Dyeing Performance and Anti-Superbacterial Activity of Cotton Fabrics Dyed with Chamaecyparis obtusa

Abstract

:1. Introduction

2. Results and Discussion

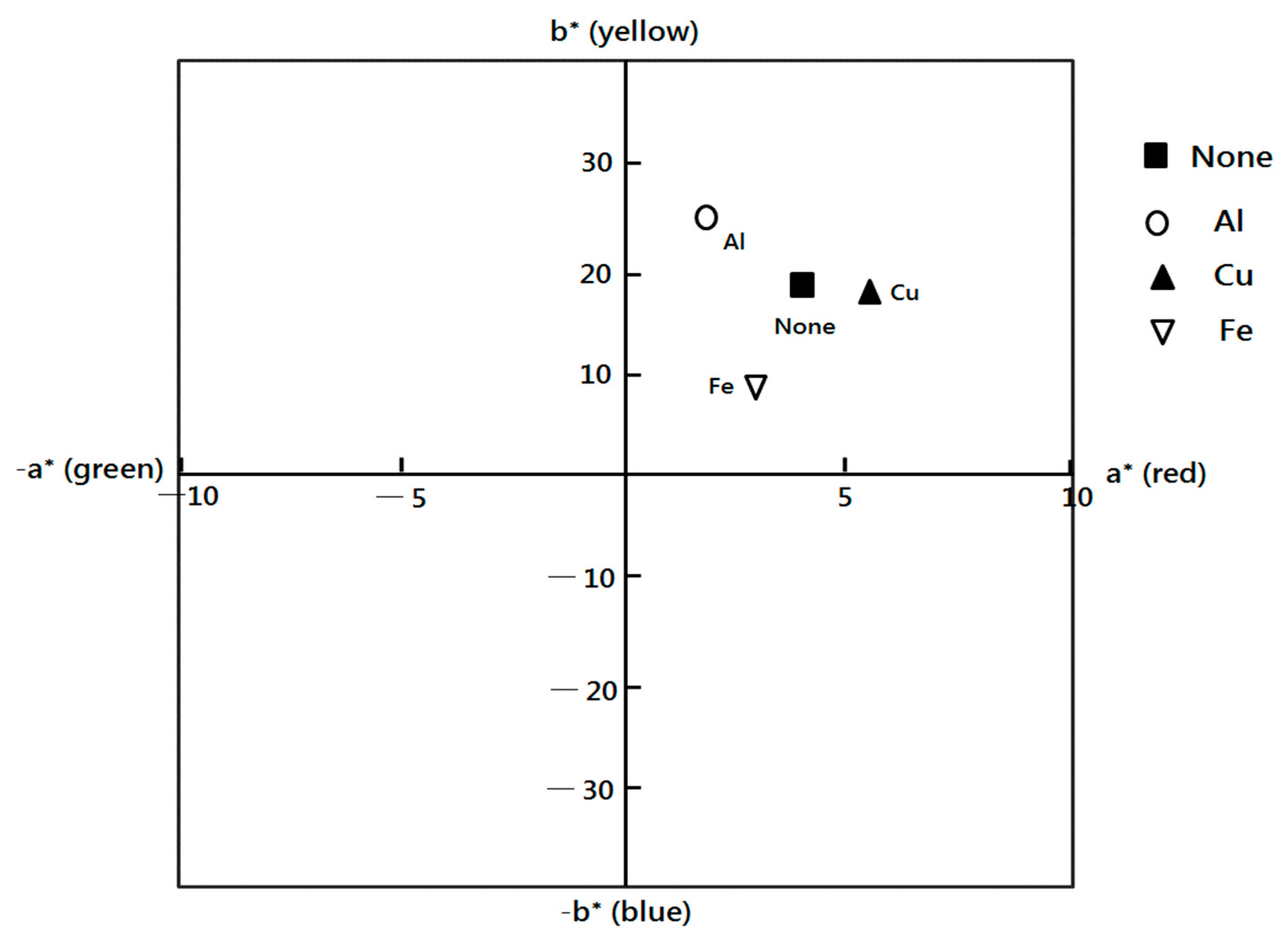

2.1. Color Characteristics

2.2. Fastness Properties

2.3. Deodorizing Performance

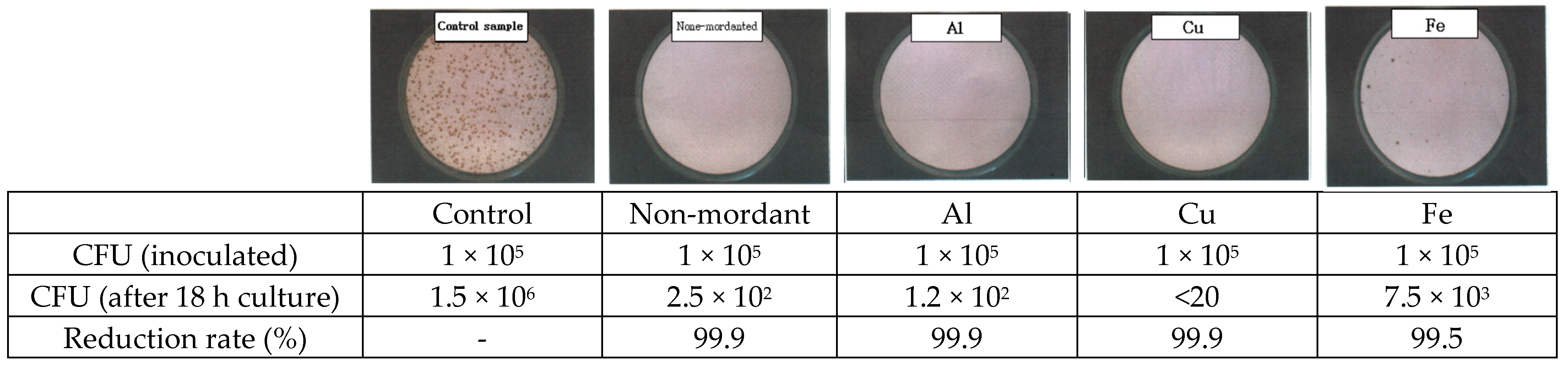

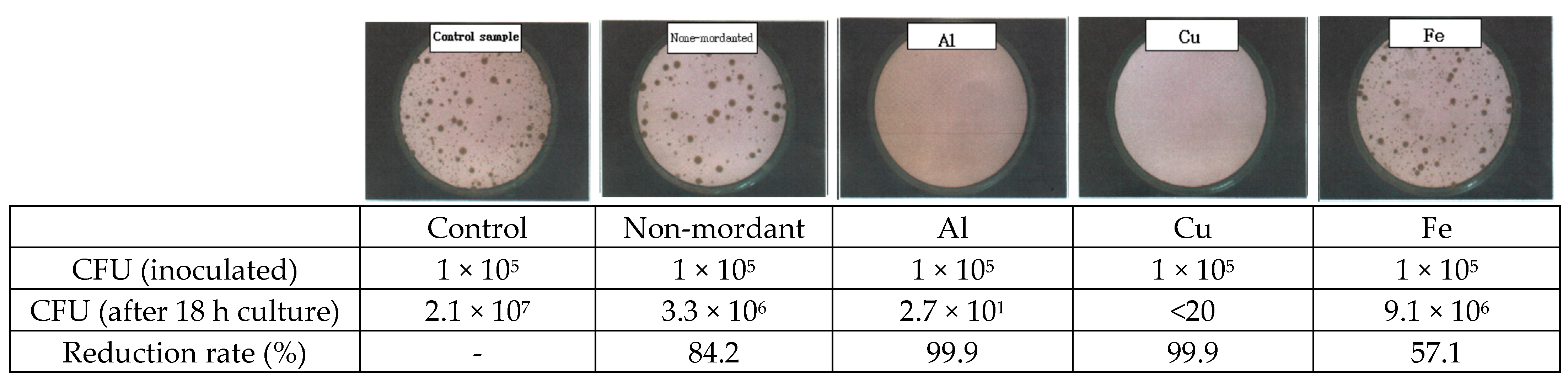

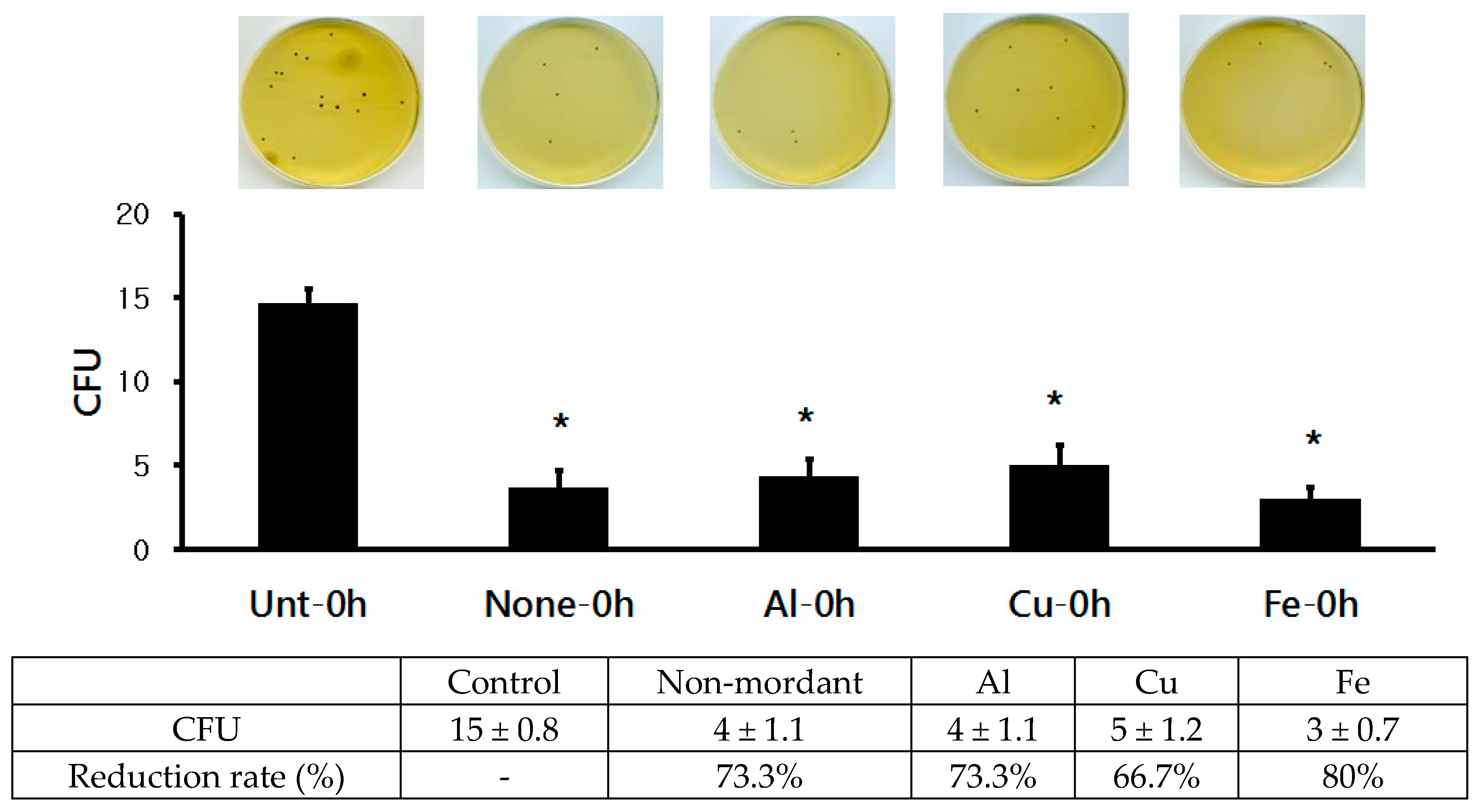

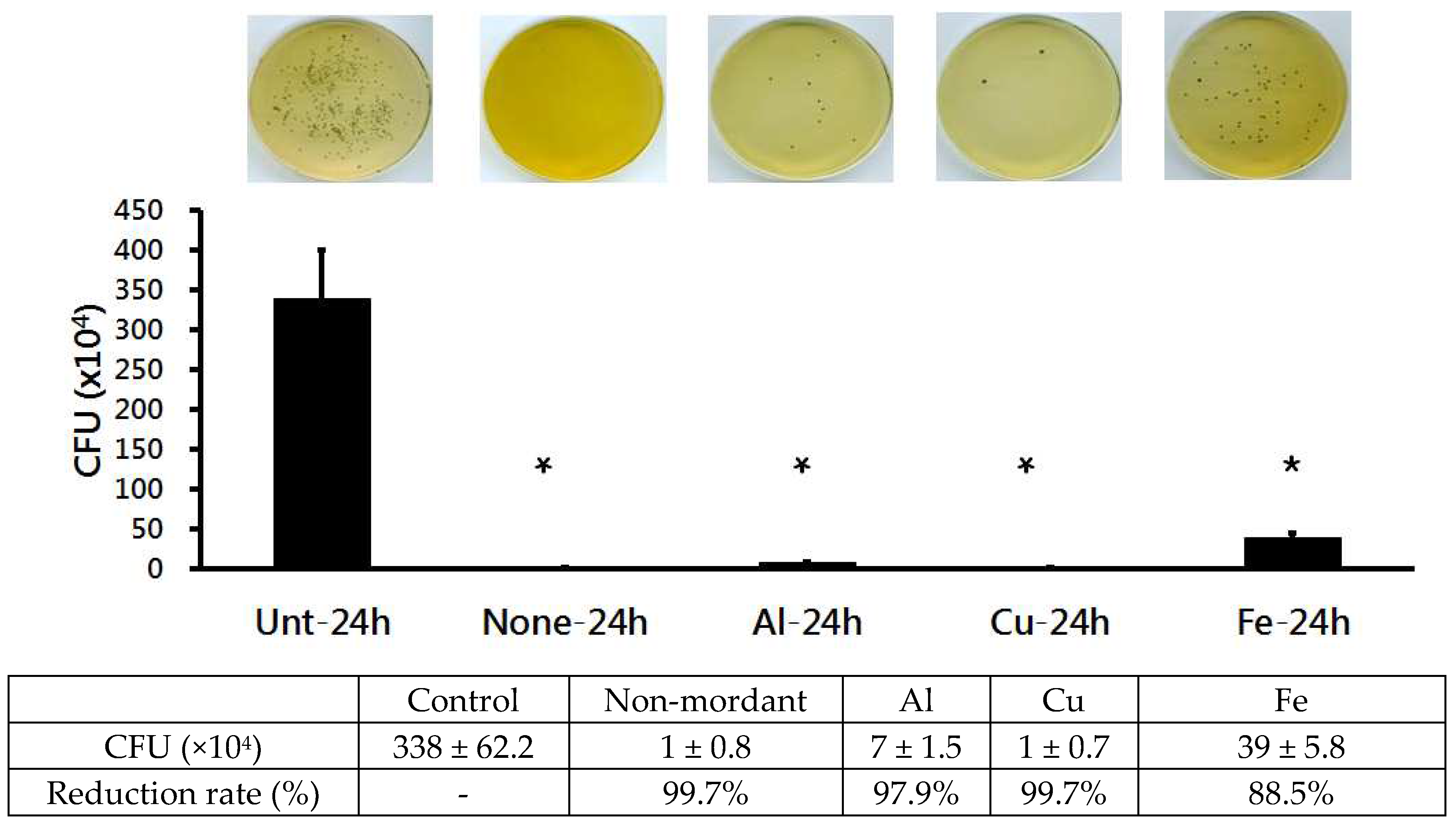

2.4. Antibacterial Activities

3. Experimental

3.1. Materials

3.2. Extraction of Dye

3.3. Dyeing

3.4. Mordanting

3.5. Color Measurement

3.6. Color Fastness Testing

3.7. Deodorization Performance Measurement

3.8. Antibacterial Activity Measurement

3.9. Statistical Analysis

4. Conclusions and Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Johnson, L.B.; Saravolatz, L.D. Community-acquired MRSA: Current epidemiology and management issues. Infect. Med. 2005, 22, 16–20. [Google Scholar]

- Scott, E.; Duty, S.; Callahan, M. A pilot study to isolate Staphylococcus aureus and methicillin-resistant S. aureus from environmental surfaces in the home. Am. J. Infect. Control 2008, 36, 458–460. [Google Scholar] [CrossRef] [PubMed]

- Yong, K.J.; Kim, I.H.; Nam, S.W. Antibacterial and Deodorization Activities of Cotton Fabrics Dyed with Amur Cork Tree extracts. J. Korea Soc. Dyers Finish. 1999, 11, 9–15. [Google Scholar]

- Dulon, M.; Haamann, F.; Peters, C.; Schablon, A.; Nienhaus, A. MRSA prevalence in European healthcare settings: A review. BMC Infect. Dis. 2011, 11, 138. [Google Scholar] [CrossRef] [PubMed]

- Sit, P.S.; Teh, C.S.J.; Idris, N.; Ponnampalavanar, S. Methicillin-resistant Staphylococcus aureus (MRSA) bacteremia: Correlations between clinical, phenotypic, genotypic characteristics and mortality in a tertiary teaching hospital in Malaysia. Infect. Genet. Evol. 2018, 59, 132–141. [Google Scholar] [CrossRef]

- Morell, E.A.; Balkin, D.M. Methicillin-resistant Staphylococcus aureus: A pervasive pathogen highlights the need for new antimicrobial development. Yale J. Biol. Med. 2010, 83, 223–233. [Google Scholar] [PubMed]

- Lakhundi, S.; Zhang, K. Methicillin-Resistant Staphylococcus aureus: Molecular characterization, evolution, and epidemiology. Clin. Microbiol. Rev. 2018, 31, e00020-18. [Google Scholar] [CrossRef]

- Wiener-Well, Y.; Galuty, M.; Rudensky, B.; Schlesinger, Y.; Attias, D.; Yinnon, A.M. Nursing and physician attire as possible source of nosocomial infections. Am. J. Infect. Control 2011, 39, 555–559. [Google Scholar] [CrossRef]

- Morgan, D.J.; Rogawski, E.; Thom, K.A.; Johnson, J.K.; Perencevich, E.N.; Shardell, M.; Leekha, S.; Harris, A.D. Transfer of multidrug-resistant bacteria to healthcare workers’ gloves and gowns after patient contact increases with environmental contamination. Crit. Care Med. 2012, 40, 1045–1051. [Google Scholar] [CrossRef]

- Kim, H.S.; Han, S.K.; Mang, J.Y. Evaluations on the deodorization effect and antibacterial activity of Chamaecyparis obtusa Essential Oil. Korean J. Odor Res. Eng. 2009, 8, 111–117. [Google Scholar]

- Kim, S.H.; Kim, N.M. Do Consumers Purchase Green Products to Show to Others?: The Interaction Effects between Consumer Characteristics and Public vs. Private Products. J. Mark. Stud. 2015, 23, 75–94. [Google Scholar]

- Choi, N.Y. Comparison of the fastness of dyed fabric using natural extracts and its antibacterial efficacy against antibiotic-resistant strains. J. Korea Fash. Costume Des. Assoc. 2022, 24, 63–71. [Google Scholar]

- Choi, S.C.; Jung, J.S. Study on the Antimicrobial Activity of Impatiens balsamina (III). J. Korean Fiber Soc. 1999, 36, 338–343. [Google Scholar]

- Son, H.J.; Kim, Y.S.; Kim, N.Y.; Lee, H.B.; Park, W.G. A Consideration of the possibility of planting Cryptomeria japonica and Chamaecyparis obtusa on the east sea area in Gangwon-province by tree ring dating and climatic factor analysis. J. For. Environ. Sci. 2014, 30, 36–44. [Google Scholar]

- Yang, A.R.; Hwang, J.H.; Cho, M.S. Regional early growth performances of planted Chamaecyparis obtusa seedlings in relation to site properties. J. Korean For. Soc. 2014, 103, 375–382. [Google Scholar] [CrossRef]

- Kang, S.K.; Shin, M.K.; Auh, Q.S.; Chun, Y.H.; Hong, J.P. Antibacterial effect on oral pathogenic bacteria of phytoncide from Chamaecyparis obtusa. J. Oral Med. Pain 2007, 32, 45–55. [Google Scholar]

- Kim, J.H.; Lee, S.O.; Do, K.B.; Ji, W.D.; Kim, S.G.; Back, Y.D.; Kim, K.J. Analysis of the component and immunological efficacy of Chamaecyparis obtusa leaf extract. Korean J. Clin. Lab. Sci. 2018, 50, 37–43. [Google Scholar] [CrossRef]

- Ahn, J.Y.; Lee, S.S.; Kang, H.Y. Biological activities of essential oil from Chamaecyparis obtusa. J. Soc. Cosmet. Sci. Korea 2004, 30, 503–507. [Google Scholar]

- Park, M.J.; Choi, W.S.; Min, B.C.; Kim, H.Y.; Kang, H.Y.; Choi, I.G. Antioxidant activities of essential oils from Chamaecyparis obtusa. J. Korean Wood Sci. Technol. 2008, 36, 159–167. [Google Scholar]

- Lee, D.S.; Lim, M.S.; Kwon, S.S.; Kim, S.Y.; Park, S.N. Antioxidative activity and componential analysis of Chamaecyparis obtusa leaf extract. Appl. Chem. Eng. 2012, 23, 93–99. [Google Scholar]

- Lee, S.K.; Kim, J.K.; Ham, Y.H.; Bae, Y.S. Extractives from the leaves of Chamaecyparis obtusa Endlicher. J. Forest Environ. Sci. 2002, 18, 53–60. [Google Scholar]

- Cho, S.E.; Yi, D.H. Antioxidant and anti-inflammatory activity of leaves extracts of Chamaecyparis Obtusa. J. Korean Soc. Cosmetol. 2011, 17, 970–975. [Google Scholar]

- Kim, S.H.; Lee, S.Y.; Hong, C.Y.; Gwak, K.S.; Yeo, H.M.; Lee, J.J.; Choi, I.G. Whitening and Antioxidant Activities of Essential Oils from Cryptomeria japonica and Chamaecyparis obtusa. J. Korean Wood Sci. Technol. 2011, 39, 291–302. [Google Scholar] [CrossRef]

- Ko, E.; Lee, H.; Han, C. Dyeability and functionality of wool fabrics dyed with Chamaecyparis obtusa leaf extract. J. Korean Soc. Cloth. Text. 2019, 43, 288–296. [Google Scholar] [CrossRef]

- Choi, N.Y.; Kim, J.H. Antibacterial function of fabrics dyed with extract from Chamaecyparis obtusa leaves against Methicillin-resistant Staphylococcus aureus. Fash. Text. Res. J. 2017, 19, 331–336. [Google Scholar] [CrossRef]

- Jang, H.J.; Jung, J.S. Surface color and functionality of silk dyed with extract from Chamaecyparis obtusa and mixture extracts from Chamaecyparis obtusa and Rubia tinctorum. Fash. Text. Res. J. 2017, 19, 486–492. [Google Scholar]

- Choi, N.Y.; Kang, S.Y.; Kim, K.J. Artemisia princeps Inhibits Biofilm Formation and Virulence-Factor Expression of Antibiotic-Resistant Bacteria. BioMed Res. Int. 2015, 2015, 239519. [Google Scholar] [CrossRef]

- Choi, N.Y. Antimicrobial activity of silk fabrics dyed with Caesalpinia sappan on antibiotic resistant strains. Korean J. Hum. Ecol. 2019, 28, 491–500. [Google Scholar]

- Park, Y.M. Characteristics of cotton fabric dyed with Euphorbia extract at different concentrations of cellulosic nanoparticles(CNP). Fash. Text. 2023, 10, 3. [Google Scholar] [CrossRef]

- Choi, N.Y.; Choi, N.Y. Antimicrobial activity of natural dyes cotton using Caesalpinia sappan ethanol extract. Korean J. Hum. Ecol. 2019, 28, 271–277. [Google Scholar] [CrossRef]

- El-Apasery, M.A.; Hussein, A.M.; Nour El-Din, N.M.; Saleh, M.O.; El-Adasy, A. Microwave-assisted dyeing of wool fabrics with natural dyes as eco-friendly dyeing method: Part I. Dyeing performance and fastness properties. Egypt. J. Chem. 2012, 64, 3751–3759. [Google Scholar]

- El-Apasery, M.A.; Hussein, A.M.; Nour El-Din, N.M.; Saleh, M.O.; El-Adasy, A. Microwave-assisted dyeing of wool fabrics with natural dyes as eco-friendly dyeing method: Part II. The effect of using different mordants. Egypt. J. Chem. 2012, 64, 3761–3766. [Google Scholar]

- Choi, N.Y.; Park, H.S. Antibiosis against super bacteria from natural dyeing with elm bark extract. Fash. Text. Res. J. 2015, 17, 838–843. [Google Scholar] [CrossRef]

- Koch, A.L. Growth measurement. In Manual of Methods for General Bacteriology; American Society for Microbiology: Washington, DC, USA, 1981; pp. 179–207. [Google Scholar]

| Mordants | λmax (nm) | K/S | L* | a* | b* |

|---|---|---|---|---|---|

| None | 400 | 14.62 | 70.84 | 4.31 | 19.65 |

| Al | 400 | 15.38 | 67.74 | 2.71 | 24.25 |

| Cu | 400 | 11.37 | 56.44 | 5.51 | 19.15 |

| Fe | 400 | 11.43 | 49.34 | 1.84 | 8.35 |

| Mordants | Washing | Dry Cleaning | Light | |||

|---|---|---|---|---|---|---|

| Color Change | Stain | Color Change | Test Liquid | Color Change | ||

| Silk | Cotton | |||||

| None | 2 | 4–5 | 4–5 | 4 | 4–5 | 3 |

| Al | 2 | 4–5 | 4–5 | 4 | 4–5 | 3 |

| Cu | 2–3 | 4–5 | 4–5 | 4 | 4–5 | 3–4 |

| Fe | 2 | 4–5 | 4–5 | 4–5 | 4–5 | 3–4 |

| Mordants | Perspiration | Rubbing | ||||||

|---|---|---|---|---|---|---|---|---|

| Acid | Alkaline | Dry | Wet | |||||

| Color Change | Stain Cotton | Stain Wool | Color Change | Stain Cotton | Stain Wool | |||

| None | 4 | 4 | 4 | 4 | 4 | 4 | 4–5 | 4 |

| Al | 3 | 4 | 4 | 3 | 4 | 4 | 4–5 | 4–5 |

| Cu | 2–3 | 4 | 4 | 2–3 | 4 | 4 | 4–5 | 3–4 |

| Fe | 3 | 4 | 4–5 | 4 | 4–5 | 4–5 | 4–5 | 3 |

| Deodorization Activity (%) | ||||

|---|---|---|---|---|

| None | Al | Cu | Fe | |

| 30 min | 95 | 96 | 96 | 86 |

| 60 min | 97 | 97 | 97 | 88 |

| 90 min | 98 | 98 | 98 | 90 |

| 120 min | 98 | 98 | 98 | 90 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, N.-Y.; Park, B.-I. Dyeing Performance and Anti-Superbacterial Activity of Cotton Fabrics Dyed with Chamaecyparis obtusa. Molecules 2023, 28, 6497. https://doi.org/10.3390/molecules28186497

Choi N-Y, Park B-I. Dyeing Performance and Anti-Superbacterial Activity of Cotton Fabrics Dyed with Chamaecyparis obtusa. Molecules. 2023; 28(18):6497. https://doi.org/10.3390/molecules28186497

Chicago/Turabian StyleChoi, Na-Young, and Bog-Im Park. 2023. "Dyeing Performance and Anti-Superbacterial Activity of Cotton Fabrics Dyed with Chamaecyparis obtusa" Molecules 28, no. 18: 6497. https://doi.org/10.3390/molecules28186497

APA StyleChoi, N.-Y., & Park, B.-I. (2023). Dyeing Performance and Anti-Superbacterial Activity of Cotton Fabrics Dyed with Chamaecyparis obtusa. Molecules, 28(18), 6497. https://doi.org/10.3390/molecules28186497