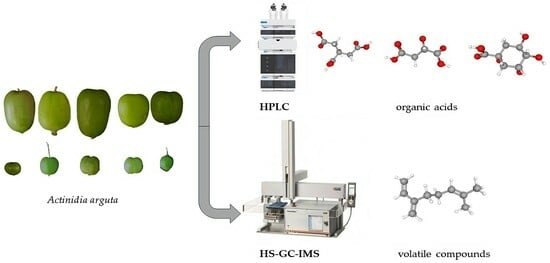

Flavor Quality Analysis of Ten Actinidia arguta Fruits Based on High-Performance Liquid Chromatography and Headspace Gas Chromatography–Ion Mobility Spectrometry

Abstract

:1. Introduction

2. Results and Discussion

2.1. Analysis of Sugar–Acid Content of A. arguta Fruits of Different Varieties

2.2. Analysis of Organic Acids in A. arguta Fruit of Different Varieties

2.3. Analysis of Volatile Flavor Substances in Different Varieties of A. arguta Fruits

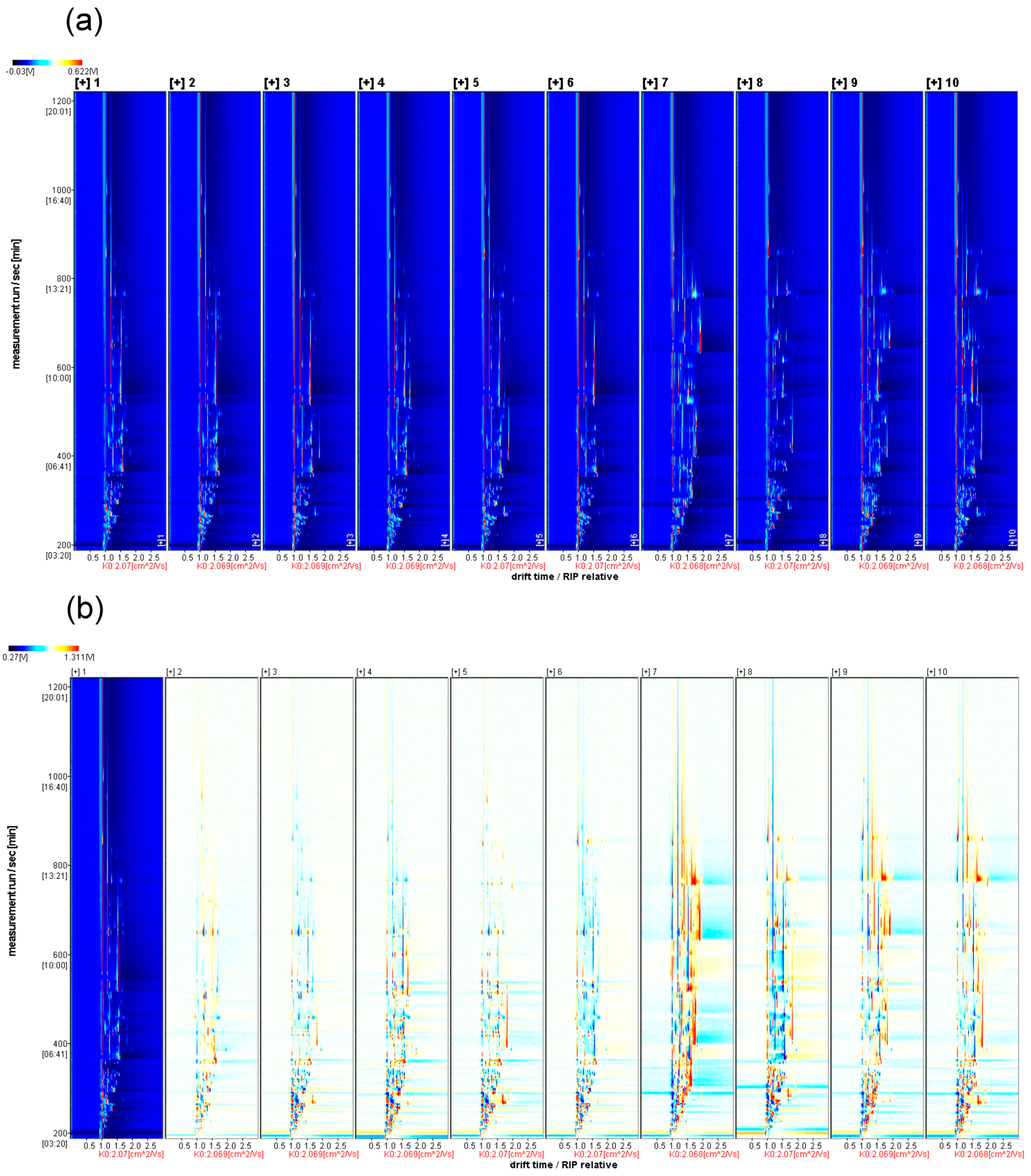

2.3.1. Two-Dimensional Top-View Spectrogram Analysis

2.3.2. Difference Spectrum Analysis

2.3.3. Qualitative Analysis of Volatile Compounds in Different Varieties of A. arguta Fruits

2.3.4. Gallery Plot Fingerprint Analysis of Volatiles in A. arguta Fruits

2.4. Content Analysis of Volatile Compounds in A. arguta Fruits

2.4.1. Esters

2.4.2. Aldehydes

2.4.3. Alcohols

2.4.4. Ketones

2.4.5. Others

2.5. PCA Analysis of A. arguta Fruit Aroma Substances

2.6. OAV Analysis of Aroma Components of Different Varieties of A. arguta Fruit

2.6.1. Heat Map Analysis of Volatile Compounds with OAVs > 1

2.6.2. Correlation Analysis of Volatile Compounds with OAVs > 1

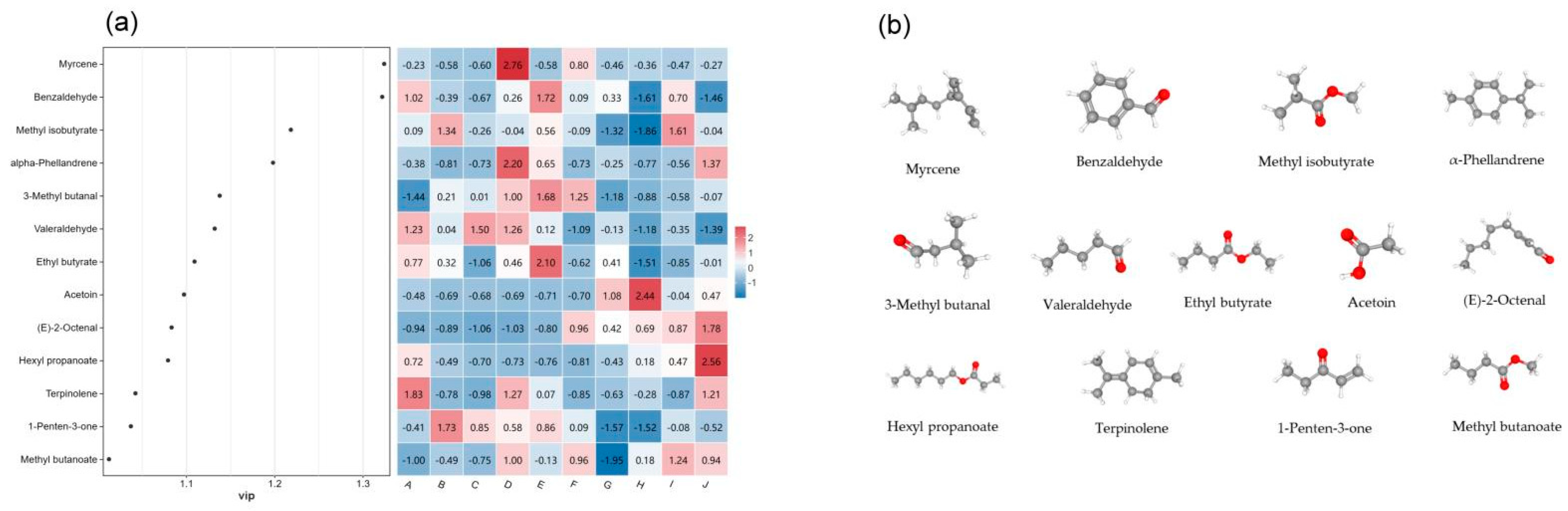

2.6.3. OPLS-DA Analysis of Volatile Compounds with OAVs > 1

3. Materials and Methods

3.1. Materials and Reagents

3.1.1. Plant Materials

3.1.2. Overview of the Sampling Sit

3.1.3. Reagents and Instruments

3.2. Experimental Methods

3.2.1. Determination of Sugar and Acid Content

3.2.2. Detection of Organic Acids Content

3.2.3. Detection of Volatile Compounds

3.2.4. Odor Activity Value (OAV) Calculation

3.3. Data Processing and Statistical Analyses

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lai, J.J.; Li, Z.Z.; Man, Y.P.; Lei, R.; Wang, Y.C. Genetic diversity of five wild Actinidia arguta populations native to China as revealed by SSR markers. Sci. Hortic. 2015, 191, 101–107. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, H.X.; Lou, X.; Zhao, L.N.; Yan, D.L. Characterization of world Actinidia arguta variety resources and breeding trends. Chin. J. Ecol. 2017, 36, 3289–3297. [Google Scholar] [CrossRef]

- Baranowska-Wojcik, E.; Szwajgier, D. Characteristics and pro-health properties of mini kiwi (Actinidia arguta). Hortic. Environ. Biotechnol. 2019, 60, 217–225. [Google Scholar] [CrossRef]

- Wen, J.L.; Cao, W.Y.; Wang, Y.; He, Y.L.; Sun, Y.N.; Yuan, P.Q.; Sun, B.W. Comprehensive evaluation of fruit quality of Actinidia arguta based on principal component analysis and cluster analysis. Sci. Technol. Food Ind. 2023, 1–16. [Google Scholar] [CrossRef]

- Hale, I.L.; Connolly, B.A. Actinidia arguta: A new record of a naturalized introduction in connecticut. Rhodora 2014, 116, 352–355. [Google Scholar] [CrossRef]

- Wojdylo, A.; Nowicka, P.; Oszmianski, J.; Golis, T. Phytochemical compounds and biological effects of Actinidia fruits. J. Funct. Foods 2017, 30, 194–202. [Google Scholar] [CrossRef]

- Pinto, D.; Delerue-Matos, C.; Rodrigues, F. Bioactivity, phytochemical profile and pro-healthy properties of Actinidia arguta: A review. Food Res. Int. 2020, 136, 109449. [Google Scholar] [CrossRef]

- Zhao, N.; Chai, J.H.; He, T.T.; Wan, C.L.; Jing, Y.R.; Zhang, L. Research progress on chemical constituents and biological activities of Actinidia arguta. Food Res. Dev. 2020, 41, 211–215. [Google Scholar]

- Liu, Q.; Jia, D.F.; Huang, C.H.; Zhong, M.; Miao, G.L.; Xu, X.B. Research progress on germplasm resources of Actinidia arguta. No. Hort. 2020, 22, 132–137. [Google Scholar] [CrossRef]

- Latocha, P.; Krupa, T.; Wolosiak, R.; Worobiej, E.; Wilczak, J. Antioxidant activity and chemical difference in fruit of different Actinidia sp. Int. J. Food Sci. Nutr. 2010, 61, 381–394. [Google Scholar] [CrossRef]

- Huang, G.H. Main varieties and cultivation techniques of Actinidia arguta. No. Fruits 2020, 4, 44–47. [Google Scholar] [CrossRef]

- Ozden, E.M.; Bingol, Z.; Mutlu, M.; Karagecili, H.; Koksal, E.; Goren, A.C.; Alwasel, S.H.; Gulcin, I. Antioxidant, Antiglaucoma, Anticholinergic, and Antidiabetic Effects of Kiwifruit (Actinidia deliciosa) Oil: Metabolite Profile Analysis Using LC-HR/MS, GC/MS and GC-FID. Life 2023, 13, 1939. [Google Scholar] [CrossRef] [PubMed]

- Cao, W.; Shu, N.; Yang, Y.; Wen, J.; Lu, W. Comprehensive evaluation of nine grape varieties based on fundamental physical and chemical indicators, color and volatile compounds. J. Berry Res. 2023, 13, 121–144. [Google Scholar] [CrossRef]

- Tian, Z.; Zhang, M.; Wang, Y.; Liu, Y.P.; Yue, T.L.; Huo, Y.J. Characterization of aroma fingerprint of kiwifruit juice of different varieties based on headspace gas chromatography-ion mobility spectrometry. Food Ferment. Ind. 2023, 49, 279–287. [Google Scholar] [CrossRef]

- Ye, L.; Yang, C.; Li, W.; Hao, J.; Sun, M.; Zhang, J.; Zhang, Z. Evaluation of volatile compounds from Chinese dwarf cherry (Cerasus humilis (Bge.) Sok.) germplasms by headspace solid-phase microextraction and gas chromatography-mass spectrometry. Food Chem. 2017, 217, 389–397. [Google Scholar] [CrossRef]

- Batista-Silva, W.; Nascimento, V.L.; Medeiros, D.B.; Nunes-Nesi, A.; Ribeiro, D.M.; Zsogon, A.; Araujo, W.L. Modifications in Organic Acid Profiles During Fruit Development and Ripening: Correlation or Causation? Front. Plant Sci. 2018, 9, 1689. [Google Scholar] [CrossRef] [PubMed]

- Latocha, P. The Nutritional and Health Benefits of Kiwiberry (Actinidia arguta)—A Review. Plant Foods Hum. Nutr. 2017, 72, 325–334. [Google Scholar] [CrossRef]

- Weerawatanakorn, M.; Wu, J.-C.; Pan, M.-H.; Ho, C.-T. Reactivity and stability of selected flavor compounds. J. Food Drug Anal. 2015, 23, 176–190. [Google Scholar] [CrossRef]

- Garcia, C.V.; Quek, S.-Y.; Stevenson, R.J.; Winz, R.A. Kiwifruit flavour: A review. Trends Food Sci. Technol. 2012, 24, 82–91. [Google Scholar] [CrossRef]

- Garcia, C.V.; Quek, S.Y.; Stevenson, R.J.; Winz, R.A. Characterization of the Bound Volatile Extract from Baby Kiwi (Actinidia arguta). J. Agric. Food Chem. 2011, 59, 8358–8365. [Google Scholar] [CrossRef]

- Matich, A.J.; Young, H.; Allen, J.M.; Wang, M.Y.; Fielder, S.; McNeilage, M.A.; MacRae, E.A. Actinidia arguta: Volatile compounds in fruit and flowers. Phytochemistry 2003, 63, 285–301. [Google Scholar] [CrossRef]

- Xin, G.; Zhang, B.; Feng, F.; Li, T.C.; Liu, C.J.; Xu, J.G. Analysis of aromatic constituents of Actinidia arguta Sieb.et Zucc Fruit. Food Sci. 2009, 30, 230–232. [Google Scholar]

- Yang, M.F.; Zhao, Q.Y.; Liu, G.P. Analysis of constituents of essential oil by GC-MS from Actinidia arguta. Bull. Bot. Res. 2006, 26, 128–130. [Google Scholar]

- Al-Othman, Z.A.; Al-Warthan, A.; Ali, I. Advances in enantiomeric resolution on monolithic chiral stationary phases in liquid chromatography and electrochromatography. J. Sep. Sci. 2014, 37, 1033–1057. [Google Scholar] [CrossRef] [PubMed]

- Yu, K.L. Research progress on detection methods of organic acids in fruit. China Food Saf. Mag. 2023, 11, 190–192. [Google Scholar] [CrossRef]

- Bottcher, S.; von Baum, H.; Hoppe-Tichy, T.; Benz, C.; Sonntag, H.G. An HPLC assay and a microbiological assay to determine levofloxacin in soft tissue, bone, bile and serum. J. Pharmaceut. Biomed. Anal. 2001, 25, 197–203. [Google Scholar] [CrossRef] [PubMed]

- Pang, M.; Cai, S.L.; Liu, Q. Research progress on the analysis methods of organic acids in wine. J. Food Saf. Qual. 2019, 10, 1588–1593. [Google Scholar]

- Cao, W.; Shu, N.; Wen, J.; Yang, Y.; Jin, Y.; Lu, W. Characterization of the Key Aroma Volatile Compounds in Nine Different Grape Varieties Wine by Headspace Gas Chromatography-Ion Mobility Spectrometry (HS-GC-IMS), Odor Activity Values (OAV) and Sensory Analysis. Foods 2022, 11, 2767. [Google Scholar] [CrossRef]

- Han, J.; Fu, C.; Wan, Y.; Guo, J.; Wei, C.; Liu, W. Characterizing the Volatile Profile and Flavor of Four Kinds of Hotpot Seasonings in China Using HS-GC-MS, HS-GC-IMS, and Sensory Evaluation. Eur. J. Lipid Sci. Technol. 2023, 125, 2200197. [Google Scholar] [CrossRef]

- Zhou, Y.; Fu, H.F.; Hu, Y.F. Evolution analysis of enzymatically released volatiles from kiwifruit juices using electronic nose and gas chromatography-mass spectrometry analysis. J. Northwest AF Univ. 2021, 49, 101–109. [Google Scholar] [CrossRef]

- Fu, X.; Zhang, H.B.; Nie, Q.Y.; Feng, T.T.; Liu, D.; Zhang, Y.; Li, X. Different varieties of kiwifruit: Analysis of differences in quality indexes and volatile components in Juice by gas chromatography-ion mobility spectrometry. Food Sci. 2022, 43, 247–254. [Google Scholar]

- Jiang, H.; Duan, W.; Zhao, Y.; Liu, X.; Wen, G.; Zeng, F.; Liu, G. Development of a Flavor Fingerprint Using HS-GC-IMS for Volatile Compounds from Steamed Potatoes of Different Varieties. Foods 2023, 12, 2252. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, X.; Wang, J.; Xing, W.; Liu, Y.; Wan, Y.; Li, N.; Wang, J.; Liu, G.; Wang, R.; et al. Characterization of the volatile compounds in white radishes under different organic fertilizer treatments by HS-GC-IMS with PCA. Flavour Frag. J. 2023, 38, 83–94. [Google Scholar] [CrossRef]

- An, J.; Liu, M.; Jia, J.L.; Lian, Z.; Piao, Y.L. Changes of sugar and acid components and contents during fruit development of Actinidia arguta. J. Northeast Agric. Sci. 2020, 45, 88–91. [Google Scholar] [CrossRef]

- He, Y.; Qin, H.; Wen, J.; Cao, W.; Yan, Y.; Sun, Y.; Yuan, P.; Sun, B.; Fan, S.; Lu, W.; et al. Characterization of Key Compounds of Organic Acids and Aroma Volatiles in Fruits of Different Actinidia argute Resources Based on High-Performance Liquid Chromatography (HPLC) and Headspace Gas Chromatography-Ion Mobility Spectrometry (HS-GC-IMS). Foods 2023, 12, 3615. [Google Scholar] [CrossRef] [PubMed]

- Lindhorst, A.C.; Steinhaus, M. Aroma-active compounds in the fruit of the hardy kiwi (Actinidia arguta) cultivars Ananasnaya, Bojnice, and Dumbarton Oaks: Differences to common kiwifruit (Actinidia deliciosa ‘Hayward’). Eur. Food Res. Technol. 2016, 242, 967–975. [Google Scholar] [CrossRef]

- Yang, E.; Zhao, Y.; Qian, M.C. Effect of Edible Coating on Volatile Compounds of Hardy Kiwifruit during Storage. In Proceedings of the 236th National Meeting of the American-Chemical-Society, Philadelphia, PA, USA, 18 March 2010. [Google Scholar]

- Sun, Y.; Ci, Z.J.; Liu, Z.P.; Lu, L.Y.; Liu, G.P.; Chen, X.Z.; Li, R.H.; You, W.Z. Analysis on fruit quality and aroma components of different Actinidia arguta cultivars. China Fruits 2021, 5, 52–55+60. [Google Scholar] [CrossRef]

- Wang, R.C.; Shu, P.; Zhang, C.; Zhang, J.L.; Chen, Y.; Zhang, Y.X.; Du, K.; Xie, Y.; Li, M.Z.; Ma, T.; et al. Integrative analyses of metabolome and genome-wide transcriptome reveal the regulatory network governing flavor formation in kiwifruit (Actinidia chinensis). New Phytol. 2022, 233, 373–389. [Google Scholar] [CrossRef]

- Wang, G.; Wang, T.; Pan, D.L.; Jia, Z.H.; Zhang, J.Y.; Guo, Z.R. The components and contents of organic acid in kiwifruit fruits from different cultivars. J. Agric. 2017, 7, 81–84. [Google Scholar]

- Hervalejo, A.; Arjona-Lopez, J.M.; Ordonez-Diaz, J.L.; Romero-Rodriguez, E.; Calero-Velazquez, R.; Moreno-Rojas, J.M.; Arenas-Arenas, F.J. Influence of Harvesting Season on Morphological and Sensory Quality, Bioactive Compounds and Antioxidant Activity of Three Late-Season Orange Cultivars ‘Barberina’, ‘Valencia Midknight’ and ‘Valencia Delta Seedless’. Agronomy 2021, 11, 673. [Google Scholar] [CrossRef]

- Wang, J.; Wan, Z.B.; Xu, C.L.; Zhang, K.; Wang, W.X.; Zhang, Z.Z. Comparative analysis of organic acids in wine grape fruits from Xinjiang. Mod. Food Sci. Technol. 2020, 36, 249–254+269. [Google Scholar] [CrossRef]

- Sha, S.F. Analysis and Genetic Identification of Organic Acid Components and Content Changes in Pears. Ph.D. Thesis, Nanjing Agricultural Unversity, Nanjing, China, 2012. (In Chinese). [Google Scholar]

- Boyes, S.; Strubi, P.; Marsh, H. Sugar and organic acid analysis of Actinidia arguta and rootstock-scion combinations of Actinidia arguta. LWT-Food Sci. Technol. 1997, 30, 390–397. [Google Scholar] [CrossRef]

- Ma, B.; Yuan, Y.; Gao, M.; Li, C.; Ogutu, C.; Li, M.; Ma, F. Determination of Predominant Organic Acid Components in Malus Species: Correlation with Apple Domestication. Metabolites 2018, 8, 74. [Google Scholar] [CrossRef]

- Wojdylo, A.; Nowicka, P. Anticholinergic effects of Actinidia arguta fruits and their polyphenol content determined by liquid chromatography-photodiode array detector-quadrupole/time of flight-mass spectrometry (LC-MS-PDA-Q/TOF). Food Chem. 2019, 271, 216–223. [Google Scholar] [CrossRef] [PubMed]

- Rovio, S.; Sirén, K.; Sirén, H. Application of capillary electrophoresis to determine metal cations, anions, organic acids, and carbohydrates in some Pinot Noir red wines. Food Chem. 2010, 124, 1194–1200. [Google Scholar] [CrossRef]

- Zhao, Y. Analysis of Characteristic Aroma Substances in Kiwifruit Juice and Study on the Effect of Sterilization on Aroma Composition. Master’s Thesis, Shaanxi Normal University, Xi’an, China, 2021. (In Chinese). [Google Scholar]

- Zhao, Y.; Zhan, P.; Wang, P.; Tian, H.L. Analysis of key aroma compounds in Kiwifruits. Food Sci. 2021, 42, 118–124. [Google Scholar]

- Bylesjo, M.; Rantalainen, M.; Cloarec, O.; Nicholson, J.K.; Holmes, E.; Trygg, J. OPLS discriminant analysis: Combining the strengths of PLS-DA and SIMCA classification. J. Chemometr. 2006, 20, 341–351. [Google Scholar] [CrossRef]

- Shu, N. Study on Fermentation Characteristics and Dry Red Wine Brewing Technology of New Grape New Vitis Amurensis Cultivar ‘Beiguohong’. Master’s Thesis, Chinese Academy of Agricultural Sciences, Beijing, China, 2019. (In Chinese). [Google Scholar]

- Jin, Y.; Shu, N.; Xie, S.; Cao, W.; Xiao, J.; Zhang, B.; Lu, W. Comparison of ‘Beibinghong’ dry red wines from six producing areas based on volatile compounds analysis, mineral content analysis, and sensory evaluation analysis. Eur. Food Res. Technol. 2021, 247, 1461–1475. [Google Scholar] [CrossRef]

| Research Methods | Major Compounds | Reference | |

|---|---|---|---|

| Organic acids | HPLC | Citric acid, quinic acid, ascorbic acid, and malic acid | [34] |

| HPLC | citric acid, quinic acid | [35] | |

| Volatile compounds | GC-O, GC-MS | Ethyl butanoate, Hexanoate, 2-Methylbutanoate, 2-Methylpropanoate, Hexanal and Hex-E2-enal | [7] |

| GC-MS | Ethyl butanoate, Furaneol, 1-Penten-3-one, Pentanal, Hexanal, (E)-2-Hexenal, 1-Octen-3-ol, Linalool, Terpinen-4-ol, and α-terpineol | [21] | |

| GC-MS | 1-Methyl-4-(1-methylethylidene)-cyclohexene, Butanoic acid ethyl ester, Ethanol, Hexanoic acid ethyl ester, Benzoic acid methyl ester, β-Myrcene,D-Limonene and β-Pinene | [22] | |

| GC-MS | Ethyl butyrate | [23] | |

| GC-IMS | Isoamyl acetate, 3-Methyl-1-butanol, 1-Hexanol, and Butanal | [35] | |

| GC-MS | Ethyl butanoate | [36] | |

| GC-MS | 2,5-Dimethyl-4-hydroxy-3(2 H)-furanone (Furaneol), Benzyl alcohol, 3-Hydroxy-beta-damascone, Hexanal, and (Z)-3-Hexen-1-ol | [37] | |

| GC-MS | E-2-Hexenal | [38] |

| Variety | Oxalic Acid g/L | Quinic Acid g/L | Malic Acid g/L | Shikimic Acid g/L | Lactic Acid g/L | Citric Acid g/L |

|---|---|---|---|---|---|---|

| ‘Kuilv’ | 0.09 ± 0.01 d | 7.01 ± 0.51 c | 2.48 ± 0.15 d | 0.06 ± 0.01 b | 0.37 ± 0.02 e | 11.34 ± 0.76 b |

| ‘Fenglv’ | 0.4 ± 0.05 a | 8.48 ± 0.33 a | 4.4 ± 0.23 a | 0.03 ± 0.01 ef | 0.77 ± 0.02 b | 11.58 ± 0.95 a |

| ‘Jialv’ | 0.05 ± 0.01 e | 4.43 ± 0.216 g | 3.42 ± 0.29 b | 0.03 ± 0.01 de | 0.36 ± 0.09 e | 3.65 ± 0.13 h |

| ‘Wanlv’ | 0.01 ± 0.01 f | 3.69 ± 0.11 i | 1.12 ± 0.15 j | 0.06 ± 0.01 bc | 0.46 ± 0.02 d | 6.04 ± 0.24 f |

| ‘Xinlv’ | 0.1 ± 0.01 d | 5.47 ± 0.15 d | 1.68 ± 0.16 g | 0.04 ± 0.01 cd | 0.5 ± 0.03 d | 5.74 ± 0.25 g |

| ‘Pinglv’ | 0.04 ± 0.01 e | 2.87 ± 0.21 j | 1.71 ± 0.08 f | 0.02 ± 0 f | 0.23 ± 0.06 f | 3.17 ± 0.16 j |

| ‘Lvbao’ | 0.23 ± 0.01 b | 5.12 ± 0.11 f | 1.31 ± 0.06 h | 0.1 ± 0.02 a | 0.56 ± 0.04 c | 6.79 ± 0.33 e |

| ‘Cuiyu’ | 0.17 ± 0.01 c | 5.28 ± 0.34 e | 2.41 ± 0.24 e | 0.02 ± 0.01 ef | - | 6.92 ± 0.36 d |

| ‘Tianxinbao’ | 0.09 ± 0.01 d | 3.77 ± 0.36 h | 3.11 ± 0.29 c | 0.03 ± 0.01 ef | 0.83 ± 0.12 a | 3.23 ± 0.13 i |

| ‘Longcheng No.2’ | 0.08 ± 0.01 d | 7.13 ± 0.44 b | 1.25 ± 0.11 i | 0.052 ± 0.01 bc | 0.47 ± 0.05 d | 9.62 ± 0.76 c |

| Compound | Threshold (μg/kg) | ‘Kuilv’ | ‘Fenglv’ | ‘Jialv’ | ‘Wanlv’ | ‘Xinlv’ | ‘Pinglv’ | ‘Lvbao’ | ‘Cuiyu’ | ‘Tianxinbao’ | ‘Longcheng No.2’ |

|---|---|---|---|---|---|---|---|---|---|---|---|

| (E)-2-Hexenal | 82 | 84.62 | 98.44 | 89.11 | 72.73 | 88.68 | 79.1 | 27.22 | 27.27 | 51.79 | 54.8 |

| (E)-2-Octenal | 4 | 8.71 | 9.35 | 7.14 | 7.64 | 10.57 | 32.91 | 26.05 | 29.45 | 31.85 | 43.44 |

| (Z)-4-Heptenal | 0.8 | 43.52 | 48.4 | 54.9 | 69.57 | 66.67 | 64.24 | 247.51 | 79.01 | 94.39 | 93.66 |

| 1-Hexanal | 350 | 5.87 | 6.95 | 6.98 | 6.68 | 7.07 | 4.73 | <1 | 1.3 | 4.11 | 3.49 |

| 1-Nonanal | 1.1 | 29.29 | 35.08 | 27.77 | 37.71 | 35.25 | 31.08 | 22.53 | 18.07 | 25.58 | 19.66 |

| Valeraldehyde | 20 | 15.95 | 11.86 | 16.86 | 16.04 | 12.14 | 8.02 | 11.28 | 7.71 | 10.53 | 6.98 |

| 3-Methyl butanal | 80 | <1 | 1.42 | 1.29 | 1.95 | 2.40 | 2.11 | <1 | <1 | <1 | 1.24 |

| Benzaldehyde | 3 | 4.82 | 3.66 | 3.43 | 4.20 | 5.40 | 4.06 | 4.25 | 2.66 | 4.56 | 2.78 |

| 1-Octen-3-ol | 1.5 | 32.85 | 57.09 | 30.91 | 51.64 | 69.29 | 51.72 | 28.03 | 23.95 | 36.51 | 30.66 |

| 1-Penten-3-one | 398 | <1 | 1.41 | 1.07 | <1 | 1.08 | <1 | <1 | <1 | <1 | <1 |

| Acetoin | 55 | 3.44 | 1.86 | 1.93 | 1.88 | 1.69 | 1.78 | 14.84 | 24.83 | 6.64 | 10.4 |

| α-Phellandrene | 40 | 1.50 | <1 | <1 | 6.54 | 3.52 | <1 | 1.76 | <1 | 1.16 | 4.92 |

| α-Pinene | 2.2 | 9.55 | 2.02 | 2.07 | 11.45 | 5.53 | 3.81 | 2.18 | 5.10 | 4.23 | 9.51 |

| Myrcene | 16.6 | 1.91 | 1.18 | 1.13 | 8.21 | 1.17 | 4.08 | 1.42 | 1.63 | 1.41 | 1.84 |

| Terpinolene | 41 | 6.14 | <1 | <1 | 5.01 | 2.59 | <1 | 1.17 | 1.87 | <1 | 4.89 |

| Ethyl butyrate | 20 | 7.37 | 6.38 | 3.36 | 6.68 | 10.25 | 4.32 | 6.57 | 2.38 | 3.83 | 5.66 |

| Butyl isovalerate | 78 | 2.74 | 2.92 | 2.4 | 2.72 | 2.58 | 2.26 | 34.51 | 8.39 | 21.18 | 7.9 |

| Butyl acetate | 66 | 2.45 | 6.52 | 4.8 | 2.52 | 5.71 | 7.11 | 14.75 | 6.07 | 4.35 | 3.66 |

| Hexyl acetate | 2 | 14.08 | 9.93 | 10.54 | 10.66 | 10.03 | 11.01 | 40.50 | 15.33 | 19.24 | 15.57 |

| Hexyl propanoate | 8 | 7.79 | 3.24 | 2.46 | 2.36 | 2.22 | 2.05 | 3.47 | 5.74 | 6.83 | 14.64 |

| Isopentyl acetate | 30 | 4.76 | 4.29 | 4.06 | 4.23 | 4.47 | 4.01 | 100.27 | 18.62 | 16.14 | 8.52 |

| Isobutyl acetate | 500 | <1 | <1 | <1 | <1 | <1 | <1 | 4.15 | <1 | <1 | <1 |

| Methyl isobutyrate | 7 | 19.32 | 25.68 | 17.55 | 18.62 | 21.68 | 18.39 | 12.14 | 9.38 | 27.06 | 18.66 |

| Methyl butanoate | 10 | 2.82 | 3.72 | 3.26 | 6.37 | 4.37 | 6.29 | 1.13 | 4.91 | 6.80 | 6.26 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wen, J.; Wang, Y.; He, Y.; Shu, N.; Cao, W.; Sun, Y.; Yuan, P.; Sun, B.; Yan, Y.; Qin, H.; et al. Flavor Quality Analysis of Ten Actinidia arguta Fruits Based on High-Performance Liquid Chromatography and Headspace Gas Chromatography–Ion Mobility Spectrometry. Molecules 2023, 28, 7559. https://doi.org/10.3390/molecules28227559

Wen J, Wang Y, He Y, Shu N, Cao W, Sun Y, Yuan P, Sun B, Yan Y, Qin H, et al. Flavor Quality Analysis of Ten Actinidia arguta Fruits Based on High-Performance Liquid Chromatography and Headspace Gas Chromatography–Ion Mobility Spectrometry. Molecules. 2023; 28(22):7559. https://doi.org/10.3390/molecules28227559

Chicago/Turabian StyleWen, Jinli, Yue Wang, Yanli He, Nan Shu, Weiyu Cao, Yining Sun, Pengqiang Yuan, Bowei Sun, Yiping Yan, Hongyan Qin, and et al. 2023. "Flavor Quality Analysis of Ten Actinidia arguta Fruits Based on High-Performance Liquid Chromatography and Headspace Gas Chromatography–Ion Mobility Spectrometry" Molecules 28, no. 22: 7559. https://doi.org/10.3390/molecules28227559

APA StyleWen, J., Wang, Y., He, Y., Shu, N., Cao, W., Sun, Y., Yuan, P., Sun, B., Yan, Y., Qin, H., Fan, S., & Lu, W. (2023). Flavor Quality Analysis of Ten Actinidia arguta Fruits Based on High-Performance Liquid Chromatography and Headspace Gas Chromatography–Ion Mobility Spectrometry. Molecules, 28(22), 7559. https://doi.org/10.3390/molecules28227559