1-Tetradecanol, Diethyl Phthalate and Tween 80 Assist in the Formation of Thermo-Responsive Azoxystrobin Nanoparticles

Abstract

1. Introduction

2. Results

2.1. Combinations of TDA, T80 and DEP Affect the Softening Points of Oil-Phase Mixtures

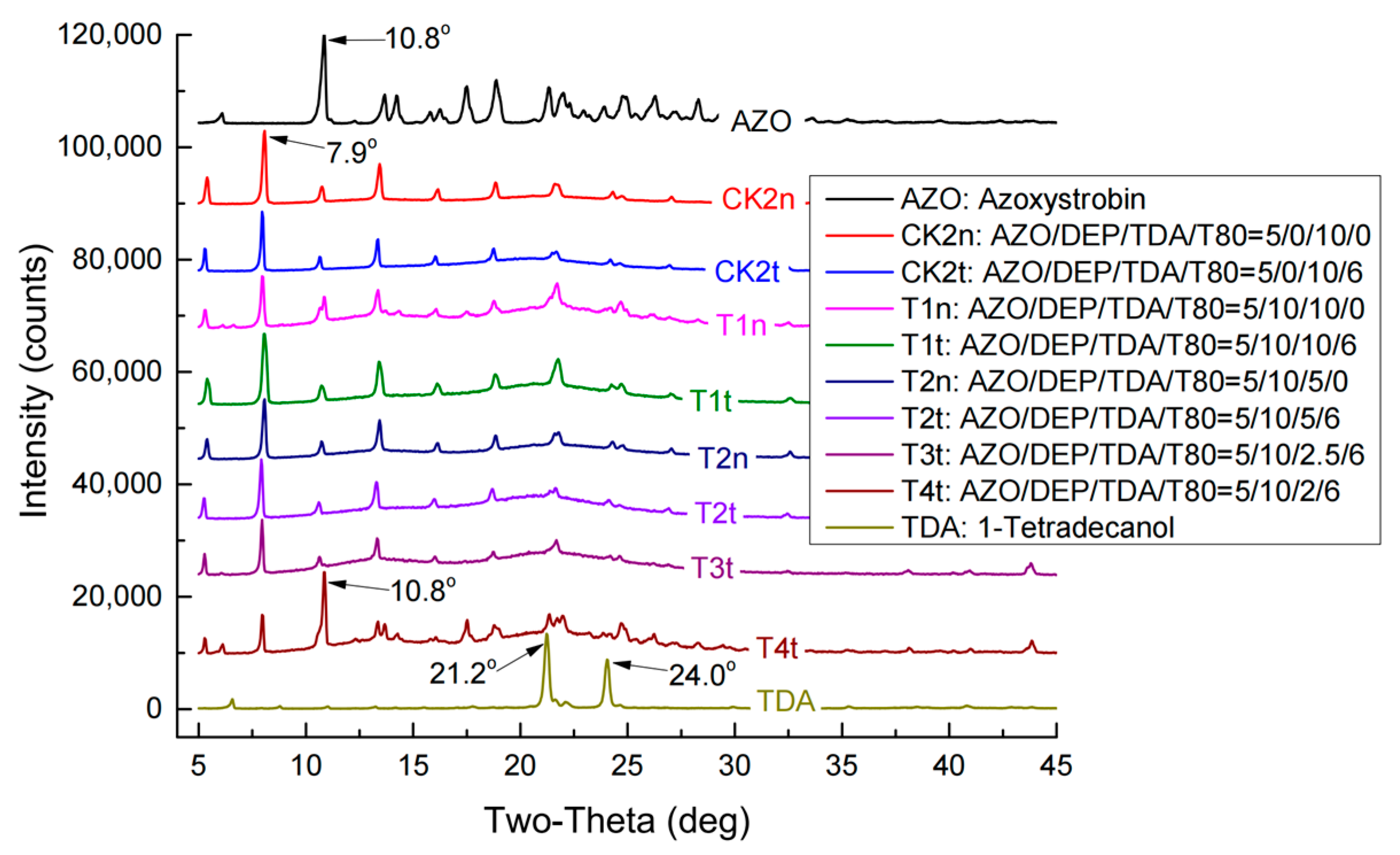

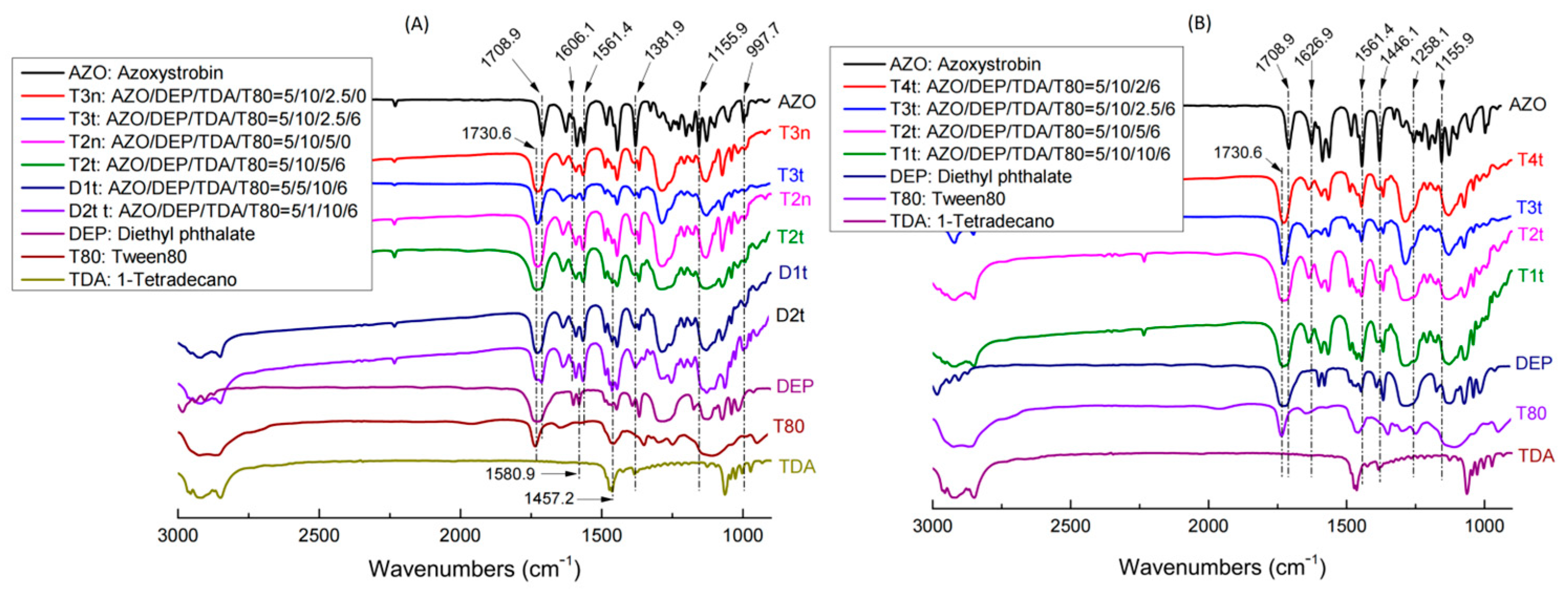

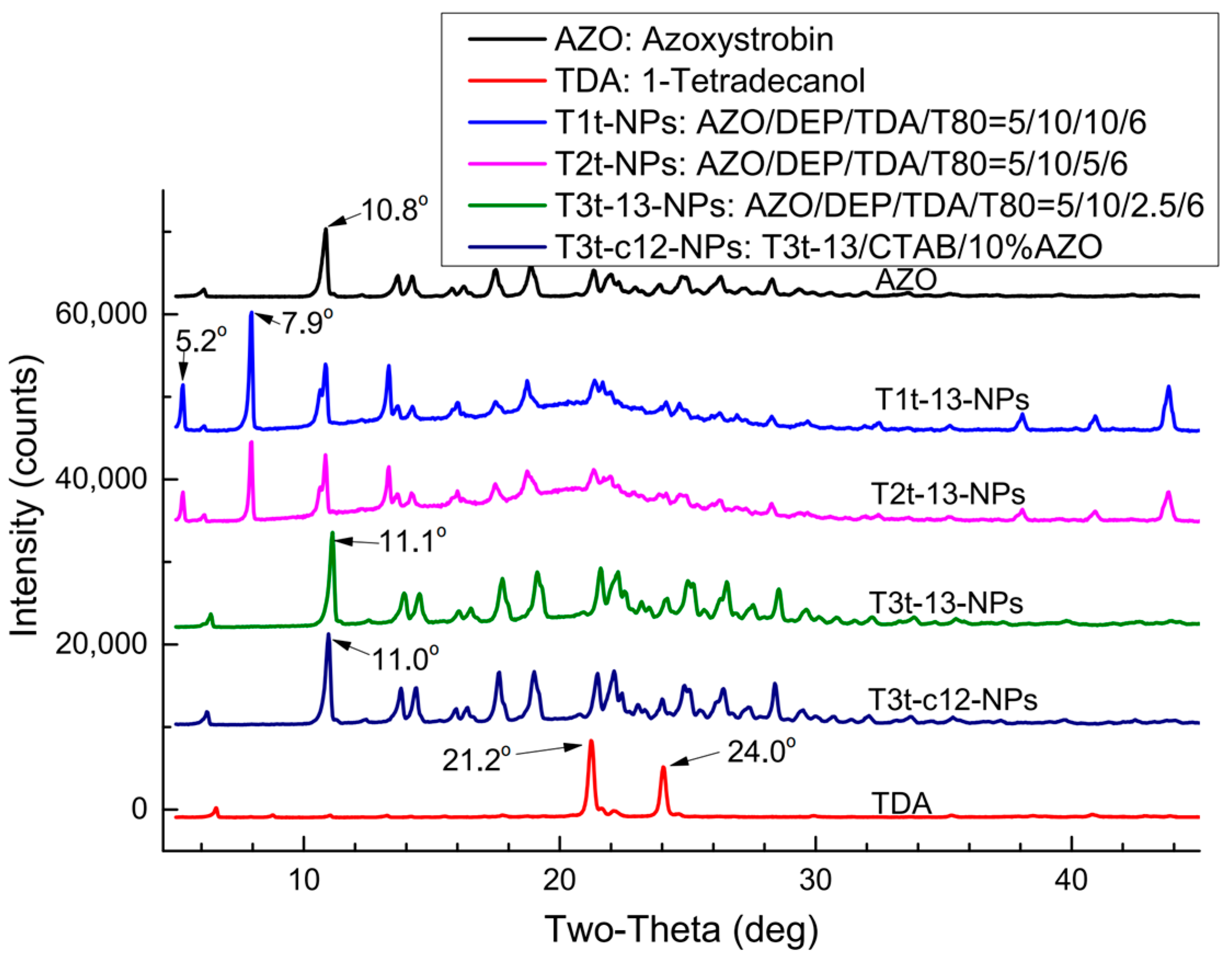

2.2. TDA and DEP Play the Critical Role in AZO Crystallization in Oil-Phase Mixtures

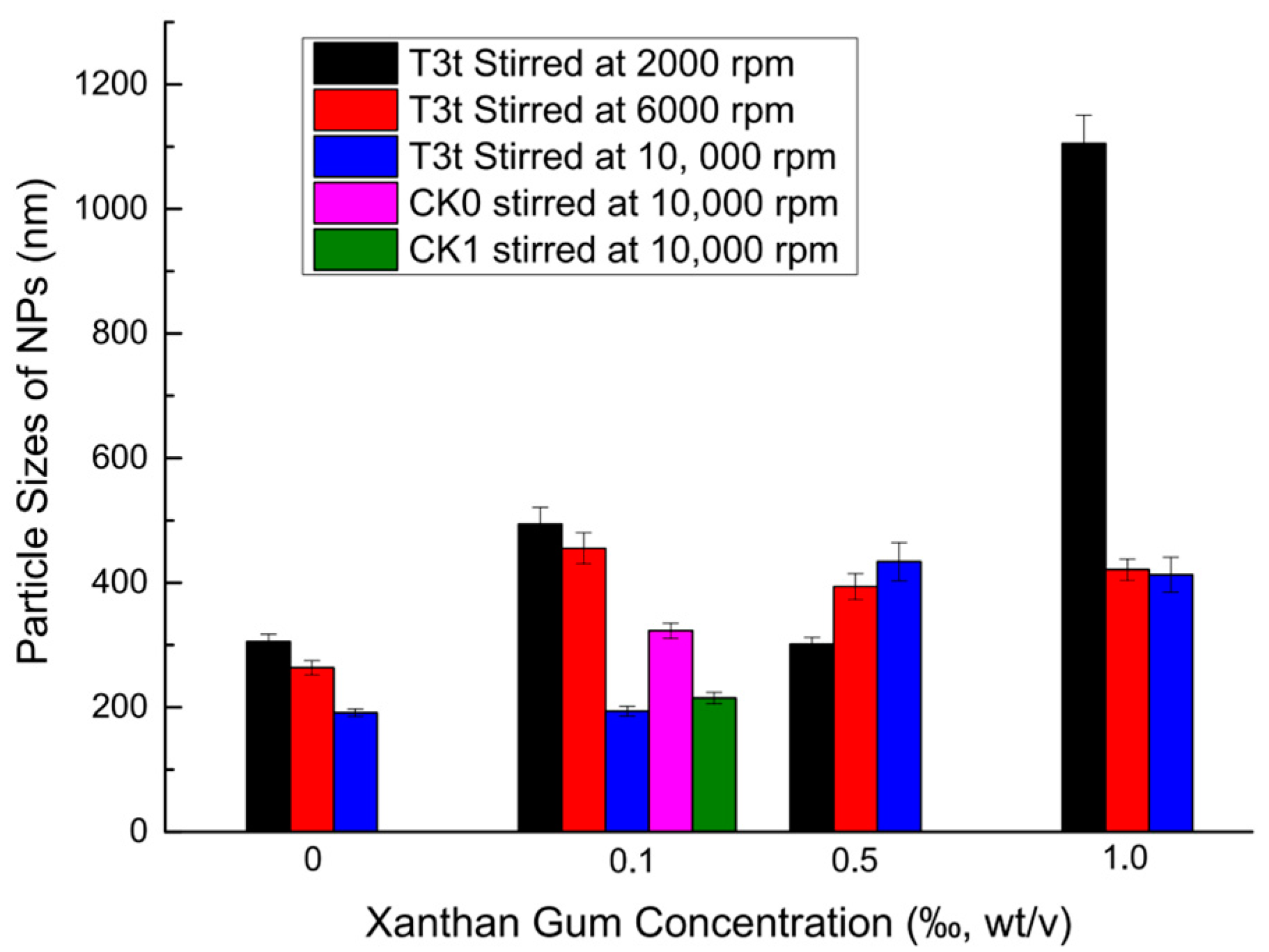

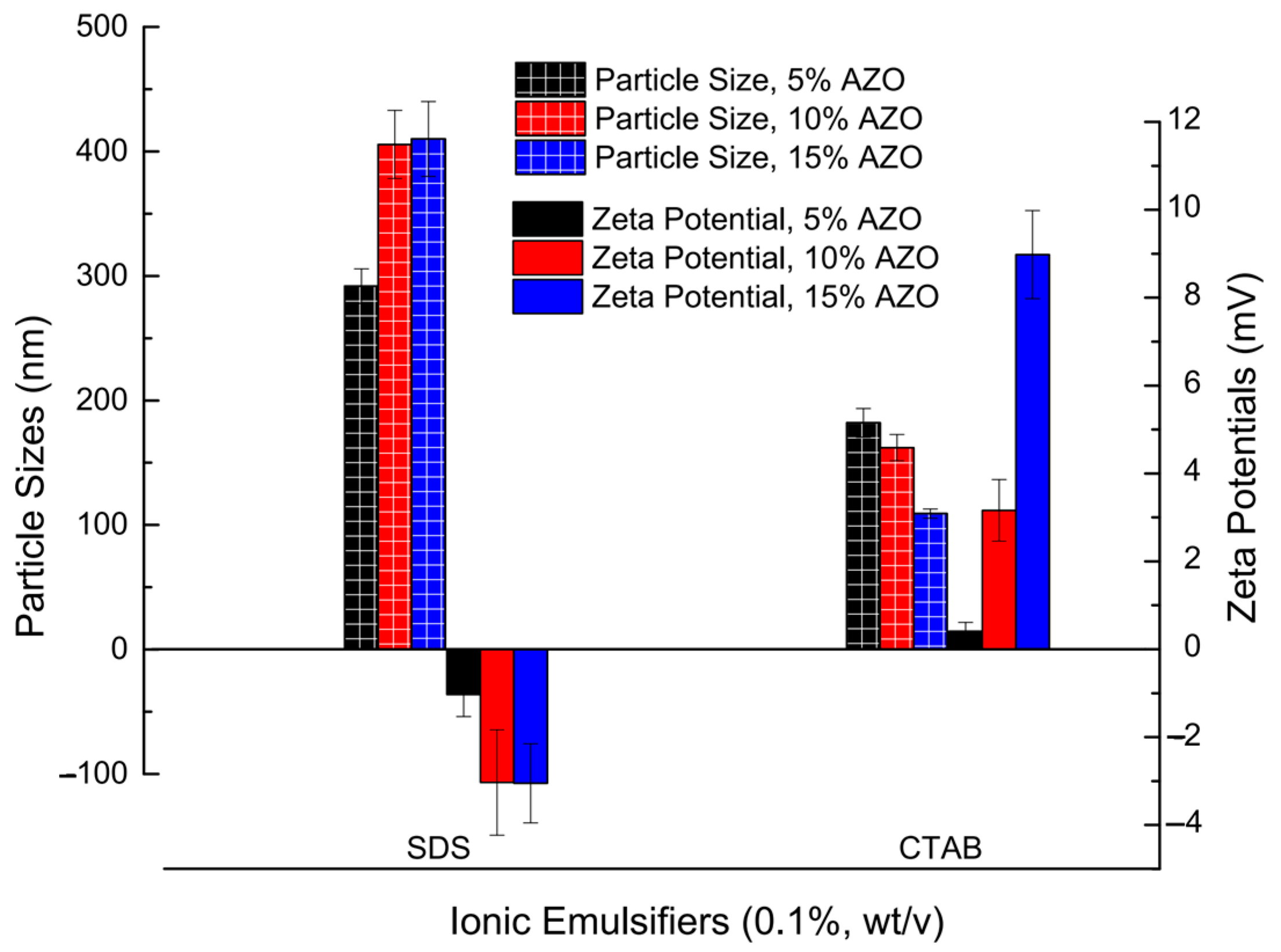

2.3. Combination of Suitable Co-Efficients for Viscosity, Stirring Speed and Ionic Surfactant for the Creation of Stable AZO-Loaded NP Suspension

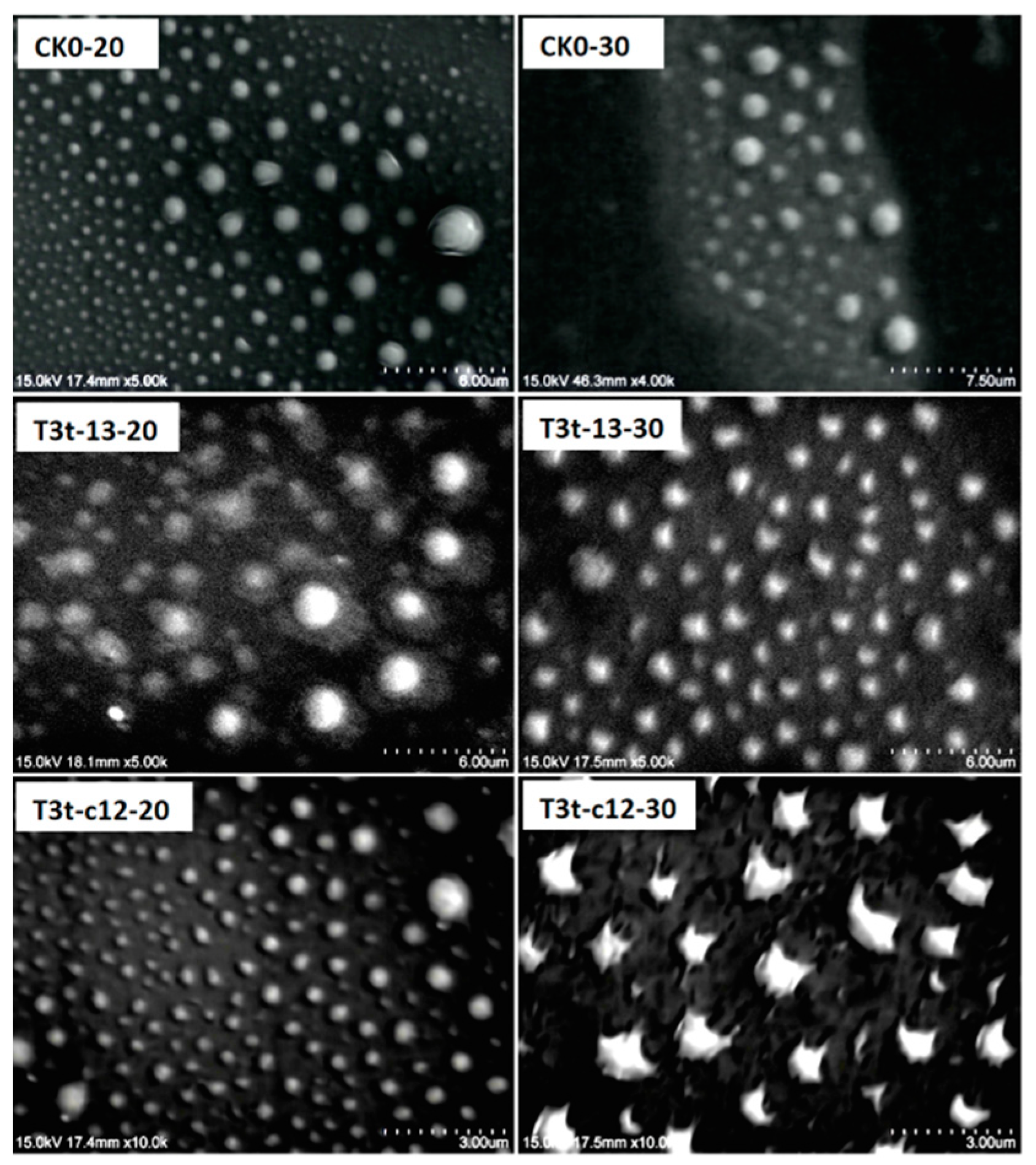

2.4. Thermo-Responsive AZO-Loaded NPs Underwent Morphological Transformations at 30 °C and Original AZO Crystals Were Recovered after Drying

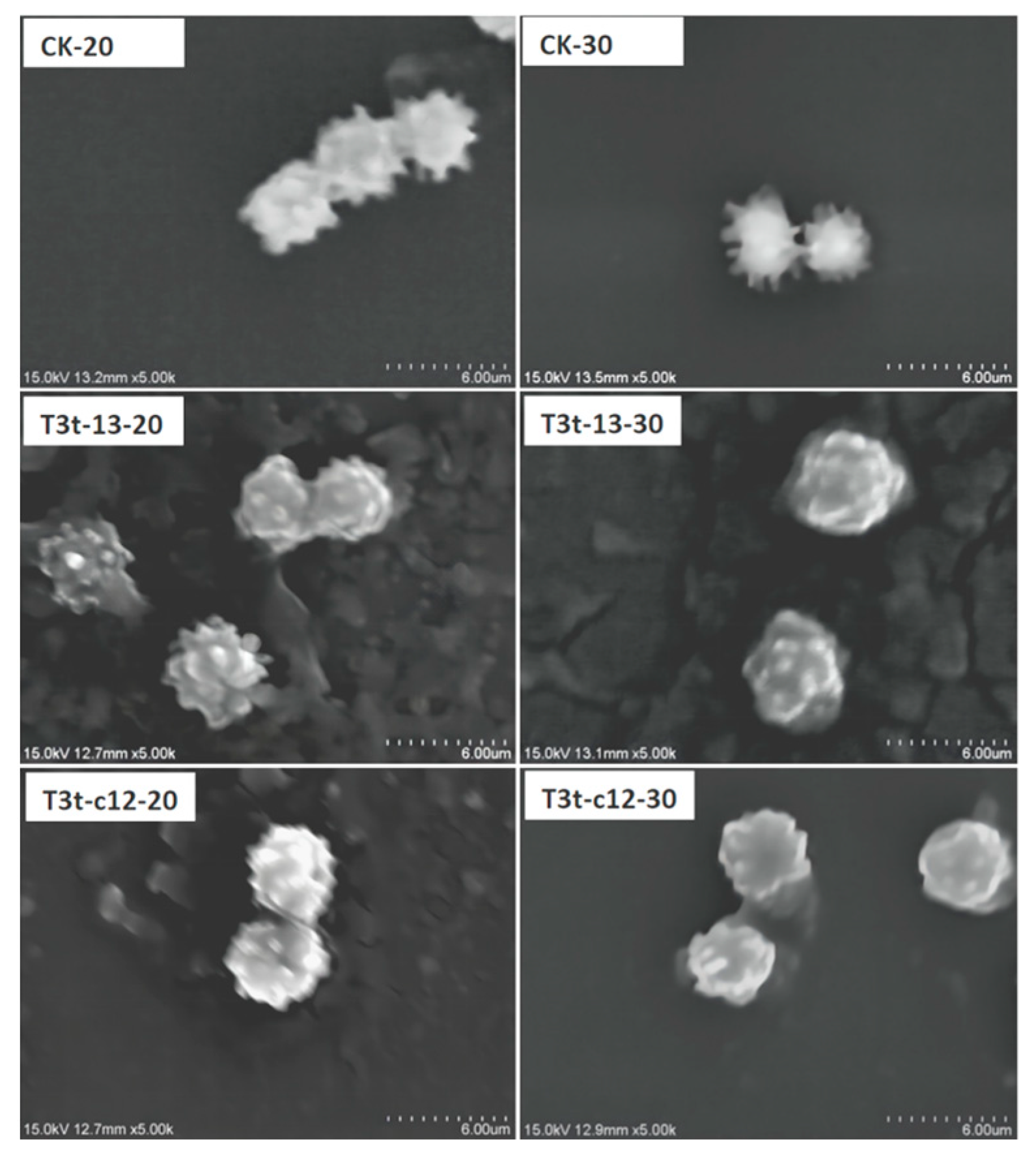

2.5. Thermo-Responsive AZO-Loaded NPs Attached to A1513 Spores Resulted in Morphological Changes

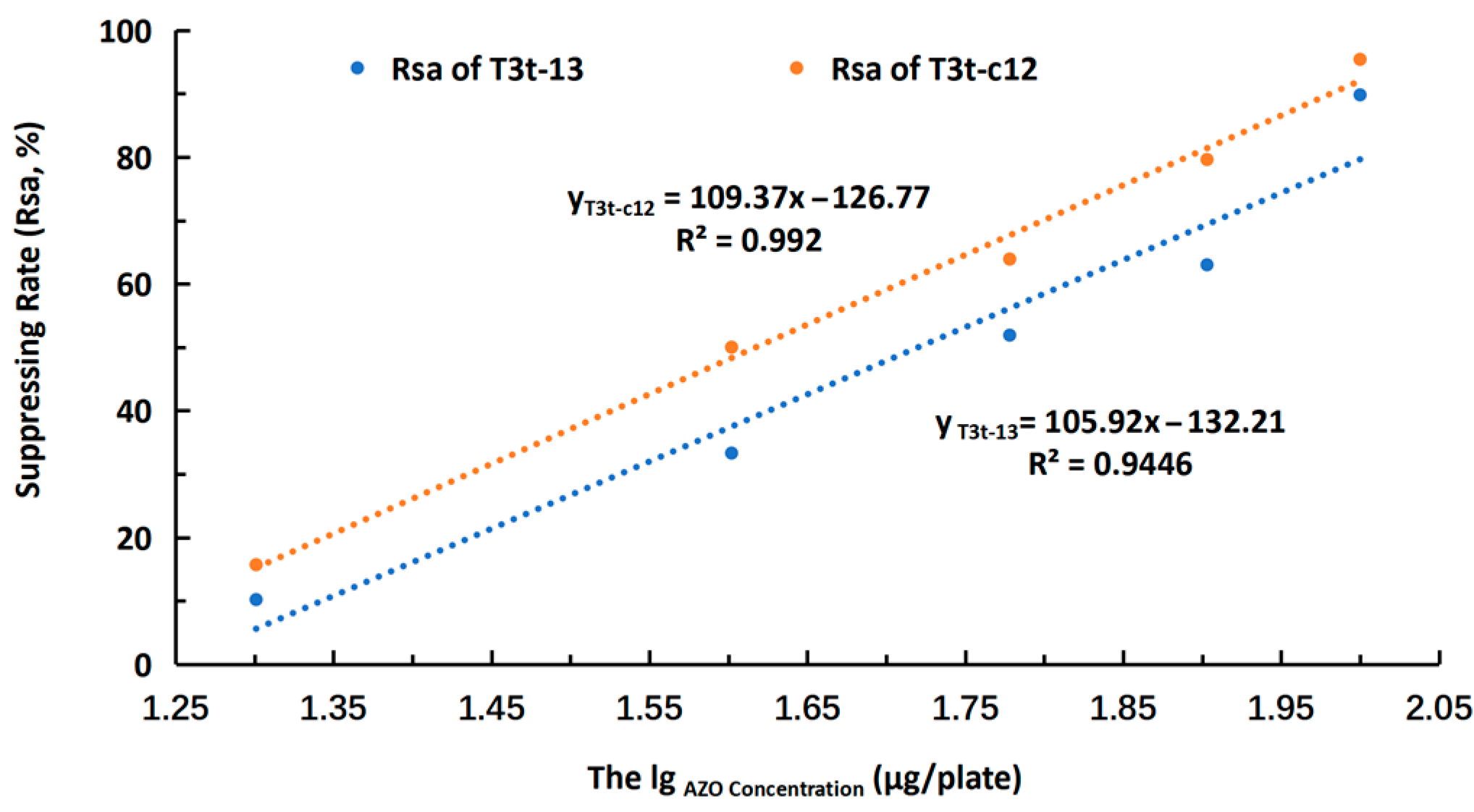

2.6. T3t-13 and T3t-c12 Showed Satisfactory Antifungal Efficacy against A. niger A1513 Spores

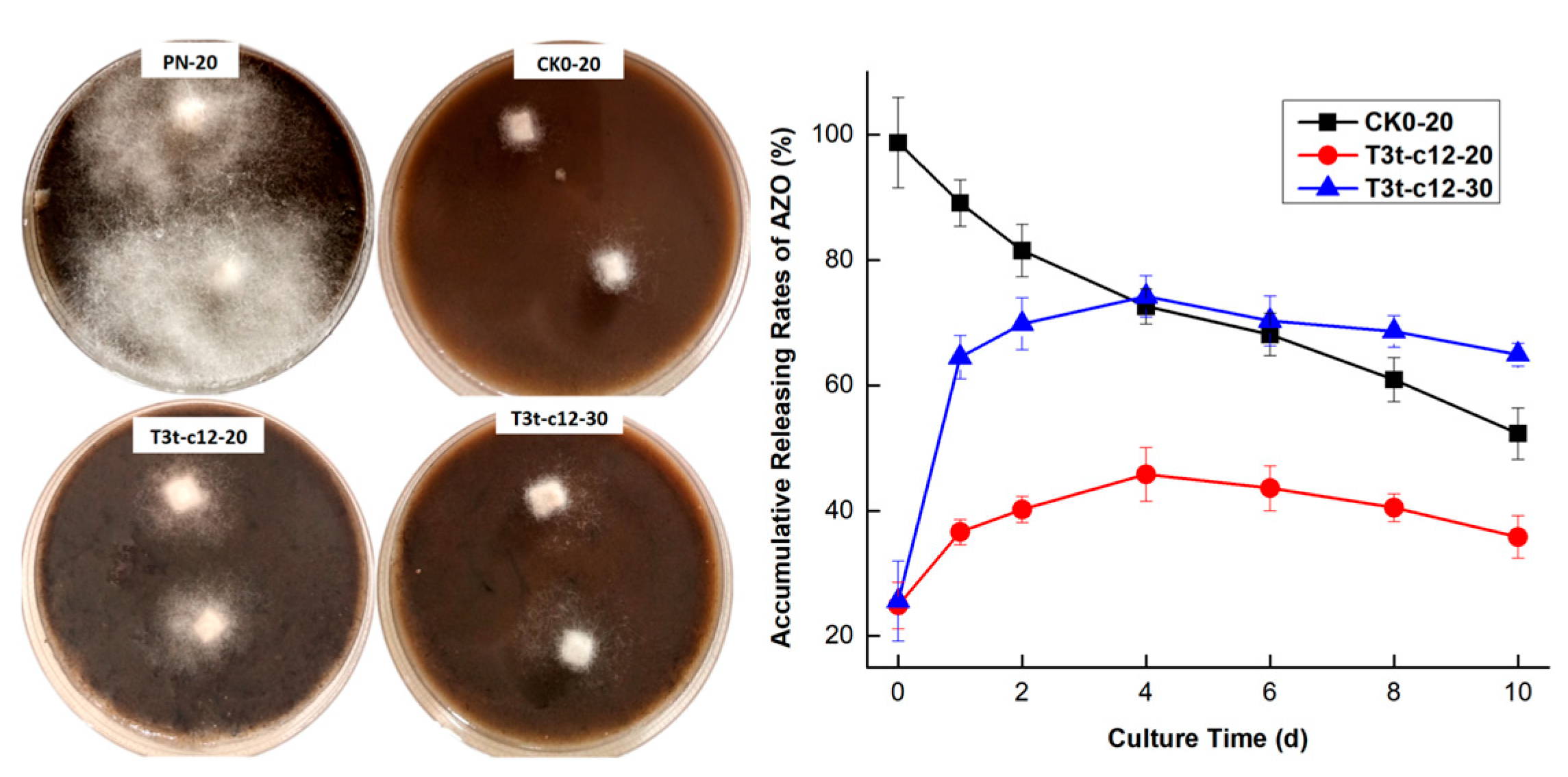

2.7. T3t-c12 Showed Satisfactory Antifungal Efficacy against the Mycelium of P. nicotiana PNgz07

3. Discussion

3.1. DEP Mediated the Miscibility between AZO and TDA

3.2. Quick Solidification of TDA Suppressed the Growth of AZO Crystals

3.3. Thermo-Responsive Property of Agrichemical NPs in Warm Temperature Regions Can Match the Requirements for Agricultural Application

4. Materials and Methods

4.1. Materials and Instruments

4.2. Preparation of Thermo-Responsive AZO-Loaded NPs

4.2.1. Screening for an AZO Oil-Phase Formula with a Softening Point Close to 30 °C

4.2.2. Optimization of Emulsification Conditions to Prepare Thermo-Responsive AZO-Loaded NPs

4.3. Preparation of AZO-Loaded NPs with Ionic Emulsifiers and Optimization of O/W Ratios

4.4. Characterization of the Particle Sizes, Zeta Potentials and Morphologies of AZO-Loaded NPs

4.5. Antifungal Activity Evaluation of Thermo-Responsive AZO NPs

4.5.1. Suppressing Efficacy of AZO-Loaded NPs on the Germination of A1513 Spores

4.5.2. Suppression Efficacy of AZO-Loaded NPs on the Growth of PNgz07 Mycelium

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Balba, H. Review of strobilurin fungicide chemicals. J. Environ. Sci. Health B 2007, 42, 441–451. [Google Scholar] [CrossRef]

- Hammer, K.A.; Carson, C.F.; Riley, T.V. Antifungal activity of the components of Melaleuca alternifolia (tea tree) oil. J. Appl. Microbiol. 2003, 95, 853–860. [Google Scholar] [CrossRef]

- Lu, W.C.; Huang, D.W.; Wang, C.C.; Yeh, C.H.; Tsai, J.C.; Huang, Y.T. Preparation, characterization, and antimicrobial activity of nanoemulsions incorporating citral essential oil. J. Food Drug Anal. 2017, 26, 82–91. [Google Scholar] [CrossRef]

- Davies, C.R.; Wohlgemuth, F.; Young, T.; Violet, J.; Dickinson, M.; Sanders, J.; Vallieres, C.; Avery, S.V. Evolving challenges and strategies for fungal control in the food supply chain. Fungal. Biol. Rev. 2021, 36, 15–26. [Google Scholar] [CrossRef]

- Aktar, M.W.; Sengupta, D.; Chowdhury, A. Impact of pesticides use in agriculture: Their benefits and hazards. Interdiscip. Toxicol. 2009, 2, 1–12. [Google Scholar] [CrossRef]

- Arancibia, C.; Riquelme, N.; Zuniga, R.; Matiacevich, S. Comparing the effectiveness of natural and synthetic emulsifiers on oxidative and physical stability of avocado oil-based nanoemulsions. Innov. Food Sci. Emerg. Technol. 2017, 44, 159–166. [Google Scholar] [CrossRef]

- Abd-Elsalam, K.A.; Khokhlov, A.R. Eugenol oil nanoemulsion: Antifungal activity against Fusarium oxysporum f. sp. Vasinfectum and phytotoxicity on cottonseeds. Appl. Nanosci. 2015, 5, 255–265. [Google Scholar] [CrossRef]

- Gupta, A.; Eral, H.B.; Hatton, T.A.; Doyle, P.S. Nanoemulsions: Formation, properties and applications. Soft Matter. 2016, 12, 2826–2841. [Google Scholar] [CrossRef]

- Ghosh, V.; Mukherjee, A.; Chandrasekaran, N. Ultrasonic emulsification of food-grade nanoemulsion formulation and evaluationof its bactericidal activity. Ultrason. Sonochem. 2013, 20, 338–382. [Google Scholar] [CrossRef]

- Hazra, D.; Purkait, A. Role of pesticide formulations for sustainable crop protection and environment management: A review. J. Pharmacogn. Phytochem. 2019, 8, 686–693. [Google Scholar]

- Poonia, A.K. Assessment of antifungal efficacy and release behavior of fungicide-loaded chitosan-carrageenan nanoparticles against phytopathogenic Fungi. Polymers 2021, 14, 41. [Google Scholar]

- Tleuova, A.B.; Wielogorska, E.; Talluri, V.S.S.L.P.; Štěpánek, F.; Elliott, C.T.; Grigoriev, D.O. Recent advances and remaining barriers to producing novel formulations of fungicides for safe and sustainable agriculture. J. Controll. Release 2020, 326, 468–481. [Google Scholar] [CrossRef]

- Baldassarre, F.; Tatulli, G.; Vergaro, V.; Mariano, S.; Scala, V.; Nobile, C.; Pucci, N.; Dini, L.; Loreti, S.; Ciccarella, G. Sonication-assisted production of fosetyl-Al nanocrystals: Investigation of human toxicity and in vitro antibacterial efficacy against Xylella fastidiosa. Nanomaterials 2020, 10, 1174. [Google Scholar] [CrossRef]

- Qi, Y.; Dai, X.; Wei, L.; Luo, H.; Liu, Y.; Dong, X.; Yang, D.; Li, Y. Nano-AgCu alloy on wood surface for mold resistance. Nanomaterials 2022, 12, 1192. [Google Scholar] [CrossRef]

- Musrat, A.; Wang, X.K.; Urooj, H.; Hassan, J.C.; Asif, K.; Qurban, A.; Muhammad, H.S.; Kamal, U.; Aishah, A.; Shafaqat, A.; et al. Antifungal activity of Zinc nitrate derived nano Zno fungicide synthesized from Trachyspermum ammi to control fruit rot disease of grapefruit. Ecotox. Environ. Saf. 2022, 233, 113311. [Google Scholar]

- Bartlett, D.W.; Clough, J.M.; Godwin, J.R.; Hall, A.A.; Hamer, M.; Parr-Dobrzanski, B. The strobilurin fungicides. Pest Manag. Sci. 2002, 58, 649–662. [Google Scholar] [CrossRef]

- Du, B.B.; Zhang, Z.Y.; Liu, W.Y.; Ye, Y.Z.; Fu, Z.W.; Qian, H.F. Acute toxicity of the fungicide azoxystrobin on the diatom Phaeodactylum tricornutum. Ecotox. Environ. Saf. 2019, 198, 72–79. [Google Scholar] [CrossRef]

- Lu, T.; Zhu, Y.; Xu, J.; Ke, M.; Zhang, M.; Tan, C.; Fu, Z.; Qian, H. Evaluation of the toxic response induced by azoxystrobin in the non-target green alga Chlorella pyrenoidosa. Environ. Pollut. 2018, 234, 379–388. [Google Scholar] [CrossRef]

- Yao, J.; Cui, B.; Zhao, X.; Wang, Y.; Zeng, Z.H.; Sun, C.J.; Yang, D.S.; Liu, G.Q.; Gao, J.M.; Cui, H.X. Preparation, characterization, and evaluation of azoxystrobin nanosuspension produced by wet media milling. Appl. Nanosci. 2018, 8, 297–307. [Google Scholar] [CrossRef]

- Camiletti, B.X.; Camacho, N.M.; Paredes, A.J.; Allemandi, D.A.; Palma, S.D.; Grosso, N.R. Self-dispersible nanocrystals of azoxystrobin and cyproconazole with increased efficacy against soilborne fungal pathogens isolated from peanut crops. Powder Technol. 2020, 372, 455–465. [Google Scholar] [CrossRef]

- Zhu, Z.X.; Shao, C.H.; Guo, Y.L.; Feng, J.G.; Chen, C.; Yang, H.B. Facile pathway to generate agrochemical nanosuspensions integrating super-high load, eco-friendly excipients, intensified preparation process, and enhanced potency. Nano Res. 2021, 14, 2179–2187. [Google Scholar] [CrossRef]

- Xu, C.L.; Cao, L.D.; Zhao, P.Y.; Zhou, Z.L.; Cao, C.; Li, F.M.; Huang, Q.L. Emulsion-based synchronous pesticide encapsulation and surface modification of mesoporous silica nanoparticles with carboxymethyl chitosan for controlled azoxystrobin release. Chem. Eng. J. 2018, 348, 244–254. [Google Scholar] [CrossRef]

- Xu, C.L.; Shan, Y.P.; Bilal, M.; Xu, B.; Cao, L.D.; Huang, Q.L. Copper ions chelated mesoporous silica nanoparticles via dopamine chemistry for controlled pesticide release regulated by coordination bonding. Chem. Eng. J. 2020, 395, 125093. [Google Scholar] [CrossRef]

- Bueno, V.; Gao, X.Y.; Rahim, A.A.; Wang, P.Y.; Bayen, S.; Ghoshal, S. Uptake and translocation of a silica nanocarrier and an encapsulated organic pesticide following foliar application in tomato plants. Environ. Sci. Technol. 2022, 56, 6722–6732. [Google Scholar] [CrossRef]

- Bueno, V.; Wang, P.Y.; Harrisson, O.; Bayen, S.; Ghoshal, S. Impacts of a porous hollow silica nanoparticle- encapsulated pesticide applied to soils on plant growth and soil microbial community. Environ. Sci. Nano 2022, 9, 1476–1488. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, X.M.; Fang, X.Z.; Yao, N.; Lei, H.D.; Yang, G.; Wang, Z.K.; Dong, Y.C.; Hua, Z. Rationally designing renewable plant oil-based polymers as efficient nanocarriers for sustained pesticide delivery. Chem. Eng. J. 2022, 450, 138294. [Google Scholar] [CrossRef]

- Yu, M.L.; Sun, C.J.; Xue, Y.M.; Liu, C.; Qiu, D.W.; Cui, B.; Zhang, Y.; Cui, H.X.; Zeng, Z.H. Tannic acid-based nanopesticides coating with highly improved foliage adhesion to enhance foliar retention. RSC Adv. 2019, 9, 27096–27104. [Google Scholar] [CrossRef]

- Machado, T.O.; Beckers, S.J.; Fischer, J.; Müller, B.; Sayer, C.; Araújo, P.H.H.D.; Landfester, K.; Wurm, F.R. Bio-based lignin nanocarriers loaded with fungicides as a versatile platform for drug delivery in plants. Biomacromolecules 2020, 2, 2755–2763. [Google Scholar] [CrossRef]

- Zhi, H.; Chen, H.Y.; Yu, M.L.; Wang, C.; Cui, B.; Zhao, X.; Wang, Y.; Cui, H.X.; Zhang, B.H.; Zeng, Z.H. Layered double hydroxide nanosheets improve the adhesion of fungicides to leaves and the antifungal performance. ACS Appl. Nano Mater. 2022, 5, 5316–5325. [Google Scholar] [CrossRef]

- Guan, Y.; Ge, X.; Abdalkarim, S.Y.H.; Yu, H.; Marek, J.; Yao, J. Fabrication of a novel temperature sensitive phase change system based on ZnO@PNIPAM core-satellites and 1-tetradecanol as gatekeeper. Mater. Sci. Energy Technol. 2020, 3, 482–486. [Google Scholar] [CrossRef]

- Zeng, J.L.; Gan, J.; Zhu, F.R.; Yu, S.B.; Xiao, Z.L.; Yan, W.P.; Zhu, L.; Liu, Z.Q.; Sun, L.X.; Cao, Z. Tetradecanol/expanded graphite composite form-stable phase change material for thermal energy storage. Sol. Energy Mater. Sol. Cells 2014, 127, 122–128. [Google Scholar] [CrossRef]

- Mu, B.Y.; Li, M. Fabrication and thermal properties of tetradecanol/graphene aerogel form-stable composite phase change materials. Sci. Rep. 2018, 8, 8878. [Google Scholar] [CrossRef]

- Cunha, I.L.C.; Teixeira, A.C.S.C. Degradation of pesticides present in tomato rinse water by direct photolysis and UVC/H2O2, optimization of process conditions through sequential Doehlert design. Environ. Sci. Pollut. Res. 2021, 28, 24191–24205. [Google Scholar] [CrossRef]

- Chastain, J.; Halle, A.T.; Claire, P.D.S.; Voyard, G.; Traikï, M.; Richard, C. Phototransformation of azoxystrobin fungicide in organic solvents. Photoisomerization vs. photodegradation. Photochem. Photobiol. Sci. 2013, 12, 2076–2083. [Google Scholar] [CrossRef]

- Boudina, A.; Emmelin, C.; Baaliouamer, A.; Païssé, O.; Chovelon, J.M. Photochemical transformation of azoxystrobin in aqueous solutions. Chemosphere 2007, 68, 1280–1288. [Google Scholar] [CrossRef]

- Ghosh, R.K.; Singh, N. Effect of organic manure on sorption and degradation of azoxystrobin in soil. J. Agric. Food Chem. 2009, 57, 632–636. [Google Scholar] [CrossRef]

- Ghosh, R.K.; Singh, N. Leaching behaviour of azoxystrobin and metabolites in soil columns. Pest Manag. Sci. 2009, 65, 1009–1014. [Google Scholar] [CrossRef]

- Mpofu, E.; Alias, A.; Tomita, K.; Suzuki-Minakuchi, C.; Tomita, K.; Chakraborty, J.; Malon, M.; Ogura, Y.; Takikawa, H.; Okada, K.; et al. Azoxystrobin amine: A novel azoxystrobin degradation product from Bacillus licheniformis strain TAB7. Chemosphere 2021, 273, 129663. [Google Scholar] [CrossRef]

- Romeh, A.A.A. Phytoremediation of azoxystrobin and its degradation products in soil by P. major L. under cold and salinity stress. Pestic. Biochem. Physiol. 2017, 142, 21–31. [Google Scholar] [CrossRef]

- Adetutu, E.M.; Ball, A.S.; Osborn, A.M. Azoxystrobin and soil interactions: Degradation and impact on soil bacterial and fungal communities. J. Appl. Microbiol. 2008, 105, 1777–1790. [Google Scholar] [CrossRef]

- Marcilla, A.; Beltrán, M. 5-Mechanisms of plasticizers action. In Handbook of Plasticizers, 3rd ed.; Wypych, G., Ed.; ChemTec Publishing: Toronto, ON, Canada, 2017; pp. 119–134. [Google Scholar]

- Haynes, W.M. (Ed.) Handbook of Chemistry and Physics, 95th ed.; CRC Press LLC: Boca Raton, FL, USA, 2014; pp. 3–498. [Google Scholar]

- Yalkowsky, S.H.; He, Y.; Jain, P. Handbook of Aqueous Solubility Data, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2010; p. 1037. [Google Scholar]

- Lide, D.R. Handbook of Chemistry and Physics, 86th ed.; Taylor & Francis: Boca Raton, FL, USA, 2005; pp. 3–170. [Google Scholar]

- National Center for Biotechnology Information. “PubChem Compound Summary for CID 3034285, Azoxystrobin” PubChem. Available online: https://pubchem.ncbi.nlm.nih.gov/compound/Azoxystrobin (accessed on 16 November 2022).

- Erhan, Y.M. Development of a Quantitative Model for Solute Diffusion in Biopolymers Based on Free-Volume Theory and Rheological Properties. Ph.D. Thesis, University of New Jersey, New Brunswick, NJ, USA, 2003. [Google Scholar]

- Geng, X.Y.; Li, W.; Yin, Q.; Wang, Y.; Han, N.; Wang, N.; Bian, J.M.; Wang, J.P.; Zhang, X.X. Design and fabrication of reversible thermochromic microencapsulated phase change materials for thermal energy storage and its antibacterial activity. Energy 2018, 15, 857–869. [Google Scholar] [CrossRef]

- Feller, U.; Vaseva, I.I. Extreme climatic events: Impacts of drought and high temperature on physiological processes in agronomically important plants. Front. Env. Sci. 2014, 2, 39. [Google Scholar] [CrossRef]

- Castañares, E.; Cabral, L.D.C.; Dinolfo, M.I.; Andersen, B.; Sebastián, A.S.; Andrea, P. Alternaria in malting barley: Characterization and distribution in relation with climatic conditions and barley cultivars. Int. J. Food Microbiol. 2021, 357, 109367. [Google Scholar] [CrossRef]

- Tooley, P.W.; Browning, M.; Kyde, K.L.; Berner, D. Effect of temperature and moisture period on infection of Rhododendron ‘Cunningham’s White’ by Phytophthora ramorum. Ecolog. Epidem. 2009, 99, 9. [Google Scholar] [CrossRef]

- Wei, T.; Tang, Z.C.; Yu, Q.; Chen, H. Smart antibacterial surfaces with switchable bacteria-killing and bacteria-releasing capabilities. ACS Appl. Mater. Interfaces 2017, 9, 37511–37523. [Google Scholar] [CrossRef]

- Mirjana, S.J.; Velkoska-Markovska, L.; Petanovska-Ilievska, B.; Ilievski, U. Application of high performance liquid chromatography for determination of metalaxyl, acetamiprid and azoxystrobine in tomato samples. J. Anal. Chem. 2019, 74, 339–344. [Google Scholar] [CrossRef]

- Abdelraheem, E.M.H.; Hassan, S.M.; Arief, M.M.H.; Mohammad, S.G. Validation of quantitative method for azoxystrobin residues in green beans and peas. Food Chem. 2015, 182, 246–250. [Google Scholar] [CrossRef]

| Sample Name | Softening Points (°C) | Endothermic Peaks in DSC (°C) |

|---|---|---|

| CK2t | 36.1 | 34.7, 111.6 |

| T1t | 37.5 | 31.1, 37.8, 114.9 |

| T2t | 35.4 | 29.7, 34.3 |

| T3t | 31.5 | 28.1, 33.7 |

| T4t | 28.7 | 26.8, 31.1, 105.3 |

| D1t | 39.2 | N/A |

| D2t | 39.4 | N/A |

| T5t | 40.5 | N/A |

| Sample Names | AZO/g | DEP/mL | TDA/g | T80/mL |

|---|---|---|---|---|

| CK2n | 5 | 0 | 10 | 0 |

| CK2t | 5 | 0 | 10 | 6 |

| T1n | 5 | 10 | 10 | 0 |

| T1t | 5 | 10 | 10 | 6 |

| T2n | 5 | 10 | 5 | 0 |

| T2t | 5 | 10 | 5 | 6 |

| T3n | 5 | 10 | 2.5 | 0 |

| T3t | 5 | 10 | 2.5 | 6 |

| T4n | 5 | 10 | 2 | 0 |

| T4t | 5 | 10 | 2 | 6 |

| D1n | 5 | 5 | 10 | 0 |

| D1t | 5 | 5 | 10 | 6 |

| D2n | 5 | 1 | 10 | 0 |

| D2t | 5 | 1 | 10 | 6 |

| T5t | 5 | 5 | 5 | 6 |

| Sample Names | Xanthan Gum (‰, wt/v) | Stirring Speeds (rpm × 1000) | Xanthan Gum Water Solution (mL) |

|---|---|---|---|

| T3t-01 | 0 | 2.0 | 81.5 |

| T3t-02 | 0 | 6.0 | 81.5 |

| T3t-03 | 0 | 10.0 | 81.5 |

| T3t-11 | 0.1 | 2.0 | 81.5 |

| T3t-12 | 0.1 | 6.0 | 81.5 |

| T3t-13 | 0.1 | 10.0 | 81.5 |

| T3t-21 | 0.5 | 2.0 | 81.5 |

| T3t-22 | 0.5 | 6.0 | 81.5 |

| T3t-23 | 0.5 | 10.0 | 81.5 |

| T3t-31 | 1.0 | 2.0 | 81.5 |

| T3t-32 | 1.0 | 6.0 | 81.5 |

| T3t-33 | 1.0 | 10.0 | 81.5 |

| CK0 | 0.1 | 10.0 | 82.0 |

| Sample Names | SDS (%, wt/v) | CTAB (%, wt/v) | Surfactant Water Solution (mL) | AZO Concentration (%, wt/v) |

|---|---|---|---|---|

| T3t-s11 | 0.1 | 0 | 81.5 | 5.0 |

| T3t-s12 | 0.1 | 0 | 31.5 | 10.0 |

| T3t-s13 | 0.1 | 0 | 14.8 | 15.0 |

| T3t-c11 | 0 | 0.1 | 81.5 | 5.0 |

| T3t-c12 | 0 | 0.1 | 31.5 | 10.0 |

| T3t-c13 | 0 | 0.1 | 14.8 | 15.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, G.; Gao, J.; Shang, S.; Zhang, H.; Luo, Q.; Wu, Y.; Liu, Y.; Chen, X.; Sun, Y. 1-Tetradecanol, Diethyl Phthalate and Tween 80 Assist in the Formation of Thermo-Responsive Azoxystrobin Nanoparticles. Molecules 2022, 27, 7959. https://doi.org/10.3390/molecules27227959

Lin G, Gao J, Shang S, Zhang H, Luo Q, Wu Y, Liu Y, Chen X, Sun Y. 1-Tetradecanol, Diethyl Phthalate and Tween 80 Assist in the Formation of Thermo-Responsive Azoxystrobin Nanoparticles. Molecules. 2022; 27(22):7959. https://doi.org/10.3390/molecules27227959

Chicago/Turabian StyleLin, Guan, Juntao Gao, Shenghua Shang, Huanbo Zhang, Qiangke Luo, Yutong Wu, Yong Liu, Xingjiang Chen, and Yan Sun. 2022. "1-Tetradecanol, Diethyl Phthalate and Tween 80 Assist in the Formation of Thermo-Responsive Azoxystrobin Nanoparticles" Molecules 27, no. 22: 7959. https://doi.org/10.3390/molecules27227959

APA StyleLin, G., Gao, J., Shang, S., Zhang, H., Luo, Q., Wu, Y., Liu, Y., Chen, X., & Sun, Y. (2022). 1-Tetradecanol, Diethyl Phthalate and Tween 80 Assist in the Formation of Thermo-Responsive Azoxystrobin Nanoparticles. Molecules, 27(22), 7959. https://doi.org/10.3390/molecules27227959