The Effect of Hemp Cake (Cannabis sativa L.) on the Characteristics of Meatballs Stored in Refrigerated Conditions

Abstract

1. Introduction

2. Results

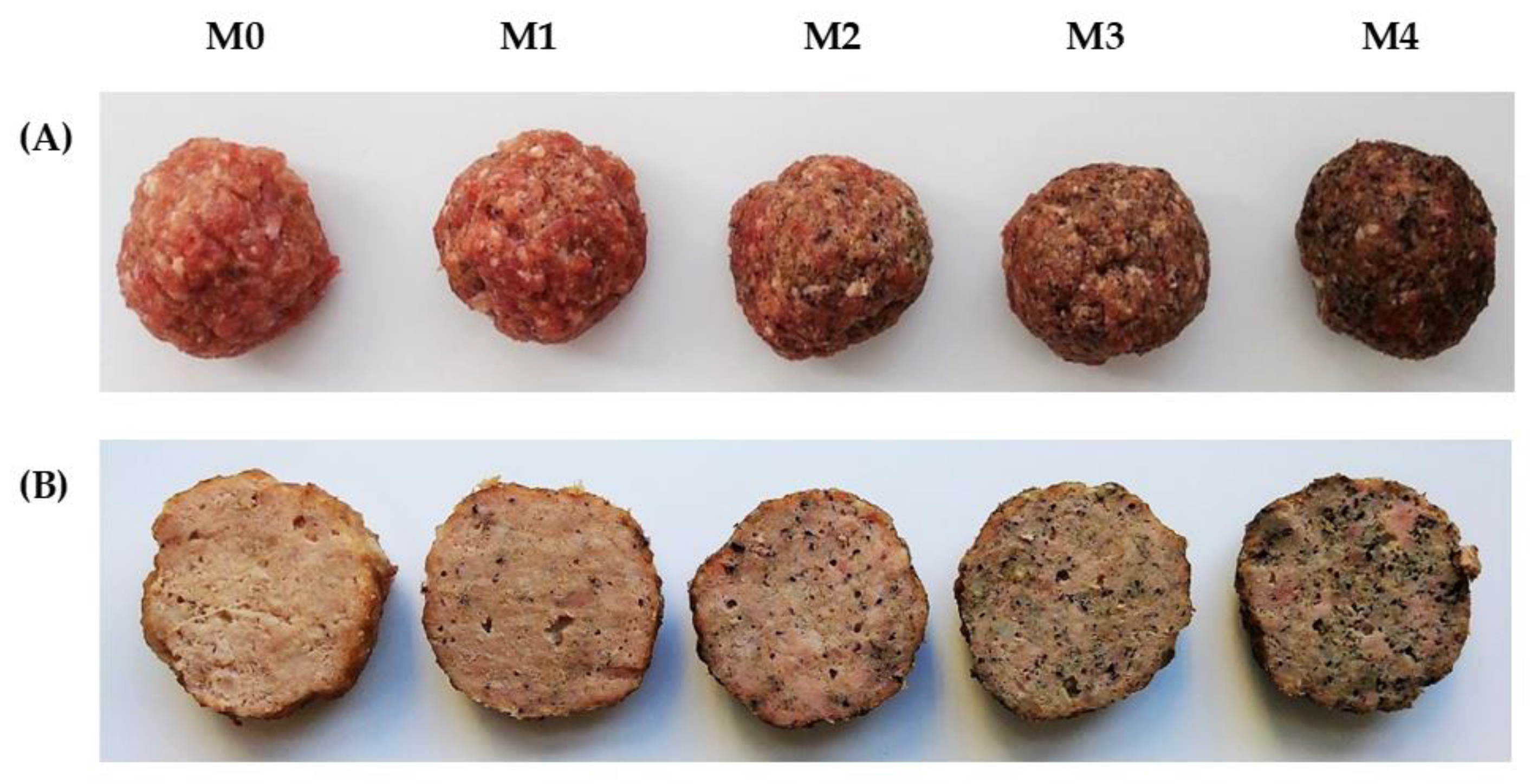

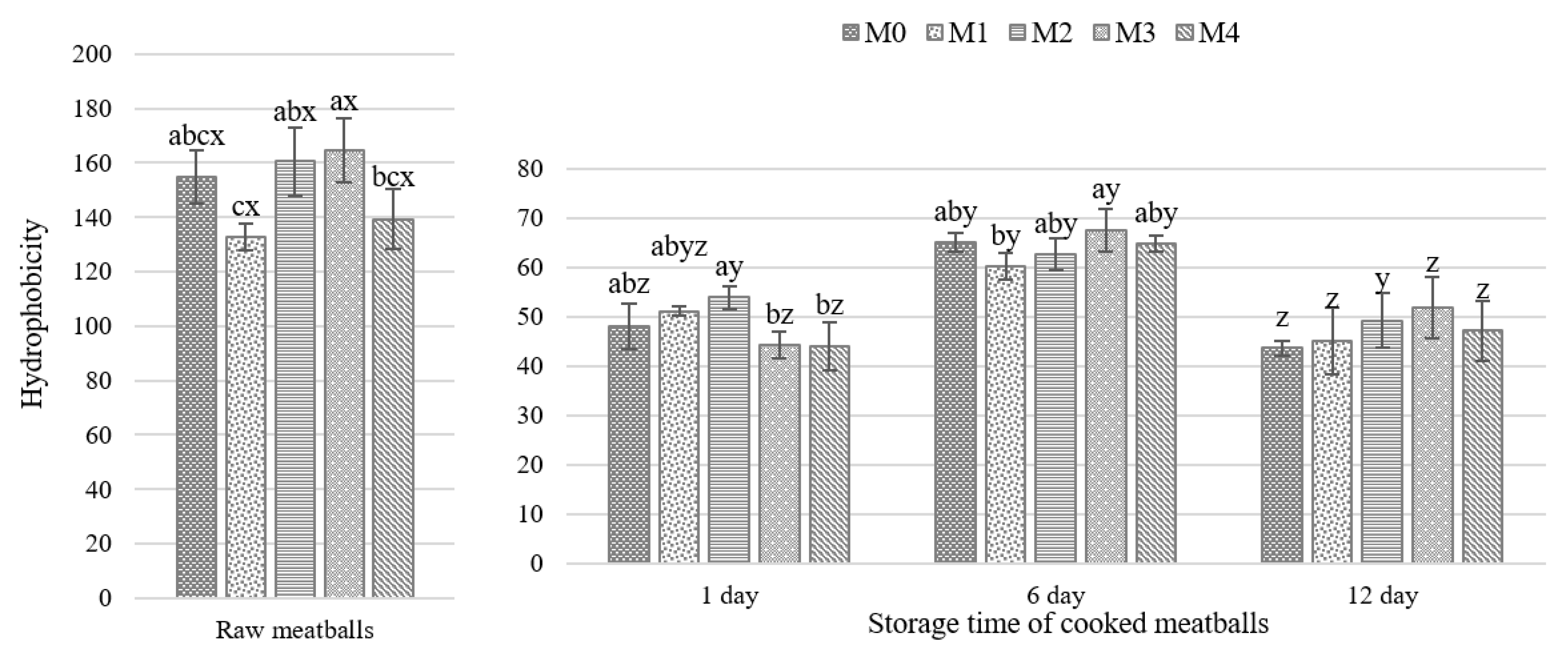

2.1. Changes in the Composition, and Physicochemical and Textural Properties

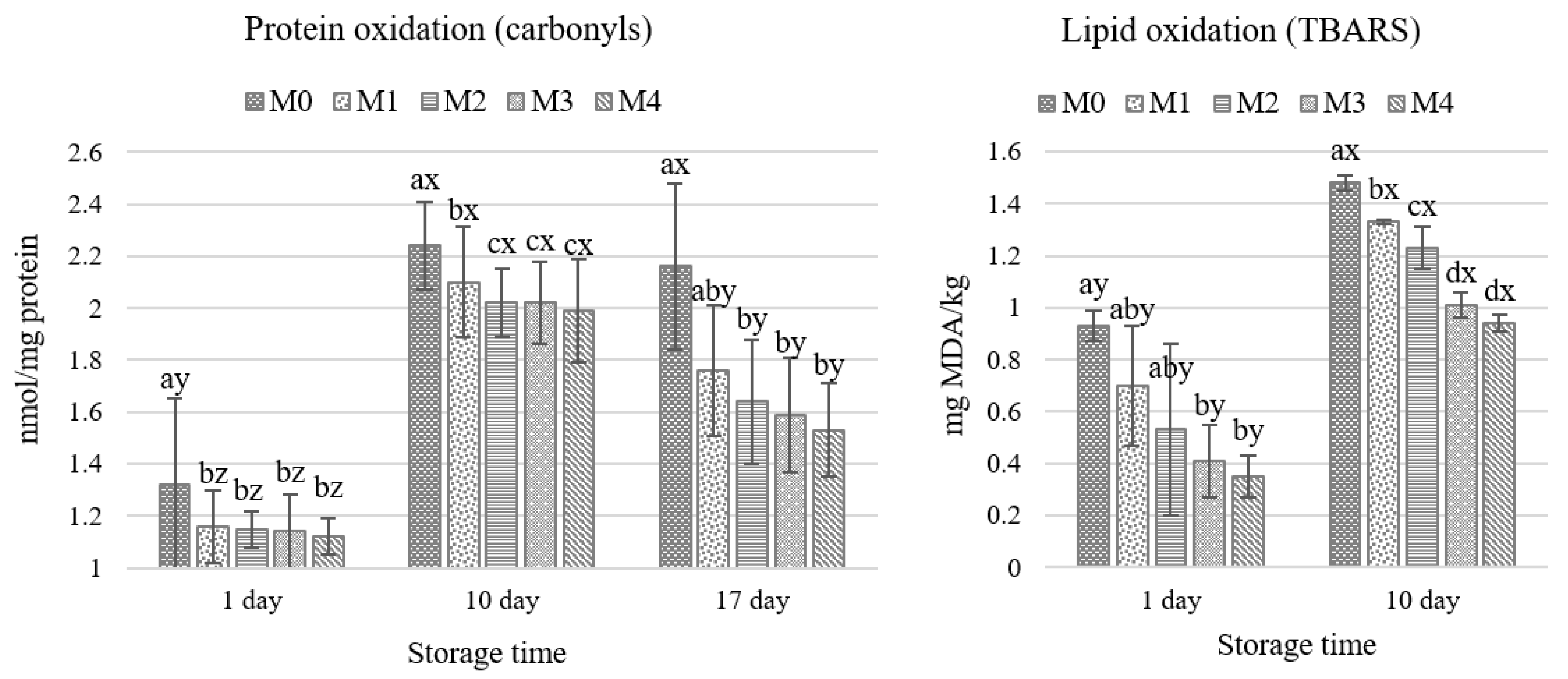

2.2. Protein and Lipid Oxidation

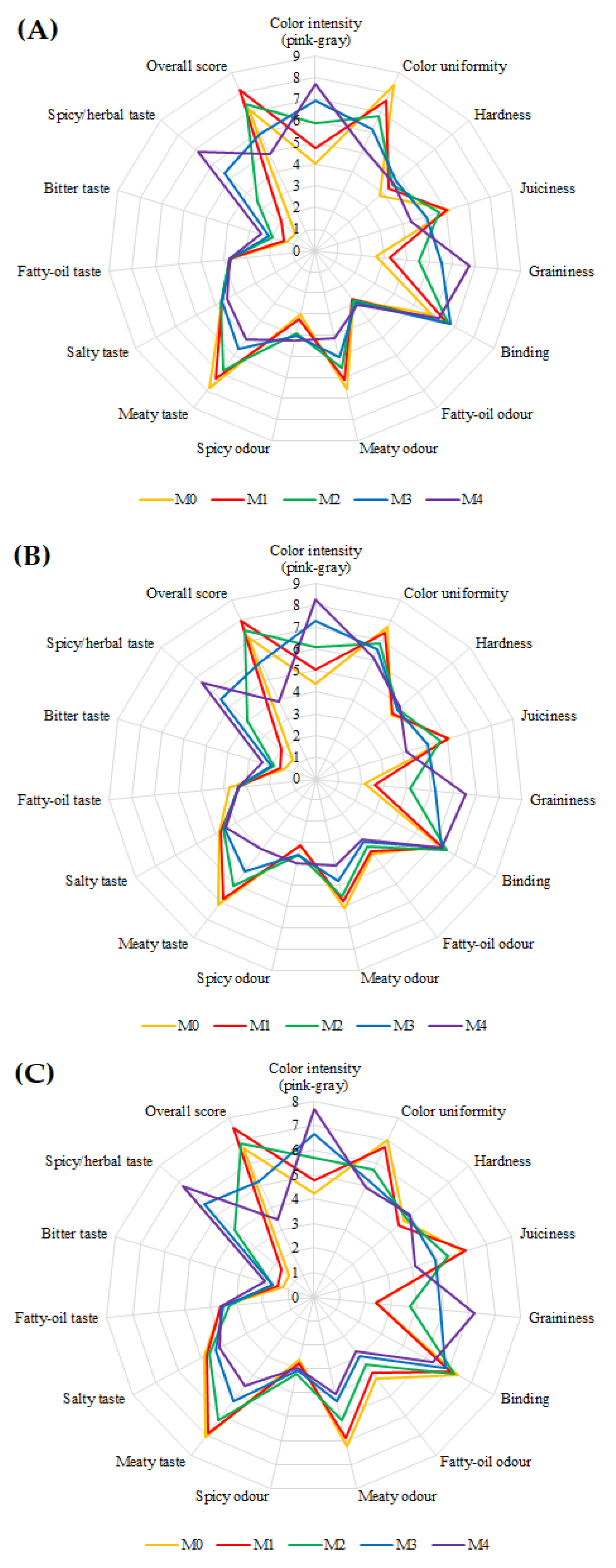

2.3. Sensory Evaluation

3. Materials and Methods

3.1. Preparation of Meatballs

3.2. Proximate Composition

3.3. pH, Color, and Water Activity Measurements

3.4. Cooking and Storage Losses

3.5. Texture Profile Analysis

3.6. Protein Surface Hydrophobicity

3.7. Protein Oxidation (Carbonyl Content)

3.8. Lipid Oxidation

3.9. Sensory Evaluation

3.10. Statistical Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Shahbandeh, M. Per Capita Consumption of Meat Worldwide from 2016 to 2018, with a Forecast for 2028, by Region (In Kilos). Available online: https://www.statista.com/statistics/1037429/per-capita-consumption-of-meat-worldwide-by-region/ (accessed on 12 December 2020).

- Hygreeva, D.; Pandey, M.C.; Radhakrishna, K. Potential applications of plant based derivatives as fat replacers, antioxidants and antimicrobials in fresh and processed meat products. Meat Sci. 2014, 98, 47–57. [Google Scholar] [CrossRef]

- Kang, Z.L.; Zhu, D.Y.; Li, B.; Ma, H.J.; Song, Z.J. Effect of pre-emulsified sesame oil on physical-chemical and rheological properties of pork batters. Food Sci. Technol. 2017, 37, 620–626. [Google Scholar] [CrossRef][Green Version]

- Mora-Gallego, H.; Guàrdia, M.D.; Serra, X.; Gou, P.; Arnau, J. Sensory characterisation and consumer acceptability of potassium chloride and sunflower oil addition in small-caliber non-acid fermented sausages with a reduced content of sodium chloride and fat. Meat Sci. 2016, 112, 9–15. [Google Scholar] [CrossRef] [PubMed]

- Tahmasebi, M.; Labbafi, M.; Emam-Djomeh, Z.; Yarmand, M.S. Manufacturing the novel sausages with reduced quantity of meat and fat: The product development, formulation optimization, emulsion stability and textural characterization. LWT 2016, 68, 76–84. [Google Scholar] [CrossRef]

- Merenkova, S.P.; Zinina, O.V.; Khayrullin, M.F.; Bychkova, T.S.; Moskvina, L.A. Study of the rheological properties of meat-vegetable minces. IOP Conf. Ser. Earth Environ. Sci. 2020, 613, 012078. [Google Scholar] [CrossRef]

- Semwogerere, F.; Katiyatiya, L.F.C.; Chikwanha, O.C.; Marufu, M.C.; Mapiye, C. Bioavailability and Bioefficacy of Hemp By-Products in Ruminant Meat Production and Preservation: A Review. Front. Vet. Sci. 2020, 7, 572906. [Google Scholar] [CrossRef]

- Wang, Q.; Xiong, Y.L. Processing, nutrition, and functionality of hempseed protein: A review. Compr. Rev. Food Sci. Food Saf. 2019, 10, 1541–4337. [Google Scholar] [CrossRef]

- Zając, M.; Guzik, P.; Kulawik, P.; Tkaczewska, J.; Florkiewicz, A.; Migdał, W. The quality of pork loaves with the addition of hemp seeds, de-hulled hemp seeds, hemp protein and hemp flour. LWT 2019, 105, 190–199. [Google Scholar] [CrossRef]

- Leonard, W.; Zhang, P.; Ying, D.; Fang, Z. Hempseed in food industry: Nutritional value, health benefits, and industrial applications. Compr. Rev. Food Sci. Food Saf. 2019, 19, 282–308. [Google Scholar] [CrossRef]

- Kotecka-Majchrzak, K.; Sumara, A.; Fornal, E.; Montowska, M. Oilseed proteins – Properties and application as a food ingredient. Trends Food Sci. Technol. 2020, 106, 160–170. [Google Scholar] [CrossRef]

- Lin, Y.; Pangloli, P.; Meng, X.; Dia V., P. Effect of heating on the digestibility of isolated hempseed (Cannabis sativa L.) protein and bioactivity of its pepsin-pancreatin digests. Food Chem. 2020, 314, 126198. [Google Scholar] [CrossRef]

- Malomo, S.A.; Onuh, J.O.; Girgih, A.T.; Aluko, R.E. Structural and antihypertensive properties of enzymatic hemp seed protein hydrolysates. Nutrients 2015, 7, 7616–7632. [Google Scholar] [CrossRef] [PubMed]

- Mamone, G.; Picariello, G.; Ramondo, A.; Nicolai, M.A.; Ferranti, P. Production, digestibility and allergenicity of hemp (Cannabis sativa L.) protein isolates. Food Res. Int. 2019, 115, 562–571. [Google Scholar] [CrossRef] [PubMed]

- Orio, L.P.; Boschin, G.; Recca, T.; Morelli, C.F.; Ragona, L.; Francescato, P.; Arnoldi, A.; Speranza, G. New ACE-inhibitory peptides from hemp seed (Cannabis sativa L.) proteins. J. Agric. Food Chem. 2017, 65, 10482–10488. [Google Scholar] [CrossRef]

- Dabija, A.; Codina, G.G.; Gatlan, A.M.; Sanduleac, E.T.; Rusu, L. Effects of some vegetable proteins addition on yogurt quality. Scien. Study Res. -Chem. Chem. Eng. Biotech. Food Ind. 2018, 19, 181–192. [Google Scholar]

- Korus, J.; Witczak, M.; Ziobro, R.; Juszczak, L. Hemp (Cannabis sativa subsp. sativa) flour and protein preparation as natural nutrients and structure forming agents in starch based gluten-free bread. LWT 2017, 84, 143–150. [Google Scholar] [CrossRef]

- Naumova, N.; Lukin, A.; Bitiutskikh, K. Organoleptic evaluation of the quality of the enriched chopped semi-finished meat products. Bull. Transilv. Univ. Bras. Ser. II -For. Wood Ind. Agric. Food Eng. 2017, 10, 125–132. [Google Scholar]

- Zahari, I.; Ferawati, F.; Helstad, A.; Ahlström, C.; Östbring, K.; Rayner, M.; Purhagen, J.K. Development of high-moisture meat analogues with hemp and soy protein using extrusion cooking. Foods 2020, 9, 772. [Google Scholar] [CrossRef]

- Malomo, S.A.; He, R.; Aluko, R.E. Structural and functional properties of hemp seed protein products. J. Food Sci. 2014, 79, 1512–1521. [Google Scholar] [CrossRef]

- Hadnađev, M.; Dapčević-Hadnađev, T.; Lazaridou, A.; Moschakis, T.; Michaelidou, A.-M.; Popović, S.; Biliaderis, C.G. Hempseed meal protein isolates prepared by different isolation techniques. Part I. Physicochemical properties. Food Hydrocoll. 2018, 79, 526–533. [Google Scholar] [CrossRef]

- Tang, C.; Ten, Z.; Wang, X.; Yang, X. Physicochemical and functional properties of hemp (Cannabis sativa L.) protein isolate. J. Agric. Food Chem. 2006, 54, 8945–8950. [Google Scholar] [CrossRef]

- Ghribi, A.M.; Amira, A.B.; Gafsi, I.M.; Lahiani, M.; Bejar, M.; Triki, M.; Zouari, A.; Attia, H.; Besbes, S. Toward the enhancement of sensory profile of sausage “Merguez” with chickpea protein concentrate. Meat Sci. 2018, 143, 74–80. [Google Scholar] [CrossRef] [PubMed]

- Salejda, A.M.; Janiewicz, U.; Korzeniowska, M.; Kolniak-Ostek, J.; Krasnowska, G. Effect of walnut green husk addition on some quality properties of cooked sausages. LWT 2016, 65, 751–757. [Google Scholar] [CrossRef]

- Cheng, J.; Xu, L.; Xiang, R.; Liu, X.; Zhu, M. Effects of mulberry polyphenols on oxidation stability of sarcoplasmic and myofibrillar proteins in dried minced pork slices during processing and storage. Meat Sci. 2020, 160, 107973. [Google Scholar] [CrossRef] [PubMed]

- Filgueras, R.S.; Gatellier, P.; Ferreira, C.; Zambiazi, R.C.; Santé-Lhoutellier, V. Nutritional value and digestion rate of rhea meat proteins in association with storage and cooking processes. Meat Sci. 2011, 89, 6–12. [Google Scholar] [CrossRef]

- Mitra, B.; Rinnan, Å.; Ruiz-Carrascal, J. Tracking hydrophobicity state, aggregation behaviour and structural modifications of pork proteins under the influence of assorted heat treatments. Food Res. Int. 2017, 101, 266–273. [Google Scholar] [CrossRef] [PubMed]

- Wen, R.; Hu, Y.; Zhang, L.; Wang, Y.; Chen, Q.; Kong, B. Effect of NaCl substitutes on lipid and protein oxidation and flavor development of Harbin dry sausage. Meat Sci. 2019, 156, 33–43. [Google Scholar] [CrossRef]

- Turgut, S.S.; Ayla Soyer, A.; Işıkçı, F. Effect of pomegranate peel extract on lipid and protein oxidation in beef meatballs during refrigerated storage. Meat Sci. 2016, 116, 126–132. [Google Scholar] [CrossRef]

- Stadtman, E.R.; Levine, R.L. Free radical-mediated oxidation of free amino acids and amino acid residues in proteins. Amino Acids 2003, 25, 207–218. [Google Scholar] [CrossRef]

- Girgih, A.T.; He, R.; Malomo, S.; Offengenden, M.; Wu, J.; Aluko, R.E. Structural and functional characterization of hemp seed (Cannabis sativa L.) protein-derived antioxidant and antihypertensive peptides. J. Funct. Foods 2014, 6, 384–394. [Google Scholar] [CrossRef]

- Chen, T.P.; He, J.F.; Zhang, J.C.; Li, X.H.; Zhang, H.; Hao, J.X.; Li, L. The isolation and identification of two compounds with predominant radical scavenging activity in hempseed (seed of Cannabis sativa L.). Food Chem. 2012, 134, 1030–1037. [Google Scholar] [CrossRef] [PubMed]

- Yu, L.L.; Zhou, K.K.; Parry, J. Antioxidant properties of cold-pressed black caraway, carrot, cranberry, and hemp seed oils. Food Chem. 2005, 91, 723–729. [Google Scholar] [CrossRef]

- Doolaege, E.H.A.; Vossen, E.; Raes, K.; De Meulenaer, B.; Verhe, R.; Paelinck, H.; De Smet, S. Effect of rosemary extract dose on lipid oxidation, colour stability and antioxidant concentrations, in reduced nitrite liver pates. Meat Sci. 2012, 90, 925–931. [Google Scholar] [CrossRef]

- Norajit, K.; Gu, B.; Ryu, G. Effects of the addition of hemp powder on the physicochemical properties and energy bar qualities of extruded rice. Food Chem. 2011, 129, 1919–1925. [Google Scholar] [CrossRef]

- Korus, A.; Gumul, D.; Krystyjan, M.; Juszczak, L.; Korus, J. Evaluation of the quality, nutritional value and antioxidant activity of gluten-free biscuits made from corn-acorn four or corn-hemp four composites. Eur. Food Res. Technol. 2017, 243, 1429–1438. [Google Scholar] [CrossRef]

- Mikulec, A.; Kowalski, S.; Sabat, R.; Skoczylas, L.; Tabaszewska, M.; Wywrocka-Gurgul, A. hemp flour as a valuable component for enriching physicochemical and antioxidant properties of wheat bread. LWT 2019, 102, 164–172. [Google Scholar] [CrossRef]

- Radočaj, O.; Dimić, E.; Tsao, R. Effects of hemp (Cannabis sativa L.) seed oil press-cake and decaffeinated green tea leaves (Camellia sinensis) on functional characteristics of gluten-free crackers. J. Food Sci. 2014, 79, 318–325. [Google Scholar] [CrossRef] [PubMed]

- Kotecka-Majchrzak, K.; Sumara, A.; Fornal, E.; Montowska, M. Proteomic analysis of oilseed cake: A comparative study of species-specific proteins and peptides extracted from ten seed species. J. Sci. Food Agric. 2021, 101, 297–306. [Google Scholar] [CrossRef]

- Li-Chan, E.; Nakai, S.; Wood, D.F. Hydrophobicity and solubility of meat proteins and their relationship to emulsifying properties. J. Food Sci. 1984, 49, 345–350. [Google Scholar] [CrossRef]

- Joo, S.T.; Kauffman, R.G.; Kim, B.C.; Park, G.B. The relationship of sarcoplasmic and myofibrillar protein solubility to colour and water-holding capacity in porcine longissimus muscle. Meat Sci. 1999, 52, 291–297. [Google Scholar] [CrossRef]

- Levine, R.L.; Williams, J.A.; Stadtman, E.R.; Shacter, E. Carbonyl assays for determination of oxidatively modified proteins. Oxyg. Radic. Biol. Syst. 1994, 233, 346–357. [Google Scholar] [CrossRef]

- Bellés, M.; Alonso, V.; Roncalés, P.; Beltrán, J.A. The combined effects of superchilling and packaging on the shelf life of lamb. Meat Sci. 2017, 133, 126–132. [Google Scholar] [CrossRef]

| Ingredients | Meatballs | ||||

|---|---|---|---|---|---|

| M0 | M1 | M2 | M3 | M4 | |

| Pork shoulder | 66.0 | 65.4 | 64.3 | 63.2 | 61.1 |

| Rabbit meat | 10.9 | 10.8 | 10.6 | 10.4 | 10.1 |

| Guinea fowl meat | 7.3 | 7.2 | 7.1 | 7.0 | 6.7 |

| Water | 8.9 | 8.8 | 8.6 | 8.5 | 8.2 |

| Bread crumbs | 5.3 | 5.3 | 5.2 | 5.1 | 5.0 |

| Salt | 1.3 | 1.3 | 1.3 | 1.3 | 1.2 |

| Pepper | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| Garlic | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Hemp cake | 0.0 | 0.9 | 2.6 | 4.2 | 7.4 |

| Parameter | Meatballs | Hemp Cake HC | ||||

|---|---|---|---|---|---|---|

| M0 | M1 | M2 | M3 | M4 | ||

| Protein | 18.04 ± 0.84 | 18.33 ± 0.46 | 18.36 ± 0.72 | 18.70 ± 0.37 | 19.40 ± 1.00 | 31.47 ± 0.23 |

| Moisture | 67.88 ± 0.57 a | 68.01 ± 0.85 a | 67.37 ± 0.67 a,b | 65.86 ± 0.71 b | 63.57 ± 1.57 c | 9.84 ± 0.17 |

| Fat | 6.82 ± 0.13 | 6.98 ± 0.08 | 7.84 ± 1.45 | 7.78 ± 0.93 | 7.41 ± 1.36 | 1.51 ± 0.20 |

| Dry matter | 25.30 ± 0.60 b,c | 25.01 ± 0.92 c | 24.79 ± 0.99 c | 26.36 ± 0.33 b | 29.02 ± 0.07 a | 88.65 ± 0.08 |

| Ash | 2.20 ± 0.07 | 2.13 ± 0.06 | 2.30 ± 0.24 | 2.11 ± 0.19 | 2.35 ± 0.12 | 7.05 ± 0.08 |

| Parameter | Day | Meatballs | ||||

|---|---|---|---|---|---|---|

| M0 | M1 | M2 | M3 | M4 | ||

| pH | 1 | 6.48 ± 0.08 a,b | 6.43 ± 0.03 a,b | 6.51 ± 0.03 a | 6.40 ± 0.02 a,b | 6.36 ± 0.10 b |

| 6 | 6.51 ± 0.03 a,b | 6.46 ± 0.05 b | 6.59 ± 0.03 a | 6.50 ± 0.1 a,b | 6.41 ± 0.04 b | |

| 12 | 6.38 ± 0.05 b | 6.40 ± 0.05 b | 6.55 ± 0.07 a | 6.48 ± 0.08 a,b | 6.41 ± 0.06 b | |

| L | 1 | 65.52 ± 1.36 a | 61.73 ± 1.11 b | 57.72 ± 2.19 c | 58.06 ± 0.48 c,x | 52.76 ± 1.17 d |

| 6 | 64.25 ± 1.09 a | 62.50 ± 0.26 b | 56.02 ± 0.71 c | 56.00 ± 0.42 c,y | 53.00 ± 0.91 d | |

| 12 | 63.95 ± 0.75 a | 60.83 ± 0.40 b | 59.43 ± 0.85 b,c | 58.20 ± 1.62 c,x | 54.80 ± 0.9 d | |

| a* | 1 | 5.14 ± 0.38 a,x | 4.43 ± 0.24 b | 4.00 ± 0.23 b | 3.96 ± 0.27 b,x | 3.22 ± 0.29 c,x |

| 6 | 4.33 ± 0.35 a,y | 4.28 ± 0.13 a | 3.60 ± 0.24 b | 2.83 ± 0.17 b,y | 2.50 ± 0.32 c,y | |

| 12 | 4.58 ± 0.22a,y | 4.25 ± 0.26 a,b | 4.00 ± 0.52 a,b | 3.84 ± 0.32 b,x | 2.54 ± 0.32 c,y | |

| b* | 1 | 11.40 ± 0.30 a,b | 12.48 ± 0.67 a,x | 9.64 ± 0.86 c,x,y | 10.36 ± 0.97 b,c | 11.26 ± 0.98 a,b |

| 6 | 11.28 ± 0.45 a | 11.85 ± 0.30 a,x,y | 8.10 ± 0.47 c,y | 10.23 ± 0.63 b | 10.90 ± 0.48 a,b | |

| 12 | 11.88 ± 0.46 a | 11.43 ± 0.25 a,b,y | 10.25 ± 0.48 b,c,x | 9.76 ± 0.99 c | 9.92 ± 0.66 c | |

| Water activity | 1 | 0.9792 ± 0.0033 a,b | 0.9803 ± 0.0014 a | 0.9788 ± 0.0007 a,b | 0.9779 ± 0.0015 a,b | 0.9770 ± 0.0010 b |

| Cooking loss [%] | 0 | 12.72 ± 1.17 | 12.04 ± 0.86 | 11.64 ± 0.65 | 11.13 ± 1.07 | 10.71 ± 1.08 |

| Storage loss [%] | 1 | 2.19 ± 0.38 a,z | 1.74 ± 0.25 a,b,z | 1.84 ± 0.48 a,b,z | 1.36 ± 0.48 b,z | 1.6 ± 0.39 a,b,y |

| 6 | 3.24 ± 0.55 a,y | 2.76 ± 0.36 a,b,y | 2.91 ± 0.39 a,b,y | 2.29 ± 0.41 b,y | 2.42 ± 0.75 a,b,y | |

| 12 | 4.19 ± 0.76 x | 3.7 ± 0.48 x | 3.88 ± 0.65 x | 3.25 ± 0.46 x | 3.41 ± 0.60 x | |

| Parameter | Day | Meatballs | ||||

|---|---|---|---|---|---|---|

| M0 | M1 | M2 | M3 | M4 | ||

| Hardness [N] | 1 | 9.70 ± 1.69 c | 11.16 ± 2.71 a,b,c | 11.21 ± 1.12 a,b,c | 11.00 ± 1.72 b,c | 11.15 ± 2.50 a,b,c |

| 6 | 12.84 ± 1.96 a,b | 13.11 ± 3.35 a,b | 13.72 ± 1.64 a,b | 12.80 ± 1.48 a,b | 13.14 ± 2.87 a,b | |

| 12 | 11.80 ± 1.86 a,b,c | 13.21 ± 3.25 a,b | 13.96 ± 1.22 a | 13.34 ± 1.1 a,b | 13.68 ± 2.52 a,b | |

| Springiness | 1 | 0.67 ± 0.04 a,b | 0.65 ± 0.09 a,b | 0.66 ± 0.04 a,b | 0.65 ± 0.05 a,b | 0.62 ± 0.08 b |

| 6 | 0.70 ± 0.04 a,b | 0.72 ± 0.06 a | 0.69 ± 0.05 a,b | 0.66 ± 0.04 a,b | 0.65 ± 0.07 a,b | |

| 12 | 0.66 ± 0.09 a,b | 0.72 ± 0.04 a | 0.71 ± 0.04 a | 0.66 ± 0.04 a,b | 0.66 ± 0.07 a,b | |

| Cohesiveness | 1 | 0.39 ± 0.05 | 0.41 ± 0.09 | 0.40 ± 0.06 | 0.39 ± 0.07 | 0.38 ± 0.07 |

| 6 | 0.39 ± 0.05 | 0.39 ± 0.06 | 0.42 ± 0.05 | 0.40 ± 0.04 | 0.37 ± 0.07 | |

| 12 | 0.38 ± 0.06 | 0.43 ± 0.07 | 0.43 ± 0.05 | 0.40 ± 0.04 | 0.38 ± 0.06 | |

| Gumminess | 1 | 3.87 ± 1.03 b | 4.8 ± 2.02 a,b | 4.5 ± 1.17 a,b | 4.41 ± 1.4 a,b | 4.34 ± 1.57 a,b |

| 6 | 5.08 ± 1.28 a,b | 5.20 ± 2.05 a,b | 5.82 ± 1.31 a,b | 5.11 ± 1.06 a,b | 5.01 ± 1.80 a,b | |

| 12 | 4.53 ± 1.08 a,b | 5.89 ± 2.26 a | 6.06 ± 1.05 a | 5.41 ± 0.84 a,b | 5.36 ± 1.68 a,b | |

| Chewiness | 1 | 2.62 ± 0.81 b | 3.23 ± 1.59 a,b | 2.97 ± 0.8 a,b | 2.85 ± 0.81 a,b | 2.76 ± 1.19 a,b |

| 6 | 3.54 ± 0.91 a,b | 3.78 ± 1.54 a,b | 4.05 ± 1.08 a,b | 3.39 ± 0.87 a,b | 3.34 ± 1.44 a,b | |

| 12 | 3.07 ± 1.01 a,b | 4.24 ± 1.71 a | 4.31 ± 0.88 a | 3.58 ± 0.74 a,b | 3.63 ± 1.39 a,b | |

| Resilience | 1 | 0.16 ± 0.03 a,b | 0.17 ± 0.05 a,b | 0.16 ± 0.03 a,b | 0.15 ± 0.04 a,b | 0.14 ± 0.04 a,b |

| 6 | 0.16 ± 0.02 a,b | 0.16 ± 0.03 a,b | 0.17 ± 0.02 a,b | 0.15 ± 0.02 a,b | 0.13 ± 0.03 b | |

| 12 | 0.15 ± 0.03 a,b | 0.18 ± 0.04 a | 0.18 ± 0.03 a | 0.15 ± 0.02 a,b | 0.14 ± 0.03 a,b | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kotecka-Majchrzak, K.; Kasałka-Czarna, N.; Spychaj, A.; Mikołajczak, B.; Montowska, M. The Effect of Hemp Cake (Cannabis sativa L.) on the Characteristics of Meatballs Stored in Refrigerated Conditions. Molecules 2021, 26, 5284. https://doi.org/10.3390/molecules26175284

Kotecka-Majchrzak K, Kasałka-Czarna N, Spychaj A, Mikołajczak B, Montowska M. The Effect of Hemp Cake (Cannabis sativa L.) on the Characteristics of Meatballs Stored in Refrigerated Conditions. Molecules. 2021; 26(17):5284. https://doi.org/10.3390/molecules26175284

Chicago/Turabian StyleKotecka-Majchrzak, Klaudia, Natalia Kasałka-Czarna, Anita Spychaj, Beata Mikołajczak, and Magdalena Montowska. 2021. "The Effect of Hemp Cake (Cannabis sativa L.) on the Characteristics of Meatballs Stored in Refrigerated Conditions" Molecules 26, no. 17: 5284. https://doi.org/10.3390/molecules26175284

APA StyleKotecka-Majchrzak, K., Kasałka-Czarna, N., Spychaj, A., Mikołajczak, B., & Montowska, M. (2021). The Effect of Hemp Cake (Cannabis sativa L.) on the Characteristics of Meatballs Stored in Refrigerated Conditions. Molecules, 26(17), 5284. https://doi.org/10.3390/molecules26175284