Enhancing the Performance of Evolutionary Algorithm by Differential Evolution for Optimizing Distillation Sequence

Abstract

:1. Introduction

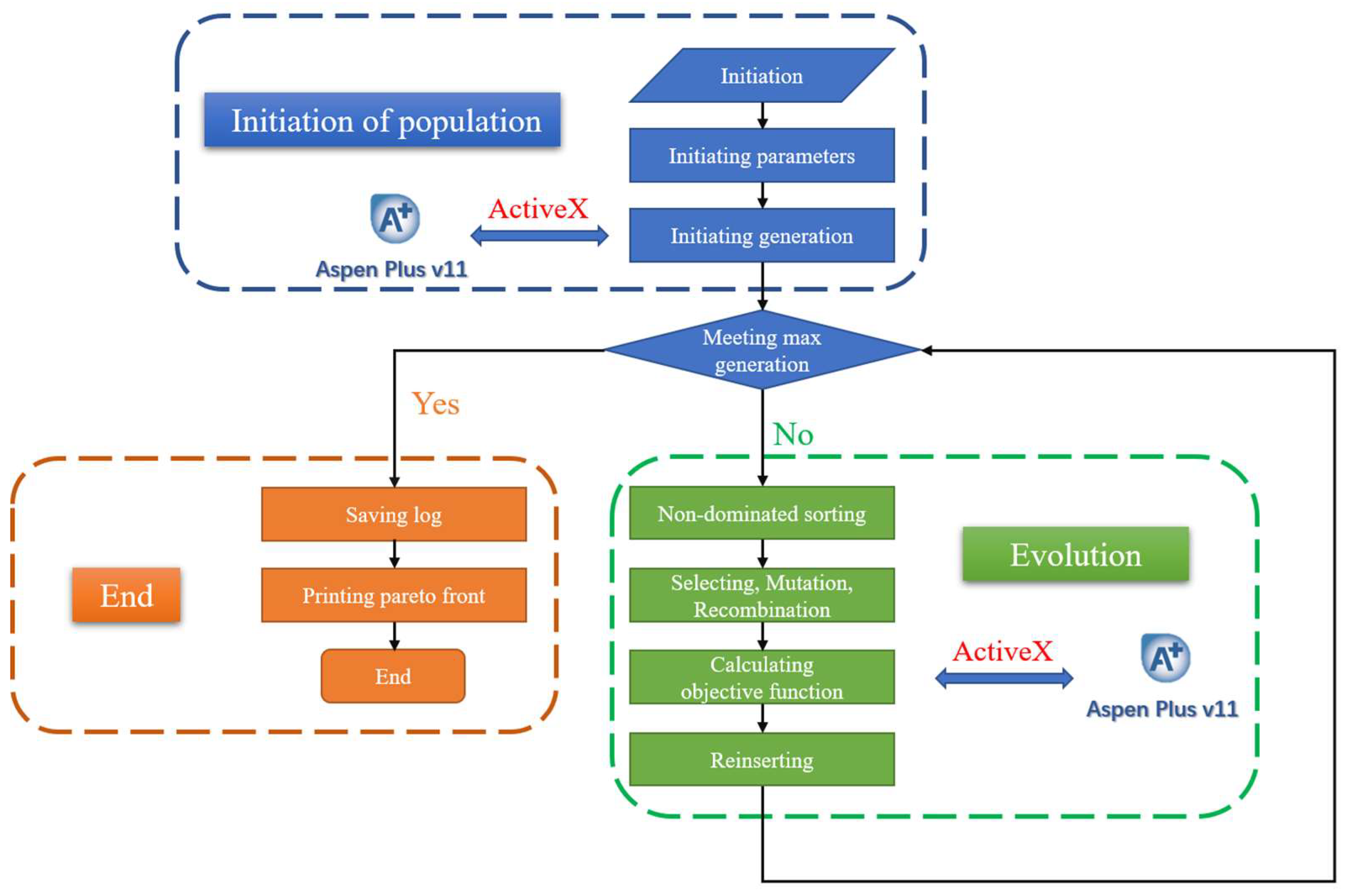

2. Evolutionary Algorithm

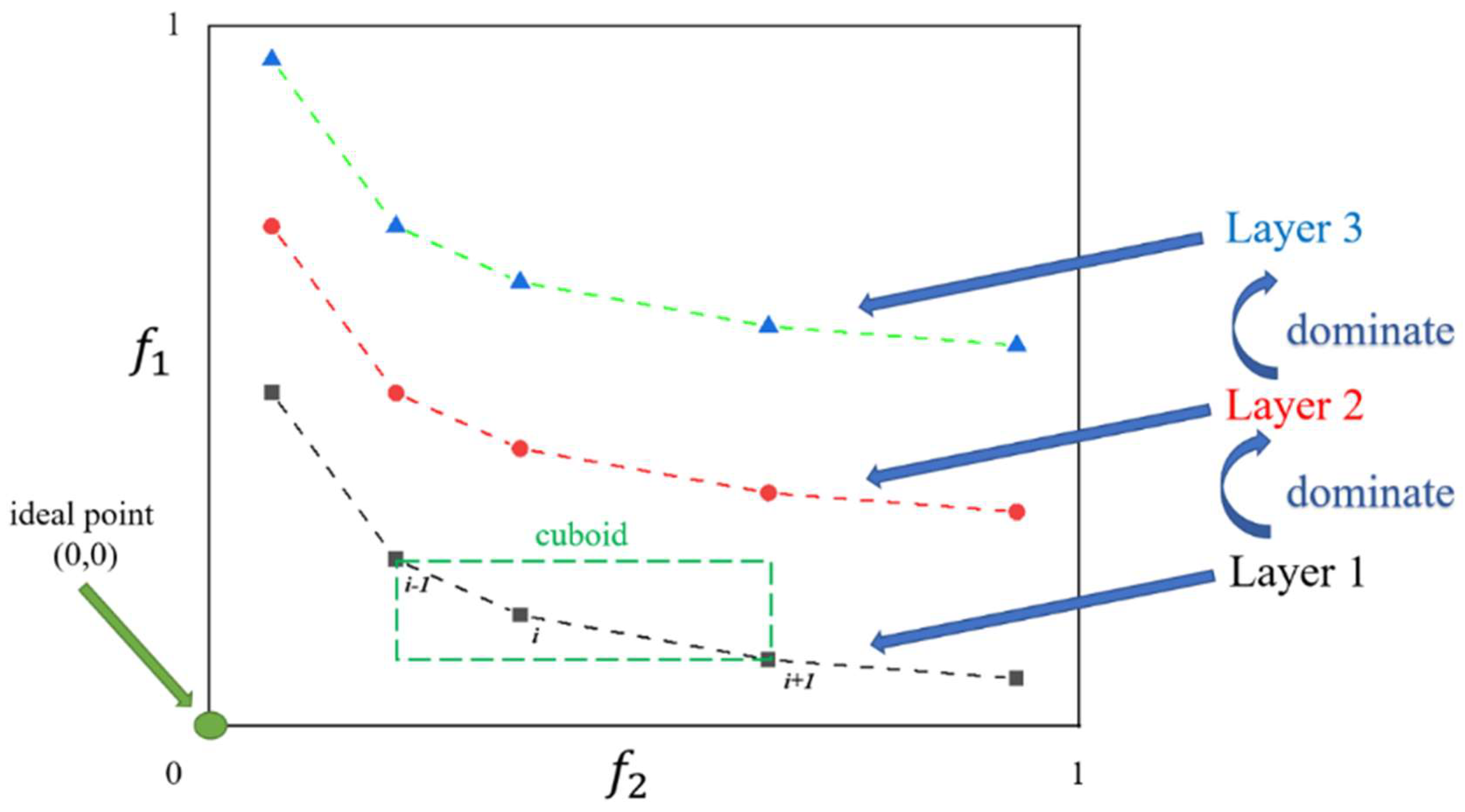

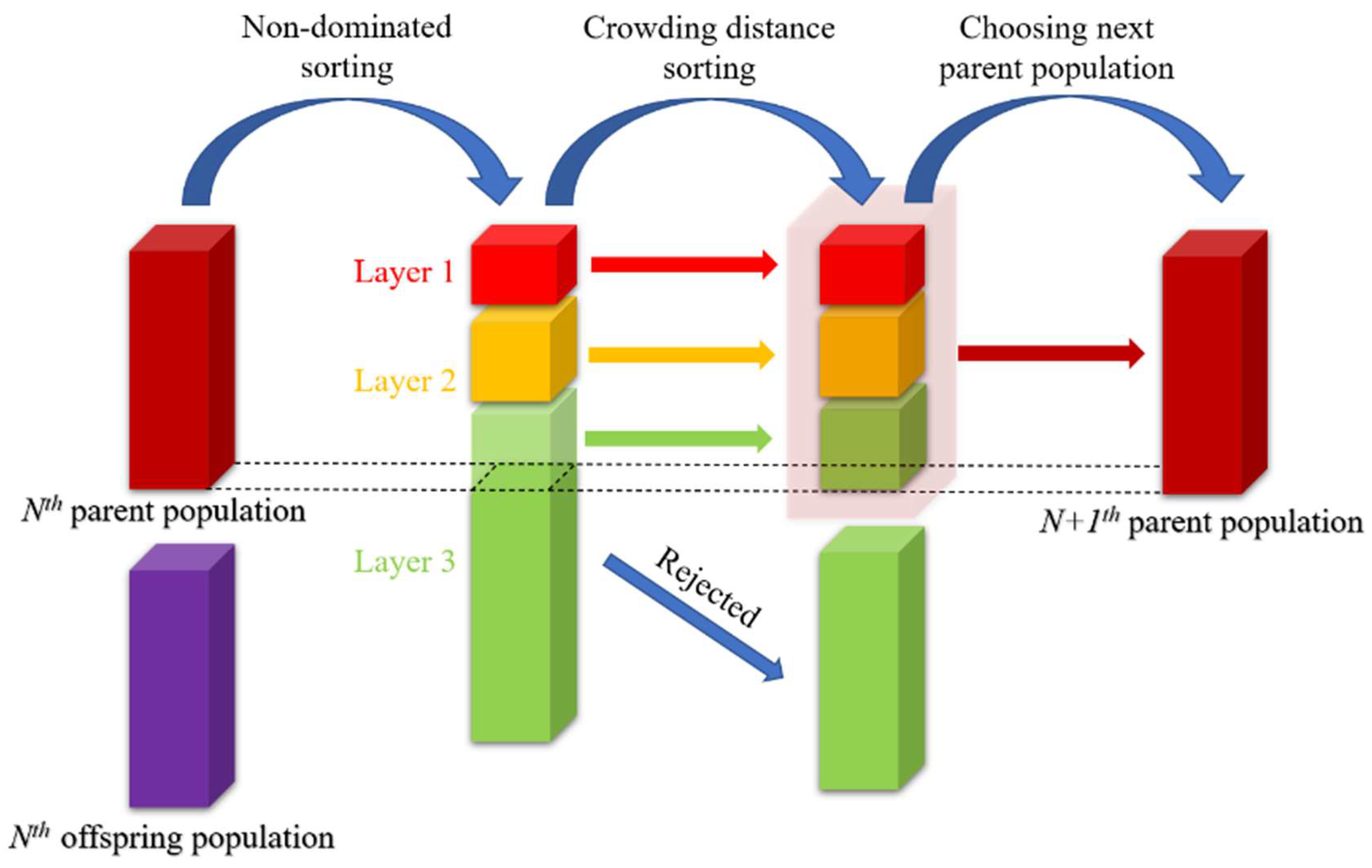

2.1. NSGA-II

2.2. NSGA-III

2.3. MOEA/D

2.4. Differential Evolution with NSGA-II, NSGA-III, and MOEA/D

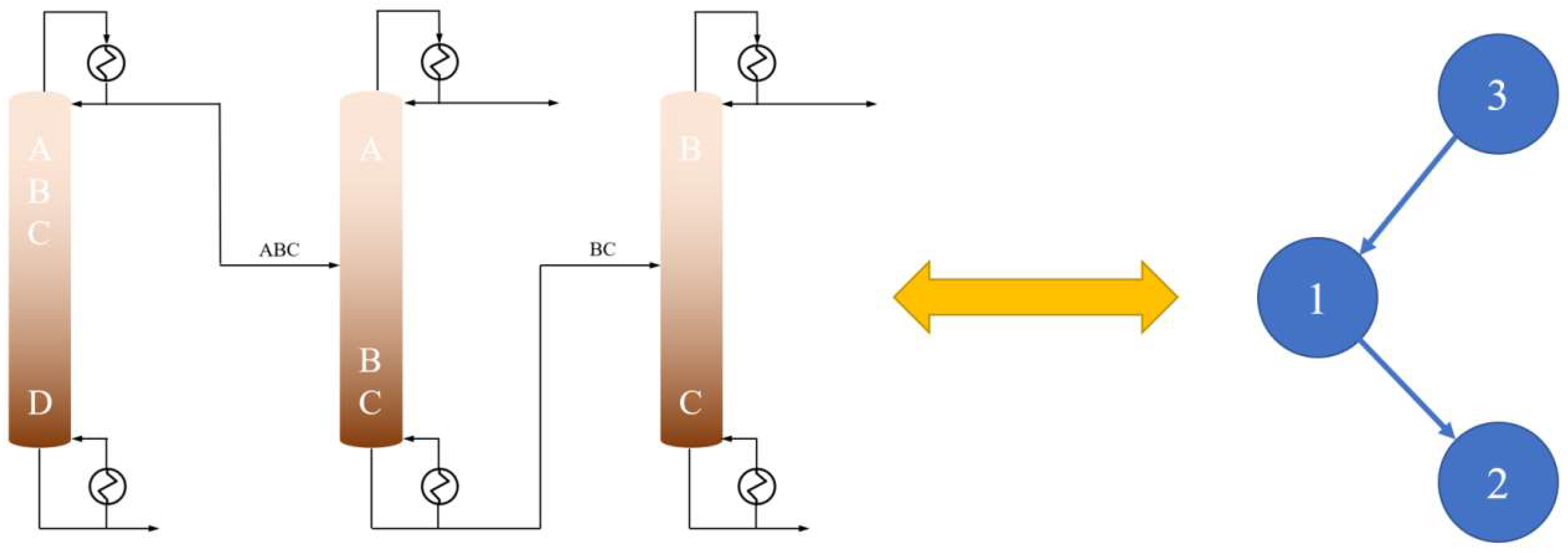

3. Binary Tree Coding

4. Comparative Study of Evolutionary Algorithms

5. Optimization of the Base Case

5.1. Separation Flowsheet and Thermodynamic Modeling

5.2. Performance Indicators

5.3. Optimization Methodology and Objective Function

5.4. Optimization Results

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Lockhart, F.J. Multi-column distillation of natural gasoline. Pet. Refin. 2016, 26, 104. [Google Scholar]

- Siirola, J.J.; Powers, G.J.; Rudd, D.F. Synthesis of system designs: III. Toward a process concept generator. AIChE. J. 1971, 17, 677–682. [Google Scholar] [CrossRef]

- Gao, X.C.; Li, Z.; Chen, C.; Da, C.; Liu, L.; Tian, S.; Ji, G.C. The determination of pore shape and interfacial barrier of entry for light gases transport in amorphous teos-derived silica: A finite element method. ACS Appl. Mater. Interfaces 2021, 13, 4804–4812. [Google Scholar] [CrossRef] [PubMed]

- Gao, X.C.; Da, C.; Chen, C.; Li, Z.H.; Gu, X.H.; Bhatia, S.K. The induced orientation effect of linear gases during transport in a NaA zeolite membrane modified by alkali lignin. J. Membr. Sci. 2021, 620, 118971. [Google Scholar] [CrossRef]

- Wang, J.C.; Zhang, J.Q.; Hong, Z.; Gao, X.C.; Gu, X.H. A coupling process of distillation with vapor permeation and adsorption for production of fuel ethanol: A comparative analysis on energy consumption. Ind. Eng. Chem. Res. 2022, 61, 1167–1178. [Google Scholar] [CrossRef]

- Gao, X.C.; Wang, S.H.; Wang, J.C.; Xu, S.F.; Gu, X.H. The study on the coupled process of column distillation and vapor permeation by NaA zeolite membrane for ethanol dehydration. Chem. Eng. Res. Des. 2019, 150, 246–253. [Google Scholar] [CrossRef]

- Han, W.T.; Han, Z.W.; Gao, X.C.; Hong, Z.; Li, X.G.; Li, H.; Gu, X.H.; Gao, X. Inter-integration reactive distillation with vapor permeation for ethyl levulinate production: Equipment development and experimental validating. AIChE J. 2022, 68, e17441. [Google Scholar] [CrossRef]

- Heaven, L.D. Optimum Sequencing of Distillation Columns in Multicomponent Fractionation; University of California: Berkeley, CA, USA, 1969. [Google Scholar]

- Thompson, R.W.; King, C.J. Systematic synthesis of separation schemes. AIChE J. 1972, 18, 941–948. [Google Scholar] [CrossRef]

- Freshwater, D.C.; Henry, B.D. Optimal configuration of multicomponent distillation systems. Chem. Eng. 1975, 9, 533–540. [Google Scholar]

- Seader, J.D.; Westerberg, A.W. A combined heuristic and evolutionary strategy for synthesis of simple separation sequences. AIChE J. 1977, 23, 951–954. [Google Scholar] [CrossRef]

- Tayal, M.C.; Fu, Y.; Diwekar, U.M. Optimal design of heat exchangers: A genetic algorithm framework. Ind. Eng. Chem. Res. 1999, 38, 456–467. [Google Scholar] [CrossRef]

- Aggarwal, A.; Floudas, C.A. Synthesis of general distillation sequences-nonsharp separations. Comput. Chem. Eng. 1990, 14, 631–653. [Google Scholar] [CrossRef]

- Floquet, P.; Pibouleau, L.; Domenech, S. Separation sequence synthesis: How to use simulated annealing procedure? Comput. Chem. Eng. 1994, 18, 1141–1148. [Google Scholar] [CrossRef]

- Leboreiro, J.; Acevedo, J. Processes synthesis and design of distillation sequences using modular simulators: A genetic algorithm framework. Comput. Chem. Eng. 2004, 28, 1223–1236. [Google Scholar] [CrossRef]

- Errico, M.; Pirellas, P.; Torres-Ortega, C.E.; Rong, B.G.; Segovia-Hernandez, J.G. A combined method for the design and optimization of intensified distillation systems. Chem. Eng. Process. Process Intensif. 2014, 85, 69–76. [Google Scholar] [CrossRef]

- Vázquez-Castillo, J.A.; Segovia-Hernández, J.G.; Ponce-Ortega, J.M. Multiobjective optimization approach for integrating design and control in multicomponent distillation sequences. Ind. Eng. Chem. Res. 2015, 54, 12320–12330. [Google Scholar] [CrossRef]

- Contreras-Zarazúa, G.; Vázquez-Castillo, J.A.; Ramírez-Márquez, C.; Segovia-Hernández, J.G.; Alcántara-Ávila, J.R. Multi-objective optimization involving cost and control properties in reactive distillation processes to produce diphenyl carbonate. Comput. Chem. Eng. 2017, 105, 185–196. [Google Scholar] [CrossRef]

- Cabrera-Ruiz, J.; Santaella, M.A.; Alcántara-Ávila, J.R.; Segovia-Hernández, J.G.; Hernández, S. Open-loop based controllability criterion applied to stochastic global optimization for intensified distillation sequences. Chem. Eng. Res. Des. 2017, 123, 165–179. [Google Scholar] [CrossRef]

- Alcocer-García, H.; Segovia-Hernández, J.G.; Prado-Rubio, O.A.; Sánchez-Ramírez, E.; Quiroz-Ramírez, J.J. Multi-objective optimization of intensified processes for the purification of levulinic acid involving economic and environmental objectives. Chem. Eng. Process. 2019, 136, 123–137. [Google Scholar] [CrossRef]

- Sun, S.R.; Chun, W.; Yang, A.; Shen, W.F.; Cui, P.Z.; Ren, J.Z. The separation of ternary azeotropic mixture: Thermodynamic insight and improved multi-objective optimization. Energy 2020, 206, 118117. [Google Scholar] [CrossRef]

- Zhang, Y.Z.; He, N.E.; Masuku, C.M.; Biegler, L.T. A multi-objective reactive distillation optimization model for Fischer-Tropsch synthesis. Comput. Chem. Eng. 2020, 135, 106754. [Google Scholar] [CrossRef]

- Zhao, F.; Xu, Z.F.; Zhao, J.G.; Wang, J.; Hu, M.Y.; Li, X.; Zhu, Z.Y.; Cui, P.Z.; Wang, Y.L.; Ma, Y.X. Process design and multi-objective optimization for separation of ternary mixtures with double azeotropes via integrated quasi-continuous pressure-swing batch distillation. Sep. Purif. Technol. 2021, 276, 119288. [Google Scholar] [CrossRef]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef] [Green Version]

- Deb, K.; Jain, J. An evolutionary many-objective optimization algorithm using reference-point-based nondominated sorting approach, part I: Solving problems with box constraints. IEEE Trans. Evol. Comput. 2014, 18, 577–601. [Google Scholar] [CrossRef]

- Tanabe, R.; Fukunaga, A. Reevaluating exponential crossover in differential evolution. In International Conference on Parallel Problem Solving from Nature; Springer: Cham, Switzerland, 2014. [Google Scholar]

- Zhang, Q.; Li, H. MOEA/D: A multiobjective evolutionary algorithm based on decomposition. IEEE Trans. Evol. Comput. 2007, 11, 712–731. [Google Scholar] [CrossRef]

- Li, H.; Zhang, Q. Multiobjective optimization problems with complicated Pareto sets, MOEA/D and NSGA-II. IEEE. Trans. Evol. Comput. 2009, 13, 284–302. [Google Scholar] [CrossRef]

- Mayevskiy, M.; Frolkova, A.; Frolkova, A. Separation and purification of methyl isobutyl ketone from acetone + isopropanol + water + methyl isobutyl ketone + methyl isobutyl carbinol + diisobutyl ketone mixture. ACS Omega 2020, 5, 25365–25370. [Google Scholar] [CrossRef]

- Srinivas, N.; Deb, K. Multiobjective optimization using nondominated sorting in genetic algorithms. Evol. Comput. 1994, 2, 221–248. [Google Scholar] [CrossRef]

- Hillermeier, C. Nonlinear Multiobjective Optimization; Birkhauser Verlag: Basel, Switzerland, 2001. [Google Scholar]

- Jaszkiewicz, A. On the performance of multiple-objective genetic local search on the 0/1 knapsack problem-a comparative experiment. IEEE Trans. Evol. Comput. 2000, 6, 402–412. [Google Scholar] [CrossRef]

- Storn, R.; Price, K. Differential evolution: A simple and efficient adaptive scheme for global optimization over continuous spaces. ICSI Berkeley 1995, 11, 341–359. [Google Scholar]

- Storn, R.; Price, K. Differential evolution: A simple and efficient heuristic for global optimization over continuous spaces. J. Glob. Optim. 1997, 11, 341–359. [Google Scholar] [CrossRef]

- Pan, X.Y.; Zhu, J.; Chen, H.; Chen, X.J.; Hu, K.K. A differential evolution-based hybrid NSGA-II for multi-objective optimization. In Proceedings of the 2015 IEEE 7th International Conference on Cybernetics and Intelligent Systems (CIS) and IEEE Conference on Robotics, Automation and Mechatronics (RAM), Siem Reap, Cambodia, 15–17 July 2015; pp. 81–86. [Google Scholar]

- Angira, R.; Babu, B.V. Non-dominated sorting differential evolution (NSDE): An extension of differential evolution for multi-objective optimization. In Proceedings of the 2nd Indian International Conference on Artificial Intelligence, DBLP, Pune, India, 20–22 December 2005. [Google Scholar]

- Malone, M.F.; Glinos, K.; Marquez, F.E.; Douglas, J.M. Simple analytical criteria for the sequencing of distillation columns. AIChE J. 1985, 31, 683–689. [Google Scholar] [CrossRef]

- Shi, B.C.; Wang, J.H. Establishment and application of relative cost function for multicomponent separating column series. J. Chem. Ind. Eng. 1997, 48, 175–179. [Google Scholar]

- Zou, R.J. Petrochemical Separation Principles and Technology; Chemical Industry Press: Beijing, China, 1983. [Google Scholar]

- Nath, R.; Motard, L.R. Evolutionary synthesis of separation process. AIChE J. 1981, 27, 578–587. [Google Scholar] [CrossRef]

- Zitzler, E. Evolutionary algorithms for multiobjective optimization: Methods and applications. Ph.D. Thesis, Swiss Federal Institute of Technology, Zürich, Switzerland, 1999. [Google Scholar]

- Czyzzak, P.; Jaszkiewicz, A. Pareto simulated annealing-a metaheuristic technique for multiple-objective combinatorial optimization. J. Multi-Criteria. Decis. Anal. 1998, 7, 34–47. [Google Scholar] [CrossRef]

- Douglas, J.M. Conceptual Design of Chemical Processes; McGraw-Hill, Inc.: New York, NY, USA, 1998. [Google Scholar]

- Luyben, W.L. A counter-intuitive heuristic for specifying the composition of recycle streams. Chem. Eng. Process. 2018, 133, 234–244. [Google Scholar] [CrossRef]

- Oliveira, T.A.; Cocchini, U.; Scarpello, J.T.; Livingston, A.G. Pervaporation mass transfer with liquid flow in the transition regime. J. Membr. Sci. 2001, 183, 119–133. [Google Scholar] [CrossRef]

- Gadalla, M.A.; Olujic, Z.; Jansens, P.J.; Jobson, M.; Smith, R. Reducing CO2 emissions and energy consumption of heat-integrated distillation systems. Environ. Sci. Technol. 2005, 39, 6860–6870. [Google Scholar] [CrossRef]

- Su, Y.; Jin, S.M.; Zhang, X.P.; Shen, W.F.; Eden, M.R.; Ren, J.Z. Stakeholder-oriented multi-objective process optimization based on an improved genetic algorithm. Comput. Chem. Eng. 2020, 132, 106618. [Google Scholar] [CrossRef]

| Component ID | Component | Molar Feeds (kmol/h) | K-Values | Boiling Points (°C) |

|---|---|---|---|---|

| A | methane | 230 | 256.99 | −161.49 |

| B | ethane | 100 | 93.25 | −88.60 |

| C | propane | 40 | 45.63 | −42.04 |

| D | n-butane | 50 | 22.37 | −0.50 |

| E | n-pentane | 130 | 11.34 | 36.07 |

| F | n-hexane | 100 | 5.86 | 68.73 |

| G | n-heptane | 110 | 3.08 | 98.43 |

| H | n-octane | 180 | 1.61 | 125.68 |

| I | n-nonane | 120 | 0.86 | 150.82 |

| J | n-decane | 30 | 0.46 | 174.16 |

| K | n-undecane | 150 | 0.26 | 195.93 |

| L | n-dodecane | 190 | 0.14 | 216.32 |

| M | n-tridecane | 90 | 0.07 | 235.47 |

| N | n-tetradecane | 140 | 0.04 | 253.58 |

| Evolution Algorithm | Parameters |

|---|---|

| NSGA-II | dim = 2; size = 100; gen = 100; cf = 1; mf = 1/dim |

| NSGA-III | dim = 2; size = 100; gen = 100; cf = 1; mf = 1/dim |

| MOEA/D | dim = 2; size = 100; gen = 100; cf = 1; mf = 1/dim; ps = 0.9; sn = size/10 |

| NSGA-II-DE | dim = 2; size = 100; gen = 100; f = 0.5; Cr = 0.5 mf = 1/dim; ps = 0.9 |

| NSGA-III-DE | dim = 2; size = 100; gen = 100; f = 0.5; Cr = 0.5 mf = 1/dim; ps = 0.9 |

| MOEA/D-DE | dim = 2; size = 100; gen = 100; f = 0.5; Cr = 0.5 mf = 1/dim; sn = size/10 |

| Component i | Component j | Aij | Aji | Bij | Bji |

|---|---|---|---|---|---|

| Acetone | Isopropanol | −2.4106 | 2.4494 | 822.4892 | −583.3452 |

| Acetone | Water | 6.3981 | 0.0544 | −1808.9910 | 419.9716 |

| Isopropanol | Water | −1.3115 | 6.8284 | 426.3978 | −1483.4573 |

| Acetone | MIBK | −5.4452 | 5.3013 | 1833.5227 | −1735.9082 |

| Isopropanol | MIBK | 0.0000 | 0.0000 | 160.6435 | 28.1164 |

| Water | MIBK | 9.1629 | −3.2305 | −1248.7440 | 1208.8770 |

| Water | MIBC | 10.2983 | −3.2359 | −1367.8159 | 998.0640 |

| Water | DIBK | 11.6082 | −0.3283 | −969.9380 | 730.5226 |

| MIBK | MIBC | 0.3818 | −0.1565 | 0.0000 | 0.0000 |

| Acetone | MIBC | 0 | 0 | 222.1975 | 7.9431 |

| Acetone | DIBK | 0 | 0 | 335.0488 | −164.9281 |

| Isopropanol | MIBC | 0 | 0 | 159.3051 | −122.9533 |

| Isopropanol | DIBK | 0 | 0 | 263.2273 | 125.6002 |

| MIBK | DIBK | 0 | 0 | 123.9190 | −77.4980 |

| MIBC | DIBK | 0 | 0 | 89.2102 | 172.8563 |

| Decision Variable | Variable Category | Change Range |

|---|---|---|

| T1 total number of trays | integer | [30,60] |

| T1 ratio of the feed stage to the total number of trays | real number | [0.1,0.95] |

| T1 operative pressure | integer | [40,100] |

| T2 total number of trays | integer | [30,60] |

| T2 ratio of the feed stage to the total number of trays | real number | [0.1,0.95] |

| T2 operative pressure | integer | [40,85] |

| T3 total number of trays | integer | [30,60] |

| T3 ratio of the feed stage to the total number of trays | real number | [0.1,0.95] |

| T3 operative pressure | integer | [60,100] |

| Operation Parameters | Base Case [29] | After Optimization (Min Euclidean Distance) |

|---|---|---|

| T1 total number of trays | 35 | 56 |

| T1 feed stage | 30 | 47 |

| T1 operative pressure (kPa) | 101.32 | 100 |

| T2 total number of trays | 36 | 43 |

| T2 feed stage | 31 | 37 |

| T2 operative pressure (kPa) | 70.93 | 58 |

| T3 total number of trays | 32 | 58 |

| T3 feed stage | 10 | 23 |

| T3 operative pressure (kPa) | 70.93 | 100 |

| TAC (million$) | 2.912 | 1.044 |

| CO2 Emission (kt/year) | 6.083 | 1.083 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, Z.; Li, P.; Liu, Y. Enhancing the Performance of Evolutionary Algorithm by Differential Evolution for Optimizing Distillation Sequence. Molecules 2022, 27, 3802. https://doi.org/10.3390/molecules27123802

Hu Z, Li P, Liu Y. Enhancing the Performance of Evolutionary Algorithm by Differential Evolution for Optimizing Distillation Sequence. Molecules. 2022; 27(12):3802. https://doi.org/10.3390/molecules27123802

Chicago/Turabian StyleHu, Zehua, Peilong Li, and Yefei Liu. 2022. "Enhancing the Performance of Evolutionary Algorithm by Differential Evolution for Optimizing Distillation Sequence" Molecules 27, no. 12: 3802. https://doi.org/10.3390/molecules27123802

APA StyleHu, Z., Li, P., & Liu, Y. (2022). Enhancing the Performance of Evolutionary Algorithm by Differential Evolution for Optimizing Distillation Sequence. Molecules, 27(12), 3802. https://doi.org/10.3390/molecules27123802