Preparation and Performance Study of Microemulsion Acid for Comprehensive Plugging Removal in Carbonate Reservoir

Abstract

1. Introduction

2. Preparation of Microemulsion Acid System

2.1. Optimization of Oil Phase Solvent

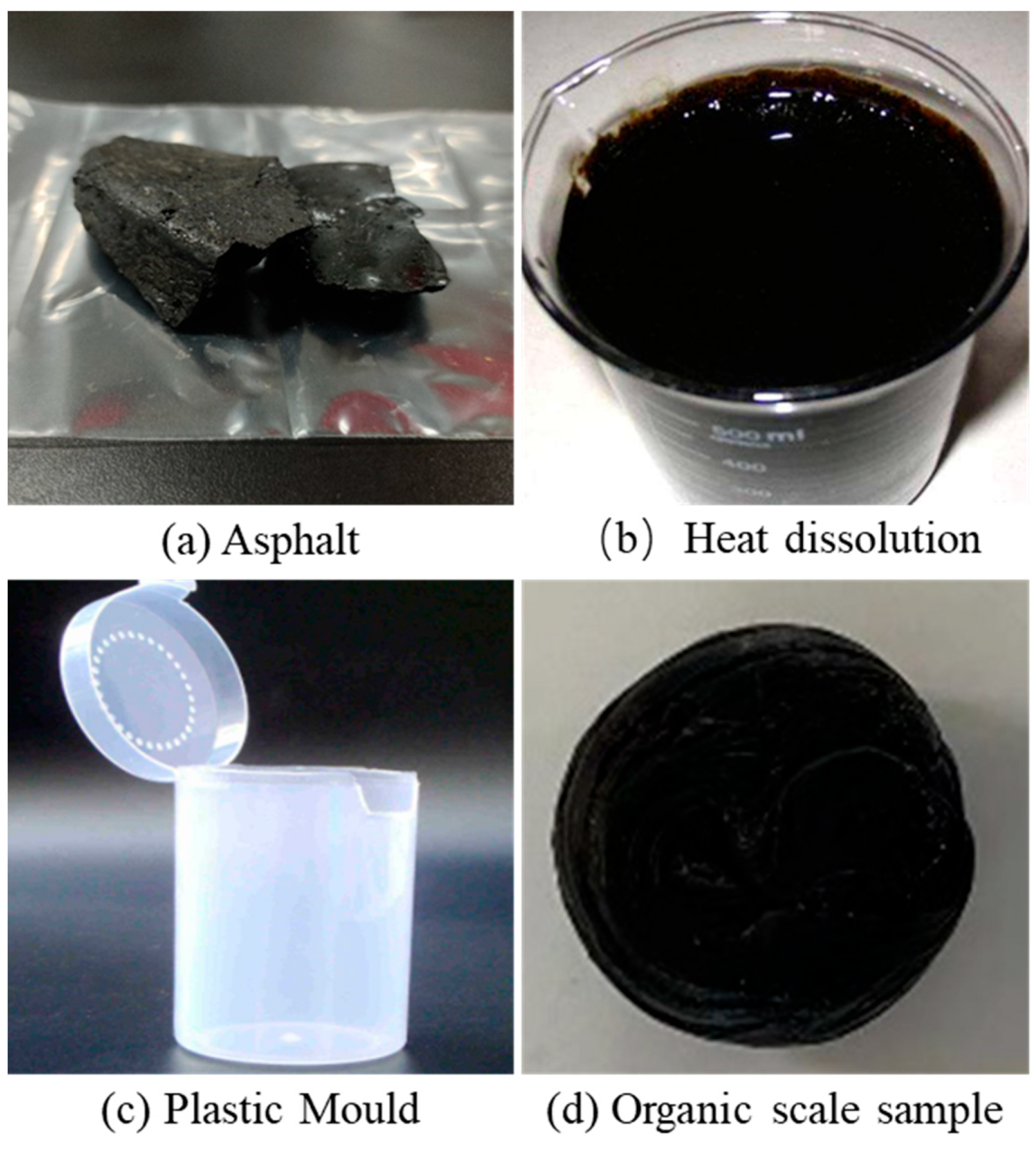

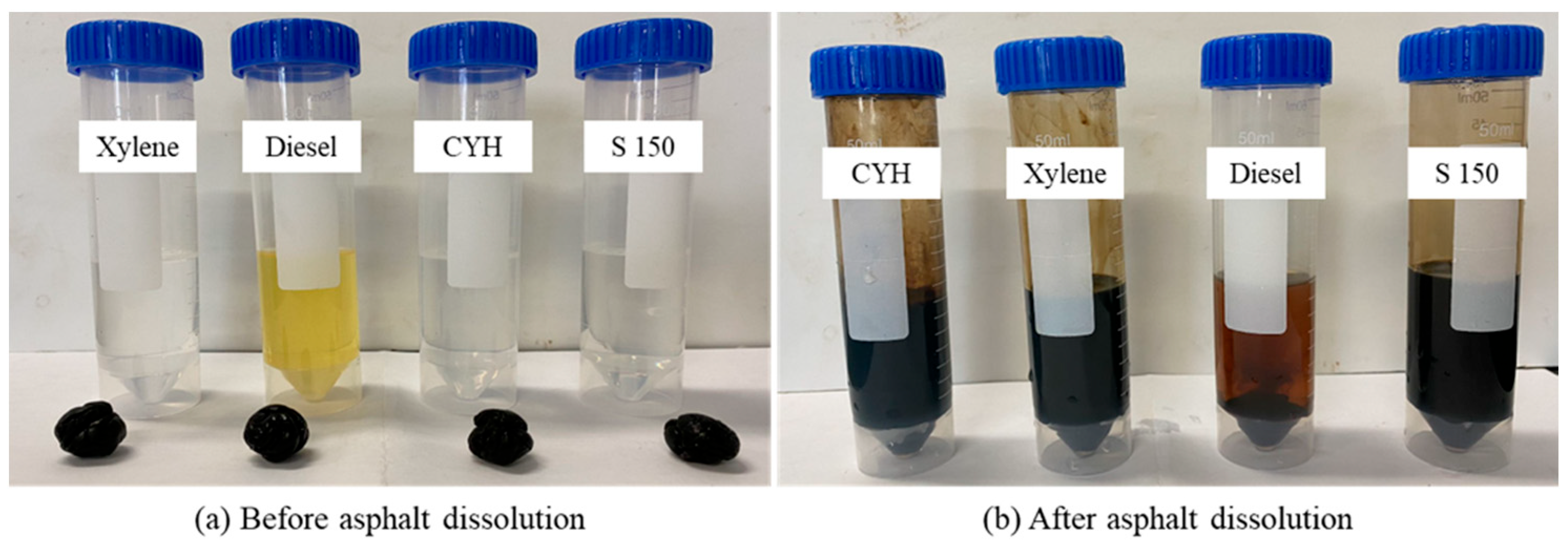

2.1.1. Experimental Method

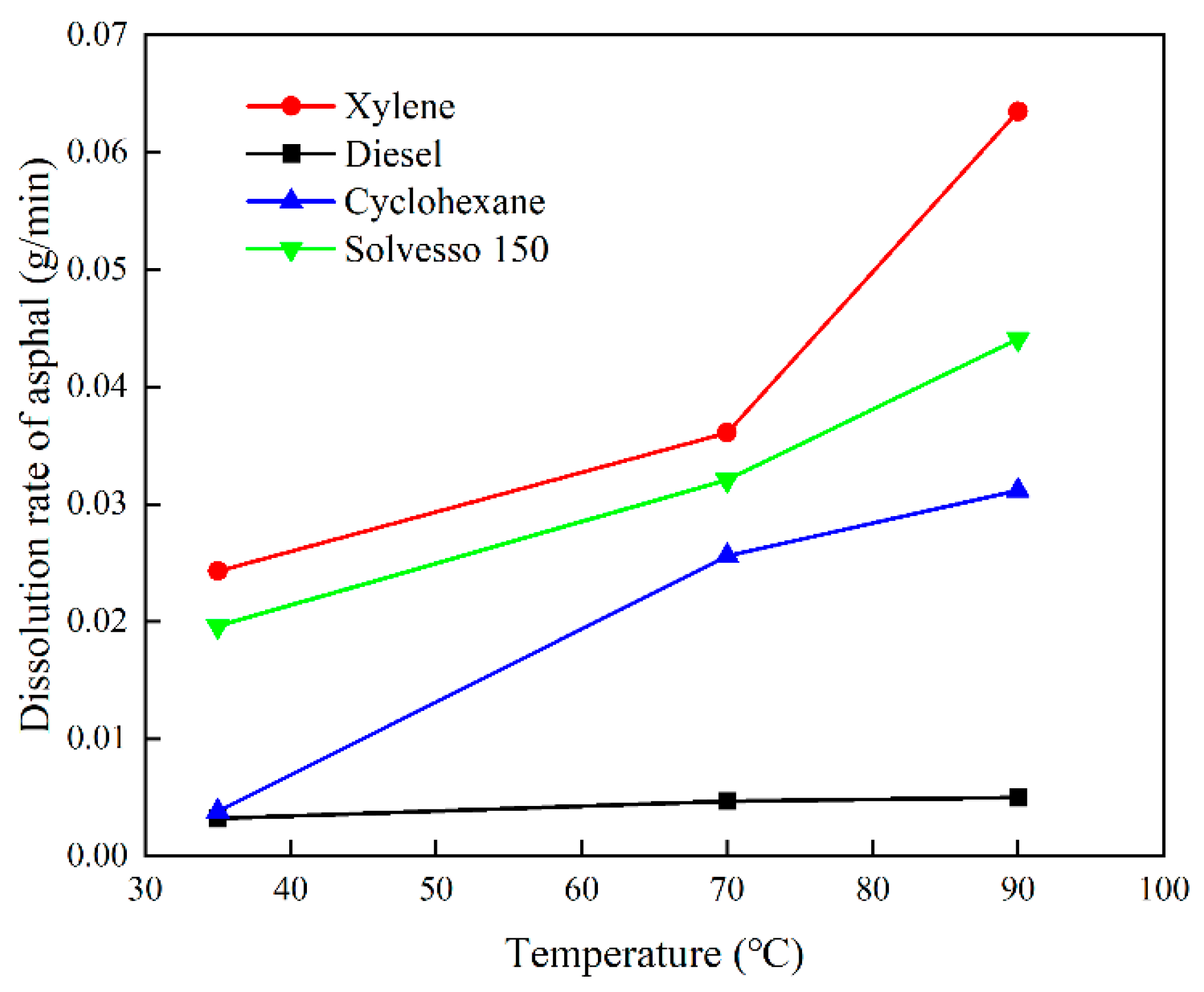

2.1.2. Experimental Results and Analysis

2.2. Preparation of Microemulsion Acid System

2.2.1. Experimental Materials and Methods

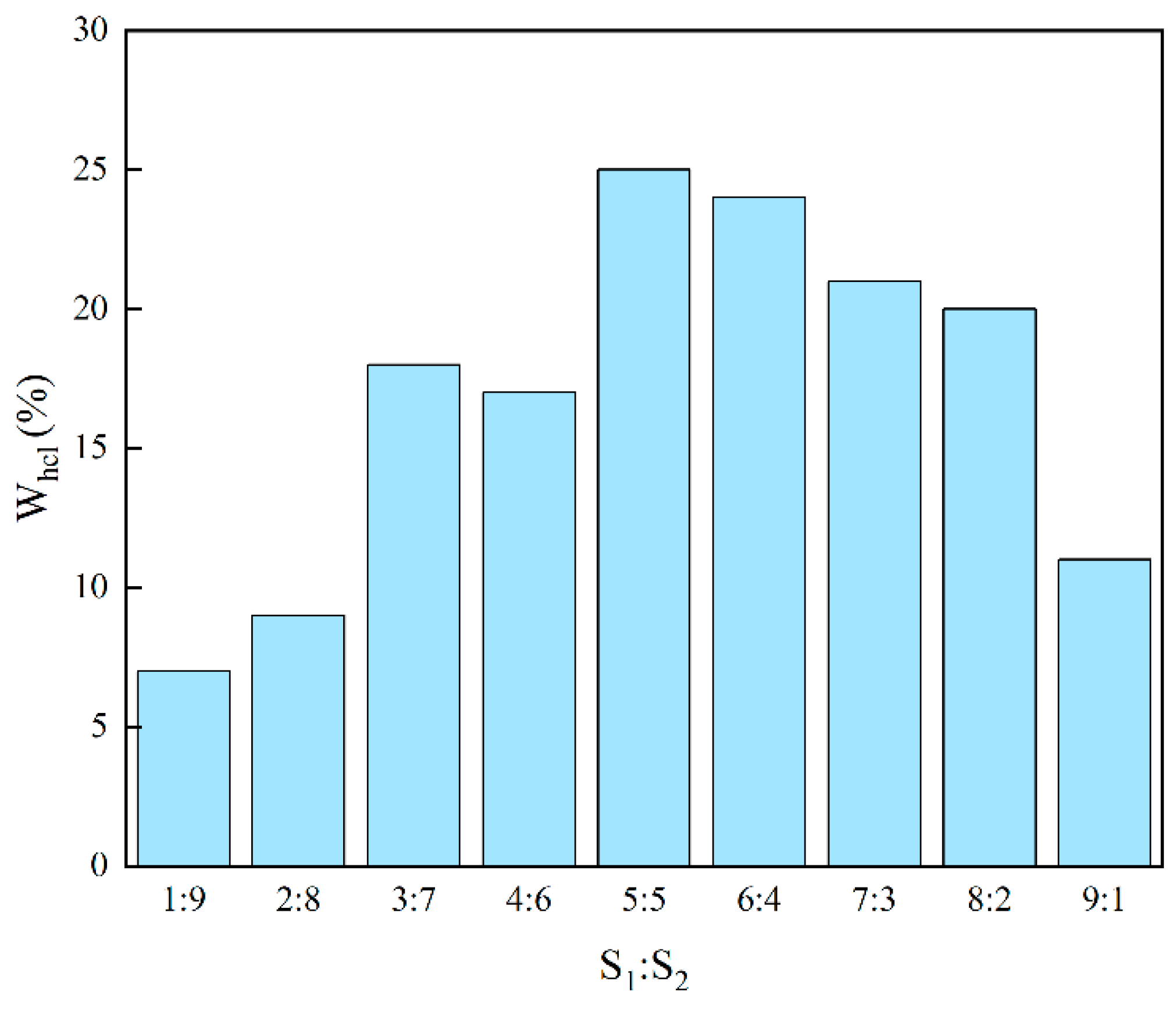

2.2.2. Ability of Microemulsion to Solubilize Hydrochloric Acid

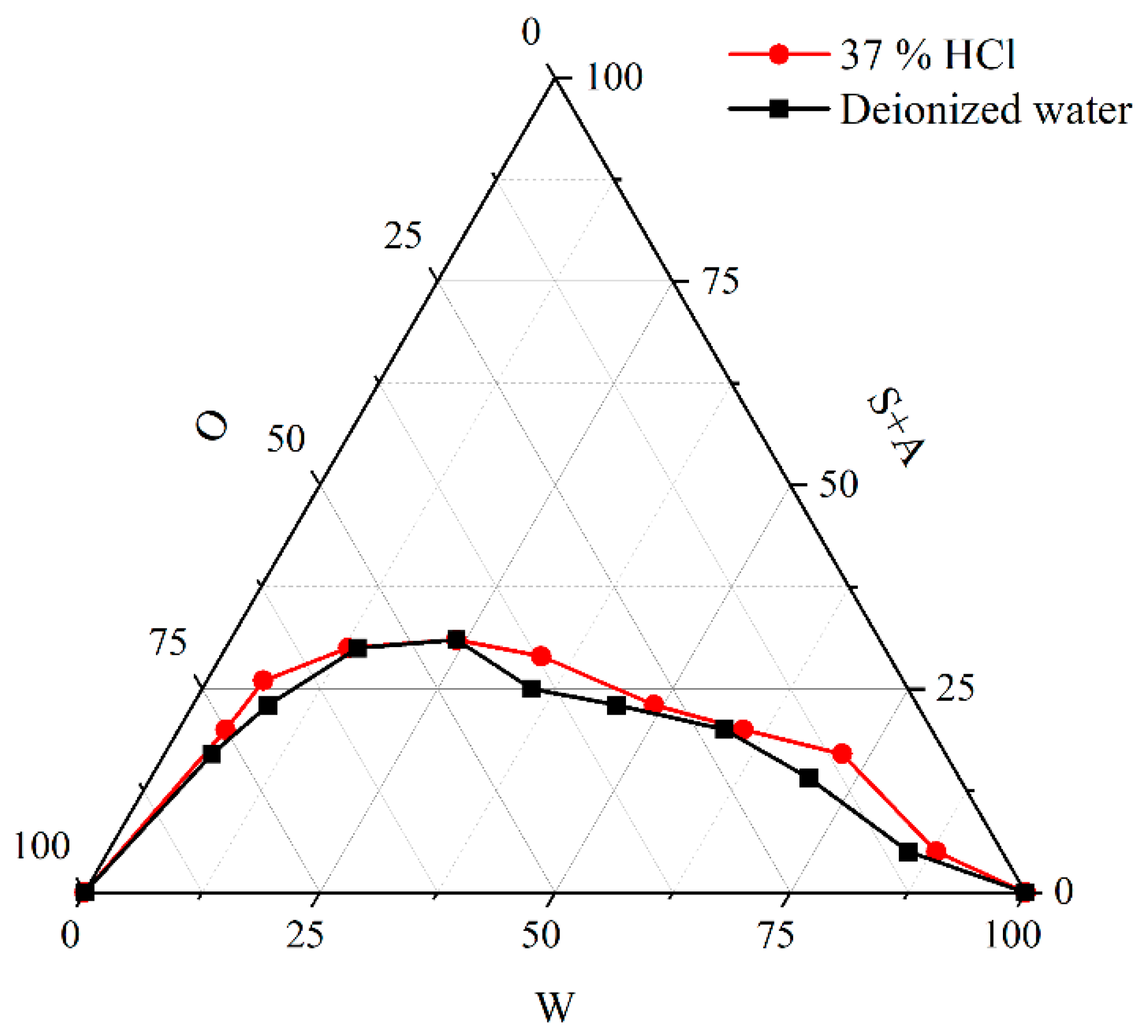

2.2.3. Study on Pseudo-Ternary Phase Diagram of Non-Ionic Microemulsion

3. Study the Reaction Law of Microemulsion Acid

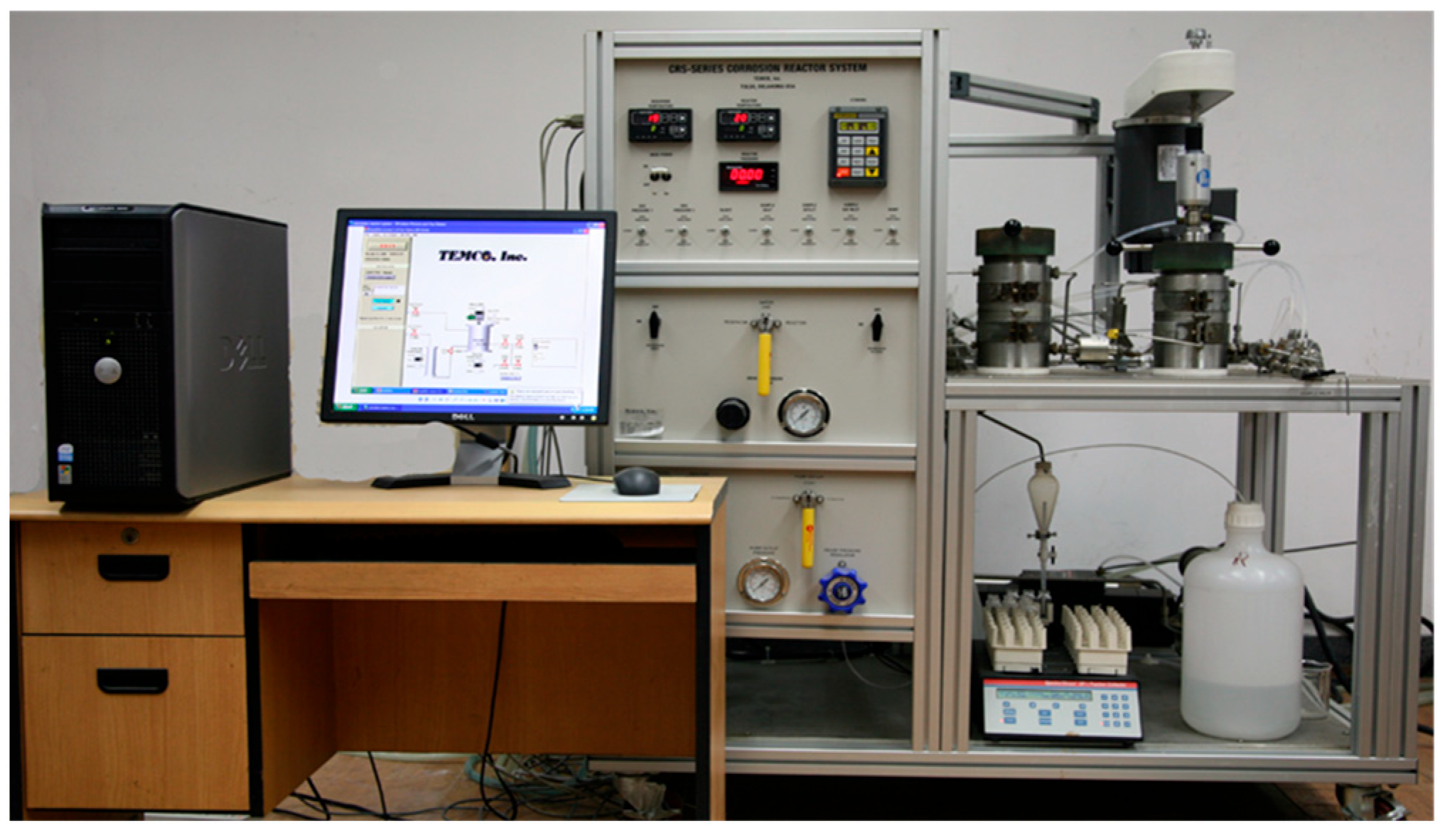

3.1. Experimental Materials and Methods

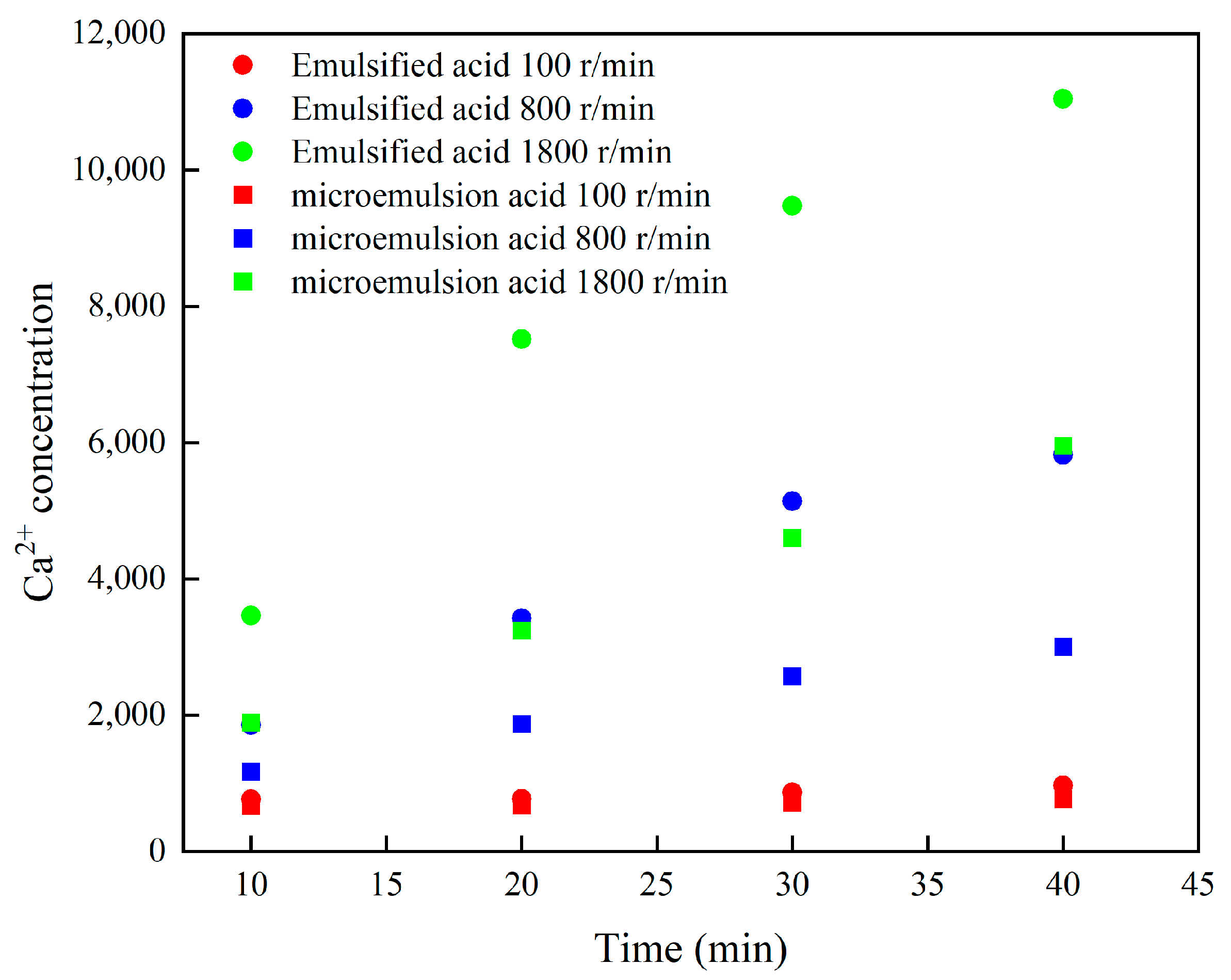

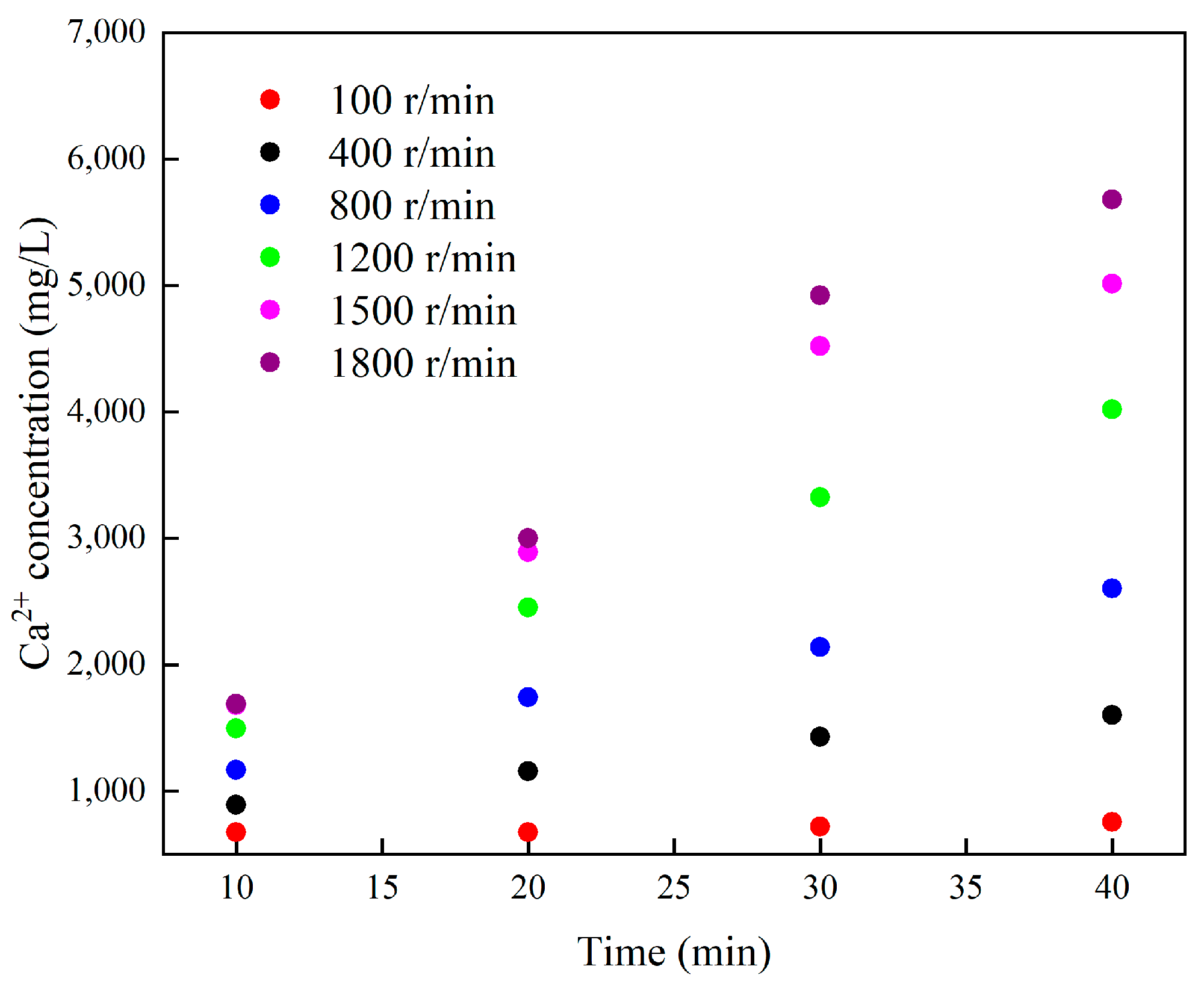

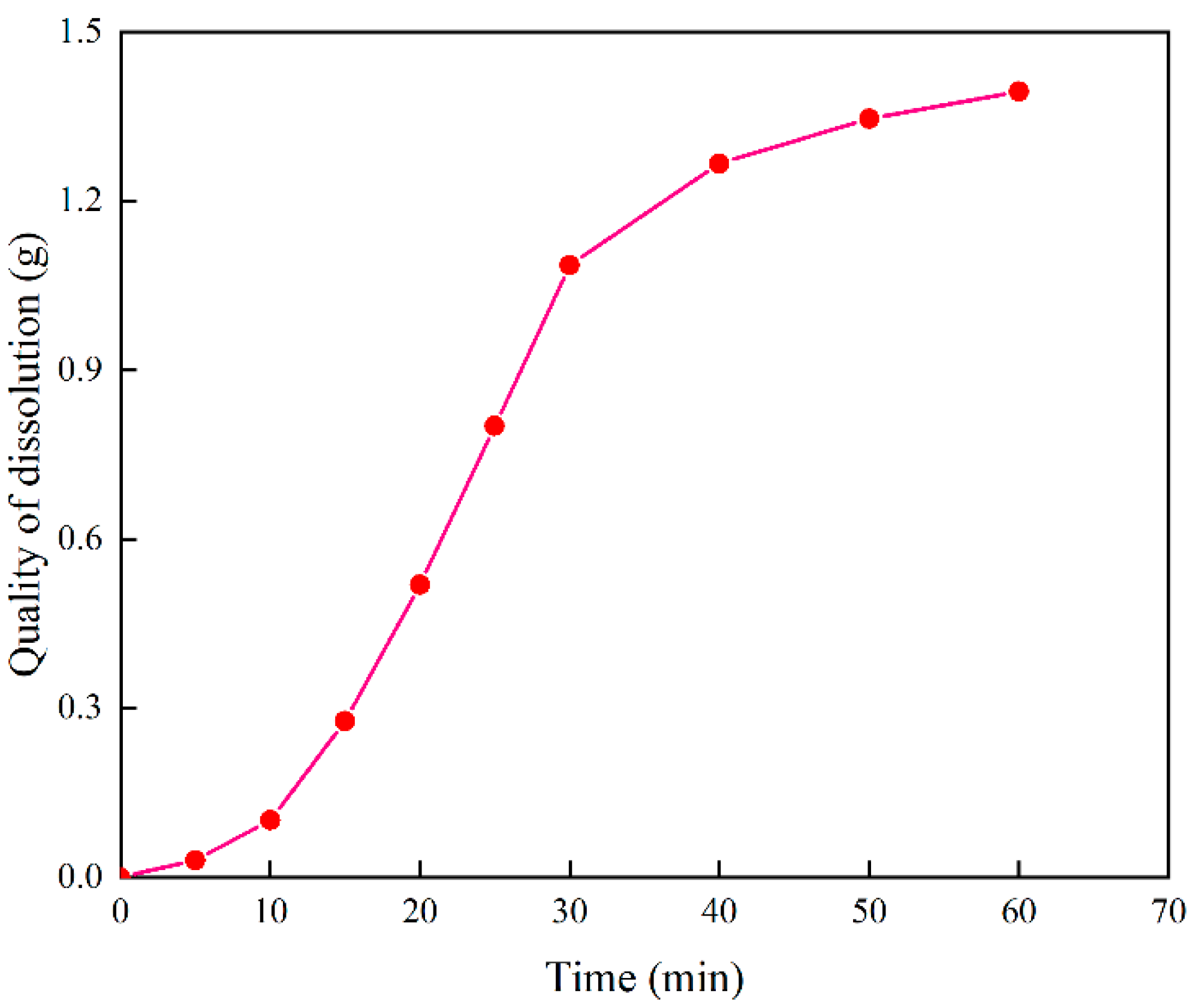

3.2. Reaction Rate of Microemulsion Acid

4. Study on Plugging Removal Performance of Microemulsion Acid

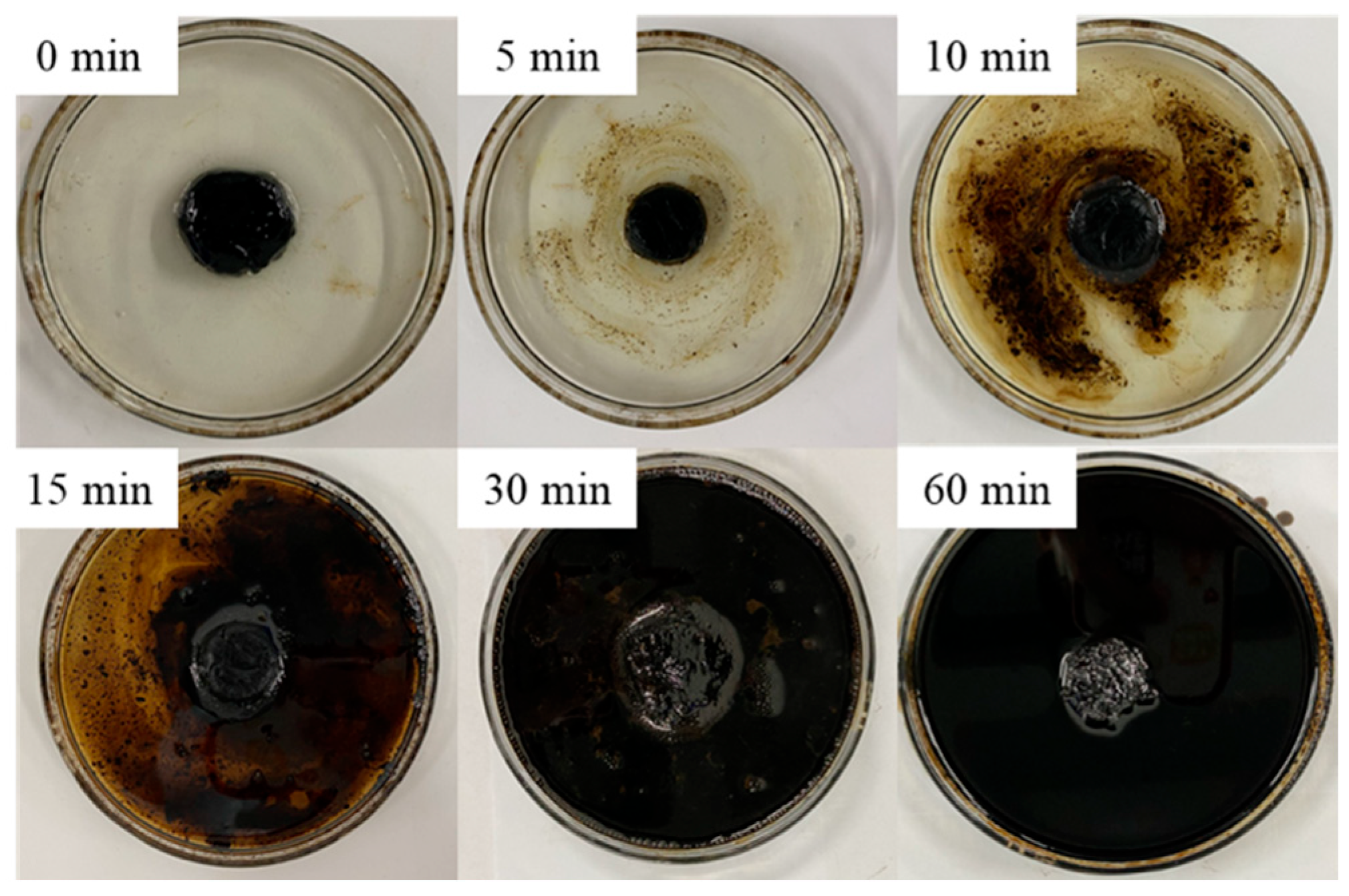

4.1. Dissolving Scale Ability of Microemulsion Acid

4.2. Comprehensive Plugging Removal Performance of Microemulsion

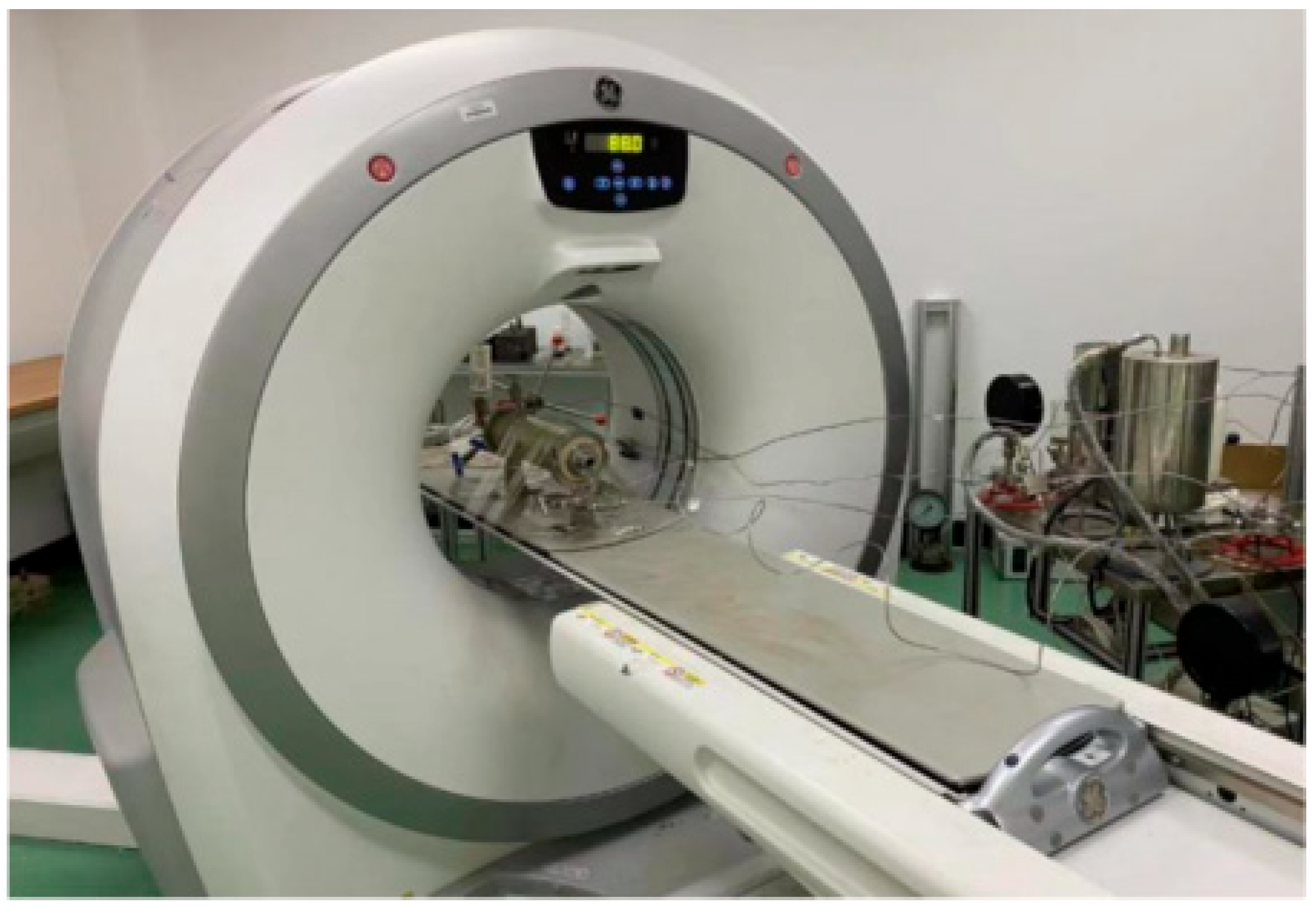

4.2.1. Experimental Materials and Methods

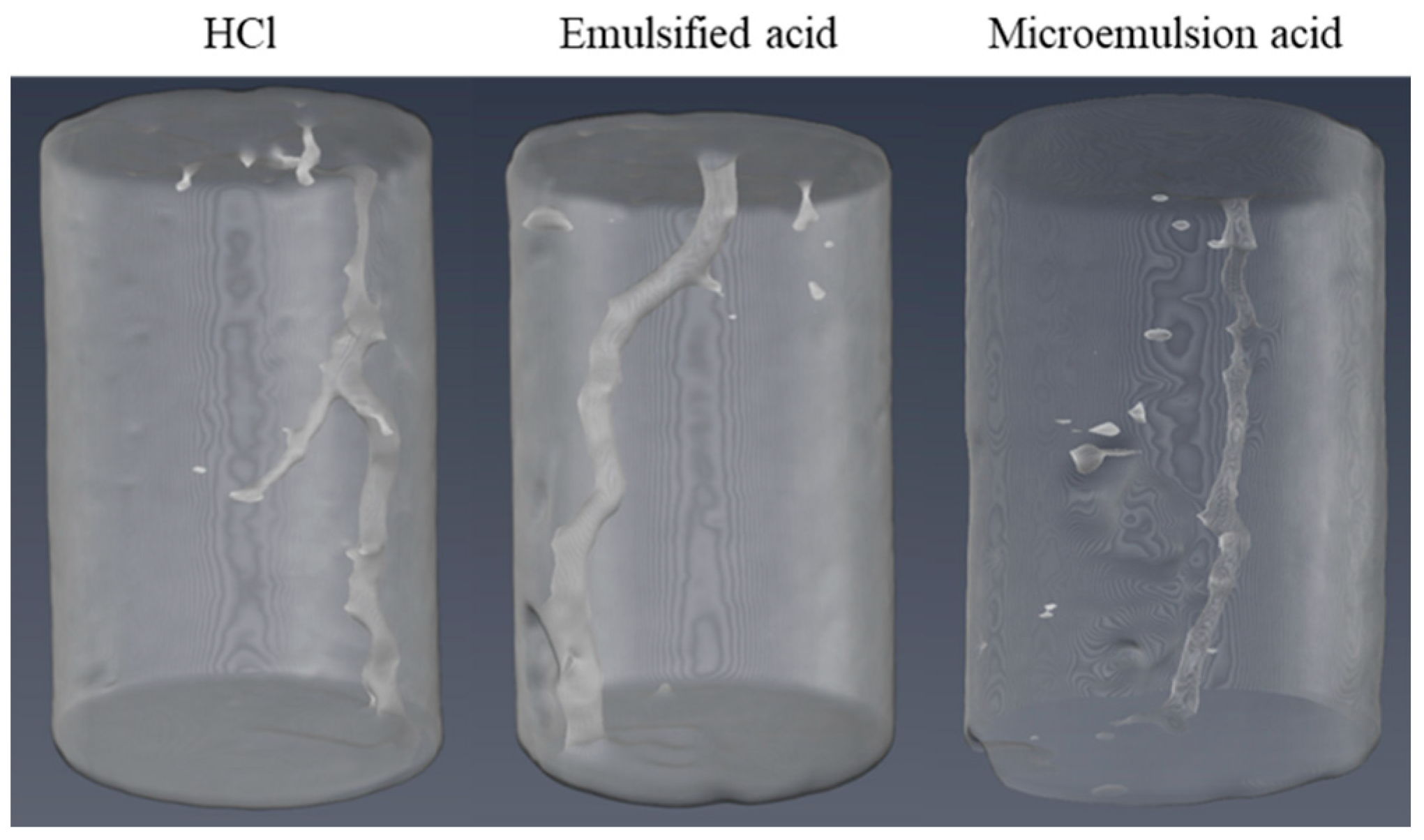

4.2.2. Experimental Results and Analysis

5. Conclusions

- (1)

- Solvesso 150 with low toxicity, flash point of 69 °C and ability to dissolve scale of 0.0441 g/min at 90 °C was selected as the oil phase. The ratio of surfactant and the ratio of surfactant to cosurfactant were optimized according to the ability to solubilize HCl. When NP−4: OP−10: A = 3: 3: 4, the system had the strongest ability to solubilize hydrochloric acid, which solved the problem of low H+ concentration.

- (2)

- The particle size of microemulsion acid is smaller than that of emulsified acid in the external oil phase, further reducing the diffusion rate. The mass transfer coefficient of microemulsion acid is 3.2 × 10−8 cm2/s at 60 °C, which is one order of magnitude smaller than that of emulsified acid. It is limited by the mass transfer process in the acid-rock reaction.

- (3)

- Microemulsion acid shows good dissolution performance in dissolving both organic and inorganic scales, and the combined solubility of mixed scales can reach 98.28%. The stronger scale dissolving ability and lower acid rock reaction rate enable microemulsion acid to form a thin and straight main wormhole, thus enhancing the acidizing and plugging removal efficiency.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Tackie-Otoo, B.N.; Ayoub Mohammed, M.A.; Zalghani, H.A.B.M.; Hassan, A.M.; Murungi, P.I.; Tabaaza, G.A. Interfacial Properties, Wettability Alteration and Emulsification Properties of an Organic Alkali–Surface Active Ionic Liquid System: Implications for Enhanced Oil Recovery. Molecules 2022, 27, 2265. [Google Scholar] [CrossRef]

- Al-Jaber, H.A.; Arsad, A.; Tahir, M.; Nuhma, M.J.; Bandyopadhyay, S.; Abdulmunem, A.R.; Abdul Rahman, A.F.; Harun, Z.B.; Agi, A. Enhancing Oil Recovery by Polymeric Flooding with Purple Yam and Cassava Nanoparticles. Molecules 2023, 28, 4614. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, F.; Zhang, Y.; Wang, Y.; Su, H.; Dong, R.; Wang, Q.; Bai, H. Numerical studies and analysis on reaction characteristics of limestone and dolomite in carbonate matrix acidizing. Geoenergy Sci. Eng. 2023, 222, 211452. [Google Scholar] [CrossRef]

- Peng, Y.; Zhao, J.; Sepehrnoori, K.; Li, Z.; Xu, F. Study of delayed creep fracture initiation and propagation based on semi-analytical fractional model. Appl. Math. Model. 2019, 72, 700–715. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, F.; Su, H. Performance evaluation of microemulsion acid for integrated acid fracturing in Middle Eastern carbonate reservoirs. Pet. Explor. Dev. 2023, 50, 1–8. [Google Scholar]

- Hoefner, M.L.; Fogler, H.S. Effective matrix acidizing in carbonates using microemulsions. Chem. Eng. Prog. 1985, 81, 5. Available online: https://www.osti.gov/biblio/6405788 (accessed on 25 June 2023).

- Sun, Y.; Zhang, W.; Li, J.; Han, R.; Lu, C. Mechanism and Performance Analysis of Nanoparticle-Polymer Fluid for Enhanced Oil Recovery: A Review. Molecules 2023, 28, 4331. [Google Scholar] [CrossRef]

- Yu, F.; Jiang, H.; Fan, Z. Features and imbibition mechanisms of WinsorItype surfactant solution in oil-wet porous media. Pet. Explor. Dev. 2019, 46, 950–958. [Google Scholar] [CrossRef]

- Zhi, L.; Shi, X.; Zhang, E.; Gao, C.; Gai, H.; Wang, H.; Liu, Z.; Zhang, T. Synthesis and Performance of Double-Chain Quaternary Ammonium Salt Glucosamide Surfactants. Molecules 2022, 27, 2149. [Google Scholar] [CrossRef] [PubMed]

- Carvalhoa, R.T.R.; Oliveira, P.F.; Palermo, L.C.M.; Ferreira, A.A.G.; Mansur, C.R.E. Prospective acid microemulsions development for matrix acidizing petroleum reservoirs. Fuel 2019, 238, 75–85. [Google Scholar] [CrossRef]

- Zhu, D.; Wang, Y.; Cui, M.; Zhou, F.; Zhang, Y.; Liang, C.; Zou, H.; Yao, F. Effects of spent viscoelastic-surfactant acid flow on wormholes propagation and diverting performance in heterogeneous carbonate reservoir. Energy Rep. 2022, 8, 8321–8332. [Google Scholar] [CrossRef]

- Adewunmi, A.A.; Solling, T.; Sultan, A.S.; Saikia, T. Emulsified acid systems for oil well stimulation: A review. J. Pet. Sci. Eng. 2022, 208, 109569. [Google Scholar] [CrossRef]

- Peng, Y.; Zhao, J.; Sepehrnoori, K.; Li, Z. Fractional model for simulating the viscoelastic behavior of artificial fracture in shale gas. Eng. Fract. Mech. 2020, 228, 106892. [Google Scholar] [CrossRef]

- Dong, R.; Lee, S.; Wheeler, M. Numerical Simulation of Matrix Acidizing in Fractured Carbonate Reservoirs Using Adaptive Enriched Galerkin Method. In Proceedings of the SPE Reservoir Simulation Conference, Galveston, TX, USA, 10–11 April 2019. [Google Scholar] [CrossRef]

- Almutairi, S.H. Effect of Droplet size on the Behavior and Characteristics of Emulsified Acid. Ph.D. Thesis, Texas A&M University, College Station, TX, USA, 2008. [Google Scholar]

- Zhu, D.; Wang, Y.; Cui, M.; Zhou, F.; Wang, Y.; Liang, C.; Zou, H.; Yao, F. Acid System and Stimulation Efficiency of Multistage Acid Fracturing in Porous Carbonate Reservoirs. Processes 2022, 10, 1883. [Google Scholar] [CrossRef]

- Dong, R.; Wheeler, M.F.; Su, H.; Ma, K. Modeling Acid Fracturing Treatments in Heterogeneous Carbonate Reservoirs. In Proceedings of the SPE International Conference on Oilfield Chemistry, The Woodlands, TX, USA, 6–7 December 2021. [Google Scholar] [CrossRef]

- Dong, R.; Wheeler, M.F.; Su, H.; Ma, K. Modeling Acid Fracturing Treatments with Multi-Stage Alternating Injection of Pad and Acid Fluids. In Proceedings of the SPE Reservoir Simulation Conference, Galveston, TX, USA, 4–6 October 2021. [Google Scholar] [CrossRef]

- Quintero, L.; Passanha, W.D.; Aubry, E.; Poitrenaud, H. Advanced Microemulsion Cleaner Fluid Applications in Deepwater Wells. In Proceedings of the OTC Brasil, Rio de Janeiro, Brazil, 27–29 October 2015. [Google Scholar] [CrossRef]

- Quintero, L.; Ponnapati, R.; Felipe, M.J. Cleanup of Organic and Inorganic Wellbore Deposits Using Microemulsion Formulations: Laboratory Development and Field Applications. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 1–4 May 2017. [Google Scholar] [CrossRef]

- Dong, R.; Wheeler, M.F.; Su, H.; Ma, K. Modeling Multistage Acid Fracturing Treatments in Carbonate Reservoirs. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, Virtual, 4–6 May 2021. [Google Scholar] [CrossRef]

- Hu, D.; Guo, R.; Feng, M.; Wang, L.; Wei, L.; Wu, Y.; Luo, Y.; Tian, P. Development Optimisation and Application in a Giant Carbonate Oilfield Under Low Remuneration Fee, Y Oilfield in Iraq. In Proceedings of the International Petroleum Technology Conference, Kuala Lumpur, Malaysia, 10–12 December 2014. [Google Scholar] [CrossRef]

- Peng, Y.; Zhao, J.; Sepehrnoori, K.; Li, Y.; Yu, W.; Zeng, J. Study of the Heat Transfer in the Wellbore During Acid/Hydraulic Fracturing Using a Semianalytical Transient Model. SPE J. 2019, 24, 877–890. [Google Scholar] [CrossRef]

- Xiao, L.; Hou, J.; Wen, Y. Imbibition mechanisms of high temperature resistant microemulsion system in ultra-low permeability and tight reservoir. Pet. Explor. Dev. 2022, 49, 1–11. [Google Scholar] [CrossRef]

- Quintero, L.; Felipe, M.J.; Miller, K.; Ponnapati, R.; Loya, M. Microemulsions Increase Well Productivity by Removing Organic Deposits and Inorganic Scale in One Step. In Proceedings of the SPE International Conference and Exhibition on Formation Damage Control, Lafayette, LA, USA, 19–21 February 2018. [Google Scholar] [CrossRef]

- Aum, P.T.P.; Gurgel Aum, Y.K.P.; de Andrade Araújo, E.; de Almeida Cavalcante, L.; Nobre Nunes da Silva, D.; Regis dos Santos Lucas, C.; de Castro Dantas, T.N. Evaluation of oil-in-water microemulsion base ethoxylated surfactant under acid conditions. Fuel 2021, 290, 120045. [Google Scholar] [CrossRef]

- Dong, R.; Wheeler, M.F.; Ma, K.; Su, H. A 3D Acid Transport Model for Acid Fracturing Treatments with Viscous Fingering. In Proceedings of the SPE Annual Technical Conference and Exhibition, Virtual, 27–29 October 2020. [Google Scholar] [CrossRef]

- Dong, R.; Alpak, F.O.; Wheeler, M.F. Accurate Two-Phase Flow Simulation in Faulted Reservoirs by Combining Two-Point Flux Approximation and Mimetic Finite Difference Methods. SPE J. 2023, 28, 111–129. [Google Scholar] [CrossRef]

- Rabie, A.I.; Gomaa, A.M.; Nasr-El-Din, H.A. Reaction of In-Situ-Gelled Acids With Calcite: Reaction-Rate Study. SPE J. 2011, 16, 981–992. [Google Scholar] [CrossRef]

- Taylor, K.C.; Nasr-El-Din, H.A.; Mehta, S. Anomalous Acid Reaction Rates in Carbonate Reservoir Rocks. SPE J. 2006, 11, 488–496. [Google Scholar] [CrossRef]

- Su, H.; Zhou, F.; Zheng, A.; Wang, L.; Wang, C.; Yu, F.; Kang, L.; Li, J. Heavy Oil Recovery by Alkaline-Cosolvent-Polymer Flood: A Multiscale Research Using Micromodels and Computed Tomography Imaging. SPE J. 2022, 27, 1480–1492. [Google Scholar] [CrossRef]

| Number | Mineral Content/% | Clay Minerals and Content/% | |||

|---|---|---|---|---|---|

| Calcite | Dolomite | Quartz | Clay Minerals | ||

| 1 | 96.8 | 0.0 | 1.4 | 1.8 | Illite 100% |

| 2 | 96.9 | 0.0 | 1.2 | 1.9 | Illite 100% |

| 3 | 97.5 | 0.0 | 1.0 | 1.5 | Illite 100% |

| 4 | 97.8 | 0.0 | 1.1 | 1.1 | Illite 100% |

| 5 | 94.5 | 0.0 | 3.0 | 2.5 | Illite 100% |

| Average | 96.7 | 0.0 | 1.5 | 1.8 | Illite 100% |

| Liquid | Before Reaction/g | After Reaction/g | Dissolution/% |

|---|---|---|---|

| HCl | 2.0731 | 0.1152 | 94.44 |

| S150 | 2.0028 | 1.9945 | 0.41 |

| Emulsified acid | 2.0193 | 0.1540 | 92.37 |

| Microemulsion acid | 2.0249 | 0.1201 | 94.07 |

| Liquid | Before Reaction/g | After Reaction/g | Dissolution/% |

|---|---|---|---|

| HCl | 2.1074 | 2.1024 | 0.24 |

| S150 | 2.0849 | 1.6309 | 21.78 |

| Emulsified acid | 2.1405 | 1.9881 | 7.12 |

| Microemulsion acid | 2.1054 | 1.6839 | 20.02 |

| Liquid | Before Reaction/g | After Reaction/g | Dissolution/% |

|---|---|---|---|

| HCl | 2.0894 | 2.0324 | 2.73 |

| S150 | 2.1142 | 1.0632 | 49.69 |

| Emulsified acid | 2.0149 | 1.6893 | 16.16 |

| Microemulsion acid | 2.0926 | 0.0360 | 98.28 |

| Number | Treating Fluid | Injection Rate/mL/min | PVbt |

|---|---|---|---|

| 1 | HCl | 2 | 7.12 |

| 2 | Emulsified acid | 2 | 6.11 |

| 3 | Microemulsion acid | 2 | 5.14 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Zhou, F.; Zou, Y.; Wang, Z.; Wang, Y. Preparation and Performance Study of Microemulsion Acid for Comprehensive Plugging Removal in Carbonate Reservoir. Molecules 2023, 28, 5606. https://doi.org/10.3390/molecules28145606

Wang Y, Zhou F, Zou Y, Wang Z, Wang Y. Preparation and Performance Study of Microemulsion Acid for Comprehensive Plugging Removal in Carbonate Reservoir. Molecules. 2023; 28(14):5606. https://doi.org/10.3390/molecules28145606

Chicago/Turabian StyleWang, Yunjin, Fujian Zhou, Yeping Zou, Zhenhua Wang, and Yaocong Wang. 2023. "Preparation and Performance Study of Microemulsion Acid for Comprehensive Plugging Removal in Carbonate Reservoir" Molecules 28, no. 14: 5606. https://doi.org/10.3390/molecules28145606

APA StyleWang, Y., Zhou, F., Zou, Y., Wang, Z., & Wang, Y. (2023). Preparation and Performance Study of Microemulsion Acid for Comprehensive Plugging Removal in Carbonate Reservoir. Molecules, 28(14), 5606. https://doi.org/10.3390/molecules28145606