Plasmonic Titanium Nitride Tubes Decorated with Ru Nanoparticles as Photo-Thermal Catalyst for CO2 Methanation

Abstract

:1. Introduction

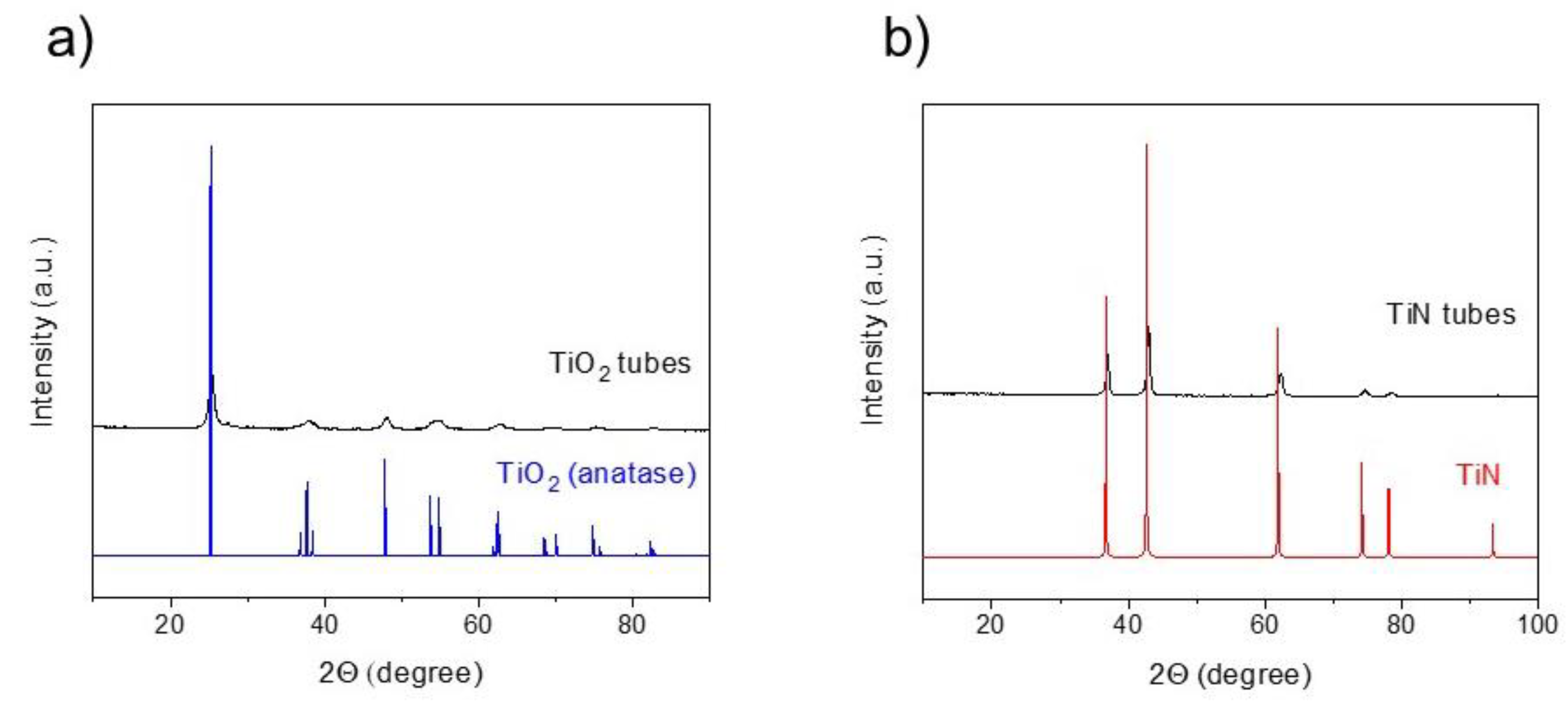

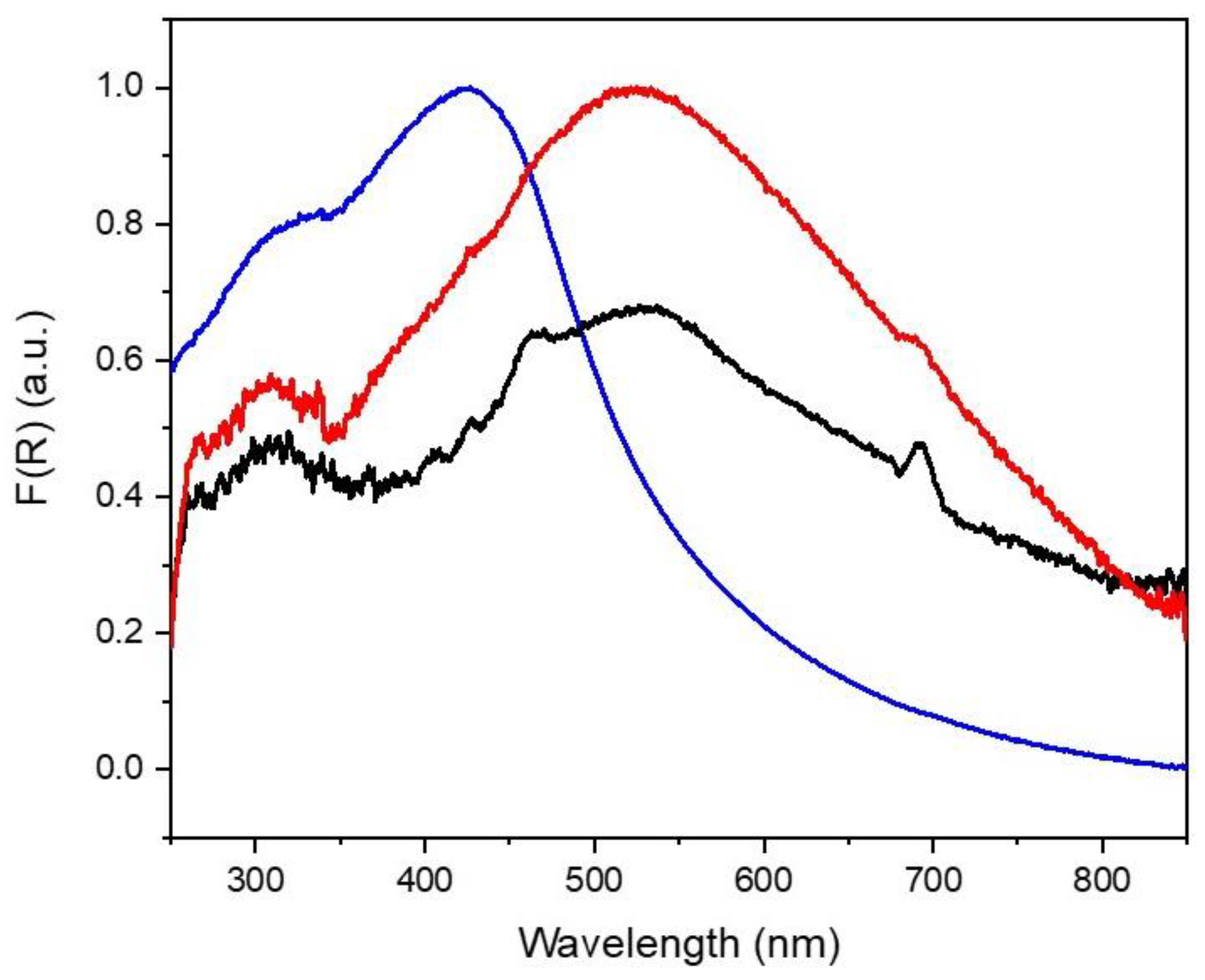

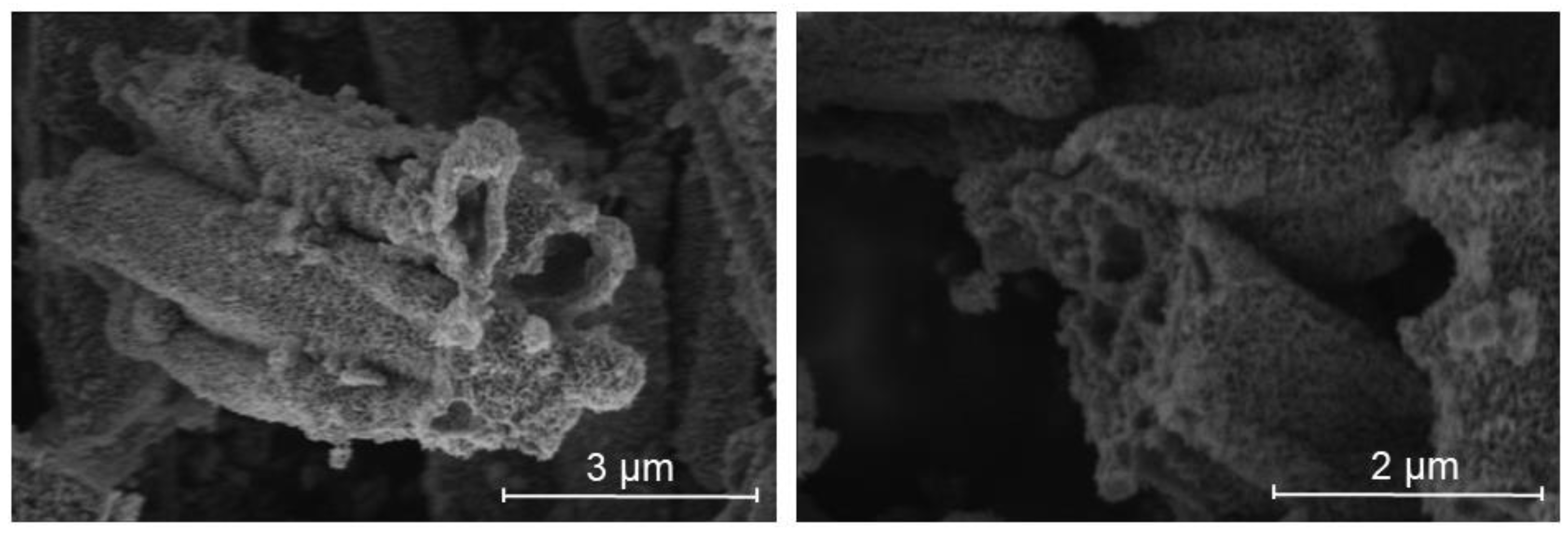

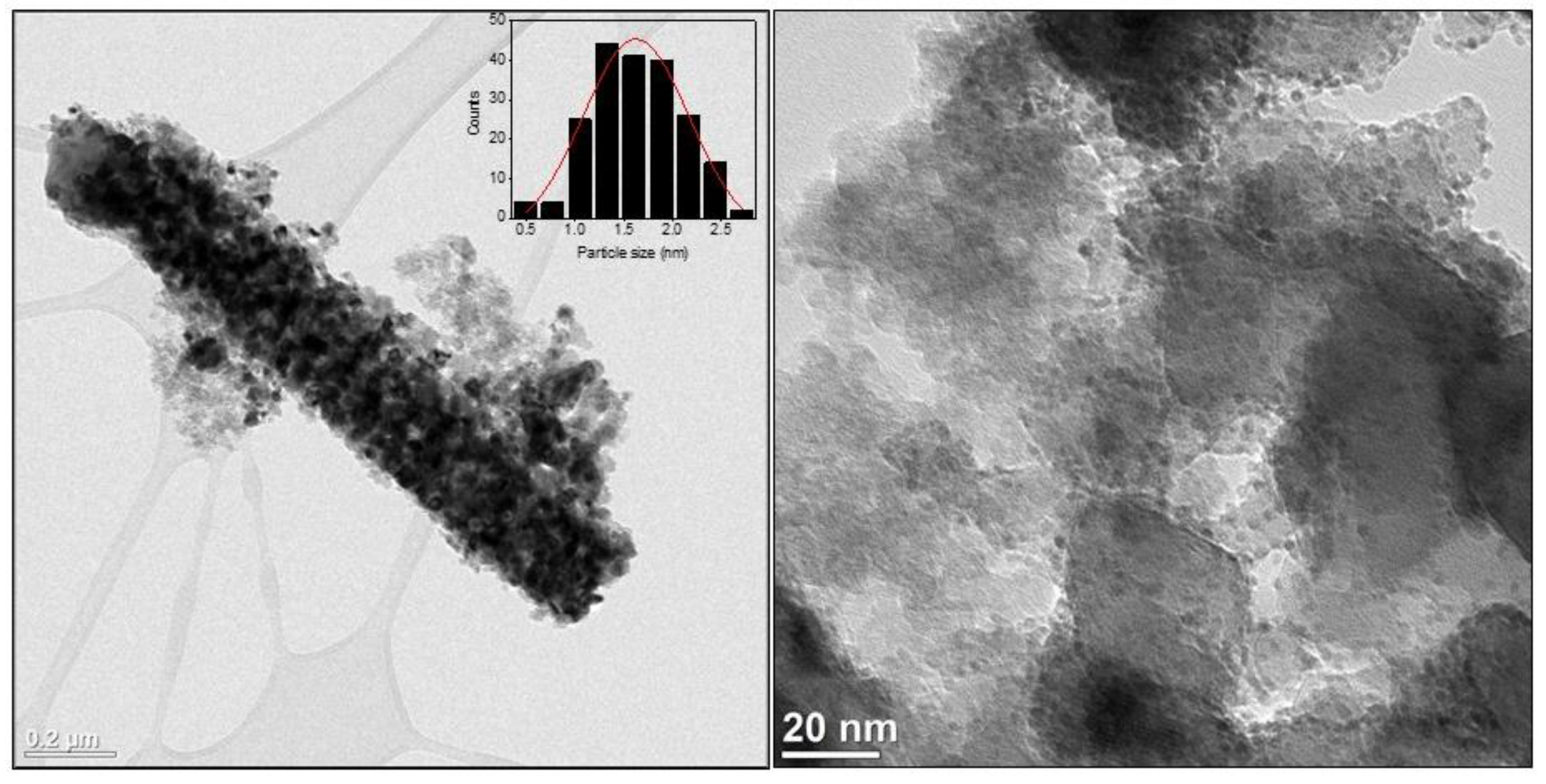

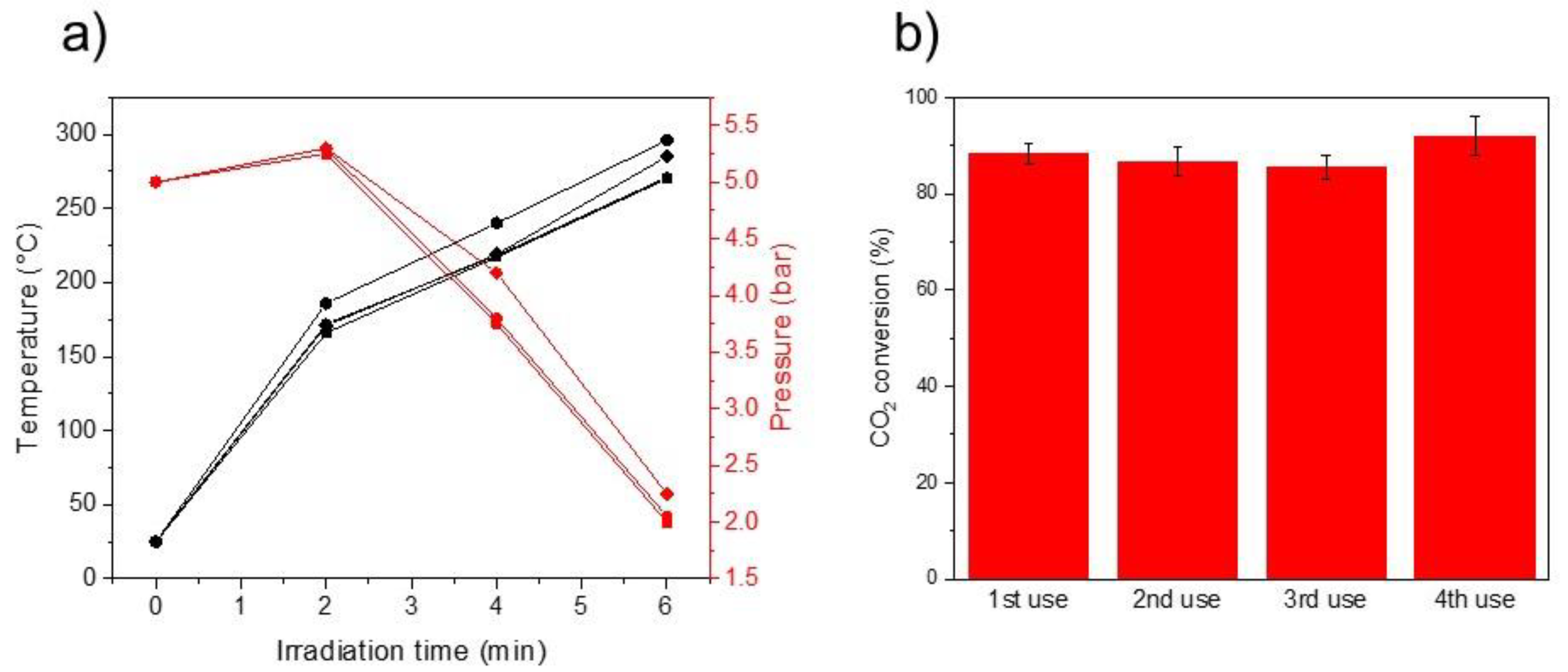

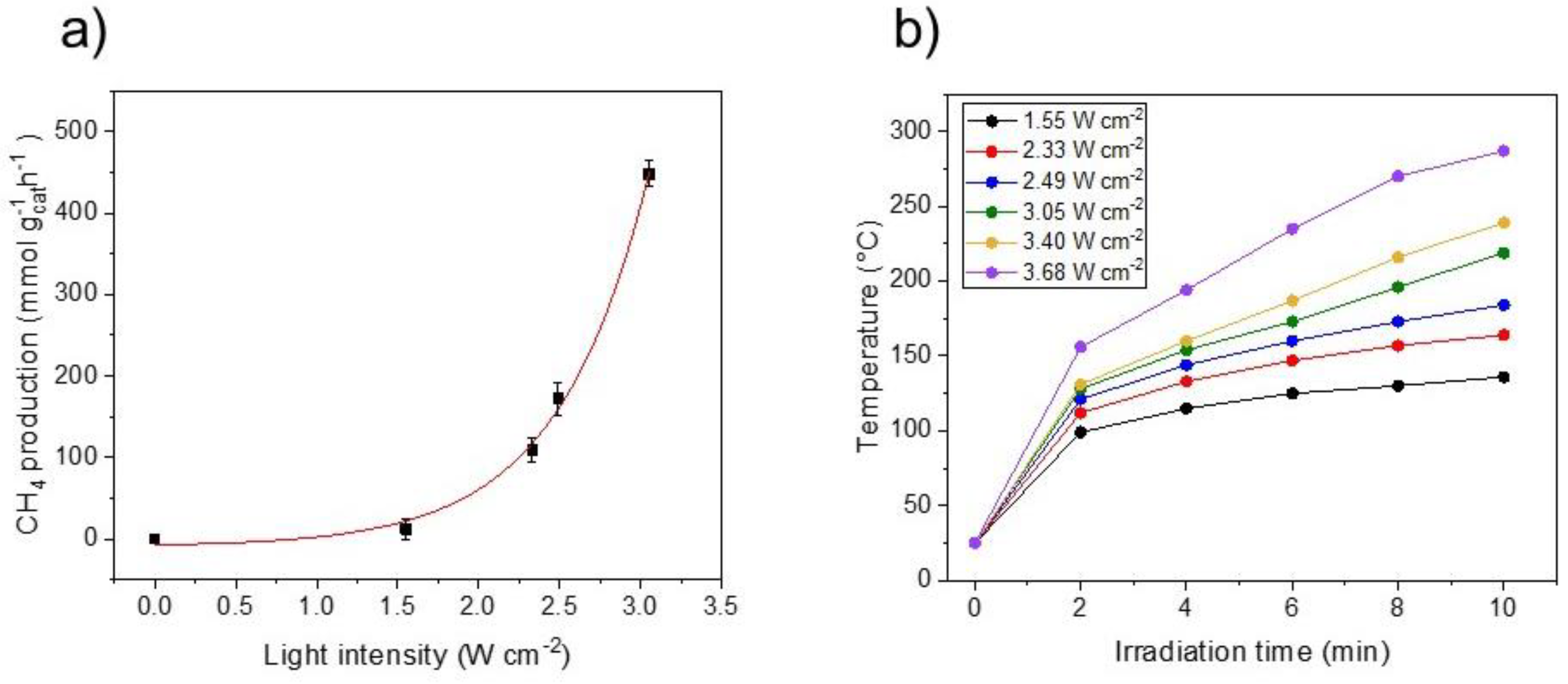

2. Results

3. Materials and Methods

3.1. Material Synthesis

3.2. Material Characterization

3.3. Photo-Thermal Tests

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Ghoussoub, M.; Xia, M.; Duchesne, P.N.; Segal, D.; Ozin, G. Principles of photothermal gas-phase heterogeneous CO2 catalysis. Energy Environ. Sci. 2019, 12, 1122–1142. [Google Scholar] [CrossRef]

- Mateo, D.; Cerrillo, J.L.; Durini, S.; Gascon, J. Fundamentals and applications of photo-thermal catalysis. Chem. Soc. Rev. 2021, 50, 2173–2210. [Google Scholar] [CrossRef] [PubMed]

- Keller, N.; Ivanez, J.; Highfield, J.; Ruppert, A.M. Photo-/thermal synergies in heterogeneous catalysis: Towards low-temperature (solar-driven) processing for sustainable energy and chemicals. Appl. Catal. B 2021, 296, 120320. [Google Scholar] [CrossRef]

- Wang, Z.J.; Song, H.; Liu, H.; Ye, J. Coupling of solar energy and thermal energy for carbon dioxide reduction: Status and prospects. Angew. Chem. Int. Ed. 2020, 59, 8016–8035. [Google Scholar] [CrossRef]

- Zhang, F.; Li, Y.-H.; Qi, M.-Y.; Yamada, Y.M.; Anpo, M.; Tang, Z.-R.; Xu, Y.-J. Photothermal catalytic CO2 reduction over nanomaterials. Chem. Catal. 2021, 1, 272–297. [Google Scholar] [CrossRef]

- Liu, H.; Shi, L.; Zhang, Q.; Qi, P.; Zhao, Y.-h.; Meng, Q.; Feng, X.; Wang, H.; Ye, J. Photothermal catalysts for hydrogenation reactions. Chem. Commun. 2021, 57, 1279–1294. [Google Scholar] [CrossRef]

- Jia, J.; Wang, H.; Lu, Z.; O’Brien, P.G.; Ghoussoub, M.; Duchesne, P.; Zheng, Z.; Li, P.; Qiao, Q.; Wang, L. Photothermal catalyst engineering: Hydrogenation of gaseous CO2 with high activity and tailored selectivity. Adv. Sci. 2017, 4, 1700252. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.-J.; Song, H.; Pang, H.; Ning, Y.; Dao, T.D.; Wang, Z.; Chen, H.; Weng, Y.; Fu, Q.; Nagao, T. Photo-assisted methanol synthesis via CO2 reduction under ambient pressure over plasmonic Cu/ZnO catalysts. Appl. Catal. B 2019, 250, 10–16. [Google Scholar] [CrossRef]

- Mao, C.; Yu, L.; Li, J.; Zhao, J.; Zhang, L. Energy-confined solar thermal ammonia synthesis with K/Ru/TiO2-xHx. Appl. Catal. B 2018, 224, 612–620. [Google Scholar] [CrossRef]

- Mateo, D.; Morlanes, N.; Maity, P.; Shterk, G.; Mohammed, O.F.; Gascon, J. Efficient Visible-Light Driven Photothermal Conversion of CO2 to Methane by Nickel Nanoparticles Supported on Barium Titanate. Adv. Funct. Mater. 2021, 31, 2008244. [Google Scholar] [CrossRef]

- Song, C.; Liu, X.; Xu, M.; Masi, D.; Wang, Y.; Deng, Y.; Zhang, M.; Qin, X.; Feng, K.; Yan, J. Photothermal conversion of CO2 with tunable selectivity using Fe-based catalysts: From oxide to carbide. ACS Catal. 2020, 10, 10364–10374. [Google Scholar] [CrossRef]

- Takami, D.; Yamamoto, A.; Yoshida, H. Dry reforming of methane over alumina-supported rhodium catalysts at low temperatures under visible and near-infrared light. Catal. Sci. Technol. 2020, 10, 5811–5814. [Google Scholar] [CrossRef]

- Mateo, D.; Maity, P.; Shterk, G.; Mohammed, O.F.; Gascon, J. Tunable Selectivity in CO2 Photo-Thermal Reduction by Perovskite-Supported Pd Nanoparticles. ChemSusChem 2021, 14, 5525–5533. [Google Scholar] [CrossRef] [PubMed]

- Han, B.; Zhang, Y.L.; Chen, Q.D.; Sun, H.B. Carbon-based photothermal actuators. Adv. Funct. Mater. 2018, 28, 1802235. [Google Scholar] [CrossRef]

- Ye, M.; Jia, J.; Wu, Z.; Qian, C.; Chen, R.; O’Brien, P.G.; Sun, W.; Dong, Y.; Ozin, G.A. Synthesis of black TiOx nanoparticles by Mg reduction of TiO2 nanocrystals and their application for solar water evaporation. Adv. Energy Mater. 2017, 7, 1601811. [Google Scholar] [CrossRef]

- Tian, Q.; Tang, M.; Sun, Y.; Zou, R.; Chen, Z.; Zhu, M.; Yang, S.; Wang, J.; Wang, J.; Hu, J. Hydrophilic flower-like CuS superstructures as an efficient 980 nm laser-driven photothermal agent for ablation of cancer cells. Adv. Mater. 2011, 23, 3542–3547. [Google Scholar] [CrossRef]

- Qiu, J.; Wei, W.D. Surface plasmon-mediated photothermal chemistry. J. Phys. Chem. C 2014, 118, 20735–20749. [Google Scholar] [CrossRef]

- Fan, W.K.; Tahir, M. Recent developments in photothermal reactors with understanding on the role of light/heat for CO2 hydrogenation to fuels: A review. Chem. Eng. J. 2021, 427, 131617. [Google Scholar] [CrossRef]

- Molina, P.M.; Meulendijks, N.; Xu, M.; Verheijen, M.A.; den Hartog, T.; Buskens, P.; Sastre, F. Low temperature sunlight-powered reduction of CO2 to CO using a plasmonic Au/TiO2 nanocatalyst. ChemCatChem 2021, 13, 1–8. [Google Scholar]

- Qiao, P.; Sun, B.; Li, H.; Pan, K.; Tian, G.; Wang, L.; Zhou, W. Surface Plasmon Resonance-Enhanced Visible-NIR-Driven Photocatalytic and Photothermal Catalytic Performance by Ag/Mesoporous Black TiO2 Nanotube Heterojunctions. Chem.—Asian J. 2019, 14, 177–186. [Google Scholar] [CrossRef]

- Habib, A.; Florio, F.; Sundararaman, R. Hot carrier dynamics in plasmonic transition metal nitrides. J. Opt. 2018, 20, 064001. [Google Scholar] [CrossRef] [Green Version]

- Kumar, M.; Umezawa, N.; Ishii, S.; Nagao, T. Examining the performance of refractory conductive ceramics as plasmonic materials: A theoretical approach. ACS Photonics 2016, 3, 43–50. [Google Scholar] [CrossRef] [Green Version]

- Naldoni, A.; Guler, U.; Wang, Z.; Marelli, M.; Malara, F.; Meng, X.; Besteiro, L.V.; Govorov, A.O.; Kildishev, A.V.; Boltasseva, A. Broadband hot-electron collection for solar water splitting with plasmonic titanium nitride. Adv. Opt. Mater. 2017, 5, 1601031. [Google Scholar] [CrossRef] [Green Version]

- Clatworthy, E.B.; Yick, S.; Murdock, A.T.; Allison, M.C.; Bendavid, A.; Masters, A.F.; Maschmeyer, T. Enhanced photocatalytic hydrogen evolution with TiO2–TiN nanoparticle composites. J. Phys. Chem. C 2019, 123, 3740–3749. [Google Scholar] [CrossRef]

- Rej, S.; Mascaretti, L.; Santiago, E.Y.; Tomanec, O.; Kment, S.; Wang, Z.; Zbořil, R.; Fornasiero, P.; Govorov, A.O.; Naldoni, A. Determining plasmonic hot electrons and photothermal effects during H2 evolution with TiN–Pt nanohybrids. ACS Catal. 2020, 10, 5261–5271. [Google Scholar] [CrossRef]

- Nguyen, N.T.; Yan, T.; Wang, L.; Loh JY, Y.; Duchesne, P.N.; Mao, C.; Li, P.C.; Jelle, A.A.; Xia, M.; Ghoussoub, M. Plasmonic Titanium Nitride Facilitates Indium Oxide CO2 Photocatalysis. Small 2020, 16, 2005754. [Google Scholar] [CrossRef]

- Deng, D.-R.; An, T.-H.; Li, Y.-J.; Wu, Q.-H.; Zheng, M.-S.; Dong, Q.-F. Hollow porous titanium nitride tubes as a cathode electrode for extremely stable Li–S batteries. J. Mater. Chem. A 2016, 4, 16184–16190. [Google Scholar] [CrossRef]

- Dam, D.T.; Nam, K.-D.; Song, H.; Wang, X.; Lee, J.-M. Partially oxidized titanium carbonitride as a non-noble catalyst for oxygen reduction reactions. Int. J. Hydrogen Energy 2012, 37, 15135–15139. [Google Scholar] [CrossRef]

- Baffou, G.; Quidant, R.; Girard, C. Heat generation in plasmonic nanostructures: Influence of morphology. Appl. Phys. Lett. 2009, 94, 153109. [Google Scholar] [CrossRef] [Green Version]

- Bell, A.P.; Fairfield, J.A.; McCarthy, E.K.; Mills, S.; Boland, J.J.; Baffou, G.; McCloskey, D. Quantitative study of the photothermal properties of metallic nanowire networks. ACS Nano 2015, 9, 5551–5558. [Google Scholar] [CrossRef]

- Piallat, F.; Gassilloud, R.; Caubet, P.; Vallée, C. Investigation of TiN thin film oxidation depending on the substrate temperature at vacuum break. J. Vac. Sci. Technol. A 2016, 34, 051508. [Google Scholar] [CrossRef]

- Bertoti, I.; Mohai, M.; Sullivan, J.; Saied, S. Surface characterisation of plasma-nitrided titanium: An XPS study. Appl. Surf. Sci. 1995, 84, 357–371. [Google Scholar] [CrossRef]

- Saha, N.C.; Tompkins, H.G. Titanium nitride oxidation chemistry: An X-ray photoelectron spectroscopy study. J. Appl. Phys. 1992, 72, 3072–3079. [Google Scholar] [CrossRef]

- Morgan, D.J. Resolving ruthenium: XPS studies of common ruthenium materials. Surf. Interface Anal. 2015, 47, 1072–1079. [Google Scholar] [CrossRef]

- Kale, M.J.; Avanesian, T.; Christopher, P. Direct photocatalysis by plasmonic nanostructures. ACS Catal. 2014, 4, 116–128. [Google Scholar] [CrossRef]

- Meng, X.; Wang, T.; Liu, L.; Ouyang, S.; Li, P.; Hu, H.; Kako, T.; Iwai, H.; Tanaka, A.; Ye, J. Photothermal Conversion of CO2 into CH4 with H2 over Group VIII Nanocatalysts: An Alternative Approach for Solar Fuel Production. Angew. Chem. Int. Ed. 2014, 53, 11478–11482. [Google Scholar] [CrossRef]

- O’Brien, P.G.; Sandhel, A.; Wood, T.E.; Jelle, A.A.; Hoch, L.B.; Perovi, D.D.; Mims, C.A.; Ozin, G.A. Photomethanation of Gaseous CO2 over Ru/Silicon Nanowire Catalysts with Visible and Near-Infrared Photons. Adv. Sci. 2014, 1, 1400001. [Google Scholar] [CrossRef]

- Mateo, D.; Albero, J.; Garcia, H. Titanium-Perovskite-Supported RuO2 Nanoparticles for Photocatalytic CO2 Methanation. Joule 2019, 3, 1949–1962. [Google Scholar] [CrossRef]

- Kim, C.; Hyeon, S.; Lee, J.; Kim, W.D.; Lee, D.C.; Kim, J.; Lee, H. Energy-efficient CO2 hydrogenation with fast response using photoexcitation of CO2 adsorbed on metal catalysts. Nat. Commun. 2018, 9, 3027. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Zhang, Y.; Fan, G.; Song, L.; Jia, G.; Huang, H.; Ouyang, S.; Ye, J.; Li, Z.; Zou, Z. Cooperative catalysis coupling photo-/photothermal effect to drive Sabatier reaction with unprecedented conversion and selectivity. Joule 2021, 5, 3235–3251. [Google Scholar] [CrossRef]

- Khan, I.S.; Mateo, D.; Shterk, G.; Shoinkhorova, T.; Poloneeva, D.; Garzón-Tovar, L.; Gascon, J. Frontispiece: An Efficient Metal–Organic Framework-Derived Nickel Catalyst for the Light Driven Methanation of CO2. Angew. Chem. Int. Ed. 2021, 60, 26476–26482. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Gao, Y.; Zhang, M.; Gao, H.; Chen, J.; Jia, H. Efficient infrared-light-driven photothermal CO2 reduction over MOF-derived defective Ni/TiO2. Appl. Catal. B Environ. 2022, 303, 120905. [Google Scholar] [CrossRef]

- Goodwin, J.R.J.G.; Kim, S.; Rhodes, W.D. Meanings, Functionalities and Relationships. Catalysis 2004, 17, 320. [Google Scholar]

- Borodziński, A.; Bonarowska, M. Relation between crystallite size and dispersion on supported metal catalysts. Langmuir 1997, 13, 5613–5620. [Google Scholar] [CrossRef]

| Catalyst | Metal Loading (%) | CH4 Production Rate (mmol g−1 h−1) | TOF (s−1) |

|---|---|---|---|

| Ru(2)-TiN tubes | 1.7 | 1215.8 | 9.1 |

| Ru(2)-TiN commercial | 1.6 | 338.7 | 2.5 |

| Ru(2)-TiO2 tubes | 0.7 | 11.6 | - |

| TiN | - | 0.09 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mateo, D.; Navarro, J.C.; Khan, I.S.; Ruiz-Martinez, J.; Gascon, J. Plasmonic Titanium Nitride Tubes Decorated with Ru Nanoparticles as Photo-Thermal Catalyst for CO2 Methanation. Molecules 2022, 27, 2701. https://doi.org/10.3390/molecules27092701

Mateo D, Navarro JC, Khan IS, Ruiz-Martinez J, Gascon J. Plasmonic Titanium Nitride Tubes Decorated with Ru Nanoparticles as Photo-Thermal Catalyst for CO2 Methanation. Molecules. 2022; 27(9):2701. https://doi.org/10.3390/molecules27092701

Chicago/Turabian StyleMateo, Diego, Juan Carlos Navarro, Il Son Khan, Javier Ruiz-Martinez, and Jorge Gascon. 2022. "Plasmonic Titanium Nitride Tubes Decorated with Ru Nanoparticles as Photo-Thermal Catalyst for CO2 Methanation" Molecules 27, no. 9: 2701. https://doi.org/10.3390/molecules27092701

APA StyleMateo, D., Navarro, J. C., Khan, I. S., Ruiz-Martinez, J., & Gascon, J. (2022). Plasmonic Titanium Nitride Tubes Decorated with Ru Nanoparticles as Photo-Thermal Catalyst for CO2 Methanation. Molecules, 27(9), 2701. https://doi.org/10.3390/molecules27092701