Comparative Analysis of Ethylene/Diene Copolymerization and Ethylene/Propylene/Diene Terpolymerization Using Ansa-Zirconocene Catalyst with Alkylaluminum/Borate Activator: The Effect of Conjugated and Nonconjugated Dienes on Catalytic Behavior and Polymer Microstructure

Abstract

1. Introduction

2. Experiments

2.1. Materials

2.2. Polymerization

2.3. Characterization

2.3.1. Spectroscopic Analysis (13C NMR 1HNMR)

2.3.2. Gel-Permeation Chromatography (GPC)

3. Results and Discussion

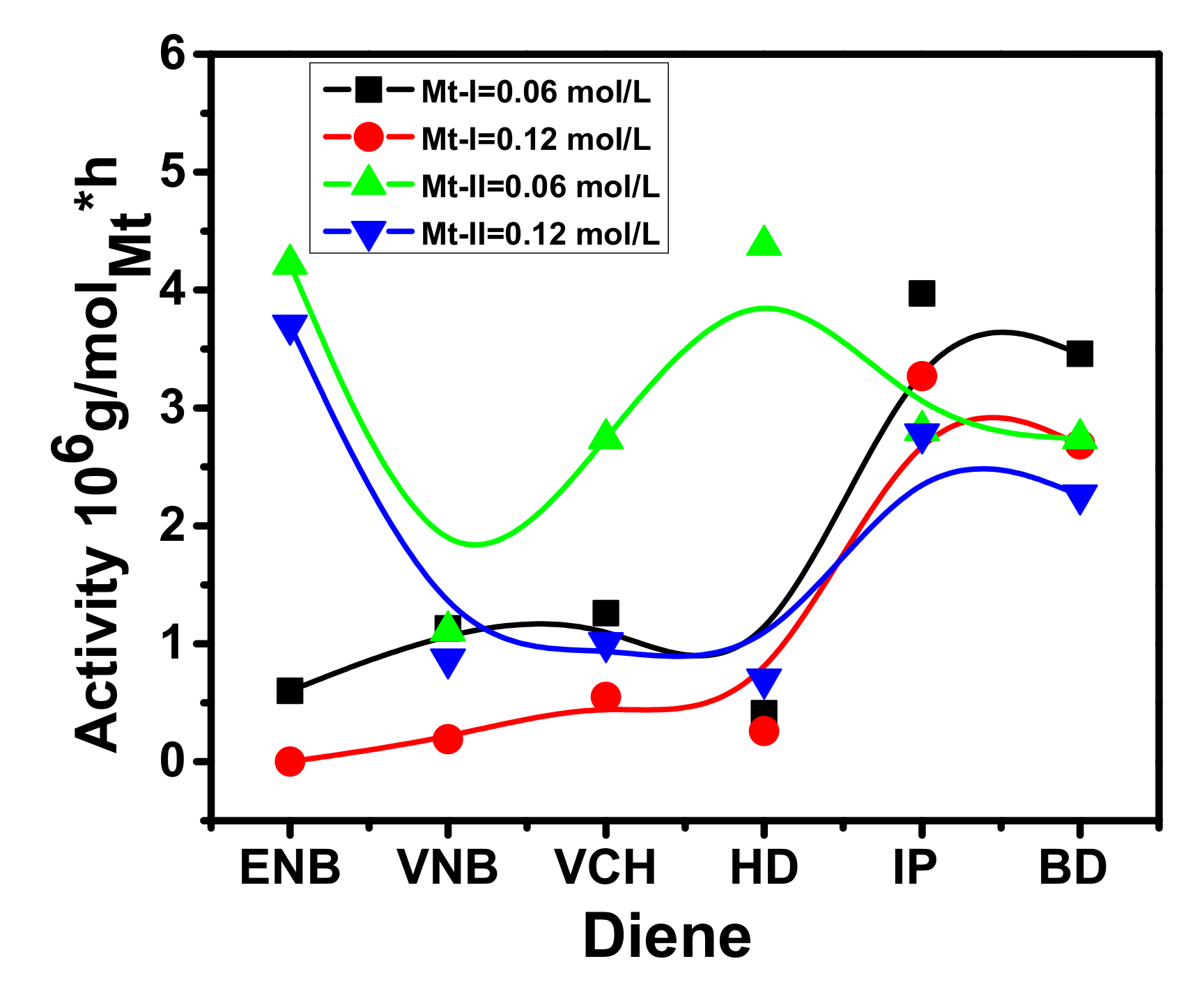

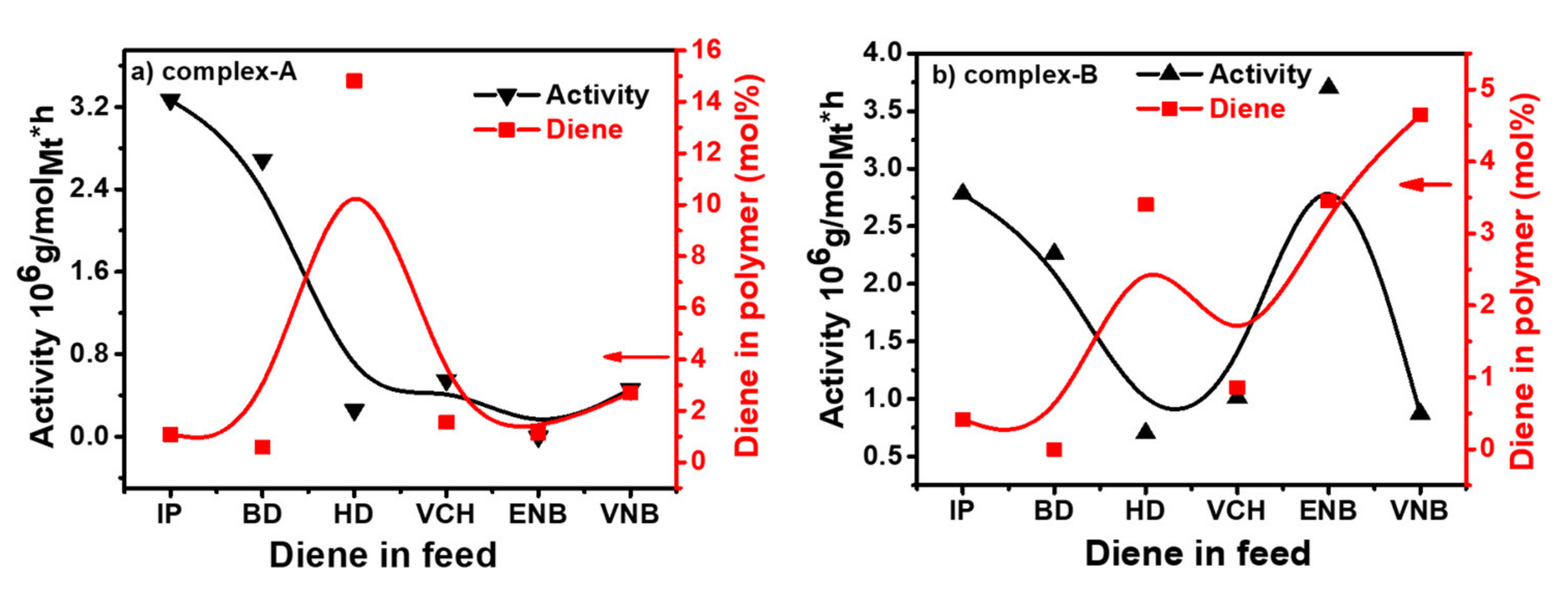

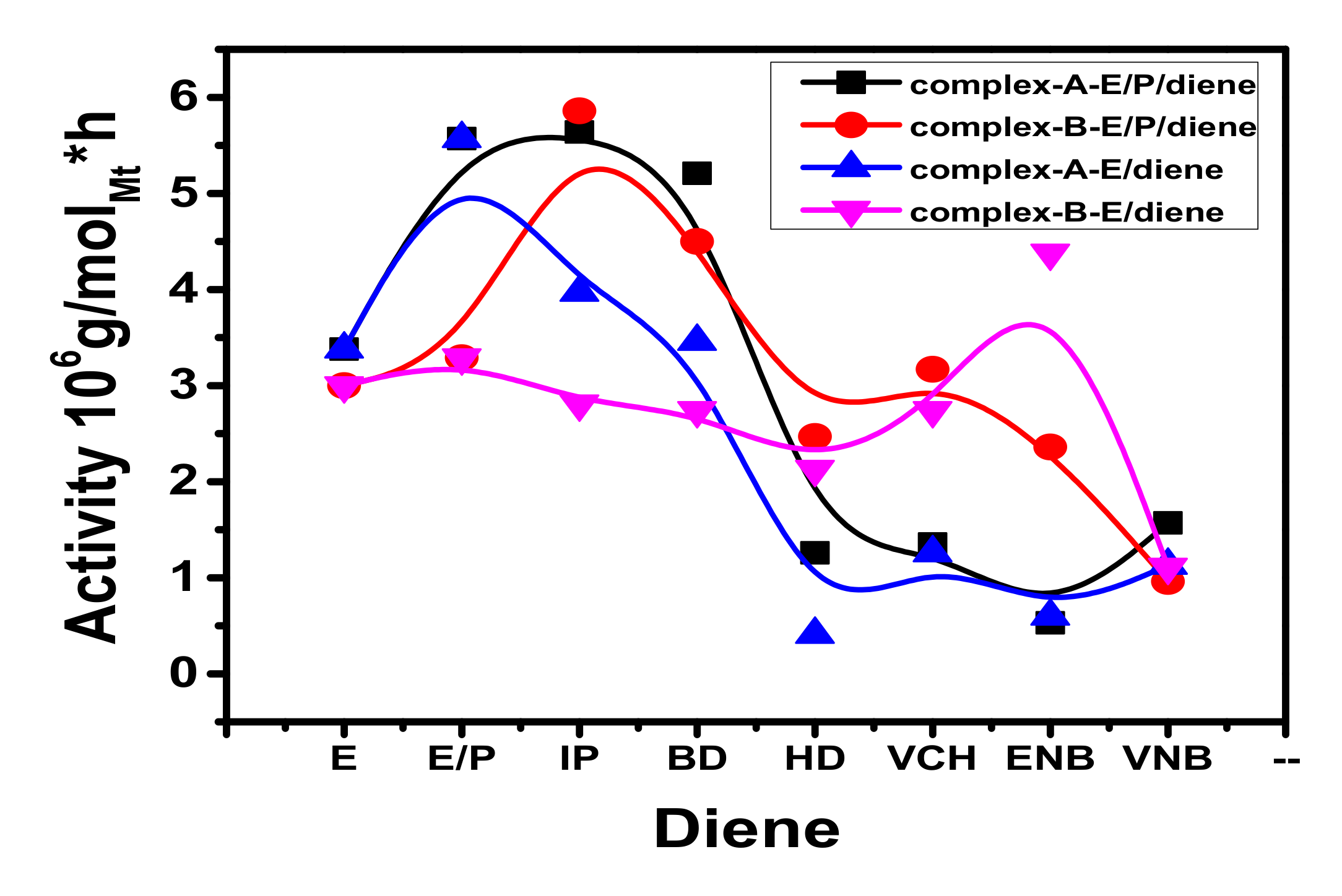

3.1. Ethylene, Propylene, and Diene Monomer Copolymerization

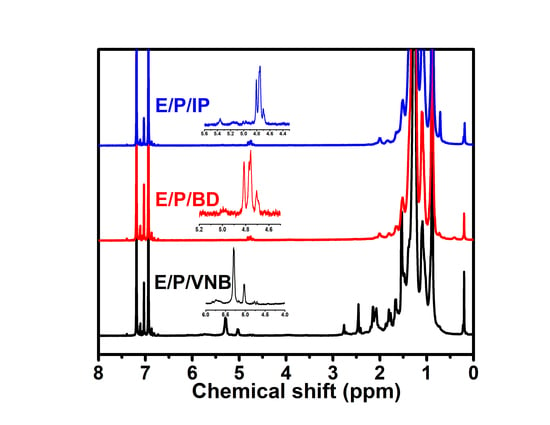

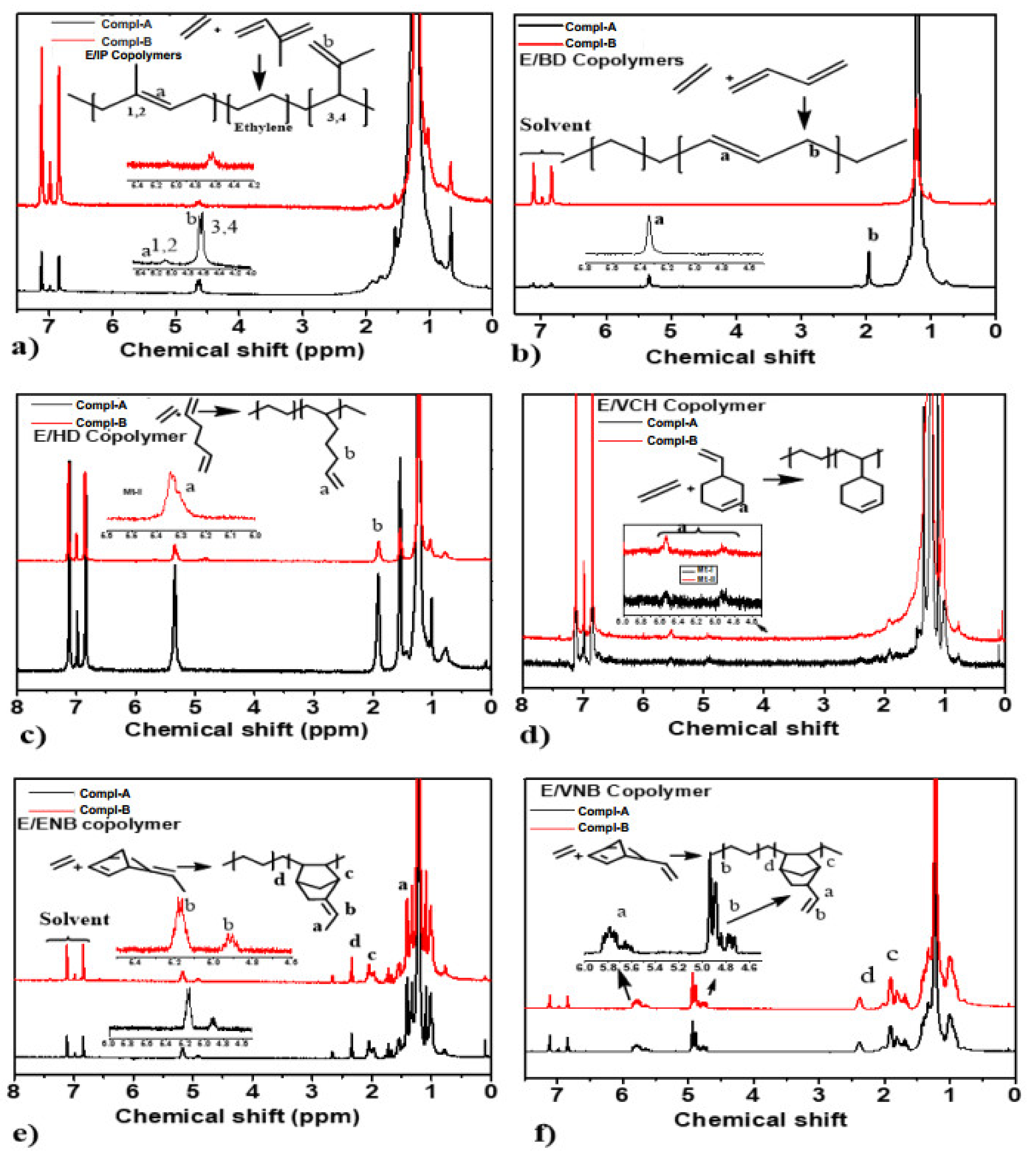

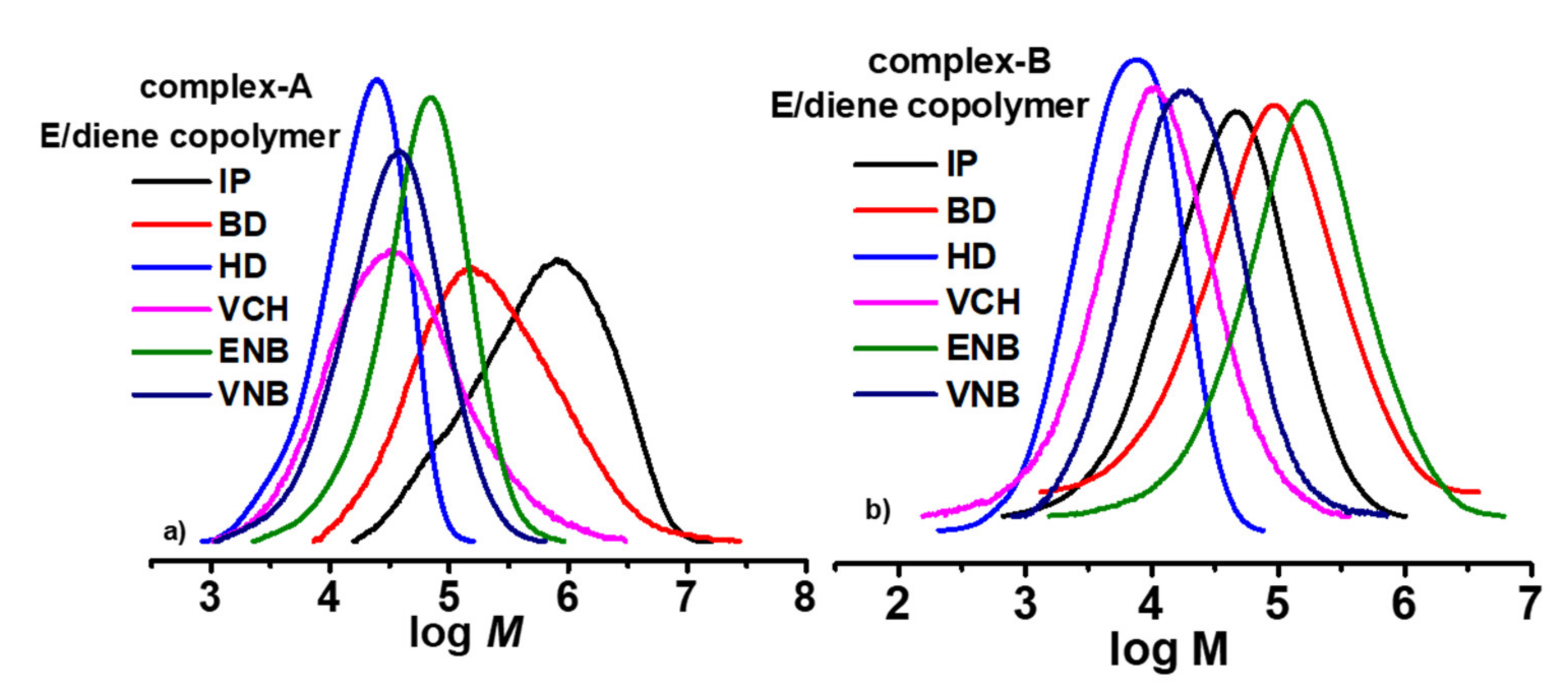

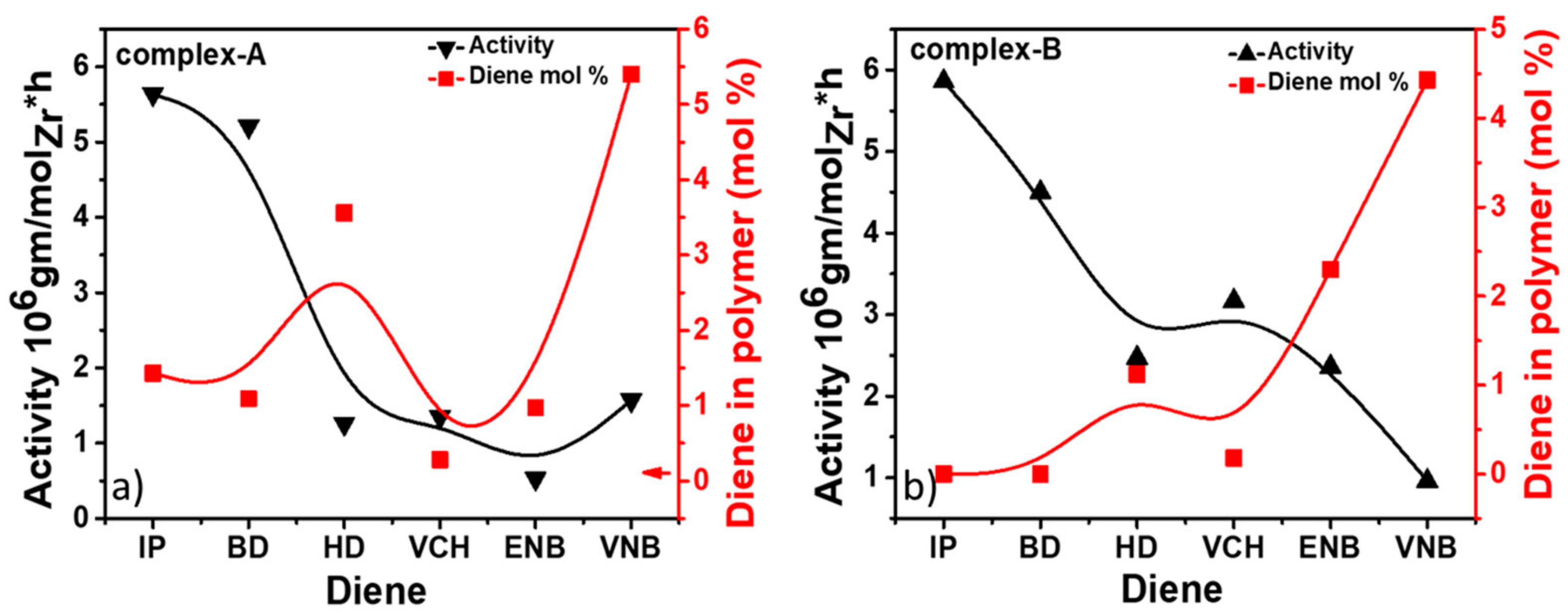

3.2. Chain Structure of Copolymers

3.3. Ethylene, Propylene and Diene Monomer Terpolymerization

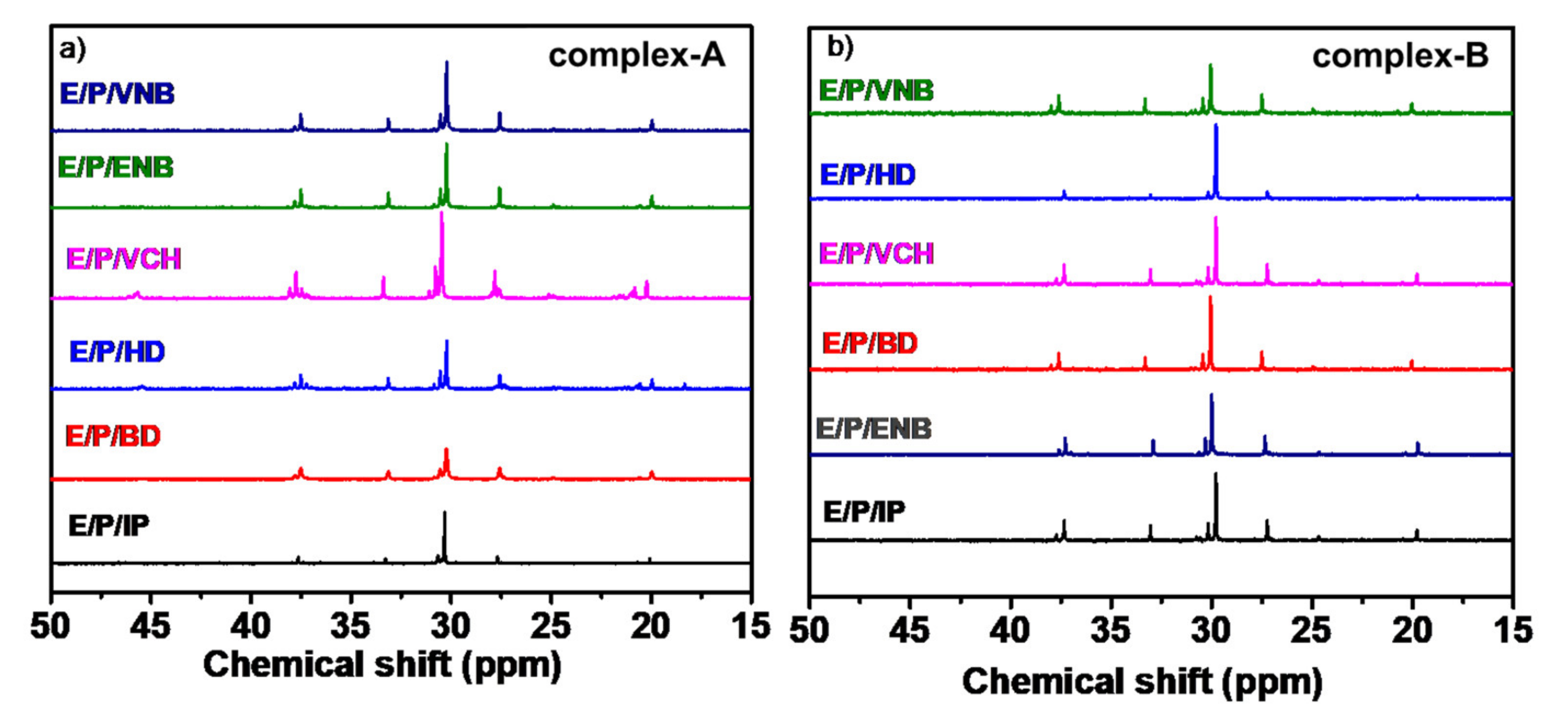

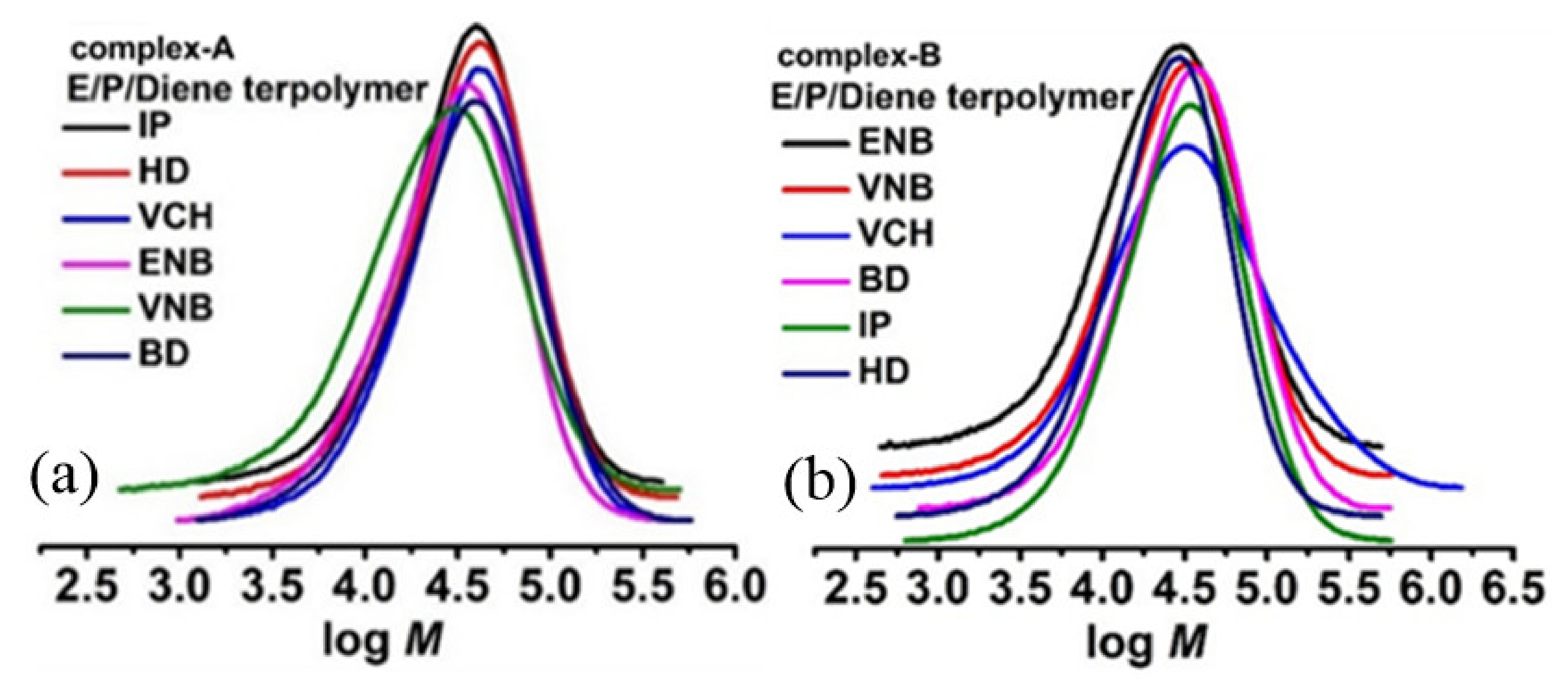

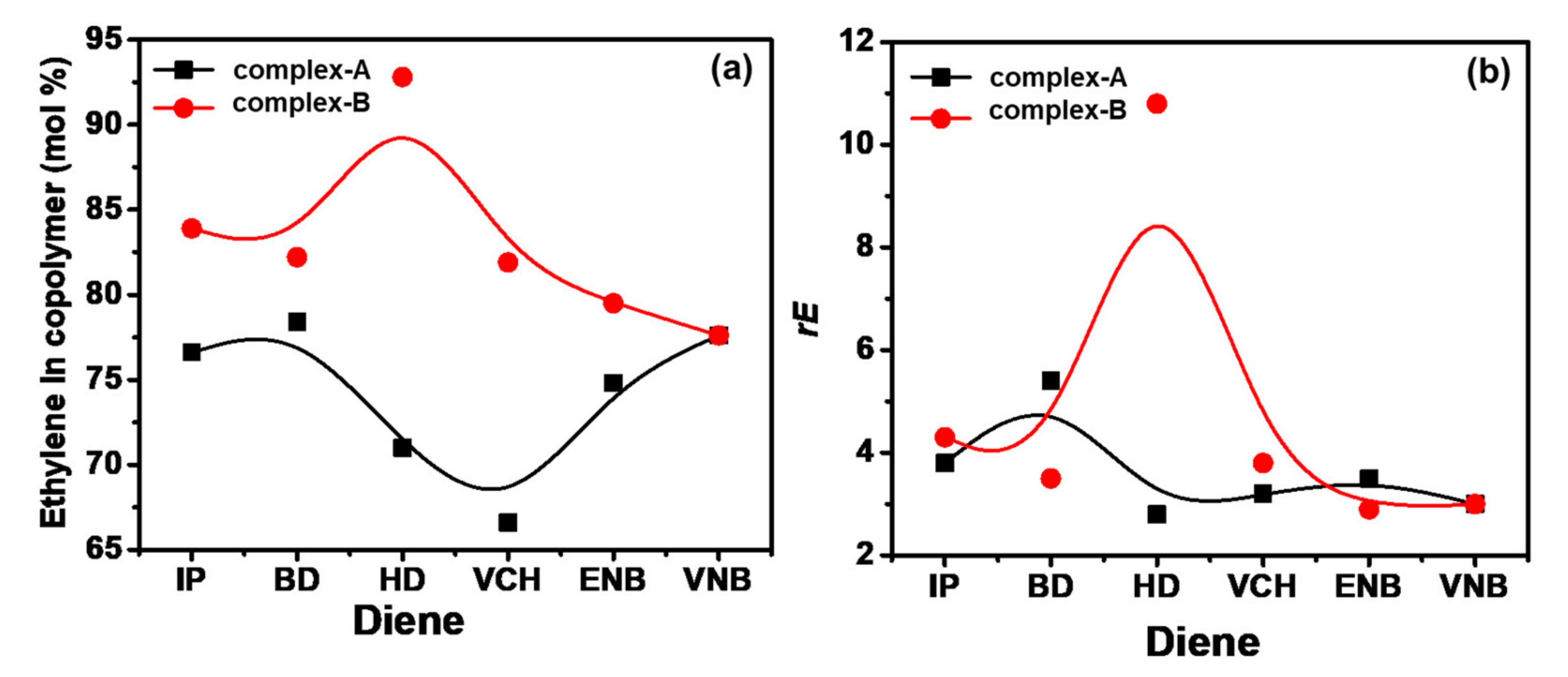

3.4. Chain Structure of Terpolymers

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Landis, C.R.; Rosaaen, K.A.; Sillars, D.R. Direct Observation of Insertion Events at r ac-(C2H4 (1-indenyl) 2) Zr (MeB (C6F5) 3)− Polymeryl Intermediates: Distinction between Continuous and Intermittent Propagation Modes. J. Am. Chem. Soc. 2003, 125, 1710–1711. [Google Scholar] [CrossRef] [PubMed]

- Bochmann, M. Kinetic and mechanistic aspects of metallocene polymerisation catalysts. J. Organomet. Chem. 2004, 689, 3982–3998. [Google Scholar] [CrossRef]

- Song, F.; Cannon, A.R.D.; Bochmann, M. Zirconocene-Catalyzed Propene Polymerization: A Quenched-Flow Kinetic Study. J. Am. Chem. Soc. 2003, 125, 7641–7653. [Google Scholar] [CrossRef] [PubMed]

- Ali, A.; Muhammad, N.; Hussain, S.; Jamil, M.; Uddin, A.; Aziz, T.; Tufail, M.; Guo, Y.; Wei, T.; Rasool, G.; et al. Kinetic and Thermal Study of Ethylene and Propylene Homo Polymerization Catalyzed by ansa-Zirconocene Activated with Alkylaluminum/Borate: Effects of Alkylaluminum on Polymerization Kinetics and Polymer Structure. Polymers 2021, 13, 268. [Google Scholar] [CrossRef]

- Li, Y.; Yang, J.; Wang, B. Efficient copolymerization of ethylene with norbornene or its derivatives using half-metallocene zirconium(IV) catalysts. RSC Adv. 2016, 6, 59590–59599. [Google Scholar] [CrossRef]

- Kaminsky, W.; Miri, M. Ethylene propylene diene terpolymers produced with a homogeneous and highly active zirconium catalyst. J. Polym. Sci. Polym. Chem. Ed. 1985, 23, 2151–2164. [Google Scholar] [CrossRef]

- Muhammad, N.; Zia-ul-Haq, M.; Ali, A.; Han, D.; Intisar, A.; Cui, H.; Cui, H.; Zhu, Y.; Zhong, J.-L.; Rahman, A.; et al. Ion chromatography coupled with fluorescence/UV detector: A comprehensive review of its applications in pesticides and pharmaceutical drug analysis. Arab. J. Chem. 2020, 14, 102972. [Google Scholar] [CrossRef]

- Si, Q.; Ali, A.; Yuan, J.; Fall, I.; Muhammad Yasin, F. Flow-induced noises in a centrifugal pump: A review. Sci. Adv. Mater. 2019, 11, 909–924. [Google Scholar] [CrossRef]

- Si, Q.; Shen, C.; Ali, A.; Cao, R.; Yuan, J.; Wang, C. Experimental and numerical study on gas-liquid two-phase flow behavior and flow induced noise characteristics of radial blade pumps. Processes 2019, 7, 920. [Google Scholar] [CrossRef]

- Mortazavi, M.M.; Arabi, H.; Ahmadjo, S.; Nekoomanesh, M.; Zohuri, G.H. Comparative study of copolymerization and terpolymerization of ethylene/propylene/diene monomers using metallocene catalyst. J. Appl. Polym. Sci. 2011, 122, 1838–1846. [Google Scholar] [CrossRef]

- Phoowakeereewiwat, S.; Jongsomjit, B.; Praserthdam, P. Investigation of diene addition on ethylene–propylene (EP) copolymerization with a zirconocene catalyst: Effects of diene types and E/P ratios. J. Mater. Process. Technol. 2009, 209, 520–524. [Google Scholar] [CrossRef]

- Dong, Q.; Fan, Z.-Q.; Fu, Z.-S.; Xu, J.-T. Fractionation and characterization of an ethylene–propylene copolymer produced with a MgCl2/SiO2/TiCl4/diester-type ziegler–natta catalyst. J. Appl. Polym. Sci. 2007, 107, 1301–1309. [Google Scholar] [CrossRef]

- Tan, R.; Shi, Z.; Guo, F.; He, L.; Han, L.; Li, Y. The terpolymerization of ethylene and propylene with isoprene via THF-containing half-sandwich scandium catalysts: A new kind of ethylene–propylene–diene rubber and its functionalization. Polym. Chem. 2017, 8, 4651–4658. [Google Scholar] [CrossRef]

- Meshkova, I.N.; Grinev, V.G.; Kiseleva, E.B.; Raspopov, L.N.; Shchegolikhin, A.N.; Kuznetsov, S.P.; Mitrofanov, A.V.; Shestov, S.V.; Udovenko, A.I.; Ladygina, T.A.; et al. Polyolefins functionalization by copolymerization of ethylene (propylene) with substituted norbornene. Polimery 2008, 53, 345–352. [Google Scholar] [CrossRef]

- Ramakrishnan, S.; Berluche, E.; Chung, T.C. Functional group-containing copolymers prepared by Ziegler-Natta process. Macromolecules 1990, 23, 378–382. [Google Scholar] [CrossRef]

- Bruzzone, M.; Carbonaro, A.; Corno, C. Ethylene-butadiene copolymers, 1. Preparation with modified vanadium catalysts. Die Makromol. Chem. Macromol. Chem. Phys. 1978, 179, 2173–2185. [Google Scholar] [CrossRef]

- Muhammad, N.; Zhang, Y.; Li, W.; Zhao, Y.-G.; Ali, A.; Subhani, Q.; Mahmud, T.; Liu, J.; Cui, H.; Zhu, Y. Determination of nitenpyram and 6-chloronicotinic acid in environmental samples by ion chromatography coupled with online photochemically induced fluorescence detector. J. Sep. Sci. 2018, 41, 4096–4104. [Google Scholar] [CrossRef]

- Song, S.; Liu, X.; Zhang, H.; Fu, Z.; Xu, J.; Fan, Z. Trans -1,4-stereospecific copolymerization of ethylene and isoprene catalyzed by MgCl2 -supported Ziegler-Natta catalyst. J. Polym. Sci. Part A Polym. Chem. 2018, 56, 2715–2722. [Google Scholar] [CrossRef]

- Rabagliati, F.M.; Muñoz, L.A.; Quijada, R. Styrene copolymerization using a metallocenic initiator. Homo- and copolymerization of styrene with isoprene through zirconocene–MAO initiating systems. Polym. Bull. 2011, 67, 1425–1434. [Google Scholar] [CrossRef]

- Jiang, B.; Zhang, B.; Guo, Y.; Ali, A.; Guo, W.; Fu, Z.; Fan, Z. Effects of titanium dispersion state on distribution and reactivity of active centers in propylene polymerization with MgCl 2 -supported Ziegler-Natta catalysts: A kinetic study based on active center counting. ChemCatChem 2020, 12, 5140–5148. [Google Scholar] [CrossRef]

- Du, G.; Xue, J.; Peng, D.; Yu, C.; Wang, H.; Zhou, Y.; Bi, J.; Zhang, S.; Dong, Y.; Li, X. Copolymerization of isoprene with ethylene catalyzed by cationic half-sandwich fluorenyl scandium catalysts. J. Polym. Sci. Part A Polym. Chem. 2015, 53, 2898–2907. [Google Scholar] [CrossRef]

- Khan, A.; Guo, Y.; Zhang, Z.; Ali, A.; Fu, Z.; Fan, Z. Kinetics of short-duration ethylene-propylene copolymerization with MgCl2 -supported Ziegler-Natta catalyst: Differentiation of active centers on the external and internal surfaces of the catalyst particles. J. Appl. Polym. Sci. 2018, 135. [Google Scholar] [CrossRef]

- Haag, M.; Dos Santos, J.; Stedile, F.; Dupont, J. Residual metal content in Ethylene-Propylene-Diene Monomers synthesized using vanadium-and zirconocene-based catalysts. J. Appl. Polym. Sci. 1999, 74, 1997–2003. [Google Scholar] [CrossRef]

- Zohuri, G.; Sadegvandi, F.; Jamjah, R.; Ahmadjo, S.; Nekoomanesh, M.; Bigdelli, E. Copolymerization of ethylene/propylene elastomer using high-activity Ziegler–Natta catalyst system of MgCl2 (ethoxide type)/EB/PDMS/TiCl4/PMT. J. Appl. Polym. Sci. 2002, 84, 785–790. [Google Scholar] [CrossRef]

- Akram, M.A.; Liu, X.; Jiang, B.; Zhang, B.; Ali, A.; Fu, Z.; Fan, Z. Effect of alkylaluminum cocatalyst on ethylene/1-hexene copolymerization and active center distribution of MgCl2-supported Ziegler-Natta catalyst. J. Macromol. Sci. Part A 2021, 2021, 1–11. [Google Scholar] [CrossRef]

- Galland, G.B.; dos Santos, J.H.Z.; Dall’Agnol, M.; Bisatto, R. Study of Ethylene-Propylene-1-Hexene Co-and Terpolymers Obtained with Homogeneous and Supported Metallocene Catalysts. In Macromolecular Symposia: 2006; WILEY-VCH Verlag: Weinheim, Germany, 2006; Volume 245, pp. 42–50. [Google Scholar]

- Ali, A.; Liu, X.; Guo, Y.; Akram, M.A.; Wu, H.; Liu, W.; Khan, A.; Jiang, B.; Fu, Z.; Fan, Z. Kinetics and mechanism of ethylene and propylene polymerizations catalyzed with ansa-zirconocene activated by borate/TIBA. J. Organomet. Chem. 2020, 922, 121366. [Google Scholar] [CrossRef]

- Dolatkhani, M.; Cramail, H.; Deffieux, A. Linear non-conjugated dienes from biomass as termonomers in EPDM synthesis, 3. Conventional versus metallocene catalysis. Macromol. Chem. Phys. 1996, 197, 2481–2491. [Google Scholar] [CrossRef]

- Kaminsky, W.; Laban, A. Metallocene catalysis. Appl. Catal. A Gen. 2001, 222, 47–61. [Google Scholar] [CrossRef]

- Pragliola, S.; Costabile, C.; Venditto, V. Ethylene/1,3-butadiene cyclocopolymerization catalyzed by zirconocene systems. Eur. Polym. J. 2014, 58, 157–163. [Google Scholar] [CrossRef]

- Aziz, T.; Iqbal, M.; Ullah, R.; Jamil, M.I.; Raheel, M.; Ali, A. Improving Adhesive Properties of Cellulose Nanocrystals Modifying By 3-Glycidoxypropyltrimethoxy Silane (KH-560) Coupling Agents. Biomed. J. Sci. Tech. Res. 2021, 34. [Google Scholar] [CrossRef]

- Guo, L.; Zhang, D. Cyclic poly (α-peptoid) s and their block copolymers from N-heterocyclic carbene-mediated ring-opening polymerizations of N-substituted N-carboxylanhydrides. J. Am. Chem. Soc. 2009, 131, 18072–18074. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Nishiura, M.; Hu, L.; Mori, K.; Hou, Z. Alternating and Random Copolymerization of Isoprene and Ethylene Catalyzed by Cationic Half-Sandwich Scandium Alkyls. J. Am. Chem. Soc. 2009, 131, 13870–13882. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Li, J.; Zhang, Y.; Mu, Y. Homo-and copolymerization of 5-ethylidene-2-norbornene with ethylene by [2-C5Me4-4, 6-tBu2C6H2O] TiCl2/AliBu3/Ph3CB (C6F5) 4 catalyst system and epoxidation of the resulting copolymer. Polymer 2008, 49, 2839–2844. [Google Scholar] [CrossRef]

- Jongsomjit, B.; Phoowakeereewiwat, S.; Thongyai, S.; Shiono, T.; Praserthdam, P. Impact of diene addition on properties for ethylene–propylene copolymerization with rac-Et[Ind]2ZrCl2/MAO catalyst. Mater. Lett. 2005, 59, 3771–3774. [Google Scholar] [CrossRef]

- Tritto, I.; Boggioni, L.; Jansen, J.C.; Thorshaug, K.; Sacchi, M.C.; Ferro, D.R. Ethylene−Norbornene Copolymers from Metallocene-Based Catalysts: Microstructure at Tetrad Level and Reactivity Ratios. Macromolecules 2002, 35, 616–623. [Google Scholar] [CrossRef]

- Laine, A.; Coussens, B.B.; Hirvi, J.T.; Berthoud, A.; Friederichs, N.; Severn, J.R.; Linnolahti, M. Effect of Ligand Structure on Olefin Polymerization by a Metallocene/Borate Catalyst: A Computational Study. Organometallics 2014, 34, 2415–2421. [Google Scholar] [CrossRef]

- Lu, L.; Niu, H.; Zhao, X.; Hu, X.; Dong, J.-Y. Ethylene/propylene copolymerization over three conventional C2-symmetric metallocene catalysts: Correlation between catalyst configuration and copolymer microstructure. J. Appl. Polym. Sci. 2010, 118, 3218–3226. [Google Scholar] [CrossRef]

- Naga, N.; Shiono, T.; Ikeda, T. Profiles of ethylene polymerization with zirconocene–trialkylaluminum/borane compound. J. Mol. Catal. A Chem. 1999, 150, 155–162. [Google Scholar] [CrossRef]

- Simanke, A.G.; Mauler, R.S.; Galland, G.B. Ethylene copolymerization with cyclic dienes using rac-Et[Ind]2ZrCl2–Methylaluminoxane. J. Polym. Sci. Part A Polym. Chem. 2002, 40, 471–485. [Google Scholar] [CrossRef]

- Liu, P.; Liu, W.; Wang, W.-J.; Li, B.-G.; Zhu, S. A Comprehensive Review on Controlled Synthesis of Long-Chain Branched Polyolefins: Part 1, Single Catalyst Systems. Macromol. React. Eng. 2016, 10, 156–179. [Google Scholar] [CrossRef]

- Jongsomjit, B.; Praserthdam, P.; Kaewkrajang, P. A comparative study on supporting effect during copolymerization of ethylene/1-olefins with silica-supported zirconocene/MAO catalyst. Mater. Chem. Phys. 2004, 86, 243–246. [Google Scholar] [CrossRef]

- Naga, N.; Ohbayashi, Y.; Mizunuma, K. Study of molecular size in ethylene-propene copolymerization with zirconocene and hafnocene catalysts. Macromol. Rapid Commun. 1997, 18, 837–851. [Google Scholar] [CrossRef]

- Ali, A.; Akram, M.A.; Guo, Y.; Wu, H.; Liu, W.; Khan, A.; Liu, X.; Fu, Z.; Fan, Z. Ethylene–propylene copolymerization and their terpolymerization with dienes using ansa-Zirconocene catalysts activated by borate/alkylaluminum. J. Macromol. Sci. Part A 2020, 57, 156–164. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, Z.; Guo, W.; Khan, A.; Fu, Z.; Xu, J.; Fan, Z. Kinetics and mechanism of metallocene-catalyzed olefin polymerization: Comparison of ethylene, propylene homopolymerizations, and their copolymerization. J. Polym. Sci. Part A Polym. Chem. 2016, 55, 867–875. [Google Scholar] [CrossRef]

- Sobhan, M.K.; Hajizadeh, A. Comparative studies on ethylene/propylene/diene terpolymerization. Iranian Polym. J. 2004, 13, 257–262. [Google Scholar]

| Run | Diene Type | Diene (mol/L) | Yield (g) | Activity (106 g/mmolMt·h) | Diene b (mol%) | Mwc (kg/mol) | Ɖ c |

|---|---|---|---|---|---|---|---|

| 1.1 | E | 0 | 1.41 | 3.38 | 0.0 | 244.4 | 8.7 |

| 1.2 | IP | 0.06 | 1.61 | 3.97 | N/A | N/A | N/A |

| 1.3 | IP | 0.12 | 1.35 | 3.27 | 1.08 | 952946 | 3.98 |

| 1.4 | BD | 0.06 | 1.43 | 3.46 | N/A | N/A | N/A |

| 1.5 | BD | 0.12 | 1.11 | 2.69 | 0.60 | 445359 | 4.65 |

| 1.6 | HD | 0.06 | 0.17 | 0.41 | N/A | N/A | N/A |

| 1.7 | HD | 0.12 | 0.11 | 0.26 | 14.81 | 23586 | 1.99 |

| 1.8 | VCH | 0.06 | 0.52 | 1.26 | N/A | N/A | N/A |

| 1.9 | VCH | 0.12 | 0.23 | 0.55 | 1.55 | 36479 | 3.1 |

| 1.10 | ENB | 0.06 | 0.25 | 0.60 | 1.12 | 85226 | 2.21 |

| 1.11 | ENB | 0.12 | N/A | N/A | N/A | N/A | N/A |

| 1.12 | VNB | 0.06 | 0.47 | 1.13 | N/A | N/A | N/A |

| 1.13 | VNB | 0.12 | 0.19 | 0.46 | 2.70 | 48676 | 2.59 |

| Run | Diene Type | Diene (mol/L) | Yield (g) | Activity (106gm/mmolMt·h) | Diene b (mol%) | Mw c (kg/mol) | Ɖc |

|---|---|---|---|---|---|---|---|

| 2.1 | E | N/A | 1.26 | 3.00 | N/A | 88 | 4.4 |

| 2.2 | IP | 0.06 | 1.17 | 2.81 | N/A | N/A | N/A |

| 2.3 | IP | 0.12 | 1.16 | 2.78 | 0.41 | 65 | 3.52 |

| 2.4 | BD | 0.06 | 1.13 | 2.74 | N/A | N/A | N/A |

| 2.5 | BD | 0.12 | 1.10 | 2.26 | 00 | 80 | 4.12 |

| 2.6 | HD | 0.06 | 1.05 | 2.13 | N/A | N/A | N/A |

| 2.7 | HD | 0.12 | 0.29 | 0.70 | 3.4 | 5 | 2.08 |

| 2.8 | VCH | 0.06 | 1.14 | 2.74 | N/A | N/A | N/A |

| 2.9 | VCH | 0.12 | 0.42 | 1.01 | 0.86 | 16 | 3.06 |

| 2.10 | ENB | 0.06 | 1.81 | 4.38 | N/A | N/A | N/A |

| 2.11 | ENB | 0.12 | 1.53 | 3.70 | 3.45 | 84 | 3.87 |

| 2.12 | VNB | 0.06 | 0.46 | 1.11 | N/A | N/A | N/A |

| 2.13 | VNB | 0.12 | 0.36 | 0.87 | 4.65 | 10 | 2.31 |

| Run | Complex | Diene Type | Yield (g) | Activity (106 g/mmolMt·h) | Diene b (mol%) | E mol% | Mw (kg/mol) | Ɖ |

|---|---|---|---|---|---|---|---|---|

| 3.1 | A | E/P | 2.32 | 5.57 | 0 | 77.9 | 18.1 | 3.3 |

| 3.2 | A | IP | 2.33 | 5.64 | 1.43 | 76.6 | 94.2 | 2.49 |

| 3.3 | A | BD | 2.15 | 5.21 | 1.09 | 78.4 | 50.8 | 3.40 |

| 3.4 | A | HD | 0.52 | 1.26 | 3.56 | 71.0 | 41.6 | 2.08 |

| 3.5 | A | VCH | 0.56 | 1.35 | 0.28 | 66.6 | 49.1 | 2.15 |

| 3.6 | A | ENB | 0.22 | 0.53 | 0.97 | 74.8 | 38.1 | 2.09 |

| 3.7 | A | VNB | 0.65 | 1.57 | 5.4 | 77.6 | 25.3 | 2.59 |

| 3.8 | B | E/P | 1.37 | 3.29 | N/A | 79.0 | 13.9 | 2.5 |

| 3.9 | B | IP | 1.34 | 3.22 | N/A | 83.9 | 39.8 | 2.38 |

| 3.10 | B | BD | 1.27 | 3.05 | N/A | 82.2 | N/A | N/A |

| 3.11 | B | HD | 1.02 | 2.47 | 1.12 | 92.2 | 41.3 | 2.11 |

| 3.12 | B | VCH | 1.31 | 3.14 | 0.18 | 81.9 | 51.0 | 2.79 |

| 3.13 | B | ENB | 1.48 | 3.55 | 2.30 | 79.5 | 35.3 | 2.52 |

| 3.14 | B | VNB | 0.40 | 0.96 | 4.43 | 77.6 | 23.5 | 3.50 |

| Run | Diene | Complex | EEE | PEE+EEP | PEP | EPE | EPP+PPE | PPP | E | P | re | rp | rerp | nP a | nE a |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3.1 | IP | A | 45.2 | 24.9 | 6.5 | 14.6 | 2.8 | 1.2 | 76.6 | 18.6 | 3.8 | 0.2 | 0.6 | 4.1 | 1.0 |

| 3.2 | BD | A | 47.2 | 24.1 | 7.1 | 17.5 | 2.3 | 1.8 | 78.4 | 21.6 | 5.4 | 0.1 | 0.5 | 4.2 | 1.2 |

| 3.3 | HD | A | 35.6 | 28.7 | 6.7 | 12.6 | 16.2 | 0.2 | 71.0 | 29.0 | 2.8 | 0.4 | 1.0 | 3.5 | 1.4 |

| 3.4 | VCH | A | 31.7 | 25.4 | 6.5 | 12.7 | 15.4 | 5.3 | 66.6 | 34.4 | 3.2 | 0.6 | 1.8 | 3.6 | 1.8 |

| 3.5 | ENB | A | 42.2 | 23.1 | 9.5 | 18.5 | 3.2 | 1.4 | 74.8 | 23.2 | 3.5 | 0.1 | 0.3 | 3.8 | 1.2 |

| 3.6 | VNB | A | 44.6 | 25.4 | 7.6 | 19.4 | 2.0 | 1.0 | 77.6 | 22.4 | 3.0 | 0.1 | 0.3 | 3.9 | 1.1 |

| 3.7 | IP | B | 58.8 | 19.6 | 5.5 | 15.4 | 0.4 | 0.4 | 83.9 | 16.1 | 4.3 | 0.03 | 0.1 | 5.3 | 1.0 |

| 3.8 | BD | B | 54.0 | 23.4 | 4.8 | 16.4 | 0.5 | 0.9 | 82.2 | 17.8 | 3.5 | 0.1 | 0.2 | 4.7 | 1.0 |

| 3.9 | HD | B | 80.1 | 12.5 | 0.2 | 6.5 | 0.2 | 0.6 | 92.8 | 7.2 | 10.8 | 0.1 | 1.2 | 12.9 | 1.0 |

| 3.10 | VCH | B | 52.9 | 24.5 | 4.5 | 16.6 | 0.7 | 0.8 | 81.9 | 18.1 | 3.8 | 0.1 | 0.2 | 4.7 | 1.0 |

| 3.11 | ENB | B | 48.5 | 23.7 | 7.3 | 18.3 | 1.7 | 0.4 | 79.5 | 20.5 | 2.9 | 0.1 | 0.2 | 4.0 | 1.0 |

| 3.12 | VNB | B | 44.6 | 25.4 | 7.6 | 19.4 | 1.9 | 1.1 | 77.6 | 22.4 | 3.0 | 0.1 | 0.3 | 3.9 | 1.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, A.; Tufail, M.K.; Jamil, M.I.; Yaseen, W.; Iqbal, N.; Hussain, M.; Ali, A.; Aziz, T.; Fan, Z.; Guo, L. Comparative Analysis of Ethylene/Diene Copolymerization and Ethylene/Propylene/Diene Terpolymerization Using Ansa-Zirconocene Catalyst with Alkylaluminum/Borate Activator: The Effect of Conjugated and Nonconjugated Dienes on Catalytic Behavior and Polymer Microstructure. Molecules 2021, 26, 2037. https://doi.org/10.3390/molecules26072037

Ali A, Tufail MK, Jamil MI, Yaseen W, Iqbal N, Hussain M, Ali A, Aziz T, Fan Z, Guo L. Comparative Analysis of Ethylene/Diene Copolymerization and Ethylene/Propylene/Diene Terpolymerization Using Ansa-Zirconocene Catalyst with Alkylaluminum/Borate Activator: The Effect of Conjugated and Nonconjugated Dienes on Catalytic Behavior and Polymer Microstructure. Molecules. 2021; 26(7):2037. https://doi.org/10.3390/molecules26072037

Chicago/Turabian StyleAli, Amjad, Muhammad Khurram Tufail, Muhammad Imran Jamil, Waleed Yaseen, Nafees Iqbal, Munir Hussain, Asad Ali, Tariq Aziz, Zhiqiang Fan, and Li Guo. 2021. "Comparative Analysis of Ethylene/Diene Copolymerization and Ethylene/Propylene/Diene Terpolymerization Using Ansa-Zirconocene Catalyst with Alkylaluminum/Borate Activator: The Effect of Conjugated and Nonconjugated Dienes on Catalytic Behavior and Polymer Microstructure" Molecules 26, no. 7: 2037. https://doi.org/10.3390/molecules26072037

APA StyleAli, A., Tufail, M. K., Jamil, M. I., Yaseen, W., Iqbal, N., Hussain, M., Ali, A., Aziz, T., Fan, Z., & Guo, L. (2021). Comparative Analysis of Ethylene/Diene Copolymerization and Ethylene/Propylene/Diene Terpolymerization Using Ansa-Zirconocene Catalyst with Alkylaluminum/Borate Activator: The Effect of Conjugated and Nonconjugated Dienes on Catalytic Behavior and Polymer Microstructure. Molecules, 26(7), 2037. https://doi.org/10.3390/molecules26072037