The Application of Hyperspectral Imaging Technologies for the Prediction and Measurement of the Moisture Content of Various Agricultural Crops during the Drying Process

Abstract

1. Introduction

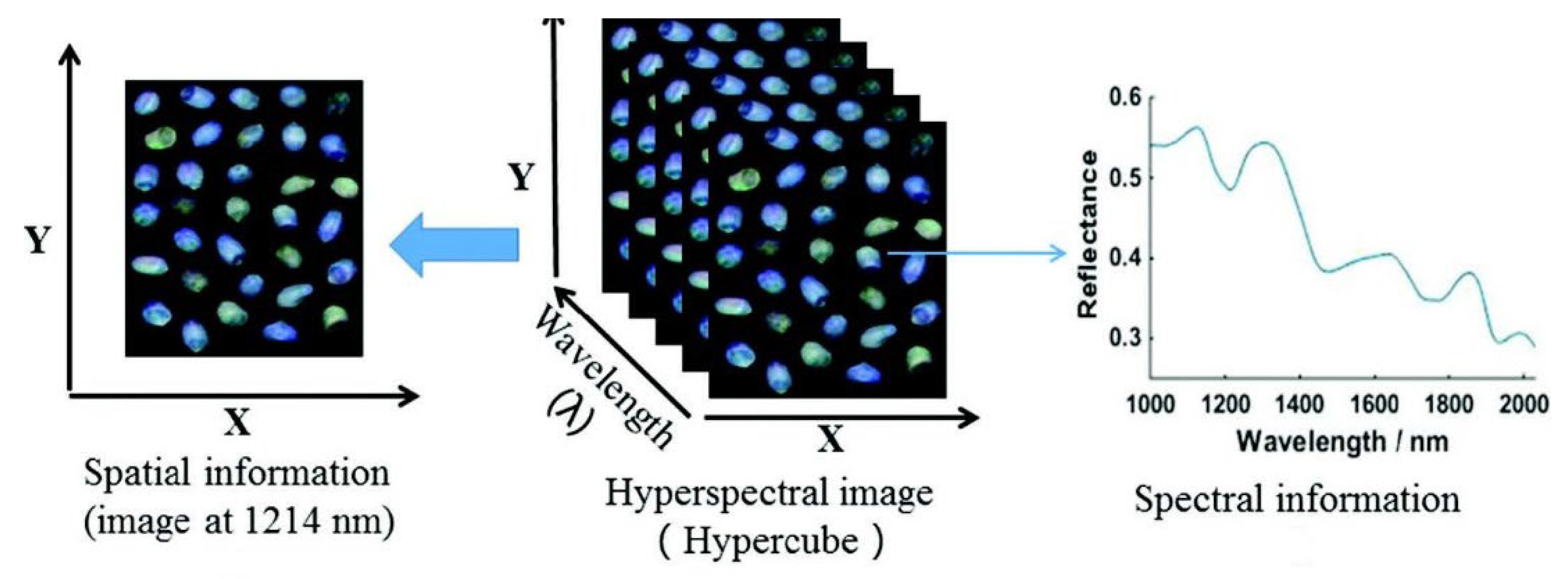

2. HSI Technology

3. Components of the HSI Technology

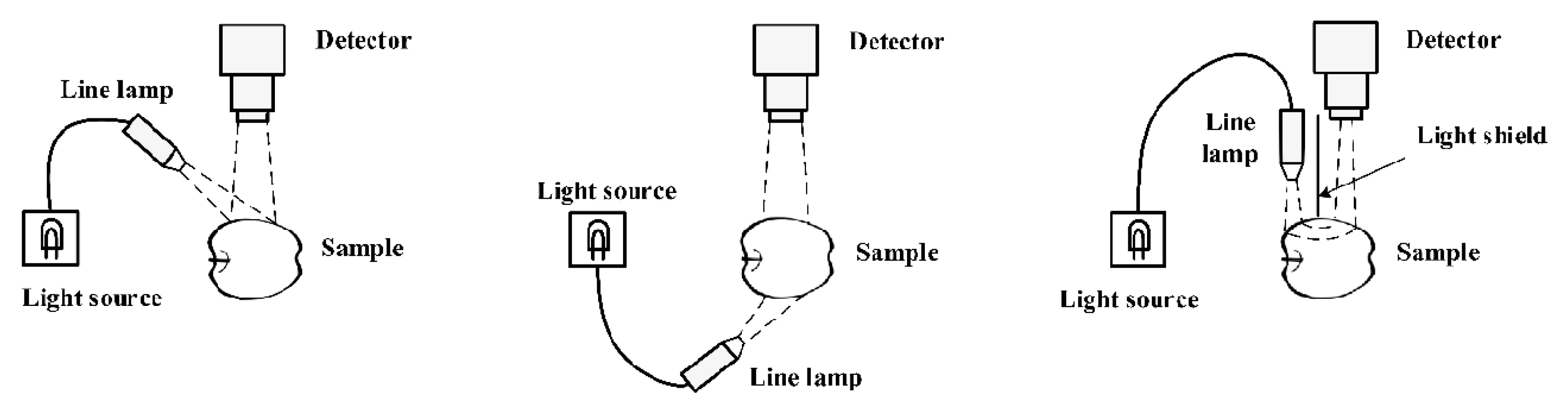

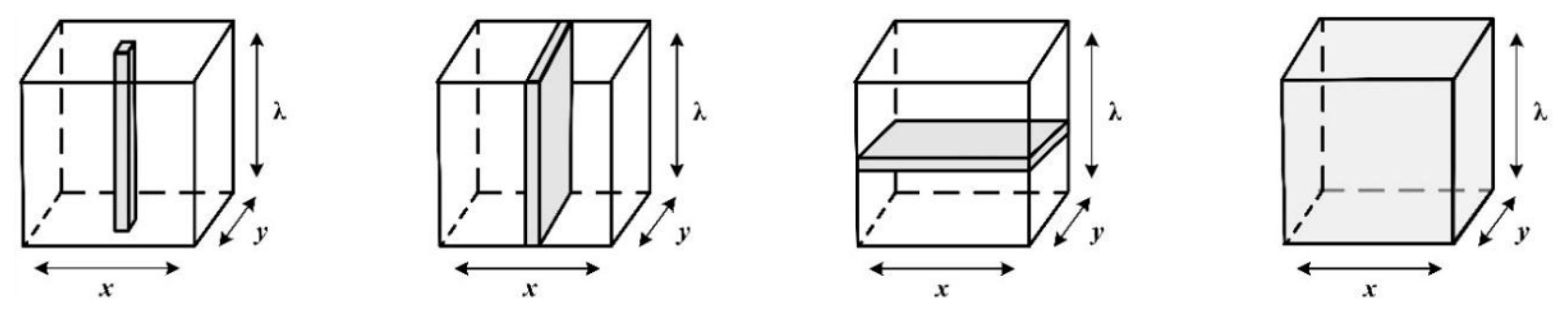

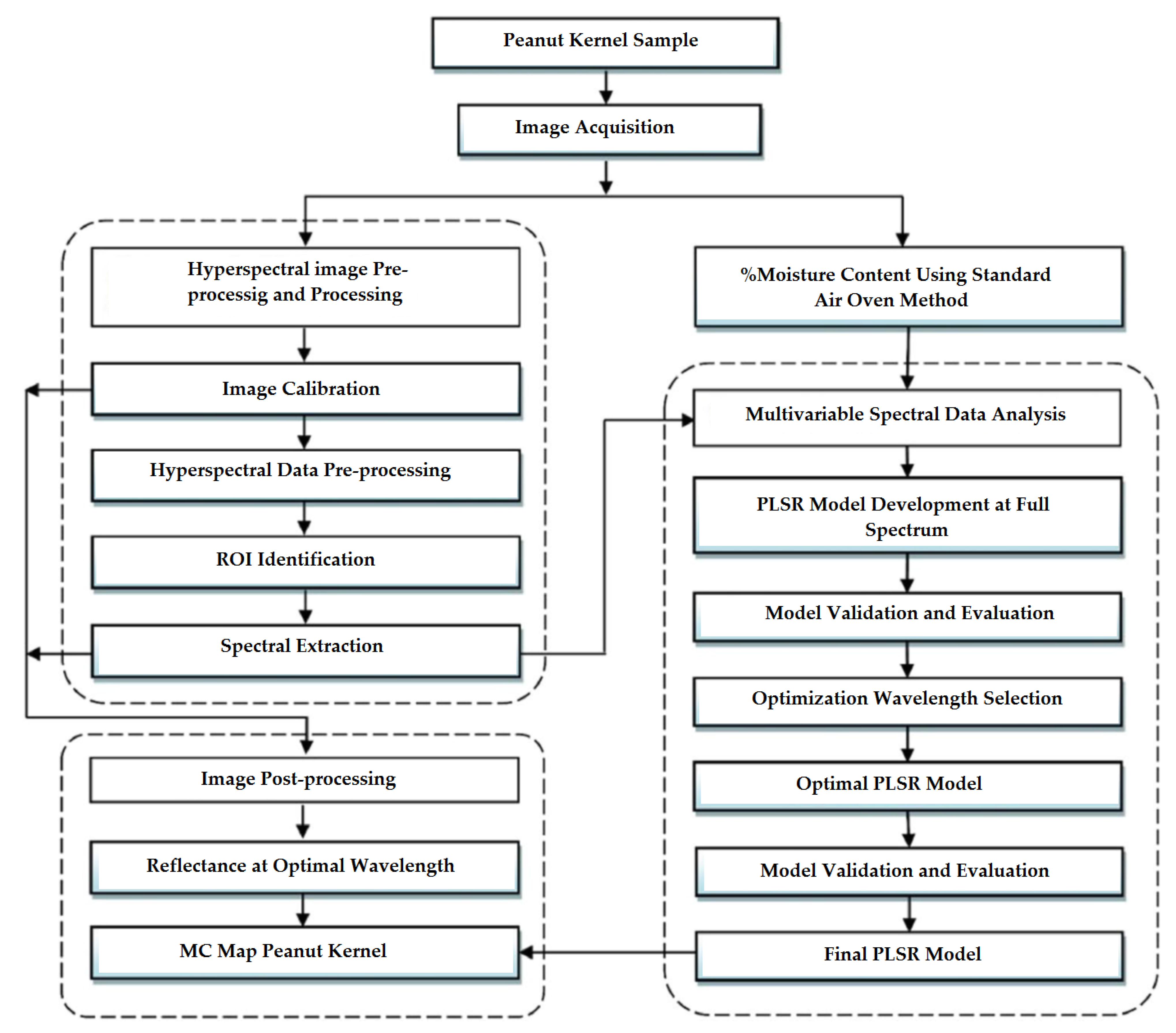

4. HSI Acquisition

5. Processes on the Spectra

5.1. Principal Component Analysis for Eliminating the Outliers

5.2. Pre-Processing

5.2.1. SNV

5.2.2. MSC

5.2.3. Smoothing

5.3. Calibration Models

5.4. Selection of the Optimal Wavelength

5.5. Development of Models Using Feature Wavelengths

6. Comparison of Various Techniques for Prediction of Moisture Content of Agricultural Products

6.1. Application of the HSI System to Predict the Moisture Content of the Agricultural Products during the Drying Process

| Products | Drying Method | Spectral Range (nm) | Data Analysis Method | Best Wavelength | Performance | Reference |

|---|---|---|---|---|---|---|

| Fresh carrot, celery stem, potato, and spinach leaves | Microwave-vacuum | 950–1655 | PLSR SVM MLR | 1190 and 1450 | R2p = 0.974 RMSEP = 4.70% | [3] |

| Apple slices | Hot air | 396–1010 | PLS | 580, 750, 970 | R2p = 0.98 RMSEP = 0.27 | [59] |

| Apple slices | Convection | 400–1000 | PLSR | 540, 817, 977 | R2p = 0.99 RMSEP = 0.13 | [4] |

| Apple slices | Hot-air | 400–1700 | PLSR | 980 and 1450 | R2p = 0.99 RMSEP = 0.89 | [11] |

| Persimmon | In the shade | 400–900 | PLSR PCR LS-SVR RBFNN | about twenty wavelengths | R2p = 0.856 RMSEP = 0.0387 | [8] |

| Wolfberry | Hot air | 400–1001 | SVM ABC GWO | 895.28 | R2p = 0.9666 | [60] |

| Potato | Oven drying | 387–1035 | XGBoost | 400 | R2p = 0.8908 RMSEP = 0.0610 | [61] |

| Carrot | Hot air | 400–1010 | PLSR | 973 | R2p = 0.90 RMSEP = 0.0816 | [62] |

| Corn | Oven | 968.05–2575.05 | CNN-LSTM | --- | R2p = 0.947 RMSEP = 0.274 | [63] |

| Almonds | Oven | 900–1700 | PLSR | 970, 1001, 1154, 1312, 1350, 1437, 1670 | R2p = 0.941 RMSEP = 0.494 | [28] |

| Peanut | Oven | 900–1700 | PLSR | Twenty wavelengths | R2p = 0.9445 RMSEP = 1.9519 | [64] |

| Blueberry | Climatic chamber | 470–900 | PLS | 706, 790, 827, 868, and 894 | R2p = 0.9445 RMSEP = 1.9519 | [34] |

| Melon | Hot air | 1000–2500 | PLS | 1400 and 1900 | R2p = 0.98 RMSEP = 2.98 | [5] |

6.2. The Possibility of Using Hyperspectral Imaging for a Smart System

7. Conclusions and Future Trends

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bashkir, I.; Defraeye, T.; Kudra, T.; Martynenko, A. Electrohydrodynamic drying of plant-based foods and food model systems. Food Eng. Rev. 2020, 12, 473–497. [Google Scholar] [CrossRef]

- Sturm, B.; Vega, A.-M.N.; Hofacker, W.C. Influence of process control strategies on drying kinetics, colour and shrinkage of air dried apples. Appl. Therm. Eng. 2014, 62, 455–460. [Google Scholar] [CrossRef]

- Lin, X.; Sun, D.-W. Development of a general model for monitoring moisture distribution of four vegetables undergoing microwave-vacuum drying by hyperspectral imaging. Dry. Technol. 2022, 40, 1478–1492. [Google Scholar] [CrossRef]

- Crichton, S.; Shrestha, L.; Hurlbert, A.; Sturm, B. Use of hyperspectral imaging for the prediction of moisture content and chromaticity of raw and pretreated apple slices during convection drying. Dry. Technol. 2018, 36, 804–816. [Google Scholar] [CrossRef]

- Netto, J.M.S.; Honorato, F.A.; Azoubel, P.M.; Kurozawa, L.E.; Barbin, D.F. Evaluation of melon drying using hyperspectral imaging technique in the near infrared region. LWT 2021, 143, 111092. [Google Scholar] [CrossRef]

- Lin, X.; Xu, J.-L.; Sun, D.-W. Evaluating drying feature differences between ginger slices and splits during microwave-vacuum drying by hyperspectral imaging technique. Food Chem. 2020, 332, 127407. [Google Scholar] [CrossRef] [PubMed]

- Frankelius, P.; Norrman, C.; Johansen, K. Agricultural innovation and the role of institutions: Lessons from the game of drones. J. Agric. Environ. Ethics 2019, 32, 681–707. [Google Scholar] [CrossRef]

- Chen, X.; Jiao, Y.; Liu, B.; Chao, W.; Duan, X.; Yue, T. Using hyperspectral imaging technology for assessing internal quality parameters of persimmon fruits during the drying process. Food Chem. 2022, 386, 132774. [Google Scholar] [CrossRef]

- Dale, L.M.; Thewis, A.; Boudry, C.; Rotar, I.; Dardenne, P.; Baeten, V.; Pierna, J.A.F. Hyperspectral imaging applications in agriculture and agro-food product quality and safety control: A review. Appl. Spectrosc. Rev. 2013, 48, 142–159. [Google Scholar] [CrossRef]

- Wu, D.; Sun, D.-W. Advanced applications of hyperspectral imaging technology for food quality and safety analysis and assessment: A review—Part ii: Applications. Innov. Food Sci. Emerg. Technol. 2013, 19, 15–28. [Google Scholar] [CrossRef]

- Arefi, A.; Sturm, B.; von Gersdorff, G.; Nasirahmadi, A.; Hensel, O. Vis-nir hyperspectral imaging along with gaussian process regression to monitor quality attributes of apple slices during drying. LWT 2021, 152, 112297. [Google Scholar] [CrossRef]

- Nurkhoeriyati, T.; Sturm, B.; Hensel, O. Non-Destructive In-Process Quality Evaluation of Plant-Sourced Food during Drying; IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2022; p. 012025. [Google Scholar]

- ElMasry, G.; Sun, D.-W. Principles of hyperspectral imaging technology. In Hyperspectral Imaging for Food Quality Analysis and Control; Elsevier: Amsterdam, The Netherlands, 2010; pp. 3–43. [Google Scholar]

- Calin, M.A.; Parasca, S.V.; Savastru, D.; Manea, D. Hyperspectral imaging in the medical field: Present and future. Appl. Spectrosc. Rev. 2014, 49, 435–447. [Google Scholar] [CrossRef]

- Goel, P.K.; Prasher, S.O.; Landry, J.-A.; Patel, R.M.; Bonnell, R.; Viau, A.A.; Miller, J. Potential of airborne hyperspectral remote sensing to detect nitrogen deficiency and weed infestation in corn. Comput. Electron. Agric. 2003, 38, 99–124. [Google Scholar] [CrossRef]

- Apan, A.; Held, A.; Phinn, S.; Markley, J. Detecting sugarcane ‘orange rust’disease using eo-1 hyperion hyperspectral imagery. Int. J. Remote Sens. 2004, 25, 489–498. [Google Scholar] [CrossRef]

- Lu, B.; Dao, P.D.; Liu, J.; He, Y.; Shang, J. Recent advances of hyperspectral imaging technology and applications in agriculture. Remote Sens. 2020, 12, 2659. [Google Scholar] [CrossRef]

- Mulla, D.J. Twenty five years of remote sensing in precision agriculture: Key advances and remaining knowledge gaps. Biosyst. Eng. 2013, 114, 358–371. [Google Scholar] [CrossRef]

- Yao, H.; Lewis, D. Spectral preprocessing and calibration techniques. In Hyperspectral Imaging for Food Quality Analysis and Control; Elsevier: Amsterdam, The Netherlands, 2010; pp. 45–78. [Google Scholar]

- Lee, D.; Lohumi, S.; Cho, B.-K.; Lee, S.H.; Jung, H. Determination of drying patterns of radish slabs under different drying methods using hyperspectral imaging coupled with multivariate analysis. Foods 2020, 9, 484. [Google Scholar] [CrossRef]

- Shrestha, L.; Crichton, S.O.; Kulig, B.; Kiesel, B.; Hensel, O.; Sturm, B. Comparative analysis of methods and model prediction performance evaluation for continuous online non-invasive quality assessment during drying of apples from two cultivars. Therm. Sci. Eng. Prog. 2020, 18, 100461. [Google Scholar] [CrossRef]

- Su, W.-H.; Bakalis, S.; Sun, D.-W. Chemometric determination of time series moisture in both potato and sweet potato tubers during hot air and microwave drying using near/mid-infrared (nir/mir) hyperspectral techniques. Dry. Technol. 2020, 38, 806–823. [Google Scholar] [CrossRef]

- von Gersdorff, G.J.; Kirchner, S.M.; Hensel, O.; Sturm, B. Impact of drying temperature and salt pre-treatments on drying behavior and instrumental color and investigations on spectral product monitoring during drying of beef slices. Meat Sci. 2021, 178, 108525. [Google Scholar] [CrossRef]

- Sun, J.; Wang, G.; Zhang, H.; Xia, L.; Zhao, W.; Guo, Y.; Sun, X. Detection of fat content in peanut kernels based on chemometrics and hyperspectral imaging technology. Infrared Phys. Technol. 2020, 105, 103226. [Google Scholar] [CrossRef]

- Nicolaï, B.M.; Defraeye, T.; De Ketelaere, B.; Herremans, E.; Hertog, M.L.; Saeys, W.; Torricelli, A.; Vandendriessche, T.; Verboven, P. Nondestructive measurement of fruit and vegetable quality. Annu. Rev. Food Sci. Technol 2014, 5, 285–312. [Google Scholar] [CrossRef]

- Lu, Y.; Huang, Y.; Lu, R. Innovative Hyperspectral Imaging-Based Techniques for Quality Evaluation of Fruits and Vegetables: A Review. Appl. Sci. 2017, 7, 189. [Google Scholar] [CrossRef]

- Sun, J.; Cong, S.; Mao, H.; Wu, X.; Yang, N. Quantitative detection of mixed pesticide residue of lettuce leaves based on hyperspectral technique. J. Food Process Eng. 2018, 41, e12654. [Google Scholar] [CrossRef]

- Panda, B.K.; Mishra, G.; Ramirez, W.A.; Jung, H.; Singh, C.B.; Lee, S.-H.; Lee, I. Rancidity and moisture estimation in shelled almond kernels using nir hyperspectral imaging and chemometric analysis. J. Food Eng. 2022, 318, 110889. [Google Scholar] [CrossRef]

- Sun, J.; Shi, X.; Zhang, H.; Xia, L.; Guo, Y.; Sun, X. Detection of moisture content in peanut kernels using hyperspectral imaging technology coupled with chemometrics. J. Food Process Eng. 2019, 42, e13263. [Google Scholar] [CrossRef]

- Feng, C.-H.; Makino, Y.; Oshita, S.; Martín, J.F.G. Hyperspectral imaging and multispectral imaging as the novel techniques for detecting defects in raw and processed meat products: Current state-of-the-art research advances. Food Control 2018, 84, 165–176. [Google Scholar] [CrossRef]

- Wang, B.; Sun, J.; Xia, L.; Liu, J.; Wang, Z.; Li, P.; Guo, Y.; Sun, X. The applications of hyperspectral imaging technology for agricultural products quality analysis: A review. Food Rev. Int. 2021, 29, 1–20. [Google Scholar] [CrossRef]

- Brereton, R.G. Chemometrics: Data Analysis for the Laboratory and Chemical Plant; John Wiley & Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

- Rossel, R.A.V. Parles: Software for chemometric analysis of spectroscopic data. Chemom. Intell. Lab. Syst. 2008, 90, 72–83. [Google Scholar] [CrossRef]

- Choi, J.-Y.; Kim, J.; Kim, J.; Jeong, S.; Kim, M.; Park, S.; Moon, K.-D. Hyperspectral imaging technigue for monitoring moisture content of blueberry during the drying process. Korean J. Food Preserv. 2021, 28, 445–455. [Google Scholar] [CrossRef]

- Barnes, R.; Dhanoa, M.S.; Lister, S.J. Standard normal variate transformation and de-trending of near-infrared diffuse reflectance spectra. Appl. Spectrosc. 1989, 43, 772–777. [Google Scholar] [CrossRef]

- Fu, X.; Ying, Y.; Lu, H.; Xu, H.; Yu, H. Ft-nir diffuse reflectance spectroscopy for kiwifruit firmness detection. Sens. Instrum. Food Qual. Saf. 2007, 1, 29–35. [Google Scholar] [CrossRef]

- Geladi, P.; MacDougall, D.; Martens, H. Linearization and scatter-correction for near-infrared reflectance spectra of meat. Appl. Spectrosc. 1985, 39, 491–500. [Google Scholar] [CrossRef]

- Nicolai, B.M.; Beullens, K.; Bobelyn, E.; Peirs, A.; Saeys, W.; Theron, K.I.; Lammertyn, J. Nondestructive measurement of fruit and vegetable quality by means of nir spectroscopy: A review. Postharvest Biol. Technol. 2007, 46, 99–118. [Google Scholar] [CrossRef]

- Williams, P.; Sobering, D. How do we do it: A brief summary of the methods we use in developing near infrared calibrations. In Near Infrared Spectroscopy: The Future Waves; Davies, A.M.C., Williams, P.C., Eds.; NIR Publications: Chichester, UK, 1996; pp. 185–188. [Google Scholar]

- Wu, D.; Chen, X.; Zhu, X.; Guan, X.; Wu, G. Uninformative variable elimination for improvement of successive projections algorithm on spectral multivariable selection with different calibration algorithms for the rapid and non-destructive determination of protein content in dried laver. Anal. Methods 2011, 3, 1790–1796. [Google Scholar] [CrossRef]

- Martynenko, A. Computer-vision system for control of drying processes. Dry. Technol. 2006, 24, 879–888. [Google Scholar] [CrossRef]

- Trincă, L.C.; Căpraru, A.-M.; Arotăriţei, D.; Volf, I.; Chiruţă, C. Monitoring methods and predictive models for water status in jonathan apples. Food Chem. 2014, 144, 80–86. [Google Scholar] [CrossRef]

- Collell, C.; Gou, P.; Arnau, J.; Muñoz, I.; Comaposada, J. Nir technology for online determination of superficial aw and moisture content during the drying process of fermented sausages. Food Chem. 2012, 135, 1750–1755. [Google Scholar] [CrossRef]

- Cuccurullo, G.; Giordano, L.; Albanese, D.; Cinquanta, L.; Di Matteo, M. Infrared thermography assisted control for apples microwave drying. J. Food Eng. 2012, 112, 319–325. [Google Scholar] [CrossRef]

- Pérez-Palacios, T.; Caballero, D.; Caro, A.; Rodríguez, P.G.; Antequera, T. Applying data mining and computer vision techniques to mri to estimate quality traits in iberian hams. J. Food Eng. 2014, 131, 82–88. [Google Scholar] [CrossRef]

- Castro-Giráldez, M.; Fito, P.; Dalla Rosa, M.; Fito, P. Application of microwaves dielectric spectroscopy for controlling osmotic dehydration of kiwifruit (actinidia deliciosa cv hayward). Innov. Food Sci. Emerg. Technol. 2011, 12, 623–627. [Google Scholar] [CrossRef]

- Castro-Giráldez, M.; Fito, P.; Fito, P. Application of microwaves dielectric spectroscopy for controlling pork meat (longissimus dorsi) salting process. J. Food Eng. 2010, 97, 484–490. [Google Scholar] [CrossRef]

- Pu, Y.-Y.; Sun, D.-W. Vis-nir hyperspectral imaging in visualising moisture distribution of mango slices during microwave-vacuum drying. Food Chem. 2015, 188, 271–278. [Google Scholar] [CrossRef] [PubMed]

- Sinelli, N.; Casiraghi, E.; Barzaghi, S.; Brambilla, A.; Giovanelli, G. Near infrared (nir) spectroscopy as a tool for monitoring blueberry osmo–air dehydration process. Food Res. Int. 2011, 44, 1427–1433. [Google Scholar] [CrossRef]

- Kapoor, R.; Malvandi, A.; Feng, H.; Kamruzzaman, M. Real-time moisture monitoring of edible coated apple chips during hot air drying using miniature nir spectroscopy and chemometrics. LWT 2022, 154, 112602. [Google Scholar] [CrossRef]

- Büning-Pfaue, H. Analysis of water in food by near infrared spectroscopy. Food Chem. 2003, 82, 107–115. [Google Scholar] [CrossRef]

- Porep, J.U.; Kammerer, D.R.; Carle, R. Online application of near infrared (nir) spectroscopy in food production. Trends Food Sci. Technol. 2015, 46, 211–230. [Google Scholar] [CrossRef]

- Su, Y.; Zhang, M.; Mujumdar, A.S. Recent developments in smart drying technology. Dry. Technol. 2015, 33, 260–276. [Google Scholar] [CrossRef]

- Fazeli Burestan, N.; Afkari Sayyah, A.H.; Taghinezhad, E. Prediction of some quality properties of rice and its flour by near-infrared spectroscopy (nirs) analysis. Food Sci. Nutr. 2021, 9, 1099–1105. [Google Scholar] [CrossRef]

- Nazarloo, A.S.; Sharabiani, V.R.; Gilandeh, Y.A.; Taghinezhad, E.; Szymanek, M. Evaluation of different models for non-destructive detection of tomato pesticide residues based on near-infrared spectroscopy. Sensors 2021, 21, 3032. [Google Scholar] [CrossRef]

- Soltani Nazarloo, A.; Rasooli Sharabiani, V.; Abbaspour Gilandeh, Y.; Taghinezhad, E.; Szymanek, M.; Sprawka, M. Feasibility of using vis/nir spectroscopy and multivariate analysis for pesticide residue detection in tomatoes. Processes 2021, 9, 196. [Google Scholar] [CrossRef]

- Samrat, N.H.; Johnson, J.B.; White, S.; Naiker, M.; Brown, P. A rapid non-destructive hyperspectral imaging data model for the prediction of pungent constituents in dried ginger. Foods 2022, 11, 649. [Google Scholar] [CrossRef]

- Wu, D.; Nie, P.; He, Y.; Bao, Y. Determination of calcium content in powdered milk using near and mid-infrared spectroscopy with variable selection and chemometrics. Food Bioprocess Technol. 2012, 5, 1402–1410. [Google Scholar] [CrossRef]

- Shrestha, L.a.; Moscetti, R.b.; Crichton, S.O.J.; Hensel, O.a.; Sturm, B. Organic apples (cv. Elstar) quality evaluation during hot-air drying using vis/nir hyperspectral imaging. In 21st International Drying Symposium; València, E.U.P.D., Ed.; Universitat Politecnica de Valencia: València, Spain, 2018; pp. 973–980. [Google Scholar]

- Nirere, A.; Sun, J.; Atindana, V.A.; Hussain, A.; Zhou, X.; Yao, K. A comparative analysis of hybrid svm and ls-svm classification algorithms to identify dried wolfberry fruits quality based on hyperspectral imaging technology. J. Food Process. Preserv. 2022, 46, e16320. [Google Scholar] [CrossRef]

- Zou, Z.; Wu, Q.; Chen, J.; Long, T.; Wang, J.; Zhou, M.; Zhao, Y.; Yu, T.; Wang, Y.; Xu, L. Rapid determination of water content in potato tubers based on hyperspectral images and machine learning algorithms. Food Sci. Technol. 2022, 42, e46522. [Google Scholar] [CrossRef]

- Md Saleh, R.; Kulig, B.; Arefi, A.; Hensel, O.; Sturm, B. Prediction of total carotenoids, color, and moisture content of carrot slices during hot air drying using non-invasive hyperspectral imaging technique. J. Food Process. Preserv. 2022, 46, e16460. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, Q.; Wu, J.; Liu, Y.; Yu, L.; Chen, Y. Moisture detection of single corn seed based on hyperspectral imaging and deep learning. Infrared Phys. Technol. 2022, 125, 104279. [Google Scholar] [CrossRef]

- Rabanera, J.D.; Guzman, J.D.; Yaptenco, K.F. Rapid and Non-destructive measurement of moisture content of peanut (Arachis hypogaea L.) kernel using a near-infrared hyperspectral imaging technique. J. Food Meas. Charact. 2021, 15, 3069–3078. [Google Scholar] [CrossRef]

- Moscetti, R.; Sturm, B.; Crichton, S.O.; Amjad, W.; Massantini, R. Postharvest monitoring of organic potato (cv. Anuschka) during hot-air drying using visible–NIR hyperspectral imaging. J. Sci. Food Agric 2018, 98, 2507–2517. [Google Scholar] [CrossRef]

| Drying Method | Drying Time (min) | Initial Moisture Contents (%) | Final Moisture Contents (%) | Time Intervals (min) | Reference | |

|---|---|---|---|---|---|---|

| Carrot slices | Microwave-vacuum | 50 | 87 | 11 ± 2 | 0, 6, 12, 16, 20, 24.5, 29, 35, 41, 50 | [3] |

| Celery stalks | Microwave-vacuum | 53 | 95 | 16 ± 6 | 0, 15, 20, 24.5, 29, 31.5, 38, 42.5, 47, 53 | [3] |

| Potato slices | Microwave-vacuum | 30.5 | 85 | 12 ± 2 | 0, 3, 5.5, 8, 12.5, 17, 21.5, 24.5, 27.5, 30.5 | [3] |

| Spinach leaves | Microwave-vacuum | 20 | 93 | 8 ± 3 | 0, 4, 6, 8, 10, 12, 14, 16, 18, 20 | [3] |

| Apple | Convection | 240 | 88 | 16 ± 2 | 0, 30, 60, 90, 120, 150, 180, 240 | [4] |

| Melon | Hot air | 90 | 40 | 15 | 10, 15, 30, 50, 90 | [5] |

| ginger slices | Microwave -vacuum | 80 | 66.2 | 14.1 | 0, 25, 40, 55, 80 | [6] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Taghinezhad, E.; Szumny, A.; Figiel, A. The Application of Hyperspectral Imaging Technologies for the Prediction and Measurement of the Moisture Content of Various Agricultural Crops during the Drying Process. Molecules 2023, 28, 2930. https://doi.org/10.3390/molecules28072930

Taghinezhad E, Szumny A, Figiel A. The Application of Hyperspectral Imaging Technologies for the Prediction and Measurement of the Moisture Content of Various Agricultural Crops during the Drying Process. Molecules. 2023; 28(7):2930. https://doi.org/10.3390/molecules28072930

Chicago/Turabian StyleTaghinezhad, Ebrahim, Antoni Szumny, and Adam Figiel. 2023. "The Application of Hyperspectral Imaging Technologies for the Prediction and Measurement of the Moisture Content of Various Agricultural Crops during the Drying Process" Molecules 28, no. 7: 2930. https://doi.org/10.3390/molecules28072930

APA StyleTaghinezhad, E., Szumny, A., & Figiel, A. (2023). The Application of Hyperspectral Imaging Technologies for the Prediction and Measurement of the Moisture Content of Various Agricultural Crops during the Drying Process. Molecules, 28(7), 2930. https://doi.org/10.3390/molecules28072930