Morphology-Controlled Synthesis of V1.11S2 for Electrocatalytic Hydrogen Evolution Reaction in Acid Media

Abstract

1. Introduction

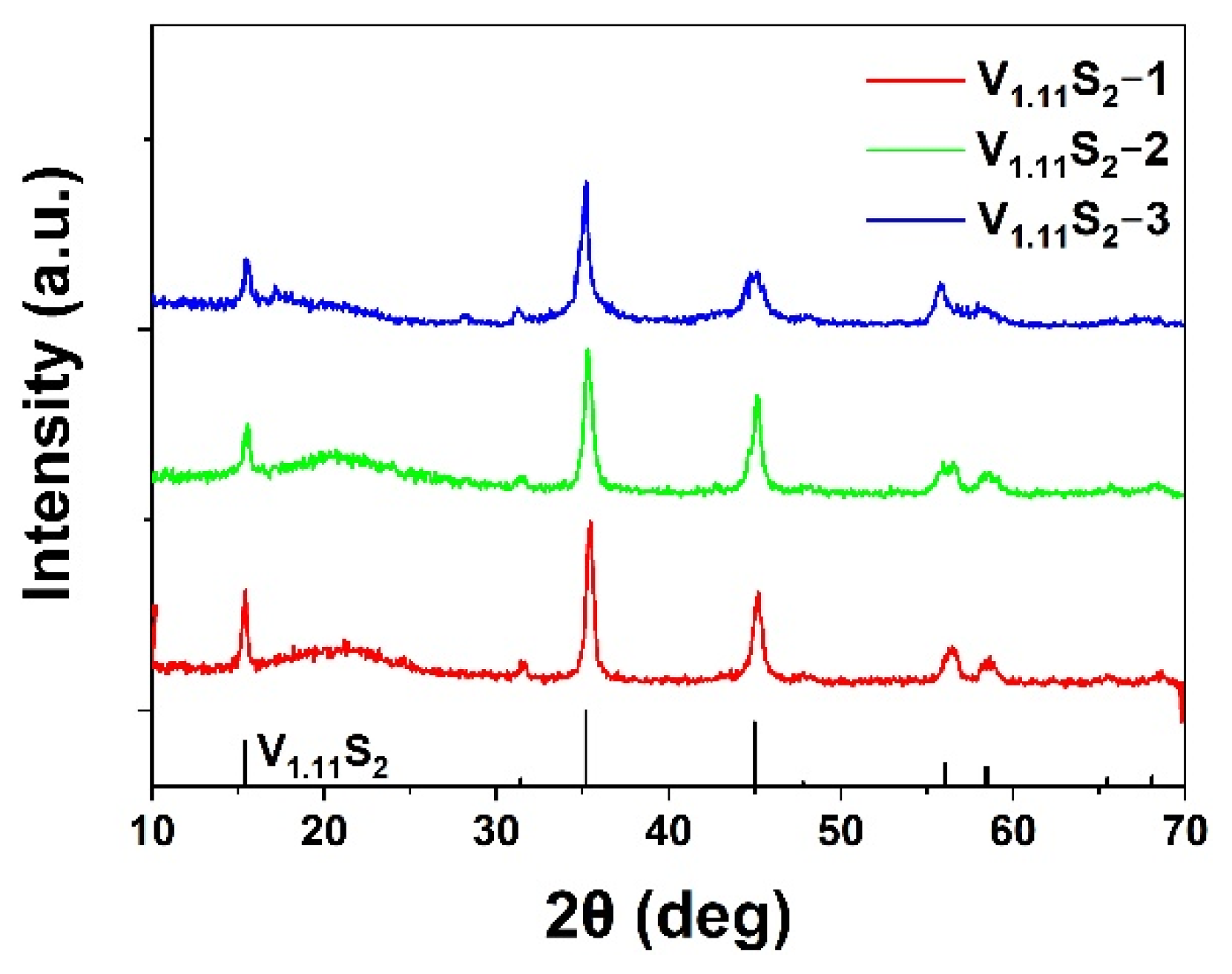

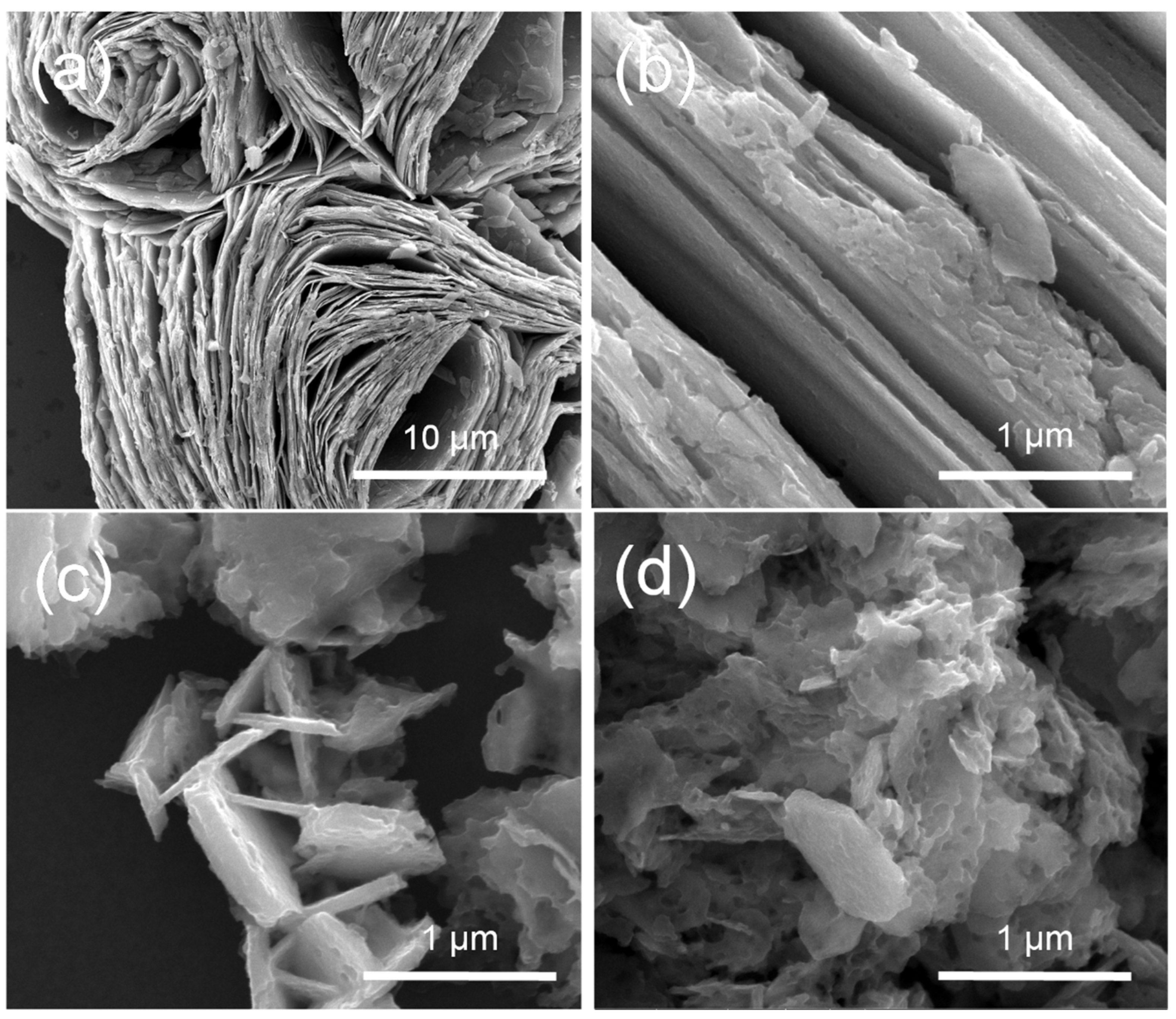

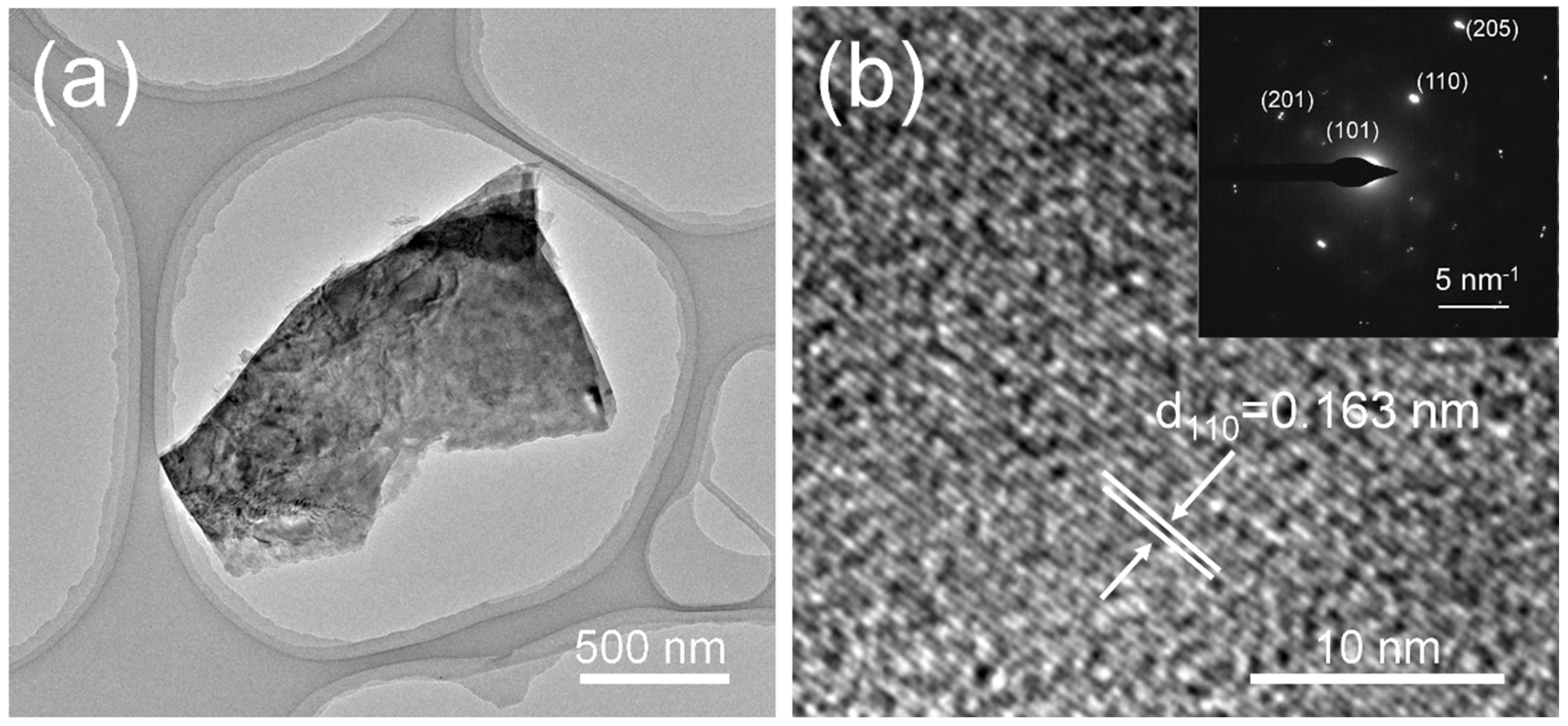

2. Results and Discussion

3. Experimental Section

3.1. Materials

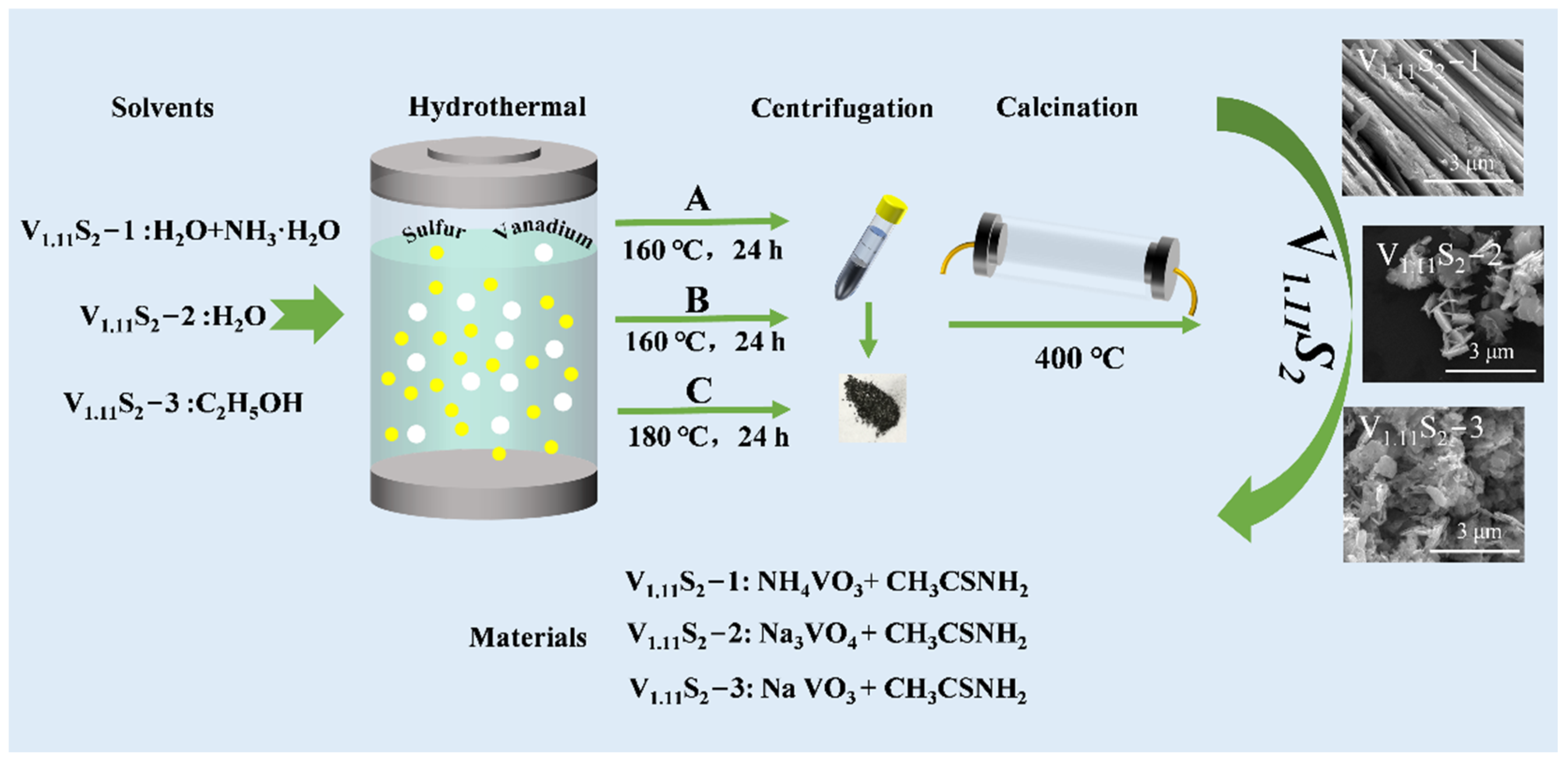

3.2. Synthesis of V1.11S2 Materials

3.3. Materials Characterization

3.4. Electrochemical Measurements

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, W.; Jia, J.; Lu, J.; Yang, L.; Hou, D.; Li, G.; Chen, S. Recent developments of carbon−based electrocatalysts for hydrogen evolution reaction. Nano Energy 2016, 28, 29–43. [Google Scholar] [CrossRef]

- Chen, Z.; Duan, X.; Wei, W.; Wang, S.; Ni, B.J. Recent advances in transition metal−based electrocatalysts for alkaline hydrogen evolution. J. Mater. Chem. A 2019, 7, 14971–15005. [Google Scholar] [CrossRef]

- Zhu, J.; Hu, L.; Zhao, P.; Lee, L.Y.S.; Wong, K.Y. Recent Advances in Electrocatalytic Hydrogen Evolution Using Nanoparticles. Chem. Rev. 2020, 120, 851–918. [Google Scholar] [CrossRef]

- Hu, K.; Ohto, T.; Nagata, Y.; Wakisaka, M.; Aoki, Y.; Fujita, J.I.; Ito, Y. Catalytic activity of graphene-covered non-noble metals governed by proton penetration in electrochemical hydrogen evolution reaction. Nat. Commun. 2021, 12, 203. [Google Scholar] [CrossRef]

- Yang, C.; Zhao, R.; Xiang, H.; Wu, J.; Zhong, W.; Li, W.; Zhang, Q.; Yang, N.; Li, X. Ni-Activated Transition Metal Carbides for Efficient Hydrogen Evolution in Acidic and Alkaline Solutions. Adv. Energy Mater. 2020, 10, 2002260. [Google Scholar] [CrossRef]

- Li, Y.; Wei, X.; Chen, L.; Shi, J. Electrocatalytic Hydrogen Production Trilogy. Angew. Chem. Int. Ed. Engl. 2020, 10, 1–21. [Google Scholar]

- Du, H.; Kong, R.M.; Guo, X.; Qu, F.; Li, J. Recent progress in transition metal phosphides with enhanced electrocatalysis for hydrogen evolution. Nanoscale 2018, 10, 21617–21624. [Google Scholar] [CrossRef]

- Wang, C.; Tian, B.; Wu, M.; Wang, J. Revelation of the Excellent Intrinsic Activity of MoS2|NiS|MoO3 Nanowires for Hydrogen Evolution Reaction in Alkaline Medium. ACS Appl. Mater. Inter. 2017, 9, 7084–7090. [Google Scholar] [CrossRef]

- Zheng, Y.; Jiao, Y.; Jaroniec, M.; Qiao, S.Z. Advancing the Electrochemistry of the Hydrogen−Evolution Reaction through Combining Experiment and Theory. Angew. Chem. Int. Ed. 2015, 54, 52–65. [Google Scholar] [CrossRef]

- Eftekhari, A. Electrocatalysts for hydrogen evolution reaction. Int. J. Hydrogen Energy 2017, 42, 11053–11077. [Google Scholar] [CrossRef]

- Wang, J.; Cui, W.; Liu, Q.; Xing, Z.; Asiri, A.M.; Sun, X. Recent Progress in Cobalt−Based Heterogeneous Catalysts for Electrochemical Water Splitting. Adv. Mater. 2016, 28, 215–230. [Google Scholar] [CrossRef] [PubMed]

- Zhu, W.; Zhang, R.; Qu, F.; Asiri, A.M.; Sun, X. Design and Application of Foams for Electrocatalysis. ChemCatChem 2017, 9, 1721–1743. [Google Scholar] [CrossRef]

- Hu, J.; Zhang, C.; Meng, X.; Lin, H.; Hu, C.; Long, X.; Yang, S. Hydrogen evolution electrocatalysis with binary−nonmetal transition metal compounds. J. Mater. Chem. A 2017, 5, 5995–6012. [Google Scholar] [CrossRef]

- Li, G.; Zhang, D.; Yu, Y.; Huang, S.; Yang, W.; Cao, L. Activating MoS2 for pH-Universal Hydrogen Evolution Catalysis. J. Am. Chem. Soc. 2017, 139, 16194–16200. [Google Scholar] [CrossRef]

- Chen, L.X.; Chen, Z.W.; Wang, Y.; Yang, C.C.; Jiang, Q. Design of Dual-Modified MoS2 with Nanoporous Ni and Graphene as Efficient Catalysts for the Hydrogen Evolution Reaction. ACS Catal. 2018, 8, 8107–8114. [Google Scholar] [CrossRef]

- Luo, Z.; Ouyang, Y.; Zhang, H.; Xiao, M.; Ge, J.; Jiang, Z.; Wang, J.; Tang, D.; Cao, X.; Liu, C.; et al. Chemically activating MoS2 via spontaneous atomic palladium interfacial doping towards efficient hydrogen evolution. Nat. Commun. 2018, 9, 2120. [Google Scholar] [CrossRef]

- Sun, T.; Wang, J.; Chi, X.; Lin, Y.; Chen, Z.; Ling, X.; Qiu, C.; Xu, Y.; Song, L.; Chen, W.; et al. Engineering the Electronic Structure of MoS2 Nanorods by N and Mn Dopants for Ultra-Efficient Hydrogen Production. ACS Catal. 2018, 8, 7585–7592. [Google Scholar] [CrossRef]

- Zhang, H.; Yu, L.; Chen, T.; Zhou, W.; Lou, X.W. Surface Modulation of Hierarchical MoS2 Nanosheets by Ni Single Atoms for Enhanced Electrocatalytic Hydrogen Evolution. Adv. Funct. Mater. 2018, 28, 1807086. [Google Scholar] [CrossRef]

- Wan, Y.; Zhang, Z.; Xu, X.; Zhang, Z.; Li, P.; Fang, X.; Zhang, K.; Yuan, K.; Liu, K.; Ran, G.; et al. Engineering active edge sites of fractal-shaped single-layer MoS2 catalysts for high-efficiency hydrogen evolution. Nano Energy 2018, 51, 786–792. [Google Scholar] [CrossRef]

- Jaramillo, T.F.; Jørgensen, K.P.; Bonde, J.; Nielsen, J.H.; Horch, S.; Chorkendorff, I. Identification of active edge sites for electrochemical H2 evolution from MoS2 nanocatalysts. Science 2007, 317, 100–102. [Google Scholar] [CrossRef]

- Pan, H. Metal Dichalcogenides Monolayers: Novel Catalysts for Electrochemical Hydrogen Production. Sci. Rep. 2014, 4, 5348. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, X.; Huang, Y.; Zhang, C.; Li, F.; Shu, H. The Role of Intrinsic Defects in Electrocatalytic Activity of Monolayer VS2 Basal Planes for the Hydrogen Evolution Reaction. J. Phys. Chem. C 2017, 121, 1530–1536. [Google Scholar] [CrossRef]

- Liang, H.; Shi, H.; Zhang, D.; Ming, F.; Wang, R.; Zhuo, J.; Wang, Z. Solution Growth of Vertical VS2 Nanoplate Arrays for Electrocatalytic Hydrogen Evolution. Chem. Mater. 2016, 28, 5587–5591. [Google Scholar] [CrossRef]

- Qu, Y.; Shao, M.; Shao, Y.; Yang, M.; Xu, J.; Kwok, C.T.; Shi, X.; Lu, Z.; Pan, H. Ultra-high electrocatalytic activity of VS2 nanoflowers for efficient hydrogen evolution reaction. J. Mater. Chem. A 2017, 5, 15080–15086. [Google Scholar] [CrossRef]

- Moutaabbid, H.; Le Godec, Y.; Taverna, D.; Baptiste, B.; Klein, Y.; Loupias, G.; Gauzzi, A. High-Pressure Control of Vanadium Self−Intercalation and Enhanced Metallic Properties in 1T-V1+xS2 Single Crystals. Inorg. Chem. 2016, 55, 6481–6486. [Google Scholar] [CrossRef]

- Yang, M.; Cao, L.; Wang, Z.; Qu, Y.; Shang, C.; Guo, H.; Xiong, W.; Zhang, J.; Shi, R.; Zou, J.; et al. Vanadium self-intercalated C/V1.11S2 nanosheets with abundant active sites for enhanced electro-catalytic hydrogen evolution. Electrochimi. Acta 2019, 300, 208–216. [Google Scholar] [CrossRef]

- Yang, H.G.; Sun, C.H.; Qiao, S.Z.; Zou, J.; Liu, G.; Smith, S.C.; Cheng, H.M.; Lu, G.Q. Anatase TiO2 single crystals with a large percentage of reactive facets. Nature 2008, 453, 638. [Google Scholar] [CrossRef]

- Mohan, P.; Yang, J.; Jena, A.; Shin, H.S. VS2/rGO hybrid nanosheets prepared by annealing of VS4/rGO. J. Solid State Chem. 2015, 224, 82–87. [Google Scholar] [CrossRef]

- Chen, X.; Yu, K.; Shen, Y.; Feng, Y.; Zhu, Z. Synergistic effect of MoS2 nanosheets and VS2 for the hydrogen evolution reaction with enhanced humidity−sensing performance. ACS Appl. Mater. Interfaces 2017, 9, 42139–42148. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Huang, J.; Feng, L.; Cao, L.; Liu, Y.; Pan, L. Nano-grain dependent 3D hierarchical VS2 microrods with enhanced intercalation kinetic for sodium storage properties. J. Power Sources 2018, 398, 91–98. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, C.; Wang, Z.; Zhu, J.; Wen, Z.; Zhao, X.; Zhang, X.; Xu, J.; Lu, Z. Synergistic Interlayer and Defect Engineering in VS2 Nanosheets toward Efficient Electrocatalytic Hydrogen Evolution Reaction. Small 2018, 14, 1703098. [Google Scholar] [CrossRef] [PubMed]

- Kumar, G.M.; Ilanchezhiyan, P.; Cho, H.D.; Lee, D.J.; Kim, D.Y.; Kang, T.W. Ultrathin VS2 nanodiscs for highly stable electro catalytic hydrogen evolution reaction. Int. J. Energ Res 2020, 44, 811–820. [Google Scholar] [CrossRef]

- Yu, S.H.; Tang, Z.; Shao, Y.; Dai, H.; Wang, H.Y.; Yan, J.; Pan, H.; Chua, D.H. In Situ Hybridizing MoS2 Microflowers on VS2 Microflakes in a One−Pot CVD Process for Electrolytic Hydrogen Evolution Reaction. ACS Appl. Energy Mater. 2019, 2, 5799–5808. [Google Scholar] [CrossRef]

- Guo, T.; Song, Y.; Sun, Z.; Wu, Y.; Xia, Y.; Li, Y.; Sun, J.; Jiang, K.; Dou, S.; Sun, J. Bio-templated formation of defect-abundant VS2 as a bifunctional material toward high-performance hydrogen evolution reactions and lithium-sulfur batteries. J. Energy Chem. 2020, 42, 34–42. [Google Scholar] [CrossRef]

- Cao, L.; Wang, L.; Feng, L.; Kim, J.H.; Du, Y.; Yang Kou, L.D.; Huang, J. Co-N-doped single-crystal V3S4 nanoparticles as pH-universal electrocatalysts for enhanced hydrogen evolution reaction. Electrochim. Acta 2020, 335, 135696. [Google Scholar] [CrossRef]

- Shi, Y.; Zhou, Y.; Yang, D.R.; Xu, W.X.; Wang, C.; Wang, F.B.; Xu, J.J.; Xia, X.H.; Chen, H.Y. Energy Level Engineering of MoS2 by Transition-Metal Doping for Accelerating Hydrogen Evolution Reaction. J. Am. Chem. Soc. 2017, 139, 15479–15485. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, Y.; Sun, C.; Xi, P.; Peng, S.; Gao, D.; Xue, D. Accelerated Hydrogen Evolution Reaction in CoS2 by Transition-Metal Doping. ACS Energy Letter. 2018, 3, 779–786. [Google Scholar] [CrossRef]

- Ye, S.; Luo, F.; Zhang, Q.; Zhang, P.; Xu, T.; Wang, Q.; He, D.; Guo, L.; Zhang, Y.; He, C.; et al. Highly stable single Pt atomic sites anchored on aniline-stacked graphene for hydrogen evolution reaction. Energy Environ. Sci. 2019, 12, 1000–1007. [Google Scholar] [CrossRef]

- Yu, J.; Guo, Y.; She, S.; Miao, S.; Ni, M.; Zhou Liu, M.W.; Shao, Z. Bigger is Surprisingly Better: Agglomerates of Larger RuP Nanoparticles Outperform Benchmark Pt Nanocatalysts for the Hydrogen Evolution Reaction. Adv. Mater. 2018, 30, 1800047–1800056. [Google Scholar] [CrossRef]

- Qu, Y.; Pan, H.; Kwok, C.T.; Wang, Z. A first-principles study on the hydrogen evolution reaction of VS2 nanoribbons. Phys. Chem. Chem. Phys. 2015, 17, 24820–24825. [Google Scholar] [CrossRef]

- Liu, Y.; Liang, X.; Gu, L.; Zhang, Y.; Li, G.D.; Zou, X.; Chen, J.S. Corrosion engineering towards efficient oxygen evolution electrodes with stable catalytic activity for over 6000 hours. Nat. Commun. 2018, 9, 2609. [Google Scholar] [CrossRef] [PubMed]

- Parishani, M.; Malekfar, R.; Bayat, A.; Gharibi, H. Hydrogen evolution reaction on VS2-NiS2 hybrid nanostructured electrocatalyst in acidic media: A binder-free electrode. J. Iran. Chem. Soc. 2022, 19, 4299–4307. [Google Scholar] [CrossRef]

- Feng, T.; Ouyang, C.; Zhan, Z.; Lei, T.; Yin, P. Cobalt doping VS2 on nickel foam as a high efficient electrocatalyst for hydrogen evolution reaction. Int. J. Hydrogen Energy 2022, 47, 10646–10653. [Google Scholar] [CrossRef]

- Singh, V.K.; Nakate, U.T.; Bhuyan, P.; Chen, J.; Tran, D.T.; Park, S. Mo/Co doped 1T-VS2 nanostructures as a superior bifunctional electrocatalyst for overall water splitting in alkaline media. J. Mater. Chem. A 2022, 10, 9067–9079. [Google Scholar] [CrossRef]

- Lin, Z.; Lin, B.; Wang, Z.; Chen, S.; Wang, C.; Dong, M.; Gao, Q.; Shao, Q.; Ding, T.; Liu, H.; et al. Facile Preparation of 1T/2H Mo(S1-xSex)2 Nanoparticles for Boosting Hydrogen Evolution Reaction. ChemCatChem 2019, 11, 2217–2222. [Google Scholar] [CrossRef]

| Catalyst | V1.11S2-1 | V1.11S2-2 | V1.11S2-3 |

|---|---|---|---|

| Rs(Ω) | 0.36 ± 0.023 | 0.34 ± 0.014 | 0.49 ± 0.021 |

| Rct1 (Ω) | 49.54 ± 0.48 | 114.3 ± 3.27 | 60.8 ± 1.08 |

| CPE2-T(F) | 2.03 × 10−3 ± 7.77 × 10−6 | 1.84 × 10−4 ± 1.32 × 10−5 | 2.15 × 10−3 ± 4.84 × 10−5 |

| CPE2-P(F) | 0.82 ± 5.33 × 10−3 | 0.90 ± 0.012 | 0.69 ± 3.89 × 10−3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Q.; Tian, S.; Liu, X.; An, X.; Zhang, J.; Xu, L.; Yao, W.; Kong, Q. Morphology-Controlled Synthesis of V1.11S2 for Electrocatalytic Hydrogen Evolution Reaction in Acid Media. Molecules 2022, 27, 8019. https://doi.org/10.3390/molecules27228019

Chen Q, Tian S, Liu X, An X, Zhang J, Xu L, Yao W, Kong Q. Morphology-Controlled Synthesis of V1.11S2 for Electrocatalytic Hydrogen Evolution Reaction in Acid Media. Molecules. 2022; 27(22):8019. https://doi.org/10.3390/molecules27228019

Chicago/Turabian StyleChen, Qiuyue, Siqi Tian, Xiaonan Liu, Xuguang An, Jingxian Zhang, Longhan Xu, Weitang Yao, and Qingquan Kong. 2022. "Morphology-Controlled Synthesis of V1.11S2 for Electrocatalytic Hydrogen Evolution Reaction in Acid Media" Molecules 27, no. 22: 8019. https://doi.org/10.3390/molecules27228019

APA StyleChen, Q., Tian, S., Liu, X., An, X., Zhang, J., Xu, L., Yao, W., & Kong, Q. (2022). Morphology-Controlled Synthesis of V1.11S2 for Electrocatalytic Hydrogen Evolution Reaction in Acid Media. Molecules, 27(22), 8019. https://doi.org/10.3390/molecules27228019