Volumetric Scalability of Microfluidic and Semi-Batch Silk Nanoprecipitation Methods

Abstract

:1. Introduction

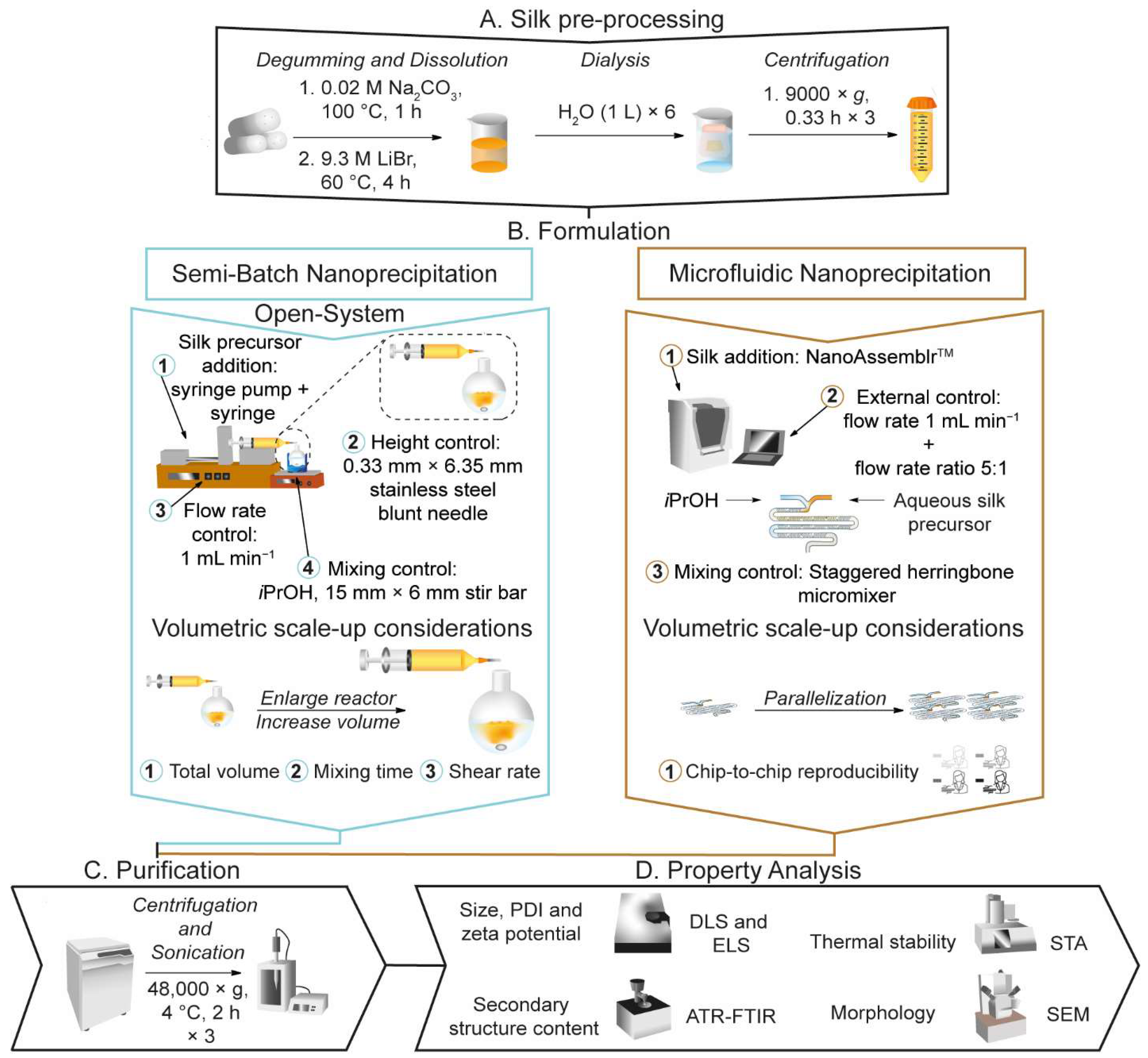

2. Results

2.1. Silk Nanoparticle Physicochemical Characterization

2.1.1. Volumetric Scale-Up in Semi-Batch Format

2.1.2. Volumetric Scale-Up by Parallelization in Microfluidic Format

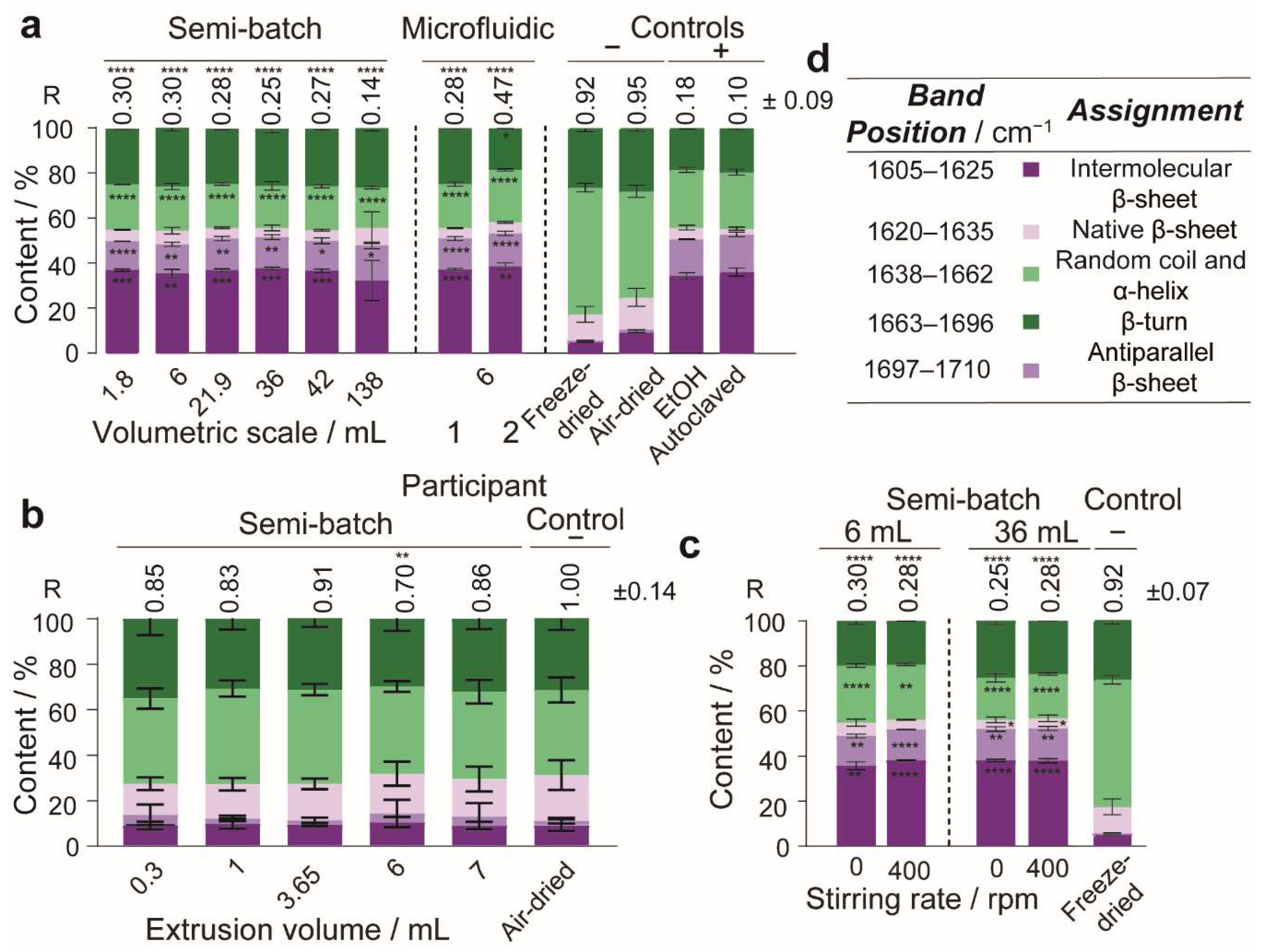

2.2. Secondary Structure Measurement

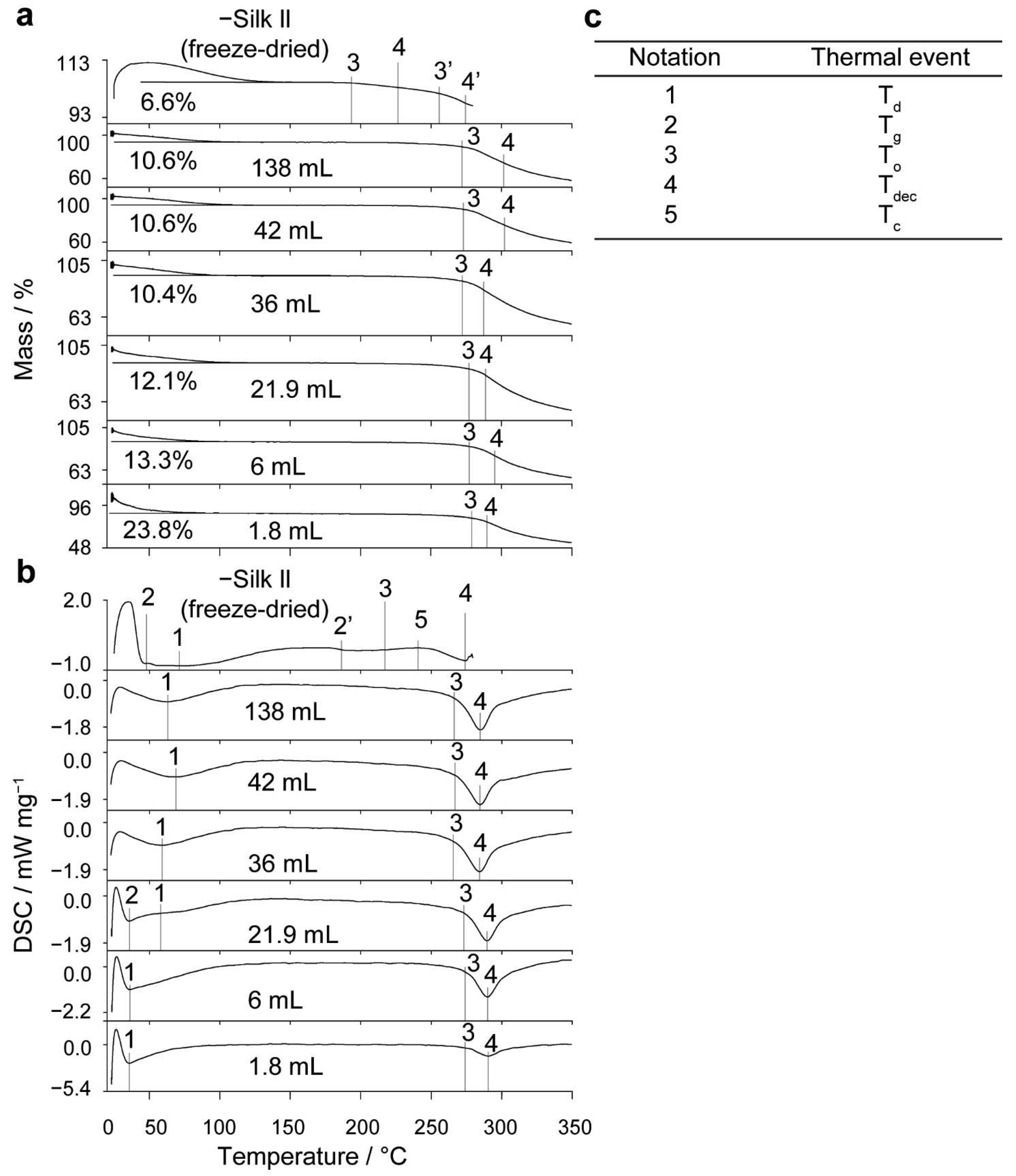

2.3. Thermal Analysis

2.4. The Impact of Volumetric Scale on the Colloidal Stability of Silk Nanoparticles

3. Discussion

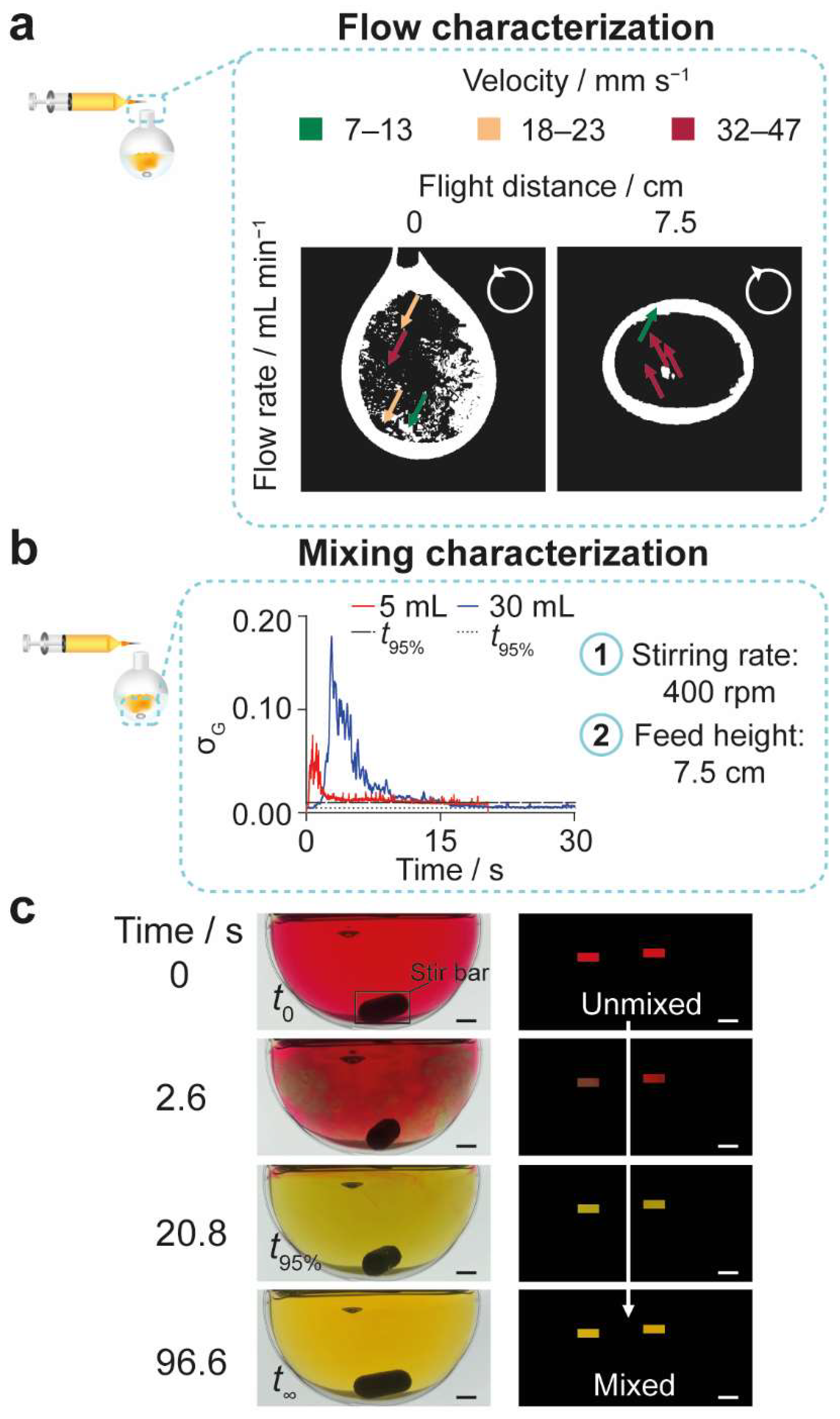

3.1. The Impact of Volumetric Scale on Reproducibility of Semi-Batch Silk Nanoprecipitation

3.2. The Reproducibility of Silk Nanoprecipitation in a Parallelizable Microfluidic Format

3.3. The Production Rates of Silk Nanoprecipitation in the Semi-Batch and Microfluidic Formats

3.4. The Impact of Volumetric Scale on the Colloidal Stability of Silk Nanoparticles

4. Materials and Methods

4.1. Regeneration of B. mori Silk

4.2. General Manufacture of Silk Nanoparticles in Semi-Batch Format

4.3. Volumetric Scale-Up of Semi-Batch Silk Nanoparticle Manufacture

4.4. Dual Indicator System for Mixing Time in the Semi-Batch Format

4.5. Semi-Batch Droplet Analysis

4.5.1. Volume and Time of Flight

4.5.2. Fluid Velocity, Droplet Diameter, and Diffusion Scales

4.6. Manufacture of Silk Nanoparticles in Microfluidic Format

4.7. Yield of Silk Nanoparticles

4.8. Physicochemical Characterization of the Silk Nanoparticles and Stability in Water

4.9. Secondary Structure Measurements of Silk Nanoparticles

4.10. Thermal Analysis of Silk Nanoparticles

4.11. Scanning Electron Microscopy of Silk Nanoparticles

4.12. Statistical Analyses

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Agrahari, V.; Agrahari, V. Facilitating the translation of nanomedicines to a clinical product: Challenges and opportunities. Drug Discov. Today 2018, 23, 974–991. [Google Scholar] [CrossRef] [PubMed]

- Muthu, M.S.; Wilson, B. Challenges posed by the scale-up of nanomedicines. Nanomedicine 2012, 7, 307–309. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Đorđević, S.; Gonzalez, M.M.; Conejos-Sánchez, I.; Carreira, B.; Pozzi, S.; Acúrcio, R.C.; Satchi-Fainaro, R.; Florindo, H.F.; Vicent, M.J. Current hurdles to the translation of nanomedicines from bench to the clinic. Drug Deliv. Transl. Res. 2022, 12, 500–525. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Meng, H. Consideration for the scale-up manufacture of nanotherapeutics—A critical step for technology transfer. View 2021, 2, 20200190. [Google Scholar] [CrossRef]

- Muthu, M.S.; Feng, S.-S. Pharmaceutical stability aspects of nanomedicines. Future Med. 2009, 4, 857–860. [Google Scholar] [CrossRef] [PubMed]

- McNeil, S.E. Nanoparticle therapeutics: A personal perspective. Wiley Interdiscip. Rev. Nanomed. Nanobiotechnol. 2009, 1, 264–271. [Google Scholar] [CrossRef]

- Wacker, M. Nanocarriers for intravenous injection-The long hard road to the market. Int. J. Pharm. 2013, 457, 50–62. [Google Scholar] [CrossRef]

- Chouhan, D.; Mandal, B.B. Silk biomaterials in wound healing and skin regeneration therapeutics: From bench to bedside. Acta Biomater. 2020, 103, 24–51. [Google Scholar] [CrossRef]

- Maitz, M.F.; Sperling, C.; Wongpinyochit, T.; Herklotz, M.; Werner, C.; Seib, F.P. Biocompatibility assessment of silk nanoparticles: Hemocompatibility and internalization by human blood cells. Nanomed. NBM 2017, 13, 2633–2642. [Google Scholar] [CrossRef] [Green Version]

- Lozano-Pérez, A.A.; Montalbán, M.G.; Aznar-Cervantes, S.D.; Cragnolini, F.; Cenis, J.L.; Víllora, G. Production of silk fibroin nanoparticles using ionic liquids and high-power ultrasounds. J. Appl. Polym. Sci. 2015, 132, 41702. [Google Scholar] [CrossRef]

- Tomeh, M.A.; Hadianamrei, R.; Zhao, X. Silk Fibroin as a Functional Biomaterial for Drug and Gene Delivery. Pharmaceutics 2019, 11, 494. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Zuo, Y.; Wen, S.; Hu, Y.; Min, Y. Distinctive Stress-Stiffening Responses of Regenerated Silk Fibroin Protein Polymers under Nanoscale Gap Geometries: Effect of Shear on Silk Fibroin-Based Materials. Biomacromolecules 2018, 19, 1223–1233. [Google Scholar] [CrossRef]

- Wongpinyochit, T.; Johnston, B.F.; Seib, F.P. Manufacture and drug delivery applications of silk nanoparticles. J. Vis. Exp. 2016, 116, e54669. [Google Scholar] [CrossRef] [Green Version]

- Wongpinyochit, T.; Totten, J.D.; Johnston, B.F.; Seib, F.P. Microfluidic-assisted silk nanoparticle tuning. Nanoscale Adv. 2019, 1, 873–883. [Google Scholar] [CrossRef] [Green Version]

- Solomun, J.I.; Totten, J.D.; Wongpinyochit, T.; Florence, A.J.; Seib, F.P. Manual versus Microfluidic-assisted Nanoparticle Manufacture: Impact of Silk Fibroin Stock on Nanoparticle Characteristics. ACS Biomater. Sci. Eng. 2020, 6, 2796–2804. [Google Scholar] [CrossRef]

- Jin, H.-J.; Kaplan, D.L. Mechanism of silk processing in insects and spiders. Nature 2003, 424, 1057–1061. [Google Scholar] [CrossRef]

- Lu, Q.; Zhu, H.; Zhang, C.; Zhang, F.; Zhang, B.; Kaplan, D.L. Silk Self-Assembly Mechanisms and Control From Thermodynamics to Kinetics. Biomacromolecules 2012, 13, 826–832. [Google Scholar] [CrossRef] [Green Version]

- Seib, F.P. Silk nanoparticles-an emerging anticancer nanomedicine. AIMS Bioeng. 2017, 4, 239–258. [Google Scholar] [CrossRef]

- Wenk, E.; Wandrey, A.J.; Merkle, H.P.; Meinel, L. Silk fibroin spheres as a platform for controlled drug delivery. J. Control. Release 2008, 132, 26–34. [Google Scholar] [CrossRef]

- Seib, F.P.; Jones, G.T.; Rnjak-Kovacina, J.; Lin, Y.; Kaplan, D.L. pH-Dependent Anticancer Drug Release from Silk Nanoparticles. Adv. Healthc. Mater. 2013, 2, 1606–1611. [Google Scholar] [CrossRef] [Green Version]

- Konwarh, R. Can the venerated silk be the next-generation nanobiomaterial for biomedical-device designing, regenerative medicine and drug delivery? Prospects and hitches. Bio-Des. Manuf. 2019, 2, 278–286. [Google Scholar] [CrossRef]

- Subia, B.; Chandra, S.; Talukdar, S.; Kundu, S.C. Folate conjugated silk fibroin nanocarriers for targeted drug delivery. Integr. Biol. 2014, 6, 203–214. [Google Scholar] [CrossRef]

- Totten, J.D.; Wongpinyochit, T.; Carrola, J.; Duarte, I.F.; Seib, F.P. PEGylation-Dependent Metabolic Rewiring of Macrophages with Silk Fibroin Nanoparticles. ACS Appl. Mater. Interfaces 2019, 11, 14515–14525. [Google Scholar] [CrossRef] [Green Version]

- Wongpinyochit, T.; Uhlmann, P.; Urquhart, A.J.; Seib, F.P. PEGylated Silk Nanoparticles for Anticancer Drug Delivery. Biomacromolecules 2015, 16, 3712–3722. [Google Scholar] [CrossRef] [Green Version]

- Lepeltier, E.; Bourgaux, C.; Couvreur, P. Nanoprecipitation and the "Ouzo effect": Application to drug delivery devices. Adv. Drug Deliv. Rev. 2014, 71, 86–97. [Google Scholar] [CrossRef]

- Botet, R.; Roger, K. How do interactions control droplet size during nanoprecipitation? Curr. Opin. Colloid Interface Sci. 2016, 22, 108–112. [Google Scholar] [CrossRef] [Green Version]

- Pham, D.T.; Saelim, N.; Tiyaboonchai, W. Design of experiments model for the optimization of silk fibroin based nanoparticles. Int. J. Appl. Pharm. 2018, 10, 195–201. [Google Scholar] [CrossRef]

- Mehrotra, S.; Chouhan, D.; Konwarh, R.; Kumar, M.; Jadi, P.K.; Mandal, B.B. Comprehensive Review on Silk at Nanoscale for Regenerative Medicine and Allied Applications. ACS Biomater. Sci. Eng. 2019, 5, 2054–2078. [Google Scholar] [CrossRef]

- Zhang, Y.-Q.; Shen, W.-D.; Xiang, R.-L.; Zhuge, L.-J.; Gao, W.-J.; Wang, W.-B. Formation of silk fibroin nanoparticles in water-miscible organic solvent and their characterization. J. Nanopart. Res. 2007, 9, 885–900. [Google Scholar] [CrossRef]

- Matthew, S.A.L.; Totten, J.D.; Phuagkhaopong, S.; Egan, G.; Witte, K.; Perrie, Y.; Seib, F.P. Silk Nanoparticle Manufacture in Semi-Batch Format. ACS Biomater. Sci. Eng. 2020, 6, 6748–6759. [Google Scholar] [CrossRef] [PubMed]

- Vauthier, C.; Bouchemal, K. Methods for the Preparation and Manufacture of Polymeric Nanoparticles. Pharm. Res. 2009, 26, 1025–1058. [Google Scholar] [CrossRef] [PubMed]

- Baldyga, J.; Pohorecki, R. Turbulent micromixing in chemical reactors-a review. Chem. Eng. J. 1995, 58, 183–195. [Google Scholar] [CrossRef]

- Anselmo, A.C.; Mitragotri, S. Nanoparticles in the clinic. Bioeng. Transl. Med. 2016, 1, 10–29. [Google Scholar] [CrossRef]

- Toprakcioglu, Z.; Challa, P.K.; Morse, D.B.; Knowles, T. Attoliter protein nanogels from droplet nanofluidics for intracellular delivery. Sci. Adv. 2020, 6, eaay7952. [Google Scholar] [CrossRef] [Green Version]

- Hamdallah, S.I.; Zoqlam, R.; Erfle, P.; Blyth, M.; Alkilany, A.M.; Dietzel, A.; Qi, S. Microfluidics for pharmaceutical nanoparticle fabrication: The truth and the myth. Int. J. Pharm. 2020, 584, 119408. [Google Scholar] [CrossRef]

- Breslauer, D.N.; Muller, S.J.; Lee, L.P. Generation of monodisperse silk microspheres prepared with microfluidics. Biomacromolecules 2010, 11, 643–647. [Google Scholar] [CrossRef]

- Stroock, A.D.; Dertinger, S.K.W.; Ajdari, A.I.; Mezic´, M.; Stone, H.A.; Whitesides, G.M. Chaotic Mixer for Microchannels. Science 2002, 295, 647–651. [Google Scholar] [CrossRef] [Green Version]

- Williams, M.S.; Longmuir, K.J.; Yager, P. A practical guide to the staggered herringbone mixer. Lab Chip 2008, 8, 1121–1129. [Google Scholar] [CrossRef] [Green Version]

- Kee, S.P.; Gavriilidis, A. Design and characterisation of the staggered herringbone mixer. Chem. Eng. J. 2008, 142, 109–121. [Google Scholar] [CrossRef]

- Melton, L.A.; Lipp, C.W.; Spradling, R.W.; Paulson, K.A. DISMT-Determination of mixing time through color changes. Chem. Eng. Commun. 2002, 189, 322–338. [Google Scholar] [CrossRef]

- Weheliye, W.; Rodriguez, G.; Anderlei, T.; Micheletti, M.; Yianneskis, M.; Ducci, A. Appraisal of shaken bioreactor mixing efficiency for different operating conditions. In Proceedings of the 14th European Conference on Mixing, Warsaw, Poland, 10–13 September 2012; pp. 503–508. [Google Scholar]

- Rodriguez, G.; Weheliye, W.; Anderlei, T.; Micheletti, M.; Yianneskis, M.; Ducci, A. Mixing time and kinetic energy measurements in a shaken cylindrical bioreactor. Chem. Eng. Res. Des. 2013, 91, 2084–2097. [Google Scholar] [CrossRef]

- Matthew, S.A.L.; Rezwan, R.; Kaewchuchuen, J.; Perrie, Y.; Seib, F.P. Mixing and flow-induced nanoprecipitation for morphology control of silk fibroin self-assembly. RSC Adv. 2022, 12, 7357–7373. [Google Scholar] [CrossRef]

- Matsumoto, A.; Lindsay, A.; Abedian, B.; Kaplan, D.L. Silk fibroin solution properties related to assembly and structure. Macromol. Biosci. 2008, 8, 1006–1018. [Google Scholar] [CrossRef]

- Griebenow, K.; Santos, A.M.; Carrasquillo, K.G. Secondary structure of proteins in the amorphous dehydrated state probed by FTIR spectroscopy. Dehydration-induced structural changes and their prevention. Int. J. Vib. Spectrosc. 1999, 3, 1–2. [Google Scholar]

- Galisteo-González, F.; Molina-Bolívar, J.A. Systematic study on the preparation of BSA nanoparticles. Colloids Surf. B 2014, 123, 286–292. [Google Scholar] [CrossRef]

- Galindo-Rodríguez, S.A.; Puel, F.; Briançon, S.; Allémann, E.; Doelker, E.; Fessi, H. Comparative scale-up of three methods for producing ibuprofen-loaded nanoparticles. Eur. J. Pharm. Sci. 2005, 25, 357–367. [Google Scholar] [CrossRef]

- Dunderdale, G.J.; Davidson, S.J.; Ryan, A.J.; Mykhaylyk, O.O. Flow-induced crystallisation of polymers from aqueous solution. Nat. Commun. 2020, 11, 3372. [Google Scholar] [CrossRef]

- Nisal, A.; Kalelkar, C.; Bellare, J.; Lele, A. Rheology and microstructural studies of regenerated silk fibroin solutions. Rheol. Acta 2013, 52, 833–840. [Google Scholar] [CrossRef]

- Joye, I.J.; McClements, D.J. Production of nanoparticles by anti-solvent precipitation for use in food system. Trends Food Sci. Technol. 2013, 34, 109–123. [Google Scholar] [CrossRef]

- Seib, F.P.; Maitz, M.F.; Hu, X.; Werner, C.; Kaplan, D.L. Impact of processing parameters on the haemocompatibility of Bombyx mori silk films. Biomaterials 2012, 33, 1017–1023. [Google Scholar] [CrossRef] [Green Version]

- Um, I.C.; Kweon, H.Y.; Park, Y.H.; Hudson, S. Structural characteristics and properties of the regenerated silk fibroin prepared from formic acid. Int. J. Biol. Macromol. 2001, 29, 91–97. [Google Scholar] [CrossRef]

- Webb, C.; Forbes, N.; Roces, C.B.; Anderluzzi, G.; Lou, G.; Abraham, S.; Ingalls, L.; Marshall, K.; Leaver, T.J.; Watts, J.A.; et al. Using microfluidics for scalable manufacturing of nanomedicines from bench to GMP: A case study using protein-loaded liposomes. Int. J. Pharm. 2020, 582, 119266. [Google Scholar] [CrossRef] [PubMed]

- Lim, J.M.; Swami, A.; Gilson, L.M.; Chopra, S.; Choi, S.; Wu, J.; Langer, R.; Karnik, R.; Farokhzad, O.C. Ultra-high throughput synthesis of nanoparticles with homogeneous size distribution using a coaxial turbulent jet mixer. ACS Nano 2014, 8, 6056–6065. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Decuzzi, P.; Peer, D.; Mascolo, D.D.; Palange, A.L.; Manghnani, P.N.; Moein Moghimi, S.; Shadi Farhangrazi, Z.; Howard, K.A.; Rosenblum, D.; Liang, T.; et al. Roadmap on nanomedicine. Nanotechnology 2021, 32, 012001. [Google Scholar] [CrossRef]

- Operti, M.C.; Bernhardt, A.; Grimm, S.; Engel, A.; Figdor, C.G.; Tagit, O. PLGA-based nanomedicines manufacturing: Technologies overview and challenges in industrial scale-up. Int. J. Pharm. 2021, 605, 120807. [Google Scholar] [CrossRef]

- Ianovska, M.A.; Mulder, P.P.M.F.A.; Verpoorte, E. Development of small-volume, microfluidic chaotic mixers for future application in two-dimensional liquid chromatography. RSC Adv. 2017, 7, 9090–9099. [Google Scholar] [CrossRef] [Green Version]

- Rode García, T.; García Ac, A.; Lalloz, A.; Lacasse, F.-X.; Hildgen, P.; Rabanel, J.-M.; Banquy, X. Unified Scaling of the Structure and Loading of Nanoparticles Formed by Diffusion-Limited Coalescence. Langmuir 2018, 34, 5772–5780. [Google Scholar] [CrossRef]

- Xie, M.H.; Zhou, G.Z.; Xia, J.Y.; Zou, C.; Yu, P.Q.; Zhang, S.L. Comparison of power number for paddle-type impellers by three methods. J. Chem. Eng. Jpn. 2011, 44, 840–844. [Google Scholar] [CrossRef]

- Kamei, N.; Hiraoka, S.; Kato, Y. Effects of impeller and baffle dimensions on power consumption under turbulent flow in an agitated vessel with paddle impeller. Kagaku Kogaku Ronbunshu 1996, 22, 249–256. [Google Scholar] [CrossRef] [Green Version]

- Berry, A.L. The Effects of Shear and Mixing on a Continuously-Fed Stirred Tank Reactor for Aerobic, Biological Wastewater Treatment. Ph.D. Thesis, Cranfield University, Milton Keynes, UK, 2002; pp. 5–7. [Google Scholar]

- Mialdun, A.; Yasnou, V.; Shevtsova, V.; Königer, A.; Köhler, W.; Alonso De Mezquia, D.; Bou-Ali, M.M. A comprehensive study of diffusion, thermodiffusion, and Soret coefficients of water-isopropanol mixtures. J. Chem. Phys. 2012, 136, 244512. [Google Scholar] [CrossRef]

- Tomar, S. Converting video formats with FFmpeg. Linux J. 2006, 146, 10. [Google Scholar]

- Rodriguez, G.; Anderlei, T.; Micheletti, M.; Yianneskis, M.; Ducci, A. On the measurement and scaling of mixing time in orbitally shaken bioreactors. Biochem. Eng. J. 2014, 82, 10–21. [Google Scholar] [CrossRef] [Green Version]

- Jiang, X.; Zheng, L.; Wu, H.; Zhang, J. Investigations into the role of non-bond interaction on gelation mechanism of silk fibroin hydrogel. MBE 2021, 18, 4071–4083. [Google Scholar] [CrossRef]

- Xu, Z.; Lu, C.; Riordon, J.; Sinton, D.; Moffitt, M.G. Microfluidic Manufacturing of Polymeric Nanoparticles: Comparing Flow Control of Multiscale Structure in Single-Phase Staggered Herringbone and Two-Phase Reactors. Langmuir 2016, 32, 12781–12789. [Google Scholar] [CrossRef]

- ASTM E691-19e1; Standard Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method. ASTM International: West Conshohocken, PA, USA, 2019.

- Pang, F.-M.; Seng, C.-E.; Teng, T.-T.; Ibrahim, M.H. Densities and viscosities of aqueous solutions of 1-propanol and 2-propanol at temperatures from 293.15 K to 333.15 K. J. Mol. Liq. 2007, 136, 71–78. [Google Scholar] [CrossRef]

- Son, Y. Determination of shear viscosity and shear rate from pressure drop and flow rate relationship in a rectangular channel. Polymer 2007, 48, 632–637. [Google Scholar] [CrossRef]

- Yang, H.; Yang, S.; Kong, J.; Dong, A.; Yu, S. Obtaining information about protein secondary structures in aqueous solution using Fourier transform IR spectroscopy. Nat. Protoc. 2015, 10, 382–396. [Google Scholar] [CrossRef]

- Shimanovich, U.; Ruggeri, F.S.; De Genst, E.; Adamcik, J.; Barros, T.P.; Porter, D.; Müller, T.; Mezzenga, R.; Dobson, C.M.; Vollrath, F.; et al. Silk micrococoons for protein stabilisation and molecular encapsulation. Nat. Commun. 2017, 8, 15902. [Google Scholar] [CrossRef] [Green Version]

- Aggarwal, N.; Eliaz, D.; Cohen, H.; Rosenhek-Goldian, I.; Cohen, S.R.; Kozell, A.; Mason, T.O.; Shimanovich, U. Protein nanofibril design via manipulation of hydrogen bonds. Commun. Chem. 2021, 4, 62. [Google Scholar] [CrossRef]

- Paquet-Mercier, F.; Lefèvre, T.; Auger, M.; Pézolet, M. Evidence by infrared spectroscopy of the presence of two types of β-sheets in major ampullate spider silk and silkworm silk. Soft Matter 2013, 9, 208. [Google Scholar] [CrossRef]

- Hu, X.; Kaplan, D.; Cebe, P. Determining beta-sheet crystallinity in fibrous proteins by thermal analysis and infrared spectroscopy. Macromolecules 2006, 39, 6161–6170. [Google Scholar] [CrossRef]

- Riesen, R.; Vogel, K.; Schubnell, M. DSC by the TGA/SDTA851e considering mass changes. J. Therm. Anal. Calorim. 2001, 64, 243–252. [Google Scholar] [CrossRef]

| Semi-Batch Format | Microfluidic Format | |||

|---|---|---|---|---|

| Total Volume/mL | Stirring Rate/rpm | Mixing Time/s | Residence Time/ms | Mixing Time/ms |

| 5 | 400 | 8.4 ± 4.4 | 120 | 21 |

| 30 | 400 | 29.4 ± 6.0 | ||

| Semi-Batch Format | Microfluidic Format | |||||

|---|---|---|---|---|---|---|

| Needle Internal Diameter/mm | Flow Rate/mL min−1 | Residence Time/ms | Maximum Shear Rate/s−1 | Re | Maximum Shear Rate/s−1 | Re |

| 0.33 | 1.00 | 43 | 4724 | 2.4 | 80,114 | 40 |

| Thermal Property | Semi-Batch | Microfluidic | Negative Silk II Control | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Volumetric Scale/mL | |||||||||

| 1.8 1 | 6 | 21.9 | 36 | 42 | 138 | 6 | Freeze-Dried Powder | ||

| DSC | Tg/°C | - | 59.3 ± 0.01 | 57.9 1 | 58.6 ± 1.0 2 | - | - | 71.6 1 | 47.7 ± 0.5 |

| Td/°C | 35.7 | 39.1 ± 5.3 | 54.2 ± 15.9 | 43.5 ± 13.5 | 66.2 ± 2.8 | 67.5 ± 4.2 | 59.9 ± 0.3 | 60.7 ± 8.8 | |

| ∆Hd/J g−1 | −267.7 | −207.8 ± 98.0 | −197.5 ± 4.6 | −197.5 ± 30.1 | −211.8 ± 15.8 | −191.9 ± 8.9 | −191.8 ± 0.9 | −276.9 ± 4.21 | |

| Tg’/°C | - | - | - | - | - | - | - | 184.5 ± 0.7 | |

| Tc/°C | - | - | - | - | - | - | - | 241.0 ± 0.8 | |

| ∆Hc/J g−1 | - | - | - | - | - | - | - | 9.9 ± 2.3 | |

| To/°C | 274.1 | 274.0 ± 0.3 | 273.4 ± 0.6 | 267.4 ± 1.7 | 267.8 ± 0.8 | 265.7 ± 1.5 | 264.4 ± 0.1 | - | |

| Tdec/°C | 290.4 | 289.5 ± 0.5 | 289.5 ± 0.3 | 284.7 ± 0.4 | 284.9 ± 0.5 | 284.0 ± 1.0 | 282.1 ± 0.4 | 274.9 ± 1.1 1 | |

| TGA | Water content/% (w/w) | 23.8 | 13.0 ± 1.7 | 11.7 ± 0.8 | 11.2 ± 0.7 | 10.7 ± 0.7 | 10.2 ± 0.6 | 5.2 ± 0.5 | 5.8 ± 0.8 |

| To/°C | 278.8 | 277.3 ± 0.2 | 278.1 ± 1.0 | 272.3 ± 0.1 | 273.2 ± 0.6 | 271.5 ± 0.9 | 271.2 ± 0.5 | 198.5 ± 2.2 | |

| To’/°C | - | - | - | - | - | - | - | 261.4 ± 2.0 | |

| Tdec/°C | 289.7 | 299.6 ± 6.6 | 293.1 ± 4.1 | 299.0 ± 10.3 | 297.7 ± 5.5 | 298.1 ± 11.3 | 293.4 ± 5.8 | 222.3 ± 13.3 | |

| Tdec’/°C | - | - | - | - | - | - | - | 275.0 ± 2.7 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matthew, S.A.L.; Rezwan, R.; Perrie, Y.; Seib, F.P. Volumetric Scalability of Microfluidic and Semi-Batch Silk Nanoprecipitation Methods. Molecules 2022, 27, 2368. https://doi.org/10.3390/molecules27072368

Matthew SAL, Rezwan R, Perrie Y, Seib FP. Volumetric Scalability of Microfluidic and Semi-Batch Silk Nanoprecipitation Methods. Molecules. 2022; 27(7):2368. https://doi.org/10.3390/molecules27072368

Chicago/Turabian StyleMatthew, Saphia A. L., Refaya Rezwan, Yvonne Perrie, and F. Philipp Seib. 2022. "Volumetric Scalability of Microfluidic and Semi-Batch Silk Nanoprecipitation Methods" Molecules 27, no. 7: 2368. https://doi.org/10.3390/molecules27072368

APA StyleMatthew, S. A. L., Rezwan, R., Perrie, Y., & Seib, F. P. (2022). Volumetric Scalability of Microfluidic and Semi-Batch Silk Nanoprecipitation Methods. Molecules, 27(7), 2368. https://doi.org/10.3390/molecules27072368