Thickness Effects on Boron Doping and Electrochemical Properties of Boron-Doped Diamond Film

Abstract

1. Introduction

2. Results and Discussions

3. Materials and Methods

3.1. Reagents

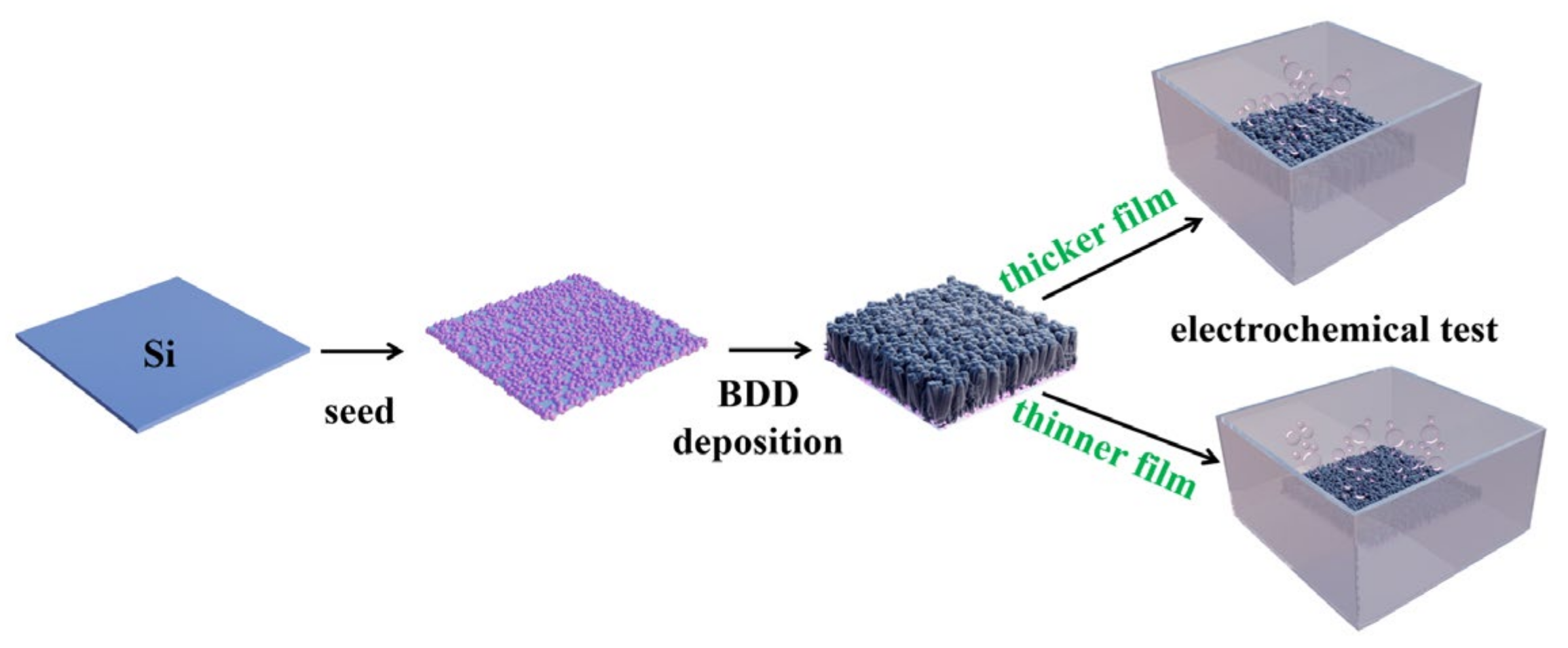

3.2. BDD Film Deposition

3.3. Apparatus

3.4. Electrochemical Measurements

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Luong, J.H.; Male, K.B.; Glennon, J.D. Boron-doped diamond electrode: Synthesis, characterization, functionalization and analytical applications. Analyst 2009, 134, 1965–1979. [Google Scholar] [CrossRef] [PubMed]

- Yu, X.; Zhou, M.; Hu, Y.; Groenen, S.K.; Yu, F. Recent updates on electrochemical degradation of bio-refractory organic pollutants using BDD anode: A mini review. Environ. Sci. Pollut. Res. 2014, 21, 8417–8431. [Google Scholar] [CrossRef] [PubMed]

- Fortin, E.; Chane-Tune, J.; Delabouglise, D.; Bouvier, P.; Livache, T.; Mailley, P.; Marcus, B.; Mermoux, M.; Petit, J.P.; Szunerits, S. Interfacing Boron Doped Diamond and Biology: An Insight on Its Use for Bioanalytical Applications. Electroanalysis 2005, 17, 517–526. [Google Scholar] [CrossRef]

- Lee, K.W.; Pickett, W.E. Superconductivity in boron-doped diamond. Phys. Rev. Lett. 2004, 93, 237003. [Google Scholar] [CrossRef]

- Li, S.; Ma, L.; Long, H.; Yu, X.; Luo, H.; Wang, Y.; Zhu, H.; Yu, Z.; Ma, M.; Wei, Q. Enhanced electron field emission properties of diamond/microcrystalline graphite composite films synthesized by thermal catalytic etching. Appl. Surf. Sci. 2016, 367, 473–479. [Google Scholar] [CrossRef]

- Xu, J.; Chen, Q.; Swain, G.M. Anthraquinonedisulfonate Electrochemistry: A Comparison of Glassy Carbon, Hydrogenated Glassy Carbon, Highly Oriented Pyrolytic Graphite, and Diamond Electrodes. Anal. Chem. 1998, 70, 3146–3154. [Google Scholar] [CrossRef]

- Macpherson, J.V. A practical guide to using boron doped diamond in electrochemical research. Phys. Chem. Chem. Phys. 2015, 17, 2935–2949. [Google Scholar] [CrossRef]

- Hu, H.; Ou, J.Z.; Xu, X.; Lin, Y.; Zhang, Y.; Zhao, H.; Chen, D.; He, M.; Huang, Y.; Deng, L. Graphene-assisted construction of electrocatalysts for carbon dioxide reduction. Chem. Eng. J. 2021, 425, 130587. [Google Scholar] [CrossRef]

- Švorc, Ĺ.; Jambrec, D.; Vojs, M.; Barwe, S.; Clausmeyer, J.; Michniak, P.; Marton, M.; Schuhmann, W. Doping Level of Boron-Doped Diamond Electrodes Controls the Grafting Density of Functional Groups for DNA Assays. ACS Appl. Mater. Interfaces 2015, 7, 18949. [Google Scholar] [CrossRef]

- Hu, H.; Quan, A.; Zhu, H.; Wei, W.; Chen, H.; Ou, D.; Zhen, J. Recent advances in two-dimensional transition metal dichalcogenides for biological sensing. Biosens. Bioelectron. 2019, 142, 111573. [Google Scholar] [CrossRef]

- Wei, J.J.; Li, C.M.; Gao, X.H.; Hei, L.F.; Lvun, F.X. The influence of boron doping level on quality and stability of diamond film on Ti substrate. Appl. Surf. Sci. 2012, 258, 6909–6913. [Google Scholar] [CrossRef]

- Iida, K.; Yamaguchi, F.; Hibi, K.; Tate, G.; Ohyama, B.; Numata, S.; Hashimoto, T.; Sato, M.; Uchida, T.; Sueki, H. Influence of boron concentration on growth characteristic and electro-catalytic performance of boron-doped diamond electrodes prepared by direct current plasma chemical vapor deposition. Appl. Surf. Sci. 2011, 257, 3433–3439. [Google Scholar]

- Matsushima, J.T.; Silva, W.M.; Azevedo, A.F.; Baldan, M.R.; Ferreira, N.G. The influence of boron content on electroanalytical detection of nitrate using BDD electrodes. Appl. Surf. Sci. 2009, 256, 757–762. [Google Scholar] [CrossRef]

- Bustarret, E.; Achatz, P.; Sacépé, B.; Chapelier, C.; Marcenat, C.; Ortéga, L.; Klein, T. Metal-to-insulator transition and superconductivity in boron-doped diamond. Philos. Trans. A Math. Phys. Eng. Sci. 2008, 366, 267–279. [Google Scholar] [CrossRef]

- Gheeraert, E.; Deneuville, A.; Mambou, J. Boron-related infra-red absorption in homoepitaxial diamond films. Diam. Relat. Mater. 1998, 7, 1509–1512. [Google Scholar] [CrossRef]

- Holt, K.B.; Bard, A.J.; Show, Y.; Swain, G.M. Scanning Electrochemical Microscopy and Conductive Probe Atomic Force Microscopy Studies of Hydrogen-Terminated Boron-Doped Diamond Electrodes with Different Doping Levels. J. Phys. Chem. B 2004, 108, 15117–15127. [Google Scholar] [CrossRef]

- Patten, H.V.; Meadows, K.E.; Hutton, L.A.; Iacobini, J.G.; Battistel, D.; McKelvey, K.; Colburn, A.W.; Newton, M.E.; Macpherson, J.V.; Unwin, P.R. Electrochemical Mapping Reveals Direct Correlation between Heterogeneous Electron-Transfer Kinetics and Local Density of States in Diamond Electrodes. Angew. Chem. Int. Ed. 2012, 51, 7002–7006. [Google Scholar] [CrossRef]

- Maier, F.; Riedel, M.; Mantel, B.; Ristein, J.; Ley, L. Origin of Surface Conductivity in Diamond. Phys. Rev. Lett. 2000, 85, 3472–3475. [Google Scholar] [CrossRef]

- Yagi, I.; Notsu, H.; Kondo, T.; Tryk, D.A.; Fujishima, A. Electrochemical selectivity for redox systems at oxygen-terminated diamond electrodes. J. Electroanal. Chem. 1999, 473, 173–178. [Google Scholar] [CrossRef]

- Salazar-Banda, G.R.; de Carvalho, A.E.; Andrade, L.S.; Rocha-Filho, R.C.; Avaca, L.A. On the activation and physical degradation of boron-doped diamond surfaces brought on by cathodic pretreatments. J. Appl. Electrochem. 2010, 40, 1817–1827. [Google Scholar] [CrossRef]

- Buijnsters, J.G.; Tsigkourakos, M.; Hantschel, T.; Gomes, F.O.V.; Nuytten, T.; Favia, P.; Bender, H.; Arstila, K.; Celis, J.-P.; Vandervorst, W. Effect of Boron Doping on the Wear Behavior of the Growth and Nucleation Surfaces of Micro- and Nanocrystalline Diamond Films. ACS Appl. Mater. Interfaces 2016, 8, 26381–26391. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Nakai, T.; Uno, M.; Nishiki, Y.; Sugimoto, W. Effect of the boron content on the steam activation of boron-doped diamond electrodes. Carbon 2013, 65, 206–213. [Google Scholar] [CrossRef]

- Fierro, S.P.; Abe, K.; Comninellis, C.; Einaga, Y. Influence of Doping Level on the Electrochemical Oxidation of Formic Acid on Boron Doped Diamond Electrodes. J. Electrochem. Soc. 2011, 158, F183. [Google Scholar] [CrossRef]

- Trouillon, R.; O’Hare, D.; Einaga, Y. Effect of the doping level on the biological stability of hydrogenated boron doped diamond electrodes. Phys. Chem. Chem. Phys. 2011, 13, 5422–5429. [Google Scholar] [CrossRef] [PubMed]

- Liao, X.Z.; Zhang, R.J.; Lee, C.S.; Lee, S.T.; Lam, Y.W. The influence of boron doping on the structure and characteristics of diamond thin films. Diam. Relat. Mater. 1997, 6, 521–525. [Google Scholar] [CrossRef]

- Alegre, M.P.; Araújo, D.; Fiori, A.; Pinero, J.C.; Lloret, F.; Villar, M.P.; Achatz, P.; Chicot, G.; Bustarret, E.; Jomard, F. Critical boron-doping levels for generation of dislocations in synthetic diamond. Appl. Phys. Lett. 2014, 105, 173103. [Google Scholar] [CrossRef]

- Ushizawa, K.; Watanabe, K.; Ando, T.; Sakaguchi, I.; Nishitani-Gamo, M.; Sato, Y.; Kanda, H. Boron concentration dependence of Raman spectra on {100} and {111} facets of B-doped CVD diamond. Diam. Relat. Mater. 1998, 7, 1719–1722. [Google Scholar] [CrossRef]

- Barnard, A.S.; Sternberg, M. Substitutional Boron in Nanodiamond, Bucky-Diamond, and Nanocrystalline Diamond Grain Boundaries. J. Phys. Chem. B 2006, 110, 19307–19314. [Google Scholar] [CrossRef]

- Pieve, F.; Tendeloo, G. Local boron environment in B-doped nanocrystalline diamond films. Nanoscale 2012, 4, 5960–5964. [Google Scholar]

- Lu, Y.-G.; Turner, S.; Verbeeck, J.; Janssens, S.D.; Wagner, P.; Haenen, K.; Van Tendeloo, G. Direct visualization of boron dopant distribution and coordination in individual chemical vapor deposition nanocrystalline B-doped diamond grains. Appl. Phys. Lett. 2012, 101, 041907. [Google Scholar] [CrossRef]

- Cifre, J.; Puigdollers, J.; Polo, M.C.; Esteve, J. Trimethylboron doping of CVD diamond thin films. Diam. Relat. Mater. 1994, 3, 628–631. [Google Scholar] [CrossRef]

- Azevedo, A.F.; Mendes de Barros, R.C.; Serrano, S.H.P.; Ferreira, N.G. SEM and Raman analysis of boron-doped diamond coating on spherical textured substrates. Surf. Coat. Tech. 2006, 200, 5973–5977. [Google Scholar] [CrossRef]

- Ager, J.W.; Walukiewicz, W.; McCluskey, M.; Plano, M.A.; Landstrass, M.I. Fano interference of the Raman phonon in heavily boron-doped diamond films grown by chemical vapor deposition. Appl. Phys. Lett. 1995, 66, 616–618. [Google Scholar] [CrossRef]

- Bernard, M.; Baron, C.; Deneuville, A. About the origin of the low wave number structures of the Raman spectra of heavily boron doped diamond films. Diam. Relat. Mater. 2004, 13, 896–899. [Google Scholar] [CrossRef]

- Ferrari, A.; Robertson, J. Resonant Raman spectroscopy of disordered, amorphous, and diamondlike carbon. Phys. Rev. B 2001, 64, 075414. [Google Scholar] [CrossRef]

- Locher, R.; Wagner, J.; Fuchs, F.; Maier, M.; Gonon, P.; Koidl, P. Optical and electrical characterization of boron-doped diamond films. Diam. Relat. Mater. 1995, 4, 678–683. [Google Scholar] [CrossRef]

- Bernard, M.; Deneuville, A.; Muret, P. Non-destructive determination of the boron concentration of heavily doped metallic diamond thin films from Raman spectroscopy. Diam. Relat. Mater. 2004, 13, 282–286. [Google Scholar] [CrossRef]

- Kim, D.Y.; Wang, J.; Yang, J.; Kim, H.W.; Swain, G.M. Electrolyte and Temperature Effects on the Electron Transfer Kinetics of Fe(CN)6–3/-4 at Boron-Doped Diamond Thin Film Electrodes. J. Phys. Chem. C 2011, 115, 10026–10032. [Google Scholar] [CrossRef]

- Wang, S.; Swope, V.M.; Butler, J.E.; Feygelson, T.; Swain, G.M. The structural and electrochemical properties of boron-doped nanocrystalline diamond thin-film electrodes grown from Ar-rich and H 2-rich source gases. Diam. Relat. Mater. 2009, 18, 669–677. [Google Scholar] [CrossRef]

- Actis, P.; Denoyelle, A.; Boukherroub, R.; Szunerits, S. Influence of the surface termination on the electrochemical properties of boron-doped diamond (BDD) interfaces. Electrochem. Commun. 2008, 10, 402–406. [Google Scholar] [CrossRef]

- Hutton, L.A.; Iacobini, J.G.; Bitziou, E.; Channon, R.B.; Newton, M.E.; Macpherson, J.V. Examination of the factors affecting the electrochemical performance of oxygen-terminated polycrystalline boron-doped diamond electrodes. Anal. Chem. 2013, 85, 7230–7240. [Google Scholar] [CrossRef] [PubMed]

- Granger, M.C.; Swain, G.M. The Influence of Surface Interactions on the Reversibility of Ferri/Ferrocyanide at Boron-Doped Diamond Thin-Film Electrodes. J. Electrochem. Soc. 1999, 146, 4551–4558. [Google Scholar] [CrossRef]

- Omar El, T.; Jaffrezic-Renault, N.; Sigaud, M.; Vittori, O. Anodic Stripping Voltammetry of Heavy Metals at Nanocrystalline Boron-Doped Diamond Electrode. Electroanalysis 2007, 19, 1152–1159. [Google Scholar]

- Peihong, C.; Richard, L.M. Control of Electron Transfer Kinetics at Glassy Carbon Electrodes by Specific Surface Modification. Anal. Chem. 1996, 68, 3958–3965. [Google Scholar]

- Bennett, J.A.; Jian, W.; Show, Y.; Swain, G.M. Effect of sp2-Bonded Nondiamond Carbon Impurity on the Response of Boron-Doped Polycrystalline Diamond Thin-Film Electrodes. J. Electrochem. Soc. 2003, 151, E306–E313. [Google Scholar] [CrossRef]

- Yu, P.; Zhang, J.; Zheng, T.; Wang, T. Influence of boron doped level on the electrochemical behavior of boron doped diamond electrodes and uric acid detection. Colloids Surf. A 2016, 494, 241–247. [Google Scholar] [CrossRef]

- Becker, D.; Jüttner, K. Influence of surface inhomogeneities of boron doped CVD-diamond electrodes on reversible charge transfer reactions. J. Appl. Electrochem. 2003, 33, 959–967. [Google Scholar] [CrossRef]

- Mort, J.; Kuhman, D.; Machonkin, M.; Morgan, M.; Jansen, F.; Okumura, K.; Legrice, Y.M.; Nemanich, R.J. Boron doping of diamond thin films. Appl. Phys. Lett. 1989, 55, 1121–1123. [Google Scholar] [CrossRef]

- Huang, J.; Hu, C.; Hwang, J.; Chang, H.; Lee, L. Desegregation of boron at the grain boundaries of the insitu boron doped diamond films. Appl. Phys. Lett. 1995, 67, 2382–2384. [Google Scholar] [CrossRef]

- Hsieh, H.H.; Chang, Y.K.; Pong, W.F.; Tsai, M.H.; Chien, F.Z.; Tseng, P.K.; Lin, I.N.; Cheng, H.F. X-ray-absorption studies of boron-doped diamond films. Appl. Phys. Lett. 1999, 75, 2229–2231. [Google Scholar] [CrossRef]

- Dubrovinskaia, N.; Wirth, R.; Wosnitza, J.; Papageorgiou, T.; Braun, H.F.; Miyajima, N.; Dubrovinsky, L. An insight into what superconducts in polycrystalline boron-doped diamonds based on investigations of microstructure. Proc. Natl. Acad. Sci. USA 2008, 105, 11619–11622. [Google Scholar] [CrossRef]

- Wilson, N.R.; Clewes, S.L.; Newton, M.E.; Unwin, P.R.; Macpherson, J.V. Impact of grain-dependent boron uptake on the electrochemical and electrical properties of polycrystalline boron doped diamond electrodes. J. Phys. Chem. B 2006, 110, 5639–5646. [Google Scholar] [CrossRef]

| Sample | RL (Ω cm2) | Q1 (μF cm−2 sn−1) | n1 | Rfilm Ω cm2 | Q2 (μF cm−2 sn−1) | n2 | Rct Ω cm2 | ZW (mF cm−2 s) | χ2 (10−4) |

|---|---|---|---|---|---|---|---|---|---|

| 0.1B-1 | 0.68 | 0.142 | 1 | 16.6 | 2.56 | 0.969 | 9475 | 0.165 | 33.81 |

| 0.1B-4 | 0.701 | 0.173 | 0.98 | 9.98 | 6.71 | 0.939 | 784.8 | 0.167 | 7.741 |

| 0.4B-1 | 0.64 | 0.215 | 1 | 15.9 | 2.74 | 0.961 | 3291 | 0.164 | 13.45 |

| 0.4B-4 | 0.617 | 0.237 | 0.99 | 8.07 | 6.13 | 0.938 | 595.7 | 0.169 | 7.745 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Long, H.; Hu, H.; Wen, K.; Liu, X.; Liu, S.; Zhang, Q.; Chen, T. Thickness Effects on Boron Doping and Electrochemical Properties of Boron-Doped Diamond Film. Molecules 2023, 28, 2829. https://doi.org/10.3390/molecules28062829

Long H, Hu H, Wen K, Liu X, Liu S, Zhang Q, Chen T. Thickness Effects on Boron Doping and Electrochemical Properties of Boron-Doped Diamond Film. Molecules. 2023; 28(6):2829. https://doi.org/10.3390/molecules28062829

Chicago/Turabian StyleLong, Hangyu, Huawen Hu, Kui Wen, Xuezhang Liu, Shuang Liu, Quan Zhang, and Ting Chen. 2023. "Thickness Effects on Boron Doping and Electrochemical Properties of Boron-Doped Diamond Film" Molecules 28, no. 6: 2829. https://doi.org/10.3390/molecules28062829

APA StyleLong, H., Hu, H., Wen, K., Liu, X., Liu, S., Zhang, Q., & Chen, T. (2023). Thickness Effects on Boron Doping and Electrochemical Properties of Boron-Doped Diamond Film. Molecules, 28(6), 2829. https://doi.org/10.3390/molecules28062829