Theoretical–Computational Study of Atmospheric DBD Plasma and Its Utility for Nanoscale Biocompatible Plasmonic Coating

Abstract

:1. Introduction

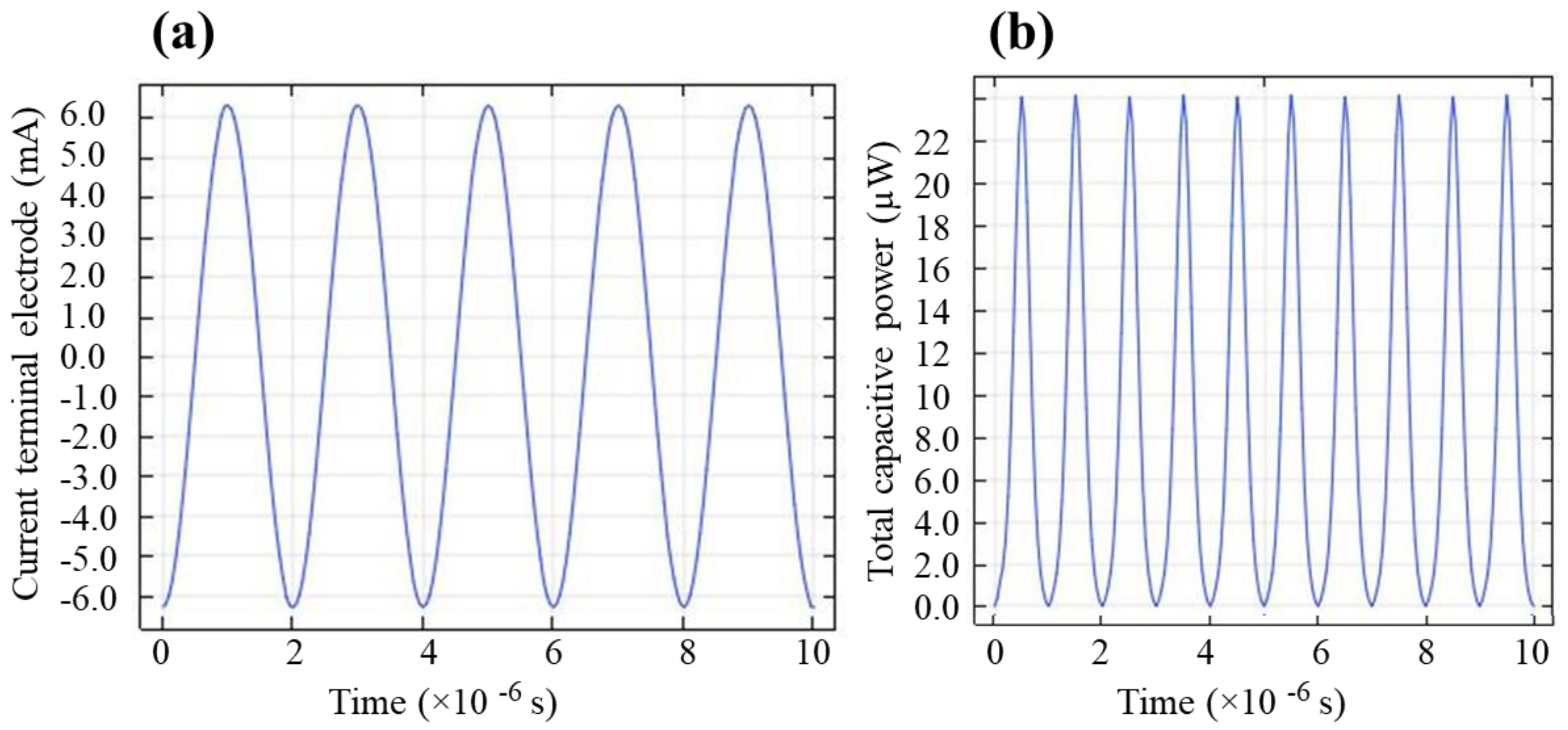

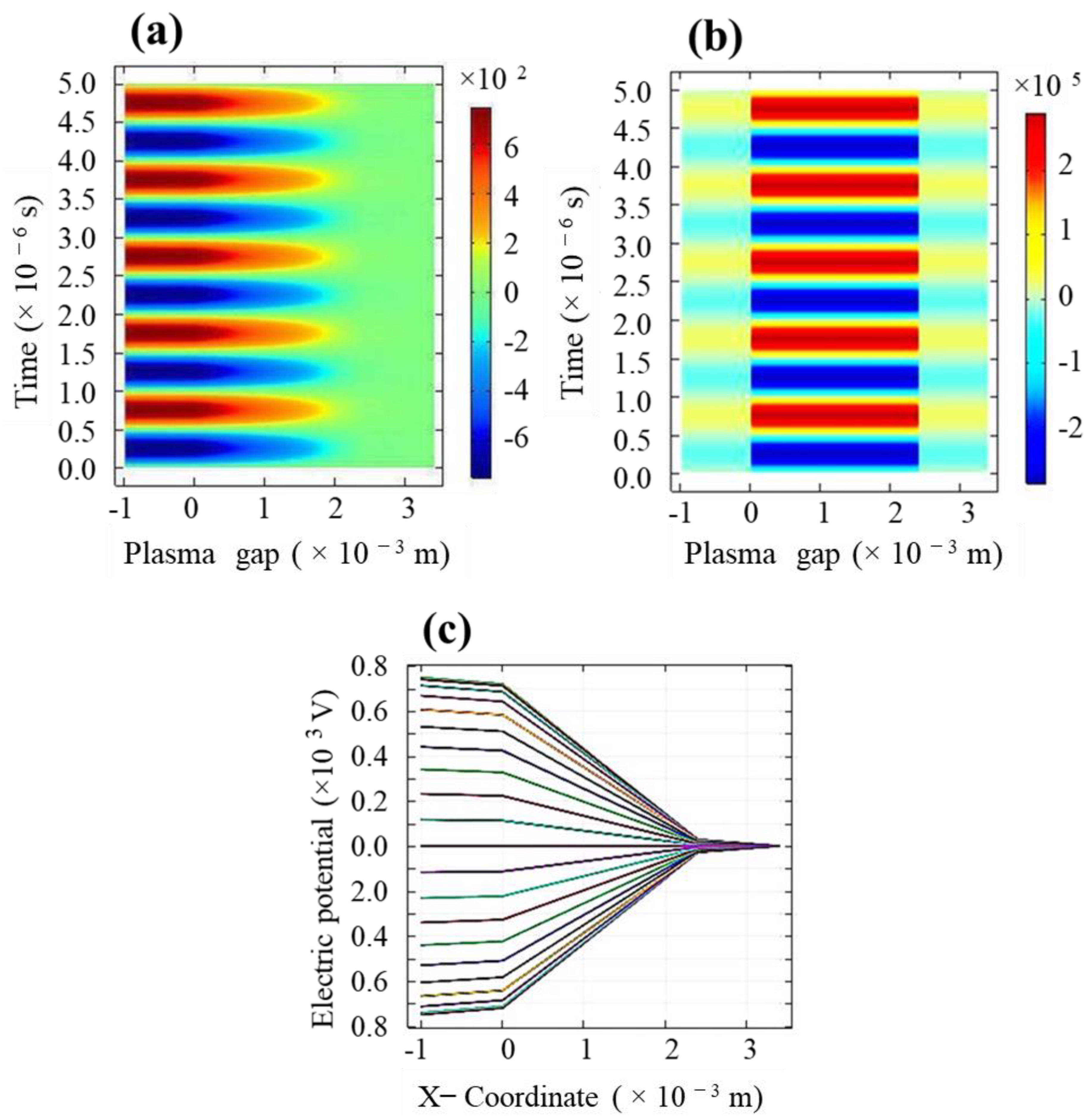

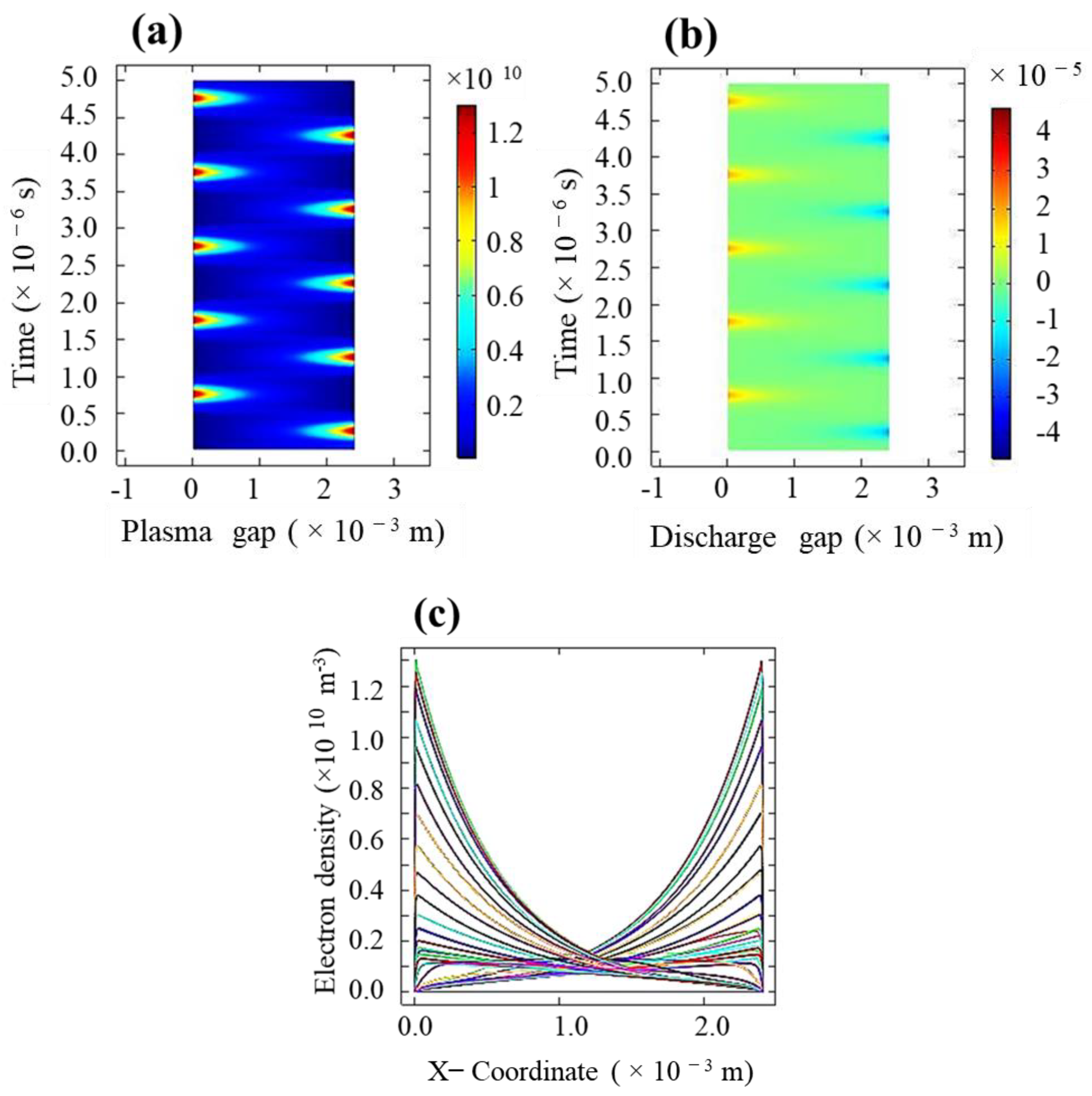

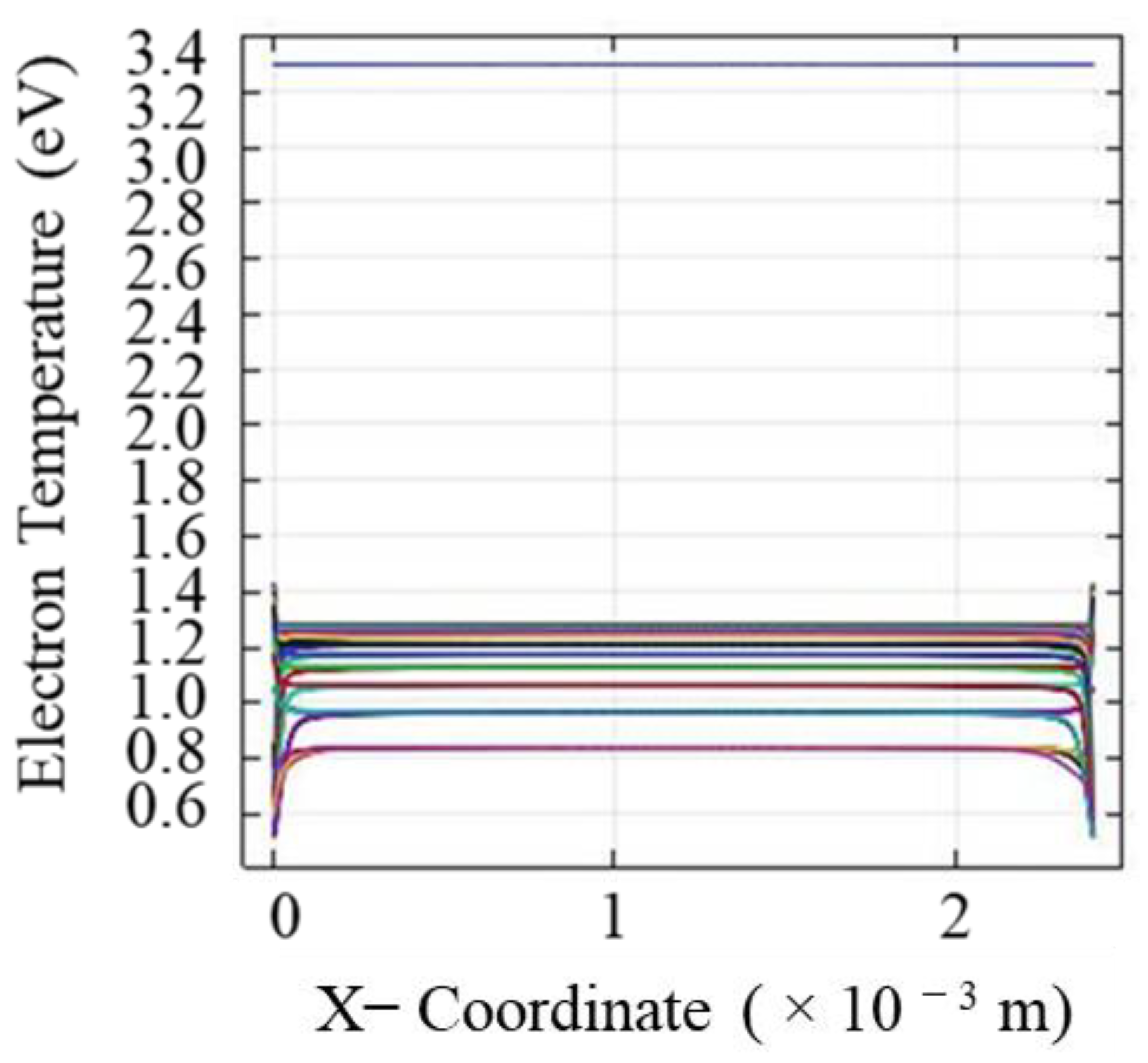

2. Results and Discussion

2.1. Simulation Results

2.2. Experimetal Results

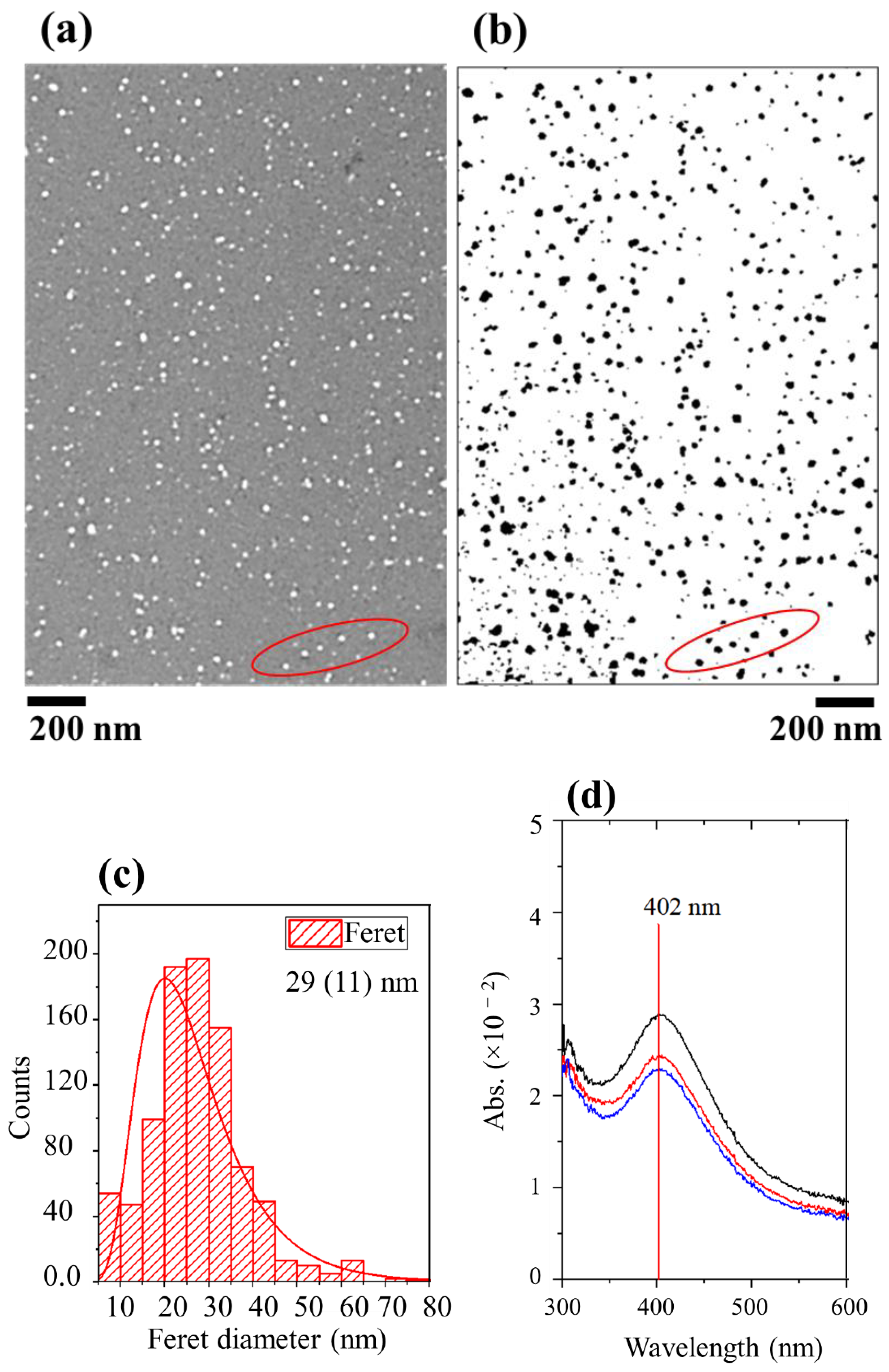

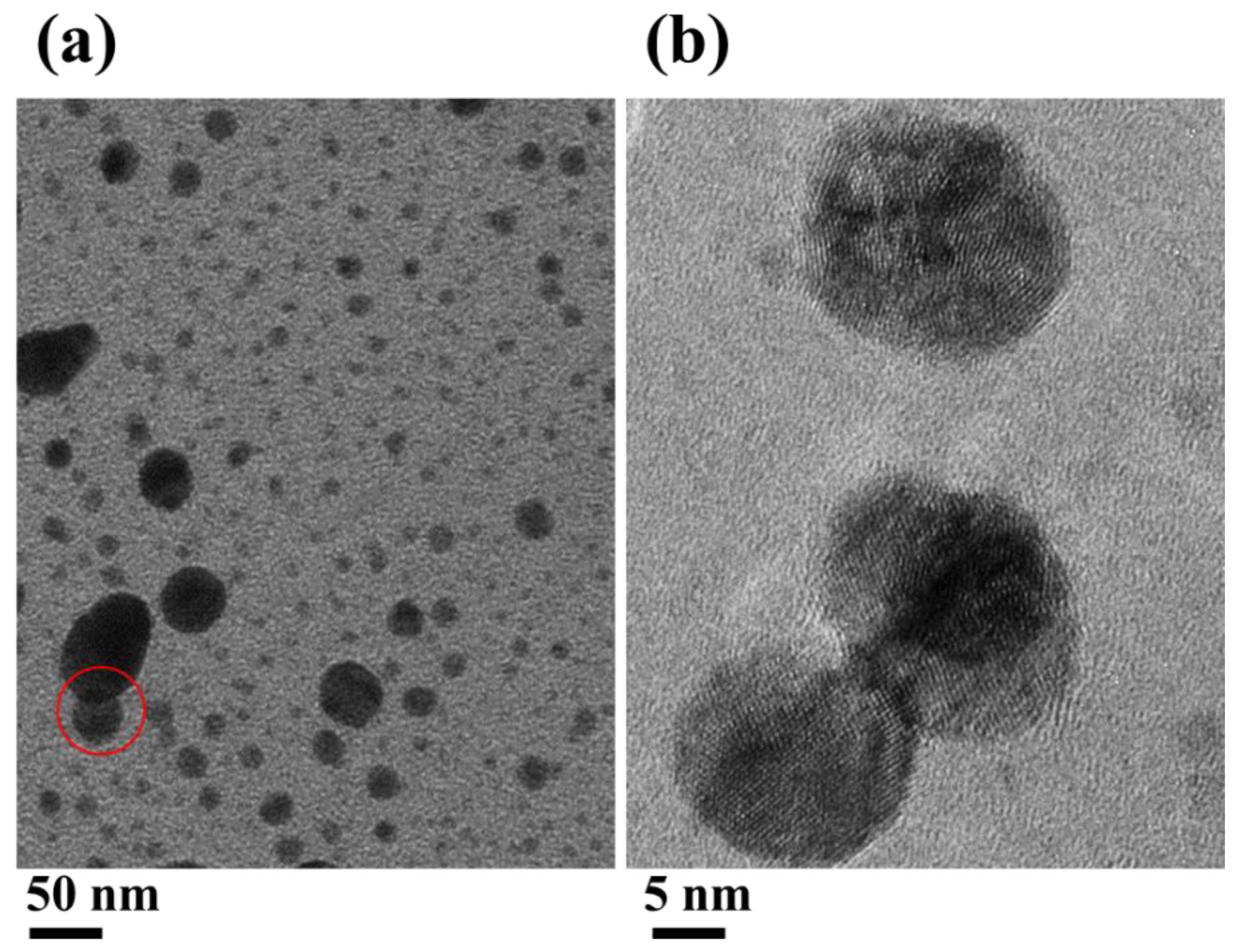

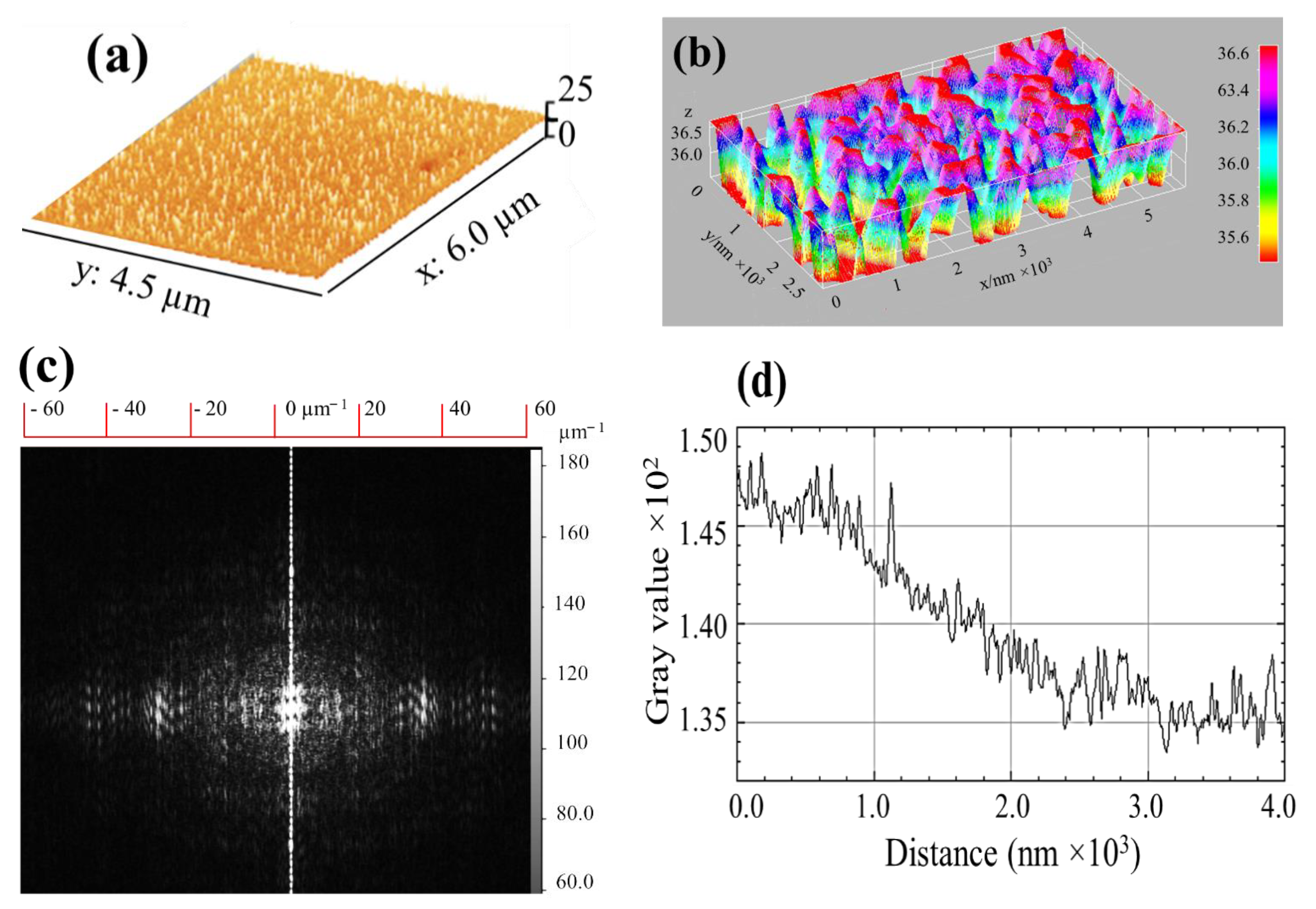

2.2.1. SDBD Plasma for Antibacterial Plasmonic Aerosols Coating

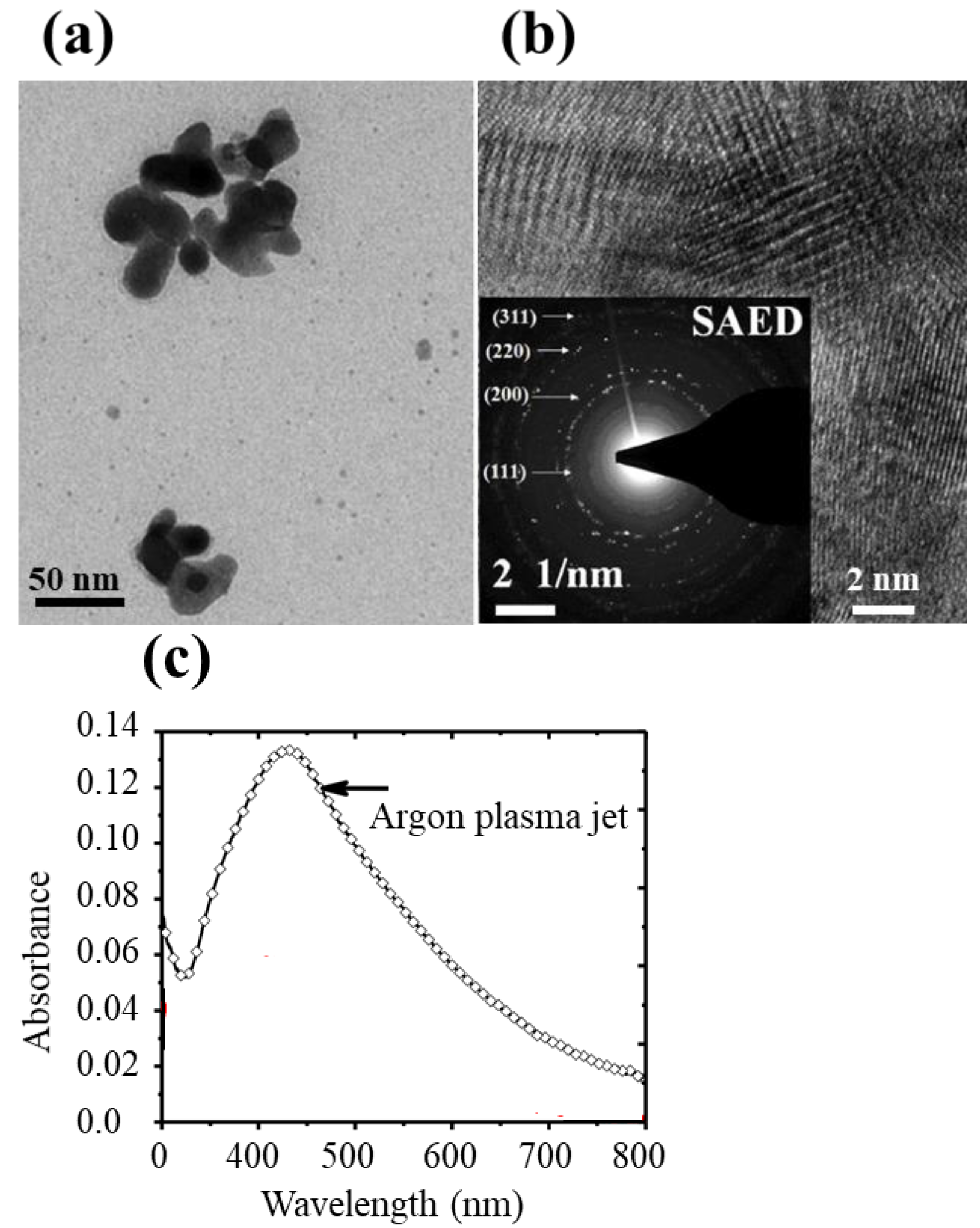

2.2.2. Comparison of SDBD and DBD Jet Coating Strategies

3. Materials and Methods

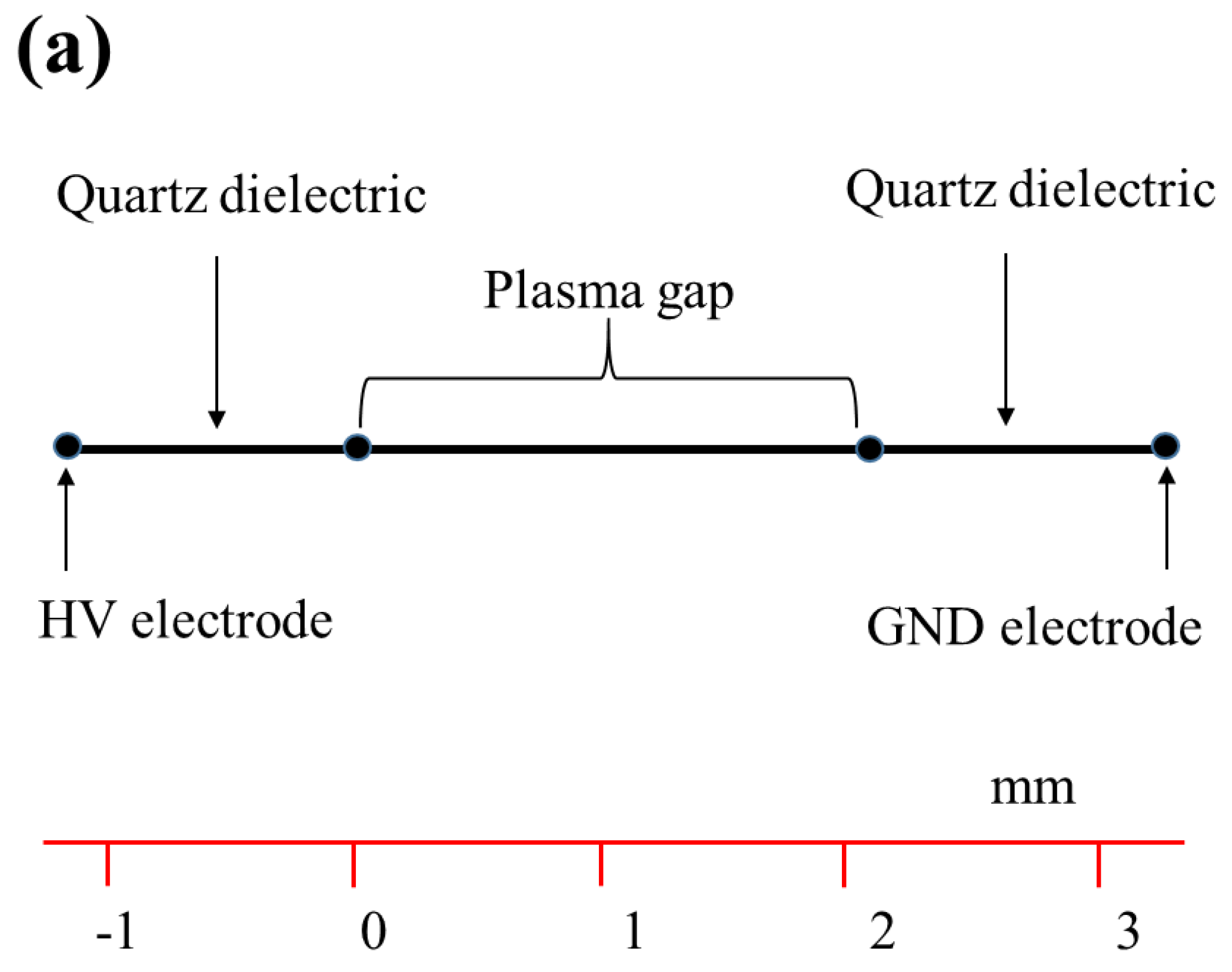

3.1. Geometry and Experimental Description

3.2. Mathematical Expressions for Simulation

4. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Kuchenbecker, M.; Bibinov, N.; Kaemlimg, A.; Wandke, D.; Awakowicz, P.; Viöl, W. Characterization of DBD plasma source for biomedical applications. J. Phys. D Appl. Phys. 2009, 42, 045212. [Google Scholar] [CrossRef]

- Keidar, M.; Beilis, I. Plasma Engineering: Applications from Aerospace to Bio and Nanotechnology; Academic Press: Oxford, FL, USA, 2013. [Google Scholar]

- Subedi, D.P.; Joshi, U.M.; Wong, C.S. Dielectric Barrier Discharge (DBD) Plasmas and Their Applications. In Plasma Science and Technology for Emerging Economies; Springer: Singapore, 2017; pp. 693–737. [Google Scholar] [CrossRef]

- Khan, T.M.; Khan, S.U.-D.; Khan, S.U.-D.; Ahmad, A.; Abbasi, S.A. A new strategy of using dielectric barrier discharge plasma in tubular geometry for surface coating and extension to biomedical application. Rev. Sci. Instrum. 2020, 91, 073902. [Google Scholar] [CrossRef] [PubMed]

- Kostov, K.G.; Rocha, V.; Koga-Ito, C.Y.; Matosb, B.M.; Algattia, M.A.; Hondaa, R.Y.; Kayamaa, M.E.; Mota, R.P. Bacterial sterilization by a dielectric barrier discharge (DBD) in air. Surf. Coat. Technol. 2010, 204, 2954–2959. [Google Scholar] [CrossRef]

- Surakerk, O.; Ratana, R.; Thammanoon, S.; Seiichi, T.; Sumaeth, C. Silver loading on DBD plasma-modified woven PET surface for antimicrobial property improvement. Plasma Chem. Plasma Process. 2010, 30, 191–206. [Google Scholar]

- Mozetič, M.; Vesel, A.; Primc, G. Introduction to plasma and plasma diagnostics. In Non-Thermal Plasma Technology for Polymeric Materials: Applications in Composites, Nanostructured Materials and Bio-Medical Fields; Thomas, S., Mozetič, M., Cvelbar, U., Spatenka, P., Praveen, K.M., Eds.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 23–65. [Google Scholar]

- Li, J.; Ma, C.H.; Zhu, S.J.; Yu, F.; Dai, B.; Yang, D. A Review of Recent Advances of Dielectric Barrier Discharge Plasma in Catalysis. Nanomaterials 2019, 9, 1428. [Google Scholar] [CrossRef] [Green Version]

- Dušan, B.; Dana, D.; Erika, H.; Henrieta, Š. Cold Atmospheric Plasma: A Powerful Tool for Modern Medicine. Int. J. Mol. Sci. 2020, 21, 2932. [Google Scholar]

- Laroussi, M.; Akan, T. Arc Generation of large volume, atmospheric pressure, non-equilibrium. Plasma Process. Polym. 2007, 4, 777–788. [Google Scholar] [CrossRef]

- Massines, F.; Segur, P.; Gherardi, N.; Khampan, C.; Ricard, A. Physics and chemistry in a glow dielectric barrier discharge at atmospheric pressure: Diagnostics and modelling. Surf. Coat. Technol. 2003, 174, 8–14. [Google Scholar] [CrossRef]

- Fridman, G.; Friedman, G.; Gutsol, A.; Shekhter, A.B.; Vasilets, V.N.; Fridman, A. Applied plasma medicines. Plasma Process. Polym. 2008, 5, 503–533. [Google Scholar] [CrossRef]

- Roth, J.R. Industrial Plasma Engineering: Applications to Nonthermal Plasma Processing; CRC Press: Boca Raton, FL, USA, 2001; Volume 2, pp. 237–352. [Google Scholar]

- Brandenburg, R. Dielectric barrier discharges: Progress on plasma sources and on the understanding of regimes and single filaments. Plasma Sources Sci. Technol. 2017, 26, 053001. [Google Scholar] [CrossRef]

- Khan, T.M.; Lunney, J.G.; O’Rourke, D.; Meyer, M.-C.; Creel, J.R.; Siewierska, K.E. Various pulsed laser deposition methods for preparation of silver-sensitised glass and paper substrates for surface-enhanced Raman spectroscopy. Appl. Phys. A 2019, 125, 659. [Google Scholar] [CrossRef]

- Wallimann, R.; Roth, C.; von Rohr, P.R. Lactose powder flowability enhancement by atmospheric pressure plasma treatment. Plasma Process. Polym. 2018, 15, 1800088. [Google Scholar] [CrossRef]

- Lee, M.-J.; Kwon, J.-S.; Jiang, H.B.; Choi, E.H.; Park, G.; Kim, K.-M. The antibacterial effect of nonthermal atmospheric pressure plasma treatment of titanium surfaces according to the bacterial wall structure. Sci. Rep. 2019, 9, 1938. [Google Scholar] [CrossRef] [Green Version]

- Khan, T.M.; Pokle, A.; Lunney, J.G. Atmospheric pulsed laser deposition of plasmonic nanoparticle films of silver with flowing gas and flowing atmospheric plasma. Appl. Phys. A 2018, 124, 336. [Google Scholar] [CrossRef]

- Kunhardt, E.E. Generation of large volume, atmospheric pressure, non-equilibrium plasmas. IEEE Trans. Plasma Sci. 2000, 28, 189–200. [Google Scholar] [CrossRef]

- Pietscha, G.J.; Gibalov, V.I. Dielectric barrier discharge and ozone synthesis. Pure Appl. Chem. 1998, 70, 1169–1174. [Google Scholar] [CrossRef] [Green Version]

- Gadkari, S.; Tu, X.; Gu, S. Fluid model for a partially packed dielectric barrier discharge plasma reactor. Phys. Plasmas 2017, 24, 093510. [Google Scholar] [CrossRef]

- Pan, J.; Li, L.; Chen, B.; Song, Y.; Zhao, Y.; Xiu, X. Numerical simulation of evolution features of the atmospheric-pressure CF4 plasma generated by the pulsed dielectric barrier discharge. Eur. Phys. J. D 2016, 70, 136. [Google Scholar] [CrossRef]

- Abidat, R.; Rebiai, S.; Benterrouche, L. Numerical simulation of atmospheric dielectric barrier discharge in helium gas using COMSOL Multiphysics. In Proceedings of the 2013 3rd International Conference on Systems and Control (ICSC), Algiers, AL, USA, 29–31 October 2013; pp. 134–139. [Google Scholar]

- Golubovskii, Y.B.; Maiorov, V.A.; Behnke, J.; Behnke, J.F. Modelling of the homogeneous barrier discharge in helium at atmospheric pressure. J. Phys. D 2002, 36, 39. [Google Scholar] [CrossRef]

- Raizer, Y.P. Gas Discharge Physics, 1st ed.; Allen, J.E., Ed.; Springer: Berlin/Heidelberg, Germany, 1997. [Google Scholar]

- Tanaka, Y.; Yasuda, H.; Kurita, H.; Takashima, K.; Mizuno, A. Analysis of the inactivation mechanism of bacteriophage uX174 by atmospheric pressure discharge plasma. IEEE Trans. Ind. Appl. 2014, 50, 1397–1401. [Google Scholar] [CrossRef]

- Kirkpatrick, M.; Dodet, B.; Odic, E. Atmospheric pressure humid argon DBD plasma for the application of sterilizationmeasurement and simulation of hydrogen, oxygen, and hydrogen peroxide formation. Int. J. Plasma Env. Sci. Technol. 2007, 1, 96–101. [Google Scholar]

- Khan, T.M.; Mujawar, M.A.; Siewerska, K.E.; Pokle, A.; Donnelly, T.; McEvoy, N.; Duesberg, G.S.; Lunney, J.G. Atmospheric pulsed laser deposition and thermal annealing of plasmonic silver nanoparticle films. Nanotechnology 2017, 28, 445601. [Google Scholar] [CrossRef] [PubMed]

- Balcon, N.; Hagelaar, G.J.M.; Boeuf, J.P. Numerical model of an argon atmospheric pressure RF discharge. IEEE Trans. Plasma Sci. 2008, 36, 2782–2787. [Google Scholar] [CrossRef]

- Chirokov, A.; Khot, S.N.; Gangoli, S.P.; Fridman, A.; Henderson, P.; Gutsol, A.F.; Dolgopolsky, A. Numerical and experimental investigation of the stability of radio-frequency (RF) discharges at atmospheric pressure. Plasma Sources Sci. Technol. 2009, 18, 025025. [Google Scholar] [CrossRef]

- Borra, J.P. Charging of aerosol and nucleation in atmospheric pressure electrical discharges Plasma. Phys. Control. Fusion 2008, 50, 124036. [Google Scholar] [CrossRef]

- Fuchs, N. On the stationary charge distribution on aerosol in a bipolar ionic atmosphere. Geofis. Pura Appl. 1963, 56, 185–193. [Google Scholar] [CrossRef]

- Pauthenier, M.M.; Moreau-Hanot, M. Charge de particules sphtriques dans un champ ionize. J. Phys. Radium 1932, 3, 590–613. [Google Scholar] [CrossRef]

- Cochet, R. Colloque International La Physique des Forces Electrostatiques et Leurs Applications; Centre National de la Recherche Scientifique: Paris, France, 1961; pp. 331–338.

- Jiang, N.; Ji, A.; Cao, Z. Atmospheric pressure plasma jet: Effect of electrode configuration, discharge behaviour and its formation mechanism. J. Appl. Phys. 2009, 106, 013308. [Google Scholar] [CrossRef] [Green Version]

- Oh, J.-S.; Walsh, J.L.; Bradley, J.W. Plasma bullet current measurements in a free-stream helium capillary jet. Plasma Sources Sci. Technol. 2012, 21, 034020. [Google Scholar] [CrossRef]

- Wu, S.; Wang, Z.; Huang, Q.; Tan, X.; Lu, X.; Ostrikov, K. Atmosphericpressure plasma jets: Effect of gas flow, active species, and snake-like, bullet propagation. Phys. Plasmas 2013, 20, 023503. [Google Scholar] [CrossRef] [Green Version]

| Parameters Used in Simulation Model | |

|---|---|

| AC Frequency | 20 (kHz) |

| Applied Voltage | −750 [V] × in (w0 × t) |

| Argon Gas Flowrate | 1.0 (lit min−1) |

| Gas Feed SS Tube Dia. | 2.0 mm |

| Electrode Thickness | 0.5 (mm) |

| Dielectric Quartz Thickness | 1.0 (mm) |

| Dielectric Strength of Quartz | 25–40 kV/mm |

| Discharge Gap | 2.4 (mm) |

| Relative Permittivity | 10 (ϵ) |

| Temperature | 300 (K) |

| Absolute Pressure | 1.0 (atm) |

| Argon Density | 1.449 (kg/m3) (at 300 K) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, T.M.; Khan, S.U.-D.; Raffi, M.; Khan, R. Theoretical–Computational Study of Atmospheric DBD Plasma and Its Utility for Nanoscale Biocompatible Plasmonic Coating. Molecules 2021, 26, 5106. https://doi.org/10.3390/molecules26165106

Khan TM, Khan SU-D, Raffi M, Khan R. Theoretical–Computational Study of Atmospheric DBD Plasma and Its Utility for Nanoscale Biocompatible Plasmonic Coating. Molecules. 2021; 26(16):5106. https://doi.org/10.3390/molecules26165106

Chicago/Turabian StyleKhan, Taj Muhammad, Shahab Ud-Din Khan, Muhammad Raffi, and Riaz Khan. 2021. "Theoretical–Computational Study of Atmospheric DBD Plasma and Its Utility for Nanoscale Biocompatible Plasmonic Coating" Molecules 26, no. 16: 5106. https://doi.org/10.3390/molecules26165106

APA StyleKhan, T. M., Khan, S. U.-D., Raffi, M., & Khan, R. (2021). Theoretical–Computational Study of Atmospheric DBD Plasma and Its Utility for Nanoscale Biocompatible Plasmonic Coating. Molecules, 26(16), 5106. https://doi.org/10.3390/molecules26165106