Advances in Thermoelectric Composites Consisting of Conductive Polymers and Fillers with Different Architectures

Abstract

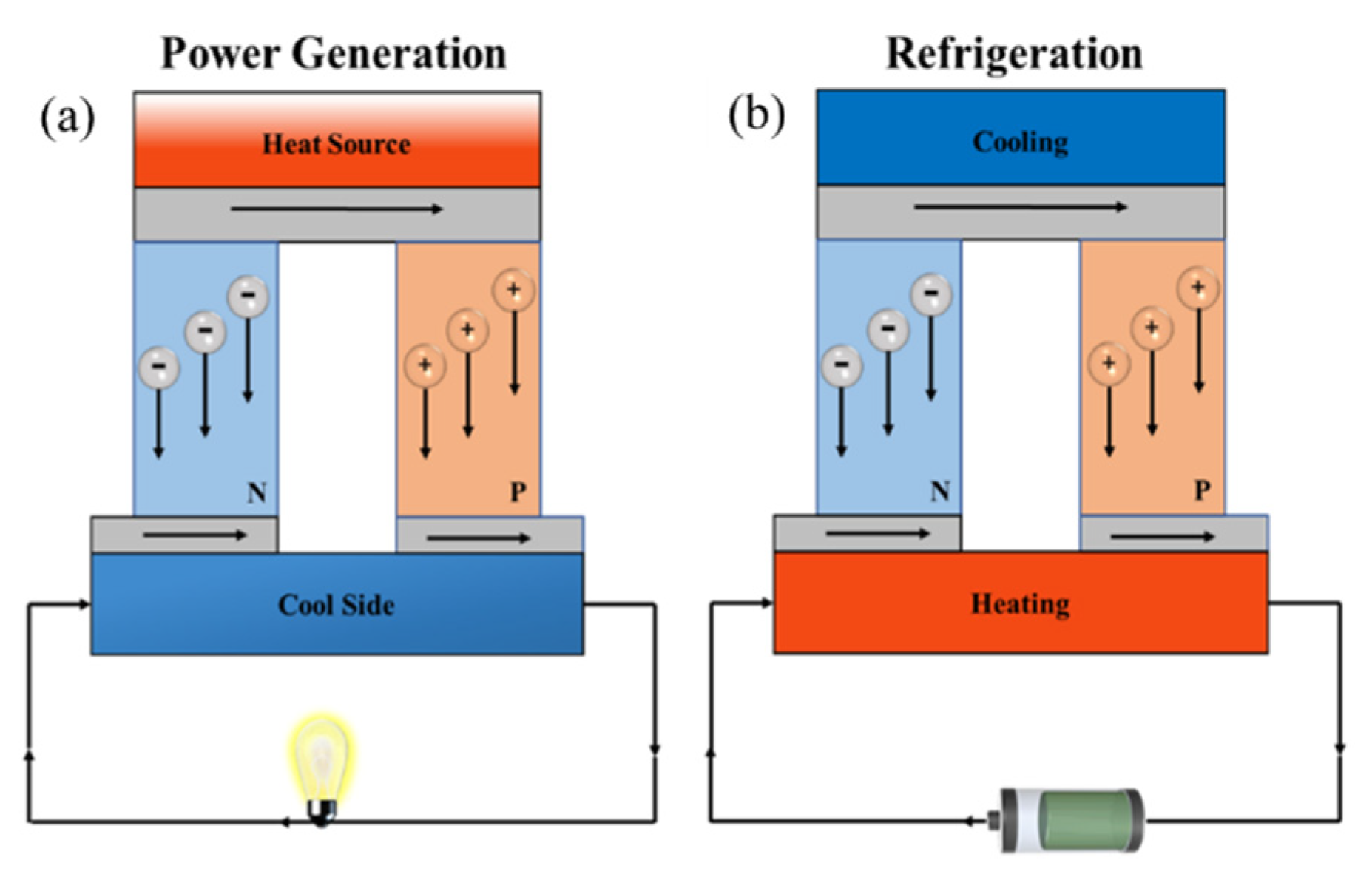

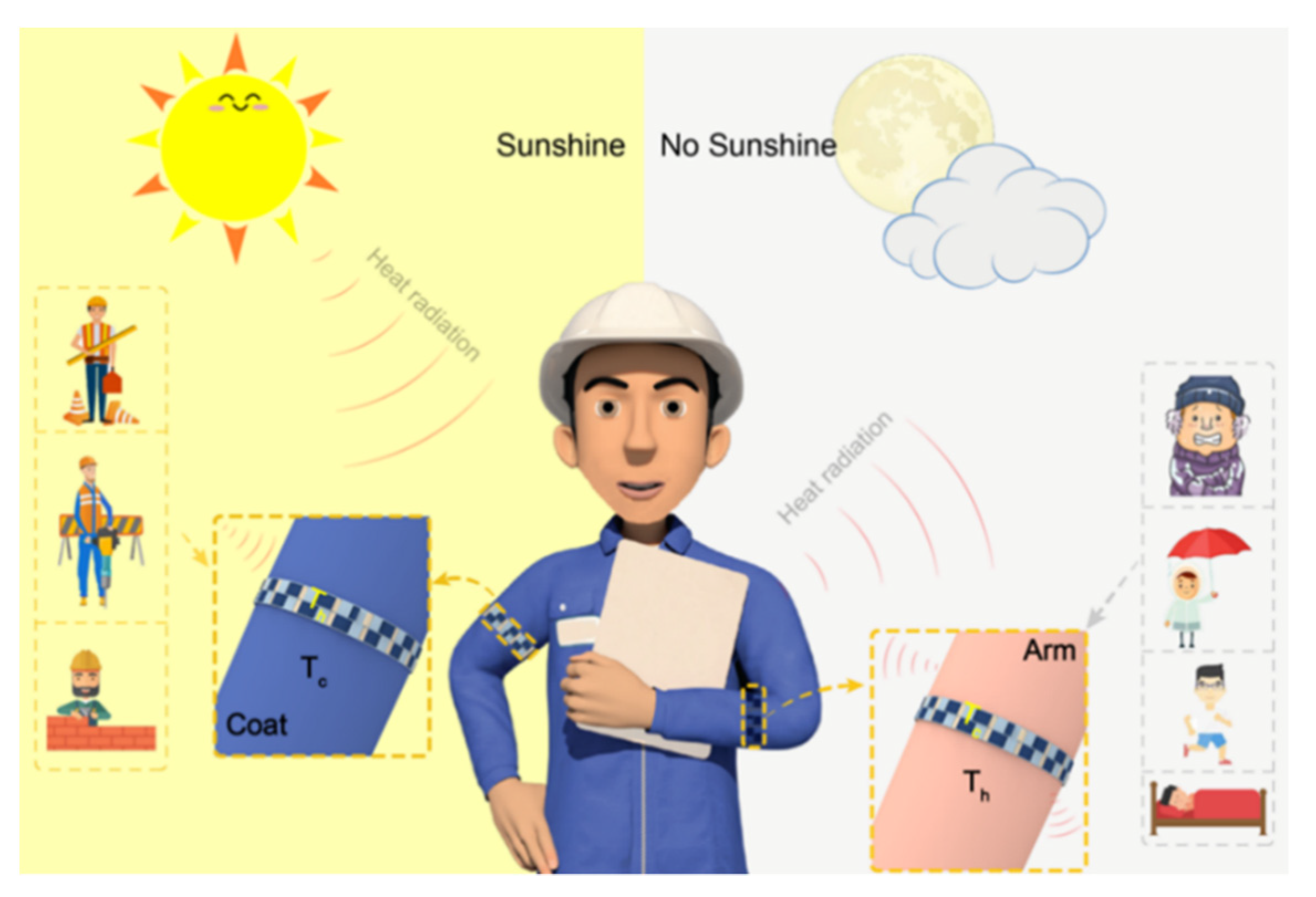

1. Introduction

2. Zero-Dimensional (0D) TE Materials

2.1. Zero-Dimensional (0D) Materials

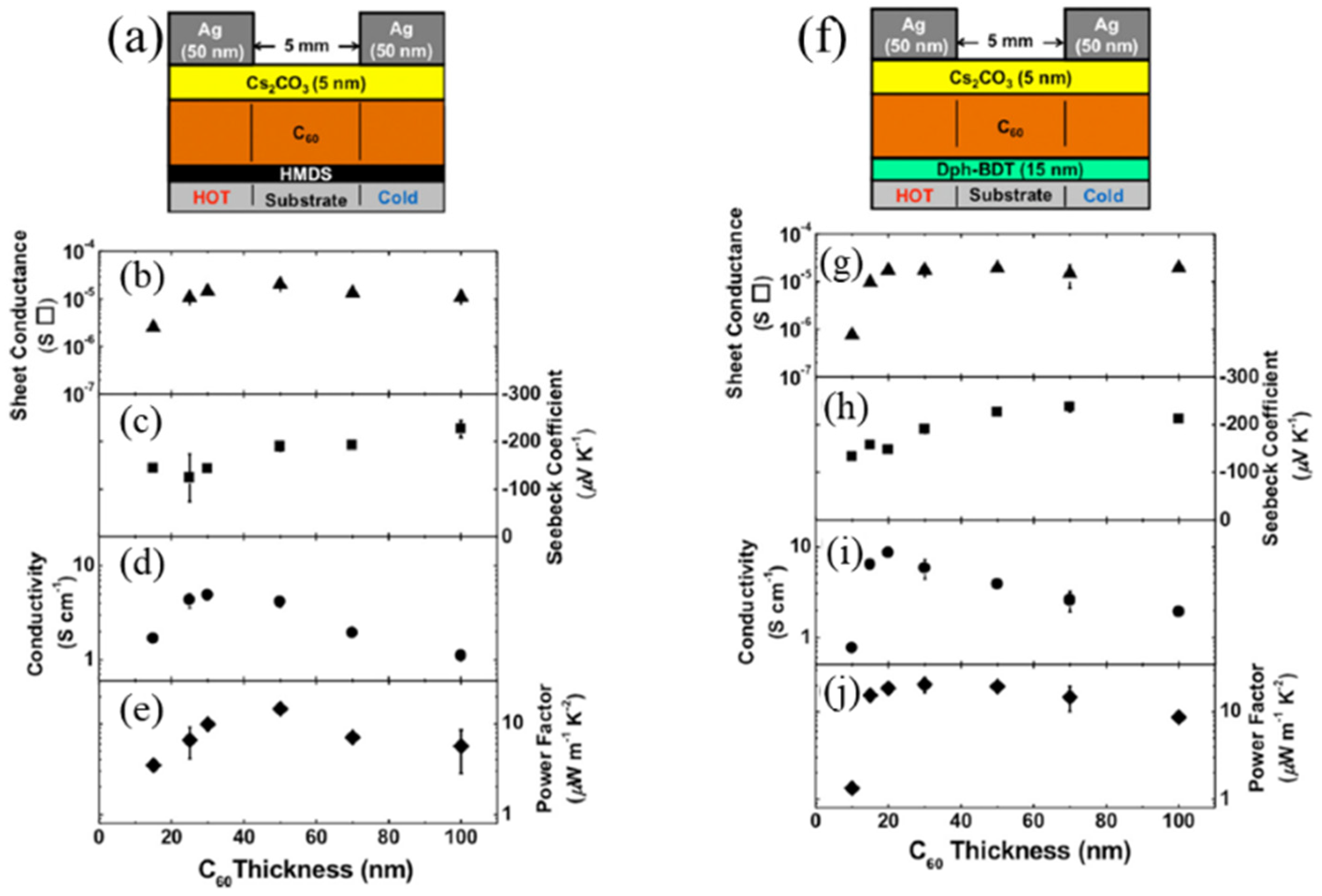

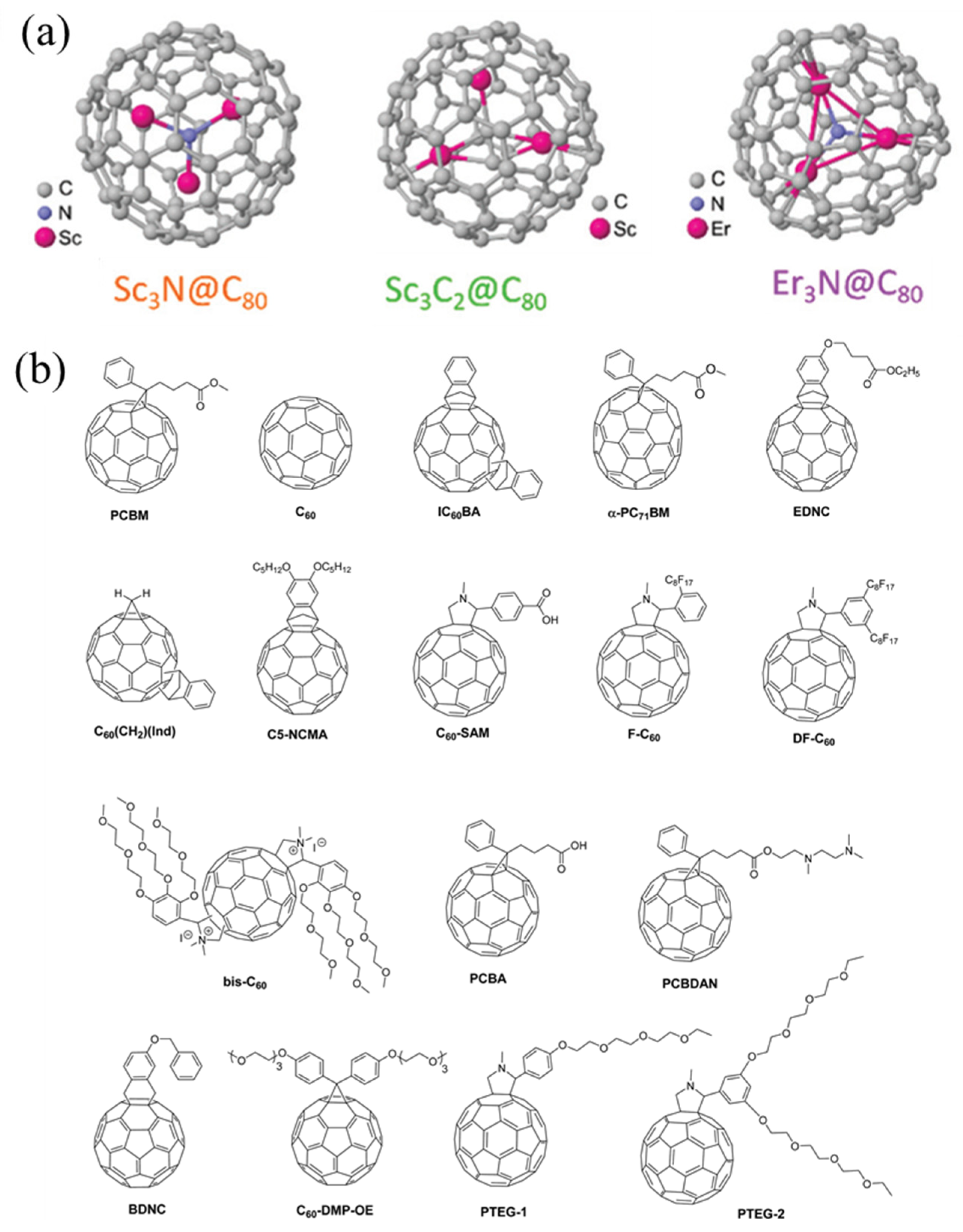

2.1.1. Fullerene

2.1.2. Quantum Dots

3. One-Dimensional (1D) TE Materials

3.1. One-Dimensional (1D) Materials

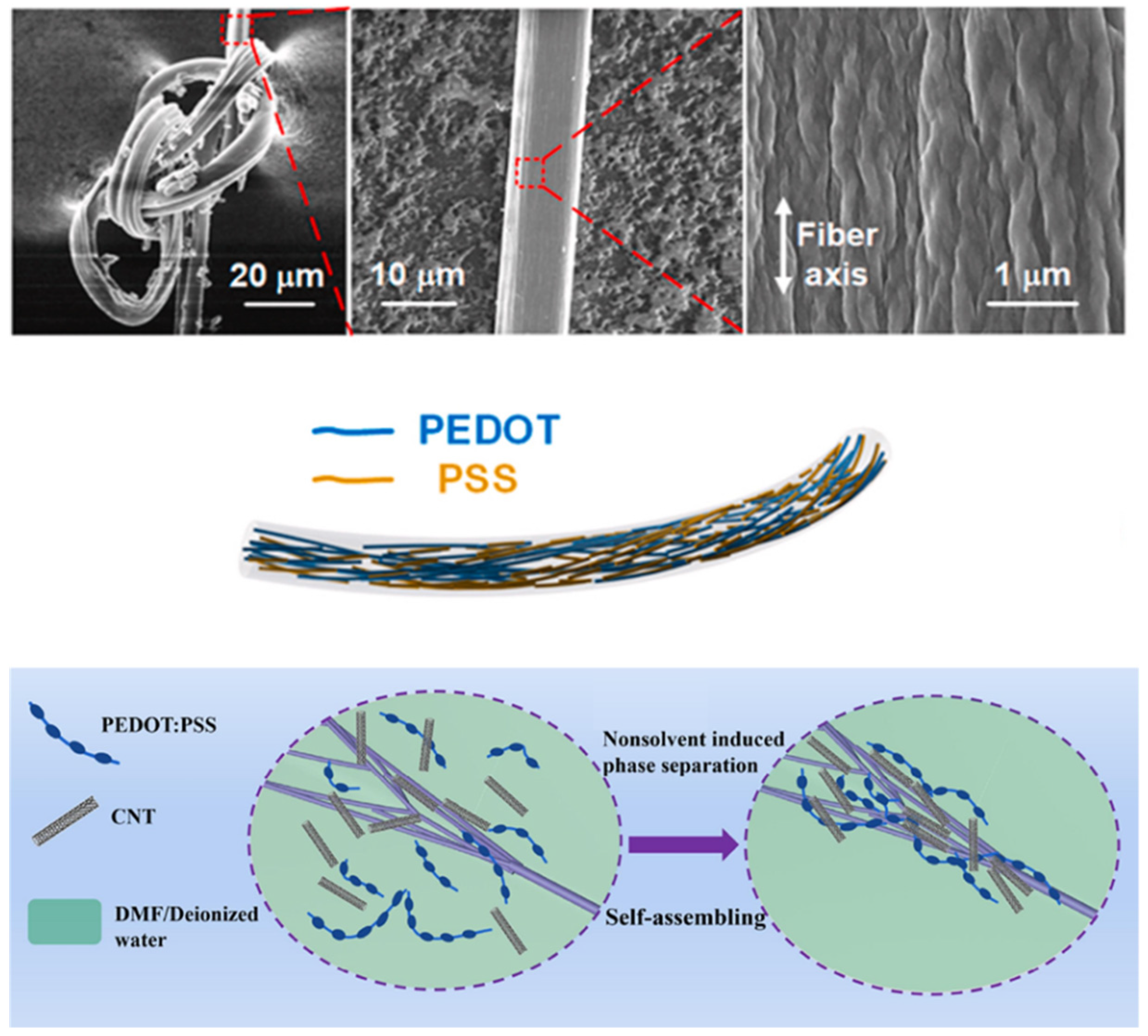

3.1.1. One-Dimensional Conductive Polymers and Related Composites

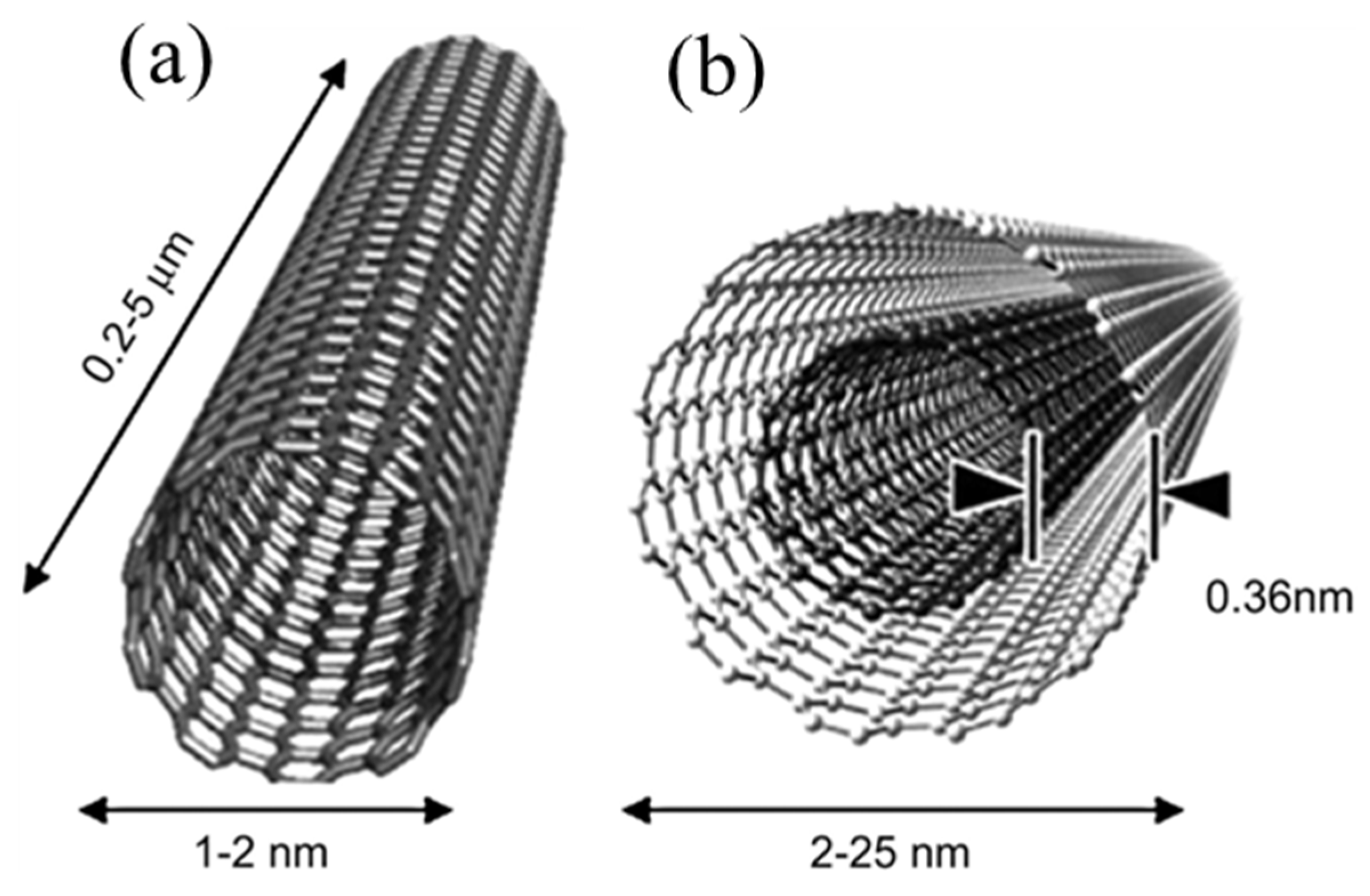

3.1.2. Carbon Nanotubes (CNTs) and Related TE Materials

4. Two-Dimensional (2D) TE Materials

4.1. Two-Dimensional Materials and Their TE Composites

4.1.1. Graphene

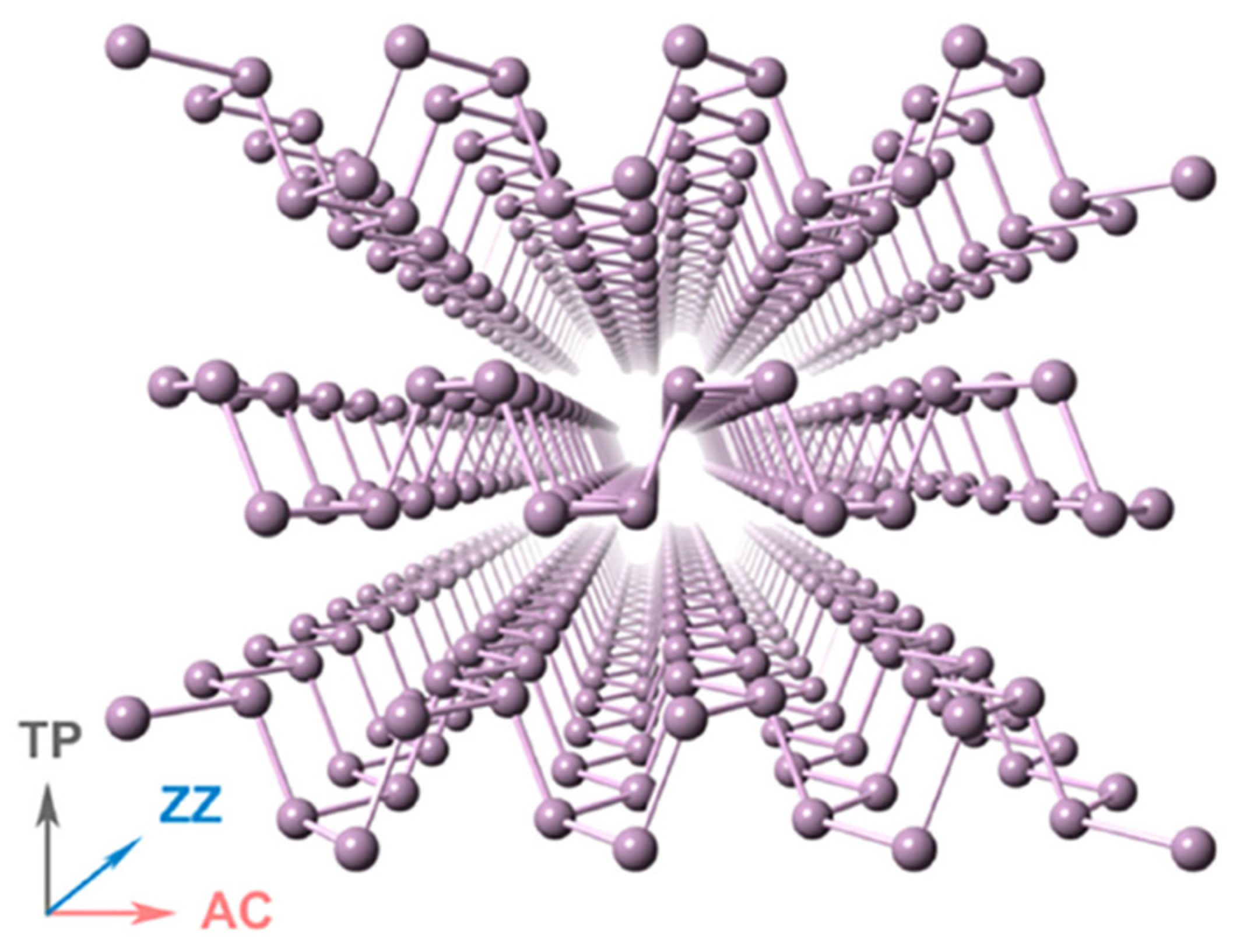

4.1.2. Black Phosphorus (BP)

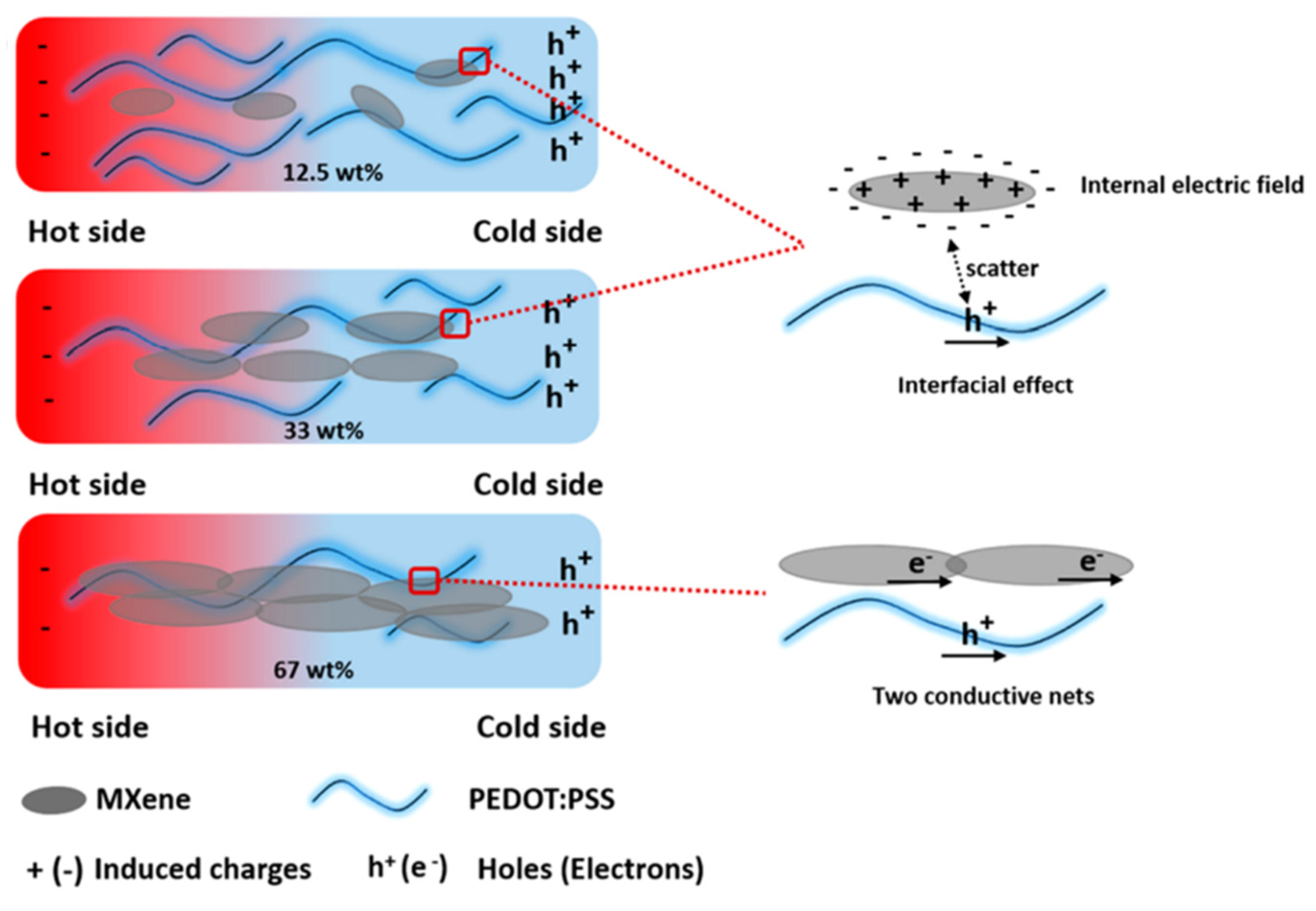

4.1.3. Transition Metal Carbides/Nitrides (MXene)

5. Three-Dimensional (3D) TE Materials

5.1. Three-Dimensional Materials and Their TE Composites

Metal-Organic Frameworks (MOFs)

6. Summary and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Li, Z.; Xiao, C.; Xie, Y. Layered thermoelectric materials: Structure, bonding, and performance mechanisms. Appl. Phys. Rev. 2022, 9, 011303. [Google Scholar] [CrossRef]

- Schultz, H.S.; Carvalho, M. Design, Greenhouse Emissions, and Environmental Payback of a Photovoltaic Solar Energy System. Energies 2022, 15, 6098. [Google Scholar] [CrossRef]

- Gogoc, S.; Data, P. Organic Thermoelectric Materials as the Waste Heat Remedy. Molecules 2022, 27, 1016. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Li, X.; Sun, Y.; Xie, Y. Rational design of electrocatalytic carbon dioxide reduction for a zero-carbon network. Chemical Soc. Rev. 2022, 51, 1234–1252. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Luo, Q.; Yin, S.; Lu, W.; He, H.; Guo, C.-Y. Organic/inorganic thermoelectric composites electrochemical synthesis, properties, and applications. J. Mater. Sci. 2021, 56, 19311–19328. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, W.; Zhang, F.; Dai, K.; Li, C.; Fan, Y.; Chen, G.; Zheng, Q. Soft Organic Thermoelectric Materials: Principles, Current State of the Art and Applications. Small 2022, 18, 2104922. [Google Scholar] [CrossRef]

- He, Y.; Kuang, F.; Che, Z.; Sun, F.; Zheng, K.; Zhang, J.; Cao, X.; Ma, Y. Achieving high out-of-plane thermal conductivity for boron nitride nano sheets/epoxy composite films by magnetic orientation. Compos. Part A Appl. Sci. Manuf. 2022, 157, 106933. [Google Scholar] [CrossRef]

- Hu, Y.; Zhang, Y.; Chen, G. Flexible films of tourmaline thermoelectric composite via acid treatment and embedding single-walled carbon nanotubes. Compos. Commun. 2022, 34, 101240. [Google Scholar] [CrossRef]

- Sa, C.; Xu, X.; Wu, X.; Chen, J.; Zuo, C.; Fang, X. A wearable helical organic–inorganic photodetector with thermoelectric generators as the power source. J. Mater. Chem. C 2019, 7, 13097–13103. [Google Scholar] [CrossRef]

- Jiang, Q.; Sun, H.; Zhao, D.; Zhang, F.; Hu, D.; Jiao, F.; Qin, L.; Linseis, V.; Fabiano, S.; Crispin, X.; et al. High Thermoelectric Performance in n-Type Perylene Bisimide Induced by the Soret Effect. Adv. Mater. 2020, 32, 2002752. [Google Scholar] [CrossRef]

- Sun, M.; Zhang, P.; Li, Q.; Tang, G.; Zhang, T.; Chen, D.; Qian, Q. Enhanced N-Type Bismuth-Telluride-Based Thermoelectric Fibers via Thermal Drawing and Bridgman Annealing. Materials 2022, 15, 5331. [Google Scholar] [CrossRef]

- Zhang, L.; Lin, S.; Hua, T.; Huang, B.; Liu, S.; Tao, X. Fiber-Based Thermoelectric Generators: Materials, Device Structures, Fabrication, Characterization, and Applications. Adv. Energy Mater. 2018, 8, 1700524. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, G. Advancing Flexible Thermoelectric Devices with Polymer Composites. Adv. Mater. Technol. 2020, 5, 2000049. [Google Scholar] [CrossRef]

- Coetzee, D.; Venkataraman, M.; Militky, J.; Petru, M. Influence of Nanoparticles on Thermal and Electrical Conductivity of Composites. Polymers 2020, 12, 742. [Google Scholar] [CrossRef] [PubMed]

- Zou, T.H.; Qin, X.Y.; Li, D.; Ren, B.J.; Sun, G.L.; Dou, Y.C.; Li, Y.Y.; Li, L.L.; Zhang, J.; Xin, H.X. Enhanced thermoelectric performance via carrier energy filtering effect in β-Zn4Sb3 alloy bulk embedded with (Bi2Te3)0.2(Sb2Te3)0.8. J. Appl. Phys. 2014, 115, 053710. [Google Scholar] [CrossRef]

- Wan, C.; Gu, X.; Dang, F.; Itoh, T.; Wang, Y.; Sasaki, H.; Kondo, M.; Koga, K.; Yabuki, K.; Snyder, G.J.; et al. Flexible n-type thermoelectric materials by organic intercalation of layered transition metal dichalcogenide TiS2. Nat. Mater. 2015, 14, 622–627. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Wang, H.; Liu, B. Carbon Nanotube-Based Organic Thermoelectric Materials for Energy Harvesting. Polymers 2018, 10, 1196. [Google Scholar] [CrossRef]

- Dresselhaus, M.S.; Chen, G.; Tang, M.Y.; Yang, R.G.; Lee, H.; Wang, D.Z.; Ren, Z.F.; Fleurial, J.P.; Gogna, P. New Directions for Low-Dimensional Thermoelectric Materials. Adv. Mater. 2007, 19, 1043–1053. [Google Scholar] [CrossRef]

- Lu, J.; Wang, R.; Ren, J.; Kulkarni, M.; Jiang, J.-H. Quantum-dot circuit-QED thermoelectric diodes and transistors. Phys. Rev. B 2019, 99, 035129. [Google Scholar] [CrossRef]

- Khan, J.; Liu, Y.; Zhao, T.; Geng, H.; Xu, W.; Shuai, Z. High performance thermoelectric materials based on metal organic coordination polymers through first-principles band engineering. J. Comput. Chem. 2018, 39, 2582–2588. [Google Scholar] [CrossRef]

- Lu, N.; Li, L.; Liu, M. A review of carrier thermoelectric-transport theory in organic semiconductors. Phys. Chem. Chem. Phys. 2016, 18, 19503–19525. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Qiu, L.; Portale, G.; Torabi, S.; Stuart, M.C.A.; Qiu, X.; Koopmans, M.; Chiechi, R.C.; Hummelen, J.C.; Anton Koster, L.J. Side-chain effects on N-type organic thermoelectrics: A case study of fullerene derivatives. Nano Energy 2018, 52, 183–191. [Google Scholar] [CrossRef]

- Zhao, C.; Li, Z.; Fan, T.; Xiao, C.; Xie, Y. Defects Engineering with Multiple Dimensions in Thermoelectric Materials. Research 2020, 2020, 9652749. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, L.-D.; Zhu, Y.; Liu, Y.; Li, F.; Yu, M.; Liu, D.-B.; Xu, W.; Lin, Y.-H.; Nan, C.-W. Synergistically Optimizing Electrical and Thermal Transport Properties of BiCuSeO via a Dual-Doping Approach. Adv. Energy Mater. 2016, 6, 1502423. [Google Scholar] [CrossRef]

- Wang, J.; Shen, M.; Liu, Z.; Wang, W. MXene materials for advanced thermal management and thermal energy utilization. Nano Energy 2022, 97, 107177. [Google Scholar] [CrossRef]

- Sumino, M.; Harada, K.; Ikeda, M.; Tanaka, S.; Miyazaki, K.; Adachi, C. Thermoelectric properties of n-type C60 thin films and their application in organic thermovoltaic devices. Appl. Phys. Lett. 2011, 99, 093308. [Google Scholar] [CrossRef]

- Rincon-Garcia, L.; Ismael, A.K.; Evangeli, C.; Grace, I.; Rubio-Bollinger, G.; Porfyrakis, K.; Agrait, N.; Lambert, C.J. Molecular design and control of fullerene-based bi-thermoelectric materials. Nat. Mater. 2016, 15, 289–293. [Google Scholar] [CrossRef] [PubMed]

- Qiu, X.; Ivasyshyn, V.; Qiu, L.; Enache, M.; Dong, J.; Rousseva, S.; Portale, G.; Stohr, M.; Hummelen, J.C.; Chiechi, R.C. Thiol-free self-assembled oligoethylene glycols enable robust air-stable molecular electronics. Nat. Mater. 2020, 19, 330–337. [Google Scholar] [CrossRef]

- Yee, S.K.; Malen, J.A.; Majumdar, A.; Segalman, R.A. Thermoelectricity in Fullerene–Metal Heterojunctions. Nano Lett. 2011, 11, 4089–4094. [Google Scholar] [CrossRef]

- Ismael, A.K.; Rincón-García, L.; Evangeli, C.; Dallas, P.; Alotaibi, T.; Al-Jobory, A.A.; Rubio-Bollinger, G.; Porfyrakis, K.; Agraït, N.; Lambert, C.J. Exploring seebeck-coefficient fluctuations in endohedral-fullerene, single-molecule junctions. Nanoscale Horiz. 2022, 7, 616–625. [Google Scholar] [CrossRef]

- Hummelen, J.C.; Knight, B.W.; LePeq, F.; Wudl, F.; Yao, J.; Wilkins, C.L. Preparation and Characterization of Fulleroid and Methanofullerene Derivatives. J. Org. Chem. 1995, 60, 532–538. [Google Scholar] [CrossRef]

- Yu, G.; Gao, J.; Hummelen, J.C.; Wudl, F.; Heeger, A.J. Polymer Photovoltaic Cells: Enhanced Efficiencies via a Network of Internal Donor-Acceptor Heterojunctions. Science 1995, 270, 1789–1791. [Google Scholar] [CrossRef]

- Wei, P.; Oh, J.H.; Dong, G.; Bao, Z. Use of a 1H-Benzoimidazole Derivative as an n-Type Dopant and To Enable Air-Stable Solution-Processed n-Channel Organic Thin-Film Transistors. J. Am. Chem. Soc. 2010, 132, 8852–8853. [Google Scholar] [CrossRef]

- Li, C.-Z.; Chueh, C.-C.; Yip, H.-L.; Ding, F.; Li, X.; Jen, A.K.Y. Solution-Processible Highly Conducting Fullerenes. Adv. Mater. 2013, 25, 2457–2461. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Qiu, L.; Shao, S. Emerging electronic applications of fullerene derivatives: An era beyond OPV. J. Mater. Chem. C 2021, 9, 16143–16163. [Google Scholar] [CrossRef]

- Kastner, M.A. Artificial Atoms. Phys. Today 1993, 46, 24–31. [Google Scholar] [CrossRef]

- Haack, G.; Giazotto, F. Efficient and tunable Aharonov-Bohm quantum heat engine. Phys. Rev. B 2019, 100, 235442. [Google Scholar] [CrossRef]

- Barman, A.; Dhongade, S.G.; Haque, A.A.; Banerjee, S.; Varshney, S.K.; Singha, A. Thermometry in dual quantum dot setup with staircase ground state configuration. Phys. E Low-Dimens. Syst. Nanostruct. 2022, 142, 115263. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, B.; Chen, Z.; Liu, D.; Jing, L.; Gao, C.; Li, J.; He, Z.; Wang, J. Bioinspired Cryoprotectants of Glucose-Based Carbon Dots. ACS Appl. Bio Mater. 2020, 3, 3785–3791. [Google Scholar] [CrossRef]

- Zhang, Y. Optimization performance of quantum Otto heat engines and refrigerators with squeezed thermal reservoirs. Phys. A Stat. Mech. Appl. 2020, 559, 125083. [Google Scholar] [CrossRef]

- Liu, W.; Bai, L.; Zhang, R. Optically manipulating thermodynamic performances of a quantum-dot heat engine. Superlattices Microstruct. 2020, 145, 106625. [Google Scholar] [CrossRef]

- Dorsch, S.; Svilans, A.; Josefsson, M.; Goldozian, B.; Kumar, M.; Thelander, C.; Wacker, A.; Burke, A. Heat Driven Transport in Serial Double Quantum Dot Devices. Nano Lett. 2021, 21, 988–994. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Zhang, Q.; Chen, G. Carbon and carbon composites for thermoelectric applications. Carbon Energy 2020, 2, 408–436. [Google Scholar] [CrossRef]

- Kim, D.; Park, Y.; Ju, D.; Lee, G.; Kwon, W.; Cho, K. Energy-Filtered Acceleration of Charge-Carrier Transport in Organic Thermoelectric Nanocomposites. Chem. Mater. 2021, 33, 4853–4862. [Google Scholar] [CrossRef]

- Feng, N.; Gao, C.; Guo, C.-Y.; Chen, G. Copper-Phenylacetylide Nanobelt/Single-Walled Carbon Nanotube Composites: Mechanochromic Luminescence Phenomenon and Thermoelectric Performance. ACS Appl. Mater. Interfaces 2018, 10, 5603–5608. [Google Scholar] [CrossRef] [PubMed]

- Liang, L.; Chen, G.; Guo, C.-Y. Enhanced thermoelectric performance by self-assembled layered morphology of polypyrrole nanowire/single-walled carbon nanotube composites. Compos. Sci. Technol. 2016, 129, 130–136. [Google Scholar] [CrossRef]

- Karbaschi, H.; Rashedi, G.; Nouri, N. Thermoelectric cooling properties of quantum dot superlattice embedded nanowires. Mater. Res. Express 2019, 6, 095071. [Google Scholar] [CrossRef]

- Qi, Y.; Wang, Z.; Zhang, M.; Yang, F.; Wang, X. Thermoelectric devices based on one-dimensional nanostructures. J. Mater. Chem. A 2013, 1, 6110–6124. [Google Scholar] [CrossRef]

- Liang, L.; Fan, J.; Wang, M.; Chen, G.; Sun, G. Ternary thermoelectric composites of polypyrrole/PEDOT:PSS/carbon nanotube with unique layered structure prepared by one-dimensional polymer nanostructure as template. Compos. Sci. Technol. 2020, 187, 107948. [Google Scholar] [CrossRef]

- He, X.; Gu, J.; Hao, Y.; Zheng, M.; Wang, L.; Yu, J.; Qin, X. Continuous manufacture of stretchable and integratable thermoelectric nanofiber yarn for human body energy harvesting and self-powered motion detection. Chem. Eng. J. 2022, 450, 137937. [Google Scholar] [CrossRef]

- Zhu, X.; Han, X.; Guo, R.; Yuan, P.; Dang, L.; Liu, Z.; Lei, Z. Vapor-phase polymerization of fibrous PEDOT on carbon fibers film for fast pseudocapacitive energy storage. Appl. Surf. Sci. 2022, 597, 153684. [Google Scholar] [CrossRef]

- Chen, G.; Li, Y.; Bick, M.; Chen, J. Smart Textiles for Electricity Generation. Chem. Rev. 2020, 120, 3668–3720. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, P.; Jiang, Q.; Jiang, F.; Liu, J.; Liu, G.; Liu, C.; Du, Y.; Xu, J. Organic/inorganic hybrid for flexible thermoelectric fibers. Chem. Eng. J. 2021, 405, 126510. [Google Scholar] [CrossRef]

- Serrano-Claumarchirant, J.F.; Brotons-Alcázar, I.; Culebras, M.; Sanchis, M.J.; Cantarero, A.; Muñoz-Espí, R.; Gómez, C.M. Electrochemical Synthesis of an Organic Thermoelectric Power Generator. ACS Appl. Mater. Interfaces 2020, 12, 46348–46356. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.; Chen, G.; Wang, X.; Wang, H. Tuning thermoelectric performance by nanostructure evolution of a conducting polymer. J. Mater. Chem. A 2015, 3, 20896–20902. [Google Scholar] [CrossRef]

- Li, X.; Liang, L.; Yang, M.; Chen, G.; Guo, C.-Y. Poly(3,4-ethylenedioxythiophene)/graphene/carbon nanotube ternary composites with improved thermoelectric performance. Org. Electron. 2016, 38, 200–204. [Google Scholar] [CrossRef]

- Zhou, H.; Zhi, X. Surfactant-assisted potentiodynamically polymerized PEDOT fibers for significantly improved electrochemical capacitive properties. Mater. Lett. 2018, 221, 309–312. [Google Scholar] [CrossRef]

- Wen, N.; Fan, Z.; Yang, S.; Zhao, Y.; Cong, T.; Xu, S.; Zhang, H.; Wang, J.; Huang, H.; Li, C.; et al. Highly conductive, ultra-flexible and continuously processable PEDOT:PSS fibers with high thermoelectric properties for wearable energy harvesting. Nano Energy 2020, 78, 105361. [Google Scholar] [CrossRef]

- Jalili, R.; Aboutalebi, S.H.; Esrafilzadeh, D.; Shepherd, R.L.; Chen, J.; Aminorroaya-Yamini, S.; Konstantinov, K.; Minett, A.I.; Razal, J.M.; Wallace, G.G. Scalable One-Step Wet-Spinning of Graphene Fibers and Yarns from Liquid Crystalline Dispersions of Graphene Oxide: Towards Multifunctional Textiles. Adv. Funct. Mater. 2013, 23, 5345–5354. [Google Scholar] [CrossRef]

- Pan, Y.; Song, Y.; Jiang, Q.; Jia, Y.; Liu, P.; Song, H.; Liu, G. Solvent treatment of wet-spinning PEDOT:PSS fiber towards wearable thermoelectric energy harvesting. Synth. Met. 2022, 283, 116969. [Google Scholar] [CrossRef]

- Liu, L.; Chen, J.; Liang, L.; Deng, L.; Chen, G. A PEDOT:PSS thermoelectric fiber generator. Nano Energy 2022, 102, 107678. [Google Scholar] [CrossRef]

- Yin, S.; Lu, W.; Wu, X.; Luo, Q.; Wang, E.; Guo, C.-Y. Enhancing Thermoelectric Performance of Polyaniline/Single-Walled Carbon Nanotube Composites via Dimethyl Sulfoxide-Mediated Electropolymerization. ACS Appl. Mater. Interfaces 2021, 13, 3930–3936. [Google Scholar] [CrossRef] [PubMed]

- Feng, X.-M.; Li, R.-M.; Ma, Y.-W.; Chen, R.-F.; Shi, N.-E.; Fan, Q.-L.; Huang, W. One-Step Electrochemical Synthesis of Graphene/Polyaniline Composite Film and Its Applications. Adv. Funct. Mater. 2011, 21, 2989–2996. [Google Scholar] [CrossRef]

- Yan, Q.; Xin, B.; Chen, Z.; Liu, Y. Enhancement in photothermal conversion property of polypyrrole-decorated polyurethane/zirconium carbide fibrous membrane. Mater. Today Commun. 2021, 28, 102584. [Google Scholar] [CrossRef]

- Zhang, X.; Li, T.-T.; Ren, H.-T.; Peng, H.-K.; Shiu, B.-C.; Wang, Y.; Lou, C.-W.; Lin, J.-H. Dual-Shell Photothermoelectric Textile Based on a PPy Photothermal Layer for Solar Thermal Energy Harvesting. ACS Appl. Mater. Interfaces 2020, 12, 55072–55082. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Chen, G.; Wang, H.; Li, X. Template-Directed In Situ Polymerization Preparation of Nanocomposites of PEDOT:PSS-Coated Multi-Walled Carbon Nanotubes with Enhanced Thermoelectric Property. Chem. Asian J. 2015, 10, 149–153. [Google Scholar] [CrossRef] [PubMed]

- Xiao, C.; Xue, Y.; Liu, M.; Xu, X.; Wu, X.; Wang, Z.; Xu, Y.; Chen, G. Polymer composites with lychee-like core covered by segregated conducting and flexible networks: Unique morphology, high flexibility, stretchability and thermoelectric performance. Compos. Sci. Technol. 2018, 161, 16–21. [Google Scholar] [CrossRef]

- Yin, S.; Wu, X.; Wang, R.; Guo, C.-Y. Composite Aerogel of Electropolymerized Polyaniline and SWCNTs with High Thermoelectric Performance. Macromol. Mater. Eng. 2022, 307, 2200094. [Google Scholar] [CrossRef]

- Kim, D.; Kim, Y.; Choi, K.; Grunlan, J.C.; Yu, C. Improved Thermoelectric Behavior of Nanotube-Filled Polymer Composites with Poly(3,4-ethylenedioxythiophene) Poly(styrenesulfonate). ACS Nano 2010, 4, 513–523. [Google Scholar] [CrossRef]

- Fan, W.; Guo, C.-Y.; Chen, G. Flexible films of poly(3,4-ethylenedioxythiophene)/carbon nanotube thermoelectric composites prepared by dynamic 3-phase interfacial electropolymerization and subsequent physical mixing. J. Mater. Chem. A 2018, 6, 12275–12280. [Google Scholar] [CrossRef]

- Chung, S.-H.; Kim, D.H.; Kim, H.; Kim, H.; Jeong, S.W. Thermoelectric properties of PEDOT: PSS and acid-treated SWCNT composite films. Mater. Today Commun. 2020, 23, 100867. [Google Scholar] [CrossRef]

- Fan, Y.; Liu, Z.; Chen, G. Constructing flexible metal-organic framework/polymer/carbon nanotubes ternary composite films with enhanced thermoelectric properties for heat-to-electricity conversion. Compos. Commun. 2022, 29, 100997. [Google Scholar] [CrossRef]

- Wei, S.; Liu, L.; Huang, X.; Zhang, Y.; Liu, F.; Deng, L.; Bilotti, E.; Chen, G. Flexible and Foldable Films of SWCNT Thermoelectric Composites and an S-Shape Thermoelectric Generator with a Vertical Temperature Gradient. ACS Appl. Mater. Interfaces 2022, 14, 5973–5982. [Google Scholar] [CrossRef] [PubMed]

- Hirsch, A. Functionalization of Single-Walled Carbon Nanotubes. Angew. Chem. Int. Ed. 2002, 41, 1853–1859. [Google Scholar] [CrossRef]

- Iijima, S. Carbon nanotubes: Past, present, and future. Phys. B Condens. Matter 2002, 323, 1–5. [Google Scholar] [CrossRef]

- Luo, J.; Cerretti, G.; Krause, B.; Zhang, L.; Otto, T.; Jenschke, W.; Ullrich, M.; Tremel, W.; Voit, B.; Pötschke, P. Polypropylene-based melt mixed composites with singlewalled carbon nanotubes for thermoelectric applications: Switching from p-type to n-type by the addition of polyethylene glycol. Polymer 2017, 108, 513–520. [Google Scholar] [CrossRef]

- Horike, S.; Wei, Q.; Akaike, K.; Kirihara, K.; Mukaida, M.; Koshiba, Y.; Ishida, K. Bicyclic-ring base doping induces n-type conduction in carbon nanotubes with outstanding thermal stability in air. Nat. Commun. 2022, 13, 3517. [Google Scholar] [CrossRef] [PubMed]

- Tang, J.; Chen, Y.; McCuskey, S.R.; Chen, L.; Bazan, G.C.; Liang, Z. Recent Advances in n-Type Thermoelectric Nanocomposites. Adv. Electron. Mater. 2019, 5, 1800943. [Google Scholar] [CrossRef]

- Nonoguchi, Y.; Nakano, M.; Murayama, T.; Hagino, H.; Hama, S.; Miyazaki, K.; Matsubara, R.; Nakamura, M.; Kawai, T. Simple Salt-Coordinated n-Type Nanocarbon Materials Stable in Air. Adv. Funct. Mater. 2016, 26, 3021–3028. [Google Scholar] [CrossRef]

- Wang, X.; Liang, L.; Lv, H.; Zhang, Y.; Chen, G. Elastic aerogel thermoelectric generator with vertical temperature-difference architecture and compression-induced power enhancement. Nano Energy 2021, 90, 106577. [Google Scholar] [CrossRef]

- Du, C.; Cao, M.; Li, G.; Hu, Y.; Zhang, Y.; Liang, L.; Liu, Z.; Chen, G. Toward Precision Recognition of Complex Hand Motions: Wearable Thermoelectrics by Synergistic 2D Nanostructure Confinement and Controlled Reduction. Adv. Funct. Mater. 2022, 32, 2206083. [Google Scholar] [CrossRef]

- Kanahashi, K.; Pu, J.; Takenobu, T. 2D Materials for Large-Area Flexible Thermoelectric Devices. Adv. Energy Mater. 2020, 10, 1902842. [Google Scholar] [CrossRef]

- Mahan, G.D. Good Thermoelectrics. In Solid State Physics; Ehrenreich, H., Spaepen, F., Eds.; Academic Press: Cambridge, MA, USA, 1998; Volume 51, pp. 81–157. [Google Scholar]

- Zhou, Y.; Zhao, L.-D. Promising Thermoelectric Bulk Materials with 2D Structures. Adv. Mater. 2017, 29, 1702676. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Kim, T.; Kim, C.S.; Choi, H.; Kim, Y.J.; Lee, G.S.; Oh, O.; Cho, B.J. Two-Dimensional Thermal Haptic Module Based on a Flexible Thermoelectric Device. Soft Robot. 2020, 7, 736–742. [Google Scholar] [CrossRef] [PubMed]

- Mardi, S.; Cataldi, P.; Athanassiou, A.; Reale, A. 3D cellulose fiber networks modified by PEDOT:PSS/graphene nanoplatelets for thermoelectric applications. Appl. Phys. Lett. 2022, 120, 033102. [Google Scholar] [CrossRef]

- Du, F.-P.; Zhang, H.; Yao, J.-A.; Chen, S.-Y.; Xiao, J.-K.; Fu, P.; Zhang, Y.-F. Enhanced thermoelectric performance by constructing PEDOT:PSS/graphene quantum dots/single-walled carbon nanotube multilayer films. J. Alloys Compd. 2022, 911, 164998. [Google Scholar] [CrossRef]

- Wang, Y.; Pang, H.; Guo, Q.; Tsujii, N.; Baba, T.; Baba, T.; Mori, T. Flexible n-Type Abundant Chalcopyrite/PEDOT:PSS/Graphene Hybrid Film for Thermoelectric Device Utilizing Low-Grade Heat. ACS Appl. Mater. Interfaces 2021, 13, 51245–51254. [Google Scholar] [CrossRef]

- Wan, K.; Liu, Z.; Schroeder, B.C.; Chen, G.; Santagiuliana, G.; Papageorgiou, D.G.; Zhang, H.; Bilotti, E. Highly stretchable and sensitive self-powered sensors based on the N-Type thermoelectric effect of polyurethane/Nax(Ni-ett)n/graphene oxide composites. Compos. Commun. 2021, 28, 100952. [Google Scholar] [CrossRef]

- Han, S.; Zhai, W.; Chen, G.; Wang, X. Morphology and thermoelectric properties of graphene nanosheets enwrapped with polypyrrole. RSC Advances 2014, 4, 29281–29285. [Google Scholar] [CrossRef]

- Xu, K.; Chen, G.; Qiu, D. Convenient construction of poly(3,4-ethylenedioxythiophene)–graphene pie-like structure with enhanced thermoelectric performance. J. Mater. Chem. A 2013, 1, 12395–12399. [Google Scholar] [CrossRef]

- Ju, H.; Park, D.; Kim, M.; Kim, J. Copper telluride with manipulated carrier concentrations for high-performance solid-state thermoelectrics. J. Mater. Sci. Technol. 2022, 129, 190–195. [Google Scholar] [CrossRef]

- Kumar, N.; Sachdeva, P.K.; Gupta, R.; Bera, C. Theoretical Design of Highly Efficient 2D Thermoelectric Device Based on Janus MoSSe and Graphene Heterostructure. ACS Appl. Energy Mater. 2022, 5, 9581–9586. [Google Scholar] [CrossRef]

- Lin, Z.; Du, Y.; Chi, C.; Dang, H.; Song, D.; Ma, W.; Li, Y.; Zhang, X. Energy-dependent carrier scattering at weak localizations leading to decoupling of thermopower and conductivity. Carbon 2022, 194, 62–71. [Google Scholar] [CrossRef]

- Ghosal, S.; Jana, D. Beyond T-graphene: Two-dimensional tetragonal allotropes and their potential applications. Appl. Phys. Rev. 2022, 9, 021314. [Google Scholar] [CrossRef]

- Wang, Y.; Bai, Z.; Guo, Y.; Liu, C.; Jiang, Q.; Jiang, F.; Yang, J.; Ding, W.; Liu, P.; Xu, J. Recent Advances in 2D Material/Conducting Polymer Composites for Thermoelectric Energy Conversion. Macromol. Mater. Eng. 2022, 307, 2200107. [Google Scholar] [CrossRef]

- Zhao, Y.; Tang, G.-S.; Yu, Z.-Z.; Qi, J.-S. The effect of graphite oxide on the thermoelectric properties of polyaniline. Carbon 2012, 50, 3064–3073. [Google Scholar] [CrossRef]

- Wang, L.; Yao, Q.; Bi, H.; Huang, F.; Wang, Q.; Chen, L. PANI/graphene nanocomposite films with high thermoelectric properties by enhanced molecular ordering. J. Mater. Chem. A 2015, 3, 7086–7092. [Google Scholar] [CrossRef]

- Yoo, D.; Kim, J.; Kim, J.H. Direct synthesis of highly conductive poly(3,4-ethylenedioxythiophene):poly(4-styrenesulfonate) (PEDOT:PSS)/graphene composites and their applications in energy harvesting systems. Nano Res. 2014, 7, 717–730. [Google Scholar] [CrossRef]

- Hu, K.; Kulkarni, D.D.; Choi, I.; Tsukruk, V.V. Graphene-polymer nanocomposites for structural and functional applications. Prog. Polym. Sci. 2014, 39, 1934–1972. [Google Scholar] [CrossRef]

- Du, Y.; Shen, S.Z.; Yang, W.; Donelson, R.; Cai, K.; Casey, P.S. Simultaneous increase in conductivity and Seebeck coefficient in a polyaniline/graphene nanosheets thermoelectric nanocomposite. Synth. Met. 2012, 161, 2688–2692. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, X.; Wang, H.; Tang, H.; Xu, L.; Li, H.; Zhang, L. Preparation of Nanoscrolls by Rolling up Graphene Oxide–Polydopamine–Au Sheets using Lyophilization Method. Chem. Asian J. 2016, 11, 1821–1827. [Google Scholar] [CrossRef] [PubMed]

- Collins, S.P.; Perim, E.; Daff, T.D.; Skaf, M.S.; Galvão, D.S.; Woo, T.K. Idealized Carbon-Based Materials Exhibiting Record Deliverable Capacities for Vehicular Methane Storage. J. Phys. Chem. C 2019, 123, 1050–1058. [Google Scholar] [CrossRef]

- Churchill, H.O.H.; Jarillo-Herrero, P. Phosphorus joins the family. Nat. Nanotechnol. 2014, 9, 330–331. [Google Scholar] [CrossRef] [PubMed]

- Galluzzi, M.; Zhang, Y.; Yu, X.-F. Mechanical properties and applications of 2D black phosphorus. J. Appl. Phys. 2020, 128, 230903. [Google Scholar] [CrossRef]

- Luo, F.; Wang, D.; Zhang, J.; Li, X.; Liu, D.; Li, H.; Lu, M.; Xie, X.; Huang, L.; Huang, W. Ultrafast Cathodic Exfoliation of Few-Layer Black Phosphorus in Aqueous Solution. ACS Appl. Nano Mater. 2019, 2, 3793–3801. [Google Scholar] [CrossRef]

- Shu, C.; Zhou, P.D.J.; Jia, P.D.Z.; Zhang, H.; Liu, Z.; Tang, W.; Sun, X. Electrochemical Exfoliation of Two-Dimensional Phosphorene Sheets and its Energy Application. Chem. Eur. J. 2022, 28, e202200857. [Google Scholar]

- Liu, Y.; Wang, Y.; Ikram, M.; Lv, H.; Chang, J.; Li, Z.; Ma, L.; Rehman, A.U.; Lu, G.; Chen, J.; et al. Facile Synthesis of Highly Dispersed Co3O4 Nanoparticles on Expanded, Thin Black Phosphorus for a ppb-Level NOx Gas Sensor. ACS Sens. 2018, 3, 1576–1583. [Google Scholar] [CrossRef]

- Novak, T.G.; Shin, H.; Kim, J.; Kim, K.; Azam, A.; Nguyen, C.V.; Park, S.H.; Song, J.Y.; Jeon, S. Low-Cost Black Phosphorus Nanofillers for Improved Thermoelectric Performance in PEDOT:PSS Composite Films. ACS Appl. Mater. Interfaces 2018, 10, 17957–17962. [Google Scholar] [CrossRef]

- Jiang, X.-P.; Tian, B.-Z.; Sun, Q.; Li, X.-L.; Chen, J.; Tang, J.; Zhang, P.; Yang, L.; Chen, Z.-G. Enhanced thermoelectric performance in MXene/SnTe nanocomposites synthesized via a facile one-step solvothermal method. J. Solid State Chem. 2021, 304, 122605. [Google Scholar] [CrossRef]

- Wei, J.; Wu, D.; Liu, C.; Zhong, F.; Cao, G.; Li, B.; Gao, C.; Wang, L. Free-standing p-Type SWCNT/MXene composite films with low thermal conductivity and enhanced thermoelectric performance. Chem. Eng. J. 2022, 439, 135706. [Google Scholar] [CrossRef]

- Faruk, M.O.; Ahmed, A.; Adak, B.; Marzana, M.; Hossain, M.M.; Mukhopadhyay, S. High performance 2D MXene based conducting polymer hybrids: Synthesis to emerging applications. J. Mater. Chem. C 2021, 9, 10193–10215. [Google Scholar] [CrossRef]

- Guan, X.; Feng, W.; Wang, X.; Venkatesh, R.; Ouyang, J. Significant Enhancement in the Seebeck Coefficient and Power Factor of p-Type Poly(3,4-ethylenedioxythiophene):Poly(styrenesulfonate) through the Incorporation of n-Type MXene. ACS Appl. Mater. Interfaces 2020, 12, 13013–13020. [Google Scholar] [CrossRef] [PubMed]

- Jiang, C.; Chen, J.; Lai, X.; Li, H.; Zeng, X.; Zhao, Y.; Zeng, Q.; Gao, J.; Wu, Z.; Qiu, Y. Mechanically robust and multifunctional polyimide/MXene composite aerogel for smart fire protection. Chem. Eng. J. 2022, 434, 134630. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, C.; Yang, Z.; Shen, Y.; Hu, M.; Wang, Q. Four-Phonon Scattering Effect and Two-Channel Thermal Transport in Two-Dimensional Paraelectric SnSe. ACS Appl. Mater. Interfaces 2022, 14, 11493–11499. [Google Scholar] [CrossRef]

- Liu, J.; Song, K.; van Aken, P.A.; Maier, J.; Yu, Y. Self-Supported Li4Ti5O12–C Nanotube Arrays as High-Rate and Long-Life Anode Materials for Flexible Li-Ion Batteries. Nano Lett. 2014, 14, 2597–2603. [Google Scholar] [CrossRef]

- Sledzinska, M.; Graczykowski, B.; Alzina, F.; Melia, U.; Termentzidis, K.; Lacroix, D.; Sotomayor Torres, C.M. Thermal conductivity in disordered porous nanomembranes. Nanotechnology 2019, 30, 265401. [Google Scholar] [CrossRef]

- Chen, P.; Su, J.; Wang, H.; Yang, L.; Cai, H.; Li, M.; Li, Z.; Liu, J.; Wen, S.; Zhou, Y.; et al. Mechanical properties and microstructure characteristics of lattice-surfaced PEEK cage fabricated by high-temperature laser powder bed fusion. J. Mater. Sci. Technol. 2022, 125, 105–117. [Google Scholar] [CrossRef]

- Kim, H.; Pyun, K.R.; Lee, M.-T.; Lee, H.B.; Ko, S.H. Recent Advances in Sustainable Wearable Energy Devices with Nanoscale Materials and Macroscale Structures. Adv. Funct. Mater. 2022, 32, 2110535. [Google Scholar] [CrossRef]

- Xu, W.; Zhao, Y.; Wang, H.; Wang, H.; Pan, F.; Xu, R.; Hou, H. Postsynthetic-Modified PANI/MOF Composites with Tunable Thermoelectric and Photoelectric Properties. Chem. Eur. J. 2021, 27, 5011–5018. [Google Scholar] [CrossRef]

- Fan, Y.; Liu, Z.; Chen, G. Recent Progress in Designing Thermoelectric Metal–Organic Frameworks. Small 2021, 17, 2100505. [Google Scholar] [CrossRef]

- Fan, W.; Liang, L.; Zhang, B.; Guo, C.-Y.; Chen, G. PEDOT thermoelectric composites with excellent power factors prepared by 3-phase interfacial electropolymerization and carbon nanotube chemical doping. J. Mater. Chem. A 2019, 7, 13687–13694. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huo, B.; Guo, C.-Y. Advances in Thermoelectric Composites Consisting of Conductive Polymers and Fillers with Different Architectures. Molecules 2022, 27, 6932. https://doi.org/10.3390/molecules27206932

Huo B, Guo C-Y. Advances in Thermoelectric Composites Consisting of Conductive Polymers and Fillers with Different Architectures. Molecules. 2022; 27(20):6932. https://doi.org/10.3390/molecules27206932

Chicago/Turabian StyleHuo, Bingchen, and Cun-Yue Guo. 2022. "Advances in Thermoelectric Composites Consisting of Conductive Polymers and Fillers with Different Architectures" Molecules 27, no. 20: 6932. https://doi.org/10.3390/molecules27206932

APA StyleHuo, B., & Guo, C.-Y. (2022). Advances in Thermoelectric Composites Consisting of Conductive Polymers and Fillers with Different Architectures. Molecules, 27(20), 6932. https://doi.org/10.3390/molecules27206932