Effects of Different Drying Methods on the Quality of Bletilla striata Scented Tea

Abstract

:1. Introduction

2. Results and Discussion

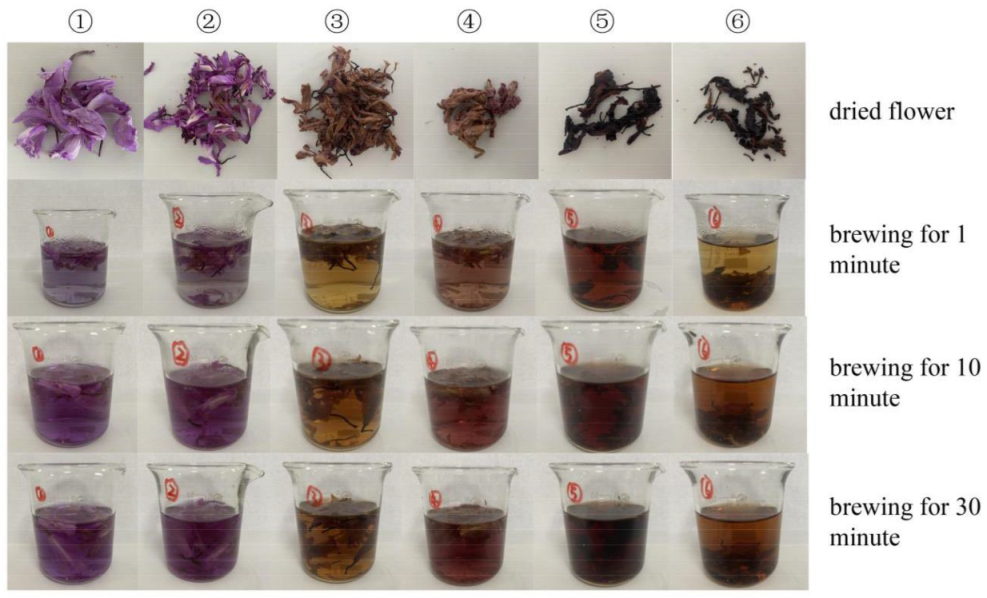

2.1. Effect of Different Drying Methods on Sensory Evaluation of Bletilla striata Scented Tea

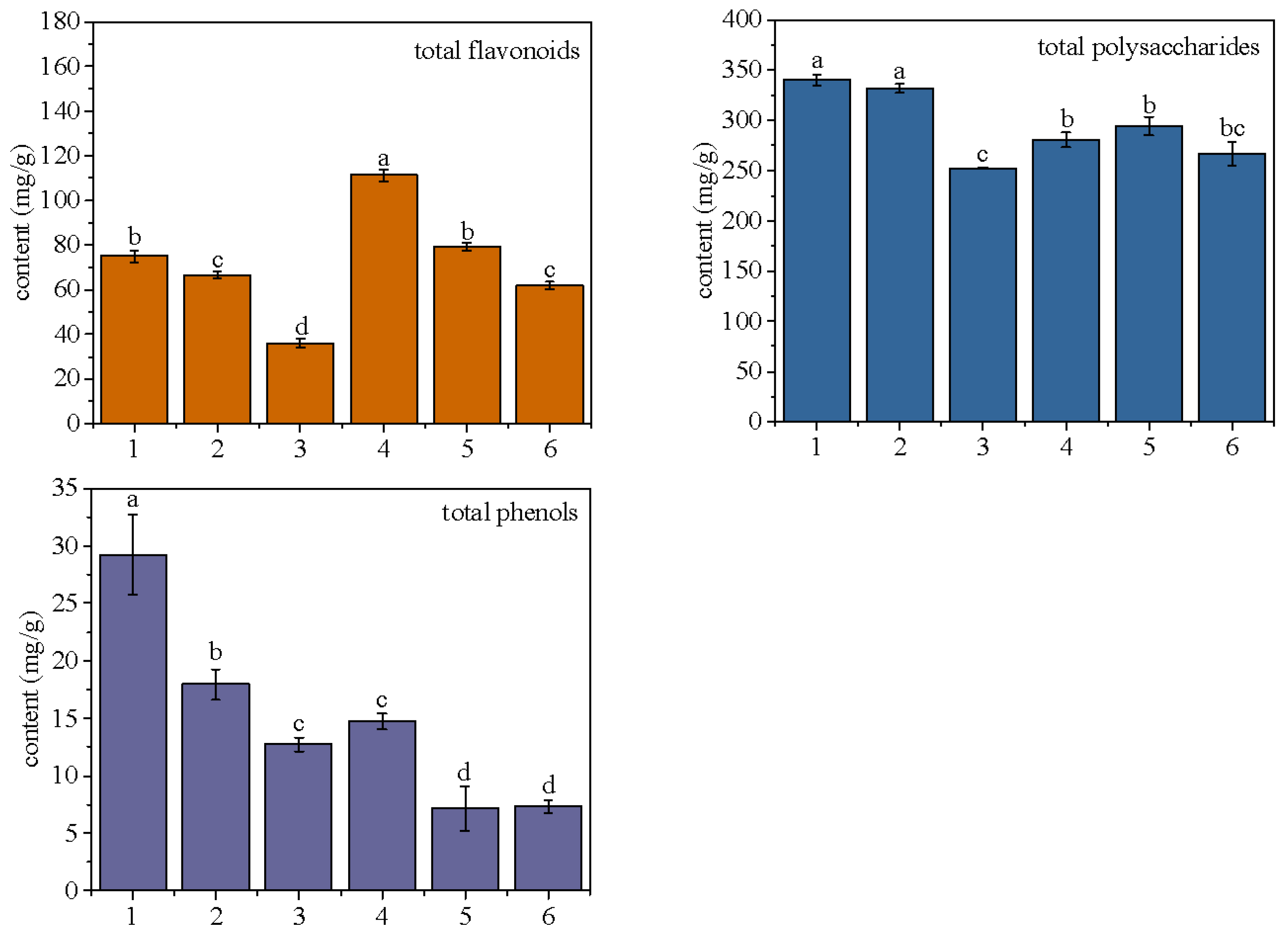

2.2. Effect of Different Drying Methods on the Components of Bletilla striata Scented Tea

2.2.1. Analysis of GC-MS

2.2.2. Analysis of ROAV Results

2.2.3. Mass Fraction Analysis of Total Flavonoids, Total Polysaccharides, and Total Phenols

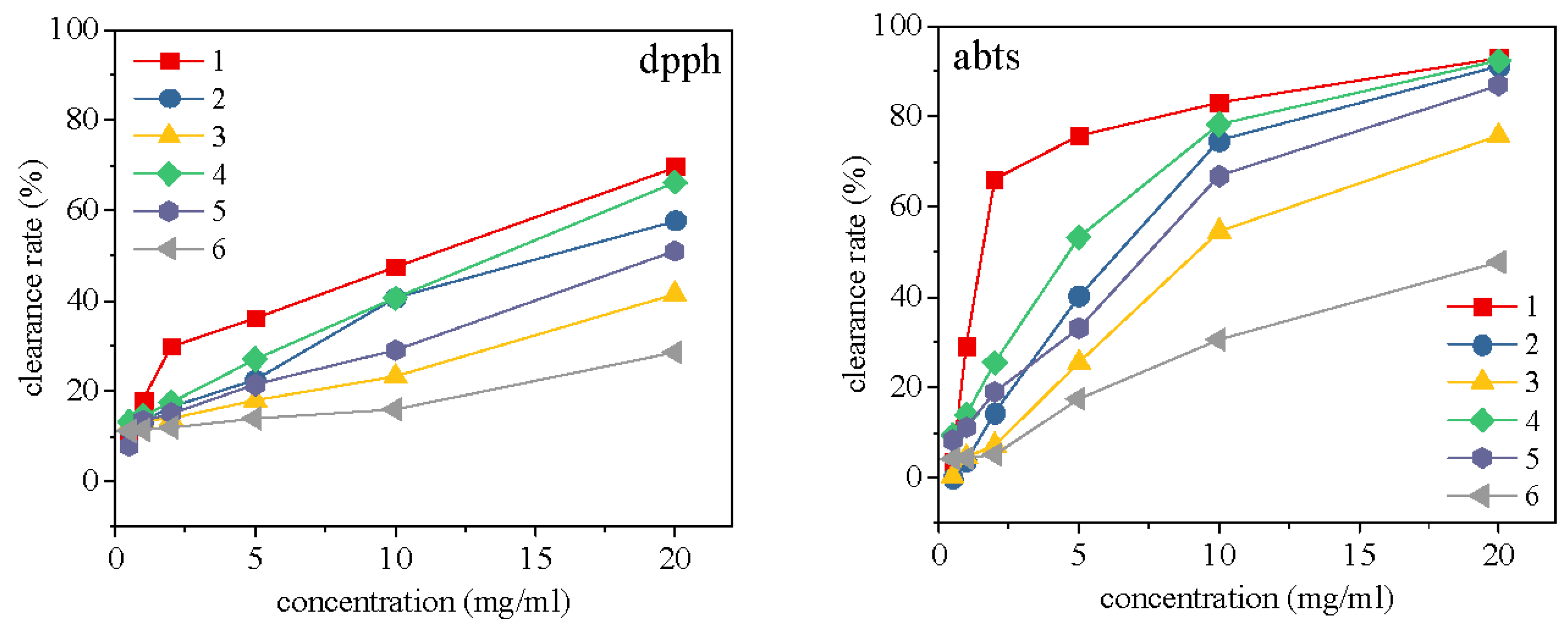

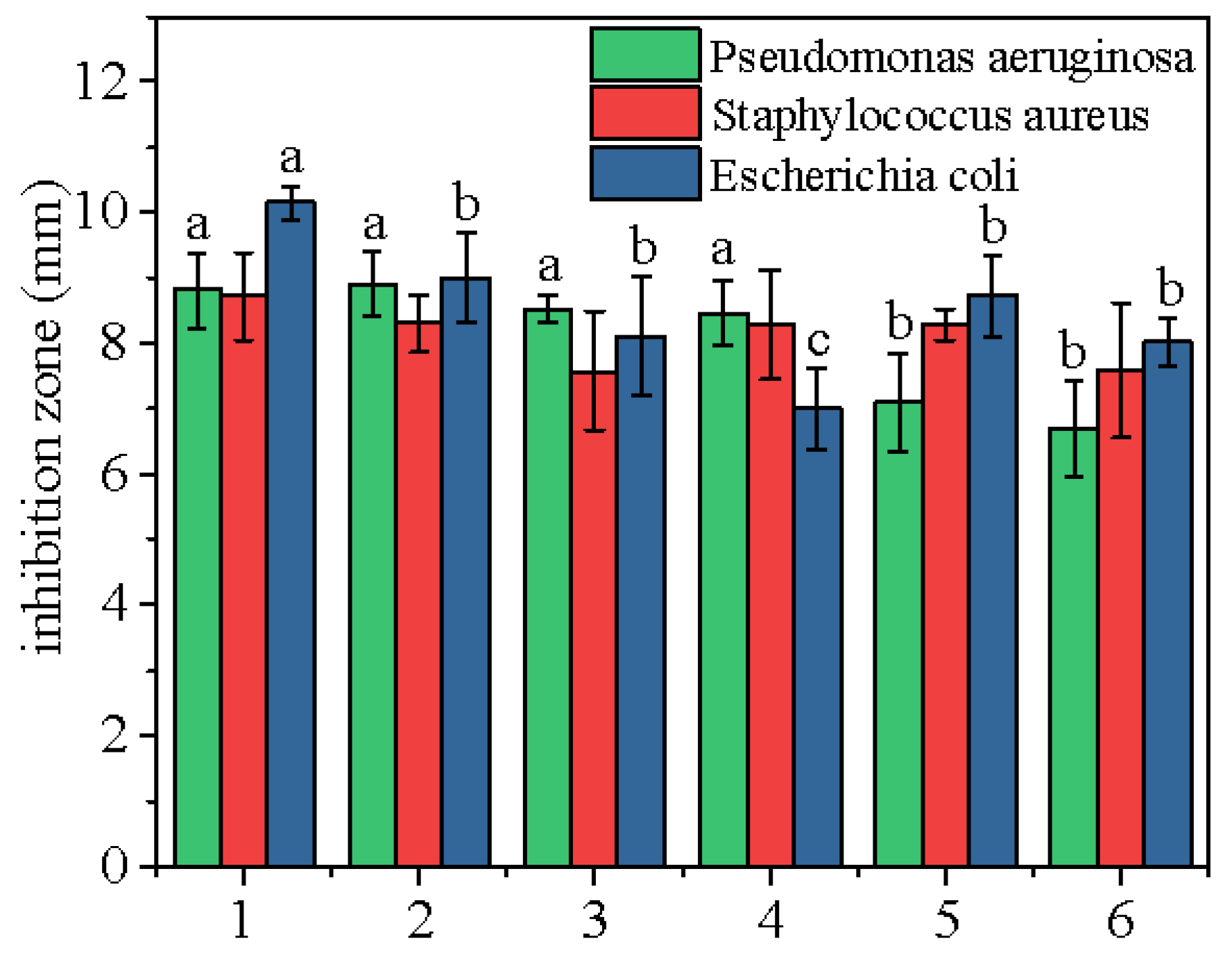

2.3. Effect of Different Drying Methods on the Efficacy of Bletilla striata Scented Tea

2.3.1. Analysis of Antioxidant Activity

2.3.2. Antibacterial Analysis

3. Materials and Methods

3.1. Materials and Reagent

3.2. Instrumentation

3.3. Treatment of Bletilla striata Flowers

3.3.1. Pre-Treatment

3.3.2. Drying

3.3.3. Sensory Evaluation

3.3.4. GC-MS Determination

3.3.5. ROAV Analysis

3.3.6. Determination of Total Flavonoids, Total Polysaccharides and Total Phenols

3.3.7. Determination of Oxidation Resistance

3.3.8. Determination of Antibacterial Ability

3.3.9. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Diao, H.; Li, X.; Chen, J.; Luo, Y.; Chen, X.; Dong, L.; Wang, C.; Zhang, C.; Zhang, J. Bletilla striata Polysaccharide Stimulates Inducible Nitric Oxide Synthase and Proinflammatory Cytokine Expression in Macrophages. J. Biosci. Bioeng. 2008, 105, 85–89. [Google Scholar] [CrossRef] [PubMed]

- Ma, X.; Tang, K.; Tang, Z.; Dong, A.; Meng, Y.; Wang, P. Organ-specific, integrated omics data-based study on the metabolic pathways of the medicinal plant Bletilla striata (Orchidaceae). BMC Plant Biol. 2021, 21, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Zhang, B.; Qin, S.; Zhou, R. Environmental quality evaluation of Guizhou Bletilla striata suitable growing areas. Guizhou Agric. Sci. 2014, 42, 207–210. [Google Scholar]

- Chen, J.; Wu, T.; Wang, X.; Zhang, W.; Wu, G.; Lu, C. Comparision Study on Bioactivities of Bletilla striata(Thunb.) Reichb.f. Polysaccharide and BSPSS. Food Sci. 2007, 28, 27–31. [Google Scholar]

- Ma, Z.; Ma, J.; Lv, J.; He, J.; Jia, D.; Yang, X.; Qu, Y.; Zeng, R. Progress in application of Bletilla striata polysaccharide in novel drug delivery systems and biomaterials. China J. Chin. Mater. Med. 2021, 46, 4666–4673. [Google Scholar]

- Saito, N.; Ku, M.; Tatsuzawa, F.; Lu, T.; Yokoi, M.; Shigihara, A.; Honda, T. Acylated cyanidin glycosides in the purple-red flowers of Bletilla striata. Phytochemistry 1995, 40, 1523–1529. [Google Scholar] [CrossRef]

- Hu, Y.; Li, J.; Chang, A.K.; Wang, Z.; Su, W.; Li, Y.; Liu, W.; Ai, J.; Tao, X.; Zheng, P. Potential active constituents responsible for treating acute pharyngitis in the flowers of Hosta plantaginea (Lam.) Aschers and their pharmacokinetics. Food Funct. 2022, 13, 3308–3317. [Google Scholar] [CrossRef]

- Xie, X.; Liu, J.; Luo, Y.; Deng, B.; Cao, N.; Jia, J. Optimization of Extraction Process of Liposoluble Components in Bletilla striata Flower and Its Biological Activity. Sci. Technol. Food Ind. 2019, 40, 200–206. [Google Scholar]

- He, X.; Wang, X.; Fang, J.; Zhao, Z.; Huang, L. Bletilla striata: Medicinal uses, phytochemistry and pharmacological activities. J. Ethnopharmacol. 2017, 195, 20–38. [Google Scholar] [CrossRef]

- Tomasz, B.; Martyna, Z.; Aleksandra, Z.; Zofia, N.; Tomasz, W.; Zofia, H. Antioxidant and Cytoprotective Properties of Plant Extract from Dry Flowers as Functional Dyes for Cosmetic Products. Molecules 2021, 26, 2809. [Google Scholar]

- Tan, S.; Tan, C.; Wu, X.; Yang, Y.; Liu, H. Optimization of Process of Hydrolysis of Dendrobium officinale Polysaccharide and Determination of Contents of Its Mannose. Sci. Technol. Food Ind. 2022, 43, 220–227. [Google Scholar]

- Sun, D.; Wang, M.; Ji, D.; Qiao, J.; He, T.; Liu, X.; Guan, Q. Synthesis of a reduction-sensitive Bletilla striata polysaccharide amphiphilic copolymer. Chin. Chem. Lett. 2018, 29, 831–833. [Google Scholar] [CrossRef]

- Tang, Y.; Ruan, C.; Ying, C.; Zhang, H. Research progress on chemical constituents and medical functions in plants of Bletilla Rchb. f. Chin. Herb. Med. 2014, 45, 2872–2964. [Google Scholar]

- Zhou, L.; Yu, C.; Cheng, B.; Wan, H.; Zhang, Q. Volatile compound analysis and aroma evaluation of tea-scented roses in China. Ind. Crop. Prod. 2020, 155, 112735. [Google Scholar]

- Xi, X.; Zeng, G.; Xie, J.; Zhou, S.; Li, S. Analysis of volatile characteristic compounds in bitter melon powder by SPME-GC-MS combined with ROAV method. China Food Addit. 2022, 33, 153–160. [Google Scholar]

- Salem, N.; Msaada, K.; Hamdaoui, G.; Limam, F.; Marzouk, B. Variation in phenolic composition and antioxidant activity during flower development of safflower (Carthamus tinctorius L.). J. Agric. Food Chem. 2011, 59, 4455–4463. [Google Scholar] [CrossRef]

- Gpfert, J.; Conrad, J.; Spring, O. 5-Deoxynevadensin, a Novel Flavone in Sunflower and Aspects of Biosynthesis during Trichome Development. Nat. Prod. Commun. 2006, 1, 935–940. [Google Scholar] [CrossRef]

- Shi, J.; Ling, Z.; He, P.; Xiong, C. Immunomodulatory and Antitumor Activity of Polysaccharide Isolated From Tea Plant Flower. Prog. Biochem. Biophys. 2010, 37, 646–653. [Google Scholar]

- Meng, Z.; Jiang, Y.; Guo, X. Study on the Stability of Flavonoids from Paulownia Tomentnose Steud Flower. Chin. J. Spectrosc. Lab. 2008, 25, 655–658. [Google Scholar]

- Han, Q.; Yu, Q.; Shi, J.; Xiong, C.; Ling, Z.; He, P. Structural Characterization and Antioxidant Activities of 2 Water-Soluble Polysaccharide Fractions Purified from Tea (Camellia sinensis) Flower. J. Food Sci. 2011, 76, 462–471. [Google Scholar]

- Chen, Z.; Zhao, Y.; Zhang, M.; Yang, X.; Wei, X. Structural characterization and antioxidant activity of a new polysaccharide from Bletilla striata fibrous roots. Carbohyd. Polym. 2019, 227, 115362. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.; Ni, J.; Zhu, X.; Zhu, L.; Li, Y.; Zhou, F. Ginkgo biloba extract protects human neuroblastoma SH-SY5Y cells against oxidative glutamate toxicity by activating redoxosome-p66Shc. Exp. Ther. Med. 2021, 22, 951. [Google Scholar] [CrossRef] [PubMed]

- Zeng, Y. Evaluation of Antibacterial Activity of 20 Kinds of Edible Flower Tea. Chin. J. Ecol. 2020, 40, 56–61. [Google Scholar]

- Wang, Y.; Li, X.; Yang, M.; Lin, Z.; Dong, X.; Xu, H. Effect of Drying Methods on Volatile Flavor Compounds of the Pileus and Stipe of Hypsizygus marmoreus. Food Sci. 2022, 127, 109428. [Google Scholar]

- Liu, D.; Zhao, Z.; Wu, J.; Zou, Y.; Wang, X.; Li, M. Effects of different smoking materials on volatile flavor compounds in smoked chicken thighs. Food Sci. 2019, 40, 220–227. [Google Scholar]

- Zhang, S.; Han, X. Determination of Total Phenol Content and Analysis of Antioxidant Activity of Allium mongolicum. China Condiment 2022, 47, 64–67. [Google Scholar]

| Part | Number | ||||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | ||

| Appearance | result | The flower shape is complete, full, and purple in color | The flower shape is more complete, fuller, color purplish red with some brown | The flowers slightly crushed, fuller brown color with purplish red | The flower shape is slightly broken, more crumpled, the color is slightly purplish red and slightly white | The flower shape is not clear, wrinkled, dark brown color | The flower shape is not clear, more broken, crumpled, dark brown color |

| score | 90 | 88 | 80 | 80 | 72 | 72 | |

| Aroma | result | The unique fragrance and rich fragrance of the Bletilla striata flowers | Unique fragrance of Bletilla striata flowers, slightly burnt | Inconspicuous aroma | Unique fragrance of Bletilla striata flowers, Slightly lighter | Caramel aroma, slightly sour | Inconspicuous aroma |

| score | 90 | 88 | 75 | 78 | 90 | 70 | |

| Soup | result | The soup is purplish red, clear, and still bright after a long time | The Soup color is purple, clear, long bubble slightly turbid | The color of the soup is brown, clear, and bright | Soup brown, red, clear, long bubble, slightly turbid | The color of the soup is dark brown–red, not clear enough and cloudy for a long time | Brown soup, clear, long bubble slightly turbid |

| score | 90 | 86 | 88 | 85 | 80 | 84 | |

| Taste | result | Mellow, sweet, sweet, good coordination | Mellow, sweet, back to sweet, slightly light, good coordination | The taste is mellow, slightly sweet and moderately harmonious | Mellow taste, slightly sweet slightly astringent, general coordination | Mellow taste, mild caramel sweet, moderate coordination | Coarse light, slightly watery, sour taste, no sense of hierarchy |

| score | 90 | 88 | 80 | 82 | 85 | 70 | |

| Leaf bottom evaluation | result | Natural stretch, lavender, even | Natural stretch, lavender red, uniform | Slightly stretched, light brown, uniform | Slightly stretched, light reddish brown, more uniform | Slight stretch, black and red, uneven | Slight stretch, black and red, uneven |

| score | 90 | 90 | 84 | 83 | 75 | 75 | |

| Score a | 90.00 | 88.2 | 78.65 | 80.75 | 83.15 | 70.90 | |

| No. | Compound | Retention Time (min) | Relative Content (%) | |||||

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | |||

| 1 | Alkane | |||||||

| 2 | 10-Methyl decadecane | 9.84 | - | 0.27 | - | - | - | - |

| 3 | 2,5-dimethylnonane | 0.99 | - | 1.02 | 1.01 | 1.18 | 1.45 | 1.26 |

| 4 | 2,6,10,14-tetramethyl hexadecane | 12.95 | 0.59 | - | - | 4.22 | 5.41 | - |

| 5 | 2,6,10-trimethylundecanone | 11.41 | - | - | - | 0.04 | 0.85 | - |

| 6 | 2,6-dimethyldecane | 3.69 | - | - | 2.83 | 1.09 | - | - |

| 7 | 2,6-dimethylundecanone | 8.12 | - | 1.75 | 1.91 | 1.94 | 1.25 | 1.28 |

| 8 | 2-Methylundecanone | 4.57 | - | - | - | - | 0.36 | 0.36 |

| 9 | 3,6-dimethyldecane | 1.76 | 2.15 | 5.88 | - | 6.03 | 2.55 | 2.69 |

| 10 | 3,6-dimethylnonane | 1.76 | 2.15 | 5.88 | - | 6.03 | 2.55 | 2.69 |

| 11 | 3,8-dimethyldecane | 18.26 | - | 0.03 | 1.19 | - | - | - |

| 12 | 4,6-dimethyldodecane | 9.98 | 0.64 | 0.24 | 0.21 | 0.60 | 0.44 | 0.69 |

| 13 | 4,6-dimethyldodecane | 8.59 | 1.05 | - | 1.47 | - | 0.92 | 1.04 |

| 14 | 4,8-dimethyldecane | 8.59 | 1.05 | - | 1.47 | - | 0.92 | 1.04 |

| 15 | 4,8-dimethylundecanone | 2.26 | 1.66 | 2.51 | 2.81 | 3.24 | 3.68 | 3.15 |

| 16 | 4-Methyldecane | 9.13 | - | 1.15 | - | 1.39 | - | - |

| 17 | 4-Methyldodecane | 6.07 | - | - | 0.20 | 0.25 | - | - |

| 18 | 4-Methylundecanone | 6.07 | - | - | - | - | 0.19 | 0.2 |

| 19 | 5-Butyl nonane | 2.14 | 0.61 | 0.75 | 0.64 | 0.74 | 0.78 | 0.77 |

| 20 | 5-Methyldecane | 10.36 | - | - | 2.27 | 2.36 | - | - |

| 21 | 5-Ethyl-2-methyl-octane | 10.36 | - | - | - | - | - | 2.07 |

| 22 | 8-methylheptadecane | 4.85 | - | - | - | - | 0.64 | - |

| 23 | Methyl tris (trimethylsilyl) silane | 4.56 | - | - | - | 0.44 | - | 0.03 |

| 24 | N-eicosane | 3.86 | 2.75 | 4.39 | 5.42 | 5.41 | 6.68 | 6.51 |

| 25 | N-decane | 19.43 | - | - | - | 0.20 | 0.04 | 0.2 |

| 26 | N-octadecane | 1.89 | 2.74 | 0.27 | 3.39 | 2.14 | 2.25 | 1.99 |

| 27 | N-dodecane | 9.42 | 0.73 | 0.53 | 0.71 | 0.10 | 1.11 | 0.82 |

| 28 | N-decadecane | 18.28 | 0.36 | 0.03 | - | - | - | - |

| 29 | N-hexadecane | 9.83 | 0.15 | - | - | - | 0.15 | - |

| 30 | N-heptadecane | 6.25 | - | 1.48 | 0.06 | 0.40 | - | - |

| 31 | N-tridecane | 9.32 | - | 0.91 | 0.05 | 1.48 | 1.03 | 0.38 |

| 32 | Tetradecane | 9.05 | 3.28 | 1.05 | 0.31 | 0.40 | 0.41 | 0.28 |

| 33 | N-pentadecane | 11.71 | - | 0.05 | - | 0.27 | 0.47 | 0.49 |

| 34 | N-undecanone | 17.64 | 0.06 | - | - | - | - | - |

| 35 | Olefin | |||||||

| 36 | 1,2,3,4-tetramethyl-5-methylene | 56.17 | 1.41 | 0.18 | 0.31 | - | - | - |

| 37 | Transsqualene | 17.22 | 0.76 | 1.39 | - | 0.89 | - | - |

| 38 | Aromatic group | |||||||

| 39 | 1,2,3,4-tetramethylbenzene | 16.78 | 0.77 | - | - | - | - | - |

| 40 | 1,2,3,5-tetramethylbenzene | 20 | - | 0.09 | 0.56 | - | 0.19 | 0.21 |

| 41 | 1,2,4,5-tetramethylbenzene | 14.45 | - | 0.22 | 0.60 | 0.22 | 0.85 | 0.07 |

| 42 | 1,3-dimethyl-2-ethylbenzene | 20.33 | 0.20 | - | - | - | - | 0.11 |

| 43 | 1,3-dimethyl-4-ethylbenzene | 38.8 | 0.09 | 0.03 | - | - | 0.05 | - |

| 44 | 1,3-dimethyl-5-ethylbenzene | 20.33 | - | - | - | - | 0.15 | - |

| 45 | 1,4-dihydro-1,4-methylbridgenaphthalene | 22.24 | 0.05 | - | 0.09 | - | 0.05 | - |

| 46 | 1-ethyl-2-isopropylbenzene | 21.98 | - | - | - | 0.22 | - | 0.12 |

| 47 | 2,3-dichlorotoluene | 37.6 | - | 0.06 | 0.06 | 0.04 | - | 0.05 |

| 48 | 2,5-dichloromethylbenzene | 20.33 | - | - | 0.19 | - | - | - |

| 49 | 2-methylnaphthalene | 21.97 | - | 0.14 | - | 0.09 | - | 0.22 |

| 50 | 2-tert-butyl toluene | 20.33 | 0.20 | - | - | - | - | 0.11 |

| 51 | 3,4-dichlorotoluene | 21.97 | - | - | - | - | 0.21 | 0.05 |

| 52 | 3,5-dimethyl-1-isopropylbenzene | 13.84 | 0.05 | - | 0.05 | - | 0.05 | - |

| 53 | 3,5-dichlorotoluene | 27.61 | - | - | 0.02 | - | - | - |

| 54 | 3-ethylo-xylene | 19.64 | - | - | - | - | - | 0.45 |

| 55 | 4-(2-methyl-2-propenyl) phenol | 13.86 | - | 0.06 | 0.20 | - | - | 0.06 |

| 56 | 4-isopropyltoluene | 42.98 | 0.10 | 0.08 | - | 0.02 | 0.03 | - |

| 57 | 5-Ethyl-3,5-dimethylbenzene | 44.92 | 1.50 | 8.22 | 0.17 | 0.19 | 0.06 | - |

| 58 | phenol | 19.64 | - | 0.67 | - | - | 0.07 | - |

| 59 | P-methylphenol | 32.25 | 0.58 | 0.57 | - | 0.37 | 0.43 | 0.4 |

| 60 | O-isopropyl methylbenzene | 27.61 | - | 0.19 | - | 0.20 | - | 0.08 |

| 61 | naphthalene | 56.67 | - | - | - | - | 0.13 | - |

| 62 | Pentamethylbenzene | 26.62 | - | - | 1.43 | - | - | - |

| 63 | Esters | |||||||

| 64 | Dibutyl 1,2-phthalate | 60.39 | 1.18 | - | - | - | - | - |

| 65 | Acetyl 4-hydroxybutyrate | 49.58 | 0.10 | 0.06 | - | 0.18 | - | 0.14 |

| 66 | Ethyl caproate | 19.01 | 1.14 | 0.51 | - | 1.00 | 0.57 | 0.99 |

| 67 | Di (2-ethylhexyl) phthalate | 23.62 | - | - | 0.23 | - | - | 1.94 |

| 68 | Dimethyl phthalate | 21.43 | - | 1.16 | - | - | - | - |

| 69 | Alcohols | |||||||

| 70 | 1-octene-3-ol | 29.76 | - | - | - | - | 0.24 | 0.08 |

| 71 | 2,3-Butanediol | 43.96 | - | - | - | - | - | 0.11 |

| 72 | α-Cyanobenzyl alcohol | 40.38 | 1.90 | 0.24 | 0.25 | 1.15 | 0.67 | 1.37 |

| 73 | Benzyl alcohol | 49.4 | 0.16 | - | - | 0.04 | 0.04 | 0.02 |

| 74 | Furfuryl alcohol | 19.25 | - | - | - | - | - | 0.29 |

| 75 | Hydrocinnitol | 14.64 | - | - | 0.16 | - | - | 2.33 |

| 76 | Phenylethanol | 36.25 | 2.61 | 1.84 | 1.19 | - | - | - |

| 77 | Cinnamyl alcohol | 43.23 | - | 0.02 | 0.04 | - | 0.41 | - |

| 78 | N-heptanol | 5.62 | - | - | - | 0.48 | - | - |

| 79 | N-hexanol | 36.26 | - | - | - | 1.24 | - | 0.68 |

| 80 | Aldehyde | |||||||

| 81 | 2,4-Dimethylbenzaldehyde | 21.72 | 1.69 | 0.40 | 1.17 | 1.54 | 1.37 | 1.74 |

| 82 | 2-pyrrolaldehyde | 43.47 | 0.05 | - | - | 0.06 | - | - |

| 83 | 2-en-hexaldehyde | 18.82 | - | 0.55 | 0.98 | - | 7.22 | 1.31 |

| 84 | 3,4-dimethylbenzaldehyde | 22.59 | 0.13 | - | - | - | - | 0.48 |

| 85 | 3,5-dimethylbenzaldehyde | 16.04 | - | 0.11 | 0.93 | 0.40 | 0.15 | - |

| 86 | Benzaldehyde | 43.45 | - | - | 0.05 | - | - | - |

| 87 | Transcinnamaldehyde | 54.37 | - | - | 0.05 | - | - | - |

| 88 | Furan formaldehyde | 6.86 | 2.20 | 2.50 | 7.68 | 3.07 | 3.53 | 2.25 |

| 89 | Trans-2-nonenal | 52.13 | 0.22 | 0.09 | 0.10 | 0.12 | 0.12 | 0.07 |

| 90 | Nonanal | 56.81 | 0.05 | 0.94 | 0.08 | 0.17 | 0.18 | - |

| 91 | Cinnamaldehyde | 18.51 | 1.26 | 3.95 | 0.95 | 2.89 | 4.77 | 2.98 |

| 92 | Vanillin | 58.73 | 1.81 | - | 0.02 | - | - | 0.07 |

| 93 | Heptaldehyde | 27.95 | 6.28 | 0.59 | 0.32 | 0.49 | 0.37 | 0.41 |

| 94 | Organic acid | |||||||

| 95 | Benzoic acid | 38.63 | 2.63 | 0.85 | 2.87 | 1.37 | 0.19 | 1.04 |

| 96 | Myristic acid | 61.12 | 0.49 | 0.89 | 0.24 | 1.01 | 0.53 | 0.15 |

| 97 | acetic acid | 20.13 | 0.19 | - | 0.16 | - | - | - |

| 98 | stearic acid | 8.89 | - | 0.09 | 0.59 | - | - | 0.25 |

| 99 | N-butyric acid | 20.85 | - | 0.16 | - | - | 0.91 | - |

| 100 | Heptanoic acid | 41.98 | - | 0.06 | - | - | 0.12 | - |

| 101 | Hexanoic acid | 7.84 | - | - | 0.19 | - | - | - |

| 102 | palmitic acid | 12.95 | 0.59 | - | - | 4.22 | 5.41 | - |

| 103 | Other | |||||||

| 104 | 2-methylindene | 25.03 | 2.96 | 2.08 | 1.00 | 1.38 | 1.03 | - |

| 105 | 2-pentylfuran | 8.89 | - | 0.09 | 0.59 | - | - | 0.25 |

| 106 | 2-Acetylfuran | 20.85 | - | 0.16 | - | - | 0.91 | - |

| 107 | 2-Acetylpyrrole | 43.23 | - | 0.02 | 0.04 | - | 0.41 | - |

| 108 | Pyrazine | 7.84 | - | - | 0.19 | - | - | - |

| 109 | N,N-dimethylformamide | 12.95 | 0.59 | - | - | 4.22 | 5.41 | - |

| 110 | Chamomile | 32.24 | - | - | 0.50 | - | - | - |

| 111 | Isophorone | 25.03 | 2.96 | 2.08 | 1.00 | 1.38 | 1.03 | - |

| Compounds | Threshold | ROAV a | |||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | ||

| phenol | 5900 | - b | 0.01 | - | - | 0.00 c | - |

| P-methylphenol | 90 | 0.31 | 0.30 | - | 0.20 | 0.23 | 0.21 |

| Ethyl caproate | 1 | 54.46 | 24.36 | - | 47.77 | 27.23 | 47.29 |

| 1-octene-3-ol | 1 | - | - | - | - | 11.46 | 3.82 |

| Furfuryl alcohol | 5000 | - | - | - | - | - | 0.00 |

| Phenylethanol | 800 | 0.16 | 0.11 | 0.07 | - | - | - |

| Cinnamyl alcohol | 40 | - | 0.02 | 0.05 | - | 0.49 | - |

| N-heptanol | 3 | - | - | - | 7.64 | - | - |

| N-hexanol | 2500 | - | - | - | 0.02 | - | 0.01 |

| 2-en-hexaldehyde | 17 | - | 1.55 | 2.75 | - | 20.29 | 3.68 |

| Benzaldehyde | 1500 | - | - | 0.00 | - | - | - |

| Nonanal | 1 | 2.39 | 44.90 | 3.82 | 8.12 | 8.60 | - |

| Cinnamaldehyde | 14 | 4.30 | 13.48 | 3.24 | 9.86 | 16.28 | 10.17 |

| Vanillin | 32 | 2.70 | - | 0.03 | - | - | 0.10 |

| Heptaldehyde | 3 | 100.00 | 9.39 | 5.10 | 7.80 | 5.89 | 6.53 |

| Myristic acid | 10,000 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| acetic acid | 22,000 | 0.00 | - | 0.00 | - | - | - |

| N-butyric acid | 6500 | - | 0.00 | - | - | 0.01 | - |

| 2-pentylfuran | 6 | - | 0.72 | 4.70 | - | - | 1.99 |

| 2-Acetylfuran | 10,000 | - | 0.00 | - | - | 0.00 | - |

| 2-Acetylpyrrole | 170,000 | - | 0.00 | 0.00 | - | 0.00 | - |

| Pyrazine | 60 | - | - | 0.15 | - | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, X.; Song, Z.; Liu, J.; Zhang, Y.; Wu, M.; Liu, H. Effects of Different Drying Methods on the Quality of Bletilla striata Scented Tea. Molecules 2023, 28, 2438. https://doi.org/10.3390/molecules28062438

Han X, Song Z, Liu J, Zhang Y, Wu M, Liu H. Effects of Different Drying Methods on the Quality of Bletilla striata Scented Tea. Molecules. 2023; 28(6):2438. https://doi.org/10.3390/molecules28062438

Chicago/Turabian StyleHan, Xue, Zhiqin Song, Jiawei Liu, Yeshan Zhang, Mingkai Wu, and Hai Liu. 2023. "Effects of Different Drying Methods on the Quality of Bletilla striata Scented Tea" Molecules 28, no. 6: 2438. https://doi.org/10.3390/molecules28062438

APA StyleHan, X., Song, Z., Liu, J., Zhang, Y., Wu, M., & Liu, H. (2023). Effects of Different Drying Methods on the Quality of Bletilla striata Scented Tea. Molecules, 28(6), 2438. https://doi.org/10.3390/molecules28062438