Multiple Technology Approach Based on Stable Isotope Ratio Analysis, Fourier Transform Infrared Spectrometry and Thermogravimetric Analysis to Ensure the Fungal Origin of the Chitosan

Abstract

1. Introduction

2. Results and Discussion

2.1. Characterisation of Fungal and Crustacean Chitosan

2.1.1. Characterisation of Chitosan from Different Origins Using SIR Analysis and Definition of Threshold Limits

2.1.2. Characterisation of Chitosan from Different Origins Using FTIR Analysis

2.1.3. Characterisation of Chitosan from Different Origins Using TGA Analysis

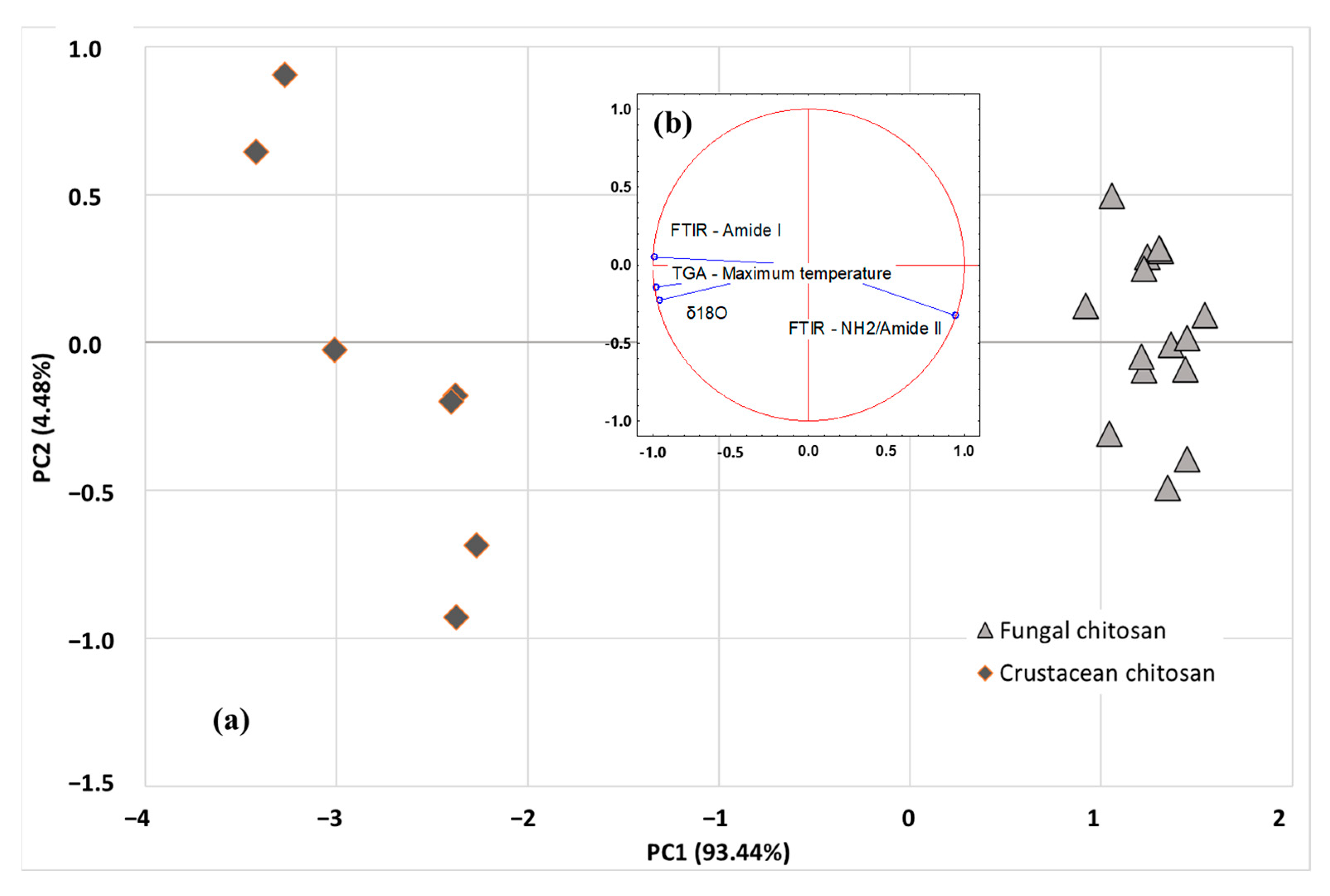

2.2. Discrimination and Clustering Based on the Origin of Chitosan

3. Materials and Methods

3.1. Sampling

3.2. Stable Isotope Analysis

3.3. Thermogravimetric Analysis

3.4. Fourier Transform Infrared Analysis

3.5. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Yang, Q.; Fukamizo, T. Targeting Chitin-Containing Organisms; Springer: Berlin/Heidelberg, Germany, 2019; ISBN 9789811373183. [Google Scholar]

- Santos, V.P.; Marques, N.S.; Maia, P.C.; Lima, M.A.B.D.; Franco, L.D.O.; Campos-Takaki, G.M.D. Seafood Waste as Attractive Source of Chitin and Chitosan Production and Their Applications. Int. J. Mol. Sci. 2020, 21, 4290. [Google Scholar] [CrossRef] [PubMed]

- Abo Elsoud, M.M.; El Kady, E.M. Current Trends in Fungal Biosynthesis of Chitin and Chitosan. Bull. Natl. Res. Cent. 2019, 43, 59. [Google Scholar] [CrossRef]

- Mujtaba, M.; Khawar, K.M.; Camara, M.C.; Carvalho, L.B.; Fraceto, L.F.; Morsi, R.E.; Elsabee, M.Z.; Kaya, M.; Labidi, J.; Ullah, H.; et al. Chitosan-Based Delivery Systems for Plants: A Brief Overview of Recent Advances and Future Directions. Int. J. Biol. Macromol. 2020, 154, 683–697. [Google Scholar] [CrossRef] [PubMed]

- Rabea, E.I.; Badawy, M.E.-T.; Stevens, C.V.; Smagghe, G.; Steurbaut, W. Chitosan as Antimicrobial Agent: Applications and Mode of Action. Biomacromolecules 2003, 4, 1457–1465. [Google Scholar] [CrossRef]

- Rinaudo, M. Chitin and Chitosan: Properties and Applications. Prog. Polym. Sci. 2006, 31, 603–632. [Google Scholar] [CrossRef]

- Rocha, M.A.M.; Coimbra, M.A.; Nunes, C. Applications of Chitosan and Their Derivatives in Beverages: A Critical Review. Curr. Opin. Food Sci. 2017, 15, 61–69. [Google Scholar] [CrossRef]

- International Code of Oenological Practices OIV/OENO, 338A/2009; Chitosan Monography. Organisation Internationale de la vigne et du vin: Dijon, France, 2009.

- International Code of Oenological Practices OIV/OENO, 337A/2009; Wines—Fining Using Chitosan. Organisation Internationale de la vigne et du vin: Dijon, France, 2009.

- International Code of Oenological Practices OIV/OENO 336A/2009; Musts—Fining Using Chitosan. Organisation Internationale de la vigne et du vin: Dijon, France, 2009.

- International Organisation of Vine and Wine. Monograph on Chitosan (No. Resolution OIV/OENO 368/2009). 2017. Available online: http://www.oiv.int/public/medias/5119/code-2017-En.pdf (accessed on 13 February 2023).

- Pellis, A.; Guebitz, G.M.; Nyanhongo, G.S. Chitosan: Sources, Processing and Modification Techniques. Gels 2022, 8, 393. [Google Scholar] [CrossRef]

- Perini, M.; Nardin, T.; Venturelli, M.; Pianezze, S.; Larcher, R. Stable Isotope Ratio Analysis as a Fast and Simple Method for Identifying the Origin of Chitosan. Food Hydrocol. 2020, 101, 105516. [Google Scholar] [CrossRef]

- Christou, C.; Agapiou, A.; Kokkinofta, R. Use of FTIR Spectroscopy and Chemometrics for the Classification of Carobs Origin. J. Advert. Res. 2018, 10, 1–8. [Google Scholar] [CrossRef]

- Gad, H.A.; Bouzabata, A. Application of Chemometrics in Quality Control of Turmeric (Curcuma longa) Based on Ultra-Violet, Fourier Transform-Infrared and 1H NMR Spectroscopy. Food Chem. 2017, 237, 857–864. [Google Scholar] [CrossRef]

- Guc, S.; Erkmen, O. Citric Acid Production from Nontreated Beet Molasses by a Novel Aspergillus niger Strain: Effects of pH, Sugar and Ingredients. J. Food Microbiol. Saf. Hyg. 2017, 2, 3. [Google Scholar] [CrossRef]

- O’Leary, M.H. Carbon Isotopes in Photosynthesis. Bioscience 1988, 38, 328–336. [Google Scholar] [CrossRef]

- Hassainia, A.; Satha, H.; Sami, B. Two Routes to Produce Chitosan from Agaricus Bisporus. J. Renew. Mater. 2020, 8, 101–111. [Google Scholar] [CrossRef]

- Chakravarty Bipasha Trends in Mushroom Cultivation and Breeding. Aust. J. Agric. Res. 2011, 2, 102–109.

- Zivanovic, S. Identification of Opportunities for Production of Ingredients Based on Further Processed Fresh Mushrooms, off-Grade Mushrooms, Bi-Products, and Waste; Mushroom Council: Knoxville, TN, USA; University of Tennessee: Knoxville, TN, USA, 2006. [Google Scholar]

- Wu, T.; Zivanovic, S.; Draughon, F.A.; Sams, C.E. Chitin and Chitosan--Value-Added Products from Mushroom Waste. J. Agric. Food Chem. 2004, 52, 7905–7910. [Google Scholar] [CrossRef]

- Zicari, G.; Rivetti, D.; Soardo, V.; Cerrato, E. The Cultivation of the Mushroom Agaricus bisporus (Champignon) and Some Environmental and Health Aspects. Ig. Sanita Pubbl. 2012, 68, 435–446. [Google Scholar]

- Inácio, C.T.; Chalk, P.M.; Magalhães, A.M.T. Principles and Limitations of Stable Isotopes in Differentiating Organic and Conventional Foodstuffs: 1. Plant Products. Crit. Rev. Food Sci. Nutr. 2015, 55, 1206–1218. [Google Scholar] [CrossRef]

- Nielson, K.E.; Bowen, G.J. Hydrogen and Oxygen in Brine Shrimp Chitin Reflect Environmental Water and Dietary Isotopic Composition. Geochim. Cosmochim. Acta 2010, 74, 1812–1822. [Google Scholar] [CrossRef]

- Sodemann, H. Tropospheric Transport of Water Vapour: Lagrangian and Eulerian Perspectives; Logos Verlag: Berlin, Germany, 2006; ISBN 9783832513849. [Google Scholar]

- Reverdin, G.; Waelbroeck, C.; Pierre, C.; Akhoudas, C.; Aloisi, G.; Benetti, M.; Bourlès, B.; Danielsen, M.; Demange, J.; Diverrès, D.; et al. The CISE-LOCEAN Seawater Isotopic Database (1998–2021). Earth Syst. Sci. Data 2022, 14, 2721–2735. [Google Scholar] [CrossRef]

- Cardenas, G.; Patricia Miranda, S. FTIR and TGA studies of chitosan composite films. J. Chil. Chem. 2004, 49, 291–295. [Google Scholar] [CrossRef]

- Duarte, M.L.; Ferreira, M.C.; Marvão, M.R.; Rocha, J. An Optimised Method to Determine the Degree of Acetylation of Chitin and Chitosan by FTIR Spectroscopy. Int. J. Biol. Macromol. 2002, 31, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Kaya, M.; Akata, I.; Baran, T.; Menteş, A. Physicochemical Properties of Chitin and Chitosan Produced from Medicinal Fungus (Fomitopsis pinicola). Food Biophys. 2015, 10, 162–168. [Google Scholar] [CrossRef]

- Pearson, F.G.; Marchessault, R.H.; Liang, C.Y. Infrared Spectra of Crystalline Polysaccharides. V. Chitin. J. Polym. Sci. 1960, 43, 101–116. [Google Scholar] [CrossRef]

- Khodaei, S.; Ghaedmohammadi, S.; Mohammadi, M.; Rigi, G.; Ghahremanifard, P.; Zadmard, R.; Ahmadian, G. Covalent Immobilization of Protein A on Chitosan and Aldehyde Double-Branched Chitosan as Biocompatible Carriers for Immunoglobulin G (Igg) Purification. J. Chromatogr. Sci. 2018, 56, 933–940. [Google Scholar] [CrossRef] [PubMed]

- Pawlak, A.; Mucha, M. Thermogravimetric and FTIR Studies of Chitosan Blends. Thermochim. Acta 2003, 396, 153–166. [Google Scholar] [CrossRef]

- Corazzari, I.; Nisticò, R.; Turci, F.; Faga, M.G.; Franzoso, F.; Tabasso, S.; Magnacca, G. Advanced Physico-Chemical Characterization of Chitosan by Means of TGA Coupled on-Line with FTIR and GCMS: Thermal Degradation and Water Adsorption Capacity. Polym. Degrad. Stab. 2015, 112, 1–9. [Google Scholar] [CrossRef]

- Diab, M.A.; El-Sonbati, A.Z.; Bader, D.M.D. Thermal Stability and Degradation of Chitosan Modified by Benzophenone. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2011, 79, 1057–1062. [Google Scholar] [CrossRef]

- Abdou, E.S.; Nagy, K.S.A.; Elsabee, M.Z. Extraction and Characterization of Chitin and Chitosan from Local Sources. Bioresour. Technol. 2008, 99, 1359–1367. [Google Scholar] [CrossRef]

- Szymańska, E.; Winnicka, K. Stability of Chitosan—A Challenge for Pharmaceutical and Biomedical Applications. Mar. Drugs 2015, 13, 1819–1846. [Google Scholar] [CrossRef]

- de Britto, D.; de Britto, D.; Campana-Filho, S.P. Kinetics of the Thermal Degradation of Chitosan. Thermochim. Acta 2007, 465, 73–82. [Google Scholar] [CrossRef]

- Romano, P.; Fabritius, H.; Raabe, D. The Exoskeleton of the Lobster Homarus Americanus as an Example of a Smart Anisotropic Biological Material. Acta Biomater. 2007, 3, 301–309. [Google Scholar] [CrossRef] [PubMed]

- Coplen, T.B. Guidelines and Recommended Terms for Expression of Stable-Isotope-Ratio and Gas-Ratio Measurement Results. Rapid Commun. Mass Spectrom. 2011, 25, 2538–2560. [Google Scholar] [CrossRef] [PubMed]

- Wassenaar, L.I.; Hobson, K.A.; Sisti, L. An Online Temperature-Controlled Vacuum-Equilibration Preparation System for the Measurement of δ2H Values of Non-Exchangeable-H and of δ18O Values in Organic Materials by Isotope-Ratio Mass Spectrometry. Rapid Commun. Mass Spectrom. 2015, 29, 397–407. [Google Scholar] [CrossRef] [PubMed]

- Wassenaar, L.I.; Hobson, K.A. Comparative Equilibration and Online Technique for Determination of Non-Exchangeable Hydrogen of Keratins for Use in Animal Migration Studies. Isot. Environ. Health Stud. 2003, 39, 211–217. [Google Scholar] [CrossRef]

| Origin | Fungal Strain/ Crustacean Species | Sample | Viscosity (cP) (1% in 1% Acetic Acid) | Degree of Deacetylation (%) | δ13C (‰, vs. V-PDB) | δ15N (‰, vs. V-PDB) | δ18O (‰, vs. V-SMOW) | δ2H (‰, vs. V-SMOW) | TGA Parameters | FTIR Parameters | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max Temperature of Degradation (DTGmax (°C)) | Weight Loss (%) | Peak Area (A.cm−1) | ||||||||||

| Amide I (1655 cm−1) | NH2/Amide II (1600 cm−1) | |||||||||||

| Fungal chitosan | A. bisporus | FC3-1 | 19.5 | 84.7 | −25.3 | 5.0 | 22.0 | 16.5 | ||||

| FC3-2 | 19.5 | 84.7 | −25.2 | 5.2 | 22.4 | 14.1 | ||||||

| FC3-3 | 19.5 | 84.7 | −25.2 | 5.2 | 24.3 | 2.7 | ||||||

| FC3-4 | 19.5 | 84.7 | −25.2 | 5.2 | 24.3 | 3.7 | ||||||

| FC3-5 | 13.9 | 84.9 | −25.4 | 4.1 | 24.1 | 1.1 | ||||||

| FC3-6 | 17.1 | 84.2 | −25.3 | 4.8 | 24.2 | 2.8 | ||||||

| FC3-7 | 21.4 | 83.2 | −25.5 | 5.1 | 24.3 | 2.6 | ||||||

| FC3-8 | 21.4 | 83.2 | −25.6 | 5.1 | 24.4 | 2.6 | ||||||

| FC3-9 | 20.8 | 84.2 | −24.8 | 3.7 | 24.8 | 2.2 | ||||||

| A. niger | FC3-10 | nd | nd | −25.6 | 3.0 | 24.3 | −31.0 | |||||

| A. niger | FC3-11 | nd | nd | −25.6 | 2.9 | 24.7 | −25.9 | |||||

| Mean | −25.3 | 4.5 | ||||||||||

| SD | 0.2 | 0.9 | ||||||||||

| Min | −25.6 | 2.9 | ||||||||||

| Max | −24.8 | 5.2 | ||||||||||

| Low Limit 95% | −25.8 | 2.7 | ||||||||||

| High Limit 95% | −24.9 | 6.3 | ||||||||||

| A. niger | FC4-1 | <15 | >70 | −13.7 | −6.0 | 23.7 | −33.3 | 282.9 | 57.7 | 3.4 | 3.7 | |

| FC4-2 | <15 | >70 | −13.8 | −6.9 | 24.8 | −34.0 | 281.1 | 62.5 | 3.0 | 4.1 | ||

| FC4-3 | <15 | >70 | −13.7 | −6.3 | 23.8 | −34.0 | 279.0 | 60.7 | 2.8 | 4.2 | ||

| FC4-4 | <15 | >70 | −13.7 | −6.7 | 23.5 | −34.1 | 279.0 | 60.2 | 3.1 | 3.7 | ||

| FC4-5 | <15 | >70 | −13.7 | −5.9 | 23.8 | −32.3 | 283.6 | 60.7 | 2.8 | 4.6 | ||

| FC4-6 | <15 | >70 | −13.7 | −6.9 | 23.7 | −34.2 | 281.6 | 59.5 | 2.9 | 4.6 | ||

| FC4-7 | <15 | >70 | −13.6 | −5.8 | 23.6 | −31.9 | 277.7 | 60.6 | 3.0 | 3.7 | ||

| FC4-8 | <15 | >70 | −13.7 | −6.7 | 24.1 | −34.4 | 277.7 | 64.2 | 2.8 | 3.6 | ||

| FC4-9 | <15 | >70 | −13.6 | −6.7 | 24.4 | −32.6 | 279.0 | 59.8 | 2.9 | 4.0 | ||

| FC4-10 | <15 | >70 | −13.6 | −6.8 | 22.9 | −27.2 | 280.3 | 59.5 | 3.2 | 3.8 | ||

| FC4-11 | 2.1 | 80.0 | −13.6 | −6.7 | 23.0 | −26.1 | 283.6 | 54 | 3.4 | 4.2 | ||

| FC4-12 | 3.0 | 82.0 | −13.7 | −6.3 | 22.7 | −27.5 | 279.7 | 59.4 | 3.3 | 4.3 | ||

| FC4-13 | 3.1 | 81.0 | −13.7 | −6.8 | 22.9 | −28.4 | 281.0 | 60.8 | 3.6 | 3.5 | ||

| FC4-14 | 2.5 | 81.0 | −13.6 | −6.6 | 23.0 | −26.2 | 281.0 | 58.7 | 3.5 | 4.3 | ||

| FC4-15 | 2.5 | 85.0 | −13.6 | −6.8 | 22.6 | −29.9 | 282.3 | 59.4 | 3.2 | 4.3 | ||

| FC4-16 | <15 | >70 | −13.8 | −4.8 | 22.8 | 7.6 | ||||||

| FC4-17 | <15 | >70 | −12.9 | −8.1 | 25.1 | 4.0 | ||||||

| FC4-18 | <15 | >70 | −14.2 | −7.2 | 22.7 | −16.9 | ||||||

| FC4-19 | <15 | >70 | −14.0 | −5.5 | 22.1 | −17.1 | ||||||

| FC4-20 | <15 | >70 | −13.2 | −5.5 | 23.6 | 26.6 | ||||||

| FC4-21 | <15 | >70 | −13.2 | −6.0 | 22.9 | 18.2 | ||||||

| FC4-22 | <15 | >70 | −13.7 | −6.4 | 22.7 | −28.7 | ||||||

| Mean | −13.6 | −6.4 | 23.6 | −14.6 | 280.6 | 59.7 | 3.2 | 4.0 | ||||

| SD | 0.3 | 0.7 | 0.8 | 19.6 | 1.9 | 2.3 | 0.5 | 0.5 | ||||

| Min | −14.2 | −8.1 | 22.0 | −34.4 | 277.7 | 54 | 2.8 | 2.5 | ||||

| Max | −12.9 | −4.8 | 25.1 | 26.6 | 283.6 | 64.2 | 5.0 | 4.6 | ||||

| Low Limit 95% | −14.2 | −7.8 | 21.9 | −53.8 | 276.8 | 55.1 | 2.2 | 3 | ||||

| High Limit 95% | −13.1 | −5.0 | 25.3 | 24.6 | 284.4 | 64.3 | 4.2 | 5 | ||||

| Crustacean chitosan | Shrimp | CC-1 | 55.0 | 83.0 | −20.7 | −5.4 | 27.9 | 20.3 | 300.2 | 68.3 | 7.1 | 2.0 |

| Shrimp | CC-2 | 55.0 | 83.0 | −20.7 | −5.5 | 28.0 | 22.4 | 300.2 | 68.3 | 7.1 | 2.0 | |

| Shrimp | CC-3 | NA | ≥75 | −21.3 | −4.5 | 27.9 | 27.8 | 299.9 | 60.3 | 8.2 | 0.3 | |

| Shrimp | CC-4 | >200 | ≥75 | −21.2 | −4.5 | 28.6 | 22.9 | 301.2 | 60.8 | 8.1 | 0.4 | |

| Shrimp | CC-5 | <200 | nd | −21.4 | −4.3 | 28.7 | 25.1 | 299.9 | 68.1 | 8.5 | 1.6 | |

| Crab | CC-6 | 148.0 | 90.0 | −20.1 | −1.0 | 29.3 | 30.1 | 301.8 | 62.8 | 6.5 | 2.6 | |

| Shrimp | CC-7 | 78.0 | 89.0 | −24.6 | −5.7 | 29.3 | 26.1 | 297.3 | 66.1 | 6.9 | 2.5 | |

| Squid | CC-8 | 3050.0 | 95.0 | −17.3 | −2.9 | 26.5 | 24.4 | |||||

| Crab | CC-9 | 55.0 | 91.5 | −19.1 | −0.3 | 27.3 | 24.2 | |||||

| Shrimp | CC-10 | 140.0 | 90.1 | −24.4 | −4.5 | 26.1 | 3.7 | |||||

| Squid | CC-11 | 2900.0 | 95.0 | −17.2 | −2.6 | 25.4 | 23.4 | |||||

| Shrimp | CC-12 | 164.0 | 88.0 | −21.7 | −4.3 | 29.6 | 29.4 | |||||

| Crab | CC-13 | >400 | nd | −19.9 | 0.0 | 29.8 | 30.9 | |||||

| Shrimp | CC-14 | <200 | nd | −22.1 | −4.1 | 28.8 | 24.8 | |||||

| Shrimp | CC-15 | >200 | ≥75 | −21.6 | −3.9 | 28.8 | 22.1 | |||||

| Crab | CC-16 | 20–300 | ≥75 | −22.0 | −4.3 | 28.9 | 29.4 | |||||

| Squid | CC-17 | nd | nd | −22.7 | −3.3 | 26.0 | 8.2 | |||||

| Mean | −21.1 | −3.6 | 28.1 | 23.2 | 299.5 | 63 | 7.5 | 1.6 | ||||

| SD | 2.0 | 1.7 | 1.4 | 7.2 | 1.9 | 5 | 2.9 | 1.1 | ||||

| Min | −24.6 | −5.7 | 25.4 | 3.7 | 296.6 | 54.5 | 6.5 | 0.3 | ||||

| Max | −17.2 | 0.0 | 29.8 | 30.9 | 301.8 | 68.3 | 8.5 | 2.6 | ||||

| Low Limit 95% | −25.1 | −7.0 | 25.4 | 8.8 | 295.7 | 53 | 1.7 | −0.6 | ||||

| High Limit 95% | −17.0 | −0.1 | 30.8 | 37.7 | 303.3 | 73 | 13.3 | 3.8 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Claverie, E.; Perini, M.; Onderwater, R.C.A.; Pianezze, S.; Larcher, R.; Roosa, S.; Yada, B.; Wattiez, R. Multiple Technology Approach Based on Stable Isotope Ratio Analysis, Fourier Transform Infrared Spectrometry and Thermogravimetric Analysis to Ensure the Fungal Origin of the Chitosan. Molecules 2023, 28, 4324. https://doi.org/10.3390/molecules28114324

Claverie E, Perini M, Onderwater RCA, Pianezze S, Larcher R, Roosa S, Yada B, Wattiez R. Multiple Technology Approach Based on Stable Isotope Ratio Analysis, Fourier Transform Infrared Spectrometry and Thermogravimetric Analysis to Ensure the Fungal Origin of the Chitosan. Molecules. 2023; 28(11):4324. https://doi.org/10.3390/molecules28114324

Chicago/Turabian StyleClaverie, Elodie, Matteo Perini, Rob C. A. Onderwater, Silvia Pianezze, Roberto Larcher, Stéphanie Roosa, Bopha Yada, and Ruddy Wattiez. 2023. "Multiple Technology Approach Based on Stable Isotope Ratio Analysis, Fourier Transform Infrared Spectrometry and Thermogravimetric Analysis to Ensure the Fungal Origin of the Chitosan" Molecules 28, no. 11: 4324. https://doi.org/10.3390/molecules28114324

APA StyleClaverie, E., Perini, M., Onderwater, R. C. A., Pianezze, S., Larcher, R., Roosa, S., Yada, B., & Wattiez, R. (2023). Multiple Technology Approach Based on Stable Isotope Ratio Analysis, Fourier Transform Infrared Spectrometry and Thermogravimetric Analysis to Ensure the Fungal Origin of the Chitosan. Molecules, 28(11), 4324. https://doi.org/10.3390/molecules28114324