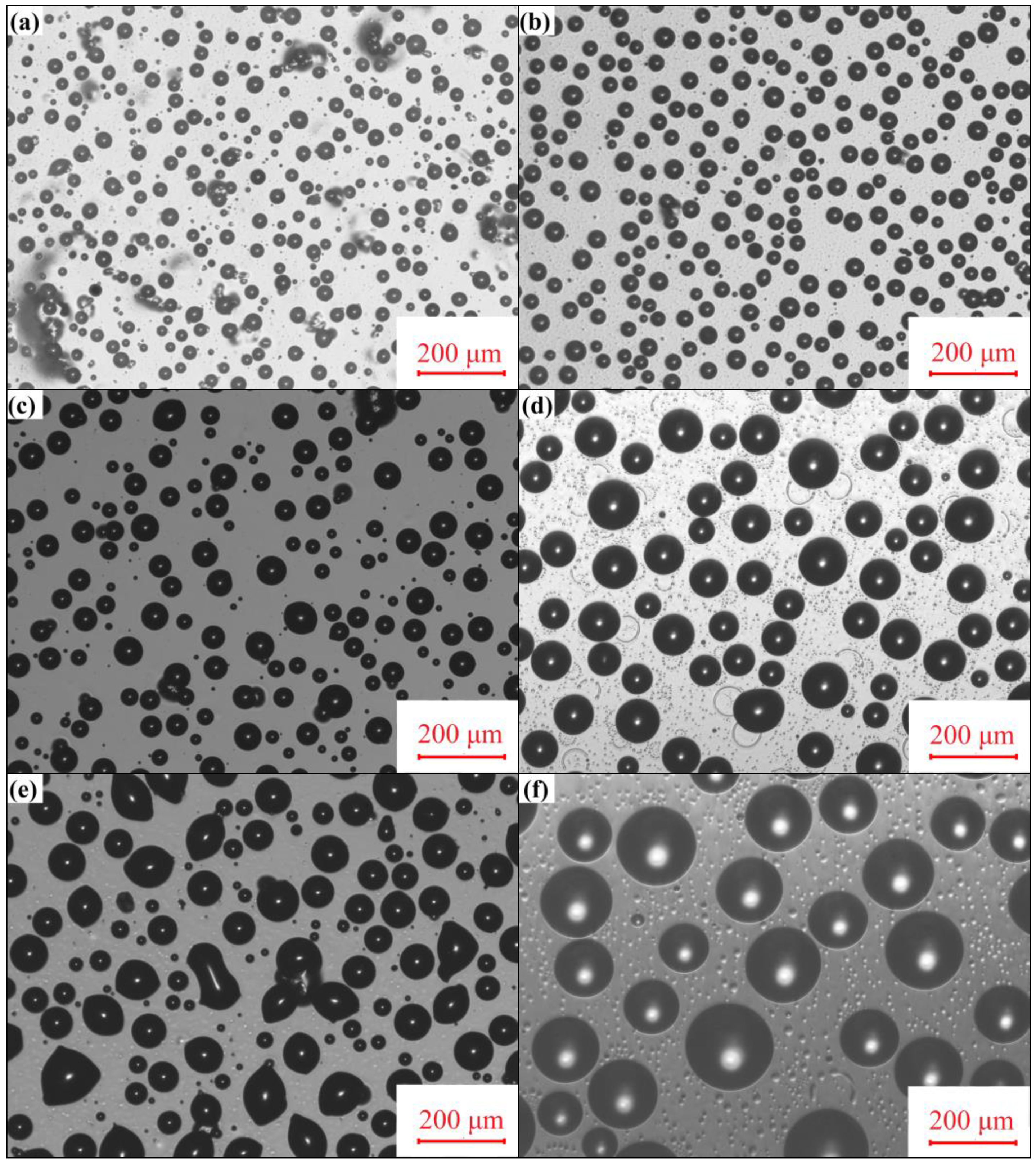

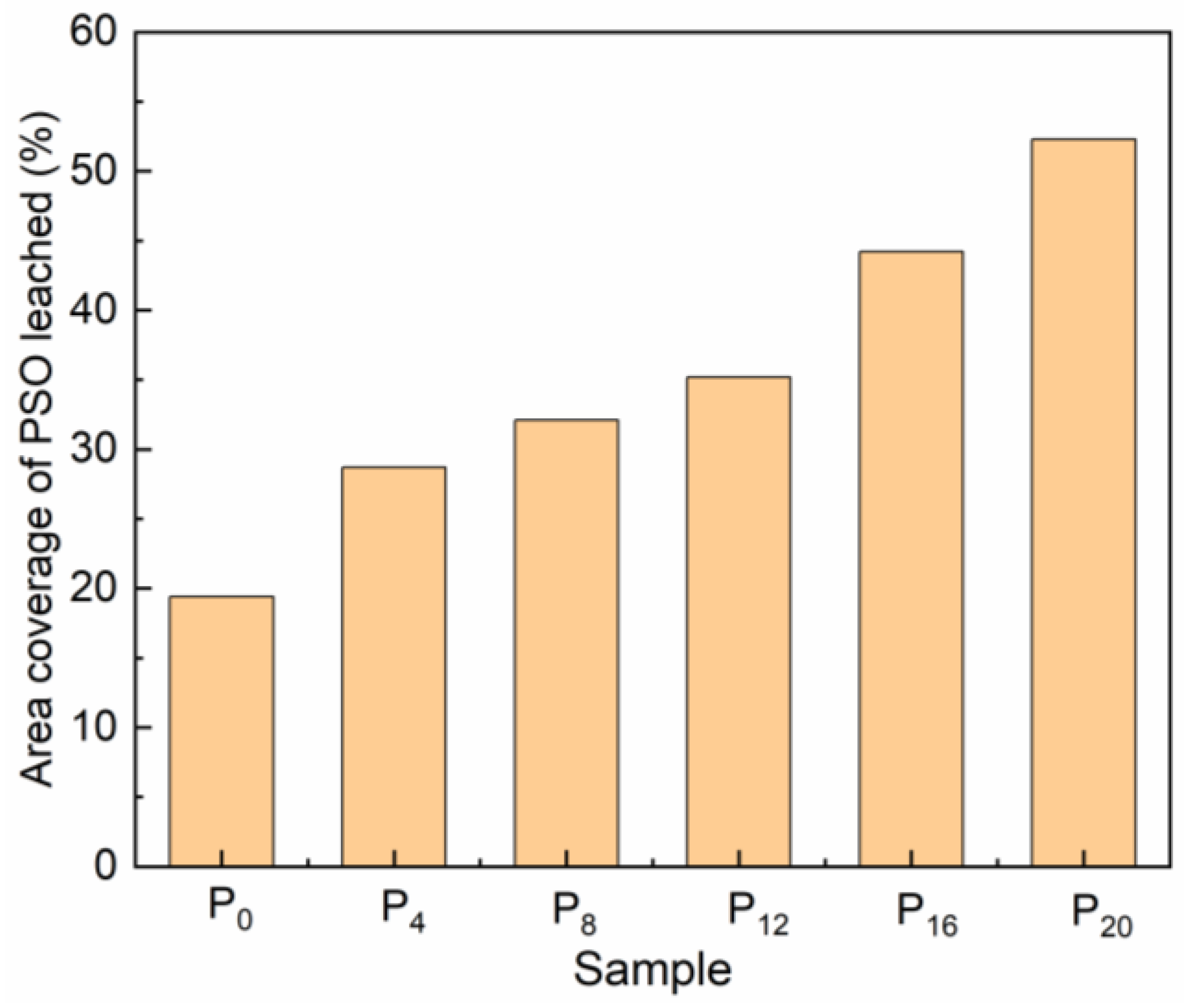

2.4. The Leaching Behavior of PSO

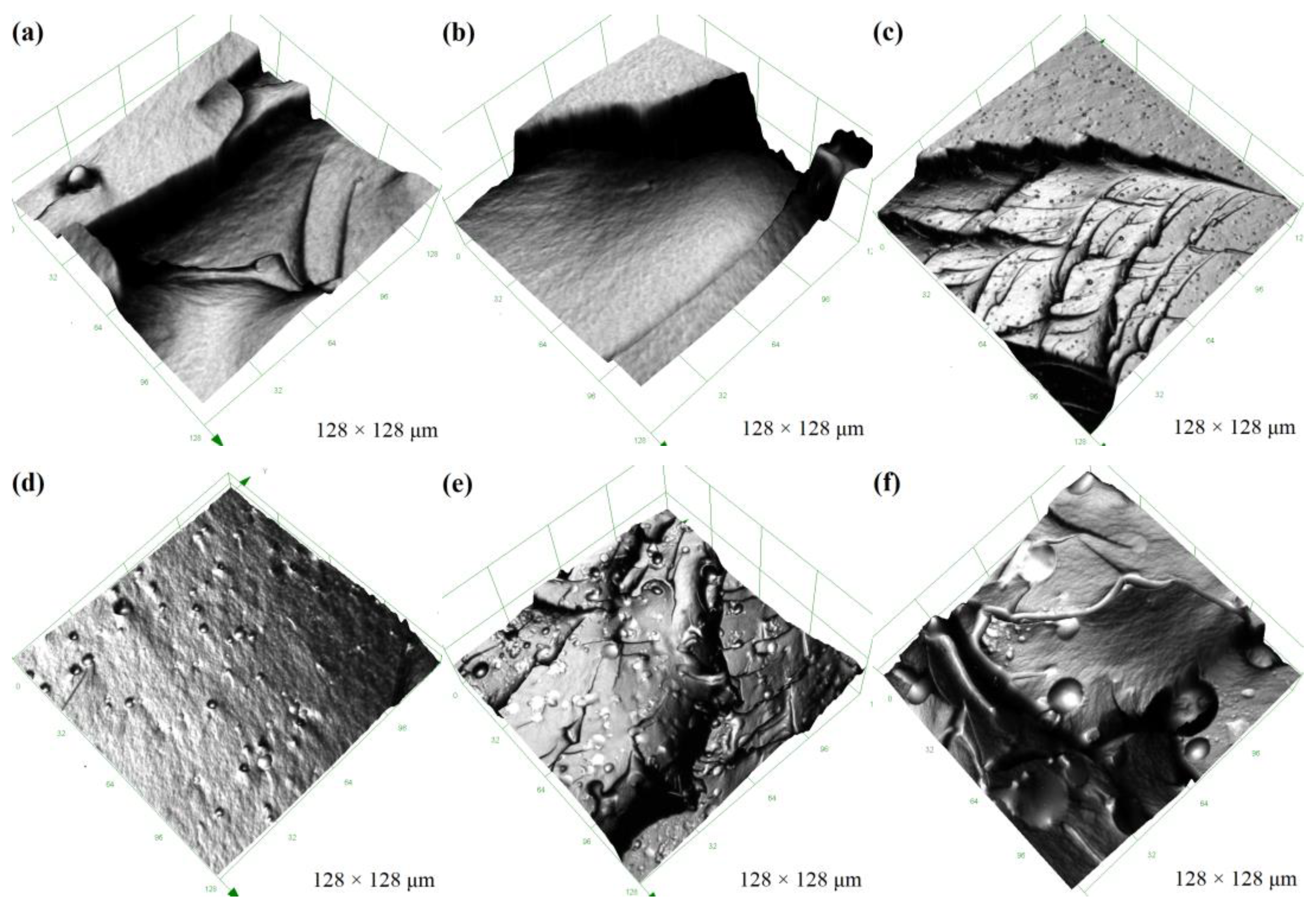

2.5. Bonding Strength between Coating and Substrate

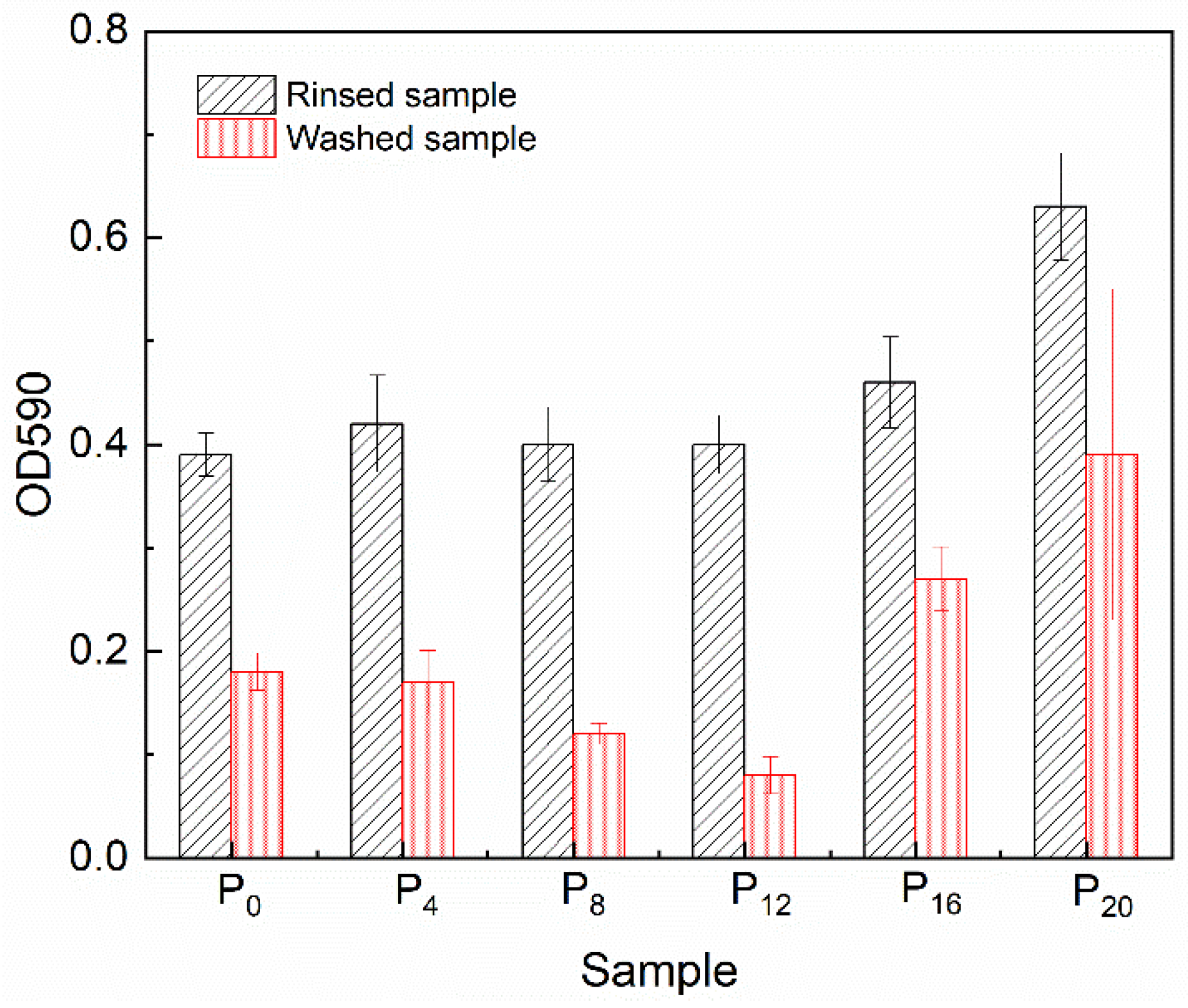

2.6. Antifouling Performance

3. Materials and Methods

3.1. Materials

3.2. Synthesis of Polymers

3.3. Preparation of Coatings

3.4. Characterization of Polymers

3.5. Surface Properties

3.6. Mechanical Properties

3.7. Coating Structure

3.8. Bonding Strength between Coating and Substrate

3.9. PSO Leaching Behavior

3.10. Coating Antifouling

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Xiong, G.; Zhang, Z.; Qi, Y. Effect of the properties of long afterglow phosphors on the antifouling performance of silicone fouling-release coating. Prog. Org. Coat. 2022, 170, 106965. [Google Scholar] [CrossRef]

- Guo, H.; Liu, X.; Zhao, W.; Xie, C.; Zhu, Y.; Wen, C.; Li, Q.; Sui, X.; Yang, J.; Zhang, L. A polyvinylpyrrolidone-based surface-active copolymer for an effective marine antifouling coating. Prog. Org. Coat. 2021, 150, 105975. [Google Scholar] [CrossRef]

- Wu, T.; Qi, Y.; Chen, Q.A.; Gu, C.; Zhang, Z. Preparation and Properties of Fluorosilicone Fouling-Release Coatings. Polymers 2022, 14, 3804. [Google Scholar] [CrossRef]

- Tian, L.; Yin, Y.; Bing, W.; Jin, E. Antifouling Technology Trends in Marine Environmental Protection. J. Bionic Eng. 2021, 18, 239–263. [Google Scholar] [CrossRef] [PubMed]

- Han, X.; Wu, J.; Zhang, X.; Shi, J.; Wei, J.; Yang, Y.; Wu, B.; Feng, Y. The progress on antifouling organic coating: From biocide to biomimetic surface. J. Mater. Sci. Technol. 2021, 61, 46–62. [Google Scholar] [CrossRef]

- Ferreira, O.; Rijo, P.; Gomes, J.F.; Santos, R.; Monteiro, S.; Vilas-Boas, C.; Correia-da-Silva, M.; Almada, S.; Alves, L.G.; Bordado, J.C.; et al. Biofouling Inhibition with Grafted Econea Biocide: Toward a Nonreleasing Eco-Friendly Multiresistant Antifouling Coating. ACS Sustain. Chem. Eng. 2020, 8, 12–17. [Google Scholar] [CrossRef]

- Chen, Q.A.; Zhang, Z.; Qi, Y. Influence of different silicone oils on properties of MWCNTs-OH/PDMS coatings. Surf. Eng. 2022, 38, 191–198. [Google Scholar] [CrossRef]

- Kolle, S.; Ahanotu, O.; Meeks, A.; Stafslien, S.; Kreder, M.; Vanderwal, L.; Cohen, L.; Waltz, G.; Lim, C.S.; Slocum, D.; et al. On the mechanism of marine fouling-prevention performance of oil-containing silicone elastomers. Sci. Rep. 2022, 12, 11799. [Google Scholar] [CrossRef] [PubMed]

- Qiu, H.; Gapeeva, A.; Hoelken, I.; Kaps, S.; Adelung, R.; Baum, M.J. Preventing algae adhesion using lubricant-modified polydimethylsiloxane/polythiourethane nanocomposite. Mater. Des. 2022, 214, 110389. [Google Scholar] [CrossRef]

- Chen, J.; Zhao, J.; Lin, F.; Zheng, X.; Jian, R.; Lin, Y.; Wei, F.; Lin, Q.; Bai, W.; Xu, Y. An FFT-based method for estimating the in-plane elastic properties of honeycomb considering geometric imperfections at large elastic deformation. Prog. Org. Coat. 2023, 177, 107411. [Google Scholar] [CrossRef]

- Gu, Y.; Yu, L.; Mou, J.; Wu, D.; Xu, M.; Zhou, P.; Ren, Y. Research Strategies to Develop Environmentally Friendly Marine Antifouling Coatings. Mar. Drugs 2020, 18, 371. [Google Scholar] [CrossRef] [PubMed]

- Guazzelli, E.; Perondi, F.; Criscitiello, F.; Pretti, C.; Oliva, M.; Casu, V.; Maniero, F.; Gazzera, L.; Galli, G.; Martinelli, E. New amphiphilic copolymers for PDMS-based nanocomposite films with long-term marine antifouling performance. J. Mater. Chem. B 2020, 8, 9764–9776. [Google Scholar] [CrossRef]

- Eduok, U.; Faye, O.; Szpunar, J. Recent developments and applications of protective silicone coatings: A review of PDMS functional materials. Prog. Org. Coat. 2017, 111, 124–163. [Google Scholar] [CrossRef]

- Hu, P.; Xie, Q.; Ma, C.; Zhang, G. Fouling resistant silicone coating with self-healing induced by metal coordination. Chem. Eng. J. 2021, 406, 126870. [Google Scholar] [CrossRef]

- Hu, P.; Xie, Q.; Ma, C.; Zhang, G. Silicone-Based Fouling-Release Coatings for Marine Antifouling. Langmuir 2020, 36, 2170–2183. [Google Scholar] [CrossRef]

- Yang, M.; Sun, Y.; Chen, G.; Wang, G.; Lin, S.; Sun, Z. Preparation of a self-healing silicone coating for inhibiting adhesion of benthic diatoms. Mater. Lett. 2020, 268, 2170–2183. [Google Scholar] [CrossRef]

- Ba, M.; Zhang, Z.-P.; Qi, Y.-H. The leaching behavior of phenylmethylsilicone oil and antifouling performance in nano-zinc oxide reinforced phenylmethylsilicone oil-Polydimethylsiloxane blend coating. Prog. Org. Coat. 2018, 125, 167–176. [Google Scholar] [CrossRef]

- Ba, M.; Zhang, Z.; Qi, Y. Fouling Release Coatings Based on Polydimethylsiloxane with the Incorporation of Phenylmethylsilicone Oil. Coatings 2018, 8, 153. [Google Scholar] [CrossRef]

- Shivapooja, P.; Cao, C.; Orihuela, B.; Levering, V.; Zhao, X.; Rittschof, D.; Lopez, G.P. Incorporation of silicone oil into elastomers enhances barnacle detachment by active surface strain. Biofouling 2016, 32, 1017–1028. [Google Scholar] [CrossRef]

- Yuan, H.; Hao, R.; Sun, H.; Zeng, W.; Lin, J.; Lu, S.; Yu, M.; Lin, S.; Li, J.; Chen, L. Engineered Janus cellulose membrane with the asymmetric-pore structure for the superhigh-water flux desalination. Carbohydr. Polym. 2022, 291, 232. [Google Scholar] [CrossRef]

- Sun, H.; Liu, Z.; Liu, K.; Gibril, M.E.; Kong, F.; Wang, S. Lignin-based superhydrophobic melamine resin sponges and their application in oil/water separation. Ind. Crops Prod. 2021, 170, 113798. [Google Scholar] [CrossRef]

- Yang, Q.; Zhang, Z.; Qi, Y.; Zhang, H. The Antifouling and Drag-Reduction Performance of Alumina Reinforced Polydimethylsiloxane Coatings Containing Phenylmethylsilicone Oil. Polymers 2021, 13, 3067. [Google Scholar] [CrossRef]

- Selim, M.S.; Elmarakbi, A.; Azzam, A.M.; Shenashen, M.A.; El-Saeed, A.M.; El-Safty, S.A. Eco-friendly design of superhydrophobic nano-magnetite/silicone composites for marine foul-release paints. Prog. Org. Coat. 2018, 116, 21–34. [Google Scholar] [CrossRef]

- Yang, W.J.; Neoh, K.-G.; Kang, E.-T.; Teo, S.L.-M.; Rittschof, D. Polymer brush coatings for combating marine biofouling. Prog. Polym. Sci. 2014, 39, 1017–1042. [Google Scholar] [CrossRef]

- Xue, J.; Wang, L.; Fan, Y.; Xu, J.; Zhao, J.; Tian, L.; Du, W. Mechanically Enhanced Self-Stratified Acrylic/Silicone Antifouling Coatings. Coatings 2022, 12, 232. [Google Scholar] [CrossRef]

- Wang, Y.-J.; He, Y.; Zheng, S.Y.; Xu, Z.; Li, J.; Zhao, Y.; Chen, L.; Liu, W. Polymer Pressure-Sensitive Adhesive with A Temperature-Insensitive Loss Factor Operating Under Water and Oil. Adv. Funct. Mater. 2021, 31, 2104296. [Google Scholar] [CrossRef]

- Galhenage, T.P.; Hoffman, D.; Silbert, S.D.; Stafslien, S.J.; Daniels, J.; Miljkovic, T.; Finlay, J.A.; Franco, S.C.; Clare, A.S.; Nedved, B.T.; et al. Fouling-Release Performance of Silicone Oil-Modified Siloxane-Polyurethane Coatings. ACS Appl. Mater. Interfaces 2016, 8, 29025–29036. [Google Scholar] [CrossRef] [PubMed]

- Owens, D.K.; Wendt, R.C. Estimation of the surface free energy of polymer. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- Zhou, H.; Zheng, Y.; Ba, M.; Kong, J.; Wang, Y. Self-stratified fouling release coatings based on polydimethylsiloxane incorporated with acrylate-MQ silicone copolymer. Prog. Org. Coat. 2021, 161, 106539. [Google Scholar] [CrossRef]

- Fan, F.; Zheng, Y.; Ba, M.; Wang, Y.; Kong, J.; Liu, J.; Wu, Q. Long time super-hydrophobic fouling release coating with the incorporation of lubricant. Prog. Org. Coat. 2021, 152, 106136. [Google Scholar] [CrossRef]

| Sample | Contact Angle (°) | Surface Free Energy (mJ/m2) | |

|---|---|---|---|

| Water | Diiodomethane | ||

| P0 | 108.6 ± 0.32 | 68.9 ± 0.65 | 23.7 |

| P4 | 108.5 ± 0.63 | 69.5 ± 0.66 | 23.4 |

| P8 | 109.8 ± 0.55 | 70.3 ± 0.47 | 22.7 |

| P12 | 111.4 ± 0.31 | 72.5 ± 0.38 | 21.8 |

| P16 | 96.1 ± 0.65 | 67.6 ± 0.31 | 24.7 |

| P20 | 88.6 ± 1.12 | 61.1 ± 1.03 | 29.1 |

| Sample | Elastic Modulus (MPa) | 100% Tensile Stress (MPa) | Breaking Elongation (%) | Shore Hardness (HA) | Crosslinking Density (Mc) |

|---|---|---|---|---|---|

| P0 | 0.31 ± 0.027 | 0.251 | 100.7 | 12.8 ± 0.55 | 19,840 ± 374 |

| P4 | 0.61 ± 0.030 | 0.290 | 123.2 | 13.3 ± 0.31 | 14,533 ± 536 |

| P8 | 0.78 ± 0.042 | 0.345 | 138.8 | 14.6 ± 0.67 | 12,011 ± 219 |

| P12 | 0.81 ± 0.102 | 0.414 | 165.7 | 16.7 ± 1.05 | 9870 ± 343 |

| P16 | 0.57 ± 0.061 | 0.278 | 197.4 | 23.5 ± 0.75 | 15,611 ± 406 |

| P20 | 0.50 ± 0.038 | 0.256 | 259.1 | 26.7 ± 0.80 | 17,520 ± 277 |

| Sample | P0 | P4 | P8 | P12 | P16 | P20 |

|---|---|---|---|---|---|---|

| Pull-off strength (MPa) | 0.08 ± 0.011 | 0.15 ± 0.027 | 0.24 ± 0.018 | 0.35 ± 0.037 | 0.41 ± 0.031 | 0.40 ± 0.040 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Nan, L.; Zhang, B.; Kong, J.; Wang, Y.; Ba, M. Polyether-Thiourea-Siloxane Copolymer Based on H-Bonding Interaction for Marine Antifouling. Molecules 2023, 28, 3574. https://doi.org/10.3390/molecules28083574

Li M, Nan L, Zhang B, Kong J, Wang Y, Ba M. Polyether-Thiourea-Siloxane Copolymer Based on H-Bonding Interaction for Marine Antifouling. Molecules. 2023; 28(8):3574. https://doi.org/10.3390/molecules28083574

Chicago/Turabian StyleLi, Mengyu, Liyang Nan, Boxuan Zhang, Junjun Kong, Yufeng Wang, and Miao Ba. 2023. "Polyether-Thiourea-Siloxane Copolymer Based on H-Bonding Interaction for Marine Antifouling" Molecules 28, no. 8: 3574. https://doi.org/10.3390/molecules28083574

APA StyleLi, M., Nan, L., Zhang, B., Kong, J., Wang, Y., & Ba, M. (2023). Polyether-Thiourea-Siloxane Copolymer Based on H-Bonding Interaction for Marine Antifouling. Molecules, 28(8), 3574. https://doi.org/10.3390/molecules28083574