Changes in Physicochemical, Free Radical Activity, Total Phenolic and Sensory Properties of Orange (Citrus sinensis L.) Juice Fortified with Different Oleaster (Elaeagnus angustifolia L.) Extracts

Abstract

1. Introduction

2. Results and Discussion

2.1. Compositional Differences of Oleaster Extracts

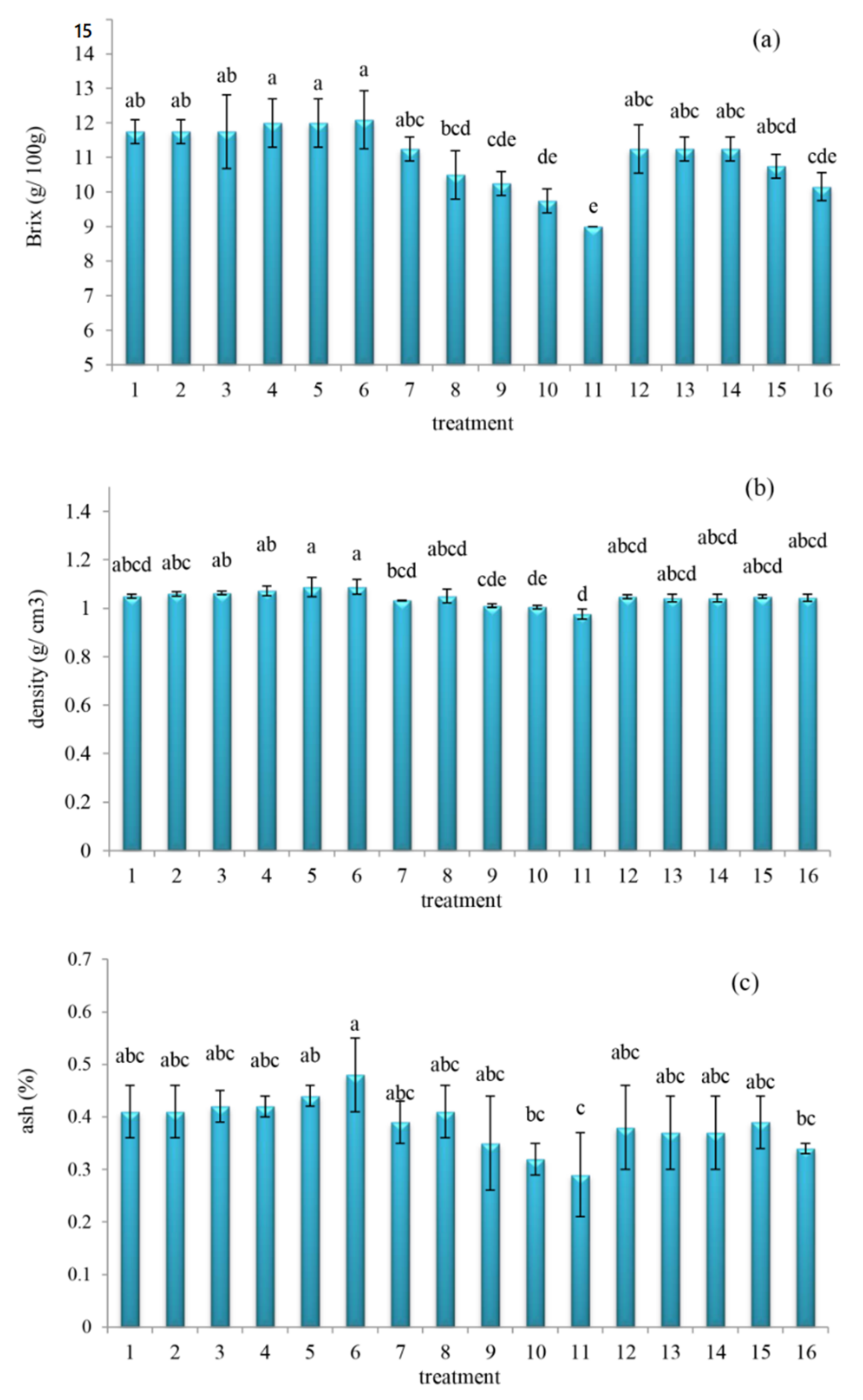

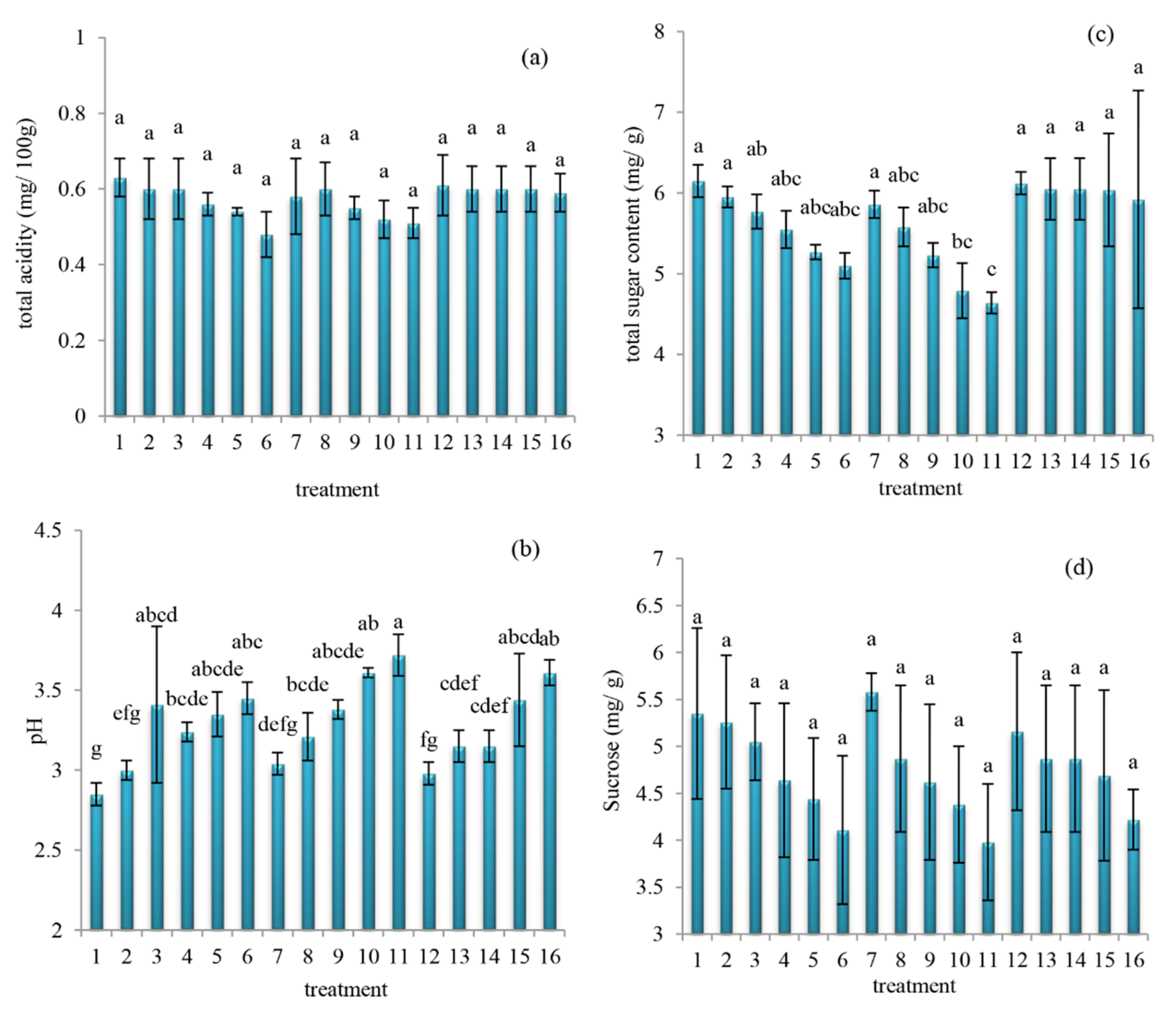

2.2. Changes in Physicochemical Properties

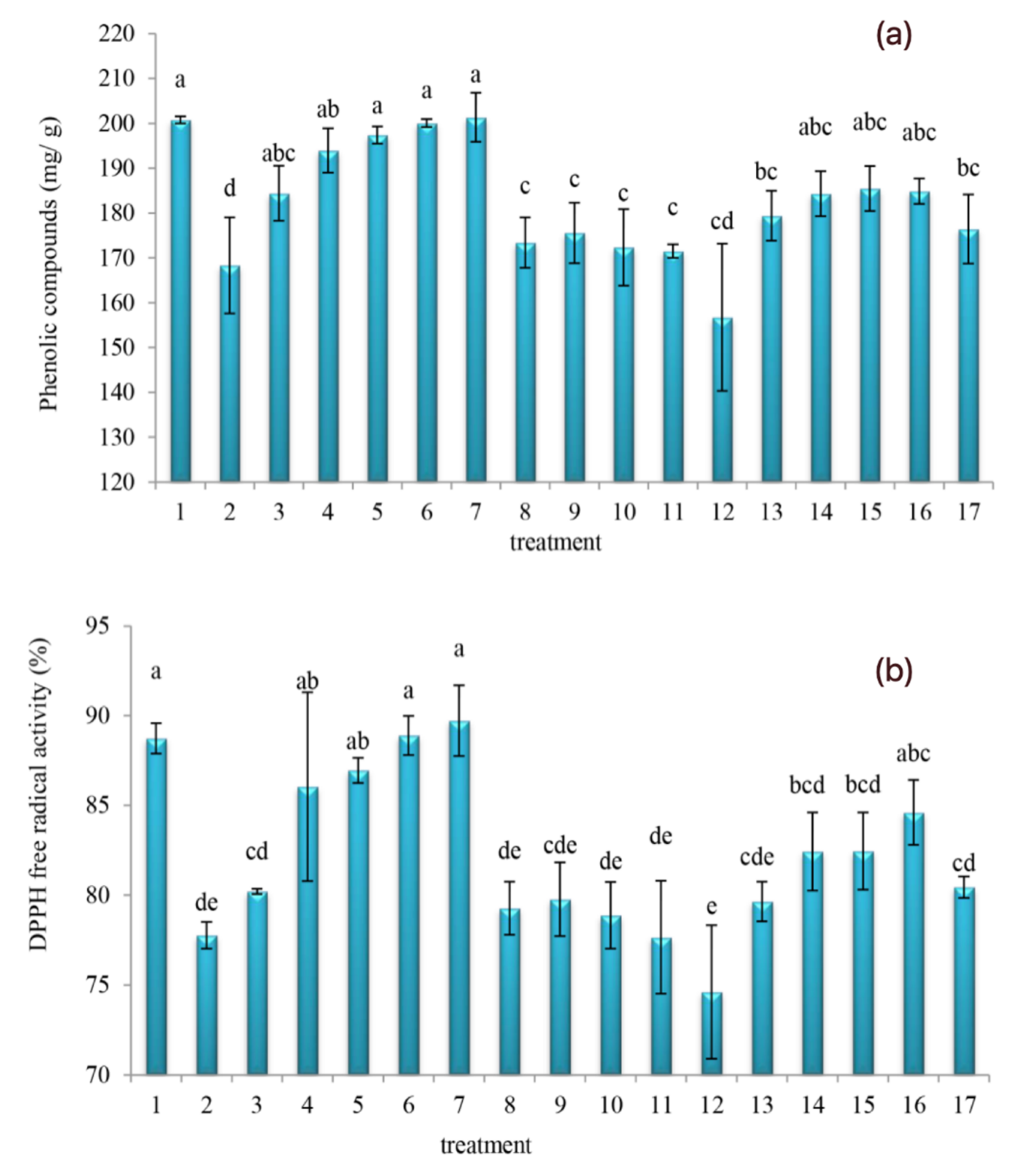

2.3. Changes in DPPH Free Radical Activity and Total Phenolic Compounds

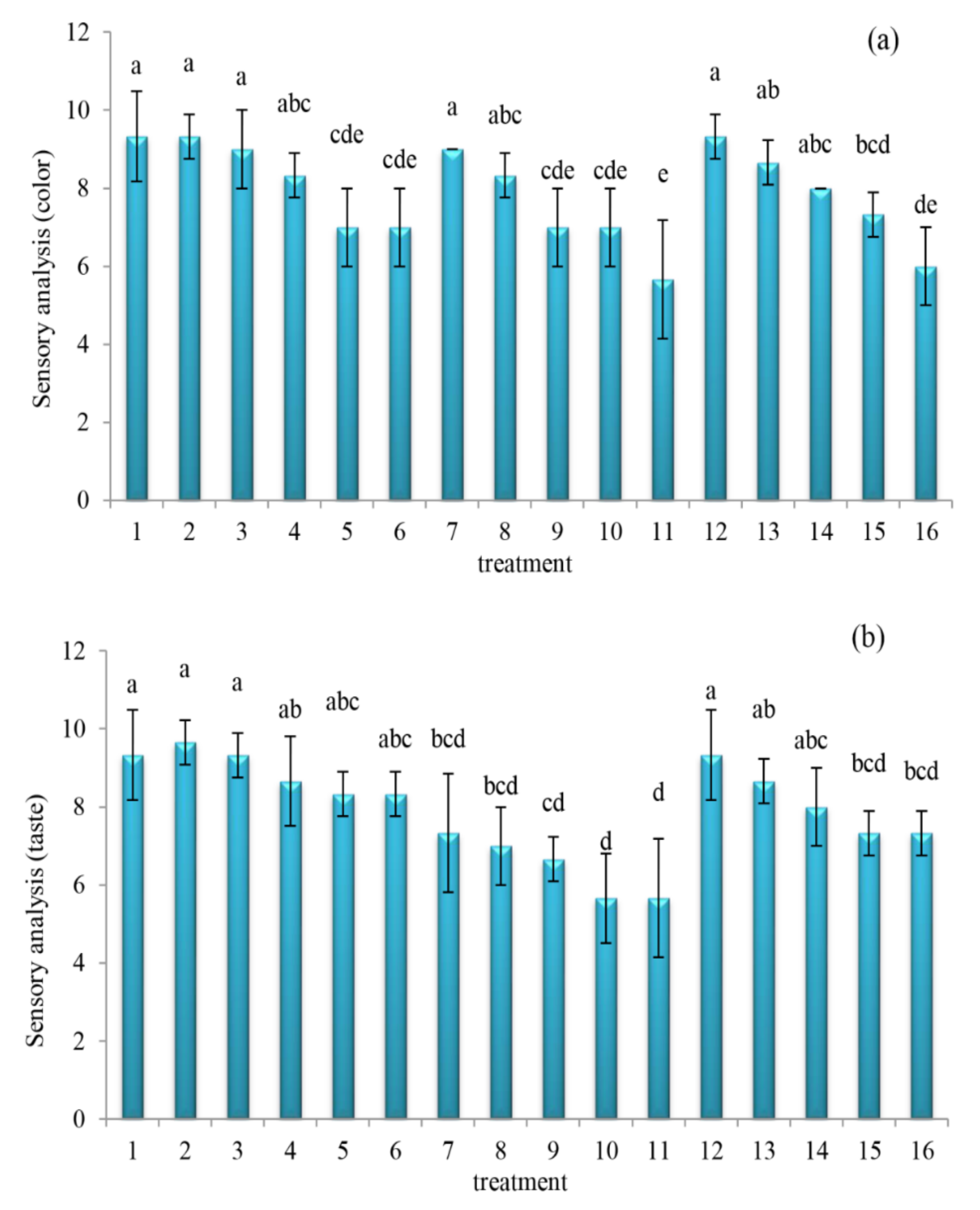

2.4. Changes in Sensory Attributes

3. Materials and Methods

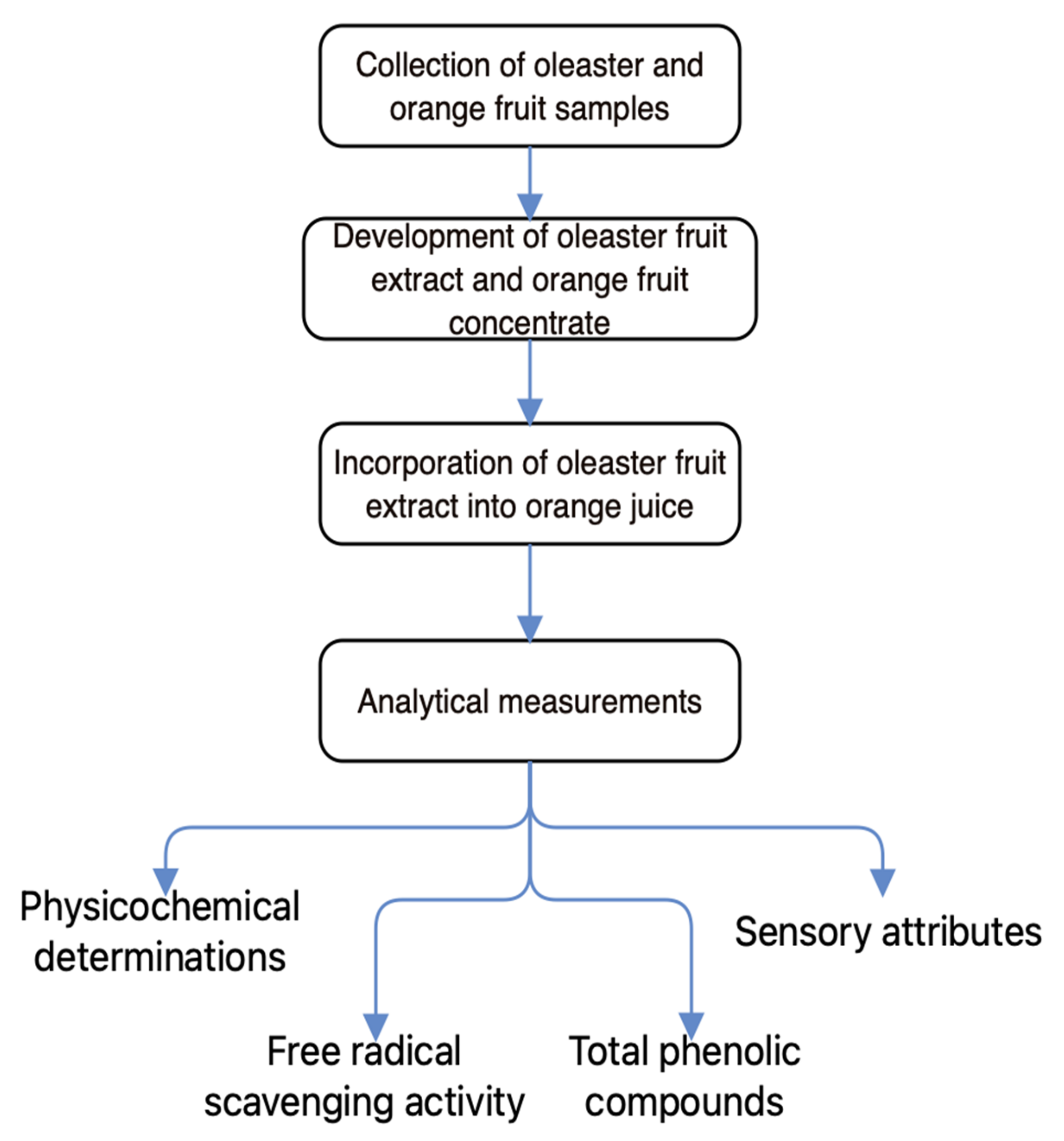

3.1. Schematic Overview of the Experimental Program

3.2. Chemical and Reagents

3.3. Identification of Oleaster and Orange Fruits

3.4. Development of the Oleaster Fruit Extract and Orange Fruit Concentrate

3.5. Incorporation of Oleaster Fruit Extracts into Orange Juice Mix

3.6. Analytical Methods

3.6.1. Physicochemical Measurements

Determination of Brix and Density

Determination of Ash Content

Determination of Total Acidity

Determination of Total Sugar Contents

Determination of pH

Determination of Sucrose

3.6.2. Determination of DPPH Free Radical Activity

3.6.3. Determination of Total Phenolic Compounds

3.6.4. Determination of Sensory Attributes

3.7. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Kolniak-Ostek:, J.; Kłopotowska, D.; Rutkowski, K.P.; Skorupińska, A.; Kruczyńska, D.E. Bioactive Compounds and Health-Promoting Properties of Pear (Pyrus communis L.) Fruits. Molecules 2020, 25, 4444. [Google Scholar] [CrossRef] [PubMed]

- Putnik, P.; Pavlić, B.; Šojić, B.; Zavadlav, S.; Žuntar, I.; Kao, L.; Kitonić, D.; Kovačević, D.B. Innovative Hurdle Technologies for the Preservation of Functional Fruit Juices. Foods 2020, 9, 699. [Google Scholar] [CrossRef] [PubMed]

- Carradori, S.; Cairone, F.; Garzoli, S.; Fabrizi, G.; Iazzetti, A.; Giusti, A.M.; Menghini, L.; Uysal, S.; Ak, G.; Zengin, G.; et al. Phytocomplex Characterization and Biological Evaluation of Powdered Fruits and Leaves from Elaeagnus angustifolia. Molecules 2020, 25, 2021. [Google Scholar] [CrossRef]

- Ephrem, E.; Najjar, A.; Charcosset, C.; Greige-Gerges, H. Encapsulation of natural active compounds, enzymes, and probiotics for fruit juice fortification, preservation, and processing: An overview. J. Funct. Foods 2018, 48, 65–84. [Google Scholar] [CrossRef]

- Farrell, K.T. Spices, Condiments and Seasonings; Springer: Berlin/Heidelberg, Germany, 1999; pp. 17–19. ISBN 978-0-8342-1337-1. [Google Scholar]

- Sharma, S.K.; Yadav, V.K.; Rao, V.K.; Dixit, A.K. Enhancement of health-promoting properties while substituting exogenous citric acid by seabuckthorn (Hippophae salicifolia) pulp in preparation of sweet orange (Citrus sinensis) ready-to-serve beverage. J. Food Process. Preserv. 2014, 38, 1427–1438. [Google Scholar] [CrossRef]

- Hashemi, J.M.; Haridy, L.A.M.; Qashqari, R.J. The Effect of Moringa oleifera leaves extract on extending the shelf life and quality of freshly sweet Orange Juice. J. Biochem. Tech. 2018, 9, 63–76. [Google Scholar]

- Kimball, D.A. Citrus Processing: A Complete Guide, 2nd ed.; Springer: New York, NY, USA, 1999; p. 450. ISBN 978-0-8342-1258-9. [Google Scholar]

- Balch, P.A. Prescription for Dietary Wellness; Avery: New York, NY, USA, 2003; p. 307. ISBN 9781583331477. [Google Scholar]

- Galaverna, G.; Dall’Asta, C. Production Processes of Orange Juice and Effects on Antioxidant Components. In Processing and Impact on Antioxidants in Beverages; Preedy, V.R., Ed.; Elsevier: Amsterdam, The Netherlands, 2014; pp. 203–214. [Google Scholar]

- Bull, M.K.; Zerdin, K.; Goicoechea, D.; Paramanandhan, P.; Stockman, R.; Sellahewa, J.; Szabo, E.A.; Johnson, R.L.; Stewart, C.M. The effect of high pressure processing on the microbial, physical and chemical properties of Valencia and Navel orange juice. Innov. Food Sci. Emerg. Technol. 2004, 5, 135–149. [Google Scholar] [CrossRef]

- Arilla, E.; García-Segovia, P.; Martínez-Monzó, J.; Codoñer-Franch, P.; Igual, M. Effect of Adding Resistant Maltodextrin to Pasteurized Orange Juice on Bioactive Compounds and Their Bioaccessibility. Foods 2021, 10, 1198. [Google Scholar] [CrossRef]

- Zargari, A. Medicinal Plants, 6th ed.; Tehran University Publications: Tehran, Iran, 1997; Volume 1. [Google Scholar]

- Panahi, Y.; Alishiri, G.H.; Bayat, N.; Hosseini, S.M.; Sahebkar, A. Efficacy of Elaeagnus angustifolia extract in the treatment of knee osteoarthritis: A randomized controlled trial. Excli J. 2016, 15, 203–210. [Google Scholar] [CrossRef]

- Ahmadiani, A.; Hosseiny, J.; Semnanian, S.; Javan, M.; Saeedi, F.; Kamalinejad, M.; Saremi, S. Antinociceptive and anti-inflammatory effects of Elaeagnus angustifolia fruit extract. J. Ethnopharmacol. 2000, 72, 287–292. [Google Scholar] [CrossRef]

- Mehdi, G.; Mahdi, E.; Mojtaba, D.; Hadi, K.; Hossein, F.; Mojtaba, K. Protective Effect of Elaeagnus angustifolia L. Fruit Hydroalcoholic Extract on Cyclophosphamide-Induced Nephrotoxicity in Mice. Shiraz E Med. J. 2018, 19, e55075. [Google Scholar]

- Hamidpour, R.; Hamidpour, S.; Hamidpour, M.; Shahlari, M.; Sohraby, M.; Shahlari, N.; Hamidpour, R. Russian olive (Elaeagnus angustifolia L.): From a variety of traditional medicinal applications to its novel roles as active antioxidant, anti-inflammatory, anti-mutagenic and analgesic agent. J. Tradit Complement Med. 2017, 7, 24–29. [Google Scholar] [CrossRef] [PubMed]

- Hassanzadeh, Z.; Hassanpour, H. Evaluation of physicochemical characteristics and antioxidant properties of Elaeagnus angustifolia L. Sci. Hortic. 2018, 238, 83–90. [Google Scholar] [CrossRef]

- Faramarz, S.; Dehghan, G.; Jahanban-Esfahlan, A. Antioxidants in different parts of Oleaster as a function of genotype. Bioimpacts 2015, 5, 79–85. [Google Scholar] [CrossRef] [PubMed]

- Scherer, R.; Godoy, H.T. Antioxidant activity index (AAI) by the 2,2-diphenyl-1-picrylhydrazyl method. Food Chem. 2009, 112, 654–658. [Google Scholar] [CrossRef]

- Brunner, G. Hydrothermal and Supercritical Water Processes, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2014; p. 604. ISBN 9780444594136. [Google Scholar]

- Truong, D.-H.; Nguyen, D.H.; Ta, N.T.A.; Bui, A.V.; Do, T.H.; Nguyen, H.C. Evaluation of the Use of Different Solvents for Phytochemical Constituents, Antioxidants, and In Vitro Anti-Inflammatory Activities of Severinia buxifolia. J. Food Qual. 2019, 2019, 8178294. [Google Scholar] [CrossRef]

- Waszkowiak, K.; Gliszczyńska-Świgło, A. Binary ethanol–water solvents affect phenolic profile and antioxidant capacity of flaxseed extracts. Eur. Food Res. Technol. 2016, 242, 777–786. [Google Scholar] [CrossRef]

- Jacotet-Navarro, M.; Laguerre, M.; Fabiano-Tixier, A.S.; Tenon, M.; Feuillère, N.; Bily, A.; Chemat, F. What is the best ethanol-water ratio for the extraction of antioxidants from rosemary? Impact of the solvent on yield, composition, and activity of the extracts. Electrophoresis 2018, 39, 1946–1956. [Google Scholar] [CrossRef]

- Jessop, P.G.; Jessop, D.A.; Fu, D.; Phan, L. Solvatochromic parameters for solvents of interest in green chemistry. Green Chem. 2012, 14, 1245–1259. [Google Scholar] [CrossRef]

- Mello, B.C.; Petrus, J.C.C.; Hubinger, M.D. Concentration of flavonoids and phenolic compounds in aqueous and ethanolic propolis extracts through nanofiltration. J. Food Eng. 2010, 96, 533–539. [Google Scholar] [CrossRef]

- Dassoff, E.S.; Guo, J.X.; Liu, Y.; Wang, S.C.; Li, Y.O. Potential development of non-synthetic food additives from orange processing by-products—A review. Food Qual. Saf. 2021, 5, fyaa035. [Google Scholar] [CrossRef]

- Martín-Diana, A.B.; Rico, D.; Barat, J.; Barry-Ryan, C. Orange juices enriched with chitosan: Optimisation for extending the shelf-life. Innov. Food Sci. Emerg. Technol. 2009, 10, 590–600. [Google Scholar] [CrossRef]

- Adeogun, O.; Adekunle, A.; Adongbede, E. Effects of Leaf Extracts of Selected Plants on Quality of Stored Citrus sinensis (Sweet Orange) Juice. Not. Sci. Biol. 2017, 9, 256–262. [Google Scholar] [CrossRef]

- Akhbari, M.; Haeri, M.R.; Babaei, M. Investigation of Anthocyanin Contents and Cytotoxic Activity in Different Extracts of Fruit Peel of Solanum melongena L. Qom Univ. Med Sci. J. 2014, 8, 11–17. [Google Scholar]

- Boudraa, S.; Hambaba, L.; Zidani, S.; Boudraa, H. Mineral and vitamin composition of fruits of five underexploited species in Algeria: Celtis australis L.; Crataegus azarolus L.; Crataegus monogyna Jacq., Elaeagnus angustifolia L. and Zizyphus lotus L. Fruits 2010, 65, 75–84. [Google Scholar] [CrossRef][Green Version]

- Aneja, K.R.; Dhiman, R.; Aggarwal, N.K.; Kumar, V.; Kaur, M. Microbes associated with freshly prepared juices of citrus and carrots. Int. J. Food Sci. 2014, 2014, 408085. [Google Scholar] [CrossRef]

- Romeo, R.; De Bruno, A.; Piscopo, A.; Medina, E.; Ramírez, E.; Brenes, M.; Poiana, M. Effects of phenolic enrichment on vitamin C and antioxidant activity of commercial orange juice. Braz. J. Food Technol. 2020, 23, e2019130. [Google Scholar] [CrossRef]

- Mu, X.; Wang, P.; Du, J.; Gao, Y.G.; Zhang, J. Comparison of fruit organic acids and metabolism-related gene expression between Cerasus humilis (Bge.) Sok and Cerasus glandulosa (Thunb.) Lois. PLoS ONE 2018, 13, e0196537. [Google Scholar] [CrossRef]

- Gloria, P.; Mubofu Egid, B.; Othman Chande, C. Post-harvest changes in physico-chemical properties and levels of some inorganic elements in off vine ripened orange (Citrus sinensis) fruits cv (Navel and Valencia) of Tanzania. Afr. J. Biotechnol. 2010, 9, 1809–1815. [Google Scholar]

- Akhtar, S.; Ali, J.; Javed, B.; Ali Khan, F. Studies on the Preparation and Storage Stability of Pomegranate Juice Based Drink. Middle East J. Sci. Res. 2013, 16, 191–195. [Google Scholar]

- Caridi, A.; De Bruno, A.; De Salvo, E.; Piscopo, A.; Poiana, M.; Sidari, R. Selected yeasts to enhance phenolic content and quality in red wine from low pigmented grapes. Eur. Food Res. Technol. 2017, 243, 367–378. [Google Scholar] [CrossRef]

- De Bruno, A.; Romeo, R.; Fedele, F.L.; Sicari, A.; Piscopo, A.; Poiana, M. Antioxidant activity shown by olive pomace extracts. J. Environ. Sci. Health Part B 2018, 53, 526–533. [Google Scholar] [CrossRef]

- Yao, Y.; Sang, W.; Zhou, M.; Ren, G. Phenolic composition and antioxidant activities of 11 celery cultivars. J. Food Sci. 2010, 75, C9–C13. [Google Scholar] [CrossRef] [PubMed]

- Rashidaie Abandansarie, S.S.; Ariaii, P.; Charmchian Langerodi, M. Effects of encapsulated rosemary extract on oxidative and microbiological stability of beef meat during refrigerated storage. Food Sci. Nutr. 2019, 11, 3969–3978. [Google Scholar] [CrossRef] [PubMed]

- Esmaeilzadeh Kenari, R.; Mohsenzadeh, F.; Amiri, Z. Antioxidant activity and total phenolic compounds of Dezful sesame cake extracts obtained by classical and ultrasound-assisted extraction methods. Food Sci. Nutr. 2014, 2, 426–435. [Google Scholar] [CrossRef] [PubMed]

- Maleki, M.; Ariaii, P.; Fallah, H. Effects of celery extracts on the oxidative stability of canola oil under thermal condition. J. Food Process. Preserv. 2016, 40, 531–540. [Google Scholar] [CrossRef]

- Cansev, A.; Sahan, Y.; Celik, G.; Taskesen, S.; Özbey, H. Chemical properties and antioxidant capacity of Elaeagnus angustifolia L. fruits. Asian J. Chem. 2011, 23, 2661–2665. [Google Scholar]

- Tometri, S.S.; Ahmady, M.; Ariaii, P.; Soltani, M.S. Extraction and encapsulation of Laurus nobilis leaf extract with nano-liposome and its effect on oxidative, microbial, bacterial and sensory properties of minced beef. Food Meas. 2020, 14, 3333–3344. [Google Scholar] [CrossRef]

- Fan, Z.; Plotto, A.; Bai, J.; Whitaker, V.M. Volatiles Influencing Sensory Attributes and Bayesian Modeling of the Soluble Solids–Sweetness Relationship in Strawberry. Front. Plant Sci. 2021, 12, 640704. [Google Scholar] [CrossRef]

- Iranian National Standards. Institute of Standards and Industrial Research of Iran. Available online: http://www.isiri.com/about.htm (accessed on 20 February 2021).

- Vaez, G.; Tavasoli, Z.; Ranjbar-Bahadori, S. Study on the different dosages of Elaeagnus angustifolia aqueous extract with and without morphine on the antinociceptive rate in mice. Res. Med. 2011, 35, 27–33. [Google Scholar]

- He, Y.; Ji, Z.; Li, S. Effective clarification of apple juice using membrane filtration without enzyme and pasteurization pretreatment. Sep. Purif. Technol. 2007, 57, 366–373. [Google Scholar] [CrossRef]

- AOAC. Association of Official Analytical Chemists. In Official Methods of Analysis of the Association of Official Analytical Chemist, 15th ed.; AOAC International: Arlington, VA, USA, 1990; ISBN 978-0935584424. [Google Scholar]

- Suzanne Nielsen, S. Food Analysis, 4th ed.; Springer Science+Business Media LLC.: New York, NY, USA, 2010; p. 586. ISBN 978-1-4419-1477-4. [Google Scholar]

- Su, M.; Silva, J. Antioxidant activity, anthocyanins, and phenolics of rabbit eye (Vaccinium ashei) by-products as affected by fermentation. Food Chem. 2006, 97, 447–451. [Google Scholar] [CrossRef]

- Meilgaard, M.C.; Thomas Carr, B.; Civille, G.V. Sensory Evaluation Techniques, 3rd ed.; CRC Press: New York, NY, USA, 1999; p. 416. ISBN 9781003040729. [Google Scholar] [CrossRef]

- Çakmakçı, S.; Topdaş, E.F.; Kalın, P.; Han, H.; Şekerci, P.; Köse, L.P.; Gülçin, İ. Antioxidant capacity and functionality of oleaster (Elaeagnus angustifolia L.) flour and crust in a new kind of fruity ice cream. Int. J. Food Sci. Technol. 2015, 50, 472–481. [Google Scholar] [CrossRef]

| Parameters | Aqueous Extract | Alcoholic Extract | Hydro-Alcoholic Extract |

|---|---|---|---|

| Brix (g/100 g) | 8.25 ± 1.43 a | 2.35 ± 0.07 c | 5.75 ± 0.09 b |

| Density (g/cm3) | 1.20 ± 0.12 a | 0.83 ± 0.03 c | 1.04 ± 0.05 b |

| Ash (%) | 0.47 ± 0.03 a | 0.012 ± 0.003 c | 0.13 ± 0.02 b |

| Total acidity (mg/100 g) | 0.34 ± 0.03 b | 0.17 ± 0.02 c | 0.54 ± 0.13 a |

| pH | 5.25 ± 0.35 b | 6.95 ± 0.23 a | 5.85 ± 0.21 a,b |

| Total sugar content (mg/g) | 1.88 ± 0.16 a | 0.23 ± 0.04 c | 0.95 ± 0.11 b |

| Sucrose (mg/g) | 0.38 ± 0.16 a | 0.11 ± 0.01 c | 0.25 ± 0.06 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sarvarian, M.; Jafarpour, A.; Awuchi, C.G.; Adeleye, A.O.; Okpala, C.O.R. Changes in Physicochemical, Free Radical Activity, Total Phenolic and Sensory Properties of Orange (Citrus sinensis L.) Juice Fortified with Different Oleaster (Elaeagnus angustifolia L.) Extracts. Molecules 2022, 27, 1530. https://doi.org/10.3390/molecules27051530

Sarvarian M, Jafarpour A, Awuchi CG, Adeleye AO, Okpala COR. Changes in Physicochemical, Free Radical Activity, Total Phenolic and Sensory Properties of Orange (Citrus sinensis L.) Juice Fortified with Different Oleaster (Elaeagnus angustifolia L.) Extracts. Molecules. 2022; 27(5):1530. https://doi.org/10.3390/molecules27051530

Chicago/Turabian StyleSarvarian, Maryam, Afshin Jafarpour, Chinaza Godswill Awuchi, Ademiku O. Adeleye, and Charles Odilichukwu R. Okpala. 2022. "Changes in Physicochemical, Free Radical Activity, Total Phenolic and Sensory Properties of Orange (Citrus sinensis L.) Juice Fortified with Different Oleaster (Elaeagnus angustifolia L.) Extracts" Molecules 27, no. 5: 1530. https://doi.org/10.3390/molecules27051530

APA StyleSarvarian, M., Jafarpour, A., Awuchi, C. G., Adeleye, A. O., & Okpala, C. O. R. (2022). Changes in Physicochemical, Free Radical Activity, Total Phenolic and Sensory Properties of Orange (Citrus sinensis L.) Juice Fortified with Different Oleaster (Elaeagnus angustifolia L.) Extracts. Molecules, 27(5), 1530. https://doi.org/10.3390/molecules27051530