Hybrid Photovoltaic/Thermoelectric Systems for Round-the-Clock Energy Harvesting

Abstract

1. Introduction

2. Basic Principles of Solar Cells

3. Basic Principles of Thermoelectricity

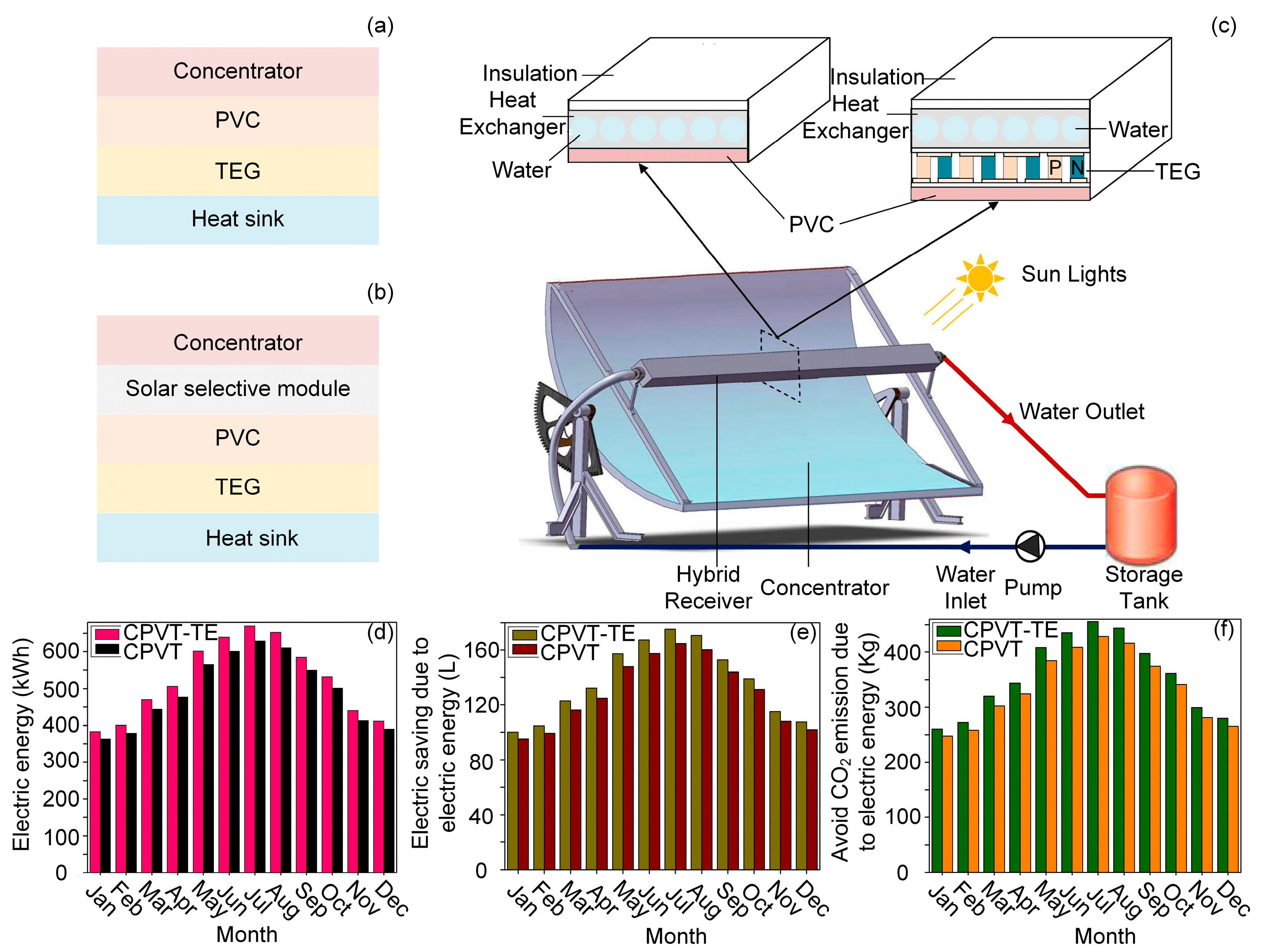

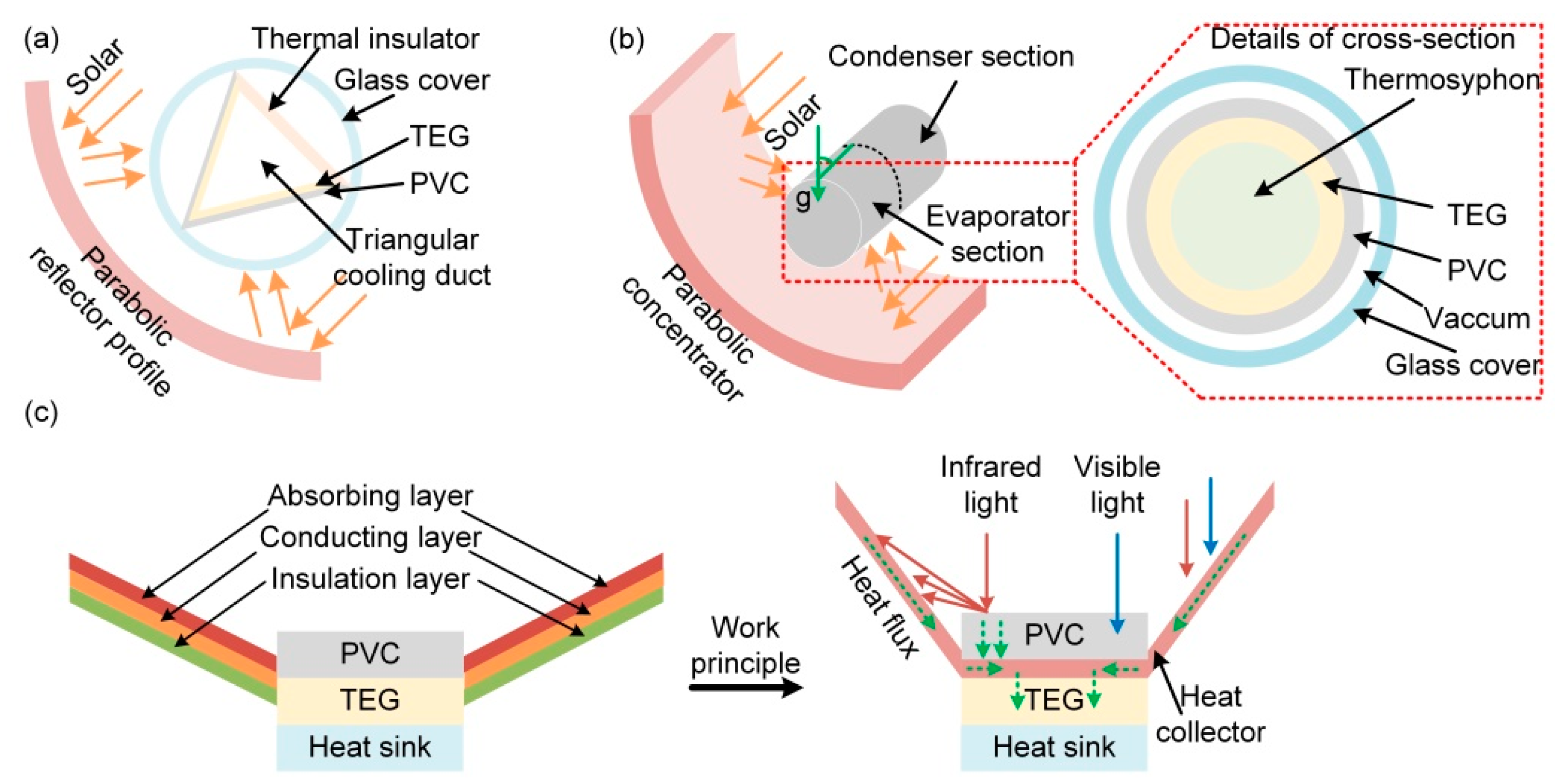

4. The Principle and Basic Configuration of the PVC–TEG Hybrid System

5. The Optimization of the Hybrid System

5.1. Internal Optimization

5.1.1. Materials

Shielding Materials

Energy Conversion Materials

Thermal Management Materials

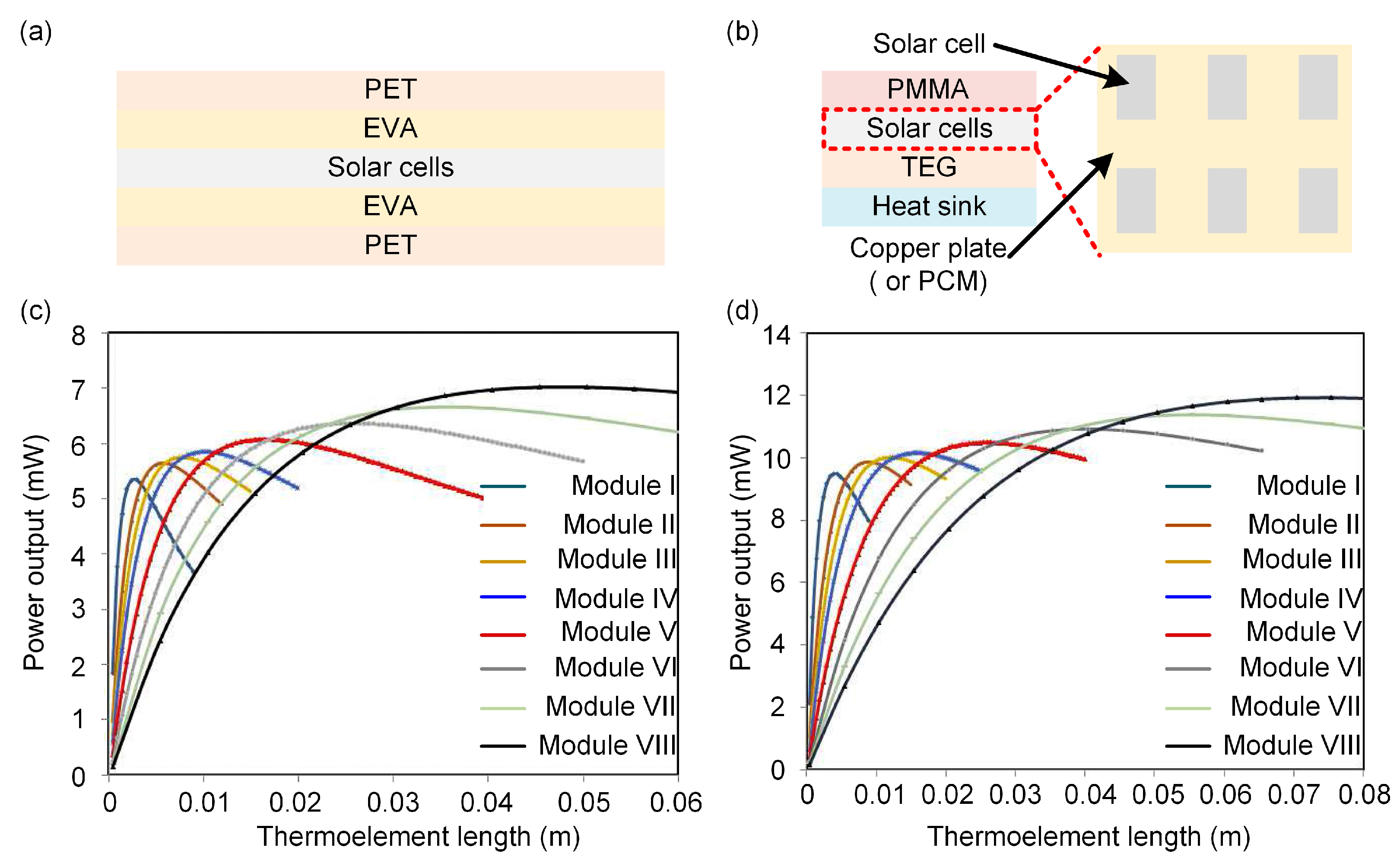

5.1.2. Geometry

5.1.3. Structure

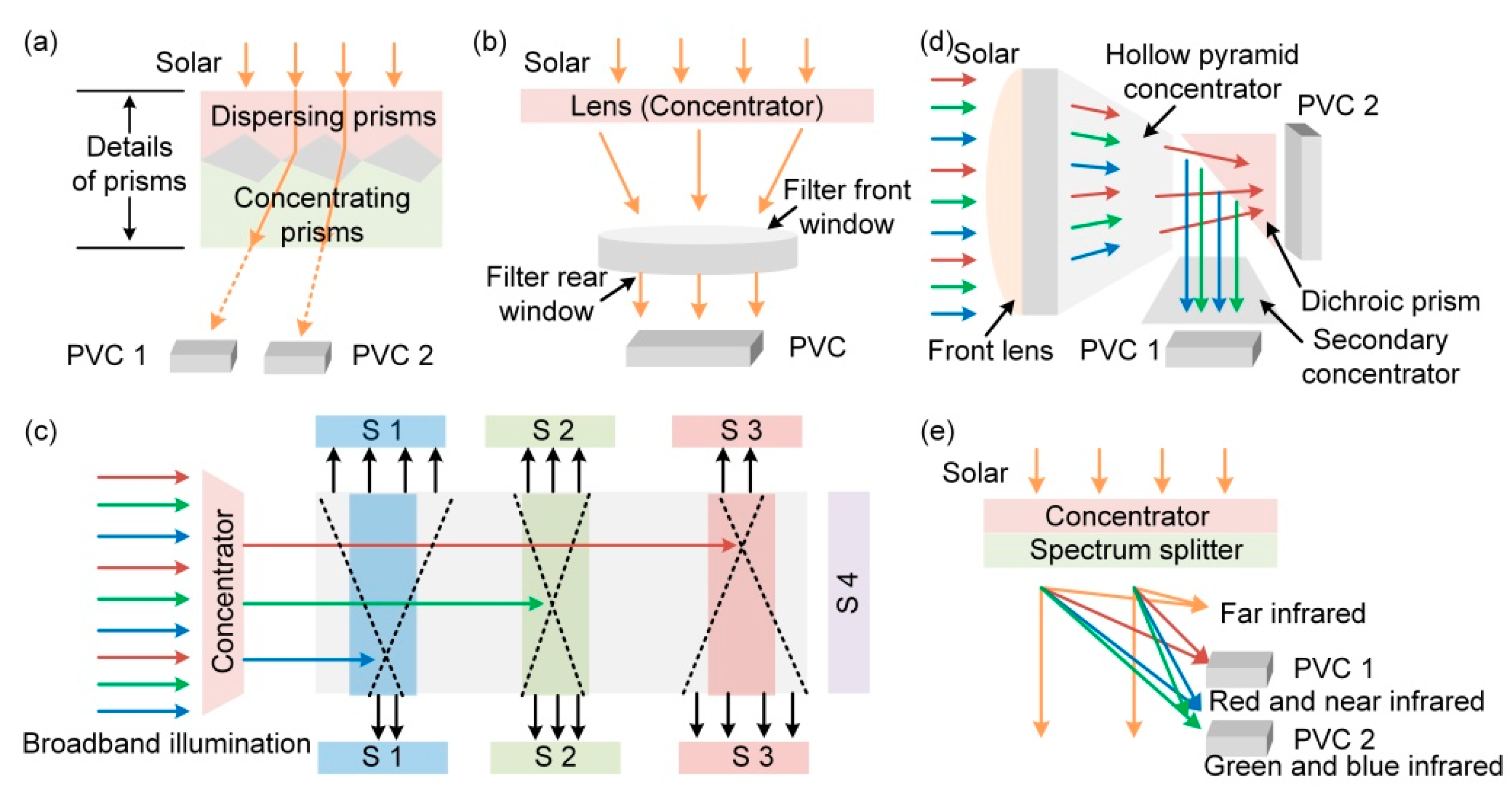

5.2. Optical Management

- (i)

- (ii)

- (iii)

- Luminescent solar concentrators [102,103,104]: concentrated sunlight enters the second component. Then, in the first segment (S1), some photons are absorbed by the fluorophores and re-emitted isotropically to the PVC, while others may propagate further according to the device and be absorbed by the following segments (S2, S3, etc.), until the unwanted part is discharged through S4 (Figure 6c);

- (iv)

- (v)

6. Economic Evaluation

7. Outlook

- (i)

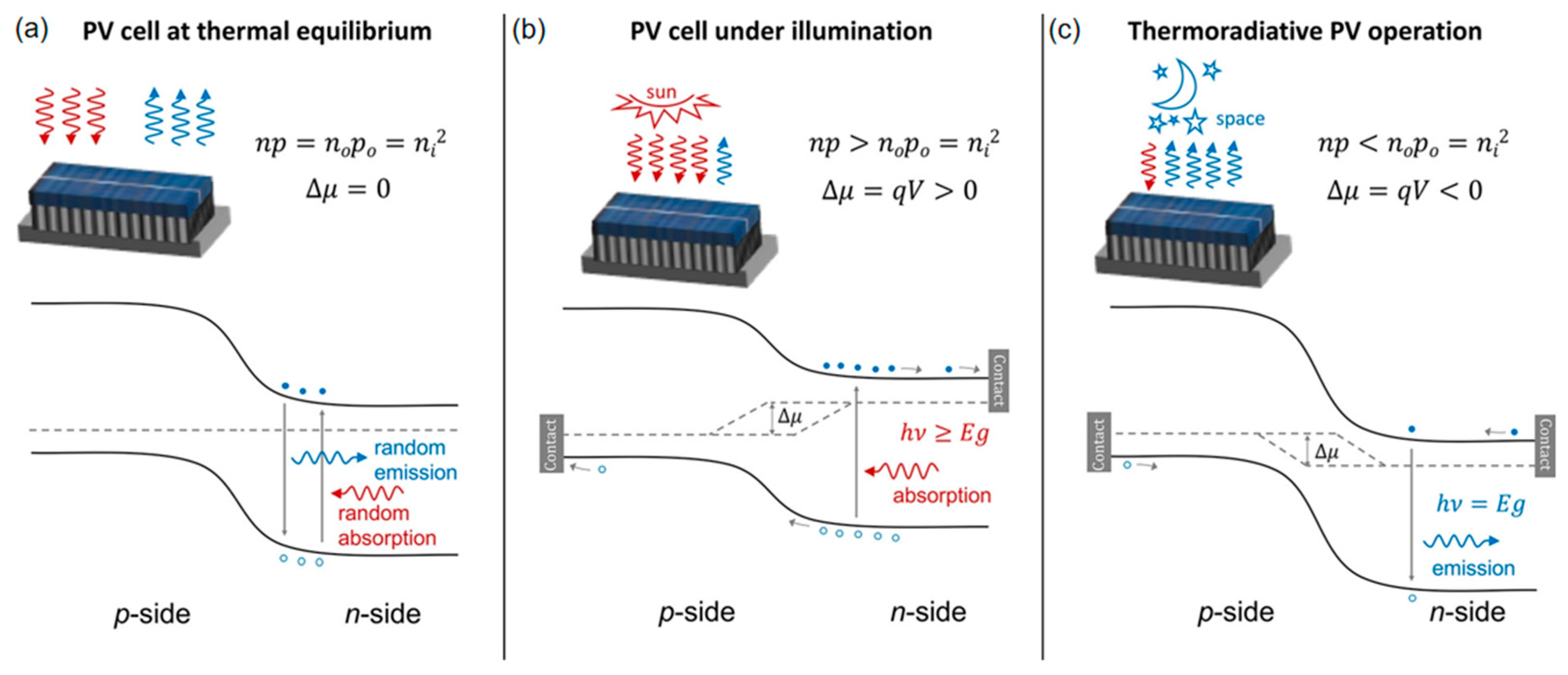

- Under the conditions of thermal equilibrium and without illumination (Figure 8a), the absorbed photons of PVCs were equal to the emitted photons, where the quantity of total electrons (n) and holes (p), intrinsic electrons (n0), intrinsic holes (p0), and the total intrinsic carrier density (ni) conform to , and the position of the Fermi level (EF) remains constant.

- (ii)

- Under the illumination conditions (Figure 8b), the absorption of photons by solar cells is greater than the emission from cells and thus generates photovoltage (vide supra). The generation of photo carriers leads to and splits EF.

- (iii)

- By contrast, when the p−n junction functions as a TRC (Figure 8c), emission from the solar cells is greater than absorption, resulting in and the EF splits in the opposite direction.

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jaziri, N.; Boughamoura, A.; Müller, J.; Mezghani, B.; Tounsi, F.; Ismail, M. A Comprehensive Review of Thermoelectric Generators: Technologies and Common Applications. Energy Rep. 2020, 6, 264–287. [Google Scholar] [CrossRef]

- Lee, S.; Bae, S.; Kim, D.; Lee, H. Historical Analysis of High-Efficiency, Large-Area Solar Cells: Toward Upscaling of Perovskite Solar Cells. Adv. Mater. 2020, 32, 2002202. [Google Scholar] [CrossRef] [PubMed]

- Yaseen, Z.M.; Ameen, A.M.S.; Aldlemy, M.S.; Ali, M.; Afan, H.A.; Zhu, S.; Al-Janabi, A.M.S.; Al-Ansari, N.; Tiyasha, T.; Tao, H. State-of-the Art-Powerhouse, Dam Structure, and Turbine Operation and Vibrations. Sustainability 2020, 12, 1676. [Google Scholar] [CrossRef]

- Blaabjerg, F.; Chen, Z.; Kjaer, S.B. Power Electronics as Efficient Interface in Dispersed Power Generation Systems. IEEE Trans. Power Electron. 2004, 19, 1184–1194. [Google Scholar] [CrossRef]

- Bell, L.E. Cooling, Heating, Generating Power, and Recovering Waste Heat with Thermoelectric Systems. Science 2008, 321, 1457–1461. [Google Scholar] [CrossRef]

- Einstein, A. Über Einen Die Erzeugung Und Verwandlung Des Lichtes Betreffenden Heuristischen Gesichtspunkt. Ann. Phys. 1905, 322, 132–148. [Google Scholar] [CrossRef]

- Goetzberger, A.; Hebling, C.; Schock, H.-W. Photovoltaic Materials, History, Status and Outlook. Mater. Sci. Eng. R Rep. 2003, 40, 1–46. [Google Scholar] [CrossRef]

- Parida, B.; Iniyan, S.; Goic, R. A Review of Solar Photovoltaic Technologies. Renew. Sustain. Energy Rev. 2011, 15, 1625–1636. [Google Scholar] [CrossRef]

- Tyagi, V.V.; Rahim, N.A.A.; Rahim, N.A.; Selvaraj, J.A.L. Progress in Solar PV Technology: Research and Achievement. Renew. Sustain. Energy Rev. 2013, 20, 443–461. [Google Scholar] [CrossRef]

- Yamamoto, K.; Nakajima, A.; Yoshimi, M.; Sawada, T.; Fukuda, S.; Suezaki, T.; Ichikawa, M.; Koi, Y.; Goto, M.; Meguro, T.; et al. A High Efficiency Thin Film Silicon Solar Cell and Module. Sol. Energy 2004, 77, 939–949. [Google Scholar] [CrossRef]

- Savin, H.; Repo, P.; von Gastrow, G.; Ortega, P.; Calle, E.; Garín, M.; Alcubilla, R. Black Silicon Solar Cells with Interdigitated Back-Contacts Achieve 22.1% Efficiency. Nat. Nanotechnol. 2015, 10, 624–628. [Google Scholar] [CrossRef] [PubMed]

- Köhler, M.; Pomaska, M.; Procel, P.; Santbergen, R.; Zamchiy, A.; Macco, B.; Lambertz, A.; Duan, W.; Cao, P.; Klingebiel, B.; et al. A Silicon Carbide-Based Highly Transparent Passivating Contact for Crystalline Silicon Solar Cells Approaching Efficiencies of 24%. Nat. Energy 2021, 6, 529–537. [Google Scholar] [CrossRef]

- Allen, T.G.; Bullock, J.; Yang, X.; Javey, A.; De Wolf, S. Passivating Contacts for Crystalline Silicon Solar Cells. Nat. Energy 2019, 4, 914–928. [Google Scholar] [CrossRef]

- Gaur, A.; Tiwari, G.N. Performance of A-Si Thin Film PV Modules with and without Water Flow: An Experimental Validation. Appl. Energy 2014, 128, 184–191. [Google Scholar] [CrossRef]

- Kondo, M.; Matsuda, A. Novel Aspects in Thin Film Silicon Solar Cells-Amorphous, Microcrystalline and Nanocrystalline Silicon. Thin Solid Film. 2004, 457, 97–102. [Google Scholar] [CrossRef]

- Liu, W.; Shi, J.; Zhang, L.; Han, A.; Huang, S.; Li, X.; Peng, J.; Yang, Y.; Gao, Y.; Yu, J.; et al. Light-Induced Activation of Boron Doping in Hydrogenated Amorphous Silicon for over 25% Efficiency Silicon Solar Cells. Nat. Energy 2022, 7, 427–437. [Google Scholar] [CrossRef]

- Ovshinsky, S.R. Amorphous Silicon Solar Cells. J. Vac. Sci. Technol. B Microelectron. Nanom. Struct. 1984, 2, 835. [Google Scholar] [CrossRef]

- Fiducia, T.A.M.; Mendis, B.G.; Li, K.; Grovenor, C.R.M.; Munshi, A.H.; Barth, K.; Sampath, W.S.; Wright, L.D.; Abbas, A.; Bowers, J.W.; et al. Understanding the Role of Selenium in Defect Passivation for Highly Efficient Selenium-Alloyed Cadmium Telluride Solar Cells. Nat. Energy 2019, 4, 504–511. [Google Scholar] [CrossRef]

- Lamb, D.A.; Irvine, S.J.C.; Baker, M.A.; Underwood, C.I.; Mardhani, S. Thin Film Cadmium Telluride Solar Cells on Ultra-Thin Glass in Low Earth Orbit—3 Years of Performance Data on the AlSat-1N CubeSat Mission. Prog. Photovolt. Res. Appl. 2021, 29, 1000–1007. [Google Scholar] [CrossRef]

- Li, X.; Zhang, W.; Guo, X.; Lu, C.; Wei, J.; Fang, J. Constructing Heterojunctions by Surface Sulfidation for Efficient Inverted Perovskite Solar Cells. Science 2022, 375, 434–437. [Google Scholar] [CrossRef]

- Li, Z.; Li, B.; Wu, X.; Sheppard, S.A.; Zhang, S.; Gao, D.; Long, N.J.; Zhu, Z. Organometallic-Functionalized Interfaces for Highly Efficient Inverted Perovskite Solar Cells. Science 2022, 376, 416–420. [Google Scholar] [CrossRef] [PubMed]

- Attivissimo, F.; Di Nisio, A.; Lanzolla, A.M.L.; Paul, M. Feasibility of a Photovoltaic-Thermoelectric Generator: Performance Analysis and Simulation Results. IEEE Trans. Instrum. Meas. 2015, 64, 1158–1169. [Google Scholar] [CrossRef]

- Geisz, J.F.; France, R.M.; Schulte, K.L.; Steiner, M.A.; Norman, A.G.; Guthrey, H.L.; Young, M.R.; Song, T.; Moriarty, T. Six-Junction III–V Solar Cells with 47.1% Conversion Efficiency under 143 Suns Concentration. Nat. Energy 2020, 5, 326–335. [Google Scholar] [CrossRef]

- Shockley, W.; Queisser, H.J. Detailed Balance Limit of Efficiency of P-n Junction Solar Cells. J. Appl. Phys. 1961, 32, 510–519. [Google Scholar] [CrossRef]

- Tiwari, A.; Alashqar, O.A.; Dimri, N. Modeling and Validation of Photovoltaic Thermoelectric Flat Plate Collector (PV-TE-FPC). Energy Convers. Manag. 2020, 205, 112378. [Google Scholar] [CrossRef]

- James, A.; Mohanraj, M.; Srinivas, M.; Jayaraj, S. Thermal Analysis of Heat Pump Systems Using Photovoltaic-Thermal Collectors: A Review. J. Therm. Anal. Calorim. 2021, 144, 1–39. [Google Scholar] [CrossRef]

- Guo, X.-Z.; Zhang, Y.-D.; Qin, D.; Luo, Y.-H.; Li, D.-M.; Pang, Y.-T.; Meng, Q.-B. Hybrid Tandem Solar Cell for Concurrently Converting Light and Heat Energy with Utilization of Full Solar Spectrum. J. Power Sources 2010, 195, 7684–7690. [Google Scholar] [CrossRef]

- Haschke, J.; Seif, J.P.; Riesen, Y.; Tomasi, A.; Cattin, J.; Tous, L.; Choulat, P.; Aleman, M.; Cornagliotti, E.; Uruena, A.; et al. The Impact of Silicon Solar Cell Architecture and Cell Interconnection on Energy Yield in Hot & Sunny Climates. Energy Environ. Sci. 2017, 10, 1196–1206. [Google Scholar] [CrossRef]

- Jošt, M.; Köhnen, E.; Al-Ashouri, A.; Bertram, T.; Tomšič, Š.; Magomedov, A.; Kasparavicius, E.; Kodalle, T.; Lipovšek, B.; Getautis, V.; et al. Perovskite/CIGS Tandem Solar Cells: From Certified 24.2% toward 30% and Beyond. ACS Energy Lett. 2022, 7, 1298–1307. [Google Scholar] [CrossRef]

- Virtuani, A.; Pavanello, D.; Friesen, G. Overview of Temperature Coefficients of Different Thin Film Photovoltaic Technologies. In Proceedings of the 25th European Photovoltaic Solar Energy Conference/5th World Conference on Photovoltaic Energy Conversion, Valencia, Spain, 6–10 September 2010; pp. 4248–4252. [Google Scholar] [CrossRef]

- He, J.; Tritt, T.M. Advances in Thermoelectric Materials Research: Looking Back and Moving Forward. Science 2017, 357, eaak9997. [Google Scholar] [CrossRef]

- Park, K.-T.; Shin, S.-M.; Tazebay, A.S.; Um, H.-D.; Jung, J.-Y.; Jee, S.-W.; Oh, M.-W.; Park, S.-D.; Yoo, B.; Yu, C.; et al. Lossless Hybridization between Photovoltaic and Thermoelectric Devices. Sci. Rep. 2013, 3, 2123. [Google Scholar] [CrossRef] [PubMed]

- Su, L.; Wang, D.; Wang, S.; Qin, B.; Wang, Y.; Qin, Y.; Jin, Y.; Chang, C.; Zhao, L. High Thermoelectric Performance Realized through Manipulating Layered Phonon-Electron Decoupling. Science 2022, 375, 1385–1389. [Google Scholar] [CrossRef] [PubMed]

- Marks, A.; Chen, X.; Wu, R.; Rashid, R.B.; Jin, W.; Paulsen, B.D.; Moser, M.; Ji, X.; Griggs, S.; Meli, D.; et al. Synthetic Nuances to Maximize N-Type Organic Electrochemical Transistor and Thermoelectric Performance in Fused Lactam Polymers. J. Am. Chem. Soc. 2022, 144, 4642–4656. [Google Scholar] [CrossRef] [PubMed]

- Ding, J.; Liu, Z.; Zhao, W.; Jin, W.; Xiang, L.; Wang, Z.; Zeng, Y.; Zou, Y.; Zhang, F.; Yi, Y.; et al. Selenium-Substituted Diketopyrrolopyrrole Polymer for High-Performance p-Type Organic Thermoelectric Materials. Angew. Chemie Int. Ed. 2019, 58, 18994–18999. [Google Scholar] [CrossRef]

- Han, C.-G.; Qian, X.; Li, Q.; Deng, B.; Zhu, Y.; Han, Z.; Zhang, W.; Wang, W.; Feng, S.-P.; Chen, G.; et al. Giant Thermopower of Ionic Gelatin near Room Temperature. Science 2020, 368, 1091–1098. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Dong, Z.; He, Y.; Zhu, W.; Yuan, Y.; Zeng, H.; Li, C.; Chen, S.; Sun, K. Multi-Ionic Hydrogel with Outstanding Heat-to-Electrical Performance for Low-Grade Heat Harvesting. Chem. An Asian J. 2022, 8, e202200850. [Google Scholar] [CrossRef]

- He, Y.; Zhang, Q.; Cheng, H.; Liu, Y.; Shu, Y.; Geng, Y.; Zheng, Y.; Qin, B.; Zhou, Y.; Chen, S.; et al. Role of Ions in Hydrogels with an Ionic Seebeck Coefficient of 52.9 MV K-1. J. Phys. Chem. Lett. 2022, 13, 4621–4627. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Q.; Odunmbaku, G.O.; He, Y.; Zheng, Y.; Chen, S.; Zhou, Y.; Li, J.; Li, M.; Sun, K. Solvent Effect on the Seebeck Coefficient of Fe2+/Fe3+ Hydrogel Thermogalvanic Cells. J. Mater. Chem. A 2022, 10, 19690–19698. [Google Scholar] [CrossRef]

- Liu, Z.; Cheng, H.; Le, Q.; Chen, R.; Li, J.; Ouyang, J. Giant Thermoelectric Properties of Ionogels with Cationic Doping. Adv. Energy Mater. 2022, 12, 2200858. [Google Scholar] [CrossRef]

- Peng, S.; Wang, D.; Lu, J.; He, M.; Xu, C.; Li, Y.; Zhu, S. A Review on Organic Polymer-Based Thermoelectric Materials. J. Polym. Environ. 2017, 25, 1208–1218. [Google Scholar] [CrossRef]

- Yang, Y.; Wei, X.J.; Liu, J. Suitability of a Thermoelectric Power Generator for Implantable Medical Electronic Devices. J. Phys. D Appl. Phys. 2007, 40, 5790–5800. [Google Scholar] [CrossRef]

- Torfs, T.; Leonov, V.; Vullers, R.J.M. Pulse Oximeter Fully Powered by Human Body Heat. Sens. Transducers J. 2007, 80, 1230–1238. [Google Scholar]

- Lay-Ekuakille, A.; Vendramin, G.; Trotta, A.; Mazzotta, G. Thermoelectric Generator Design Based on Power from Body Heat for Biomedical Autonomous Devices. In Proceedings of the 2009 IEEE International Workshop on Medical Measurements and Applications, Cetraro, Italy, 29–30 May 2009; pp. 1–4. [Google Scholar] [CrossRef]

- Van Bavel, M.; Leonov, V.; Yazicioglu, R.F.; Torfs, T.; Van Hoof, C.; Posthuma, N.E.; Vullers, R.J.M. Wearable Battery-Free Wireless 2-Channel EEG Systems Powered by Energy Scavengers. Sens. Transducers J. 2008, 94, 103–115. [Google Scholar]

- Thielen, M.; Sigrist, L.; Magno, M.; Hierold, C.; Benini, L. Human Body Heat for Powering Wearable Devices: From Thermal Energy to Application. Energy Convers. Manag. 2017, 131, 44–54. [Google Scholar] [CrossRef]

- Kishi, M.; Nemoto, H.; Hamao, T.; Yamamoto, M.; Sudou, S.; Mandai, M.; Yamamoto, S. Micro-Thermoelectric Modules and Their Application to Wristwatches as an Energy Source. In Proceedings of the Eighteenth International Conference on Thermoelectrics. Proceedings, ICT’99, Baltimore, MD, USA, 29 August–2 September 1999; pp. 301–307. [Google Scholar] [CrossRef]

- Leonov, V.; Torfs, T.; Fiorini, P.; Van Hoof, C. Thermoelectric Converters of Human Warmth for Self-Powered Wireless Sensor Nodes. IEEE Sens. J. 2007, 7, 650–656. [Google Scholar] [CrossRef]

- Ren, W.; Sun, Y.; Zhao, D.; Aili, A.; Zhang, S.; Shi, C.; Zhang, J.; Geng, H.; Zhang, J.; Zhang, L.; et al. High-Performance Wearable Thermoelectric Generator with Self-Healing, Recycling, and Lego-like Reconfiguring Capabilities. Sci. Adv. 2021, 7, eabe0586. [Google Scholar] [CrossRef]

- Lu, Z.; Zhang, H.; Mao, C.; Li, C.M. Silk Fabric-Based Wearable Thermoelectric Generator for Energy Harvesting from the Human Body. Appl. Energy 2016, 164, 57–63. [Google Scholar] [CrossRef]

- Rösch, A.G.; Gall, A.; Aslan, S.; Hecht, M.; Franke, L.; Mallick, M.M.; Penth, L.; Bahro, D.; Friderich, D.; Lemmer, U. Fully Printed Origami Thermoelectric Generators for Energy-Harvesting. npj Flex. Electron. 2021, 5, 1. [Google Scholar] [CrossRef]

- Dilhac, J.M.; Monthéard, R.; Bafleur, M.; Boitier, V.; Durand-Estèbe, P.; Tounsi, P. Implementation of Thermoelectric Generators in Airliners for Powering Battery-Free Wireless Sensor Networks. J. Electron. Mater. 2014, 43, 2444–2451. [Google Scholar] [CrossRef]

- Venkatasubramanian, R.; Siivola, E.; Colpitts, T.; O’Quinn, B.; Quinn, B.O. Thin-Film Thermoelectric Devices with High Room-Temperature Figures of Merit. Nature 2001, 413, 597–602. [Google Scholar] [CrossRef]

- Hochbaum, A.I.; Chen, R.; Delgado, R.D.; Liang, W.; Garnett, E.C.; Najarian, M.; Majumdar, A.; Yang, P. Enhanced Thermoelectric Performance of Rough Silicon Nanowires. Nature 2008, 451, 163–167. [Google Scholar] [CrossRef] [PubMed]

- Zhao, L.D.; Dravid, V.P.; Kanatzidis, M.G. The Panoscopic Approach to High Performance Thermoelectrics. Energy Environ. Sci. 2014, 7, 251–268. [Google Scholar] [CrossRef]

- Heremans, J.P.; Dresselhaus, M.S.; Bell, L.E.; Morelli, D.T. When Thermoelectrics Reached the Nanoscale. Nat. Nanotechnol. 2013, 8, 471–473. [Google Scholar] [CrossRef] [PubMed]

- Herez, A.; El Hage, H.; Lemenand, T.; Ramadan, M.; Khaled, M. Review on Photovoltaic/Thermal Hybrid Solar Collectors: Classifications, Applications and New Systems. Sol. Energy 2020, 207, 1321–1347. [Google Scholar] [CrossRef]

- Vorobiev, Y.; González-Hernández, J.; Vorobiev, P.; Bulat, L. Thermal-Photovoltaic Solar Hybrid System for Efficient Solar Energy Conversion. Sol. Energy 2006, 80, 170–176. [Google Scholar] [CrossRef]

- Vorobiev, Y.V.; González-Hernández, J.; Kribus, A. Analysis of Potential Conversion Efficiency of a Solar Hybrid System with High-Temperature Stage. J. Sol. Energy Eng. 2006, 128, 258–260. [Google Scholar] [CrossRef]

- Park, C.; Chou, P. AmbiMax: Autonomous Energy Harvesting Platform for Multi-Supply Wireless Sensor Nodes. In Proceedings of the 2006 3rd Annual IEEE Communications Society on Sensor and Ad Hoc Communications and Networks, Reston, VA, USA, 28 September 2006; Volume 1, pp. 168–177. [Google Scholar]

- Simjee, F.; Chou, P.H. Everlast: Long-Life, Supercapacitor-Operated Wireless Sensor Node. In Proceedings of the ISLPED’06 Proceedings of the 2006 International Symposium on Low Power Electronics and Design, Tegernsee, Germany, 4–6 October 2006; pp. 197–202. [Google Scholar] [CrossRef]

- Raghunathan, V.; Kansal, A.; Hsu, J.; Friedman, J.; Srivastava, M. Design Considerations for Solar Energy Harvesting Wireless Embedded Systems. In Proceedings of the IPSN 2005. Fourth International Symposium on Information Processing in Sensor Networks 2005, Boise, ID, USA, 15 April 2005; pp. 457–462. [Google Scholar] [CrossRef]

- Jiang, X.; Polastre, J.; Culler, D. Perpetual Environmentally Powered Sensor Networks. In Proceedings of the 2005 Fourth International Symposium on Information Processing in Sensor Networks, IPSN 2005, Boise, ID, USA, 15 April 2005; pp. 463–468. [Google Scholar] [CrossRef]

- Park, C.; Chou, P.H. Power Utility Maximization for Multiple-Supply Systems by a Load-Matching Switch. In Proceedings of the 2004 International Symposium on Low Power Electronics and Design, Newport Beach, CA, USA, 11 August 2004; pp. 168–173. [Google Scholar] [CrossRef]

- Zhang, X.; Chau, K.T.; Chan, C.C. Design and Implementation of a Thermoelectric-Photovoltaic Hybrid Energy Source for Hybrid Electric Vehicles. In Proceedings of the 24th International Battery, Hybrid and Fuel Cell Electric Vehicle Symposium and Exhibition 2009, EVS 24, Stavanger, Norway, 13–16 May 2009; Volume 2, pp. 862–871. [Google Scholar]

- Fisac, M.; Villasevil, F.X.; López, A.M. High-Efficiency Photovoltaic Technology Including Thermoelectric Generation. J. Power Sources 2014, 252, 264–269. [Google Scholar] [CrossRef]

- Riahi, A.; Ben Haj Ali, A.; Fadhel, A.; Guizani, A.; Balghouthi, M. Performance Investigation of a Concentrating Photovoltaic Thermal Hybrid Solar System Combined with Thermoelectric Generators. Energy Convers. Manag. 2020, 205, 112377. [Google Scholar] [CrossRef]

- Van Sark, W.G.J.H.M. Feasibility of Photovoltaic—Thermoelectric Hybrid Modules. Appl. Energy 2011, 88, 2785–2790. [Google Scholar] [CrossRef]

- Wu, Y.Y.; Wu, S.Y.; Xiao, L. Performance Analysis of Photovoltaic-Thermoelectric Hybrid System with and without Glass Cover. Energy Convers. Manag. 2015, 93, 151–159. [Google Scholar] [CrossRef]

- Kazem, A.A.; Chaichan, M.T.; Kazem, H.A. Dust Effect on Photovoltaic Utilization in Iraq: Review Article. Renew. Sustain. Energy Rev. 2014, 37, 734–749. [Google Scholar] [CrossRef]

- Mohsenzadeh, M.; Shafii, M.B.; Jafari mosleh, H. A Novel Concentrating Photovoltaic/Thermal Solar System Combined with Thermoelectric Module in an Integrated Design. Renew. Energy 2017, 113, 822–834. [Google Scholar] [CrossRef]

- Zhu, W.; Deng, Y.; Wang, Y.; Shen, S.; Gulfam, R. High-Performance Photovoltaic-Thermoelectric Hybrid Power Generation System with Optimized Thermal Management. Energy 2016, 100, 91–101. [Google Scholar] [CrossRef]

- Kossyvakis, D.N.; Voutsinas, G.D.; Hristoforou, E.V. Experimental Analysis and Performance Evaluation of a Tandem Photovoltaic-Thermoelectric Hybrid System. Energy Convers. Manag. 2016, 117, 490–500. [Google Scholar] [CrossRef]

- Su, S.; Liu, T.; Wang, Y.; Chen, X.; Wang, J.; Chen, J. Performance Optimization Analyses and Parametric Design Criteria of a Dye-Sensitized Solar Cell Thermoelectric Hybrid Device. Appl. Energy 2014, 120, 16–22. [Google Scholar] [CrossRef]

- Deng, Y.; Zhu, W.; Wang, Y.; Shi, Y. Enhanced Performance of Solar-Driven Photovoltaic–Thermoelectric Hybrid System in an Integrated Design. Sol. Energy 2013, 88, 182–191. [Google Scholar] [CrossRef]

- Yang, D.; Yin, H. Energy Conversion Efficiency of a Novel Hybrid Solar System for Photovoltaic, Thermoelectric, and Heat Utilization. IEEE Trans. Energy Convers. 2011, 26, 662–670. [Google Scholar] [CrossRef]

- Cui, T.; Xuan, Y.; Li, Q. Design of a Novel Concentrating Photovoltaic-Thermoelectric System Incorporated with Phase Change Materials. Energy Convers. Manag. 2016, 112, 49–60. [Google Scholar] [CrossRef]

- Hsueh, T.-J.; Shieh, J.-M.; Yeh, Y.-M. Hybrid Cd-Free CIGS Solar Cell/TEG Device with ZnO Nanowires. Prog. Photovolt. Res. Appl. 2015, 23, 507–512. [Google Scholar] [CrossRef]

- Fu, P.; Qin, W.; Bai, S.; Yang, D.; Chen, L.; Guo, X.; Li, C. Integrating Large-Area Perovskite Solar Module with Thermoelectric Generator for Enhanced and Stable Power Output. Nano Energy 2019, 65, 104009. [Google Scholar] [CrossRef]

- Zhou, Y.; Yin, X.; Zhang, Q.; Wang, N.; Yamamoto, A.; Koumoto, K.; Shen, H.; Lin, H. Perovskite Solar Cell-Thermoelectric Tandem System with a High Efficiency of over 23%. Mater. Today Energy 2019, 12, 363–370. [Google Scholar] [CrossRef]

- Zhou, Y.; Chen, Y.; Zhang, Q.; Zhou, Y.; Tai, M.; Koumoto, K.; Lin, H. A Highly-Efficient Concentrated Perovskite Solar Cell-Thermoelectric Generator Tandem System. J. Energy Chem. 2021, 59, 730–735. [Google Scholar] [CrossRef]

- Chang, H.; Kao, M.J.; Cho, K.C.; Chen, S.L.; Chu, K.H.; Chen, C.C. Integration of CuO Thin Films and Dye-Sensitized Solar Cells for Thermoelectric Generators. Curr. Appl. Phys. 2011, 11, S19–S22. [Google Scholar] [CrossRef]

- Lin, J.; Liao, T.; Lin, B. Performance Analysis and Load Matching of a Photovoltaic-Thermoelectric Hybrid System. Energy Convers. Manag. 2015, 105, 891–899. [Google Scholar] [CrossRef]

- Miljkovic, N.; Wang, E.N. Modeling and Optimization of Hybrid Solar Thermoelectric Systems with Thermosyphons. Sol. Energy 2011, 85, 2843–2855. [Google Scholar] [CrossRef]

- Hashim, H.; Bomphrey, J.J.; Min, G. Model for Geometry Optimisation of Thermoelectric Devices in a Hybrid PV/TE System. Renew. Energy 2016, 87, 458–463. [Google Scholar] [CrossRef]

- Narducci, D.; Lorenzi, B. Challenges and Perspectives in Tandem Thermoelectric–Photovoltaic Solar Energy Conversion. IEEE Trans. Nanotechnol. 2016, 15, 348–355. [Google Scholar] [CrossRef]

- Zhang, J.; Xuan, Y. An Integrated Design of the Photovoltaic-Thermoelectric Hybrid System. Sol. Energy 2019, 177, 293–298. [Google Scholar] [CrossRef]

- Yin, E.; Li, Q.; Xuan, Y. Optimal Design Method for Concentrating Photovoltaic-Thermoelectric Hybrid System. Appl. Energy 2018, 226, 320–329. [Google Scholar] [CrossRef]

- Kraemer, D.; Poudel, B.; Feng, H.-P.; Caylor, J.C.; Yu, B.; Yan, X.; Ma, Y.; Wang, X.; Wang, D.; Muto, A.; et al. High-Performance Flat-Panel Solar Thermoelectric Generators with High Thermal Concentration. Nat. Mater. 2011, 10, 532–538. [Google Scholar] [CrossRef]

- Kraemer, D.; Jie, Q.; McEnaney, K.; Cao, F.; Liu, W.; Weinstein, L.A.; Loomis, J.; Ren, Z.; Chen, G. Concentrating Solar Thermoelectric Generators with a Peak Efficiency of 7.4%. Nat. Energy 2016, 1, 16153. [Google Scholar] [CrossRef]

- Mahmood, Q.; Mustafa, G.M.; Morsi, M.; Albalawi, H.; Flemban, T.H.; Hassan, M.; Althib, H.; Khan, M.I.; Ghrib, T. Theoretical Investigations of Optoelectronic and Thermoelectric Properties of Halide Based Double Perovskite Halides: K2TeX6. Phys. Scr. 2021, 96, 075703. [Google Scholar] [CrossRef]

- Kraemer, D.; Hu, L.; Muto, A.; Chen, X.; Chen, G.; Chiesa, M. Photovoltaic-Thermoelectric Hybrid Systems: A General Optimization Methodology. Appl. Phys. Lett. 2008, 92, 243503. [Google Scholar] [CrossRef]

- Wang, N.; Han, L.; He, H.; Park, N.H.; Koumoto, K. A Novel High-Performance Photovoltaic-Thermoelectric Hybrid Device. Energy Environ. Sci. 2011, 4, 3676–3679. [Google Scholar] [CrossRef]

- Ju, X.; Wang, Z.; Flamant, G.; Li, P.; Zhao, W. Numerical Analysis and Optimization of a Spectrum Splitting Concentration Photovoltaic–Thermoelectric Hybrid System. Sol. Energy 2012, 86, 1941–1954. [Google Scholar] [CrossRef]

- Imenes, A.G.; Mills, D.R. Spectral Beam Splitting Technology for Increased Conversion Efficiency in Solar Concentrating Systems: A Review. Sol. Energy Mater. Sol. Cells 2004, 84, 19–69. [Google Scholar] [CrossRef]

- Barnett, A.; Kirkpatrick, D.; Honsberg, C.; Moore, D.; Wanlass, M.; Emery, K.; Carlson, D.; Bowden, S.; Aiken, D.; Gray, A.; et al. Milestones Toward 50 % Efficient Solar Cell Modules. In Proceedings of the 22nd European Photovoltaic Solar Energy Conference, Milan, Italy, 3–7 September 2007; pp. 5–10. [Google Scholar]

- Lewis, C.R.; Phillips, W.M.; Shields, V.B.; Stella, P.M.; Bekey, I. Multi-Bandgap High Efficiency Converter (RAINBOW). In Proceedings of the IECEC-97 Proceedings of the Thirty-Second Intersociety Energy Conversion Engineering Conference (Cat. No.97CH6203), Honolulu, HI, USA, 27 July–1 August 1997; Volume 1, pp. 401–406. [Google Scholar]

- Smith, M.A.; Sinharoy, S.; Weizer, V.G.; Khan, O.; Pal, A.; Clark, E.B.; Wilt, D.M.; Scheiman, D.A.; Mardesich, N. Solar Cells for NASA RAINBOW Concentrator. In Proceedings of the Conference Record of the Twenty-Eighth IEEE Photovoltaic Specialists Conference—2000 (Cat. No.00CH37036), Anchorage, AK, USA, 15–22 September 2000; Volume 2000, pp. 1139–1141. [Google Scholar]

- Converse, A.K. Refractive Spectrum Splitting Optics for Use with Photovoltaic Cells. In Proceedings of the Conference Record of the Twenty Fifth IEEE Photovoltaic Specialists Conference—1996, Washington, DC, USA, 13–17 May 1996; pp. 1299–1302. [Google Scholar]

- Sabry, M.; Gottschalg, R.; Betts, T.R.; Shaltout, M.A.M.; Hassan, A.F.; El-Nicklawy, M.M.; Infield, D.G. Optical Filtering of Solar Radiation to Increase Performance of Concentrator Systems. In Proceedings of the Conference Record of the Twenty-Ninth IEEE Photovoltaic Specialists Conference, New Orleans, LA, USA, 19–24 May 2002; pp. 1588–1591. [Google Scholar] [CrossRef]

- Hamdy, M.A.; El-Hefnawi, S.H. Effect of Spectrally Selective Liquid Absorption-Filters on Silicon Solar-Cells. Appl. Energy 1990, 35, 177–188. [Google Scholar] [CrossRef]

- Fisher, B.; Biddle, J. Luminescent Spectral Splitting: Efficient Spatial Division of Solar Spectrum at Low Concentration. Sol. Energy Mater. Sol. Cells 2011, 95, 1741–1755. [Google Scholar] [CrossRef]

- Galluzzi, F.; Scafé, E. Spectrum Shifting of Sunlight by Luminescent Sheets: Performance Evaluation of Photovoltaic Applications. Sol. Energy 1984, 33, 501–507. [Google Scholar] [CrossRef]

- Van Sark, W.G.J.H.M.; Barnham, K.W.J.; Slooff, L.H.; Chatten, A.J.; Büchtemann, A.; Meyer, A.; McCormack, S.J.; Koole, R.; Farrell, D.J.; Bose, R.; et al. Luminescent Solar Concentrators—A Review of Recent Results. Opt. Express 2008, 16, 21773. [Google Scholar] [CrossRef]

- HULL, J.; LAUER, J.; BROADBENT, D. Holographic Solar Concentrators. Energy 1987, 12, 209–215. [Google Scholar] [CrossRef]

- Ludman, J.E.; Riccobono, J.; Semenova, I.V.; Reinhand, N.O.; Tai, W.; Li, X.; Syphers, G.; Rallis, E.; Sliker, G.; Martín, J. The Optimization of a Holographic System for Solar Power Generation. Sol. Energy 1997, 60, 1–9. [Google Scholar] [CrossRef]

- Ludman, J.E.; Sampson, J.L.; Bradbury, R.A.; Martin, J.G.; Riccobono, J.R.; Sliker, G.; Rallis, E. Photovoltaic Systems Based on Spectrally Selective Holographic Concentrators; SPIE Proceedings [SPIE EI 92-San Jose, CA] Practical Holography VI; SPIE: San Jose, CA, USA, 9 March 1992; Volume 1667, pp. 182–189. [Google Scholar]

- Xu, Y.; Xuan, Y.; Yang, L. Full-Spectrum Photon Management of Solar Cell Structures for Photovoltaic-Thermoelectric Hybrid Systems. Energy Convers. Manag. 2015, 103, 533–541. [Google Scholar] [CrossRef]

- Lorenzi, B.; Mariani, P.; Reale, A.; Di Carlo, A.; Chen, G.; Narducci, D. Practical Development of Efficient Thermoelectric—Photovoltaic Hybrid Systems Based on Wide-Gap Solar Cells. Appl. Energy 2021, 300, 117343. [Google Scholar] [CrossRef]

- Bjørk, R.; Nielsen, K.K. The Performance of a Combined Solar Photovoltaic (PV) and Thermoelectric Generator (TEG) System. Sol. Energy 2015, 120, 187–194. [Google Scholar] [CrossRef]

- Beeri, O.; Rotem, O.; Hazan, E.; Katz, E.A.; Braun, A.; Gelbstein, Y. Hybrid Photovoltaic-Thermoelectric System for Concentrated Solar Energy Conversion: Experimental Realization and Modeling. J. Appl. Phys. 2015, 118, 115104. [Google Scholar] [CrossRef]

- Zhao, L.D.; Lo, S.H.; Zhang, Y.; Sun, H.; Tan, G.; Uher, C.; Wolverton, C.; Dravid, V.P.; Kanatzidis, M.G. Ultralow Thermal Conductivity and High Thermoelectric Figure of Merit in SnSe Crystals. Nature 2014, 508, 373–377. [Google Scholar] [CrossRef] [PubMed]

- Chang, C.; Wu, M.; He, D.; Pei, Y.; Wu, C.F.; Wu, X.; Yu, H.; Zhu, F.; Wang, K.; Chen, Y.; et al. 3D Charge and 2D Phonon Transports Leading to High Out-of-Plane ZT in n-Type SnSe Crystals. Science 2018, 360, 778–783. [Google Scholar] [CrossRef]

- Zhao, L.D.; Tan, G.; Hao, S.; He, J.; Pei, Y.; Chi, H.; Wang, H.; Gong, S.; Xu, H.; Dravid, V.P.; et al. Ultrahigh Power Factor and Thermoelectric Performance in Hole-Doped Single-Crystal SnSe. Science 2016, 351, 141–144. [Google Scholar] [CrossRef]

- Yan, Y.; Xue, B.; Hu, Z.; Zhao, X. AFM Tip Characterization by Using FFT Filtered Images of Step Structures. Ultramicroscopy 2016, 160, 155–162. [Google Scholar] [CrossRef]

- He, W.; Wang, D.; Wu, H.; Xiao, Y.; Zhang, Y.; He, D.; Feng, Y.; Hao, Y.-J.; Dong, J.-F.; Chetty, R.; et al. High Thermoelectric Performance in Low-Cost SnS 0.91 Se 0.09 Crystals. Science 2019, 365, 1418–1424. [Google Scholar] [CrossRef] [PubMed]

- Qin, B.; Wang, D.; Liu, X.; Qin, Y.; Dong, J.; Luo, J.; Li, J.-W.; Liu, W.; Tan, G.; Tang, X.; et al. Power Generation and Thermoelectric Cooling Enabled by Momentum and Energy Multiband Alignments. Science 2021, 373, 556–561. [Google Scholar] [CrossRef] [PubMed]

- Xiao, Y.; Zhao, L.-D. Seeking New, Highly Effective Thermoelectrics. Science 2020, 367, 1196–1197. [Google Scholar] [CrossRef]

- Lin, Z.; Hollar, C.; Kang, J.S.; Yin, A.; Wang, Y.; Shiu, H.Y.; Huang, Y.; Hu, Y.; Zhang, Y.; Duan, X. A Solution Processable High-Performance Thermoelectric Copper Selenide Thin Film. Adv. Mater. 2017, 29, 2–7. [Google Scholar] [CrossRef]

- Zhao, K.; Liu, K.; Yue, Z.; Wang, Y.; Song, Q.; Li, J.; Guan, M.; Xu, Q.; Qiu, P.; Zhu, H.; et al. Are Cu2Te-Based Compounds Excellent Thermoelectric Materials? Adv. Mater. 2019, 31, 1903480. [Google Scholar] [CrossRef] [PubMed]

- Mao, J.; Zhu, H.; Ding, Z.; Liu, Z.; Gamage, G.A.; Chen, G.; Ren, Z. High Thermoelectric Cooling Performance of N-Type Mg3Bi2-Based Materials. Science 2019, 365, 495–498. [Google Scholar] [CrossRef]

- Fu, Y.; Zhang, Q.; Hu, Z.; Jiang, M.; Huang, A.; Ai, X.; Wan, S.; Reith, H.; Wang, L.; Nielsch, K.; et al. Mg 3 (Bi,Sb) 2 -Based Thermoelectric Modules for Efficient and Reliable Waste-Heat Utilization up to 750 K. Energy Environ. Sci. 2022, 15, 3265–3274. [Google Scholar] [CrossRef]

- Bubnova, O.; Crispin, X. Towards Polymer-Based Organic Thermoelectric Generators. Energy Environ. Sci. 2012, 5, 9345–9362. [Google Scholar] [CrossRef]

- Bubnova, O.; Khan, Z.U.; Malti, A.; Braun, S.; Fahlman, M.; Berggren, M.; Crispin, X. Optimization of the Thermoelectric Figure of Merit in the Conducting Polymer Poly(3,4-Ethylenedioxythiophene). Nat. Mater. 2011, 10, 429–433. [Google Scholar] [CrossRef]

- Zhang, Q.; Sun, Y.; Xu, W.; Zhu, D. Organic Thermoelectric Materials: Emerging Green Energy Materials Converting Heat to Electricity Directly and Efficiently. Adv. Mater. 2014, 26, 6829–6851. [Google Scholar] [CrossRef]

- Russ, B.; Glaudell, A.; Urban, J.J.; Chabinyc, M.L.; Segalman, R.A. Organic Thermoelectric Materials for Energy Harvesting and Temperature Control. Nat. Rev. Mater. 2016, 1, 16050. [Google Scholar] [CrossRef]

- Fan, Z.; Li, P.; Du, D.; Ouyang, J. Significantly Enhanced Thermoelectric Properties of PEDOT:PSS Films through Sequential Post-Treatments with Common Acids and Bases. Adv. Energy Mater. 2017, 7, 1602116. [Google Scholar] [CrossRef]

- Sun, Y.; Qiu, L.; Tang, L.; Geng, H.; Wang, H.; Zhang, F.; Huang, D.; Xu, W.; Yue, P.; Guan, Y.S.; et al. Flexible N-Type High-Performance Thermoelectric Thin Films of Poly(Nickel-Ethylenetetrathiolate) Prepared by an Electrochemical Method. Adv. Mater. 2016, 28, 3351–3358. [Google Scholar] [CrossRef] [PubMed]

- Huang, D.; Yao, H.; Cui, Y.; Zou, Y.; Zhang, F.; Wang, C.; Shen, H.; Jin, W.; Zhu, J.; Diao, Y.; et al. Conjugated-Backbone Effect of Organic Small Molecules for n-Type Thermoelectric Materials with ZT over 0.2. J. Am. Chem. Soc. 2017, 139, 13013–13023. [Google Scholar] [CrossRef] [PubMed]

- Byrnes, S.J.; Blanchard, R.; Capasso, F. Harvesting Renewable Energy from Earth’s Mid-Infrared Emissions. Proc. Natl. Acad. Sci. USA 2014, 111, 3927–3932. [Google Scholar] [CrossRef] [PubMed]

- Deppe, T.; Munday, J.N. Nighttime Photovoltaic Cells: Electrical Power Generation by Optically Coupling with Deep Space. ACS Photonics 2020, 7, 1–9. [Google Scholar] [CrossRef]

- Santhanam, P.; Fan, S. Thermal-to-Electrical Energy Conversion by Diodes under Negative Illumination. Phys. Rev. B 2016, 93, 161410. [Google Scholar] [CrossRef]

- Strandberg, R. Theoretical Efficiency Limits for Thermoradiative Energy Conversion. J. Appl. Phys. 2015, 117, 055105. [Google Scholar] [CrossRef]

- Fernández, J.J. The Role of Electrochemical Potentials of Solid-State Energy Emissive Harvesters. Heliyon 2022, 8, e10853. [Google Scholar] [CrossRef]

- Hu, C.; Fu, T.; Liang, T.; Chen, X.; Su, S.; Chen, J. Efficiency Enhancement of an Updated Solar-Driven Intermediate Band Thermoradiative Device. Energy 2021, 228, 120590. [Google Scholar] [CrossRef]

- Ye, Z.; Peng, W.; Su, S.; Chen, J. Intermediate Band Thermoradiative Cells. IEEE Trans. Electron Devices 2018, 65, 5428–5433. [Google Scholar] [CrossRef]

- Luque, A.; Martí, A. Increasing the Efficiency of Ideal Solar Cells by Photon Induced Transitions at Intermediate Levels. Phys. Rev. Lett. 1997, 78, 5014–5017. [Google Scholar] [CrossRef]

- Luque, A.; Martà , A. The Intermediate Band Solar Cell: Progress Toward the Realization of an Attractive Concept. Adv. Mater. 2010, 22, 160–174. [Google Scholar] [CrossRef] [PubMed]

- Luque, A.; Linares, P.G.; Antolín, E.; Cánovas, E.; Farmer, C.D.; Stanley, C.R.; Martí, A. Multiple Levels in Intermediate Band Solar Cells. Appl. Phys. Lett. 2010, 96, 013501. [Google Scholar] [CrossRef]

- Hsu, W.C.; Tong, J.K.; Liao, B.; Huang, Y.; Boriskina, S.V.; Chen, G. Entropic and Near-Field Improvements of Thermoradiative Cells. Sci. Rep. 2016, 6, 34837. [Google Scholar] [CrossRef] [PubMed]

| Solar Cells | Label | Maximum Cell Efficiency (%) | |

|---|---|---|---|

| Crystalline Si cells | Multicrystalline | I | 23.3 |

| Single crystal (non-concentrator) | II | 26.1 | |

| Single heterostructures (HIT) | III | 26.7 | |

| Single crystal (concentrator) | IV | 27.6 | |

| Amorphous Si cell | Amorphous Si:H (stabilized) | V | 14 |

| Compound cells | Inorganic cells (CZTSSe) | VI | 13 |

| Dye-sensitized cells | VII | 13 | |

| Organic tandem cells | VIII | 14.2 | |

| Quantum dot cells (various types) | IX | 18.1 | |

| Organic cells | X | 18.2 | |

| Perovskite/CuInGaSe2 (CIGS) tandem (monolithic) | XI | 24.2 | |

| Perovskite cells | XII | 25.7 | |

| Perovskite/Si tandem (monolithic) | XIII | 31.3 | |

| CdTe | XIV | 22.1 | |

| CIGS (concentrator) | XV | 23.3 | |

| CIGS | XVI | 23.4 | |

| Thin-film crystal | XVII | 21.2 | |

| Single crystal GaAs | XVIII | 27.8 | |

| Concentrator GaAs | XIX | 29.1 | |

| Thin-film crystal GaAs | XX | 30.8 | |

| Two-junction (non-concentrator) | XXI | 32.9 | |

| Two-junction (concentrator) | XXII | 35.5 | |

| Four-junction or more (non-concentrator) | XXIII | 39.2 | |

| Three-junction (non-concentrator) | XXIV | 39.5 | |

| Three-junction (concentrator) | XXV | 44.4 | |

| Four-junction or more (concentrator) | XXVI | 47.1 | |

| Module Type | Number of Thermo-Elements | Cross-Section Area (mm2) |

|---|---|---|

| I | 62 | 0.64 |

| II | 62 | 1.44 |

| III | 62 | 1.96 |

| IV | 62 | 2.56 |

| V | 100 | 2.56 |

| VI | 150 | 2.56 |

| VII | 200 | 2.56 |

| VIII | 250 | 2.56 |

| System Types | Actual PV Cell Efficiency (%) | Total Electric Power Output (W/m2) |

|---|---|---|

| Single crystalline Si cells | 9.1 | 91 |

| Hybrid system | 10.3 | 113.3 |

| Item | Materials | Hybrid System Cost ($/m2) |

|---|---|---|

| Substrate | Fire-retardant plywood | 6.78 |

| FGM layer | Aerated polyvinyl chloride | 67.24 |

| Al powder | 22.38 | |

| Extruding tubes | 2.69 | |

| TE layer | Bulk Bi2Te3 module | 1678.25 |

| PV layer | Single crystalline Si cells | 193.64 |

| Superstrate | EVA | 9.47 |

| PV glass | 28.51 | |

| Perimeter | Al clip | 5.7 |

| Piping materials | 13.23 | |

| Pumping system | 65.84 | |

| Total cost | None | 2095.88 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Gao, P. Hybrid Photovoltaic/Thermoelectric Systems for Round-the-Clock Energy Harvesting. Molecules 2022, 27, 7590. https://doi.org/10.3390/molecules27217590

Zhang Y, Gao P. Hybrid Photovoltaic/Thermoelectric Systems for Round-the-Clock Energy Harvesting. Molecules. 2022; 27(21):7590. https://doi.org/10.3390/molecules27217590

Chicago/Turabian StyleZhang, Yingyao, and Peng Gao. 2022. "Hybrid Photovoltaic/Thermoelectric Systems for Round-the-Clock Energy Harvesting" Molecules 27, no. 21: 7590. https://doi.org/10.3390/molecules27217590

APA StyleZhang, Y., & Gao, P. (2022). Hybrid Photovoltaic/Thermoelectric Systems for Round-the-Clock Energy Harvesting. Molecules, 27(21), 7590. https://doi.org/10.3390/molecules27217590