Influence of Pre-Treatment and Drying Methods on the Quality of Dried Carrot Properties as Snacks

Abstract

:1. Introduction

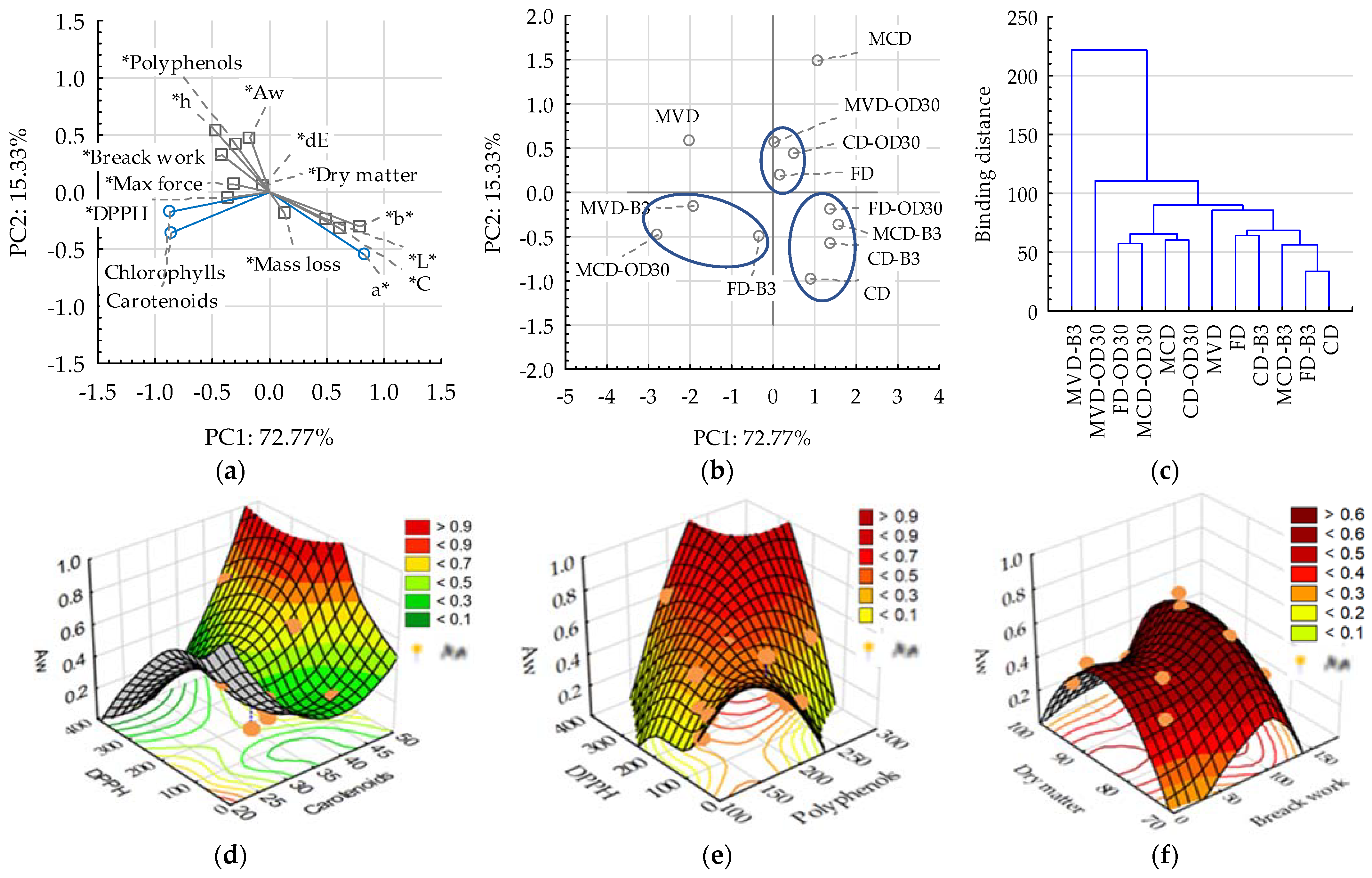

2. Results

2.1. Influence of Pre-Treatment and Drying Method on Physical Properties of Dried Carrots

2.1.1. The Dry Matter Content, Mass Loss, and Water Activity of Dried Carrots

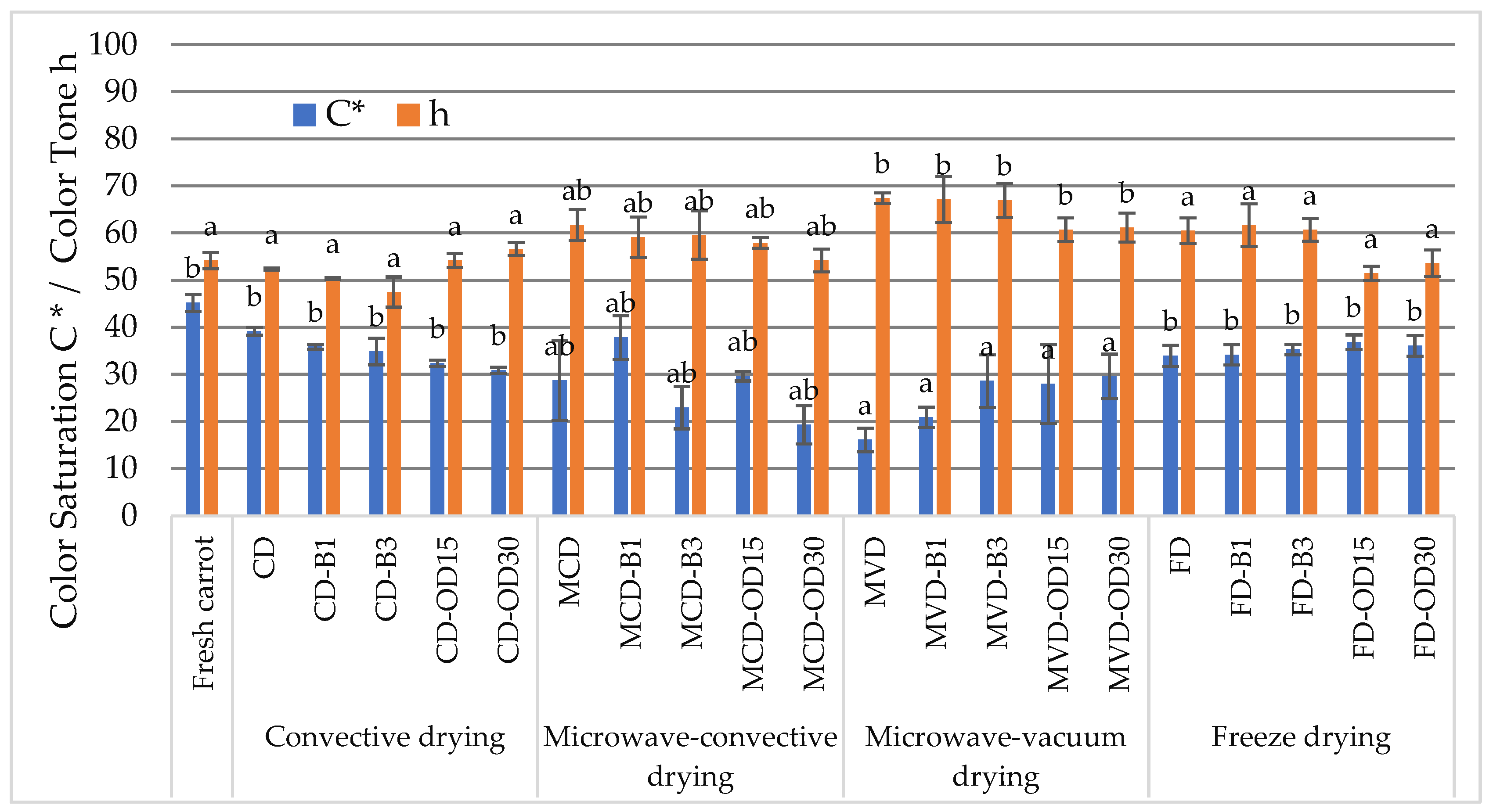

2.1.2. The Color Parameters and the Absolute Color Difference of Dried Carrot

2.1.3. The Texture Properties

2.2. Influence of Pre-Treatment and Drying Method on Chemical Properties of Carrots

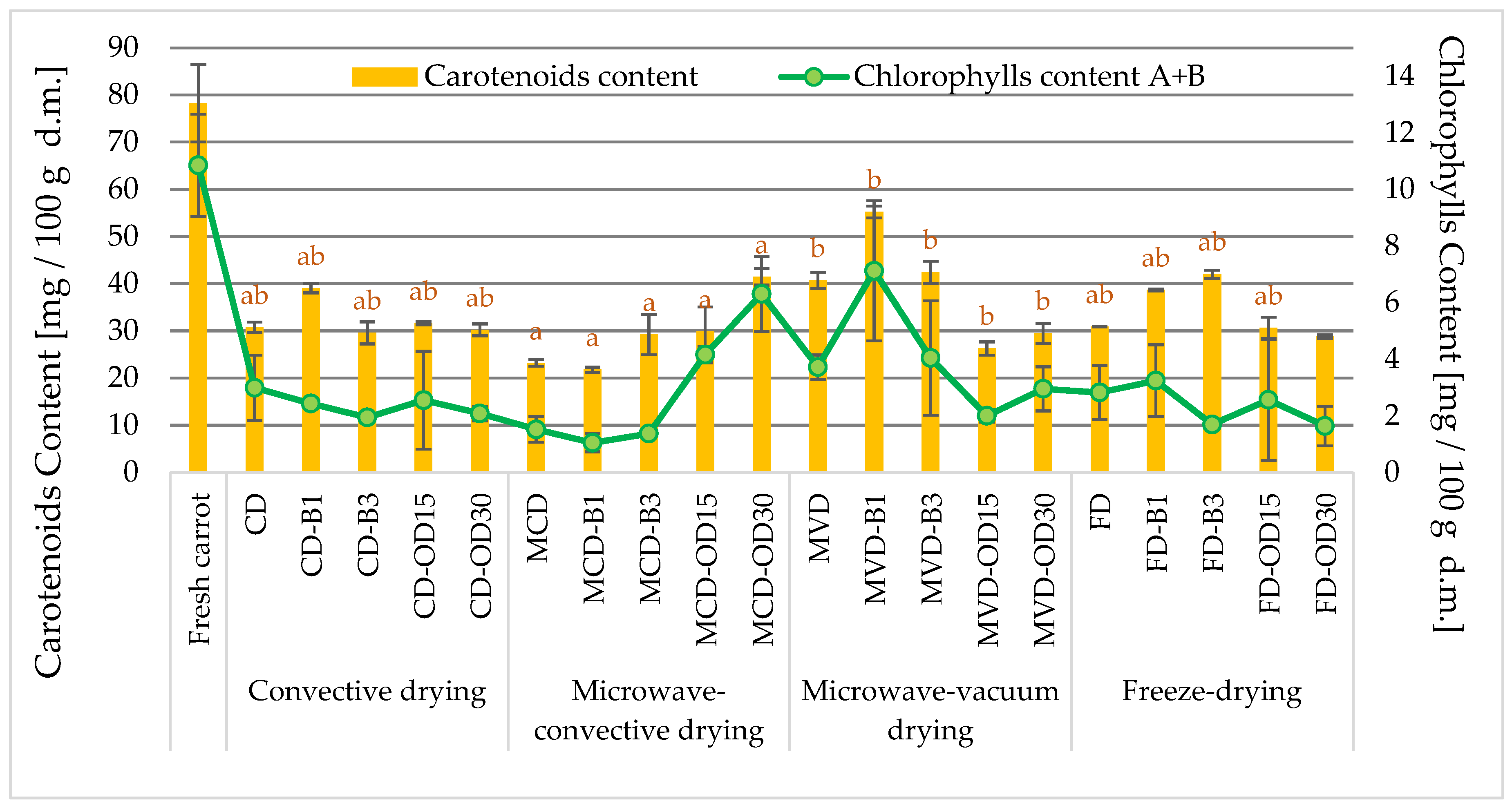

2.2.1. Content of Carotenoid and Chlorophyll Compounds

2.2.2. Total Phenolic Content and DPPH Antioxidant Activity

3. Discussion

4. Materials and Methods

4.1. Material and Experimental Procedure

4.2. Technological Methods

4.2.1. Pre-Treatment Methods

4.2.2. Drying Methods

4.3. Physical Determination

4.3.1. Dry Matter Content and Water Activity

4.3.2. Color Parameters

4.3.3. Texture Analysis

4.4. Chemical Determinations

4.4.1. Carotenoids and Chlorophyll A and B Content

4.4.2. Total Phenolic Content (TPC)

4.4.3. Antioxidant Activity (AA)

4.5. Statistical Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Czajkowska, K.; Kowalska, H. Methods of manufacturing fruit snacks enriched in natural ingredients. Technol. Prog. Food Process. 2017, 1, 110–115. [Google Scholar]

- Kowalska, H.; Marzec, A.; Kowalska, J.; Ciurzyńska, A.; Czajkowska, K.; Cichowska, J.; Rybak, K.; Lenart, A. Osmotic dehydration of Honeoye strawberries in solutions enriched with natural bioactive molecules. LWT-Food Sci. Technol. 2017, 85, 500–505. [Google Scholar] [CrossRef]

- Tarko, T.; Duda-Chodak, A.; Semik-Szczurak, D. The use of fruit extracts for production of apple chips with enhanced antioxidant activity. Ann. Natl. Inst. Hyg. 2017, 68, 161–165. [Google Scholar]

- Chen, J.; Venkitasamy, C.; Shen, Q.; McHugh, T.H.; Zhang, R.; Pan, Z. Development of healthy crispy carrot snacks using sequential infrared blanching and hot air drying method. LWT-Food Sci. Technol. 2018, 97, 469–475. [Google Scholar] [CrossRef]

- Sharma, K.D.; Karki, S.; Thakur, N.S.; Attri, S. Chemical composition, functional properties and processing of carrot—A review. J. Food Sci. Technol. 2012, 49, 22–32. [Google Scholar] [CrossRef]

- Šeregeij, V.; Vulić, J.; Ćetković, G.; Čanadanovć-Brunet, J.; Šaponjac, V.T.; Slađana, S. Natural bioactive compounds in carrot waste for food applications and health benefits. Stud. Nat. Prod. Chem. 2020, 67, 307–344. [Google Scholar] [CrossRef]

- Mohammadi, X.; Deng, Y.; Matinfar, G.; Singh, A.; Mandal, R.; Pratap-Singh, A. Impact of three different dehydration methods on nutritional values and sensory quality of dried broccoli, oranges and carrots. Foods 2020, 9, 1464. [Google Scholar] [CrossRef]

- Nagraj, G.S.; Jaiswal, S.; Harper, N.; Jaiswal, A.K. Carrot. Nutritional Composition and Antioxidant Properties of Fruits and Vegetables; Jaiswal, A.K., Ed.; Academic Press: Cambridge, MA, USA, 2020. [Google Scholar] [CrossRef]

- Grzegory, P.; Piotrowski, D. Plant materials drying by selected methods. Technol. Prog. Food Process. 2013, 1, 92–95. [Google Scholar]

- Ando, Y.; Hagiwara, S.; Nabetani, H.; Sotome, I.; Okunishi, T.; Okadome, H.; Orikasa, T.; Tagawa, A. Improvements of drying rate and structural quality of microwave-vacuum dried carrot by freeze-thaw pretreatment. LWT-Food Sci. Technol. 2019, 100, 294–299. [Google Scholar] [CrossRef]

- Kowalska, H.; Marzec, A.; Kowalska, J.; Trych, U.; Masiarz, E.; Lenart, A. The use of a hybrid drying method with pre-osmotic treatment in strawberry bio-snack technology. Int. J. Food Eng. 2020, 16, 80318–80319. [Google Scholar] [CrossRef]

- Ignaczak, A.; Masiarz, E.; Makowska, M.; Kowalska, H. Shaping properties of Helianthus tuberosus L. Jerusalem artichoke Topinambu snack produced by osmotic dehydration and drying methods. Food Sci. Technol. Qual. 2022, 29, 85–99. [Google Scholar] [CrossRef]

- Chou, S.K.; Chua, K.J. New hybrid drying technologies for heat sensitive foodstuffs. Trends Food Sci. Technol. 2001, 12, 359–369. [Google Scholar] [CrossRef]

- Nowacka, M.; Śledź, M.; Wiktor, A.; Witrowa-Rajchert, D. Physical and chemical properties of microwave dried food products. Food Sci. Technol. Qual. 2012, 6, 5–20. [Google Scholar] [CrossRef]

- Cui, Z.; Xu, S.; Sun, D. Effect of microwave-vacuum drying on the carotenoids retention of carrot slices and chlorophyll retention of Chinese chive leaves. Dry. Technol. 2004, 22, 563–575. [Google Scholar] [CrossRef]

- Orikasa, T.; Koide, S.; Sugawara, H.; Yoshida, M.; Kato, K.; Matsushima, U.; Okada, M.; Watanabe, T.; Ando, Y.; Shiina, T.; et al. Applicability of vacuum-microwave drying for tomato fruit based on evaluation of energy cost, color, functional components and sensory qualities. J. Food Process. Preserv. 2018, 42, 1–12. [Google Scholar] [CrossRef]

- Xiao, H.W.; Pan, Z.; Deng, L.Z.; El-Mashad, H.M.; Yang, X.H.; Mujumdar, A.S.; Gao, Z.J.; Zhang, Q. Recent developments and trends in thermal blanching—A comprehensive review. Inf. Process. Agric. 2017, 4, 101–127. [Google Scholar] [CrossRef]

- Rastogi, N.K. Developments in osmotic dehydration of foods. In Drying Technology in Food Processing; Jafari, S.M., Malekjani, N., Eds.; Woodhead Publishing: Cambridge, UK, 2023; pp. 241–304. [Google Scholar]

- Huang, L.L.; Zhang, M. Trends in development of dried vegetable products as snacks. Dry. Technol. 2012, 30, 448–461. [Google Scholar] [CrossRef]

- Lentas, K.; Witrowa-Rajchert, D.; Hankus, M. Effect of blanching parameters and methods of drying on mechanical properties of dried mushrooms. Acta Agrophys. 2011, 17, 359–368. [Google Scholar]

- Huang, J.; Zhang, M.; Adhikari, B.; Yang, Z. Effect of microwave air spouted drying arranged in two and three-stages on the drying uniformity and quality of dehydrated carrot cubes. J. Food Eng. 2016, 177, 80–89. [Google Scholar] [CrossRef]

- Ciurzyńska, A.; Lenart, A.; Gręda, K.J. Effect of pre-treatment conditions on content and activity of water and colour of freeze-dried pumpkin. LWT-Food Sci. Technol. 2014, 59, 1075–1081. [Google Scholar] [CrossRef]

- Pałacha, Z.; Makarewicz, M. Water activity of chosen food-stuff groups. Technol. Prog. Food Process. 2011, 2, 24–29. [Google Scholar]

- Yusuf, E.H.; Wojdyło, A.; Lech, K.; Masztalerz, K.; Nowicka, P. The effect of combined drying process (OD-CD-VMD) on nutritional, phytochemical, and sensory profiles, and biological activities of colored dried carrot. LWT 2023, 173, 114231. [Google Scholar] [CrossRef]

- Łapczyńska-Kordon, B.; Krzysztofik, B. The impact of drying methods and parameters on changes in dried fruit and vegetables colour. Agric. Eng. 2008, 1, 251–257. [Google Scholar]

- Zalewska, M.; Otreszko-Arski, A.; Zalewski, M. The influence of convective drying and freeze drying on the colour of selected fruits (In Polish). Apar. Badaw. I Dydakt. 2016, 21, 141–145. [Google Scholar]

- Lentas, K.; Witrowa-Rajchert, D. Blanching parameters influence on mechanical properties and colour of dried celery. Acta Agrophys. 2009, 13, 165–174. [Google Scholar]

- Wang, H.; Fang, X.M.; Sutar, P.P.; Meng, J.S.; Wang, J.; Yu, X.L.; Xiao, H.W. Effects of vacuum-steam pulsed blanching on drying kinetics, colour, phytochemical contents, antioxidant capacity of carrot and the mechanism of carrot quality changes revealed by texture, microstructure and ultrastructure. Food Chem. 2021, 338, 127799. [Google Scholar] [CrossRef]

- Szadzińska, J.; Łechtańska, J.; Kowalski, S.J.; Stasiak, M. The effect of high power airborne ultrasound and microwaves on convective drying effectiveness and quality of green pepper. Ultrason. Sonochem. 2017, 34, 531–539. [Google Scholar] [CrossRef]

- Nahimana, H.; Zhang, M. Shrinkage and Color Change during Microwave Vacuum Drying of Carrot. Dry. Technol. 2011, 29, 836–847. [Google Scholar] [CrossRef]

- Stockman, H.M.G.; Gevers, T. Color measurement by imaging spectrometry. Comput. Vis. Image Underst. 2000, 79, 236–249. [Google Scholar] [CrossRef]

- Stępień, B. Impact of the drying method on the process of carrot cutting. Acta Agrophys. 2007, 9, 255–267. [Google Scholar]

- Ciurzyńska, A.; Lenart, A. Effect of osmotic dehydration on mechanical properties of freeze-dried strawberries. Food Sci. Technol. Qual. 2006, 47, 56–66. [Google Scholar]

- Ciurzyńska, A.; Lenart, A.; Siemiątkowska, M. The influence of osmotic dehydration on colour and mechanical properties of freeze-dried strawberries. Acta Agrophys. 2011, 17, 17–32. [Google Scholar]

- Mezzomo, N.; Ferreira, S.R.S. Carotenoids Functionality, Sources, and Processing by Supercritical Technology: A Review. J. Chem. 2016, 2016, 3164312. [Google Scholar] [CrossRef]

- Nabi, B.G.; Mukhtar, K.; Ahmed, W.; Manzoor, M.F.; Ranjha, M.M.A.N.; Kieliszek, M.; Bhat, Z.F.; Aadil, R.M. Natural pigments: Anthocyanins, carotenoids, chlorophylls, and betalains as food colorants in food products. Food Biosci. 2023, 52, 102403. [Google Scholar] [CrossRef]

- Van Wayenbergh, E.; Struyf, N.; Rezaei, M.N.; Sagalowicz, L.; Bel-Rhlid, R.; Moccand, C.; Courtin, C.M. Cereal bran protects vitamin A from degradation during simmering and storage. Food Chem. 2020, 331, 127292. [Google Scholar] [CrossRef] [PubMed]

- Rawson, A.; Tiwari, B.K.; Tuohy, M.G.; O’Donnell, C.P.; Brunton, N. Effect of ultrasound and blanching pretreatments on polyacetylene and carotenoid content of hot air and freeze dried carrot discs. Ultrason. Sonochem. 2011, 18, 1172–1179. [Google Scholar] [CrossRef]

- Krzykowski, A.; Polak, R.; Rudy, S. The retention of carothenoids in dried paprika depending on the pretreatment and drying methods and conditions. Agric. Eng. 2011, 1, 115–121. [Google Scholar]

- Gamboa-Santos, J.; Soria, A.C.; Villamiel, M.; Montilla, A. Quality parameters in convective dehydrated carrots blanched by ultrasound and conventional treatment. Food Chem. 2013, 141, 616–624. [Google Scholar] [CrossRef]

- Zhang, D.; Hamauzu, Y. Phenolic compounds and their antioxidant properties in different tissues of carrots (Daucus carota L.). J. Food Agric. Environ. 2004, 2, 95–100. [Google Scholar] [CrossRef]

- Leja, M.; Kamińska, I.; Kramer, M.; Maksylewicz-Kaul, A.; Kammerer, D.; Carle, R.; Baranski, R. The content of phenolic compounds and radical scavenging activity varies with carrot origin and root color. Plant Foods Hum. Nutr. 2013, 68, 163–170. [Google Scholar] [CrossRef]

- Samborska, K.; Eliasson, L.; Marzec, A.; Kowalska, J.; Piotrowski, D.; Lenart, A.; Kowalska, H. The effect of adding berry fruit juice concentrates and by-product extract to sugar solution on osmotic dehydration and sensory properties of apples. J. Food Sci. Technol. 2019, 56, 1927–1938. [Google Scholar] [CrossRef] [PubMed]

- Lichtenthaler, H.K.; Buschmann, C. Chlorophylls and carotenoids: Measurement and characterization by UV-VIS spectroscopy. Curr. Protoc. Food Anal. Chem. 2001, 1, F4-3. [Google Scholar] [CrossRef]

- Kowalska, H.; Kowalska, J.; Ignaczak, A.; Masiarz, E.; Domian, E.; Galus, S.; Ciurzyńska, A.; Salamon, A.; Zając, A.; Marzec, A. Development of a high-fibre multigrain bar technology with the addition of curly kale. Molecules 2021, 26, 3939. [Google Scholar] [CrossRef] [PubMed]

| Type of Dried | Dry Matter Content [%] | Mass Loss [%] | Water Activity [-] |

|---|---|---|---|

| Fresh carrot | 9.41 ± 0.51 | - | 0.981 ± 0.006 |

| CD | 77.13 ± 1.90 | 85.83 ± 0.03 BB′C’ | 0.362 ± 0.008 ab |

| CD-B1 | 91.67 ± 1.73 | 90.10 ± 0.01 BC′ | 0.464 ± 0.016 ab |

| CD-B3 | 92.74 ± 2.70 | 88.63 ± 0.03 BC′ | 0.447 ± 0.004 ab |

| CD-OD15 | 96.49 ± 2.89 | 82.67 ± 0.03 AA′B′ | 0.387 ± 0.006 ab |

| CD-OD30 | 91.02 ± 0.44 | 78.72 ± 0.01 AA′ | 0.363 ± 0.008 ab |

| MCD | 79.12 ± 1.71 | 85.83 ± 0.03 BB′C′ | 0.621 ± 0.008 bc |

| MCD-B1 | 92.82 ± 0.58 | 89.12 ± 0.03 BC′ | 0.504 ± 0.004 bc |

| MCD-B3 | 80.82 ± 0.08 | 90.20 ± 0.02 BC′ | 0.508 ± 0.006 bc |

| MCD-OD15 | 89.65 ± 4.07 | 82.01 ± 0.01 AA′B′ | 0.503 ± 0.008 bc |

| MCD-OD30 | 79.86 ± 1.90 | 80.64 ± 0.02 AA′ | 0.297 ± 0.016 bc |

| MVD | 90.50 ± 2.74 | 87.14 ± 0.01 BB′C′ | 0.616 ± 0.008 c |

| MVD-B1 | 95.83 ± 0.22 | 90.00 ± 0.02 BC′ | 0.637 ± 0.017 c |

| MVD-B3 | 93.31 ± 0.52 | 84.15 ± 0.01 BC′ | 0.626 ± 0.014 c |

| MVD-OD15 | 79.49 ± 1.05 | 82.02 ± 0.01 AA′B′ | 0.532 ± 0.014 c |

| MVD-OD30 | 89.77 ± 0.98 | 81.28 ± 0.04 AA′ | 0.447 ± 0.022 c |

| FD | 95.76 ± 0.48 | 88.98 ± 0.02 BB′C′ | 0.294 ± 0.003 a |

| FD-B1 | 95.00 ± 1.26 | 90.25 ± 0.01 BC′ | 0.381 ± 0.004 a |

| FD-B3 | 93.60 ± 0.56 | 91.47 ± 0.08 BC′ | 0.345 ± 0.009 a |

| FD-OD15 | 94.85 ± 0.83 | 82.06 ± 0.02 AA′B′ | 0.238 ± 0.009 a |

| FD-OD30 | 94.87 ± 0.42 | 77.70 ± 0.04 AA′ | 0.253 ± 0.042 a |

| Two-way analysis of variance (ANOVA) | |||

| Factors | p-value | ||

| Type of pre-treatment (A,B) | 0.3061 | 0.0000 * | 0.1840 |

| Drying method (a,b,c) | 0.0850 | 0.9709 | 0.0006 * |

| One-way analysis of variance (ANOVA) | |||

| Pre-treatment time (A′,B′,C′) of: | |||

| Blanching | 0.5667 | 0.0001 * | 0.4137 |

| Osmotic dehydration | 0.8123 | 0.0216 * | 0.3798 |

| Type of Samples | Color Parameters | ΔE | ||

|---|---|---|---|---|

| L* | a* | b* | ||

| Fresh carrot | 65.37 ± 0.8 | 25.58 ± 1.49 | 36.83 ± 1.14 | - |

| CD | 69.51 ± 3.42 bc | 26.27 ± 3.72 b | 31.34 ± 1.77 ab | 6.88 ± 0.05 a |

| CD-B1 | 64.60 ± 2.10 bc | 23.45 ± 1.62 b | 26.87 ± 0.55 ab | 10.28 ± 0.09 a |

| CD-B3 | 59.29 ± 3.53 bc | 25.37 ± 5.39 b | 26.75 ± 2.32 ab | 11.91 ± 0.19 a |

| CD-OD15 | 59.81 ± 2.04 bc | 19.12 ± 1.64 b | 26.90 ± 0.84 ab | 12.98 ± 0.15 a |

| CD-OD30 | 58.82 ± 1.46 bc | 16.55 ± 0.47 b | 26.73 ± 1.48 ab | 15.11 ± 0.09 a |

| MCD | 56.21 ± 6.60 ab | 13.50 ± 3.28 ab | 25.36 ± 6.76 ab | 19.10 ± 0.12 ab |

| MCD-B1 | 60.98 ± 2.75 ab | 24.72 ± 5.44 ab | 34.11 ± 2.11 ab | 5.17 ± 0.09 ab |

| MCD-B3 | 54.80 ± 3.00 ab | 24.80± 7.80 ab | 31.95 ± 4.01 ab | 11.51 ± 0.22 ab |

| MCD-OD15 | 49.74 ± 3.72 ab | 13.33 ± 4.11 ab | 23.44 ± 5.31 ab | 23.85 ± 0.14 ab |

| MCD-OD30 | 42.30 ± 2.93 ab | 10.59 ± 2.99 ab | 15.67 ± 4.24 ab | 34.79 ± 0.11 ab |

| MVD | 46.14 ± 2.46 a | 6.33 ± 0.83 a | 15.17 ± 2.13 a | 34.90 ± 0.17 b |

| MVD-B1 | 46.51 ± 0.35 a | 9.10 ± 0.84 a | 18.58 ± 1.07 a | 31.11 ± 0.18 b |

| MVD-B3 | 50.03 ± 5.00 a | 10.65 ± 1.69 a | 25.26 ± 5.77 a | 24.21 ± 0.17 b |

| MVD-OD15 | 49.40 ± 5.67 a | 12.09 ± 3.06 a | 22.60 ± 7.23 a | 25.38 ± 0.14 b |

| MVD-OD30 | 50.71 ± 3.97 a | 14.83 ± 3.30 a | 24.41 ± 5.49 a | 21.96 ± 0.08 b |

| FD | 79.01 ± 1.07 c | 17.11 ± 2.37 ab | 30.08 ± 1.33 b | 17.49 ± 0.10 a |

| FD-B1 | 77.99 ± 1.54 c | 15.44 ± 3.34 ab | 29.55 ± 0.11 b | 17.85 ± 0.13 a |

| FD-B3 | 73.75 ± 4.09 c | 17.09 ± 2.48 ab | 30.01 ± 0.56 b | 13.92 ± 0.25 a |

| FD-OD15 | 62.33 ± 1.06 c | 23.64 ± 1.42 ab | 29.51 ± 1.33 b | 8.16 ± 0.07 a |

| FD-OD30 | 59.58 ± 2.68 c | 23.19 ± 2.92 ab | 29.41 ± 1.06 b | 9.71 ± 0.08 a |

| Two-way analysis of variance (ANOVA) | ||||

| Factors | p-value | |||

| Type of pre-treatment (A,B) | 0.2983 | 0.6889 | 0.4964 | 0.7169 |

| Drying method (a,b,c) | 0.0002 * | 0.0090 * | 0.0408 * | 0.0080 * |

| One-way analysis of variance (ANOVA) | ||||

| Pre-treatment time (A′,B′) of: | ||||

| Blanching | 0.7242 | 0.8058 | 0.7471 | 0.9198 |

| Osmotic Dehydration | 0.6557 | 0.8470 | 0.6610 | 0.7011 |

| Parameters/ Cycles | Cycle I | Cycle II | Cycle III | Cycle IV Stabilization |

|---|---|---|---|---|

| Pressure [kPa] | 5.0 | 5.0 | 5.0 | - |

| Microwave power [W] | 550—fresh, B1, B3 400—OD15, OD30 | - | 550—fresh, B1, B3 400—OD15, OD30 | - |

| Temperature [°C] | 70 | - | 70 | - |

| Time [s] | 270—fresh 300—B1, B3 210—OD15 200—OD30 | 270—fresh 300—B1, B3 240—OD15 210—OD30 | 270—fresh 300—B1, B3 210—OD15 200—OD30 | 270—fresh 300—B1, B3 240—OD15 210—OD30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ignaczak, A.; Salamon, A.; Kowalska, J.; Marzec, A.; Kowalska, H. Influence of Pre-Treatment and Drying Methods on the Quality of Dried Carrot Properties as Snacks. Molecules 2023, 28, 6407. https://doi.org/10.3390/molecules28176407

Ignaczak A, Salamon A, Kowalska J, Marzec A, Kowalska H. Influence of Pre-Treatment and Drying Methods on the Quality of Dried Carrot Properties as Snacks. Molecules. 2023; 28(17):6407. https://doi.org/10.3390/molecules28176407

Chicago/Turabian StyleIgnaczak, Anna, Agnieszka Salamon, Jolanta Kowalska, Agata Marzec, and Hanna Kowalska. 2023. "Influence of Pre-Treatment and Drying Methods on the Quality of Dried Carrot Properties as Snacks" Molecules 28, no. 17: 6407. https://doi.org/10.3390/molecules28176407

APA StyleIgnaczak, A., Salamon, A., Kowalska, J., Marzec, A., & Kowalska, H. (2023). Influence of Pre-Treatment and Drying Methods on the Quality of Dried Carrot Properties as Snacks. Molecules, 28(17), 6407. https://doi.org/10.3390/molecules28176407