Alkaline Degradation of Plant Fiber Reinforcements in Geopolymer: A Review

Abstract

1. Introduction

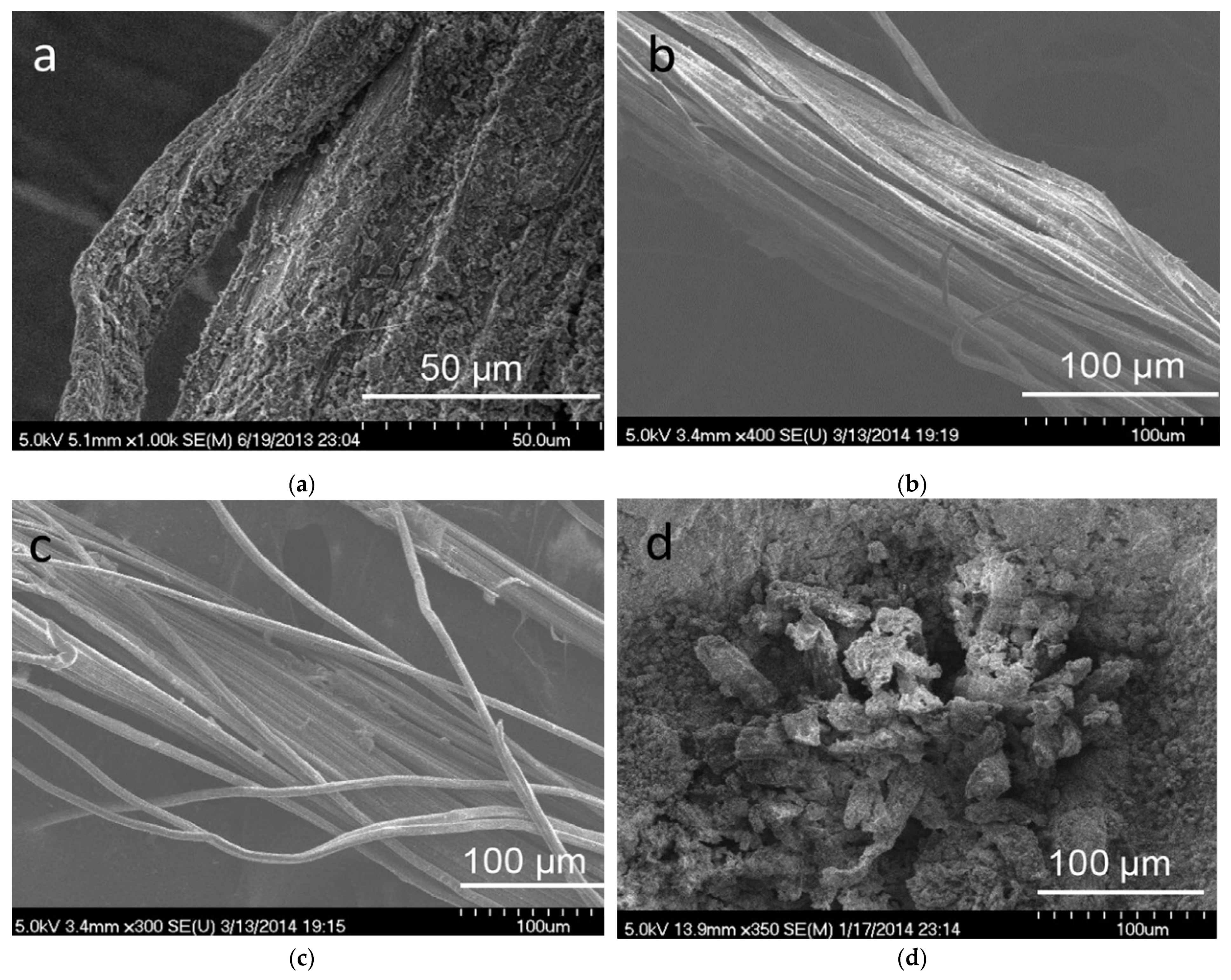

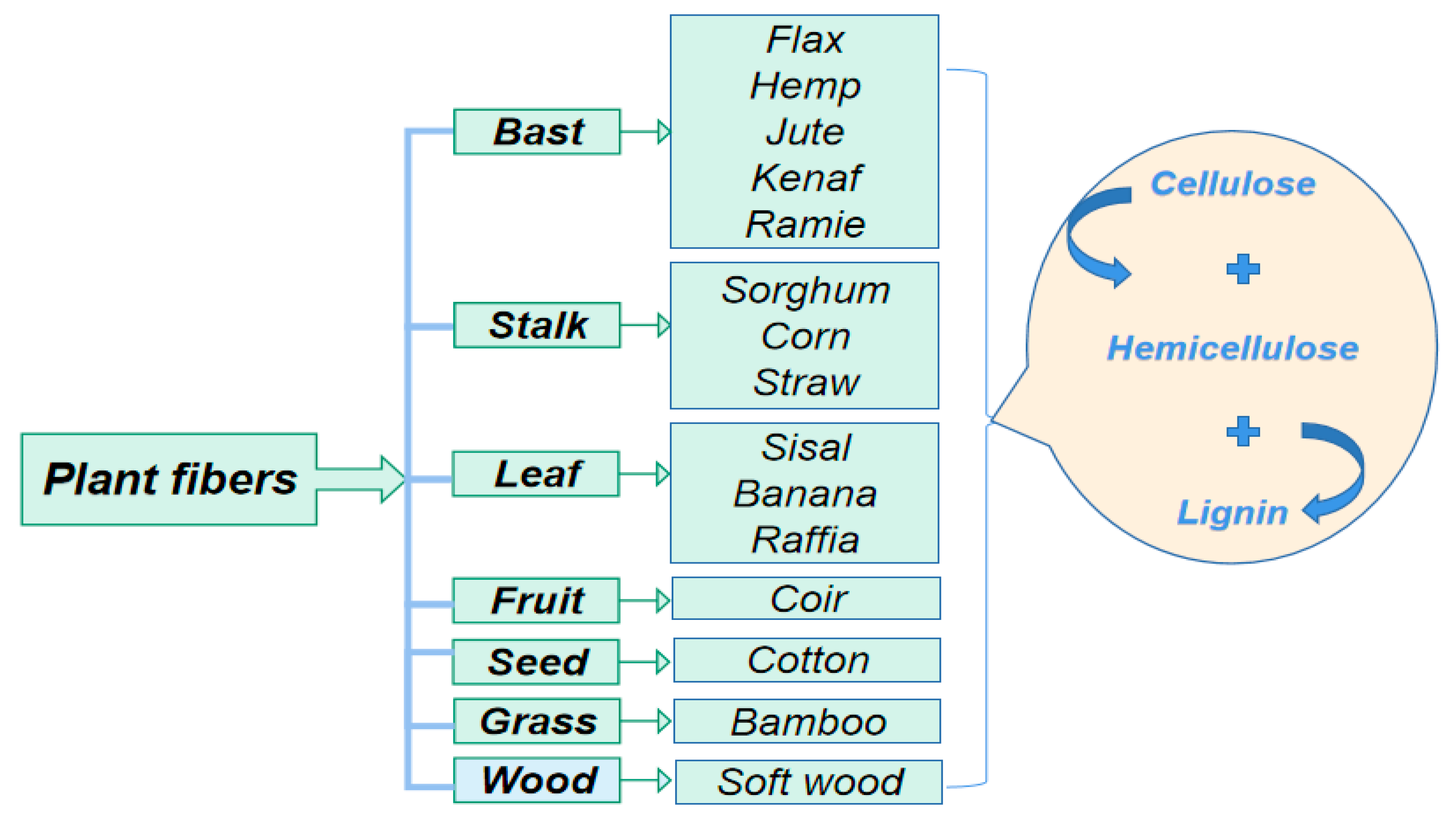

2. Classification and Mechanical Properties of PFs

| Fiber Type | Fiber Name | Density /(g·cm−3) | Tensile Strength /MPa | Tensile Modulus/GPa | Elongation/% | Ref. |

|---|---|---|---|---|---|---|

| Bast | Flax | 1.50 | 800–1 500 | 27.6–80.0 | 1.2–3.2 | [38] |

| Hemp | 1.48 | 550–900 | 70.0 | 2.0–4.0 | [39] | |

| Jute | 1.50 | 600 | 10.0–30.0 | 1.5–1.8 | [40,41] | |

| Kenaf | 1.45 | 930 | 53.0 | 1. 6 | [42] | |

| Ramie | 1.50 | 220–938 | 44.0–128.0 | 2.0–3.8 | [43] | |

| Leaf | Abaca | 1.50 | 400 | 12.0 | 3.0–10.0 | [44] |

| Sisal | 0.86 | 606 | 15.4 | 4.1 | [45] | |

| Banana | 1.35 | 600 | 17.9 | 3.4 | [43] | |

| Pineapple | 1.43 | 413–1 627 | 34.5–82.5 | 1.6 | [46] | |

| Fruit | Coir | 1.50 | 500 | 4.0–6.0 | 30.0 | [40,43] |

| Wood | Soft wood | 1.50 | 1 000 | 40.0 | 4.4 | [47] |

| Grass | Bamboo | 1.10 | 500 | 35.9 | 1.4 | [47] |

| Seed | Cotton | 1.60 | 287–597 | 5.5–12.6 | 7.0–8.0 | [47] |

3. PF-Reinforced Geopolymer Composites

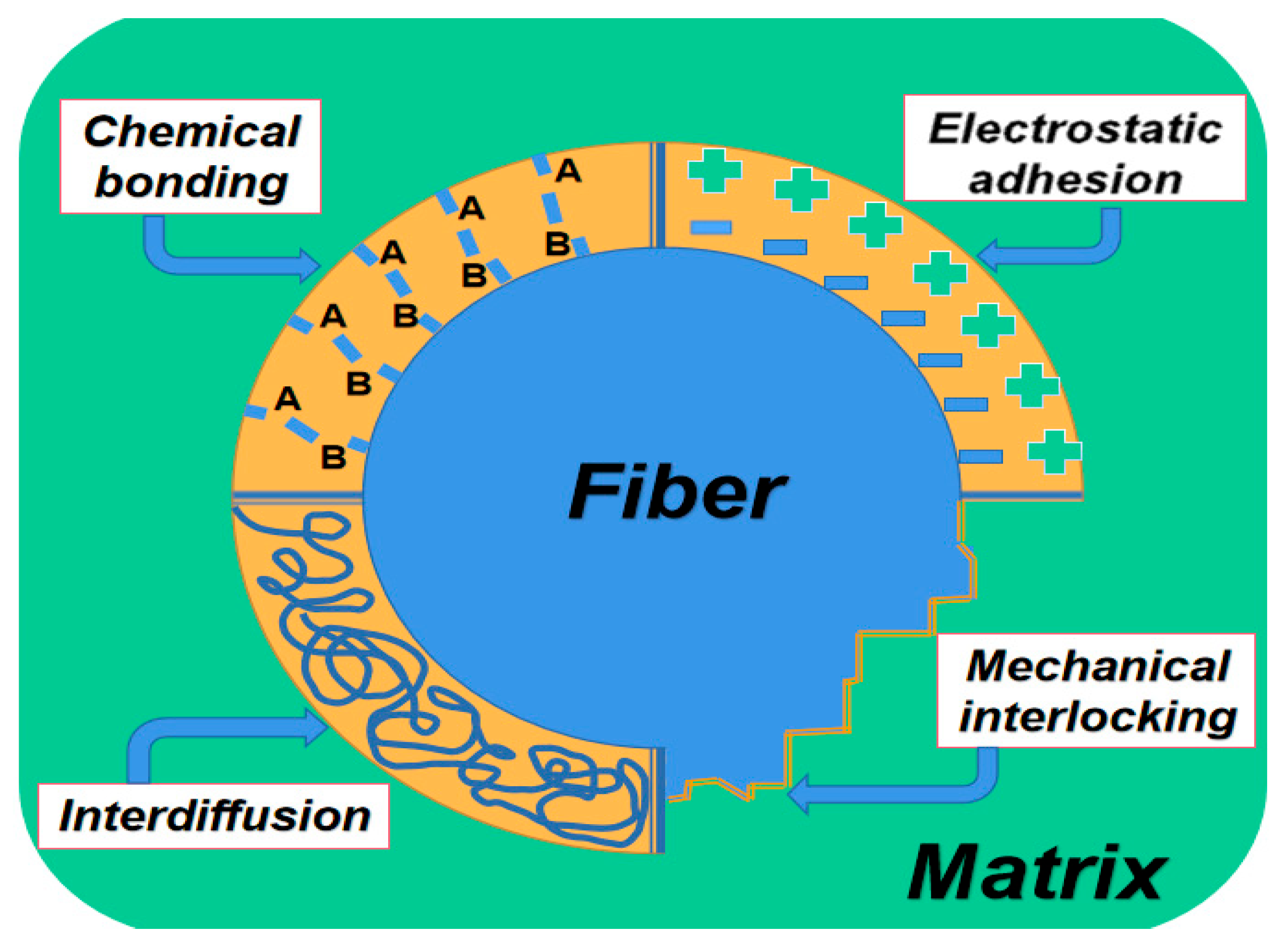

3.1. Interface Bonding Mechanisms between PFs and Matrix

3.2. Water Absorption of PF-Reinforced Geopolymers

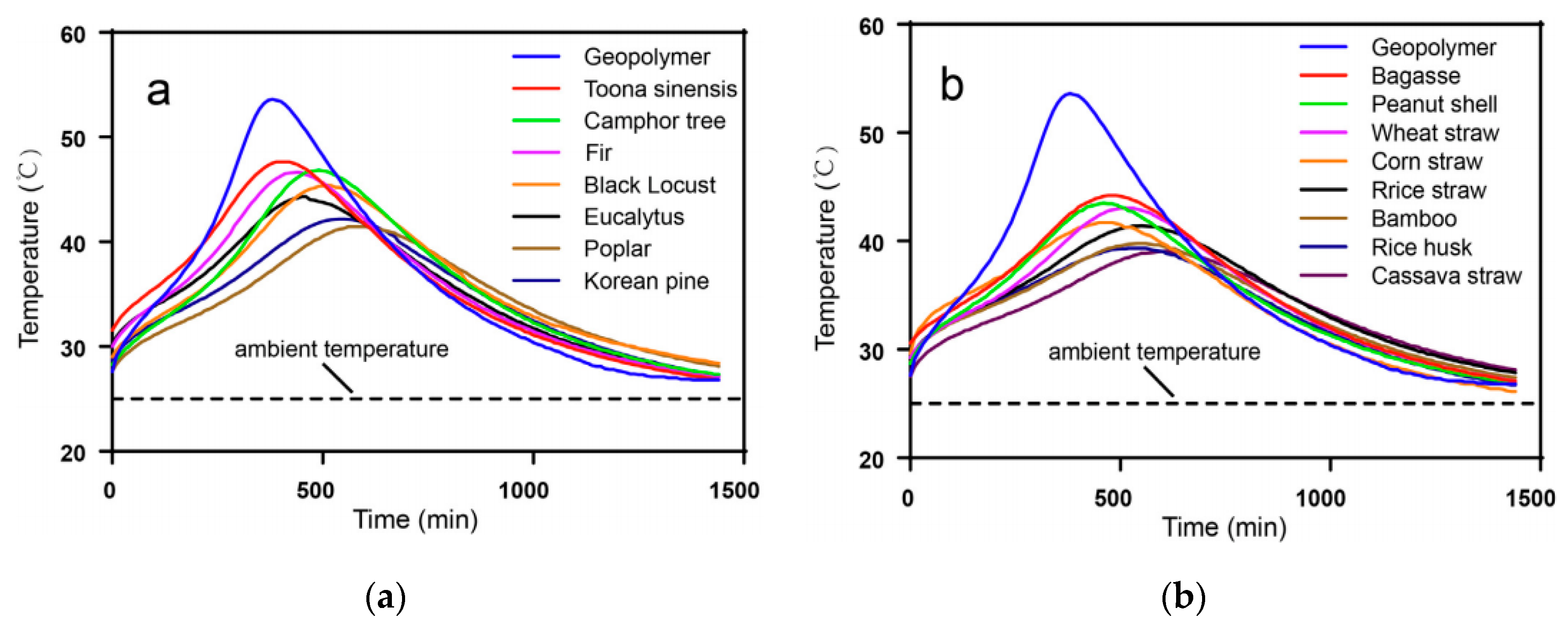

3.3. Compatibility between PF and Geopolymer Matrix

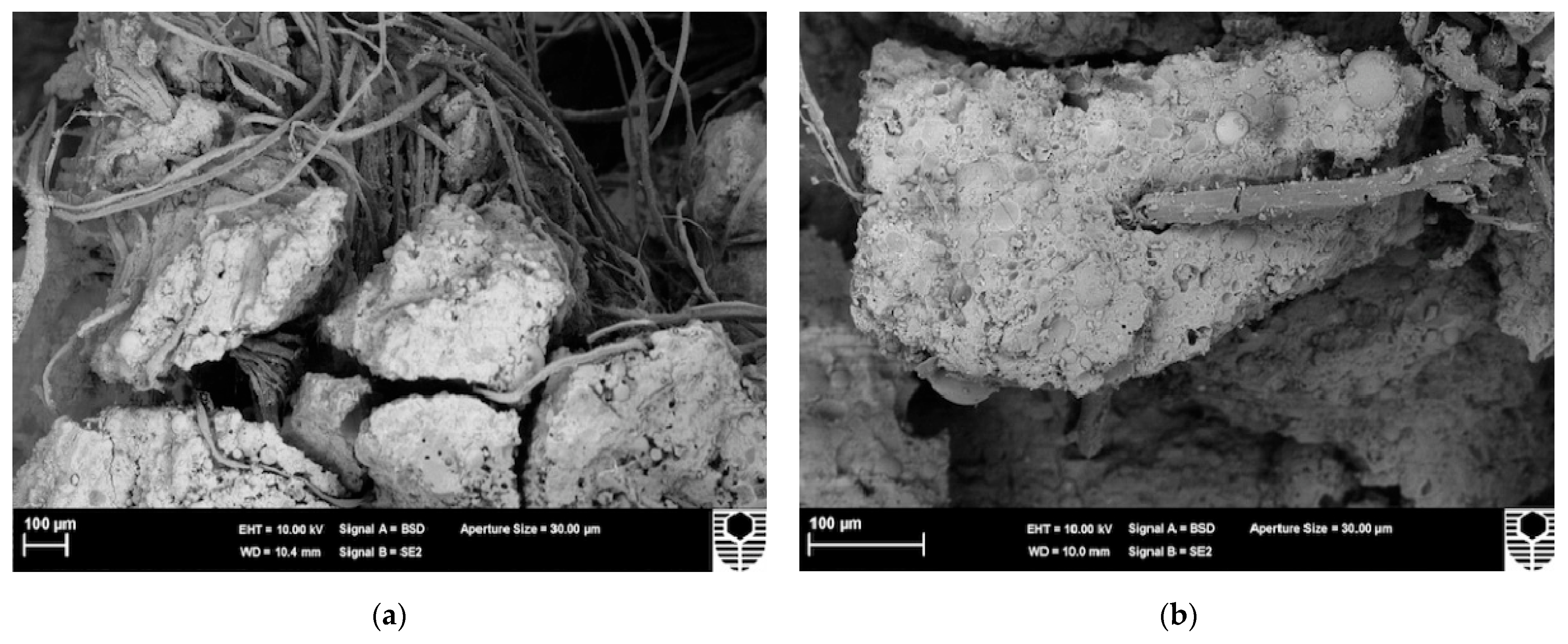

4. Degradation Behavior of PFs in Geopolymer Matrix

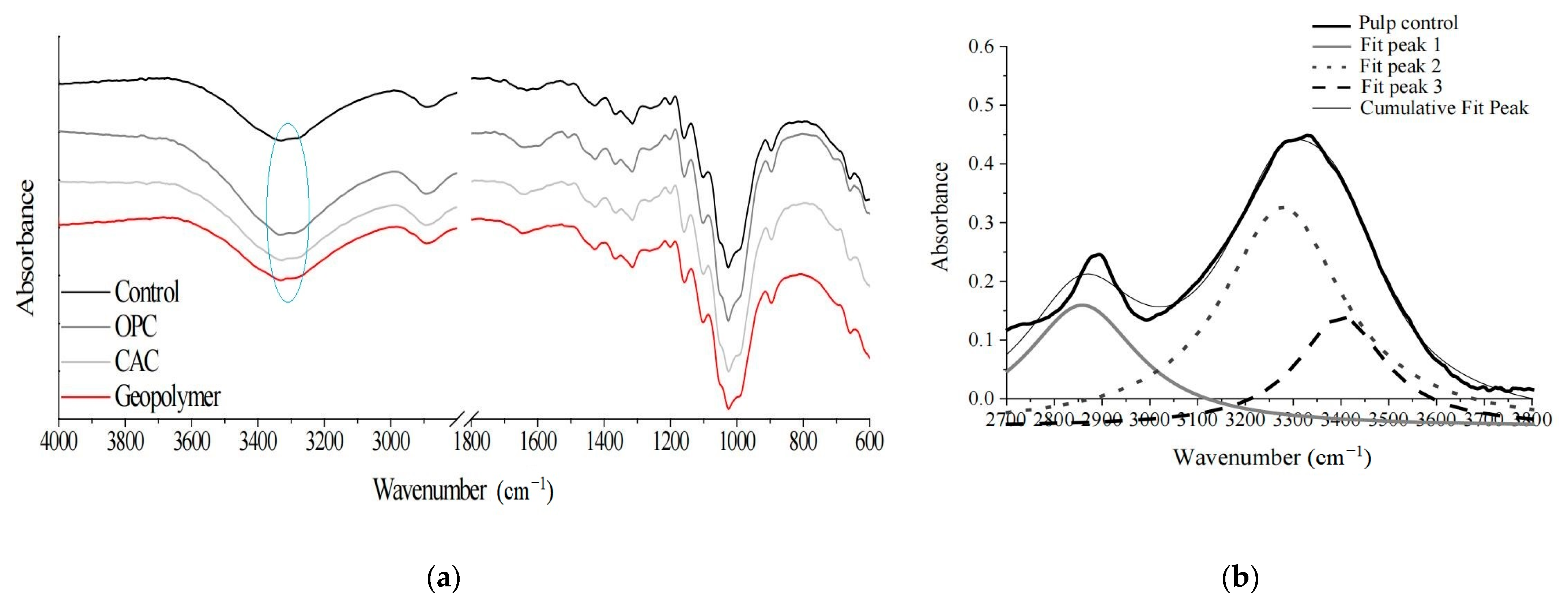

4.1. Mechanism of Degradation of PF in the Matrix

4.2. Degradation of PFs in Alkaline Solutions

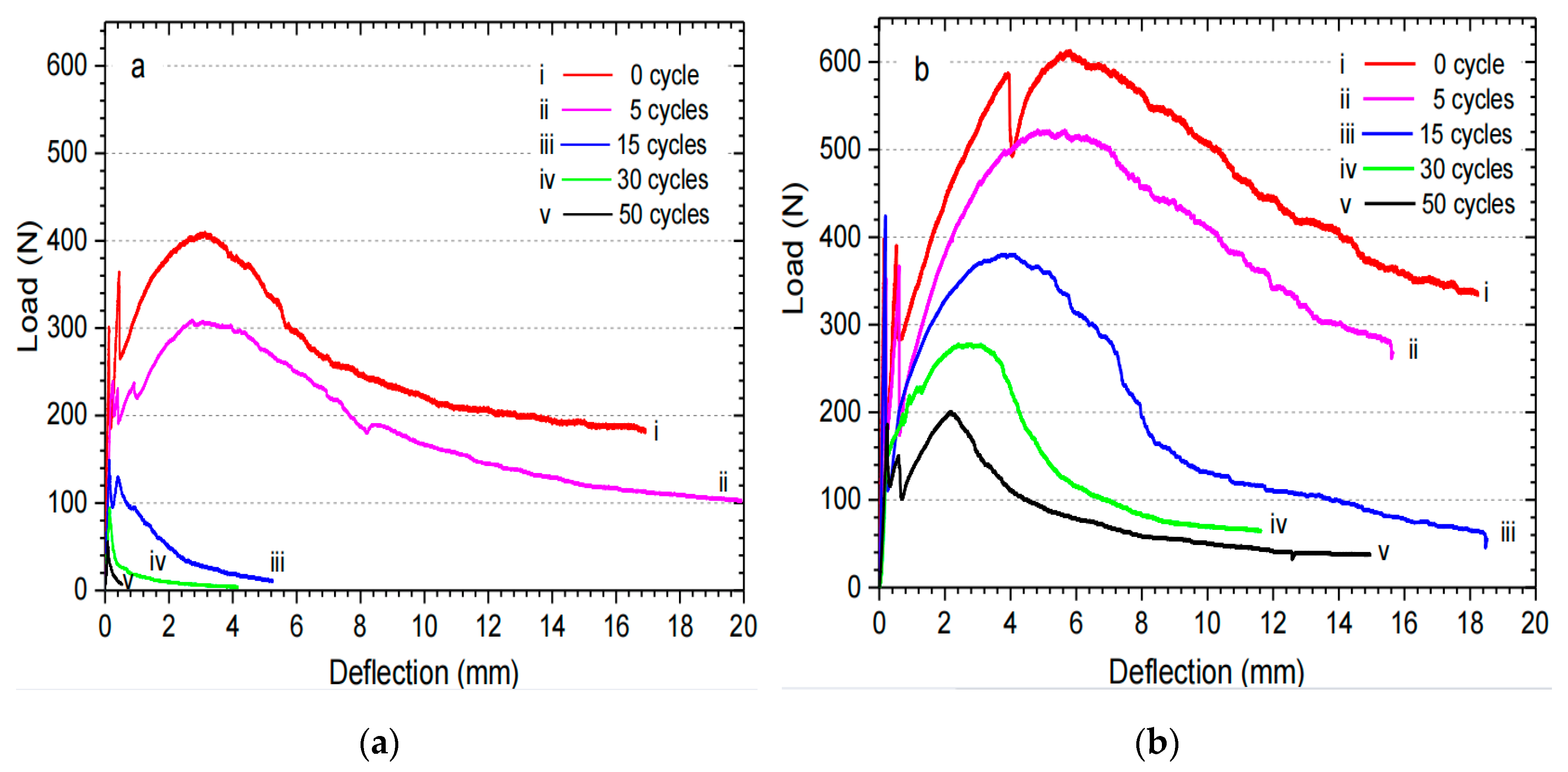

4.3. Degradation of PFs in Wetting and Drying Cycles

4.4. Alkaline Degradation of Fiber at High Temperature

4.5. Mineralization of PFs in the Matrix

5. The Path to Slow Fiber Degradation

5.1. Improve the Alkaline Environment of the Matrix

5.1.1. Accelerated Carbonization

5.1.2. Add Mineral Admixtures to the Matrix

5.2. Modification of PFs

5.3. The Influence of Nanomaterials

5.4. Influence of Toughening Matrix

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Khan, M.; Ali, M. Use of glass and nylon fibers in concrete for controlling early age micro cracking in bridge decks. Constr. Build. Mater. 2016, 125, 800–808. [Google Scholar] [CrossRef]

- Rabiaa, E.; Mohamed, R.A.S.; Sofi, W.H.; Tawfik Taher, A. Developing Geopolymer Concrete Properties by Using Nanomaterials and Steel Fibers. Adv. Mater. Sci. Eng. 2020, 21, 1–12. [Google Scholar] [CrossRef]

- Guo, X.; Xiong, G. Resistance of fiber-reinforced fly ash-steel slag based geopolymer mortar to sulfate attack and drying-wetting cycles. Constr. Build. Mater. 2021, 269, 121326. [Google Scholar] [CrossRef]

- Ma, P.; Xin, M.; Zhang, Y.; Ge, S.; Wang, D.; Jiang, C.; Zhang, L.; Cheng, X. Facile synthesis of novel dopamine-modified glass fibers for improving alkali resistance of fibers and flexural strength of fiber-reinforced cement. RSC Adv. 2021, 11, 18818–18826. [Google Scholar] [CrossRef] [PubMed]

- Wu, B.; Xu, X.; Luo, S.; Yan, D.; Song, K.; Zhang, X.; He, F. Study on the Mechanical Properties and Strengthening Mechanism of Interface-Modified Carbon Fiber Mesh Reinforced Cement-Based Composites with SCA&HMC. Molecules 2019, 24, 3989. [Google Scholar]

- Liu, J.; Lv, C. Properties of 3D-Printed Polymer Fiber-Reinforced Mortars: A Review. Polymers 2022, 14, 1315. [Google Scholar] [CrossRef]

- Haloob, A.; Andreas, L.; Andrew, C. Tensile properties of a novel fibre reinforced geopolymer composite with enhanced strain hardening characteristics. Compos. Struct. 2017, 168, 402–427. [Google Scholar]

- Liu, J.; Lv, C. Durability of Cellulosic-Fiber-Reinforced Geopolymers: A Review. Molecules 2022, 27, 796. [Google Scholar] [CrossRef]

- Kheradmand, M.; Mastali, M.; Abdollahnejad, Z.; Pacheco-Torgal, F. Experimental and numerical investigations on the flexural performance of geopolymers reinforced with short hybrid polymeric fibres. Compos. Part B-Eng. 2017, 126, 108–118. [Google Scholar] [CrossRef]

- Guo, G.; Lv, C.; Liu, J.; Wang, L. Properties of Fiber-Reinforced One-Part Geopolymers: A Review. Polymers 2022, 14, 3333. [Google Scholar] [CrossRef]

- Sankar, K.; Kriven, W. Sodium geopolymer reinforced with jute weave. Ceram. Eng. Sci. Proc. 2014, 35, 5–8. [Google Scholar]

- Wei, J.; Meyer, C. Degradation rate of natural fiber in cement composites exposed to various accelerated aging environment conditions. Corros. Sci. 2014, 88, 118–132. [Google Scholar] [CrossRef]

- Kamarudin, S.; Mohd Basri, M.; Rayung, M.; Abu, F.; Ahmad, S.; Norizan, M.; Osman, S.; Sarifuddin, N.; Desa, M.; Abdullah, U.; et al. A Review on Natural Fiber Reinforced Polymer Composites (NFRPC) for Sustainable Industrial Applications. Polymers 2022, 14, 3698. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Lv, C. Research Progress on Durability of Cellulose Fiber-Reinforced Cement-Based Composites. Int. J. Polym. Sci. 2021, 2021, 1014531. [Google Scholar] [CrossRef]

- Ahmad, I.; Wong, P.; Abdullah, I. Effects of fiber composition and graft-copoly(ethylene/maleic anhydride) on thermoplastic natural rubber composites reinforced by aramid fiber. Polym. Compos. 2006, 27, 395–401. [Google Scholar] [CrossRef]

- Şahmaran, M.; Li, V. Durability properties of micro-cracked ECC containing high volumes fly ash. Cem. Concr. Res. 2009, 39, 1033–1043. [Google Scholar] [CrossRef]

- Karahan, O.; Atis, C. The durability properties of polypropylene fiber reinforced fly ash concrete. Mater. Des. 2011, 32, 1044–1049. [Google Scholar] [CrossRef]

- Lasrado, D.; Ahankari, S.; Kar, K. Nanocellulose-based polymer composites for energy applications-A review. J. Appl. Polym. Sci. 2020, 137, 48959. [Google Scholar] [CrossRef]

- Mohanty, A.; Vivekanandhan, S.; Pin, J.; Misra, M. Composites from renewable and sustainable resources: Challenges and innovations. Science 2018, 362, 536–542. [Google Scholar] [CrossRef]

- Venkatarajan, S.; Athijayamani, A. An overview on natural cellulose fiber reinforced polymer composites. Mater. Today Proc. 2021, 37, 3620–3624. [Google Scholar] [CrossRef]

- Ali, B.; Farooq, M.; El Ouni, M.; Azab, M.; Elhag, A. The combined effect of coir and superplasticizer on the fresh, mechanical, and long-term durability properties of recycled aggregate concrete. J. Build. Eng. 2022, 59, 105009. [Google Scholar] [CrossRef]

- Santana, H.A.; Júnior NS, A.; Ribeiro, D.V.; Cilla, M.S.; Dias, C.M. Vegetable fibers behavior in geopolymers and alkali-activated cement based matrices: A review. J. Build. Eng. 2021, 44, 103291. [Google Scholar] [CrossRef]

- Sellami, A.; Merzoud, M.; Amziane, S. Improvement of mechanical properties of green concrete by treatment of the vegetals fibers. Constr. Build. Mater. 2013, 47, 1117–1124. [Google Scholar] [CrossRef]

- Filho, R.; Scrivener, K.; England, G.; Ghavami, K. Durability of alkali-sensitive sisal and coconut fibres in cement mortar composites. Cem. Concr. Compos. 2000, 22, 127–143. [Google Scholar] [CrossRef]

- Singh, S. Alkali resistance of some vegetable fibers and their adhesion with portland cement. Res. Indus. 1985, 15, 121–126. [Google Scholar]

- Mohr, B.; Nanko, H.; Kurtis, K. Durability of kraft pulp fiber-cement composites to wet/dry cycling. Cem. Concr. Compos. 2005, 27, 435–448. [Google Scholar] [CrossRef]

- Fonseca, R.; Rocha, J.; Cheriaf, M. Mechanical Properties of Mortars Reinforced with Amazon Rainforest Natural Fibers. Materials 2021, 14, 155. [Google Scholar] [CrossRef] [PubMed]

- Ayeni, O.; Mahamat, A.A.; Bih, N.L.; Stanislas, T.T.; Isah, I.; Savastano Junior, H.; Boakye, E.; Onwualu, A.P. Effect of Coir Fiber Reinforcement on Properties of Metakaolin-Based Geopolymer Composite. Appl. Sci. 2022, 12, 5478. [Google Scholar] [CrossRef]

- Filho, J.; Silva, F.; Filho, R. Degradation kinetics and aging mechanisms on sisal fiber cement composite systems. Cem. Concr. Compos. 2013, 40, 30–39. [Google Scholar] [CrossRef]

- Filho, R.; Ghavami, K.; England, G.; Scrivener, K. Development of vegetable fibre-mortar composites of improved durability. Cem. Concr. Compos. 2003, 25, 185–196. [Google Scholar] [CrossRef]

- Azwa, Z.; Yousif, B.; Manalo, A.; Karunasena, W. A review on the degradability of polymeric composites based on natural fibres. Mater. Des. 2013, 47, 424–442. [Google Scholar] [CrossRef]

- Abdellatief, M.; Alanazi, H.; Radwan, M.K.H.; Tahwia, A.M. Multiscale Characterization at Early Ages of Ultra-High Performance Geopolymer Concrete. Polymers 2022, 14, 5504. [Google Scholar] [CrossRef]

- Tahwia, A.; Abd Ellatief, M.; Heneigel, A.; Abd Elrahman, M. Characteristics of eco-friendly ultra-high-performance geopolymer concrete incorporating waste materials. Ceram. Int. 2022, 48, 19662–19674. [Google Scholar] [CrossRef]

- Ma, H.; Fu, P.; Zhao, J.; Lin, X.; Wu, W.; Yu, Z.; Xia, C.; Wang, Q.; Gao, M.; Zhou, J. Pretreatment of Wheat Straw Lignocelluloses by Deep Eutectic Solvent for Lignin Extraction. Molecules 2022, 27, 7955. [Google Scholar] [CrossRef] [PubMed]

- Yan, L.; Kasal, B.; Huang, L. A review of recent research on the use of cellulosic fibres, their fibre fabric reinforced cementitious, geo-polymer and polymer composites in civil engineering. Compos. Part B-Eng. 2016, 92, 94–132. [Google Scholar] [CrossRef]

- Ribeiro, M.; Kriven, W.M. A Review of Particle-and Fiber-Reinforced Metakaolin-Based Geopolymer Composites. J. Ceram. Sci. Technol. 2017, 8, 307–322. [Google Scholar]

- Camargo, M.M.; Taye, E.A.; Roether, J.A.; Redda, D.T.; Boccaccini, A.R. A review on natural fiber-reinforced geopolymer and cement-based composites. Materials 2020, 13, 4603. [Google Scholar] [CrossRef]

- Bos, H.; Oever, M.; Peters, O. Tensile and compressive properties of flax fibres for natural fibre reinforced composites. J. Mater. Sci. 2002, 37, 1683–1692. [Google Scholar] [CrossRef]

- Pickering, K.L.; Beckermann, G.W.; Alam, S.N.; Foreman, N.J. Optimising industrial hemp fibre for composites. Compos. Part A Appl. Sci. Manuf. 2007, 38, 461. [Google Scholar] [CrossRef]

- More, F.; Subramanian, S. Impact of Fibres on the Mechanical and Durable Behaviour of Fibre-Reinforced Concrete. Buildings 2022, 12, 1436. [Google Scholar] [CrossRef]

- Gulzar, M.; Ali, B.; Barakat, O.; Azab, M.; Najemalden, A.; Salih, M.; Alashker, Y. Influence of Jute Fiber on Tensile, Electrical, and Permeability Characteristics of Slag Concrete: A Better, Cheaper, and Eco-Friendly Substitute for Conventional Concrete. J. Nat. Fibers 2023, 20, 2170947. [Google Scholar] [CrossRef]

- Mustafa, A.; Abdollah, M.; Shuhimi, F.F.; Ismail, N.; Amiruddin, H.; Umehara, N. Selection and verification of kenaf fibres as an alternative friction material using weighted decision matrix method. Mater. Des. 2015, 67, 577–582. [Google Scholar] [CrossRef]

- Kumar, R.; Obrai, S.; Sharma, A. Chemical modifications of natural fiber for composite material. Chem. Sin. 2011, 2, 219–228. [Google Scholar]

- Haque, M.; Rahman, R.; Islam, N.; Huque, M.; Hasan, M. Mechanical properties of polypropylene composites reinforced with chemically treated coir and abaca fiber. J. Reinf. Plast. Compos. 2010, 29, 2253–2261. [Google Scholar] [CrossRef]

- Santos, G.; Oliveira, D.; Filho, J.; Silva, N. Sustainable geopolymer composite reinforced with sisal fiber: Durability to wetting and drying cycles. J. Build. Eng. 2021, 43, 102568. [Google Scholar] [CrossRef]

- Mishra, S.; Mohanty, A.; Drzal, L.; Misra, M.; Hinrichsen, G. A review on pineapple leaf fibers, sisal fibers and their biocomposites. Macromol. Mater. Eng. 2004, 289, 955. [Google Scholar] [CrossRef]

- Huda, M.; Drzal, L.; Mohanty, A.; Misra, M. Chopped glass and recycled newspaper as reinforcement fibers in injection molded poly (lactic acid) (pla) composites: A comparative study. Compos. Sci. Technol. 2015, 66, 1813–1824. [Google Scholar] [CrossRef]

- Komuraiah, A.; Kumar, N.S.; Prasad, B.D. Chemical Composition of Natural Fibers and its Influence on their Mechanical Properties. Mech. Compos. Mater. 2014, 50, 359–376. [Google Scholar] [CrossRef]

- Biagiotti, J.; Puglia, D.; Kenny, J.M. A review on natural fiber-based composites-part I: Structure, processing and properties of vegetable fibers. J. Nat. Fibers 2004, 1, 37–68. [Google Scholar] [CrossRef]

- Zareei, S.A.; Ameri, F.; Bahrami, N. Microstructure, strength, and durability of eco-friendly concretes containing sugarcane bagasse ash. Constr. Build. Mater. 2018, 184, 258–268. [Google Scholar] [CrossRef]

- Assaedi, H.; Alomayri, T.; Shaikh, F.; Low, I.M. Characterisation of mechanical and thermal properties in flax fabric reinforced geopolymer composites. J. Adv. Ceram. 2015, 4, 272–281. [Google Scholar] [CrossRef]

- Alomayri, T.; Shaikh, F.; Low, I. Synthesis and mechanical properties of cotton fabric reinforced geopolymer composites. Compos. Part B 2014, 60, 36–42. [Google Scholar] [CrossRef]

- Rao, J.; Zhou, Y.; Fan, M. Revealing the Interface Structure and Bonding Mechanism of Coupling Agent Treated WPC. Polymers 2018, 10, 266. [Google Scholar] [CrossRef] [PubMed]

- Awoyera, P.; Odutuga, O.; Effiong, J.; De Jesus Silvera Sarmiento, A.; Mortazavi, S.; Hu, J. Development of Fibre-Reinforced Cementitious Mortar with Mineral Wool and Coconut Fibre. Materials 2022, 15, 4520. [Google Scholar] [CrossRef]

- Duxson, P.; Lukey, G.C.; Separovic, F.; van Deventer, J.S.J. Effect of alkali cations on aluminum incorporation in geopolymeric gels. Ind. Eng. Chem. Res. 2005, 44, 832–839. [Google Scholar] [CrossRef]

- Assarar, M.; Scida, D.; EL Mahi, A.; Poilâne, C.; Ayad, R. Influence of water ageing on mechanical properties and damage events of two reinforced composite materials: Flax-fibres and glass-fibres. Mater. Des. 2011, 32, 788–795. [Google Scholar] [CrossRef]

- Wei, J.; Meyer, C. Degradation mechanisms of natural fiber in the matrix of cement composites. Cem. Concr. Res. 2015, 73, 1–16. [Google Scholar] [CrossRef]

- Addis, L.; Sendekie, Z.; Satheesh, N. Degradation Kinetics and Durability Enhancement Strategies of Cellulosic Fiber-Reinforced Geopolymers and Cement Composites. Adv. Mater. Sci. Eng. 2022, 2022, 1981755. [Google Scholar] [CrossRef]

- Vaisanen, T.; Das, O.; Tomppo, L. A review on new biobased constituents for natural fiber-polymer composites. J. Clean. Prod. 2017, 149, 582–596. [Google Scholar] [CrossRef]

- Chen, H.; Miao, M.; Ding, X. Influence of moisture absorption on the interfacial strength of bamboo/vinyl ester composites. Compos. Part A-Appl. Sci. Manuf. 2009, 40, 2013–2019. [Google Scholar] [CrossRef]

- Methacanon, P.; Weerawatsophon, U.; Sumransin, N.; Prahsarn, C.; Bergado, D. Properties and potential application of the selected natural fibers as limited life geotextiles. Carbohyd. Polym. 2010, 82, 1090–1096. [Google Scholar] [CrossRef]

- Na, Z.; Hya, B.; Dpa, B.; Yang, Z. Effects of alkali-treated kenaf fiber on environmentally friendly geopolymer-kenaf composites: Black liquid as the regenerated activator of the geopolymer. Constr. Build. Mater. 2021, 297, 123787. [Google Scholar]

- Yuanita, E.; Husnil, Y.; Mochtar, M.; Lailani, R.; Chalid, M. The Effect of Alkalization Treatment on Fiber-Matrix Compatibility in Natural Fiber Reinforced Composite. Key Eng. Mater. 2020, 5983, 28–33. [Google Scholar] [CrossRef]

- Hachmi, M.; Guelzim, M.; Hakam, A.; Sesbou, A. Wood-cement inhibition revisited and development of new wood-cement inhibitory and compatibility indices based on twelve wood species. Holzforschung 2017, 71, 991–998. [Google Scholar] [CrossRef]

- Tan, J.; Lu, W.; Huang, Y.; Wei, S.; Xuan, X.; Liu, L. Preliminary study on compatibility of metakaolin-based geopolymer paste with plant fibers. Constr. Build. Mater. 2019, 225, 772–775. [Google Scholar] [CrossRef]

- Wei, Y.; Zhou, Y.; Tomita, B. Hydration behavior of wood cement-based composite I: Evaluation of wood species effects on compatibility and strength with ordinary portland cement. J. Wood Sci. 2000, 46, 296–302. [Google Scholar] [CrossRef]

- Bui, H.; Levacher, D.; Boutouil, M.; Sebaibi, N. Effects of Wetting and Drying Cycles on Microstructure Change and Mechanical Properties of Coconut Fibre-Reinforced Mortar. J. Compos. Sci. 2022, 6, 102. [Google Scholar] [CrossRef]

- Ayesh, M.; Horrocks, A.R.; Kandola, B.K. The Effect of Combined Atmospheric Plasma/UV Treatments on Improving the Durability of Flame Retardants Applied to Cotton. Molecules 2022, 27, 8737. [Google Scholar] [CrossRef]

- Baghban, M.H.; Mahjoub, R. Natural Kenaf Fiber and LC3 Binder for Sustainable Fiber-Reinforced Cementitious Composite: A Review. Appl. Sci. 2020, 10, 357. [Google Scholar] [CrossRef]

- Wei, J.; Ma, S.; Thomas, D.G. Correlation between hydration of cement and durability of natural fiber-reinforced cement composites. Corros. Sci. 2016, 106, 1–15. [Google Scholar] [CrossRef]

- Wei, J.; Meyer, C. Utilization of rice husk ash in green natural fiber-reinforced cement composites: Mitigating degradation of sisal fiber. Cem. Concr. Res. 2016, 81, 94–111. [Google Scholar] [CrossRef]

- Correia, V.; Ardanuy, M.; Claramunt, J.; Junior, H. Assessment of chemical and mechanical behavior of bamboo pulp and nanofibrillated cellulose exposed to alkaline environments. Cellulose 2019, 26, 9269–9285. [Google Scholar] [CrossRef]

- Wei, J. Degradation behavior and kinetics of sisal fiber in pore solutions of sustainable cementitious composite containing metakaolin. Polym. Degrad. Stabil. 2018, 150, 1–12. [Google Scholar] [CrossRef]

- Ye, H.; Zhang, Y.; Yu, Z. Effects of cellulose, hemicellulose, and lignin on the morphology and mechanical properties of metakaolin-based geopolymer. Constr. Build. Mater. 2018, 173, 10–16. [Google Scholar] [CrossRef]

- Ali, B.; Azab, M.; Ahmed, H.; Kurda, R.; El Ouni, M.; Elhag, A. Investigation of physical, strength, and ductility characteristics of concrete reinforced with banana (Musaceae) stem fiber. J. Build. Eng. 2022, 61, 105024. [Google Scholar] [CrossRef]

- Soroushian, P.; Won, J.; Hassan, M. Durability characteristics of CO2-cured cellulose fiber reinforced cement composites. Constr. Build. Mater. 2012, 34, 44–53. [Google Scholar] [CrossRef]

- Wei, J.; Meyer, C. Sisal fiber-reinforced cement composite with Portland cement substitution by a combination of metakaolin and nanoclay. J. Mater. Sci. 2014, 49, 7604–7619. [Google Scholar] [CrossRef]

- Saulo, R.; Neven, U.; Keoma, D.; Silva, L. Effect of microcrystalline cellulose on geopolymer and Portland cement pastes mechanical performance. Constr. Build. Mater. 2021, 288, 123053. [Google Scholar]

- Holt, G.; Chow, P.; Wanjura, J.; Pelletier, M.; Wedegaertner, T. Evaluation of thermal treatments to improve physical and mechanical properties of bio-composites made from cotton byproducts and other agricultural fibers. Ind. Crop. Prod. 2014, 52, 627–632. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Jayaraman, K. Effect of UV and water spraying on the mechanical properties of flax fabric reinforced polymer composites used for civil engineering applications. Mater. Des. 2015, 71, 17–25. [Google Scholar] [CrossRef]

- John, V.; Cincotto, M.; Sjöström, C.; Agopyan, V.; Oliveira, C. Durability of slag mortar reinforced with coconut fibre. Cem. Concr. Compos. 2004, 27, 565–574. [Google Scholar] [CrossRef]

- Wei, J.; Meyer, C. Degradation of natural fiber in ternary blended cement composites containing metakaolin and montmorillonite. Corros. Sci. 2017, 120, 42–60. [Google Scholar] [CrossRef]

- Azevedo, A.; Klyuev, S.; Marvila, M.; Vatin, N.; Alfimova, N.; Lima, T.; Fediuk, R.; Olisov, A. Investigation of the Potential Use of Curauá Fiber for Reinforcing Mortars. Fibers 2020, 8, 69. [Google Scholar] [CrossRef]

- Mohr, B.; Biernacki, J.; Kurtis, K. Supplementary cementitious materials for mitigating degradation of kraft pulp fiber-cement composites. Cem. Concr. Res. 2007, 37, 1531–1543. [Google Scholar] [CrossRef]

- Wei, J.; Gencturk, B. Degradation of Natural Fiber in Cement Composites Containing Diatomaceous Earth. J. Mater. Civ. Eng. 2018, 30, 04018282. [Google Scholar] [CrossRef]

- Trindade, A.; Silva, F.; Alcamand, H.; Borges, P. On the durability behavior of natural fiber reinforced geopolymer. In Proceedings of the 41st International Conference on Advanced Ceramics and Composites: Ceramic Engineering and Science Proceedings, Daytona Beach, FL, USA, 22–27 January 2017; The American Ceramic Society: Columbus, OH, USA, 2017; Volume 38. [Google Scholar]

- Rachel, N.; Rodrigue, C.; Adeyemi, A.; Juvenal, G.; Séverin, B.; Jean, N. Performance of laterite-based geopolymers reinforced with sugarcane bagasse fibers. Case Stud. Constr. Mater. 2021, 15, e00762. [Google Scholar]

- Alomayri, T.; Shaikh, F.; Low, I. Thermal and mechanical properties of cotton fabric-reinforced geopolymer composites. J. Mater. Sci. 2013, 48, 6746–6752. [Google Scholar] [CrossRef]

- Alomayri, T.; Vickers, L.; Shaikh, F.; Low, I. Mechanical properties of cotton fabric reinforced geopolymer composites at 200–1000 °C. J. Adv. Ceram. 2014, 3, 184–193. [Google Scholar] [CrossRef]

- Alzeer, M.; MacKenzie, K. Synthesis and mechanical properties of novel composites of inorganic polymers (geopolymers) with unidirectional natural flax fibres (phormium tenax). Appl. Clay. Sci. 2013, 75–76, 148–152. [Google Scholar] [CrossRef]

- Matuana, L.; Jin, S.; Stark, N. Ultraviolet weathering of HDPE/wood-flour composites coextruded with a clear HDPE cap layer. Polym. Degrad. Stabil. 2011, 96, 97–106. [Google Scholar] [CrossRef]

- Manfredi, L.; Rodríguez, E.; Wladyka-Przybylak, M.; Vázquez, A. Thermal degradation and fire resistance of unsaturated polyester, modified acrylic resins and their composites with natural fibres. Polym. Degrad. Stabil. 2006, 91, 255–261. [Google Scholar] [CrossRef]

- Sanvezzo, P.B.; Negreiros, F.P.D.C.; Branciforti, M.C. Degradation of Polypropylene and Jute Fiber-Reinforced Composites Exposed to Natural and Accelerated Aging: Mechanical Properties and Wettability. Chemistry 2021, 3, 1392–1400. [Google Scholar] [CrossRef]

- Olayiwola, H.; Amiandamhen, S.; Meincken, M. Investigating the suitability of fly ash/metakaolin-based geopolymers reinforced with South African alien invasive wood and sugarcane bagasse residues for use in outdoor conditions. Eur. J. Wood Prod. 2021, 79, 611–627. [Google Scholar] [CrossRef]

- Tonoli, G.; Santos, S.; Joaquim, P.; Savastano, H. Effect of accelerated carbonation on cementitious roofing tiles reinforced with lignocellulosic fibre. Constr. Build. Mater. 2010, 24, 193–201. [Google Scholar] [CrossRef]

- Almeida, E.; Tonoli, G.; Santos, S.; Savastano, H. Improved durability of vegetable fiber reinforced cement composite subject to accelerated carbonation at early age. Cem. Concr. Compos. 2013, 42, 49–58. [Google Scholar] [CrossRef]

- Gutiérrez, R.; Díaz, L.; Delvasto, S. Effect of pozzolans on the performance of fiber-reinforced mortars. Cem. Concr. Compos. 2004, 27, 593–598. [Google Scholar] [CrossRef]

- Aly, M.; Hashmi, M.; Olabi, A.; Messeiry, M.; Abadir, E. Effect of nano-clay and waste glass powder on the properties of flax fibre reinforced morta. J. Eng. Appl. Sci. 2011, 6, 19–28. [Google Scholar]

- Hakamy, A.; Shaikh, F.U.A.; Low, I.M. Effect of calcined nanoclay on microstructural and mechanical properties of chemically treated hemp fabric-reinforced cement nanocomposites. Constr. Build. Mater. 2015, 95, 882–891. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Yatim, J.; Sam, A.; Awal, A. Durability performance of green concrete composites containing waste carpet fibers and palm oil fuel ash. J. Clean. Prod. 2017, 144, 448–458. [Google Scholar] [CrossRef]

- Elsaid, A.; Dawood, M.; Seracino, R.; Bobko, C. Mechanical properties of kenaf fiber reinforced concrete. Constr. Build. Mater. 2011, 25, 1991–2001. [Google Scholar] [CrossRef]

- Omoniyi, T.; Akinyemi, B. Durability based suitability of bagasse cement composite for roofing sheets. J. Civ. Eng. Const. Tech. 2012, 3, 280–290. [Google Scholar]

- Ramakrishna, G.; Sundararajan, T.; Kothandaraman, S. Evaluation of durability of natural fibre reinforced cement mortar composite-a new approach. ARPN J. Eng. Appl. Sci. 2010, 5, 44–51. [Google Scholar]

- Javadi, A.; Srithep, Y.; Pilla, S.; Lee, J.; Gong, S.; Turng, L.S. Processing and characterization of solid and microcellular PHBV/coir fiber composites. Mater. Sci. Eng. C 2010, 30, 749–757. [Google Scholar] [CrossRef]

- Bilba, K.; Arsene, M.-A. Silane treatment of bagasse fiber for reinforcement of cementitious composites. Compos. Part Appl. Sci. Manuf. 2008, 39, 1488–1495. [Google Scholar] [CrossRef]

- Claramunt, J.; Ardanuy, M.; García-Hortal, J.A.; Filho, R.D.T. The hornification of vegetable fibers to improve the durability of cement mortar composites. Cem. Concr. Compos. 2011, 33, 586–595. [Google Scholar] [CrossRef]

- Pehanich, J.L.; Blankenhorn, P.R.; Silsbee, M.R. Wood fiber surface treatment level effects on selected mechanical properties of wood fiber–cement composites. Cem. Concr. Res. 2004, 34, 59–65. [Google Scholar] [CrossRef]

- Mohammadkazemi, F.; Doosthoseini, K.; Ganjian, E.; Azin, M. Manufacturing of bacterial nano-cellulose reinforced fiber-cement composites. Constr. Build. Mater. 2015, 101, 958–964. [Google Scholar] [CrossRef]

- Kalia, S.; Kaith, B.; Kaur, I. Pretreatments of natural fibers and their application as reinforcing material in polymer composites-A review. Polym. Eng. Sci. 2009, 49, 1253–1272. [Google Scholar] [CrossRef]

- Malenab, R.; Ngo, J.; Promentilla, M. Chemical Treatment of Waste Abaca for Natural Fiber-Reinforced Geopolymer Composite. Materials 2017, 10, 579. [Google Scholar] [CrossRef]

- John, M.; Anandjiwala, R. Recent developments in chemical modification and characterization of natural fiber-reinforced composites. Polym. Compos. 2008, 29, 187–207. [Google Scholar] [CrossRef]

- Shahzad, A. Effects of alkalization on tensile, impact, and fatigue properties of hemp fiber composites. Polym. Compos. 2012, 33, 1129–1140. [Google Scholar] [CrossRef]

- Tonoli, G.; Belgacem, M.; Siqueira, G.; Bras, J.; Savastano, H., Jr.; Rocco Lahr, F.A. Processing and dimensional changes of cement based composites reinforced with surface-treated cellulose fibres. Cem. Concr. Compos. 2013, 37, 68–75. [Google Scholar] [CrossRef]

- Ardanuy, M.; Clarmunt, J.; Filho, R. Evaluation of durability to wet/dry cycling of cement mortar composites reinforced with nanofibrillated cellulose. In Brittle Matrix Composites 10; Woodhead Publishing: Sawston, UK, 2012; Volume 10, pp. 33–41. [Google Scholar]

- Cruz, E.; Radler, M.; Perello, M.; Savastano, J. Fiber cement boards modified with styrene-acrylic copolymer: An approach to address dimensional stability and cellulose fiber preservation. J. Compos. Mater. 2021, 55, 437–452. [Google Scholar] [CrossRef]

- Maichin, P.; Suwan, T.; Jitsangiam, P. Effect of self-treatment process on properties of natural fiber-reinforced geopolymer composites. Mater. Manuf. Process. 2020, 35, 1120–1128. [Google Scholar] [CrossRef]

- Maichin, P.; Suwan, T.; Jitsangiam, P. Hemp fiber reinforced geopolymer composites: Effects of NaOH concentration on fiber pre-treatment process. Key Eng. Mater. 2020, 841, 166–170. [Google Scholar] [CrossRef]

- Roy, A.; Chakraborty, S.; Kundu, S.; Basak, R.; Majumder, S.; Adhikari, B. Improvement in mechanical properties of jute fibres through mild alkali treatment as demonstrated by utilisation of the Weibull distribution model. Bioresour. Technol. 2012, 107, 222–228. [Google Scholar] [CrossRef]

- Asante, B.; Schmidt, G.; Teixeira, R.; Krause, A.; Junior, H.S. Influence of wood pretreatment and fly ash particle size on the performance of geopolymer wood composite. Eur. J. Wood Wood Prod. 2021, 79, 597–609. [Google Scholar] [CrossRef]

- Sumesh, M.; Alengaram, U.J.; Jumaat, M.Z.; Mo, K.H.; Alnahhal, M.F. Incorporation of nano-materials in cement composite and geopolymer based paste and mortar-A review. Constr. Build. Mater. 2017, 148, 62–84. [Google Scholar] [CrossRef]

- Lv, C.; Shen, H.; Liu, J.; Wu, D.; Qu, E.; Liu, S. Properties of 3D Printing Fiber-Reinforced Geopolymers Based on Interlayer Bonding and Anisotropy. Materials 2022, 15, 8032. [Google Scholar] [CrossRef]

- Assaedi, H.; Alomayri, T.; Shaikh, F.; Low, I.-M. Influence of nano silica particles on durability of flax fabric reinforced geopolymer composites. Materials 2019, 12, 1459. [Google Scholar] [CrossRef]

- Rahman, A.S.; Shah, C.; Gupta, N. Simultaneous effects of rice husk silica and silicon carbide whiskers on the mechanical properties and morphology of sodium geopolymer. J. Compos. Mater. 2020, 54, 4611–4620. [Google Scholar] [CrossRef]

- Assaedi, H.; Shaikh, F.; Low, I. Characterizations of flax fabric reinforced nanoclay-geopolymer composites. Compos. Part B Eng. 2016, 95, 412–422. [Google Scholar] [CrossRef]

- Lv, C.; Liu, J.; Guo, G.; Zhang, Y. The Mechanical Properties of Plant Fiber-Reinforced Geopolymers: A Review. Polymers 2022, 14, 41341. [Google Scholar] [CrossRef] [PubMed]

- Mazen, A.; Abu, M.; Juma, A.; Yasair, A.; Tarek, F.; Abderrazek, K.; Fernando, R. Fabrication, microstructural and mechanical characterization of Luffa Cylindrical Fibre-Reinforced geopolymer composite. Appl. Clay Sci. 2017, 143, 125–133. [Google Scholar]

- Mourak, A.; Hajjaji, M.; Alagui, A. Cured alkali-activated heated clay-cellulose composites: Microstructure, effect of glass addition and performances. Boletín Soc. Española Cerámica Vidr. 2021, 20, 62–72. [Google Scholar] [CrossRef]

- Chen, R.; Ahmari, S.; Zhang, L. Utilization of sweet sorghum fiber to reinforce fly ash-based geopolymer. J. Mater. Sci. 2014, 49, 2548–2558. [Google Scholar] [CrossRef]

- Ali, A.; Mucteba, U.; Arın, Y.; Al-mashhadani Mukhallad, M.; Orhan, C.; Furkan, S.; Yurdakul, A. Influence of wetting-drying curing system on the performance of fiber reinforced metakaolin-based geopolymer composites. Constr. Build. Mater. 2019, 225, 909–926. [Google Scholar]

| PFs | PF Content | Binder | Cure Condition | Evaluation Method | Number of Cycles | Evaluation Time | Degradation Mechanism | Ref. |

|---|---|---|---|---|---|---|---|---|

| Sisal | 2% volume fraction | PC-10% MK; 30% MK | Immersed in CH-saturated water at 23 ± 2 °C | Flexural; Separation approach | 5; 15; 30 | 7 days; 28 days | Degradation and mineralization | [57] |

| Sisal | 6% volume fraction | PC-50% MK | 100% RH, 23 ± 1°C | Flexural; Fracture behavior | 5; 10; 15; 20; 25 | 28 days; 180 days; 1 year; 5 years | Degradation and mineralization | [31] |

| Kraft pulp | 4% volume fraction | Binary composite; Wollastonite ternary blend | Immersed in limewater | Flexural strength; Post-cracking toughness | 25 | 28 days | Degradation | [84] |

| Sisal | 1% volume fraction | PC-5% DE; 10% DE; 15% DE; 20% DE | Immersed in saturated lime water at 23. 2 °C | Tensile Strength; TGA analysis | 5; 10; 15; 20 | 28 days | Degradation and mineralization | [85] |

| Jute | 10% of volume fraction | SF-, MK-, and BFS-based geopolymer | At room temperature 25 ± 2°C | Tensile and flexural tests | 15 | 7 and 28 days | No obvious degradation | [86] |

| Sugarcane bagasse | 1.5%, 3%, 4.5%, 6%, and 7.5% mass fraction | Laterite-based geopolymer | At room temperature | Mass loss; Compressive strength loss | 5; 10; 20 | 28 days | Degradation | [87] |

| Sisal | 2% mass fraction | Sludge-based geopolymer | At room temperature 27 °C and 80% RH | Flexural strength | 10 | 6 months or 3 years | No degradation | [45] |

| PF Types | Treatment Methods | Modification Types | Measurements | Authors |

|---|---|---|---|---|

| Palm; Shaving grass; Jute | Hot water; Keratinization; 8% NaOH solution; Hybridization | Physical; Chemical | No further degradation; Crystallinity index; Tensile strength | Fonseca et al. [27] |

| Eucalyptus | Silane | Chemical | Water retention; Dimensional stability | Tonoli et al. [113] |

| Canna hemp; Agave; Sisal | 5% styrene-acrylic copolymer | Chemical | Water absorption; Stiffness; Dimensional stability | Ardanuy et al. [114] |

| Ramie | NaOH solution | Chemical | Lignin removal | Kumar et al. [43] |

| Hemp | NaOH of different concentrations | Chemical | Compatibility; Cohesiveness | Maichin et al. [117] |

| Abaca | Al2 (SO4)3 solution at pH 6 | Chemical | Tensile strength; Rougher surface | Roy [118] |

| Pine; eucalyptus | Hot water | Physical | Specific strength; Compatibility | Asante et al. [119] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, C.; Liu, J. Alkaline Degradation of Plant Fiber Reinforcements in Geopolymer: A Review. Molecules 2023, 28, 1868. https://doi.org/10.3390/molecules28041868

Lv C, Liu J. Alkaline Degradation of Plant Fiber Reinforcements in Geopolymer: A Review. Molecules. 2023; 28(4):1868. https://doi.org/10.3390/molecules28041868

Chicago/Turabian StyleLv, Chun, and Jie Liu. 2023. "Alkaline Degradation of Plant Fiber Reinforcements in Geopolymer: A Review" Molecules 28, no. 4: 1868. https://doi.org/10.3390/molecules28041868

APA StyleLv, C., & Liu, J. (2023). Alkaline Degradation of Plant Fiber Reinforcements in Geopolymer: A Review. Molecules, 28(4), 1868. https://doi.org/10.3390/molecules28041868