Potential of Staphylea holocarpa Wood for Renewable Bioenergy

Abstract

1. Introduction

2. Results and Discussion

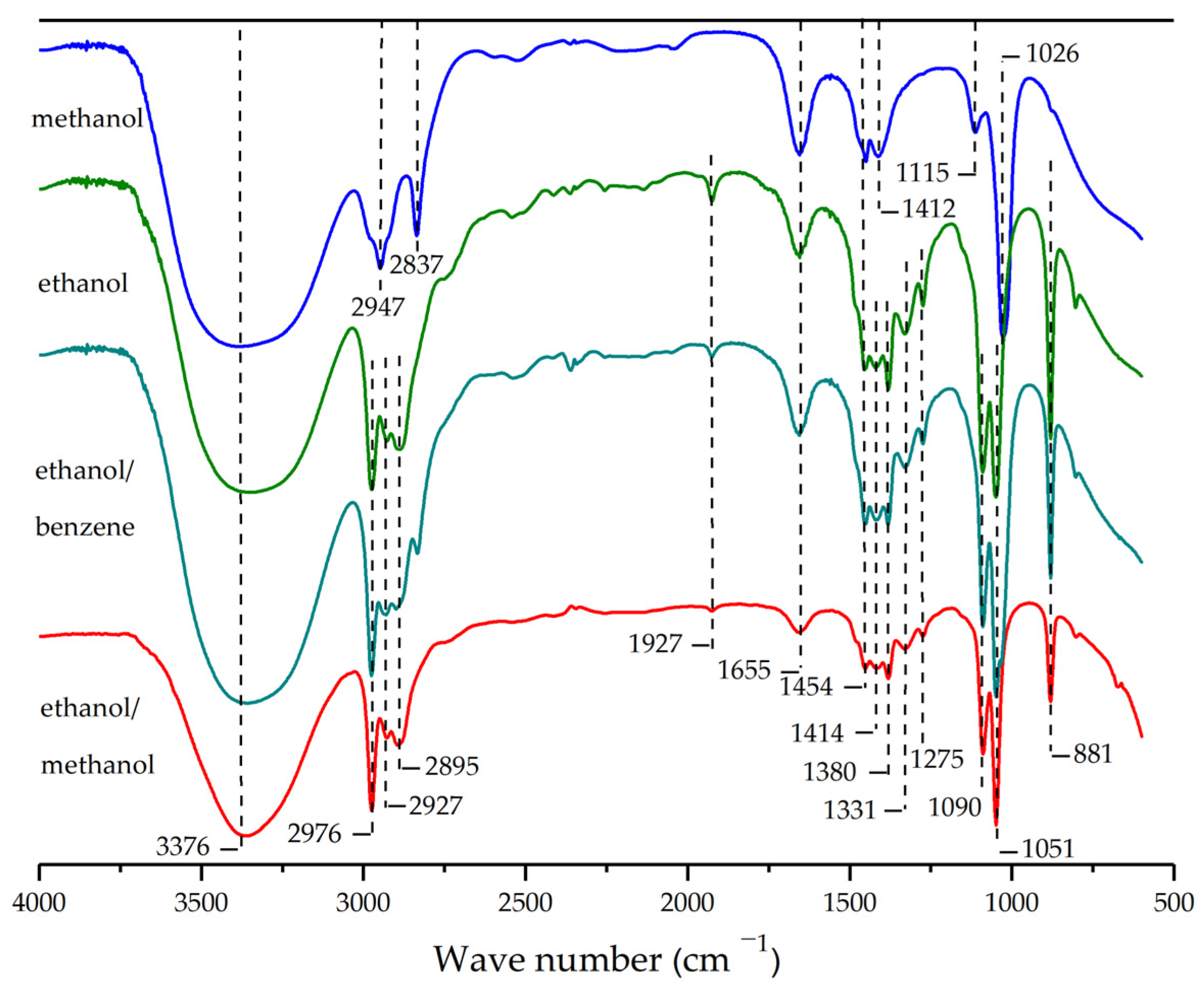

2.1. FT–IR Analysis

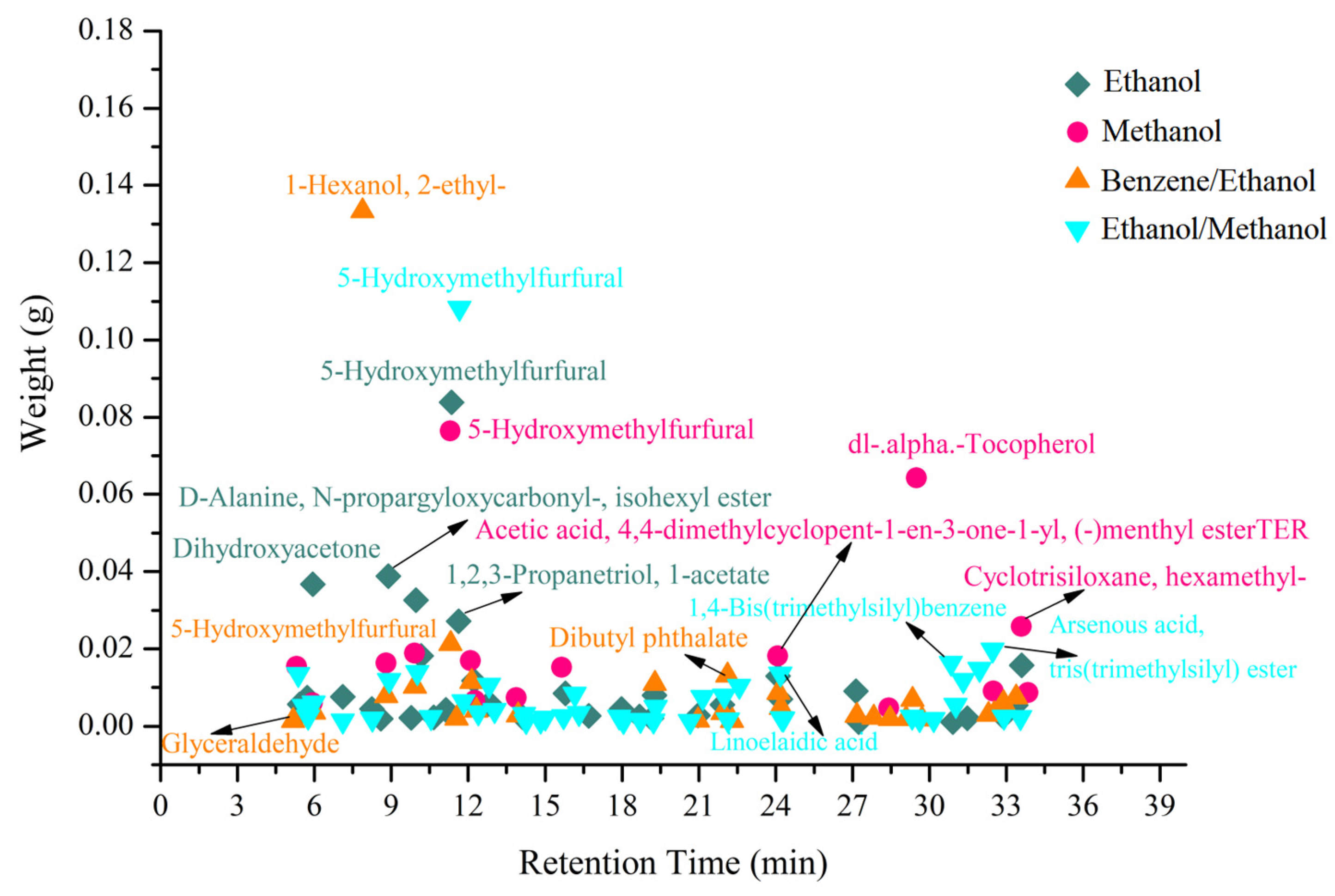

2.2. GC–MS Analysis

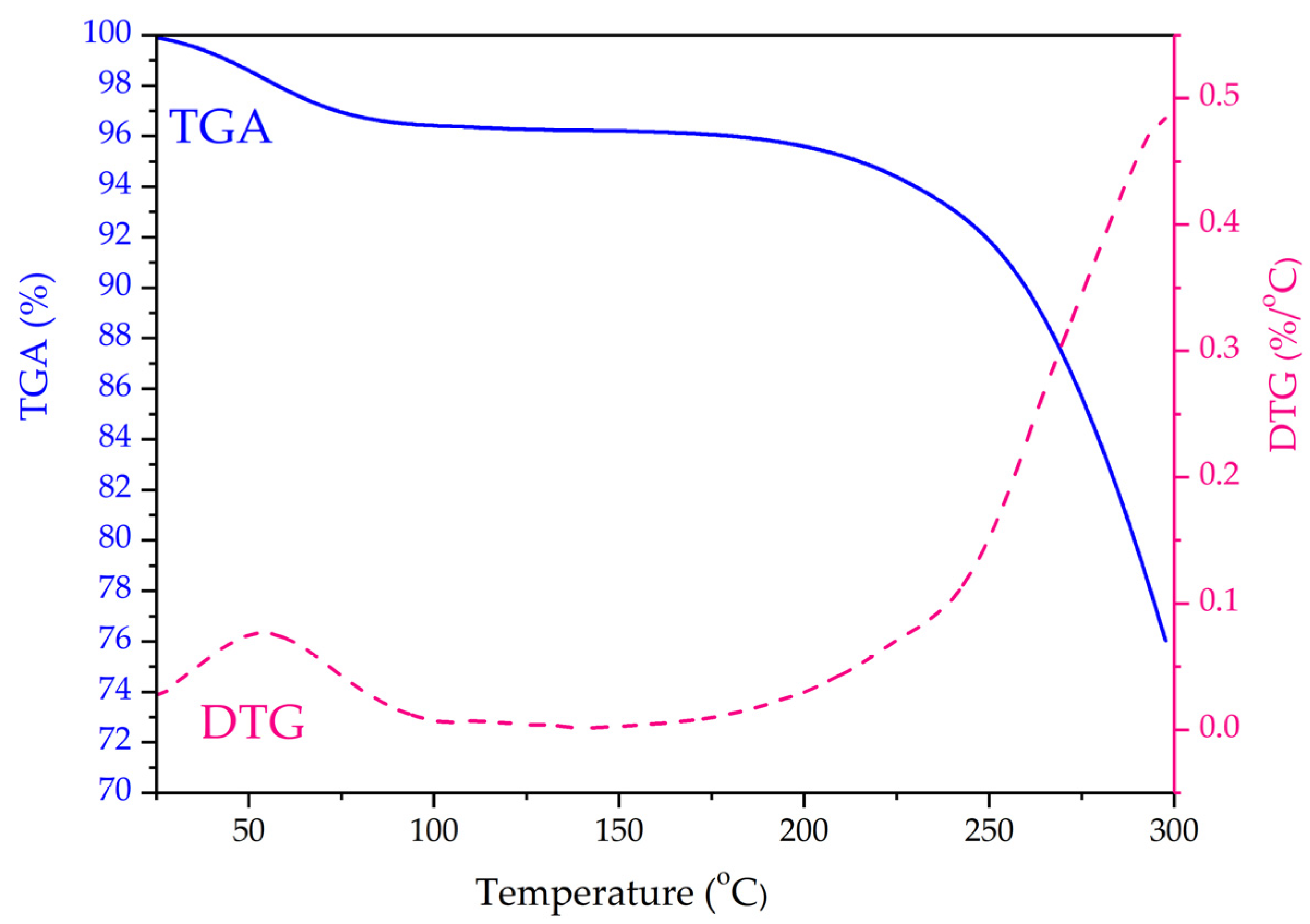

2.3. TGA Analysis

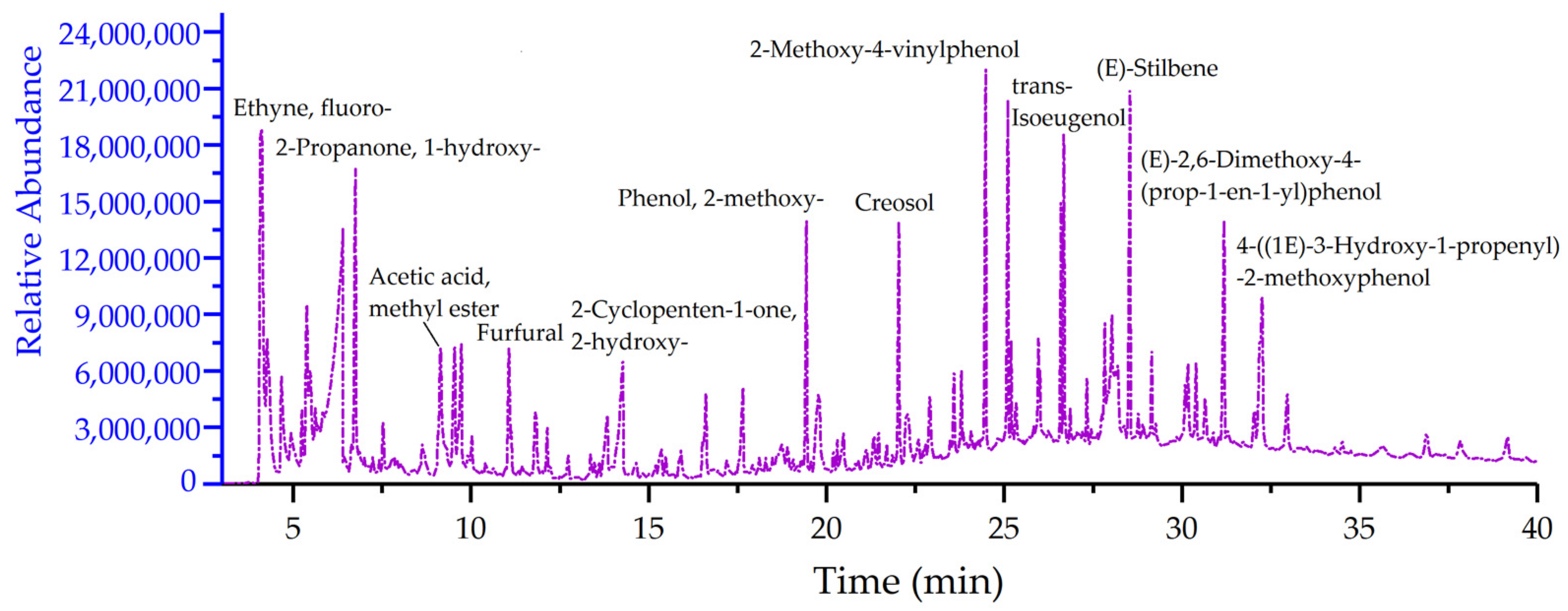

2.4. Py/GC–MS Analysis

2.5. NMR Analysis

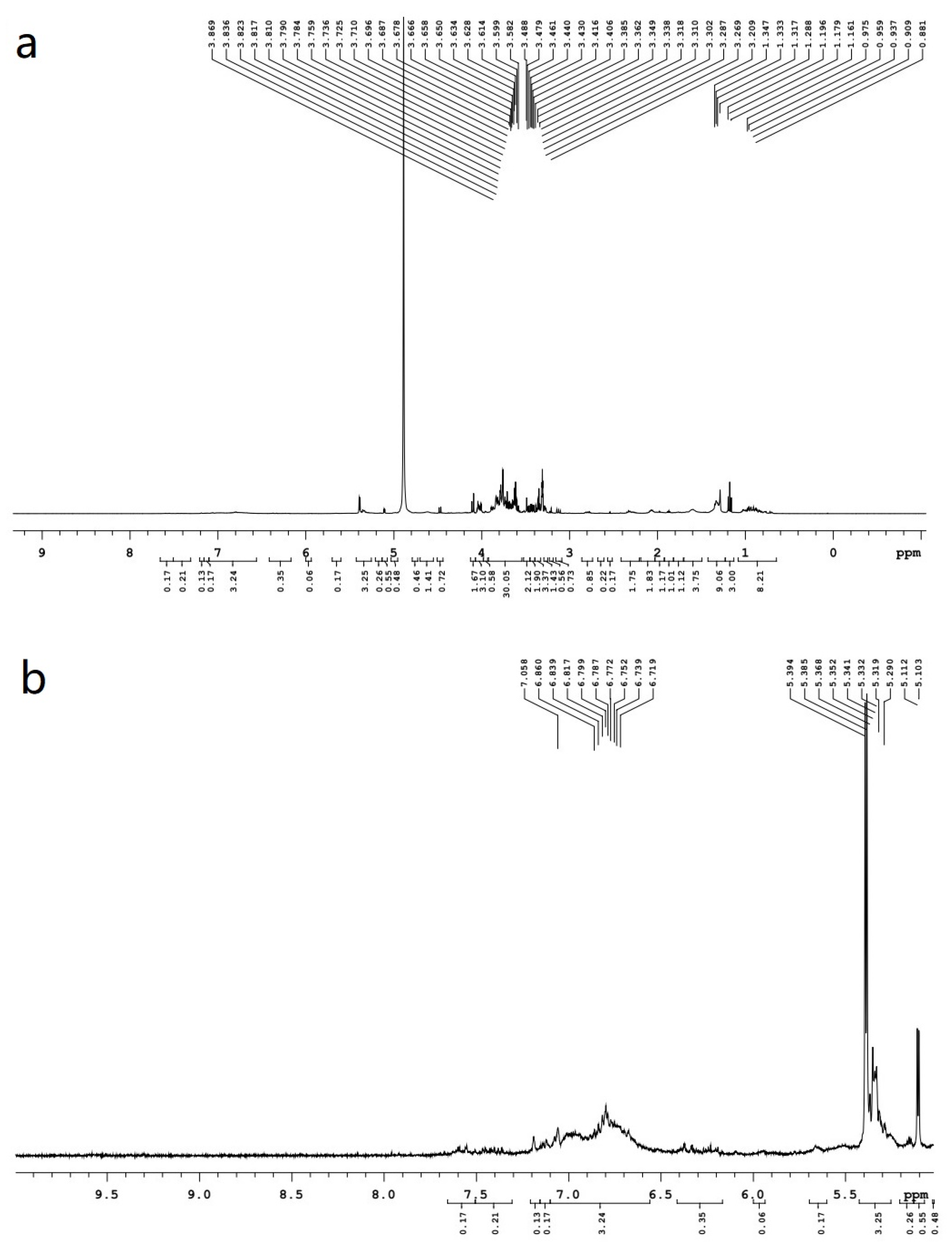

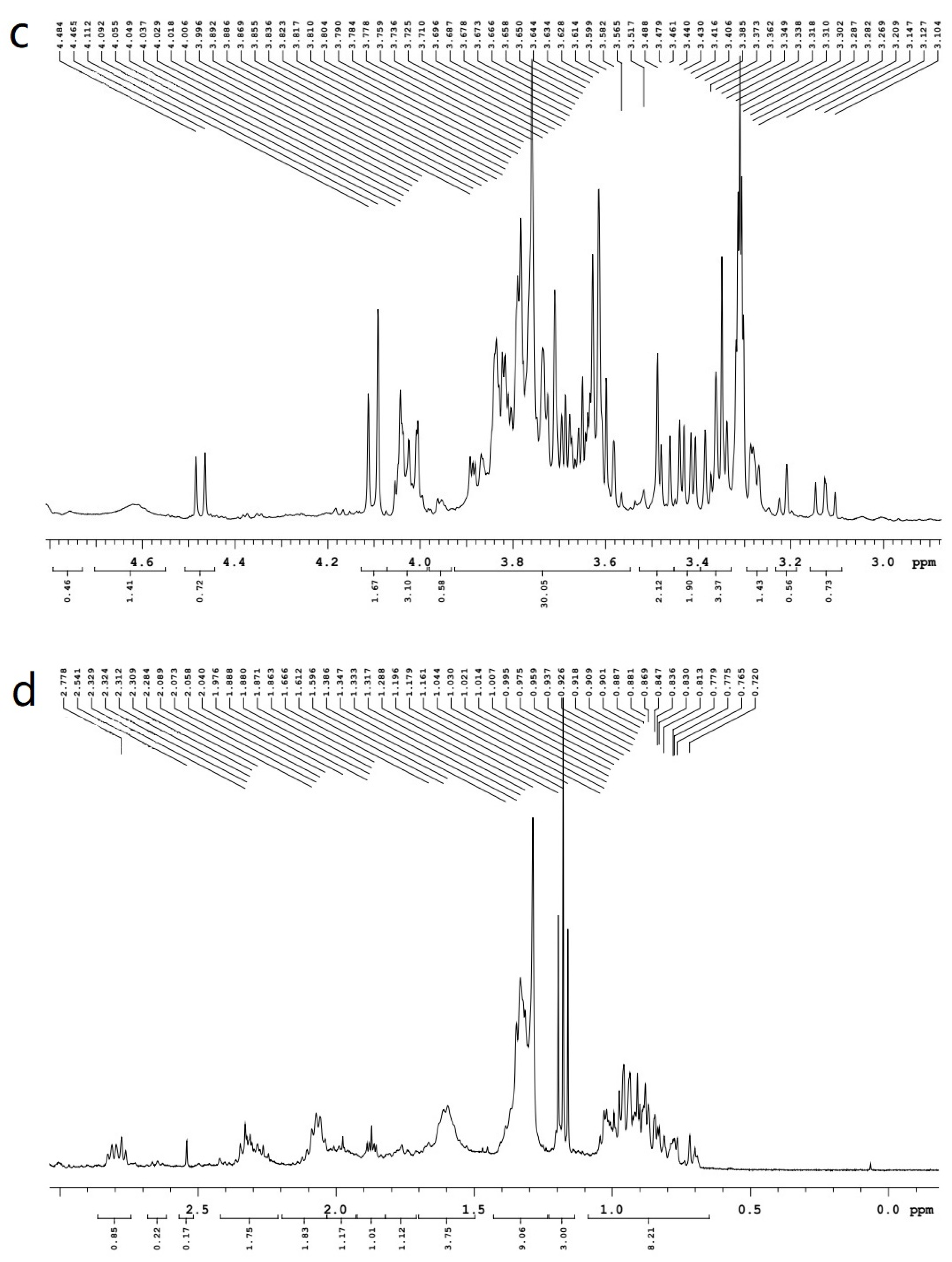

2.5.1. 1H–NMR Analysis

2.5.2. 13C–NMR Analysis

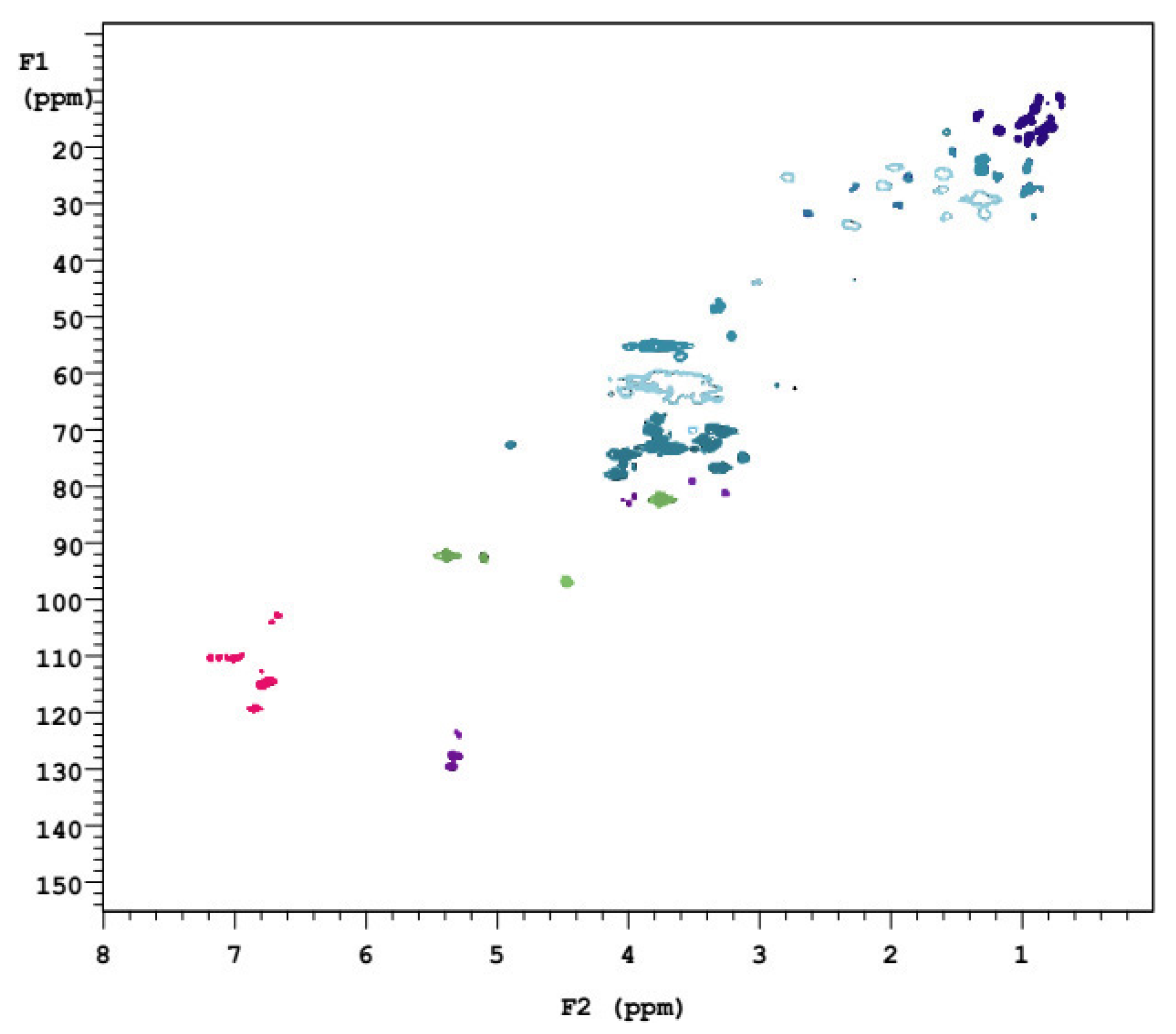

2.5.3. 2D–HSQC Analysis

3. Material and Methods

3.1. Sources of Sample and Extractives

3.2. Experiment Methods

3.2.1. FT–IR Analysis

3.2.2. GC–MS Analysis

3.2.3. TGA Analysis

3.2.4. Py/GC–MS Analysis

3.2.5. NMR Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Miao, C.; Fang, D.; Sun, L.; Luo, Q. Natural resources utilization efficiency under the influence of green technological innovation. Resour. Conserv. Recycl. 2017, 126, 153–161. [Google Scholar] [CrossRef]

- Lee, C.C.; Xing, W. The impact of energy security on income inequality: The key role of economic development. Energy 2022, 248, 123564. [Google Scholar] [CrossRef]

- Saidi, M.; Safaripour, M. Pure hydrogen and propylene coproduction in catalytic membrane reactor-assisted propane dehydrogenation. Chem. Eng. Technol. 2020, 43, 1402–1415. [Google Scholar] [CrossRef]

- Skytt, T.; Nielsen, S.N.; Fröling, M. Energy flows and efficiencies as indicators of regional sustainability-A case study of Jämtland. Sweden. Ecol. Indicat. 2019, 100, 74–98. [Google Scholar] [CrossRef]

- Fatma, S.; Hameed, A.; Noman, M.; Ahmed, T.; Shahid, M.; Tariq, M.; Sohail, I.; Tabassum, R. Lignocellulosic biomass: A sustainable bioenergy source for the future. Protein Pept. Lett. 2018, 25, 148–163. [Google Scholar] [CrossRef]

- Nikolaidis, P.; Poullikkas, A. A comparative overview of hydrogen production processes. Renew. Sustain Energy Rev. 2017, 67, 597–611. [Google Scholar] [CrossRef]

- World Bioenergy Association (WBA). Global Bioenergy Statistics. 2019. Available online: https://www.worldbioenergy.org (accessed on 10 November 2022).

- Vries, W.; de Jong, A.; Kros, J.; Spijker, J. The use of soil nutrient balances in deriving forest biomass harvesting guidelines specific to region, tree species and soil type in The Netherlands. For Ecol. Manag. 2021, 479, 118591. [Google Scholar] [CrossRef]

- Szulecka, J. Towards Sustainable Wood-Based Energy: Evaluation and Strategies for Mainstreaming Sustainability in the Sector. Sustainability 2019, 11, 493. [Google Scholar] [CrossRef]

- Masum, M.F.H.; Sahoo, K.; Dwivedi, P. Ascertaining the Trajectory of Wood-Based Bioenergy Development in the United States Based on Current Economic, Social, and Environmental Constructs. Annu. Rev. Resour. Econ. 2019, 11, 169–193. [Google Scholar] [CrossRef]

- Menucelli, J.R.; Amorim, E.P.; Freitas, M.L.M.; Zanata, M.; Cambuim, J.; de Moraes, M.L.T.; Yamaji, F.M.; da Silva, F.G.; Longui, E.L. Potential of Hevea brasiliensis Clones, Eucalyptus pellita and Eucalyptus tereticornis Wood as Raw Materials for Bioenergy Based on Higher Heating Value. BioEnerg. Res. 2019, 12, 992–999. [Google Scholar] [CrossRef]

- Silva, M.O.D.; da Silva, M.G.; Bufalino, L.; de Assis, M.R.; Goncalves, D.D.; Trugilho, P.F.; Protasio, T.D. Variations in productivity and wood properties of Amazonian tachi-branco trees planted at different spacings for bioenergy purposes. J. Forestry Res. 2021, 32, 211–224. [Google Scholar] [CrossRef]

- Buss, J.; Mansuy, N.; Laganiere, J.; Persson, D. Greenhouse gas mitigation potential of replacing diesel fuel with wood-based bioenergy in an arctic Indigenous community: A pilot study in Fort McPherson, Canada. Biomass Bioenerg. 2022, 159, 106367. [Google Scholar] [CrossRef]

- Morales-Maximo, M.; Ruiz-Garcia, V.M.; Lopez-Sosa, L.B.; Rutiaga-Quinones, J.G. Exploitation of Wood Waste of Pinus spp. for Briquette Production: A Case Study in the Community of San Francisco Pichataro, Michoacan, Mexico. Appl. Sci. 2020, 10, 2933. [Google Scholar] [CrossRef]

- Bian, H.; Chen, L.; Dong, M.; Fu, Y.; Wang, R.; Zhou, X.; Wang, X.; Xu, J.; Dai, H. Cleaner production of lignocellulosic nanofibrils: Potential of mixed enzymatic treatment. J. Clean. Prod. 2020, 270, 122506. [Google Scholar] [CrossRef]

- Parakh, P.D.; Nanda, S.; Kozinski, J.A. Eco-friendly transformation of waste biomass to biofuels. Curr. Biochem. Eng. 2020, 6, 120–134. [Google Scholar] [CrossRef]

- Wang, S.; Dai, G.; Yang, H.; Luo, Z. Lignocellulosic biomass pyrolysis mechanism: A state-of-the-art review. Prog. Energy Combust. Sci. 2017, 62, 33–86. [Google Scholar] [CrossRef]

- Valdivia, M.; Galan, J.L.; Laffarga, J.; Ramos, J.L. Biofuels 2020: Biorefineries based on lignocellulosic materials. Microb. Biotechnol. 2016, 9, 585–594. [Google Scholar] [CrossRef]

- Chen, D.; Gao, A.; Cen, K.; Zhang, J.; Cao, X.; Ma, Z. Investigation of biomass torrefaction based on three major components: Hemicellulose, cellulose, and lignin. Energy Convers. Manag. 2018, 169, 228–237. [Google Scholar] [CrossRef]

- Ge, S.B.; Manigandan, S.; Mathimani, T.; Basha, S.; Xia, C.L.; Brindhadevi, K.; Unpaprom, Y.; Whangchai, K.; Pugazhendhi, A. An assessment of agricultural waste cellulosic biofuel for improved combustion and emission characteristics. Sci. Total Environ. 2022, 813, 152418. [Google Scholar] [CrossRef]

- Yang, J.L.; Ching, Y.C.; Chuah, C.H. Applications of Lignocellulosic Fibers and Lignin in Bioplastics: A Review. Polymers 2019, 11, 751. [Google Scholar] [CrossRef]

- Ahmad, R.K.; Sulaiman, S.A.; Yusup, S.; Dol, S.S.; Inayat, M.; Umar, H.A. Exploring the potential of coconut shell biomass for charcoal production. Ain Shams Eng. J. 2022, 13, 101499. [Google Scholar] [CrossRef]

- Alayoubi, R.; Mehmood, N.; Husson, E.; Kouzayha, A.; Tabcheh, M.; Chaveriat, L.; Sarazin, C.; Gosselin, I. Low temperature ionic liquid pretreatment of lignocellulosic biomass to enhance bioethanol yield. Renew. Energy 2020, 145, 1808–1816. [Google Scholar] [CrossRef]

- Singh, N.; Singhania, R.R.; Nigam, P.S.; Dong, C.D.; Patel, A.K.; Puri, M. Global status of lignocellulosic biorefinery: Challenges and perspectives. Bioresour. Technol. 2022, 344, 126415. [Google Scholar] [CrossRef]

- Albatrni, H.; Qiblawey, H.; Al-Marri, M.J. Walnut shell based adsorbents: A review study on preparation, mechanism, and application. J. Water Process Eng. 2022, 45, 102527. [Google Scholar] [CrossRef]

- Awasthi, S.K.; Kumar, M.; Sarsaiya, S.; Ahluwalia, V.; Chen, H.; Kaur, G.; Sirohi, R.; Sindhu, R.; Binod, P.; Pandey, A.; et al. Multi-criteria research lines on livestock manure biorefinery development towards a circular economy: From the perspective of a life cycle assessment and business models strategies. J. Clean. Prod. 2022, 341, 130862. [Google Scholar] [CrossRef]

- Ge, S.B.; Liang, Y.Y.; Zhou, C.X.; Sheng, Y.Q.; Zhang, M.L.; Cai, L.P.; Zhou, Y.H.; Huang, Z.H.; Manzo, M.; Wu, C.Y.; et al. The potential of Pinus armandii Franch for high-grade resource utilization. Biomass Bioenerg. 2022, 158, 106345. [Google Scholar] [CrossRef]

- Yu, D.; Li, C.; Xie, K.; Zhang, G.; Gu, H.; Li, S. In Vitro Germination and Planflet Regeneration from Seeds of Staphylea holocarpa. Subtrop. Plant Sci. 2011, 40, 36–40. [Google Scholar]

- Xu, B.; Shi, X.; Sun, Y.; Li, N. Study on Dormancy and Germination of Staphylea Holocarpa Hems1. Seed 2002, 1, 13–14. [Google Scholar]

- Novotny, L.; Abdel-Hamid, M.E.; Hamza, H.; Masterova, I.; Grancai, D. Development of LC-MS method for determination of ursolic acid: Application to the analysis of ursolic acid in Staphylea holocarpa Hemsl. J. Pharmaceut. Biomed. 2003, 31, 961–968. [Google Scholar] [CrossRef]

- Lacikova, L.; Pferschy-Wenzig, E.M.; Masterova, I.; Grancai, D.; Bauer, R. Anti-inflammatory Potential and Fatty Acid Content of Lipophilic Leaf Extracts of Four Staphylea L. Species. Nat. Prod. Commun. 2009, 4, 543–546. [Google Scholar]

- Tian, H.X. Population Dynamics and Community Characteristics of Staphylea holocarpa in Yunqiu Mountain of Shanxi Province; Shanxi Normal University: Xi’an, China, 2016. [Google Scholar]

- Savchenko, D.; Vorlièek, V.; Kalabukhova, E.; Sitnikov, A.; Vasin, A.; Kysil, D. Infrared, Raman and Magnetic resonance spectroscopic study of SiO2:C nanopowders. J. Nano. Res. Lett. 2017, 12, 292. [Google Scholar] [CrossRef] [PubMed]

- Ge, S.B.; Brindhadevi, K.; Xia, C.L.; Elesawy, B.H.; Elfasakhany, A.; Unpaprom, Y.; Van Doan, H. Egg shell catalyst and chicken waste biodiesel blends for improved performance, combustion and emission characteristics. Fuel 2021, 306, 121633. [Google Scholar] [CrossRef]

- Shannon, M.; Lafeuille, J.L.; Fregiere-Salmomon, A.; Lefevre, S.; Galvin-King, P.; Haughey, S.A.; Burns, D.T.; Shen, X.Q.; Kapil, A.; McGrath, T.F.; et al. The detection and determination of adulterants in turmeric using fourier-transform infrared (FTIR) spectroscopy coupled to chemometric analysis and micro-FTIR imaging. Food Control 2022, 139, 109093. [Google Scholar] [CrossRef]

- Cruz, M.D.; Van Schoors, L.; Benzarti, K.; Colin, X. Thermo-oxidative degradation of additive free polyethylene. part I. Analysis of chemical modifications at molecular and macromolecular scales. J. App. Polym. Sci. 2016, 133, 43287. [Google Scholar] [CrossRef]

- Pandey, K.K. A study of chemical structure of soft and hardwood and wood polymers by FTIR spectroscopy. J. App. Polym. Sci. 2015, 71, 1969–1975. [Google Scholar] [CrossRef]

- Liu, L.; Cheng, X.; Teng, L.; Wang, Y.; Dong, X.; Chen, L.; Zhang, D.; Peng, W.X. Systematic characterization of volatile organic components and pyrolyzates from Camellia oleifera seed cake for developing high value-added products. Arab. J. Chem. 2018, 11, 802–814. [Google Scholar] [CrossRef]

- Kaya, E.M.Ö.; Özcan, A.S.; Özer, G.; Özcan, A. Adsorption kinetics and isotherm parameters of naphthalene onto natural- and chemically modified bentonite from aqueous solutions. Adsorption 2013, 19, 879–888. [Google Scholar] [CrossRef]

- Soni, A.; Yusuf, M.; Mishra, V.K.; Beg, M. An assessment of thermal impact on chemical characteristics of edible oils by using FTIR spectroscopy. Mater. Today 2022, 68, 710–716. [Google Scholar] [CrossRef]

- Gu, H.P.; Luo, X.Y.; Wang, H.Z.; Wu, L.S.; Wu, J.J.; Xu, J.M. The characteristics of phenanthrene biosorption by chemically modified biomass of Phanerochaete chrysosporium. Environ. Sci. Pollut. Res. 2015, 22, 11850–11861. [Google Scholar] [CrossRef]

- Peng, W.X.; Maleki, A.; Rosen, M.A.; Pouria, A. Optimization of a hybrid system for solar-wind-based water desalination by reverse osmosis: Comparison of approaches. Desalination 2018, 442, 16–31. [Google Scholar] [CrossRef]

- Alekhina, M.; Ershova, O.; Ebert, A.; Heikkinen, S.; Sixta, H. Softwood kraft lignin for value-added applications: Fractionation and structural characterization. Ind. Crop. Prod. 2015, 66, 220–228. [Google Scholar] [CrossRef]

- Tomak, E.D.; Topaloglu, E.; Gumuskaya, E.; Yildiz, U.C.; Ay, N. An FT-IR study of the changes in chemical composition of bamboo degraded by brown-rot fungi. Int. Biodeter. Biodegr. 2013, 85, 131–138. [Google Scholar] [CrossRef]

- Mancuso, C.; Santangelo, R. Ferulic acid: Pharmacological and toxicological aspects. Food Chem. Toxicol. 2014, 65, 185–195. [Google Scholar] [CrossRef] [PubMed]

- Koh, P.O. Ferulic acid prevents the cerebral ischemic injury-induced decrease of Akt and Bad phosphorylation. Neurosci. Lett. 2012, 507, 156–160. [Google Scholar] [CrossRef]

- Karthikeyan, S.; Kanimozhi, G.; Prasad, N.R.; Mahalakshmi, R. Radiosensitizing effect of ferulic acid on human cervical carcinoma cells in vitro. Toxicol. In Vitro 2011, 25, 1366–1375. [Google Scholar] [CrossRef]

- Zueva, I.; Lushchekina, S.; Shulnikova, P.; Lenina, O.; Petrov, K.; Molochkina, E.; Masson, P. α-tocopherol, a slow-binding inhibitor of acetylcholinesterase. Chem. Biol. Interact. 2021, 348, 109646. [Google Scholar] [CrossRef]

- Archer, C.R.; Hempenstall, S.; Royle, N.J.; Selman, C.; Willis, S.; Rapkin, J.; Blount, J.D.; Hunt, J. Testing the Effects of DL-Alpha-Tocopherol Supplementation on Oxidative Damage, Total Antioxidant Protection and the Sex-Specific Responses of Reproductive Effort and Lifespan to Dietary Manipulation in Australian Field Crickets (Teleogryllus commodus). Antioxidants 2015, 4, 768–792. [Google Scholar] [CrossRef]

- Zhang, T.W.; Li, W.Z.; Xiao, H.N.; Jin, Y.C.; Wu, S.F. Recent progress in direct production of furfural from lignocellulosic residues and hemicellulose. Bioresour. Technol. 2022, 354, 127126. [Google Scholar] [CrossRef]

- Nhien, L.C.; Long, N.V.D.; Lee, M. Novel hybrid reactive distillation with extraction and distillation processes for furfural production from an actual xylose solution. Energies 2021, 14, 1152. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, S.; Li, Q.; Zhou, G.; Xia, H. Recent advances in the conversion of furfural into bio-chemicals through chemo-and bio-catalysis. RSC Adv. 2021, 11, 27042–27058. [Google Scholar] [CrossRef]

- Zawaneh, P.N.; Singh, S.P.; Padera, R.F.; Henderson, P.W.; Spector, J.A.; Putnam, D. Design of an injectable synthetic and biodegradable surgical biomaterial. Proc. Natl. Acad. Sci. USA 2010, 107, 11014–11019. [Google Scholar] [CrossRef]

- de la Morena, S.; Acedos, M.G.; Santos, V.E.; Garcia-Ochoa, F. Dihydroxyacetone production from glycerol using Gluconobacter oxydans: Study of medium composition and operational conditions in shaken flasks. Biotechnol. Progr. 2019, 35, e2803. [Google Scholar] [CrossRef] [PubMed]

- Albonetti, S.; Hu, C.W.; Saravanamurugan, S. Preface to Special Issue on Green Conversion of HMF. ChemSusChem 2022, 15, e202201057. [Google Scholar] [CrossRef]

- Zhou, D.; Shen, D.; Lu, W.; Song, T.; Wang, M.; Feng, H.; Shentu, J.; Long, Y. Production of 5-Hydroxymethylfurfural from Chitin Biomass: A Review. Molecules 2020, 25, 541. [Google Scholar] [CrossRef]

- Song, G.X.; Huang, D.X.; Li, H.J.; Wang, X.P.; Ren, Q.Q.; Jiang, L.; Wang, Y.; Su, S.; Hu, S.; Xiang, J. Pyrolysis reaction mechanism of typical Chinese agriculture and forest waste pellets at high heating rates based on the photo-thermal TGA. Energy 2022, 244, 123164. [Google Scholar] [CrossRef]

- Kanca, A. Investigation on pyrolysis and combustion characteristics of low quality lignite, cotton waste, and their blends by TGA-FTIR. Fuel 2020, 263, 116517. [Google Scholar] [CrossRef]

- Sait, H.H.; Hussain, A.; Salema, A.A.; Ani, F.N. Pyrolysis and combustion kinetics of date palm biomass using thermogravimetric analysis. Bioresour. Technol. 2012, 118, 382–389. [Google Scholar] [CrossRef]

- nca-Couce, A.; Tsekos, C.; Retschitzegger, S.; Zimbardi, F.; Funke, A.; Banks, S.; Kraia, T.; Marques, P.; Scharler, R.; de Jong, W.; et al. Biomass pyrolysis TGA assessment with an international round robin. Fuel 2020, 276, 118002. [Google Scholar] [CrossRef]

- Mishra, R.K.; Mohanty, K. Pyrolysis kinetics and thermal behavior of waste sawdust biomass using thermogravimetric analysis. Bioresour. Technol. 2018, 251, 63–74. [Google Scholar] [CrossRef]

- Rami, J.M.; Patel, C.D.; Patel, C.M.; Patel, M.V. Thermogravimetric analysis (TGA) of some synthesized metal oxide nanoparticles. Mater. Today 2021, 43, 655–659. [Google Scholar] [CrossRef]

- Hydrogenation of fast pyrolyis oil and model compounds in a two-phase aqueous organic system using homogeneous ruthenium catalysts. J. Mol. Catal A Chem. 2007, 264, 227–236. [CrossRef][Green Version]

- Xing, J.K.; Kurose, R.; Luo, K.; Fan, J.R. Chemistry-Informed Neural Networks modelling of lignocellulosic biomass Pyrolysis. Bioresour. Technol. 2022, 355, 127275. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Xu, F.; Zong, P.; Zhang, J.; Tian, Y.; Qiao, Y. Effects of heating rate on fast pyrolysis behavior and product distribution of Jerusalem artichoke stalk by using TG-FTIR and Py-GC/MS. Renew. Energ. 2019, 132, 486–496. [Google Scholar] [CrossRef]

- Elliott, D.C.; Hart, T.R. Catalytic Hydroprocessing of Chemical Models for Bio-oil. Energ. Fuel. 2017, 23, 631–637. [Google Scholar] [CrossRef]

- Setiabudi, H.D.; Aziz, M.A.A.; Abdullah, S.; Teh, L.P.; Jusoh, R. Hydrogen production from catalytic steam reforming of biomass pyrolysis oil or bio-oil derivatives: A review. Int. J. Hydrogen Energy 2020, 45, 18376–18397. [Google Scholar] [CrossRef]

- Atchimarungsri, T.; Gao, X.H.; Ma, Q.X.; Zhang, J.L.; Fan, S.B.; He, F.G.; Tian, J.M.; Reubroycharoen, P.; Zhao, T.S. Highly Efficient Conversion of Glycerol to Acetaldehyde Over In2O3/HZSM-5 Catalysts. ACS Sustain. Chem. Eng. 2022, 10, 11078–11087. [Google Scholar] [CrossRef]

- Valentini, F.; Kozell, V.; Petrucci, C.; Marrocchi, A.; Gu, Y.L.; Gelman, D.; Vaccaro, L. Formic acid, a biomass-derived source of energy and hydrogen for biomass upgrading. Energ. Environ. Sci. 2019, 12, 2646–2664. [Google Scholar] [CrossRef]

- Upadhyay, P.; Lali, A. Engineered Pseudomonas putida for biosynthesis of catechol from lignin-derived model compounds and biomass hydrolysate. Prep. Biochem. Biotechn. 2022, 52, 80–88. [Google Scholar] [CrossRef]

- Yan, G.H.; Chen, G.F.; Peng, Z.Q.; Shen, Z.L.; Tang, X.; Sun, Y.; Zeng, X.H.; Lin, L. The Cross-Linking Mechanism and Applications of Catechol-Metal Polymer Materials. Adv. Mater. Interfaces 2021, 8, 2100239. [Google Scholar] [CrossRef]

- Silvestre, F.; Aubry, J.M.; Benvegnu, T.; Brendle, J.; Durand, M.; Lavergne, A.; Len, C.; Molinier, V.; Mouloungui, Z.; Plusquellec, D.; et al. Agro-resources for a sustainable chemistry. Actual. Chim. 2010, 338–339, 28–40. [Google Scholar]

- Liu, Y.; Wang, Y.G.; Dai, Y.J.; Bai, Y.Y.; Zhao, Q.X. Research on Combustion Properties and Pollutant Emission Characteristics of Blends of Maltol Byproduct/Pine Sawdust. ACS Omega 2022, 7, 325–333. [Google Scholar] [CrossRef] [PubMed]

- Artigues, A.; Puy, N.; Bartroli, J.; Fabregas, E. Comparative Assessment of Internal Standards for Quantitative Analysis of Bio-oil Compounds by Gas Chromatography/Mass Spectrometry Using Statistical Criteria. Energy Fuel. 2014, 28, 3908–3915. [Google Scholar] [CrossRef]

- Biswas, B.; Singh, R.; Kumar, J.; Singh, R.; Gupta, P.; Krishna, B.B.; Bhaskar, T. Pyrolysis behavior of rice straw under carbon dioxide for production of bio-oil. Renew. Energ. 2018, 129, 686–694. [Google Scholar] [CrossRef]

- Ranaware, V.; Verma, D.; Insyani, R.; Riaz, A.; Kim, S.M.; Kim, J. Highly-efficient and magnetically-separable ZnO/Co@N-CNTs catalyst for hydrodeoxygenation of lignin and its derived species under mild conditions. Green Chem. 2019, 21, 1021–1042. [Google Scholar] [CrossRef]

- Rambo, M.K.D.; Nemet, Y.K.S.; Junior, C.C.S.; Pedroza, M.M.; Rambo, M.C.D. Comparative study of the products from the pyrolysis of raw and hydrolyzed baru wastes. Biomass Convers. Bior. 2021, 11, 1943–1953. [Google Scholar] [CrossRef]

- Hayashi, Y.; Komatsu, T.; Iwashita, K.; Fukusaki, E. H-1-NMR metabolomics-based classification of Japanese sake and comparative metabolome analysis by gas chromatography-mass spectrometry. J. Biosci. Bioeng. 2021, 131, 557–564. [Google Scholar] [CrossRef] [PubMed]

- Kurihara, R.; Maruyama, I. Surface area development of Portland cement paste during hydration: Direct comparison with H-1 NMR relaxometry and water vapor/nitrogen sorption. Cem. Concr. Res. 2022, 157, 106805. [Google Scholar] [CrossRef]

- Ostrowski, S.; Lopuszyliska, B.; Mikus, A. Shielding Effects in H-1 NMR Spectra of Halogen-Substituted meso-Tetraphenylporphyrin Derivatives. Macroheterocycles 2019, 12, 17–21. [Google Scholar] [CrossRef]

- Xue, B.L.; Wen, J.L.; Sun, R.C. Lignin-Based Rigid Polyurethane Foam Reinforced with Pulp Fiber: Synthesis and Characterization. ACS Sustain. Chem. Eng. 2014, 2, 1474–1480. [Google Scholar] [CrossRef]

- Wen, J.L.; Sun, S.L.; Yuan, T.Q.; Xu, F.; Sun, R.C. Understanding the chemical and structural transformations of lignin macromolecule during torrefaction. Appl. Energ. 2014, 121, 1–9. [Google Scholar] [CrossRef]

- Kniat, A. Visualization of A Lifeboat Motion During Lowering Along Ship’s Side. Pol. Marit. Res. 2017, 24, 42. [Google Scholar] [CrossRef]

- Wani, S.A.; Najar, G.R.; Akhter, F. Characterization of available nutrients that influence pear productivity and quality in Jammu & Kashmir. India J. Environ. Biol. 2018, 39, 37. [Google Scholar]

- Río, J.C.D.; Rencoret, J.; Marques, G.; Li, J.B.; Gellerstedt, G.; Jimenez-Barbero, J.; Martinez, A.T.; Gutierrez, A. Structural Characterization of the Lignin from Jute (Corchorus capsularis) Fibers. J. Agr. Food Chem. 2009, 57, 10271–10281. [Google Scholar]

- Zhang, N.; Zhou, C.; Xia, W.; Nguyen, A.V. Volatilization of mercury in coal during conventional and microwave drying and its potential guidance for environmental protection. J. Clean Prod. 2018, 176, 1–6. [Google Scholar] [CrossRef]

- Nongqwenga, N.; Modi, A.T. Phosphorus and potassium quantity/intensity properties of selected South African soils (Kwa-zulu-natal) and their correlation with selected soil parameters. Appl. Ecol. Env. Res. 2017, 15, 1–14. [Google Scholar] [CrossRef]

- Wang, B.; Li, D.; Chen, T.; Qin, Z.; Peng, W.; Wen, J. Understanding the mechanism of self-bonding of bamboo binderless boards: Investigating the structural changes of lignin macromolecule during the molding pressing process. BioResources 2017, 12, 514–532. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, D.Q.; Su, J.; Dong, J.W.; Tan, S.K. Assessing hydrological effects and performance of low impact development practices based on future scenarios modeling. J. Clean Prod. 2018, 179, 12–23. [Google Scholar] [CrossRef]

- Li, Y.Y.; Shaheen, S.M.; Rinklebe, J.; Ma, N.L.; Yang, Y.F.; Ashraf, M.A.; Chen, X.M.; Peng, W.X. Pyrolysis of Aesculus chinensis Bunge Seed with Fe2O3/NiO as nanocatalysts for the production of bio-oil material. J. Hazard. Mater. 2021, 416, 126012. [Google Scholar] [CrossRef]

- Ge, S.B.; Shi, Y.; Xia, C.L.; Huang, Z.H.; Manzo, M.; Cai, L.P.; Ma, H.Z.; Zhang, S.; Jiang, J.C.; Sonne, C.; et al. Progress in pyrolysis conversion of waste into value-added liquid pyro-oil, with focus on heating source and machine learning analysis. Energ. Convers. Manag. 2021, 245, 114638. [Google Scholar] [CrossRef]

- Li, Y.Y.; Li, G.Y.; Yang, Y.F.; Chen, X.M.; Peng, W.X.; Li, H.Y. Incorporation of Nanocatalysts for the Production of Bio-Oil from Staphylea holocarpa Wood. Polymers 2022, 14, 4385. [Google Scholar] [CrossRef]

- Zhang, L.B.; Yang, X.; Sheng, Y.Q.; Huang, Q.G.; Yang, Z.L.; Shi, Y.; Guo, X.Q.; Ge, S.B. Influence of typical pretreatment on cotton stalk conversion activity and bio-oil property during low temperature (180–220) hydrothermal process. Fuel 2022, 328, 125250. [Google Scholar] [CrossRef]

- Pu, Y.; Cao, S.; Ragauskas, A.J. Application of quantitative 31P NMR in biomass lignin and biofuel precursors characterization. Energy Environ. Sci. 2011, 4, 3154–3166. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Liu, E.; Gu, H.; Lou, J.; Yang, Y.; Ban, L.; Peng, W.; Ge, S. Potential of Staphylea holocarpa Wood for Renewable Bioenergy. Molecules 2023, 28, 299. https://doi.org/10.3390/molecules28010299

Li Y, Liu E, Gu H, Lou J, Yang Y, Ban L, Peng W, Ge S. Potential of Staphylea holocarpa Wood for Renewable Bioenergy. Molecules. 2023; 28(1):299. https://doi.org/10.3390/molecules28010299

Chicago/Turabian StyleLi, Yiyang, Erdong Liu, Haiping Gu, Junwei Lou, Yafeng Yang, Longhai Ban, Wanxi Peng, and Shengbo Ge. 2023. "Potential of Staphylea holocarpa Wood for Renewable Bioenergy" Molecules 28, no. 1: 299. https://doi.org/10.3390/molecules28010299

APA StyleLi, Y., Liu, E., Gu, H., Lou, J., Yang, Y., Ban, L., Peng, W., & Ge, S. (2023). Potential of Staphylea holocarpa Wood for Renewable Bioenergy. Molecules, 28(1), 299. https://doi.org/10.3390/molecules28010299